A357 Alloy by LPBF for Industry Applications

Abstract

:1. Introduction

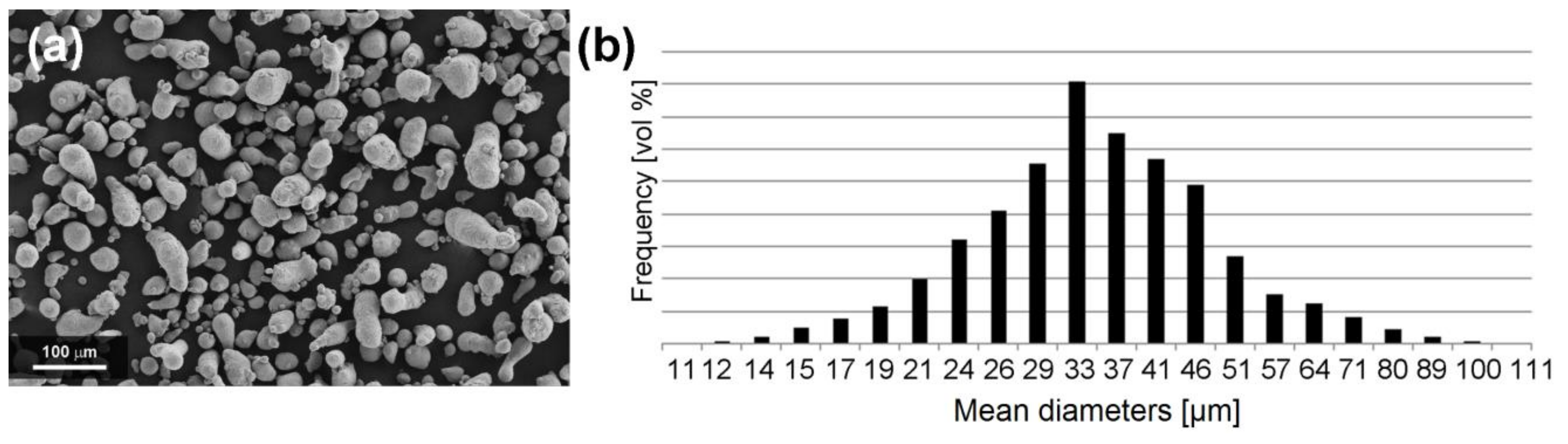

2. Materials and Methods

3. Results and Discussion

3.1. Optimization of Process Parameters

3.2. Evaluation of Micro-Hardness

3.3. Microstructure Investigation

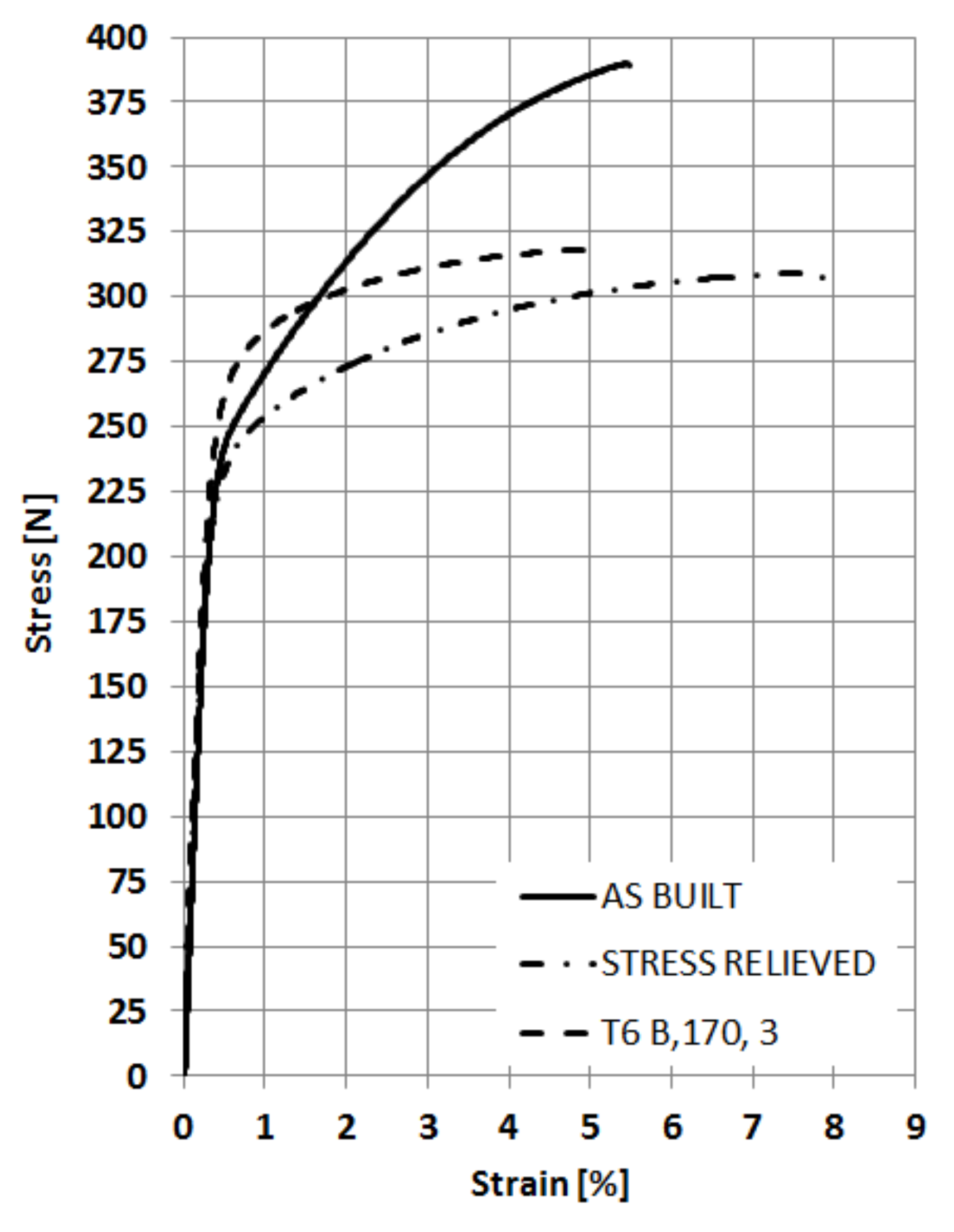

3.4. Evaluation of Tensile Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mallick, P.K. Advanced materials for automotive application: An overview. Adv. Mater. Auto Eng. 2012, 2, 5–27. [Google Scholar]

- Vilaro, T.; Abed, S.; Knapp, W. Direct manufacturing of technical parts using selective laser melting; example of automotive application. In Proceedings of the 12th European Forum Rapid Prototype, AFPR, Paris, France, 5–6 March 2008. [Google Scholar]

- Prillhofer, R.; Rank, G.; Berneder, J.; Antrekowitsch, H.; Uggowitzer, P.J.; Pogatscher, S. Property criteria for automotive Al-Mg-Si sheet alloys. Materials 2014, 7, 5047–5068. [Google Scholar] [CrossRef] [PubMed]

- Olakanmi, E.O. Selective laser sintering/melting (SLS/SLM) of pure Al, Al-Mg, and Al-Si powders: Effect of processing conditions and powder properties. J. Mater. Process. Technol. 2013, 213, 1387–1405. