1. Introduction

Masonry mortars and plasters are the basic types of mortars in traditional building practice, having a significant share in the erection and plastering of masonry walls. Traditionally, masonry mortars are used to connect masonry units, while the plaster is a mortar used to coat interior walls. Apart from function, the main difference between the two types of mortar is the consistency—plasters are more fluid than masonry mortars. Due to the changes in the desired consistency, the composition of the two types of mortar is usually connected to the different water content or admixture content [

1]. In addition to system solutions of ready-made mortars, traditional mortars based on individual recipes are still used, including renovation or restoration works, where mortar recipes are often selected individually [

2,

3,

4]. A great deal of attention has been paid to the study of mortar and its properties in the literature, for example, in relation to types of binders, additives, and admixtures, and their impact on physical and mechanical properties. Many mortar tests concern types of aggregate and fillers using waste materials, e.g., concrete waste [

5], glass waste [

6], brick flour [

7], granite flour [

8], marble powder [

9], and others. A significant part of the research is devoted to modifying mortars with various additives to improve their properties while partially replacing fillers and binders with waste materials.

For example, Harbi et al. [

10] carried out the experimental work focused on the study of the possibility of using kaolin dust as filler in the sand, combined with additions of glass powder, brick waste, and metakaolin in order to improve the mechanical performance of the mortar. Mixtures containing glass powder and/or metakaolin turned out to be better than those containing brick waste. Similar research was carried out by Boukour and Benmalek [

11], who analyzed the effect of two wastes: crushed clay brick and tire rubber aggregate in cement mortar reinforced by a resinous latex. Test results indicated a decrease in water absorption and shrinkage of such cement mortar.

Atypical addition to mortar, which has been a subject of research, is recycled polyethylene terephthalate (PET) bottles [

12]. Test results of this experiment have indicated that higher compressive and flexural strength can be obtained for thusly modified cement mortars. Other atypical additions to the mortar that have been researched are organic agents as vinegar, gram pulse, and frog contaminated water and their influence on mechanical properties and mortar’s performance [

13]. It has been concluded that organic materials chosen for the study adversely affect the compressive strength of cement mortars, especially after six months.

Research has also been carried out, attempting to replace cement with other materials in the role of the primary binder. For example, Kim et al. [

14] investigated a partial replacement of cement in a mortar with the waste glass sludge. Results showed the strength of such mortars was higher than of mortar with fly ash; however, lower than mortars with ordinary Portland cement only. An interesting study in this area was carried out by Pliya and Cree [

15] about adding lime derived from chicken eggshell waste, used as a filler in Portland cement mortar. Although compressive and tensile strengths decreased in comparison to the natural conventional lime mortars, accelerated hydration was gained at the early stages. Jasiczak and Zieliński [

16] conducted tests of the effect of protein additives, such as chicken and bovine blood (red cells) on the properties of cement mortar. In a similar vein, Fang et al. [

17] and Zhang et al. [

18] had recently brought up a topic of properties of traditional Chinese lime mortars with oxblood as an ingredient, which showed that lime mortars with oxblood exhibited better bonding strength and weather resistance (including waterproof quality) than regular lime mortar. The research conducted by Zhao et al. [

19] showed that pig blood had a similar beneficial effect on properties, such as early strength.

Modifications of mortar with fibers constitute a separate research group. For example, Çomak et al. [

20] studied the effects of hemp fibers on the characteristics of cement-based mortars. Hemp fiber addition had a positive effect on compressive strength, good adherence to cement, and more sufficient bonding between the fibers and mortar matrix. In turn, Trejbal [

21] examined the mechanical properties of lime-based mortars reinforced with plasma-treated glass fibers with increased cohesion between their surfaces and lime-based mortar matrix. Attempts were also made to recognize the properties of resin-modified mortars. For example, Schulze, in his studies [

22], showed that the addition of a styrene/acrylic polymer binder to cement mortar increased the flexural and peel strength. Moreover, both binders acted in synergy: the cement as the inorganic binder was responsible for mechanical stability as compressive strength, and the styrene/acrylic powder (organic binder) was acting as a reinforcement and was responsible for the internal tensile strength and, at sand-cement interfaces, for the adhesion-bond strength. The properties of mortars with the addition of polyester resin obtained from polyethylene terephthalate (PET) waste bottles have been the subject of other studies [

23], which show the beneficial effect of polymers on the physical properties of cement mortars.

