The New Technologies Developed from Laser Shock Processing

Abstract

1. Introduction

2. The Technical Theory of Laser Shock Processing

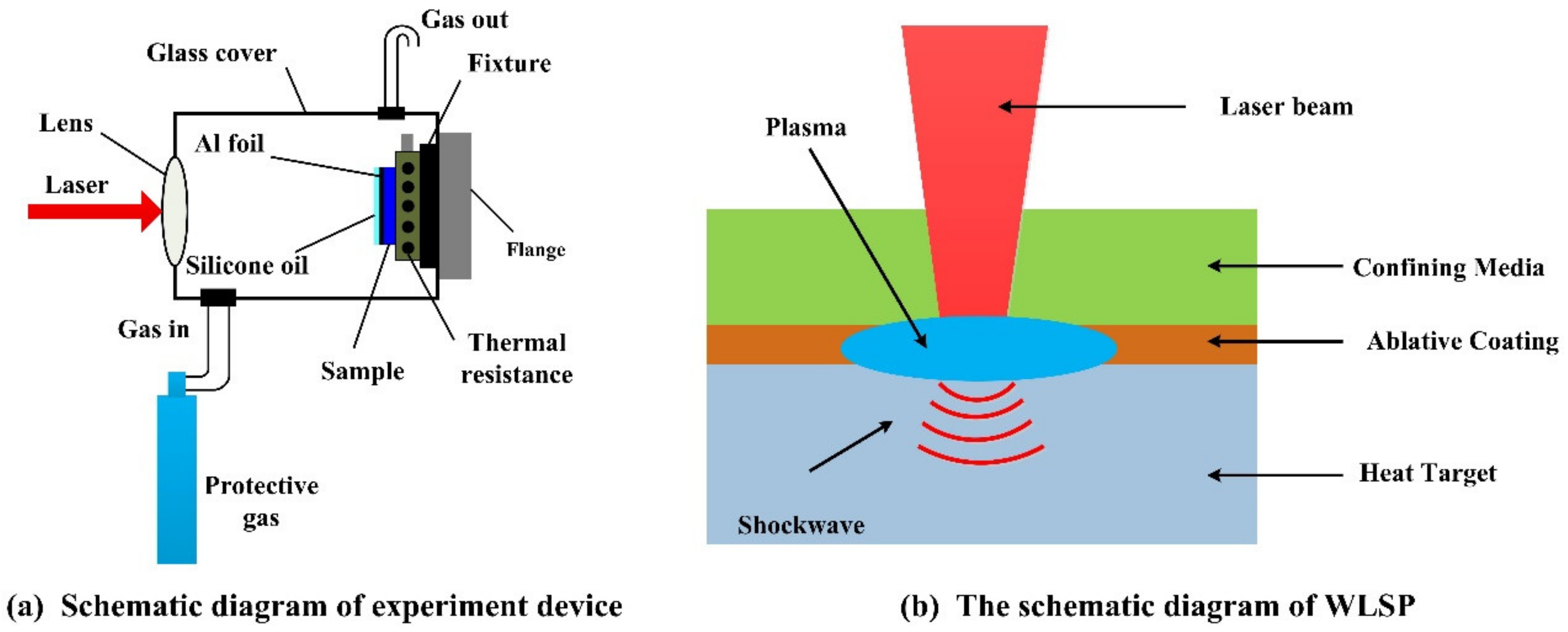

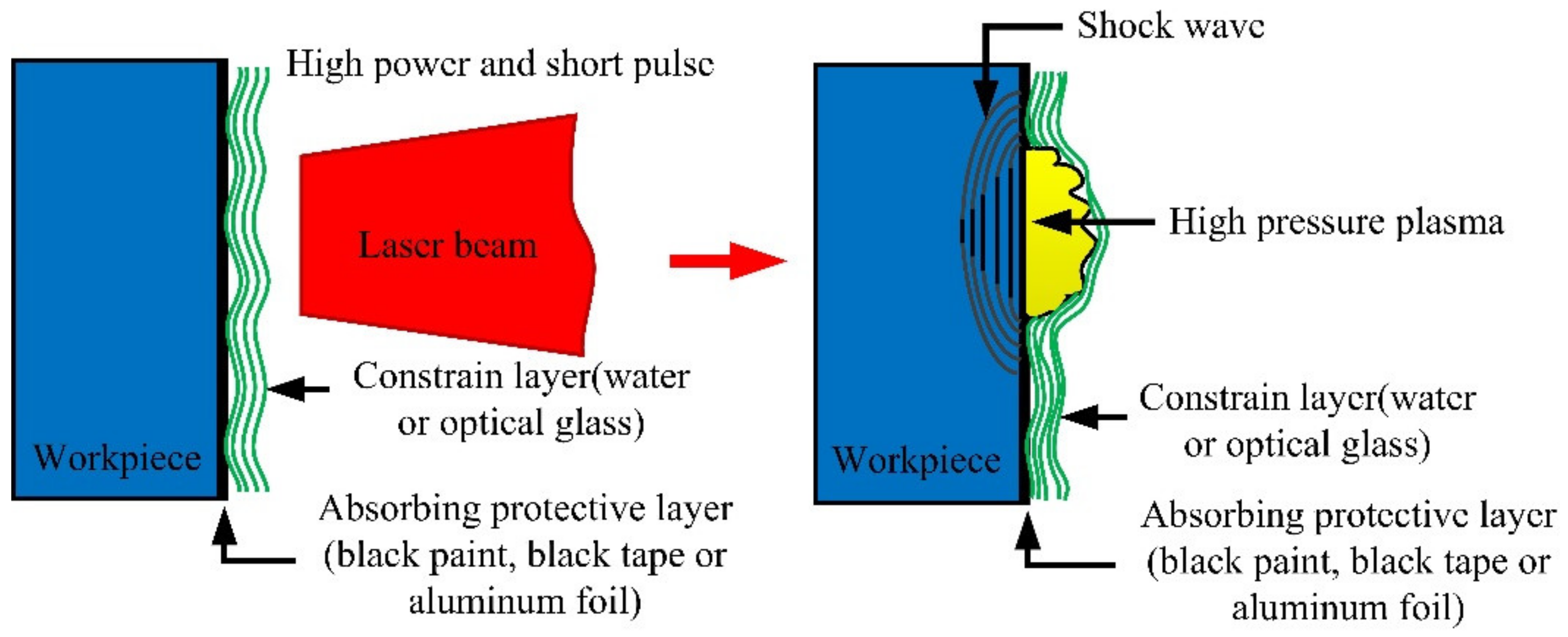

2.1. Fundamental Principle of LSP

