Effect of Rare Earth Ce on Deep Stamping Properties of High-Strength Interstitial-Free Steel Containing Phosphorus

Abstract

:1. Introduction

2. Test Method

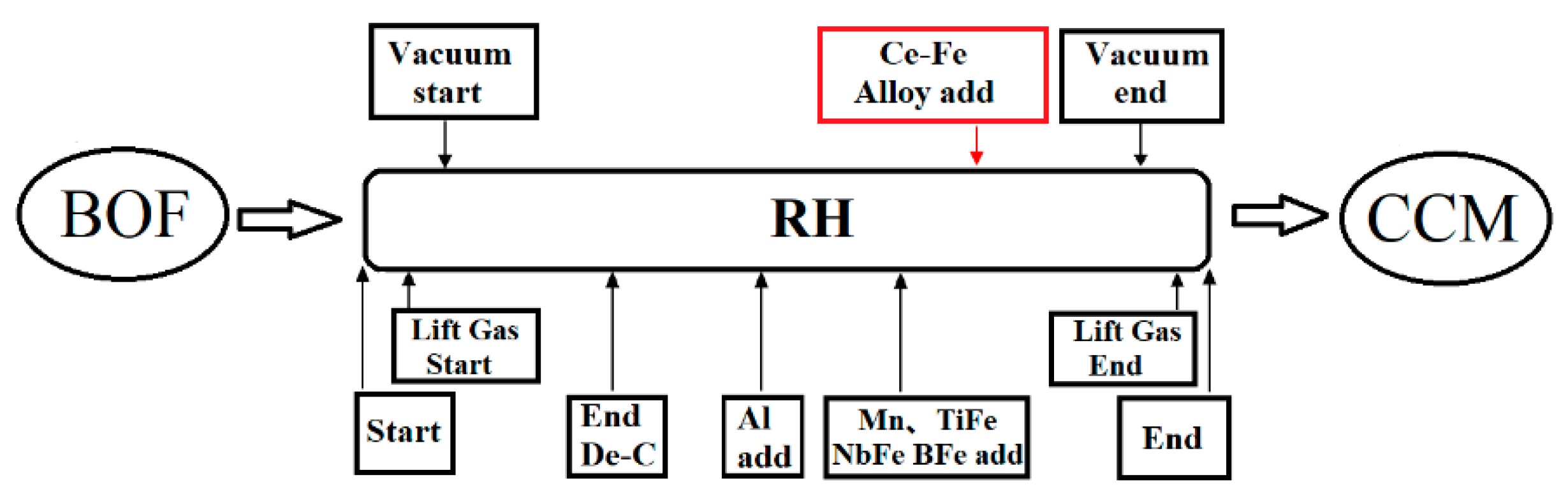

2.1. Process

2.2. Method

3. Results and Discussion

3.1. Effect of Rare Earth Ce on Inclusions

3.2. Effect of Rare Earth Ce on Microstructure Refinement of Steel Strip

3.3. Effect of Rare Earth Ce on Texture of Strip

3.4. Comparison of Stamping Properties

4. Conclusions

- (1)

- Based on the addition of rare earth in steel, the combination of Ce with activity O and S in the steel had lower Gibbs free energy, and it was easy to generate CeAlO3, Ce2O2S, and Ce2O3. Meanwhile, the inclusion size decreased obviously, but the amount of inclusions increased. The morphology of inclusions changed from chain and strip to spherical. The size of rare earth inclusions was mostly about 2–5 μm, distributed and dispersed, and their elastic modulus was close to that of steel matrix, which is conducive to improving the structure continuity of steel.

- (2)

- The rare earth compound had a high melting point. As a heterogeneous nucleation point, the nucleation rate was increased and the solidification structure was refined. Meanwhile, in the process of rolling heat treatment, rare earth can preferentially segregate grain boundaries to slow down grain growth. The addition of rare earth can improve the grain size rating of a continuous annealing strip by 1.5 grades, which is conducive to improving the strength and plasticity of strip.

- (3)

- Rare earth Ce can inhibit the segregation of P element at the grain boundary and the precipitation of Fe(Nb+Ti)P phase. It can effectively increase the solid solution amount of P element in steel, improve the solid solution strengthening effect of P element in high-strength IF steel, and obtain a large proportion of {111} favorable texture, which is conducive to improving the stamping formability index r90 value.