There are also known studies on the impact of cement aging on mortar properties [

24]. Studies have shown that aging cement negatively impacts mortar flowability, hydration process in mortar during its hardening, and decreases density and compressive strength of hardened mortar. As research has shown, mortar properties are also influenced by factors, such as temperature, dosage method, and curing. For example, the effect of temperature on mortars with the addition of epoxy and polyester resins based on a diglycidyl ether bisphenol A and an aliphatic amine hardener and POLYLITE

® 10316, respectively, was studied by Reis [

25], who showed a decrease in flexural and compressive strength at higher temperatures. The epoxy mortars turned out to be more sensitive to temperature changes than the polyester ones. Curing conditions, to which a lot of research has been devoted, are important for mortars. Sajedi [

26] investigated different methods of curing, including water, air, heated water, oven heated, air-water, and water-air. The highest and lowest compressive strengths were attributed to the mortars with ordinary Portland cement (OPC): water-cured for the duration of 6 h and air-cured in room temperature, oven heated at 60 °C after demoulding of the specimens for 20 h, respectively. In another study, higher strengths have been achieved for ordinary Portland cement and ordinary Portland cement-slag mortars with lower binder content and curing regimen in water without heating [

27]. Garijo et al. [

28] studied five factors, which had an influence on natural hydraulic lime mortars’ properties, in particular the water binder ratio, the mold material, the aggregate size, and type and curing conditions. The influence of different humidity conditions of curing was tested by Pavlík and Uzáková [

29] in their study of the influence of zeolite and metakaolin addition on the compressive strength, porosity, shrinkage, and frost resistance of lime mortars. It was found that pozzolans reduced shrinkage of freshly hydrated lime mortars. These admixtures positively affected compressive strength development and frost resistance of lime-pozzolan mortars when they were cured in the environment with the relative humidity of 100%. As can be seen, the topic of mortars as masonry mortars and plasters is a current one.

Currently, the most common way to improve the properties of masonry mortars and plasters is to use admixtures with different properties depending on their purpose [

30,

31,

32]. These can be admixtures that reduce the amount of water (plasticizing, liquefying), air-entraining, regulating setting and hardening, improving frost-resistance, affecting the water retaining and water resistance, or having a comprehensive effect. The popularization of construction chemicals means that plasticizing admixtures are increasingly used in construction practice instead of the traditional lime [

33]. It should be noted that there is a limited amount of research available, which compares the effect of adding plasticizing admixture to cement mortar, to the effect of hydrated lime addition in the binder. The comparison between the effect of lime as a plasticizing agent on mortar properties to an effect of air-entraining plasticizing admixture has been a subject of the paper by Lenart [

34]. It was shown that cement-lime mortars were less brittle and had higher compressive and flexural strength than cement mortars with air-entraining and plasticizing admixture, while no unequivocal dependence was confirmed in the case of bond strength of cement-lime mortars and cement mortars with plasticizing admixture. Bond strength of cement-lime mortars has been a subject of research; however, no consensus has been reached, with some authors stating that aerial lime enhances bond strength of cement-lime mortars [

35], while others have observed opposite results [

36]. Plasticizing admixtures with air-entraining properties, which are popular for masonry mortars and plasters, have been proven to decrease the bond strength [

37].

The issue of differences in strength of cement-lime mortars and cement mortar with plasticizing admixture was raised by O’Looney et al. [

38]. It was found that depending on the amount of lime, the relation of strength of cement-lime mortars to cement mortars with admixture was different. When lime content was less than 50% of cement mass, the mortars exhibited higher compressive and flexural strength and gained strength at a faster rate than mortars with a plasticizer. However, for mortars with equal amounts of lime and cement, the opposite was true.

Souza et al. [

39] made a comparative study of the effect of hydrated lime and three types of additives (air-entraining, plasticizing, and water-retaining) on water retention, density, porosity in a hardened state, and adhesive strength. This research had shown that cement-lime mortars were characterized by the highest density and adhesive strength, as well as the greatest open porosity. Limestone was characterized by the strongest water-retaining characteristics, which was in line with the research of Green et al. [

40], whose tests indicated that cement-lime mortars had better water-retaining properties than cement mortars with admixtures. The highest workability was obtained for mortars with water retaining admixture, while the mortars with air-entraining admixture had the lowest open porosity. Addition of plasticizer allowed to obtain average results. It should be noted, however, that the amount of admixtures in the mortar was set to the highest recommended dose, as the composition of mortar was not prepared on the basis of comparable properties (for example, consistency), what is emphasized by the authors.

The research into the effect of proportioning of aerial lime and Portland cement in masonry mortars was conducted by Wright et al. [

41]. It was shown that lime mortars had comparable bond strengths but weaker compressive strengths in comparison to cement-lime mortars of the same air content.