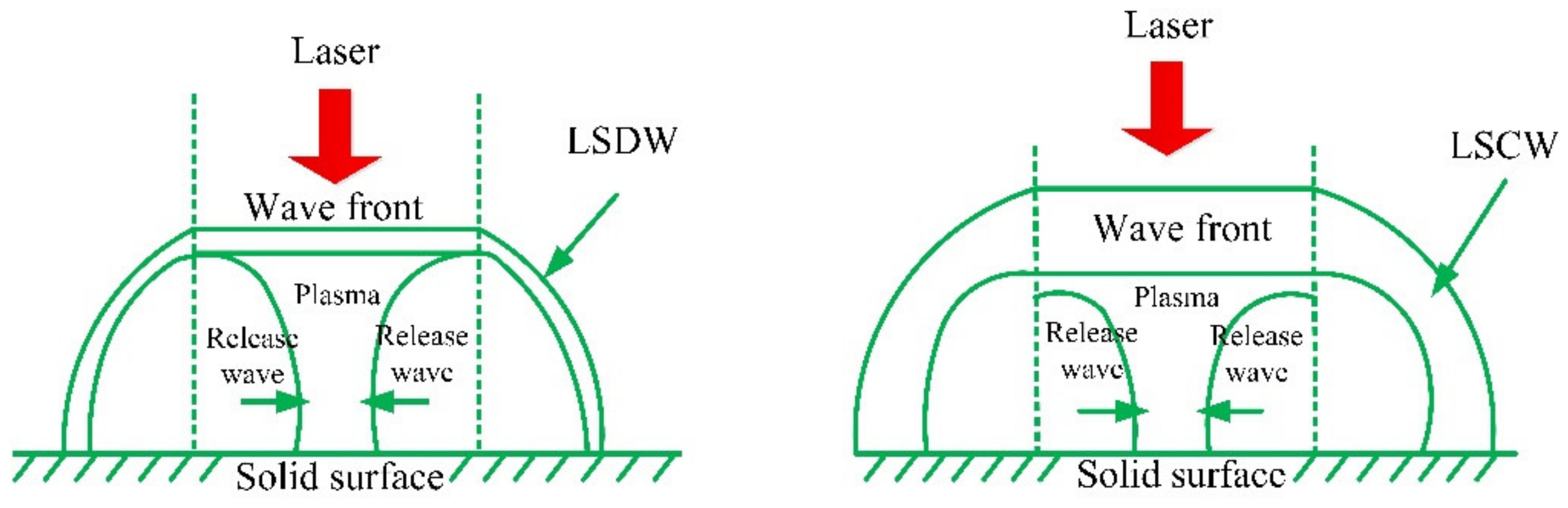

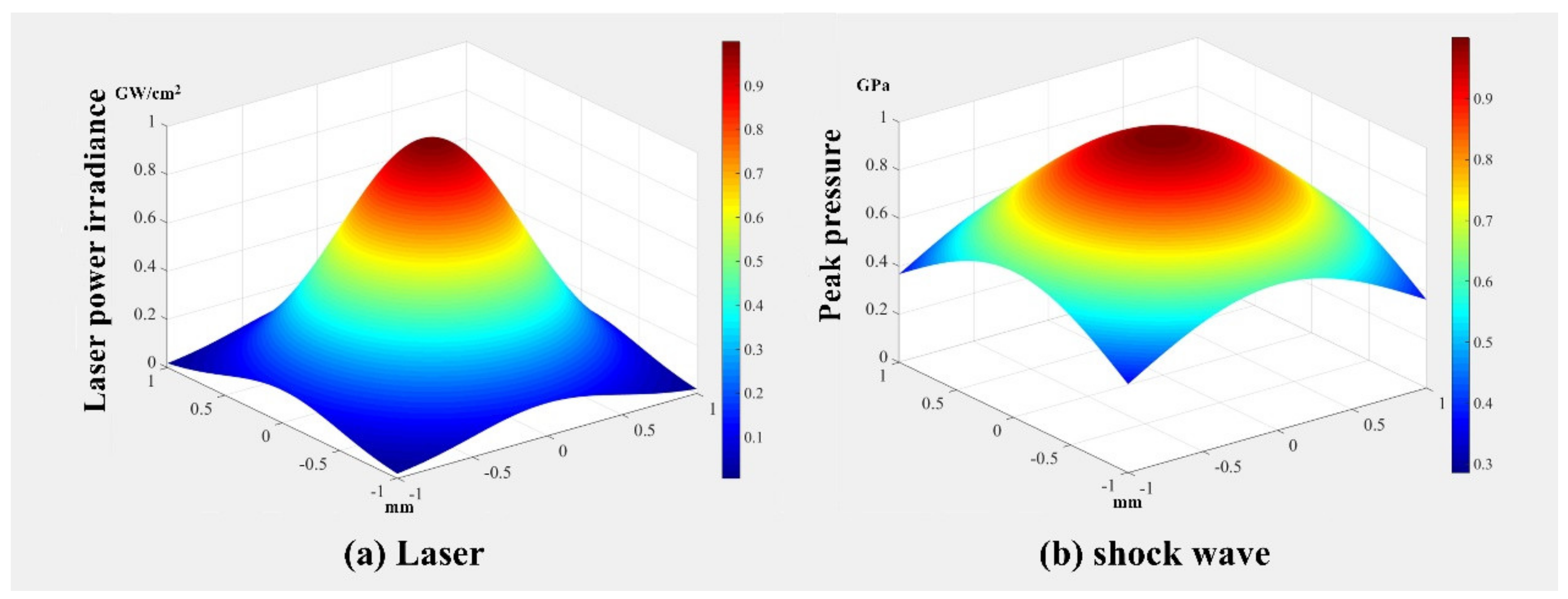

2.2. The Laser-Induced Plasma Shock Wave

3. The New Technologies Developed from LSP

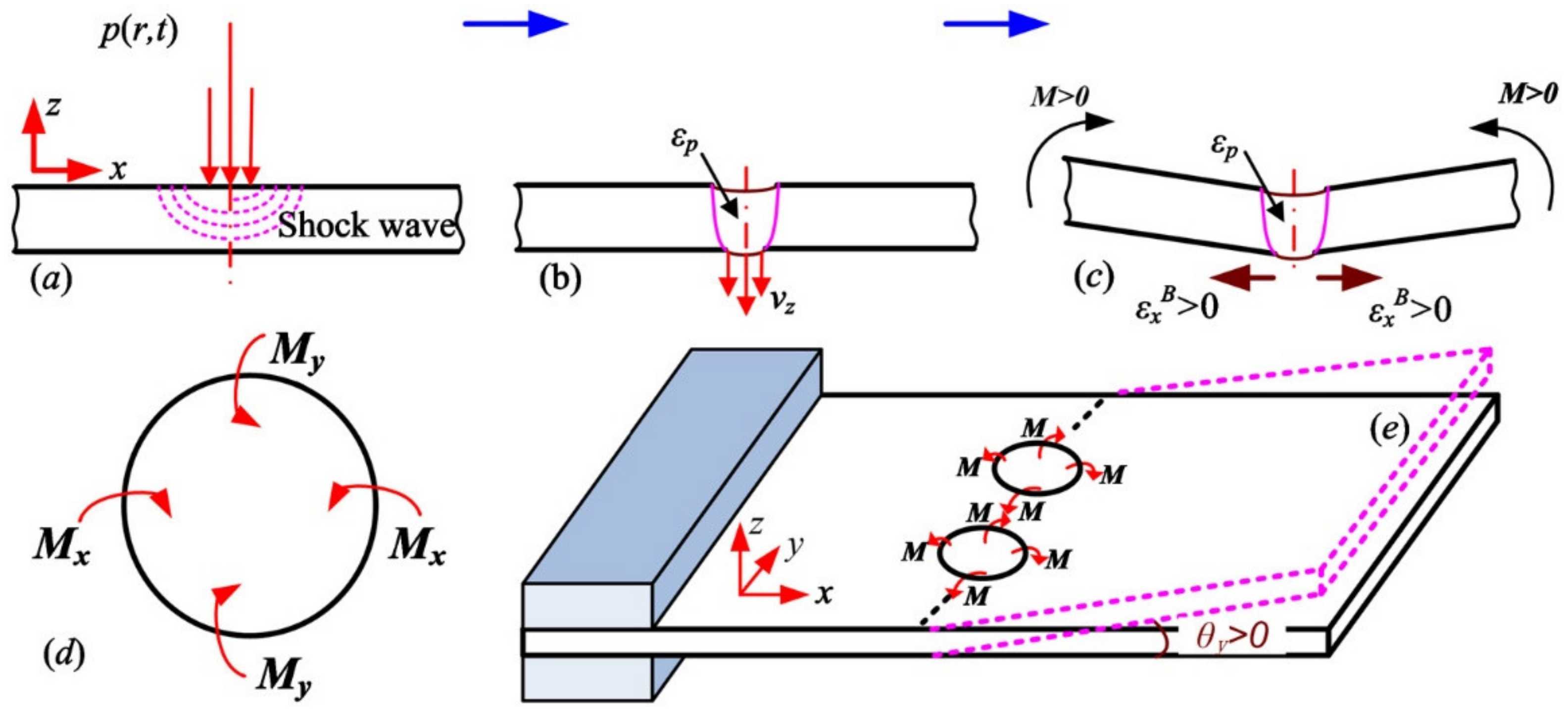

3.1. Laser Shock Forming

3.2. Warm Laser Shock Processing