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.P.; Lombardi, M.; Fino, P.; Manfredi, D. On the selective laser melting (SLM) of the AlSi10Mg alloy: Process, microstructure, and mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Z.; Lei, Y.; Zhang, H. Structure and properties of nanostructured A357 alloy produced by melt spinning compared with direct chill ingot. J. Alloys Compd. 2011, 509, 7473–7477. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Sidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminium alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Bourell, D.; Wohlert, M.; Harlan, N.; Das, S.; Beaman, J. Powder densification maps in selective laser sintering. Adv. Eng. Mater. 2002, 4, 663–669. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mat. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Li, J.P.; Wilson, C.; Wijn, J.R.; Van Blitterswijk, C.A.; Groot, K. Fabrication of porous Ti6Al4V with designed structure by rapid prototyping technology. Key Eng. Mater. 2007, 330, 1293–1296. [Google Scholar] [CrossRef]

- Ma, P.; Jia, Y.; Prashenth, K.G.; Scudino, S.; Yu, Z.; Eckert, J. Microstructure and phase formation in Al.20Si-5Fe-3Cu-1Mg synthesized by selective laser melting. J. Alloys Compd. 2016, 657, 430–435. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L. Effect of Al alloys on selective laser melting behaviour and microstructure of in situ formed particle reinforced composites. J. Alloys Compd. 2012, 541, 328–334. [Google Scholar] [CrossRef]