The similar effect of aerial lime and plasticizing admixtures on the consistency may, therefore, not provide similarity to the effects on the other properties of plaster and masonry mortar and on the sensitivity of these mortars to dosing errors or varied values of factors affecting fresh mortars, such as temperature, type, and origin of cement or hydrated lime, or mixing intensity [

42].

The environmental and technological factors, which may affect the masonry mortar or plaster, have been a subject of numerous research. Lanas et al. [

43] investigated mechanical properties of aerial and hydraulic lime-based mortars cured in different environmental conditions and concluded that mechanical properties and durability at different environments were related to the porous structure of mortar. Pavlik and Uzakova [

29] tested the humidity effect on shrinkage and compressive strength of aerial lime mortars with the addition of zeolite and metakaolin. It was shown that the mortars with aerial lime and pozzolans had better mechanical properties than aerial lime itself, regardless of humidity. Fusade et al. [

44] investigated the difference between the effect of realistic curing conditions to laboratory conditions on the chosen properties of hydraulic lime mortars. Results showed that there were significant differences in the properties of mortars exposed to naturally occurring environmental conditions or laboratory conditions, especially at an early age, mostly due to the assumed high humidity in the realistic curing conditions. Research into the effect of environmental conditions on the properties of fresh and hardened cement mortars are also available in the literature [

45,

46,

47,

48].

The influence of the mortar preparation and application process in relation to properties of lime mortars was a subject of research by Cavaco et al. [

49], Rosell et al. [

50], Balksten et al. [

51], and Sandin [

52]. It was found that the mechanical properties and consistency of lime mortars could vary depending on the exact preparation process. Davison [

53] made studies into the effect of mixing time and procedure on the strength of aerial lime mortars, which implied, that while it is hard to ascertain what is the exact effect of mixing time on properties or mortars, changes in mixing procedure affect the mortar’s strength. The effect of the mixing procedure was also studied by Fukui et al. [

54], in the context of cement mortars. It was ascertained that the mixing procedure influenced the amount of air in the case of air-entraining admixture. It should be noted that there is a lack of literature pertaining to the influence of procedures of preparing cement-lime mortar on its properties.

Therefore, to compare the magnitude and significance of changes in material and selected technological factors on the properties of cement-lime mortars without admixtures and mortars with plasticizing admixtures, model tests were conducted in laboratory conditions.

The purpose of the research was to determine and compare the impact of selected material and technological factors on the properties of cement-lime masonry mortars and plasters and cement mortars with an air-entraining plasticizing admixture (APA). The research took into account the impact of cement and hydrated lime origin, inaccuracies in the dosing of water, lime or admixture, as well as the intensity of mortar mixing and temperature changes.

The sensitivity of mortar properties to the impact of the above factors was defined as the coefficient of variation, i.e., the quotient of the absolute measure of the variability of a given property under the influence of a given material or technological factor, and the mean value of this property. The coefficient is a measure of mortar resistance to a change of a specific factor occurring during mortar preparation according to the given recipes.

3. Results and Discussion

Four types of technological factors that could affect selected basic properties of masonry and plaster mortars (namely, bulk density, consistency, air content, flexural, and compressive strength) were adopted for the analysis. Selected technological factors are related to the quantitative and qualitative composition of mortars, taking into account the origin of cement and lime, deviations in the dosing of lime, admixture, and water, as well as changing conditions of mortar preparation usually occurring in construction practice, such as mixing intensity and temperature.

3.1. Impact of Cement on the Properties of Plaster and Masonry Mortars

Five selected physical and mechanical properties were tested on nine types of plasters (

Table 3) and nine types of masonry mortars (

Table 4). The results of tests of basic properties of the mortars are presented in

Table 5 and

Table 6 and charts (

Figure 2,

Figure 3,

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8). Results were the mean of a minimum of three measurements. The standard deviation for each of the results is presented in the corresponding figures.

The consistency results turned out to be diverse in terms of the test method, the origin of cement and lime, and the type of mortar. Due to the fact that the composition of the mortars was set on the basis of the similar consistency measured with the cone method, there was no significant difference between the results of the depth of cone penetration of plasters P1 to P9 and of masonry mortars M1 to M9. However, the differences could be observed in the case of other types of consistency measurement, especially in the case of plunger penetration. This was connected to the fact that the different methods of consistency measurement are not comparable, as they measure the consistency differently in relation to its rheological properties [

64]. The greatest difference could be seen in the case of plasters with APA. This effect might be connected to the low viscosity of the mortars with air-entraining admixtures, which could affect the measurement of consistency by penetrometer and flow table [

65]. This effect was more visible in the case of plasters due to higher water content. The effect of the APA was connected to the lowering of surface tension of water; therefore, the effect was more pronounced when there was more water in the mortar.