3.3. Laser Shock Marking

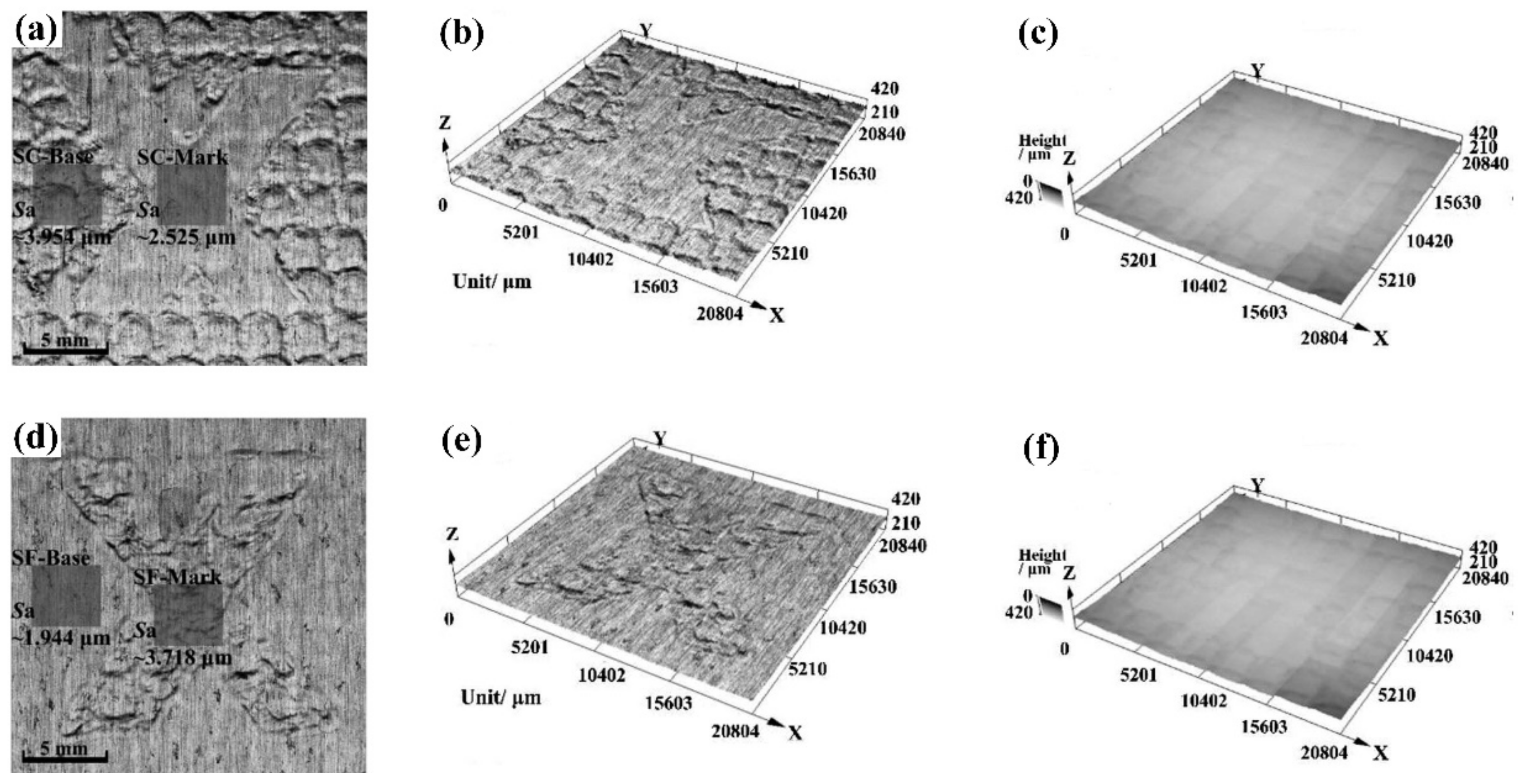

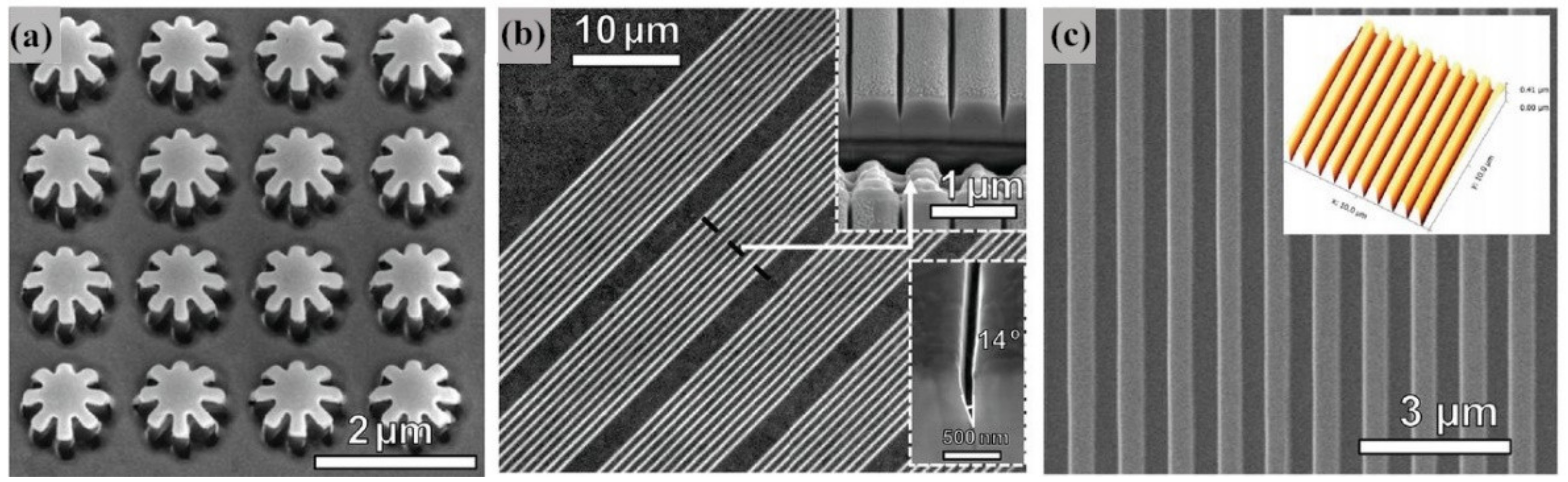

3.4. Laser Shock Imprinting

4. Conclusions

- (1)

- During LSP, the laser-generated stress effect can lead to severe plastic deformation, which will create the introduction of compressive residual stresses inside the material and the evolution of micro-structures. As a result, with LSP treatment, the mechanical properties and fatigue life of metallic materials or alloys are improved significantly.