- Pauly, S.; Lober, L.; Petters, R.; Stoica, M.; Scudino, S.; Kuhn, U.; Eckert, J. Processing metallic glasses by selective laser melting. Mater. Today 2013, 16, 37–41. [Google Scholar] [CrossRef]

- Aversa, A.; Lorusso, M.; Trevisan, F.; Ambrosio, E.P.; Calignano, F.; Manfredi, D.; Biamino, S.; Fino, P.; Lombardi, M.; Pavese, M. Effect of process and post-process conditions on the mechanical properties of an A357 alloy produced via laser powder bed fusion. Metals 2017, 7, 68. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 1294–1301. [Google Scholar] [CrossRef]

- Mercelis, P.; Kruth, J.P. Residual stresses in selective laser sintering and in selective lase melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humneeck, J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Calignano, F. Design optimization of supports for overhanging structures in aluminum and titanium alloys by selective laser melting. Mater. Des. 2014, 64, 203–213. [Google Scholar] [CrossRef]

- Kruth, J.P.; Mercelis, P.; Van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef] [Green Version]

- Dai, N.; Zhang, L.C.; Zhang, J.; Chen, Q.; Wu, M. Corrosion Behaviour of Selective Laser Melted Ti-6Al-4V Alloy in NaCl Solution. Corros. Sci. 2016, 102, 484–489. [Google Scholar] [CrossRef]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Atzeni, E. From powders to dense metal parts: Characterization of a commercial AlSi10Mg alloy processed through direct metal laser sintering. Materials 2013, 6, 856–869. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Mat. Proces. Tech. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Ashcroft, I.; Tuck, C. Reducing porosity in AlSi10Mg parts processed by selective laser melting. Addit. Manuf. 2014, 1–4, 77–86. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Iuliano, L.; Fino, P. Influence of process parameters on surface roughness of aluminum parts produced by DMLS. Int. J. Adv. Manuf. Technol. 2013, 67, 2743–2751. [Google Scholar] [CrossRef] [Green Version]

- Read, N.; Wang, W.; Essa, K.; Attllah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef] [Green Version]

- Spierings, A.B.; Herres, N.; Levy, G. Influence of the particle size distribution on surface quality and mechanical properties in AM steel parts. Rapid Prototyp. J. 2011, 17, 380–386. [Google Scholar] [CrossRef]

- Qiu, C.; Al Kindi, M.; Aladawi, A.S.; Al Hatmi, I. A comprensive study on microstructure and tensile behaviour of a selectively laser melted stainless steel. Sci. Rep. 2018, 8, 7785. [Google Scholar] [CrossRef]

- Marchese, G.; Lorusso, M.; Parizia, S.; Bassini, E.; Lee, J.W.; Calignano, F.; Manfredi, D.; Terner, M.; Hong, H.U.; Ugues, D.; et al. Influence of heat treatments on microstructure evolution and mechanical properties of Inconel 625 processed by laser powder bed fusion. Mater. Sci. Eng. A 2018, 729, 64–75. [Google Scholar] [CrossRef]

- Verhaeghe, F.; Craeghs, T.; Heulens, J.; Pandelaers, L. A pragmatic model for selective laser melting with evaporation. Acta Mater. 2009, 57, 6006–6012. [Google Scholar] [CrossRef]

- Simchi, A. Direct laser sintering of metal powders: Mechanism, kinetics and microstructural features. Mater. Sci. Eng. A 2006, 428, 148–158. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z. Microstructure and mechanical properties of Al-12Si produced by selective laser melting: Effect of heat treatment. Mater. Sci. Eng. A 2013, 590, 153–160. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Kimura, T.; Nakamoto, T. Microstructures and mechanical properties of A356 (AlSi7Mg0.3) aluminum alloy fabricated by selective laser melting. JMADE 2015, 89, 1294–1301. [Google Scholar] [CrossRef]

- Cabrini, M.; Lorenzi, S.; Testa, C.; Pastore, T.; Manfredi, D.; Lorusso, M.; Calignano, F.; Fino, P. Statistical approach for electrochemical evaluation of the effect of heat treatments on the corrosion resistance of AlSi10Mg alloy by laser powder bed fusion. Electrochim. Acta 2019, 305, 459–466. [Google Scholar] [CrossRef]