The compressive strength of masonry mortars and plasters with APA is generally lower than in the case of cement-lime mortars. This effect was to be expected due to high air content in those mortars, resulting from using air-entraining admixture [

66,

67]. The flexural strength, in turn, was less affected by the high air content, which is consistent with the available literature [

68,

69].

For each tested property, a coefficient of variation was determined, which expressed the sensitivity to changes in the value of a given mortar property under the influence of a change in the amount of ingredients by a specific value. The coefficient was defined as the quotient of the absolute measure of the variability of a given property under the influence of a given material or technological factor, and the mean value of this property (

Table 7 and

Table 8). The value of the coefficient was determined as a percentage. A higher value means higher susceptibility to changes in properties when the given material or technological factor changes.

Analyzing the results, it could be noticed that the method of consistency testing slightly affected the consistency results. For the cone method of consistency measurement, the values were similar, regardless of the origin of the cement and lime. For the other methods, the addition of lime resulted in more fluid consistency.

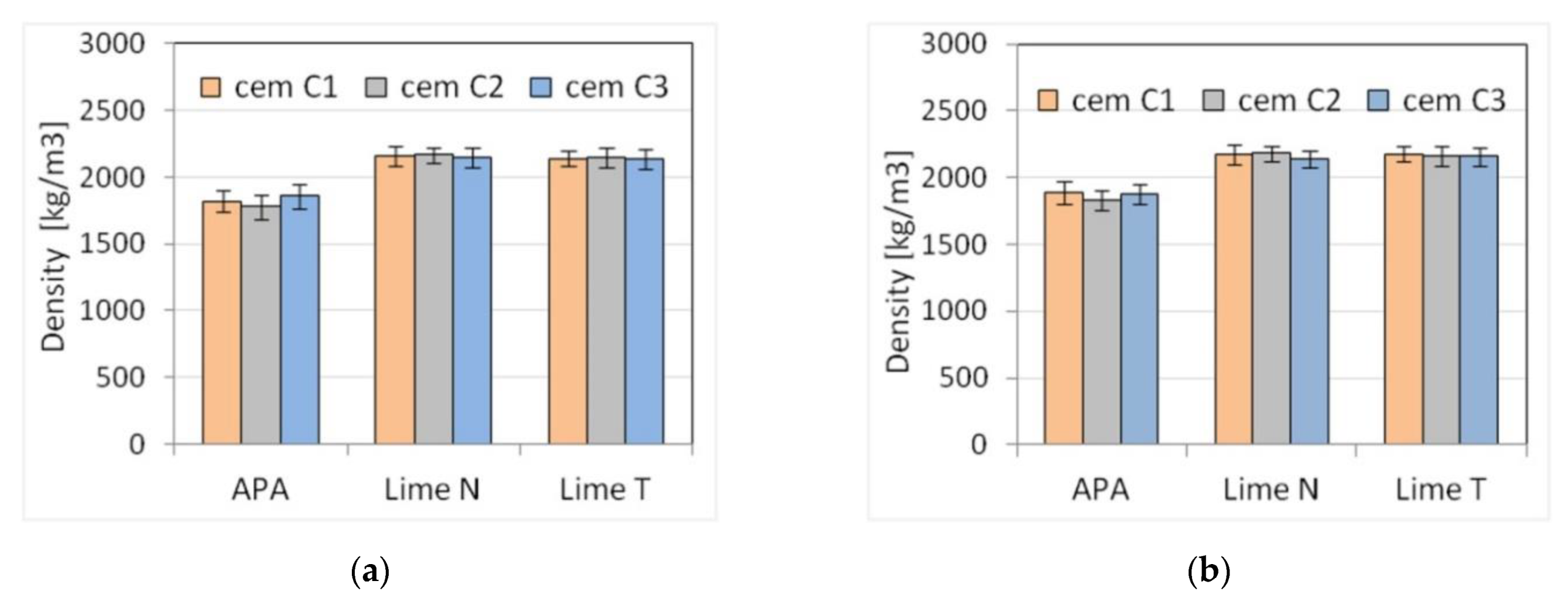

Due to set constraints, the masonry mortars obtained a lower consistency than plasters, by about 25% when measured by the cone method. APA as replacement of lime clearly reduced the density by about 15% to a value of the order of magnitude ~1800 kg/m

3 compared to a density of over 2100 kg/m

3 for mortars with lime addition (

Figure 5). It was expected; as the APA has an air-entraining effect with the increase in air content, the density must decrease. A clear, strong influence of the APA was visible on the air content (

Figure 6). Compared to lime mortar, the content increased from 5 to 9 times. In terms of mechanical properties, replacing lime with an APA could cause a reduction in compressive strength of 10–15%. The type of binder did not affect the flexural strength (

Figure 7 and

Figure 8).