- (2)

- Similar to the fundamental principle of LSP, the new technologies developed from LSP also utilize the laser-generated stress effect. LSF is utilized to modify the curvature of the metal sheet through the laser-induced high dynamic loading, and the metal sheet is found to be a convex or concave deformation that is depending on the sheet thickness and the laser power irradiance. As a thermal-mechanical surface hardening technology, WLSP combines the advantages of LSP, DSA and DP, so the material strength and the stability of residual stress and micro-structures by WLSP treatment are higher than that by LSP treatment. LSM is an effective method to obtain the visualized marks on the surface of metallic materials or alloys, and its critical aspect is the preparation of the absorbing layer with a designed shape and suitable thickness. At the high strain rates induced by LSP, LSI has the ability to complete the direct imprinting over the large-scale ultrasmooth complex 3D nanostructures arrays on the surface of crystalline metals.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hu, Y.X. Research on the Numerical Simulation and Impact Effects of Laser Shock Processing; Shanghai Jiao Tong University: Shanghai, China, 2008. [Google Scholar]

- Brabec, T.; Krausz, F. Intense few-cycle laser fields: Frontiers of nonlinear optics. Rev. Mod. Phys. 2000, 72, 545–591. [Google Scholar] [CrossRef]

- Kamiya, T.; Miyazaki, T.; Kubota, F. Social Demand of New Generation Information Network: Introduction to High Spectral Density Optical Communication Technology. High Spectr. Density Opt. Commun. Technol. 2010, 6, 3–10. [Google Scholar] [CrossRef]

- Moncorgé, R.; Chambon, B.; Rivoire, J.; Garnier, N.; Descroix, E.; Laporte, P.; Guillet, H.; Roy, S.; Mareschal, J.; Pelenc, D.; et al. Nd doped crystals for medical laser applications. Opt. Mater. 1997, 8, 109–119. [Google Scholar] [CrossRef]

- Tuchin, V.V.; Utz, S.R.; Yaroslavsky, I.V. Tissue optics, light distribution, and spectroscopy. Opt. Eng. 1994, 33, 3178–3188. [Google Scholar] [CrossRef]

- Boyd, I.W. Electronic Materials: Laser processing and diagnostics. Phys. Bull. 1984, 35, 419–420. [Google Scholar] [CrossRef]

- Zhang, G.S. Modern Laser Manufacturing Technology; Chemical Industry Press: Beijing, China, 2006. [Google Scholar]

- Zhang, Y.K.; Zhou, J.Z.; Ye, Y.X. Laser Processing Technology; Chemical Industry Press: Beijing, China, 2004. [Google Scholar]

- Yao, Z.Q.; Lawrence, Y.Y.; Wang, F.; Liu, G. Progress in advanced laser assisted manufacturing technology. Chin. J. Mech. Eng. 2003, 57–61. [Google Scholar] [CrossRef]

- Li, Y.H. Theory and Technology of Laser Shock Processing; Science Press: Beijing, China, 2013. [Google Scholar]

- Babu, P.D.; Balasubramanian, K.; Buvanashekaran, G. Laser surface hardening: A review. Int. J. Surf. Sci. Eng. 2011, 5, 131. [Google Scholar] [CrossRef]

- Allen, S. Laser chemical vapor deposition: A technique for selective area deposition. J. Appl. Phys. 1981, 52, 6501. [Google Scholar] [CrossRef]

- Biunno, N.; Narayan, J.; Hofmeister, S.K.; Srivatsa, A.R.; Singh, R.K. Low-temperature processing of titanium nitride films by laser physical vapor deposition. Appl. Phys. Lett. 1989, 54, 1519–1521. [Google Scholar] [CrossRef]

- Chi, Y.; Gu, G.; Yu, H.; Chen, C. Laser surface alloying on aluminum and its alloys: A review. Opt. Lasers Eng. 2018, 100, 23–37. [Google Scholar] [CrossRef]

- Yang, L.; Li, Z.; Zhang, Y.; Wei, S.; Liu, F. Al-TiC in situ composite coating fabricated by low power pulsed laser cladding on AZ91D magnesium alloy. Appl. Surf. Sci. 2018, 435, 1187–1198. [Google Scholar] [CrossRef]

- Wu, J.J.; Zhao, J.B.; Qiao, H.C.; Lu, Y.; Sun, B.; Hu, T.; Zhang, Y. The application status and development of laser shock processing. Opto-Electron. Eng. 2018, 45, 170690. [Google Scholar] [CrossRef]

- Wu, J.J.; Zhao, J.B.; Qiao, H.C.; Liu, X.; Zhang, Y.; Hu, T. Acoustic wave detection of laser shock peening. Opto-Electron. Adv. 2018, 1, 180016. [Google Scholar] [CrossRef]

- Qiao, H.C.; Gao, Y.; Zhao, J.B. Research process of laser peening technology. Chin. J. Nonferrous Met. 2015, 25, 1744–1755. [Google Scholar]