Author Contributions

Funding

Conflicts of Interest

References

- Wang, M.; Bao, Y.-P.; Yang, Q.; Zhao, L.-H.; Lin, L. Coordinated control of carbon and oxygen for ultra-low-carbon interstitial-free steel in a smelting process. Int. J. Miner. Metall. Mater. 2015, 22, 125. [Google Scholar] [CrossRef]

- Guo, J.-L.; Bao, Y.-P.; Wang, M. Cleanliness of Ti-bearing Al-killed ultra-low-carbon steel during different heating processes. Int. J. Miner. Metall. Mater. 2017, 24, 1370. [Google Scholar] [CrossRef] [Green Version]

- Di Giovanni, C.; Biro, E.; Zhou, N.-Y. Impact of liquid metal embrittlement cracks on resistance spot weld static strength. Sci. Technol. Welding Joining 2019, 24, 218. [Google Scholar] [CrossRef]

- Oliveiraa, J.-P.; Ponderb, K.; Brizesb, E.; Abkec, T.; Edwardsd, P.; Ramirezb, A.-J. Combining resistance spot welding and friction element welding for dissimilar joining of aluminum to high strengths steels. J. Mater. Proc. Technol. 2019, 273, 01. [Google Scholar] [CrossRef]

- Zhu, R.-Q.; Song, X.-L.; Zheng, A.-Q.; Chen, R.-D.; Jia, J.; Fan, L.-X. Strain hardening and microstructure characteristic of high strength IF bearing phosphorus steel. Iron Steel 2018, 53, 55. [Google Scholar]

- Wang, R.; Bao, Y.-P.; Li, Y.-H.; Yan, Z.-J.; Li, D.-Z.; Kang, Y. Influence of metallurgical processing parameters on defects in cold-rolled steel sheet caused by inclusions. Int. J. Miner. Metall. Mater. 2019, 26, 440. [Google Scholar] [CrossRef]

- Wang, R.; Bao, Y.-P.; Yan, Z.-J.; Li, D.-Z.; Kang, Y. Comparison between the surface defects caused by Al2O3 and TiN inclusions in interstitial-free steel auto sheets. Int. J. Miner. Metall. Mater. 2019, 26, 178. [Google Scholar] [CrossRef]

- Wang, Y.-P.; Zhao, X.-L.; Liu, J. Influence of B content on recrystallization and texture of P-containing high strength IF steel. Heat Treat. Metals 2018, 43, 54–59. [Google Scholar]

- Yang, J.-C.; Li, H.-W.; Zhou, L.; Zhang, J.; Liu, N. Mechanism of trace cerium in ultra-clean IF steel. Iron Steel 2015, 50, 81. [Google Scholar]

- Xiao, J.-G.; Chen, H.-J.; Wang, F.-M. Effects of rare earth in ship hull plate steel on its microstructure and low temperature toughness. China Rare Earths 2010, 31, 52. [Google Scholar]

- Li, H.; Yu, Y.-C.; Ren, X.; Zhang, S.-H.; Wang, S.-B. Evolution of Al2O3 inclusions by cerium treatment in low carbon high manganese. Iron Steel Res. Int. 2017, 24, 925. [Google Scholar] [CrossRef]

- Gao, S.; Wang, M.; Guo, J.-L.; Wang, H.; Zhi, J.-G.; Bao, Y.-P. Characterization transformation of inclusions using rare earth Ce treatment on Al-killed titanium alloyed interstitial free steel. Steel Res. Inter. 2019, 90, 01. [Google Scholar] [CrossRef]

- Yang, J.-C.; Li, H.-W.; Zhang, J.; Zhou, L.; Zhao, G.-S. Thermodynamic analysis and experimental study of cerium inclusions in IF steel containing cerium. Chin. Rare Earths 2018, 39, 01. [Google Scholar]

- Tian, Y.-Q.; Wang, A.-D.; Song, J.-Y.; Zhen, X.-P.; Zhao, D.-G.; Chen, L.-S. Formation reason and control measures of surface quality defects of cold rolled steel sheet for galvanization. J. Iron Steel Res. 2017, 29, 312. [Google Scholar]