The results showed that the type of cement significantly affected the consistency of mortars and also the amount of water necessary to obtain the required consistency of the tested mortars. The difference in the amount of water differed from 7.2% to 12.5%, the least for lime T, the most for lime N. The scope of this correction was similar in cement-lime mortars and cement mortars with APA. It should be noted that mortars with different types of cement, of equal consistency according to the cone method, were characterized by a different consistency according to the plunger penetration test. This applied especially to cement mortars with APA. The differences in properties of cement of the same class have been thoroughly explored in literature, for example, by Juvas et al. [

70], Priyadashana and Dissanayake [

71], and, historically, Lyse [

72]. This could be explained by the different water demand of types of cement from different manufacturers, which is also one of the reasons why the types of cement used in the tests were characterized, despite the same class, by significant differences in strength. Different water demand for types of cement led to different effective

w/

c ratios, and hence to differences in strength. Naturally, the effect was more visible in the case of plasters, which contained more water. This contributed to the increased sensitivity of the properties of mortars to the type of cement and was the reason for a significant difference between the strength of mortars with types of cement from different producers. However, it should be pointed out that the compressive strength of mortars with APA was more sensitive to the type of cement than cement-lime mortars. It must be also noted that with the same consistency, lime mortars had higher compressive strength than cement mortars with APA, which was connected with high air content in mortars with APA.

Analyzing the results of susceptibility to changes of properties due to the type of the binder (

Table 7 and

Table 8), it could be seen that it was the smallest for the density and consistency determined by the cone method and flow table and amounted to a few percent. Larger changes were visible for consistency using the plunger penetration method, in the order of magnitude of 10%; however, the susceptibility to changes was greater for mortars with APA and amounted up to 10–25%. Higher susceptibility to changes, in the range of 15–35%, was observed for strength properties. The highest variability was noted for plaster mortars, which was caused by its more fluid consistency.

In the case of all tested properties, mortars with APA were characterized by a significantly higher sensitivity to changes in the type of cement than mortars with lime. This might be associated with different compatibility of the admixture with different types of cement; in this case, CEM I 42.5 R cement [

30]. However, this effect requires further testing.

3.2. Impact of Inaccuracies in Dosing of Lime and Admixture

The tests were performed for three types of plasters and three masonry mortars made with CEM I 42.5 R–C1 cement, different types of lime, and APA. Moreover, the new composition of mortars was made with the addition of lime and APA adjusted by adding 10% more (marked by +10% LA in figures and tables) or 10% less (marked −10% LA) in relation to the initial proportions. This was done to simulate the mistakes in the dosing of lime or admixture that could occur on the construction site. An increase or decrease in the amount of lime or admixture was considered for each mortar. In this way, six types of mortars with three compositions were obtained. For each of the mortars, five properties were determined as previously: consistency, density, air content, flexural, and compressive strength. Results, standard deviation, and the number of samples used are shown in

Table 9 and

Table 10. The results of the plunger penetration tests are shown in

Figure 9, while the compressive strength of mortar is shown in

Figure 10, with standard deviation marked for each result.

Analyzing the consistency results, it could be noticed that there were only slight differences in the results for the cone method and the flow table method. Clearer differences were visible for the plunger penetration method, for which less liquid consistencies were obtained for mortars with APA. The differences in the sensitivity of consistency measurements were to be expected, as all three measurements were, in actuality, measurement of slightly different rheological phenomena, which was a subject of the doctoral thesis of Hendrickx [

73]. Therefore, the changes in the consistency of mortars for each of the testing methods could be different.

For mortars with the addition of lime, changes in the amount of lime did not affect the consistency, while in the case of using APA, more fluid consistencies were observed than in the case of lime increased by 10% and less liquid when the amount of lime was reduced. The consistency of masonry mortars was, as should be expected, lower than that of plasters, but the differences were dependent on the test procedure. The smallest differences were noticed for the flow table method (around 10%), larger ones (~30%) for the cone method, and the largest (50–70%) for the plunger penetration method (

Figure 9). The dosing inaccuracies did not affect the density of the fresh mortar. There was a difference observed between the effect of the APA on mortars in comparison to mortars with the addition of N or T lime, as a decrease in density was observed. The density of mortars with APA addition was around 1850 kg/m

3, which was about 15% lower in comparison to a density of cement-lime mortars, which was 2150 kg/m

3. A significant influence of the admixture was visible in the air content, amounting to 17% of air content for masonry mortars and 19% for plasters. Much lower air content could be observed for mortars with lime, in the range of 2–3.7%. However, no clear impact of dosing inaccuracy was observed. In terms of mechanical properties, the effect of dosing inaccuracy was present. Compressive strengths after 28 days reached about 8 MPa for plaster and 10 MPa for masonry mortar (

Figure 10). Flexural strengths for all mortars ranged within 2 MPa. A decrease in compressive and flexural strength of 10–20% was observed with both a 10% increase and a decrease in the dosed lime and APA. Major changes occurred in masonry mortars with APA and in plasters with lime N.