- Lu, G.X.; Liu, H.; Lin, C.H.; Zhang, Z.; Skulia, P.; Zhang, Y.; Yao, J. Improving the fretting performance of aero-engine tenon joint materials using surface strengthening. Mater. Sci. Technol. 2019, 35, 1781–1788. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Berthe, L.; Scherpereel, X.; Le Cornec, A. Laser shock processing with small impacts. In Proceedings of the SPIE the International Society for Optical Engineering, Besancon, France, 23 September 1996. [Google Scholar]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y.-W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

- Lu, G.X.; Sokol, D.W.; Zhang, Y.K.; Dulaney, J.L. Nanosecond pulsed laser-generated stress effect inducing macro-micro-nano structures and surface topography evolution. Appl. Mater. Today 2019, 15, 171–184. [Google Scholar] [CrossRef]

- Wu, J.J.; Zhao, J.B.; Qiao, H.C. Effect of temperature-assisted laser shock peening on mechanical properties of GH4169 alloy. J. Plast. Eng. 2019, 26, 199–205. [Google Scholar] [CrossRef]

- Peyre, P.; Fabbro, R.; Merrien, P.; Lieurade, H.P. Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater. Sci. Eng. A 1996, 210, 102–113. [Google Scholar] [CrossRef]

- Wu, J.; Liu, X.; Zhao, J.; Qiao, H.; Zhang, Y.; Zhang, H. The online monitoring method research of laser shock processing based on plasma acoustic wave signal energy. Optik 2019, 183, 1151–1159. [Google Scholar] [CrossRef]

- Vailionis, A.; Gamaly, E.G.; Mizeikis, V.; Yang, W.; Rode, A.V.; Juodkazis, S. Evidence of superdense aluminium synthesized by ultrafast microexplosion. Nat. Commun. 2011, 2, 445. [Google Scholar] [CrossRef] [PubMed]

- Glezer, E.N.; Mazur, E. Ultrafast-laser driven micro-explosions in transparent materials. Appl. Phys. Lett. 1997, 71, 882–884. [Google Scholar] [CrossRef]

- Wu, J.J.; Zhao, J.B.; Qiao, H.C.; Zhang, Y.; Hu, X.; Yu, Y. Evaluating methods for quality of laser shock processing. Optik 2020, 200, 162940. [Google Scholar] [CrossRef]

- Wu, J.J.; Liu, X.J.; Zhao, J.B. Online Detection Method of Laser Shock Peening Based on Shock Wave Signal Energy in Air. Surf. Technol. 2019, 48, 100–106. [Google Scholar] [CrossRef]

- Fairand, B.P.; Clauer, A.H. Laser Generation of High-amplitude Stress Waves in Materials. J. Appl. Phys. 1979, 50, 1497–1502. [Google Scholar] [CrossRef]

- Fairand, B.P.; Clauer, A.H. Effect of water and paint coatings on the magnitude of laser-generated shocks. Opt. Commun. 1976, 18, 588–591. [Google Scholar] [CrossRef]

- Qiao, H.C.; Hu, X.L.; Zhao, J.B. Influence Parameters and Development Application of Laser Shock Processing. Surf. Technol. 2019, 48. [Google Scholar] [CrossRef]

- Lu, G.X.; Jin, T.; Zhou, Y.Z. Research progress of applications of laser shock processing on superalloys. Chin. J. Nonferrous Met. 2018, 28, 1755–1764. [Google Scholar] [CrossRef]

- Zhang, Y.K.; Lu, J.Z.; Luo, K.Y. Laser Shock Processing of FCC Metals; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Rakziemski, L.J.; Cremers, D.A. Laser-Induced Plasmas and Applications; Marcel Dekker Inc: New York, NY, USA, 1989. [Google Scholar]

- Harilal, S.S.; Miloshevsky, G.V.; Diwakar, P.K.; LaHaye, N.L.; Hassanein, A. Experimental and computational study of complex shockwave dynamics in laser ablation plumes in argon atmosphere. Phys. Plasmas 2012, 19, 083504. [Google Scholar] [CrossRef]

- Lu, G.X. Effect of Laser Shock on Surface Topography, Microstructure and Mechanical Behaviors of Superalloys; Institute of Metal Research, Chinese Academy of Sciences: Shenyang, China, 2017. [Google Scholar]

- Fabbro, R.; Fournier, J.; Ballard, P.; Devaux, D.; Virmont, J. Physical study of laser-introduced plasma in confined geometry. J. Appl. Phys. 1990, 68, 775–784. [Google Scholar] [CrossRef]

- Ma, D.Y. Theoretical Foundation of Modern Acoustics; Science Press: Beijing, China, 2004. [Google Scholar]

- Renk, K.F. Laser Principle. In Basics of Laser Physics; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Ren, X.D. Laser Shock Processing Technology for High Temperature Service Materials; Science Press: Beijing, China, 2014; ISBN 978-7-03-042495-2. [Google Scholar]

- Zhang, W.W.; Yao, Y.L. Microscale Laser Shock Processing-Modeling, Testing, and Microstructure Characterization. J. Manuf. Process. 2001, 3, 128–143. [Google Scholar] [CrossRef]

- Braisted, W.; Brockman, R. Finite element simulation of laser shock peening. Int. J. Fatigue 1999, 21, 719–724. [Google Scholar] [CrossRef]

- Geiger, M.; Vollertsen, F. The Mechanisms of Laser Forming. CIRP Ann. Manuf. Technol. 1993, 42, 301–304. [Google Scholar] [CrossRef]