- Wang, C.; Yu, Y.; Liu, K. Forming reason and control of strip fracture in high strength IF steel containing phosphorus during hot-rollling process. China Metallurgy 2016, 26, 17. [Google Scholar]

- Chen, S.-F.; Liu, X.; Lei, H. Precipitation behavior of MnS inclusions during solidification of manganese steel. J. Univer. Sci. Technol. Liaoning 2017, 40, 241. [Google Scholar]

- Zhou, Y.; Liu, W.-D.; Yan, J.; Liu, D. Valence electron theoretical analysis of the influence of rare earth elements on the deformation ability of MnS inclusions. Chin. J. Rare Metals 2006, 02, 185. [Google Scholar]

- Wang, H.; Bao, Y.-P.; Zhao, M.; Wang, M.; Yuan, X.-M.; Gao, S. Effect of Ce on the cleanliness, microstructure and mechanical properties of high strength low alloy steel Q690E in industrial production process. Int. J. Miner. Metall. Mater. 2019, 26, 1372. [Google Scholar] [CrossRef]

- Wang, H.; Bao, Y.-P.; Liu, Y.; Wang, M.; Wang, J.-G.; Su, C. Effect of microstructure and grain size on DWTT properties of 22mm thick X80M hot rolled steel strip. Metal. Res. Technol. 2019, 220, 116. [Google Scholar]

- Xu, J.; Qi, G.-P.; Zhu, J.-X. Effect of Rare Earth on Solidification Structure and Formability of 430 Ferritic Stainless Steel Shee. J. Chin. Social. Rare Earths 2006, 24, 486. [Google Scholar]

- Li, G.; Lu, M.-G.; Lan, P. Research progress of rare earth Ce on improvement of microstructure and homogeneity of as-cast steel. J. Iron Steel Res. 2018, 30, 79. [Google Scholar]

- Huang, Y.; Cheng, G.-G.; Xie, Y. Modification Mechanism of Cerium on the Inclusions in Drill Steel. J. Acta Metall. Sin. 2018, 54, 1253. [Google Scholar]

- Wang, X.-P.; Zhao, A.-M.; Zhao, Z.-Z.; Huang, Y.; Li, L.; He, Q. Mechanical properties and characteristics of nanometer-sized precipitates in hot-rolled low-carbon ferritic steel. Int. J. Miner. Metall. Mater. 2014, 21, 266. [Google Scholar] [CrossRef]

- Hao, L.; Ren, H.-P.; Jin, Z.-L.; Wang, C.-Y.; Li, D.-Y.; Li, Y.-H. Effects of rare earth La and annealing process on microstructure of high strength IF steel. Heat Treat. Metals 2017, 42, 35. [Google Scholar]

- Yu, X.; Ren, H.-P.; Jin, Z.-L. Effect of rare earth on Recrystallization Behavior of high strength IF steel during hot rolling. Chin. Rare Earths 2018, 39, 117. [Google Scholar]

- Yang, J.-C.; Yang, C.-Q.; Wang, S.-J. Effect of micro rare earth Ce on high temperature mechanical properties of IF steel. Special Steel 2014, 35, 65. [Google Scholar]

- Lin, Q.; Guo, F.; Zhu, X.-Y. Behaviors of Lanthanum and Cerium on Grain Boundaries in Carbon Manganese Clean Steel. J. Rare Earths 2007, 25, 485. [Google Scholar] [CrossRef]

- Song, X.-L.; Yuan, Z.-X.; Li, P.-H.; Guo, A.-M.; Wang, D. Effect of recrystallization annealing on Microstructure of cold rolled IF steel containing phosphorus. J. Chin. Electron Microsc. Soc. 2008, 27, 473. [Google Scholar]

- Gupta, R.P.; Martin, G.; Lanteri, S.; Maugis, P.; Guttmann, M. Relationship between the electronic structure and the precipitation of FeTiP in interstitial-free ferritic steels. Philosoph. Magaz. 2000, 80, 2393. [Google Scholar]

- Xiong, D.-L.; Mao, W.-M. Desolvation and hardening of FeTiP phase in high strength if steel containing phosphorus. Chin. J. Engineer. 2000, 22, 350. [Google Scholar]