The sensitivity of plaster with lime and APA to changes in the amount of lime or admixture (

Table 11 and

Table 12) was similar in the context of strength, although, in the case of mortars with lime N, the coefficient of variability of strength was clearly higher. In the case of masonry mortars, cement mortars with APA were clearly more sensitive to changes in the amount of admixture in terms of consistency and strength than cement and lime mortars. This might be due to the fact that the absolute amounts of admixture and lime in mortars are of an order of magnitude different so that changes in the content of the admixture would affect the properties of the mortar to a higher degree.

Generally, it can be stated that cement mortars with an APA may show similar or lower resistance to mistakes in dosing of the admixture than cement and lime mortars to mistakes in the dosing of lime.

3.3. Impact of Inaccuracies in Dosing Water

The analysis of the impact of errors in dosing water to the mortar was also carried out for three types of plaster and masonry mortars with cement C1, two types of lime, and the addition of APA. Results, standard deviation, and the number of samples used are shown in

Table 13 and

Table 14. The results of the plunger penetration tests are shown in

Figure 11, while the compressive strength of mortar is shown in

Figure 12, with the standard deviation marked for each result. For each mortar, the addition of water was differentiated with an increase or decrease in its amount by 10% compared to the initial proportions (in tables and figures marked +10% W and −10% W respectively). Similarly, as before, five selected physical characteristics were determined for each mortar.

The impact of errors in water dosing was visible in the consistency results. Regardless of the method of measurement, an increase in the amount of water by 10% resulted in greater liquefaction and an increase in the consistency index of about 25–80%, with larger changes occurring when APA was used (

Figure 11). In turn, reducing the amount of water by 10% reduced the consistency value in the range of 10–100%. Due to the set conditions, masonry mortars exhibited worse consistencies than plasters, the difference depending on the measurement method. The smallest differences were noted for the flow table method (around 12%), larger ones (~25%) for the cone method, and the largest ones (50%) for the plunger penetration method (

Figure 11). For plaster with APA, its density of 1850 kg/m

3 turned out to be 15% lighter than in the case of plasters with lime (2170 kg/m

3). Inaccuracies in the dosing of water generally did not affect the density of fresh mortars, although, in the case of masonry mortars with APA, an increase in water by 10% resulted in an additional decrease in density by 25% to a value of 1390 kg/m

3. Such a significant decrease in density resulted from greater aeration efficiency of the admixture in the presence of more water. In turn, different types of lime did not cause changes in density.

A significant influence of APA was visible for the air content of plasters, in which the amount of air increased six times to the value in the range of 14–21%. In plasters with lime, this content was about 2–4%. In most of the analyzed cases, an increase in the amount of water caused a decrease in air content, while a decrease in the amount of water resulted in its increase. A similar effect was observed by Cesali et al. [

74]. On the basis of both research data, it could be concluded that it might be possible that it was due to differences in the volume of porous mortar occupied by water. With more water filling the volume of pores, the volume of free pores decreases, and thus the amount of air contained in them. A different effect occurred in plasters with APA. This might be due to the foaming effect of the admixture in the presence of more water. Water dosing inaccuracy showed its effect on mortar strength.

Generally, the increase in the amount of water caused a decrease in strength in all types of mortars due to the increase of the water-binder ratio. The effect of increased water-binder ratio has been the subject of numerous research, for example, by Elnemr [

75], Lawrence [

76], and Kim et al. [

77]. Both compressive and flexural strength dropped by 12–35%, depending on the type of lime (

Figure 13).