- Cabrini, M.; Calignano, F.; Fino, P.; Lorenzi, S.; Lorusso, M.; Manfredi, M.; Testa, C.; Pastore, T. Corrosion behavior of heat-treated AlSi10Mg manufactured by laser powder bed fusion. Materials 2018, 11, 1051. [Google Scholar] [CrossRef] [Green Version]

- Lorusso, M.; Aversa, A.; Manfredi, D.; Calignano, F.; Ambrosio, E.P.; Ugues, D.; Pavese, M. Tribological Behavior of Aluminum Alloy AlSi10Mg-TiB2 Composites Produced by Direct Metal Laser Sintering (DMLS). J. Mater. Eng. Perform. 2016, 25, 3152–3160. [Google Scholar] [CrossRef]

- Lorusso, M.; Aversa, A.; Marchese, G.; Calignano, F.; Manfredi, D.; Pavese, M. Understanding Friction and Wear Behavior at the Nanoscale of Aluminum Matrix Composites Produced by Laser Powder Bed Fusion. Adv. Eng. Mater. 2019, 1900815. [Google Scholar] [CrossRef]

- Buchbinder, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Selective laser melting of aluminum die-cast alloy—Correlations between process parameters, solidification conditions, and resulting mechanical properties. J. Laser Appl. 2015, 27, S29205. [Google Scholar] [CrossRef]

- Siddique, S.; Imran, M.; Wycisk, E.; Emmelmann, C.; Walther, F. Influence of process-induced microstructure and imperfections on mechanical properties of AlSi12 processed by selective laser melting. J. Mater. Process. Technol. 2015, 221, 205–213. [Google Scholar] [CrossRef]

- Sercombe, T.B.; Li, X. Selective laser melting of aluminium and aluminium metal matrix composites: Review. Mat. Tech. 2016, 31, 77–85. [Google Scholar] [CrossRef]

- Polmear, I.J. Light Alloys: From Taditional Alloys to Nanocrystals; Elsevier: Oxford, UK, 2006. [Google Scholar]

- Alexopoulos, N.D.; Pantelakis, S.G. Quality evaluation of A357 cast aluminum alloy specimens subjected to different artificial aging treatment. Mater. Des. 2004, 25, 419–430. [Google Scholar] [CrossRef]

- Gan, Y.X.; Overfelt, R.A. Fatigue property of semisolid A357 aluminum alloy under different heat treatment conditions. J. Mater. Sci. 2006, 41, 7537–7544. [Google Scholar] [CrossRef]

- Birol, Y. Response to artificial ageing of dendritic and globular Al-7Si-Mg alloys. J. Alloys Compd. 2009, 484, 164–167. [Google Scholar] [CrossRef]

- Ceschini, L.; Morri, A.; Morri, A.; Gamberini, A.; Messieri, S. Correlation between ultimate tensile strength and solidification microstructure for the sand cast A357 aluminium alloy. Mater. Des. 2009, 30, 4525–4531. [Google Scholar] [CrossRef]

- Rao, J.H.; Zhang, Y.; Zhamng, K.; Wu, X.; Huang, A. Selective laser melted Al-7Si-0.6Mg alloy in-situ precipitation via platform heating for residual strain removal. Mater. Des. 2019, 182, 1–11. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Aging response of an A357 Al alloy processed by selective laser melting. Adv. Eng. Mater. 2019, 21, 1800406. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Davies, C.H.J.; Huang, A.; Wu, X. Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting. Mater. Des. 2018, 154, 275–290. [Google Scholar] [CrossRef]

- De Menezes, J.T.O.; Castrodeza, E.M.; Casati, R. Effect of build orientation on fracture and tensile behavior of A357 Al alloy processed by Selective Laser Melting. Mater. Sci. Eng. A 2019, 766, 138392. [Google Scholar] [CrossRef]

- Manfredi, D.; Calignano, F.; Krishnan, M.; Canali, R.; Ambrosio, E.P.; Biamino, S.; Ugues, D.; Pavese, M.; Fino, P. Additive Manufacturing of Al Alloys and Aluminium Matrix Composites (AMCs). In Light Metal Alloys Applications; Waldemar, M., Ed.; IntechOpen: London, UK, 2013; pp. 3–34. [Google Scholar]

- Bremen, S.; Meiners, W.; Diatlov, A. Selective Laser Melting a manufacturing technology for the future? Rapid Manuf. 2012, 2, 33–38. [Google Scholar]