- Wang, Y.N.; Fan, Y.J.; Vukelic, S.; Yao, Y.L. Energy-Level Effects on the Deformation Mechanism in Microscale Laser Peen Forming. J. Manuf. Process 2007, 9, 1–12. [Google Scholar] [CrossRef]

- Hu, Y.X.; Xu, X.X.; Yao, Z.Q.; Hu, J. Laser peen forming induced two way bending of thin sheet metals and its mechanisms. J. Appl. Phys. 2010, 108, 235–359. [Google Scholar] [CrossRef]

- Yang, F.H.; Lu, G.X.; Yang, Q.T. Research Progress of Laser Shock Treatment in the Field of Material Forming. J. Aeronaut. Mater. 2018, 38, 5–14. [Google Scholar]

- Sitnikova, E.; Guan, Z.W.; Schleyer, G.K.; Cantwell, W.J. Modelling of perforation failure in fibre metal laminates subjected to high impulsive blast loading. Int. J. Solids Struct. 2014, 51, 3135–3146. [Google Scholar] [CrossRef]

- Hu, Y.X.; Zheng, X.W.; Wang, D.Y.; Zhang, Z.; Xie, Y.; Yao, Z. Application of laser peen forming to bend fibre metal laminates by high dynamic loading. J. Mater. Process. Technol. 2015, 226, 32–39. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Cheng, G.J. A review: Warm laser shock peening and related laser processing technique. Opt. Laser Technol. 2016, 78, 15–24. [Google Scholar] [CrossRef]

- Gujba, A.; Medraj, M. Laser Peening Process and Its Impact on Materials Properties in Comparison with Shot Peening and Ultrasonic Impact Peening. Materials 2014, 7, 7925–7974. [Google Scholar] [CrossRef]

- Zhou, Z.; Bhamare, S.; Ramakrishnan, G.; Mannava, S.R.; Langer, K.; Wen, Y.; Qian, D.; Vasudevan, V.K. Thermal relaxation of residual stress in laser shock peened Ti–6Al–4V alloy. Surf. Coat. Technol. 2012, 206, 4619–4627. [Google Scholar] [CrossRef]

- Ren, X.D.; Zhan, Q.; Yuan, S.; Zhou, J.; Wang, Y.; Ren, N.; Sun, G.; Zheng, L.; Dai, F.; Yang, H.; et al. A finite element analysis of thermal relaxation of residual stress in laser shock processing Ni-based alloy GH4169. Mater. Des. 2014, 54, 708–711. [Google Scholar] [CrossRef]

- Liao, Y.; Ye, C.; Kim, B.-J.; Suslov, S.; Stach, E.A.; Cheng, G.J. Nucleation of highly dense nanoscale precipitates based on warm laser shock peening. J. Appl. Phys. 2010, 108, 063518. [Google Scholar] [CrossRef]

- Beukel, A.V.D. Theory of the effect of dynamic strain aging on mechanical properties. Phys. Status Solidi A 1975, 30, 197–206. [Google Scholar] [CrossRef]

- Roven, H.J.; Liu, M.; Werenskiold, J.C. Dynamic precipitation during severe plastic deformation of an Al–Mg–Si aluminium alloy. Mater. Sci. Eng. A 2008, 483, 54–58. [Google Scholar] [CrossRef]

- Tong, Z.P.; Ren, X.D.; Ren, Y.P.; Dai, F.; Ye, Y.; Zhou, W.; Chen, L.; Ye, Z. Effect of laser shock peening on microstructure and hot corrosion of TC11 alloy. Surf. Coat. Technol. 2017, 335, 32–40. [Google Scholar] [CrossRef]

- Lu, Y.; Zhao, J.B.; Qiao, H.C.; Hu, T.; Sun, B.; Wu, J. A study on the surface morphology evolution of the GH4619 using warm laser shock peening. AIP Adv. 2019, 9, 085030. [Google Scholar] [CrossRef]

- Su, C.; Zhou, J.Z.; Meng, X.K. Research Progress of Temperature-Assisted Laser Shock Technology. Surf. Technol. 2016, 45, 121–128. [Google Scholar]

- Liao, Y.; Ye, C.; Gao, H.; Kim, B.-J.; Suslov, S.; Stach, E.A.; Cheng, G.J. Dislocation pinning effects induced by nano-precipitates during warm laser shock peening: Dislocation dynamic simulation and experiments. J. Appl. Phys. 2011, 110, 023518. [Google Scholar] [CrossRef]

- Tani, G.; Orazi, L.; Fortunato, A.; Ascari, A.; Campana, G. Warm Laser Shock Peening: New developments and process optimization. CIRP Ann. 2011, 60, 219–222. [Google Scholar] [CrossRef]

- Ye, C.; Liao, Y.; Suslov, S.; Lin, N.; Cheng, G.J. Ultrahigh dense and gradient nano-precipitates generated by warm laser shock peening for combination of high strength and ductility. Mater. Sci. Eng. A 2014, 609, 195–203. [Google Scholar] [CrossRef]

- Ye, C.; Liao, Y.; Cheng, G.J.; Liao, Y. Warm Laser Shock Peening Driven Nanostructures and Their Effects on Fatigue Performance in Aluminium Alloy 6160. Adv. Eng. Mater. 2010, 12. [Google Scholar] [CrossRef]

- Zhou, J.; Meng, X.; Huang, S.; Sheng, J.; Lu, J.; Yang, Z.; Su, C. Effects of warm laser peening at elevated temperature on the low-cycle fatigue behavior of Ti6Al4V alloy. Mater. Sci. Eng. A 2015, 643, 86–95. [Google Scholar] [CrossRef]