- Ghosh, P.; Ray, R.-K.; Bhattacharjee, D. Determination of the crystal structure of FeTiP-type precipitates in a few interstitial-free high-strength steels. Scripta Materialia 2007, 57, 241. [Google Scholar] [CrossRef]

- Zhang, J.-C.; Cao, Y.; Jiang, G.-W.; Di, H.-S. Effect of Annealing Temperature on the Precipitation Behavior and Texture Evolution in a Warm-Rolled P-Containing Interstitial-Free High Strength Steel. Acta Metall. Sin. 2014, 27, 395. [Google Scholar] [CrossRef]

- Guo, W.-M.; Sun, D.P.; Zhang, H.-Y.; Ding, N.; Shi, J.-B.; Zhao, B.-L. Precipitates and deep-drawability of containing phosphorus high strength IF steel. Heat Treat. Metals. 2015, 40, 99–103. [Google Scholar]

- Guo, W.-M.; Wang, Z.-C.; Li, Y.-D.; Xu, N.; Shi, J.-B. Effect of Phosphorus Content on Properties of Warm-Rolled Interstitial-Free Steel Sheets. Acta Metall. Sin. 2014, 27, 395. [Google Scholar] [CrossRef] [Green Version]

- Ren, D.; Jin, Z.-L.; Ren, H.-P.; Li, Y.-Y.; Li, Y.-M.; Zhang, J.-S. Effect of Rare Earth Lanthanum on P Element and Precipitation P-containing Precipitate in High Strength IF Steel. Chin. J. Rare Met. 2019, 01, 01. [Google Scholar]

- Jia, J.; Zhu, W.-W.; Song, X.-L.; Yuan, Z.-X. Precipitation Behavior of FeTiP in Ti-added Interstitial Free High Strength Steels. J. Iron Steel Res. 2016, 23, 692. [Google Scholar] [CrossRef]

| Heat Number | C | Si | Mn | P | S | Als 1 | Nb | Ti | B | Ce |

|---|---|---|---|---|---|---|---|---|---|---|

| 2nd | 0.0020 | 0.15 | 0.68 | 0.078 | 0.005 | 0.029 | 0.027 | 0.022 | 0.0012 | |

| 3nd | 0.0018 | 0.14 | 0.70 | 0.074 | 0.005 | 0.032 | 0.025 | 0.025 | 0.0010 | 0.0022 |

| Reaction Equations in Molten Steel | ||

|---|---|---|

| A | B | |

| 2Al + 3O = Al2O3 (s) | −1,208,271 | 390.91 |

| 2Ce + 3O = Ce2O3 (s) | −1,431,090 | 360.06 |

| Ce + 2O = CeO2 (s) | −854,274.7 | 249.11 |

| Ce + S = CeS (s) | −422,783 | 120.58 |

| 3Ce + 4S = Ce3S4 (s) | −1,493,010 | 438.9 |

| 2Ce + 2O + S = Ce2O2S (s) | −1,353,592.4 | 331.6 |

| Ce + Al + 3O = CeAlO3 (s) | −1,366,460 | 364 |

| Processes | HR {110} <001> /% | CR {111} (<110> + <112>) /% | CA {111} (<110> + <112> /%) |

|---|---|---|---|

| 1# | 3.79 | 18.8 | 21.62 |

| 2# | 5.78 | 22.7 | 24.16 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Bao, Y.; Duan, C.; Lu, L.; Liu, Y.; Zhang, Q. Effect of Rare Earth Ce on Deep Stamping Properties of High-Strength Interstitial-Free Steel Containing Phosphorus. Materials 2020, 13, 1473. https://doi.org/10.3390/ma13061473

Wang H, Bao Y, Duan C, Lu L, Liu Y, Zhang Q. Effect of Rare Earth Ce on Deep Stamping Properties of High-Strength Interstitial-Free Steel Containing Phosphorus. Materials. 2020; 13(6):1473. https://doi.org/10.3390/ma13061473

Chicago/Turabian StyleWang, Hao, Yanping Bao, Chengyi Duan, Lu Lu, Yan Liu, and Qi Zhang. 2020. "Effect of Rare Earth Ce on Deep Stamping Properties of High-Strength Interstitial-Free Steel Containing Phosphorus" Materials 13, no. 6: 1473. https://doi.org/10.3390/ma13061473