The results showed that errors in the dosing of water produced the effects as expected—deterioration of consistency and increase in mortar strength with less water added, and increase in consistency and reduction of mortar strength with more water added. The consistency of mortars changed significantly as a result of changes in the amount of water, and mortars with APA showed greater sensitivity than cement and lime mortars to these changes. Therefore, the sensitivity of consistency, in particular, the consistency determined by the plunger method, to errors in water dosing turned out to be greater compared to other properties (

Table 15 and

Table 16). This was due to the way the APA works, ensuing high aeration and consistency by reducing the surface tension of the water. Less water made the admixture less effective. The plasticizing effect of lime was associated with the filling effect, as shown by Quadir et al. [

78], and this effect was not directly dependent on the water content of the mortar. A smaller amount of air reduced the amount of paste and, in addition to reducing the amount of water, also reduced the consistency. This effect worked in the opposite way in the case of more water, which resulted in increased consistency. Errors in the water dispensing caused significant changes in mortar strength inversely proportional to the amount of water added. However, the sensitivity of compressive strength to errors in the dosing of water for mortars with APA and cement-lime mortars was similar.

3.4. Impact of Mixing Intensity

Three plaster and three masonry mortars based on cement C1 with two types of lime and APA were prepared for the test. The results are presented in

Table 17 and

Table 18.

The reference mortars were mixed, according to PN-EN 196-1 [

56], in a laboratory mixer with rotary and planetary motion, low-speed (140 rpm, 85 rpm) for 2 min and high-speed (285 rpm, 125 rpm) for 1 min. The same mortars were also mixed with two other speeds: intensively mixed with 140 rpm for 3 min (F—fast) and mixed slowly with 90 rpm for 3 min (S—slow). The results of the plunger penetration tests are shown in

Figure 13, while the compressive strength of mortar is shown in

Figure 14, with standard deviation marked for each result.

Changes in mixing speed had a proportional effect on the consistency of plasters, not exceeding 15%. An increase in speed caused an increase in the consistency and greater fluidity of the plaster. The reverse relationship could be observed in masonry mortars. With regard to consistency, it could be stated that cement-lime mortars were more sensitive to changes in the mixing procedure than mortars with APA (

Table 19 and

Table 20). This effect might be due to the possibility of uneven distribution of lime in cement-lime mortars, which could occur at high or very low mixing speeds [

79]. The admixture was added to the water and mixed by hand, and then added together with water to the mortar, and, therefore, the mixing speed might not be as crucial to an even distribution of the APA in the mortar.

Sensitivity to these changes was highest when determined by the plunger penetration method (

Table 19 and

Table 20). For masonry mortars, varied changes in consistency were noted due to the changes in mixing speed. Changes in mixing intensity did not affect mortar density or air content. Similar to other analyzed inaccuracies, the replacement of lime with APA caused a decrease in density in the range of 15%. Aerating properties of the admixture resulted in a six-fold increase in air content in comparison to the mortar with lime. The mixing procedure also did not affect the strength of cement-lime mortars, while significantly affecting the strength of cement mortar with APA, up to 35% at higher mixing speed. In this respect, cement mortars with APA showed the greatest sensitivity to changes (

Table 19 and

Table 20). Interestingly, the standard mixing procedure allowed to obtain cement mortars with APA of the highest strength, while lower or higher intensity caused a decrease in strength. This was despite the fact that the procedure had no effect on the consistency of these mortars, and there was no significant effect on their air content.

3.5. Effect of Mortar Temperature

The last technological factor examined was the temperature and the impact of its change. Three temperatures were analyzed: normal +20 °C, reduced +5 °C, and elevated +35 °C. To obtain the appropriate temperature, the mortar components were properly cooled or heated, so that after mixing, the set temperature was obtained. Only temperatures above zero were taken under consideration due to technical difficulties of obtaining conditions in the laboratory, allowing for keeping the temperature of the fresh mortar below zero. After determining the properties of fresh mortars, samples for strength tests were stored in different ways. Samples of mortars in temperature of +20 °C were cured in accordance with PN-EN 1015-11 [

60]. Samples of mortars at +5 °C and +35 °C were stored in the molds for the first 72 h at their original temperature. After demolding, the samples were stored for 25 days at 20 °C and 60% relative humidity. The results are presented in

Table 21 and

Table 22. The results of the plunger penetration tests are shown in

Figure 15, while the compressive strength of mortar is shown in

Figure 16, with standard deviation marked for each result.

The temperature of fresh mortars, both reduced and elevated, resulted in an increase in the consistency in the range of 5–26%, i.e., greater mortar liquefaction. Larger changes occurred for the reduced temperature: up to 20% for mortars with the addition of lime, and up to 30% for mortars with APA. The smallest effect was visible for the flow table method, and the largest for the plunger penetration method (

Figure 15). The temperature did not affect the mortar density, but due to the APA’s aerating properties, a decrease in density by an average of 16% could be observed in mortars with APA, similar to the previously analyzed cases. The impact of temperature changes on the content of the air was noticeable for masonry mortars. An increase in air content in the range of 2–13% was recorded for both +5 °C and +35 °C. For mortars with the addition of lime, the air content was 2.2–4.9%, and, for mortars with APA, it was 17–19.5%. On the other hand, in the case of mechanical properties, a clearly reducing impact of temperature changes could be observed, resulting in a reduction of strength by 23–59%. Decreasing or increasing the temperature in the examined range of variability reduced the strength of all tested mortars. Larger reductions occurred for mortars with APA (

Figure 16).