- Zaeh, M.F.; Branner, G. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 2010, 4, 35–45. [Google Scholar] [CrossRef]

- Zhang, D.L.; Zheng, L.H.; StJohn, D.H. Effect of a short solution treatment time on microstructure and mechanical properties of modified Al–7wt.%Si–0.3wt.%Mg alloy. J. Light Met. 2002, 2, 27–36. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Tuck, C.; Ashcroft, I.; Maskery, I.; Everitt, N.M. Precitation Hardening of Selective Laser Melted AlSi10Mg. Metall. Mater. Trans. A 2015, 46, 3337–3341. [Google Scholar] [CrossRef]

- Leuders, S.; Thöne, M.; Riemer, A.; Niendorf, T.; Tröster, T.; Richard, H.A.; Maier, H.J. On the mechanical behaviour of titanium alloy TiAl6V4 manufactured by selective laser melting. Int. J. Fatigue 2013, 48, 300–307. [Google Scholar] [CrossRef]

- Menargues, S.; Martin, E.; Baile, M.T.; Picas, J. New short T6 heat treatments for aluminum silicon alloys obtained by semisolid forming. Mater. Sci. Eng. A 2015, 621, 236–242. [Google Scholar] [CrossRef]

| Parameters | Values |

|---|---|

| Scanning speed v [mm/s] | 600, 700, 800, 1000, 1200 |

| Hatching distance hd [mm] | 0.10, 0.17, 0.20 |

| Sample | v [mm/s] | hd [mm] | ProdLPBF [mm3/s] | Relative Density [%] |

|---|---|---|---|---|

| 1 | 800 | 0.20 | 4.80 | 99.39 |

| 2 | 1000 | 0.10 | 3.00 | 99.54 |

| 3 | 1200 | 0.20 | 7.20 | 96.00 |

| 4 | 1000 | 0.20 | 6.00 | 97.92 |

| 5 | 800 | 0.17 | 4.08 | 99.78 |

| 6 | 1000 | 0.17 | 5.10 | 99.17 |

| 7 | 800 | 0.10 | 2.40 | 99.81 |

| 8 | 1200 | 0.17 | 6.12 | 98.08 |

| 9 | 1200 | 0.10 | 3.60 | 99.94 |

| 10 | 600 | 0.10 | 1.80 | 99.45 |

| 11 | 600 | 0.17 | 3.06 | 99.09 |

| 12 | 600 | 0.20 | 3.60 | 99.36 |

| 13 | 700 | 0.10 | 2.10 | 99.16 |

| 14 | 700 | 0.17 | 3.57 | 99.17 |

| 15 | 700 | 0.20 | 4.20 | 98.97 |

| LPBF A357 Specimens | HV0.1 | S.D. |

|---|---|---|

| As-built | 119 | 2 |

| Stress-relieved | 80 | 2 |

| Stress-relieved + T6B,170,3 | 116 | 2 |

| Specimens | Rp, 0.2 [MPa] | UTS [MPa] | ε [%] | |||

|---|---|---|---|---|---|---|

| Mean | S.D. | Mean | S.D. | Mean | S.D. | |

| As-built | 245 | 4 | 386 | 4 | 5.2 | 0.4 |

| Stress-relieved | 189 | 3 | 288 | 5 | 8.2 | 0.9 |

| Stress rel + T6B,170,3 | 249 | 9 | 307 | 10 | 5.1 | 0.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lorusso, M.; Trevisan, F.; Calignano, F.; Lombardi, M.; Manfredi, D. A357 Alloy by LPBF for Industry Applications. Materials 2020, 13, 1488. https://doi.org/10.3390/ma13071488

Lorusso M, Trevisan F, Calignano F, Lombardi M, Manfredi D. A357 Alloy by LPBF for Industry Applications. Materials. 2020; 13(7):1488. https://doi.org/10.3390/ma13071488

Chicago/Turabian StyleLorusso, Massimo, Francesco Trevisan, Flaviana Calignano, Mariangela Lombardi, and Diego Manfredi. 2020. "A357 Alloy by LPBF for Industry Applications" Materials 13, no. 7: 1488. https://doi.org/10.3390/ma13071488

APA StyleLorusso, M., Trevisan, F., Calignano, F., Lombardi, M., & Manfredi, D. (2020). A357 Alloy by LPBF for Industry Applications. Materials, 13(7), 1488. https://doi.org/10.3390/ma13071488