- Huang, S.; Wang, Z.W.; Sheng, J. Residual Stress Distribution and Microstructure Evolution of AA 6061-T6 Treated by Warm Laser Peening. Metals 2016, 6, 292. [Google Scholar] [CrossRef]

- Qian, K.W.; Li, X.Q.; Xiao, L.G.; Chen, W.W.; Zhang, H.; Peng, K. Dynamic strain aging phenomenon in metals and alloys. J. Fuzhou Univ. (Nat. Sci. Ed.) 2001, 26, 8–23. [Google Scholar]

- Meng, X.K.; Huang, S.; An, Z.W. Finite Element Analysis of Shock Wave Pressure Induced by Warm Laser Peening. Acta Opt. Sin. 2013, 33, 114014. [Google Scholar] [CrossRef]

- Su, C.; Zhou, J.Z.; Meng, X.K.; Sheng, J. Comparison of warm laser shock peening and laser shock peening techniques in lengthening the fatigue life of welded joints made of aluminum alloy. Int. J. Mod. Phys. B 2017, 31, 1744045. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Kalainathan, S. Warm laser shock peening without coating induced phase transformations and pinning effect on fatigue life of low-alloy steel. Mater. Des. 2016, 107, 98–107. [Google Scholar] [CrossRef]

- Li, J.; Chung, T.-F.; Chen, Y.P.; Cheng, G.J. Nanoscale Strainability of Graphene by Laser Shock-Induced Three-Dimensional Shaping. Nano Lett. 2012, 12, 4577–4583. [Google Scholar] [CrossRef]

- Leone, C.; Bassoli, E.; Genna, S.; Gatto, A. Experimental investigation and optimisation of laser direct part marking of Inconel 718. Opt. Lasers Eng. 2018, 111, 154–166. [Google Scholar] [CrossRef]

- Lu, G.X.; Li, J.; Zhang, Y.K.; Sokol, D.W. A metal marking method based on laser shock processing. Mater. Manuf. Process. 2019, 34, 598–603. [Google Scholar] [CrossRef]

- Shen, Z.B. Research on Micromould Based Laser Shock Embossing of Thin Metal Sheets; Jiangsu University: Zhenjiang, China, 2010. [Google Scholar]

- Gao, H.; Hu, Y.; Xuan, Y.; Li, J.; Yang, Y.; Martinez, R.; Li, C.; Luo, J.; Qi, M.; Cheng, G.J. Large-scale nanoshaping of ultrasmooth 3D crystalline metallic structures. Science 2014, 346, 1352–1356. [Google Scholar] [CrossRef] [PubMed]

- Guo, L.J. Nanoimprint Lithography: Methods and Material Requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Park, I.; Ko, S.H.; Pan, H.; Grigoropoulos, C.P.; Pisano, A.P.; Frechet, J.; Lee, E.-S.; Jeong, J.-H. Nanoscale Patterning and Electronics on Flexible Substrate by Direct Nanoimprinting of Metallic Nanoparticles. Adv. Mater. 2008, 20, 489–496. [Google Scholar] [CrossRef]

| References | Material | Type of Laser System | Laser Parameters | Absorbing Layer | Confining Layer | Temperature | Materials Parameters | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wavelength (nm) | Pulse Width (ns) | Power Irradiance (GW/cm2) | Diameter (mm) | Repetition Rate (Hz) | Overlap Rate | |||||||

| Liao [60]—Figure 10a | AA6061 | ND-YAG | 1064 | 5 | 0.8–2.4 | 2 | - | 75% | Al foil | BK7 glass | 20–160 °C | Hardness |

| Tani [61]—Figure 10b | AISI 1042 | Nd:YAG | - | 8 | 1.5 | 4 | single | - | No layer | Silicone oil | 300 K, 500 K | Hardness |

| Ye [62]—Figure 11a | AA 7075 | Nd:YAG | 1064 | 5 | 5 | 1 | - | 75% | Al foil | BK7 glass | 25 °C, 250 °C | Residual stress |

| Ye [63]—Figure 11b | AA 6061-T6 | Nd-YAG | 1064 | 5 | 1.5 | 2 | 4 | 75% | Al foil | BK7 glass | 25 °C, 160 °C | Residual stress |

| Zhou [64]—Figure 12 | Ti6Al4V | Nd-YAG | 1064 | 10 | 12.73 | 3 | - | 50% | Al foil | Silicone oil | 20–400 °C | Fatigue life |

| Ye [63]—Figure 13 | AA 6061-T6 | Nd-YAG | 1064 | 5 | 1.5 | 2 | 4 | 75% | Al foil | BK7 glass | 25 °C, 160 °C | Grain structure |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Zhao, J.; Qiao, H.; Hu, X.; Yang, Y. The New Technologies Developed from Laser Shock Processing. Materials 2020, 13, 1453. https://doi.org/10.3390/ma13061453

Wu J, Zhao J, Qiao H, Hu X, Yang Y. The New Technologies Developed from Laser Shock Processing. Materials. 2020; 13(6):1453. https://doi.org/10.3390/ma13061453

Chicago/Turabian StyleWu, Jiajun, Jibin Zhao, Hongchao Qiao, Xianliang Hu, and Yuqi Yang. 2020. "The New Technologies Developed from Laser Shock Processing" Materials 13, no. 6: 1453. https://doi.org/10.3390/ma13061453

APA StyleWu, J., Zhao, J., Qiao, H., Hu, X., & Yang, Y. (2020). The New Technologies Developed from Laser Shock Processing. Materials, 13(6), 1453. https://doi.org/10.3390/ma13061453