Plasters with APA showed a higher sensitivity of consistency to temperature changes than cement-lime mortars, while, in the case of masonry mortars, the sensitivity was similar or lower (

Table 23 and

Table 24). At the same time, in terms of strength, the sensitivity of cement mortars with APA was definitely higher than cement-lime mortars (

Table 23 and

Table 24). The mechanism of the lower sensitivity of cement-lime mortars could be associated with two effects, connected to the temperature of +5 °C and +35 °C. At +5 °C, the binder, of which there is more in a cement-lime mortar, gave a greater exothermic effect, thus reducing the adverse effect of low temperature. While the hydrated lime used in the research did not react in an exothermic manner, as proven by Cizer et al. [

80], and the lime could have a filler effect on cement. Due to its high specific surface area, lime could act as a filler, not allowing for the cement particles to conglomerate, and thus affecting the hydration rate on a physical level [

81,

82]. At a temperature of +35 °C, lime, as a component with a high ability to bind and hold water, reduced the possibility of rapid loss of water due to which the mortar had better maturing conditions. Those effects were not present in mortars with APA. Moreover, the admixtures might exhibit an erratic or diminished effect on the properties of mortars and concrete, as was proven by Tynes [

83] and Silva et al. [

84].

3.6. General Remarks

The conducted tests and presented relationships indicated greater variability and sensitivity of the properties of cement mortars with APA to technological factors and possible errors in dosing than cement-lime mortars, both in terms of consistency and strength. However, it should be noted that:

the variability of cement mortars with the analyzed admixture in terms of consistency measured by the cone did not exceed 15%. If expressed in absolute values for plaster and masonry mortars, it translated to ±0.7 and ±0.5 cm, respectively, which was within the permissible error;

the variability of strength of cement mortar with APA exceeded 20%, while, for cement-lime mortar, it was noticeably lower than 20%; strength of cement-lime mortars was not only more stable but also at the same consistency greater than for cement mortars with APA.

In the case of cement mortars with APA, fluctuations in mortar density were also much larger. Due to the aerating properties, the admixture reduced the mortar density by approximately 15%. The variation of air content in the mortar was smaller for these mortars; however, one should take into account the significant difference in the amount of air, which, in case of cement-lime mortars, was in the range of 2–4%, and, for cement mortars with APA, it was in the range of 17–20%. The variability of the amount of air expressed in absolute values was about 2.5% for cement mortars with APA and about 1% for cement-lime mortars.

The type of cement significantly affected the consistency of mortars. Changing the type of cement assuming a constant mortar consistency necessitated the correction of the amount of water in both cement-lime mortars and cement mortars with APA. In the case of the latter, it could be a correction of the amount of admixture. In the case of cement used in the tests, the amount of water correction for cement-lime mortars and cement mortars with APA was similar and amounted to about 10%. The compressive strength of cement mortars with APA was more sensitive to a change in cement type than cement-lime mortars.

Errors in the dosing of water were particularly evident in the consistency and strength of mortar, resulting in significantly greater changes in percentage than the error value. Water inaccuracy also affected the air content due to the water filling the space occupied by air. Additional water, therefore, reduced the amount of air. This effect was more pronounced in the presence of APA. Changes in strength could be associated with the water-binder ratio.

Changes in the intensity of mixing were unlikely to have a clear impact on the changes in the analyzed mortar properties. They were most visible for the consistency determined by the plunger penetration test, where the increase in mixing speed caused greater liquefaction. In plaster mortars with higher cone or plunger penetration depth, more intensive mixing had a fluidizing effect. In masonry mortars with lower penetration depth, the effect was the opposite. The impact of changes in mixing speed on strength was only visible for cement mortars with APA. Changes in mixing speed reduced the compressive and flexural strength. This was probably related to the plasticizing and aerating effect of the admixture. In this respect, mortars showed the greatest sensitivity to changes.

A similar effect as the one mentioned above occurred when the temperature of the fresh mortar changed. Both decreasing and increasing the temperature of mortar increased its consistency and liquefaction, as well as reduced strength. Lower temperature decreased the hydration and hardening speed of cement paste in mortars. The increased temperature might also affect this process, mostly by causing rapid hydration on the surface of cement particles, which could obstruct the hydration of deeper layers of cement particles [

85,

86].