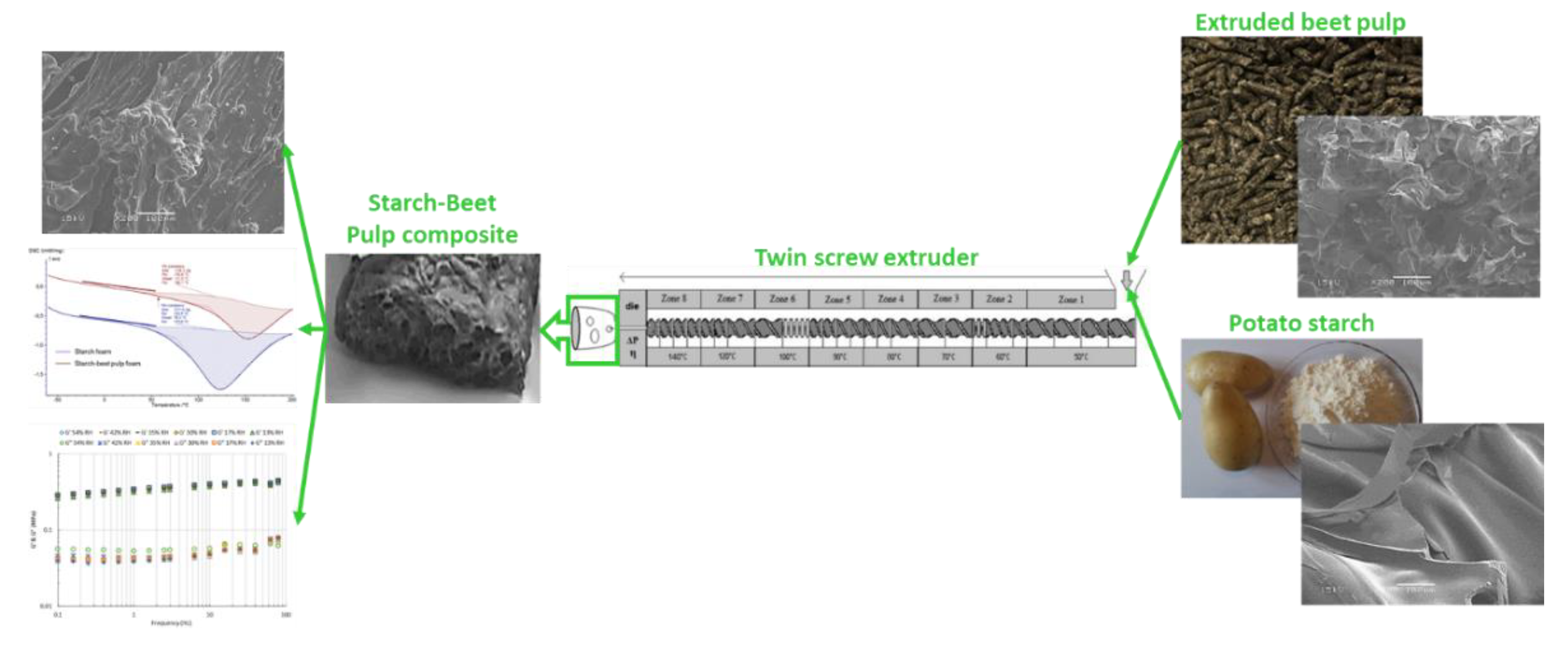

Novel Extruded Starch-Beet Pulp Composites for Packaging Foams

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Extruded Beet Pulp

2.1.2. Potato Starch

2.1.3. Composite Formulation

2.2. Methods

2.2.1. Extrusion Setup

2.2.2. Foam Density

2.2.3. Microscopy Observations

2.2.4. Thermogravimetric Analysis Procedure

2.2.5. Differential Scanning Calorimetry Procedure

2.2.6. Dynamic Mechanical Analysis Procedure

3. Results and Discussion

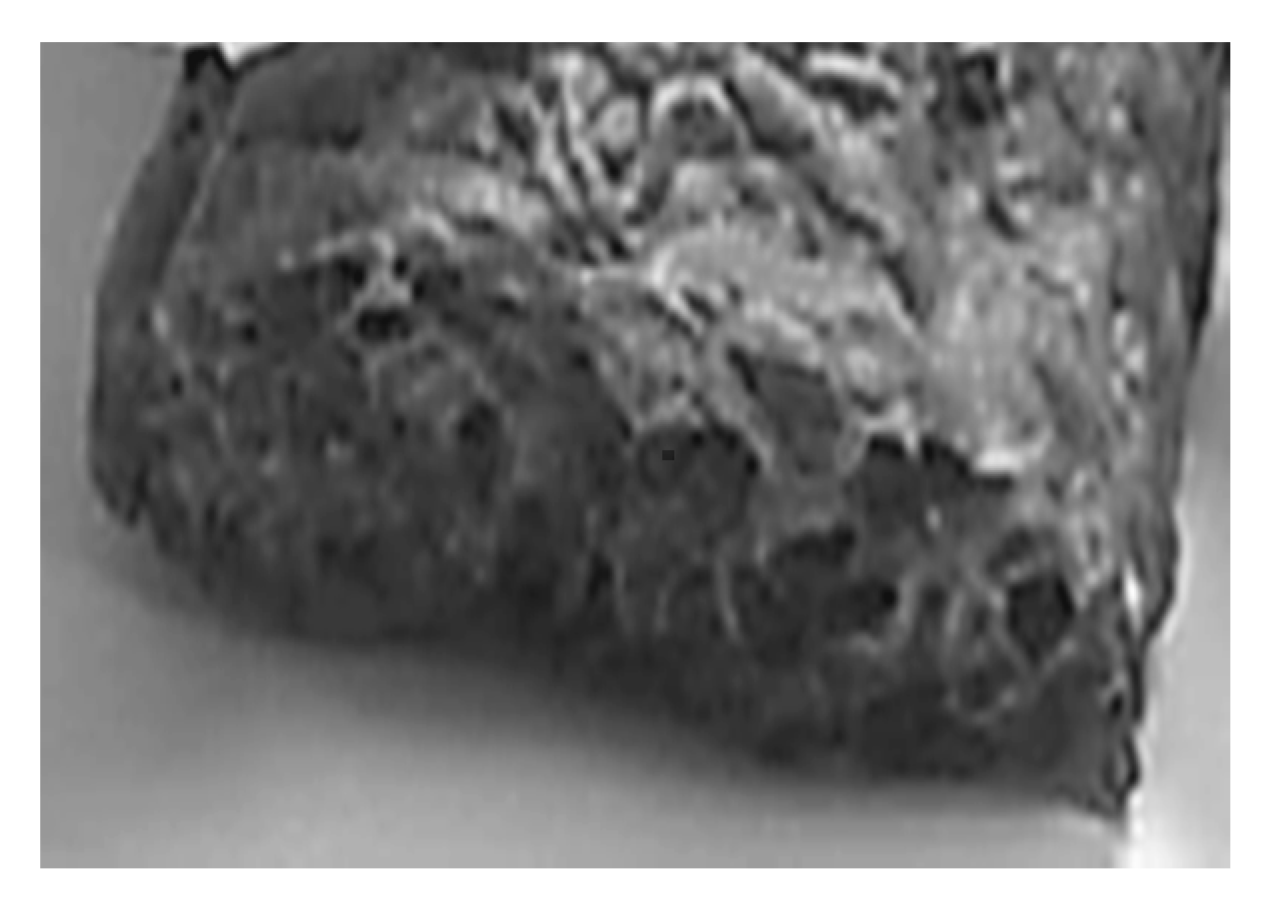

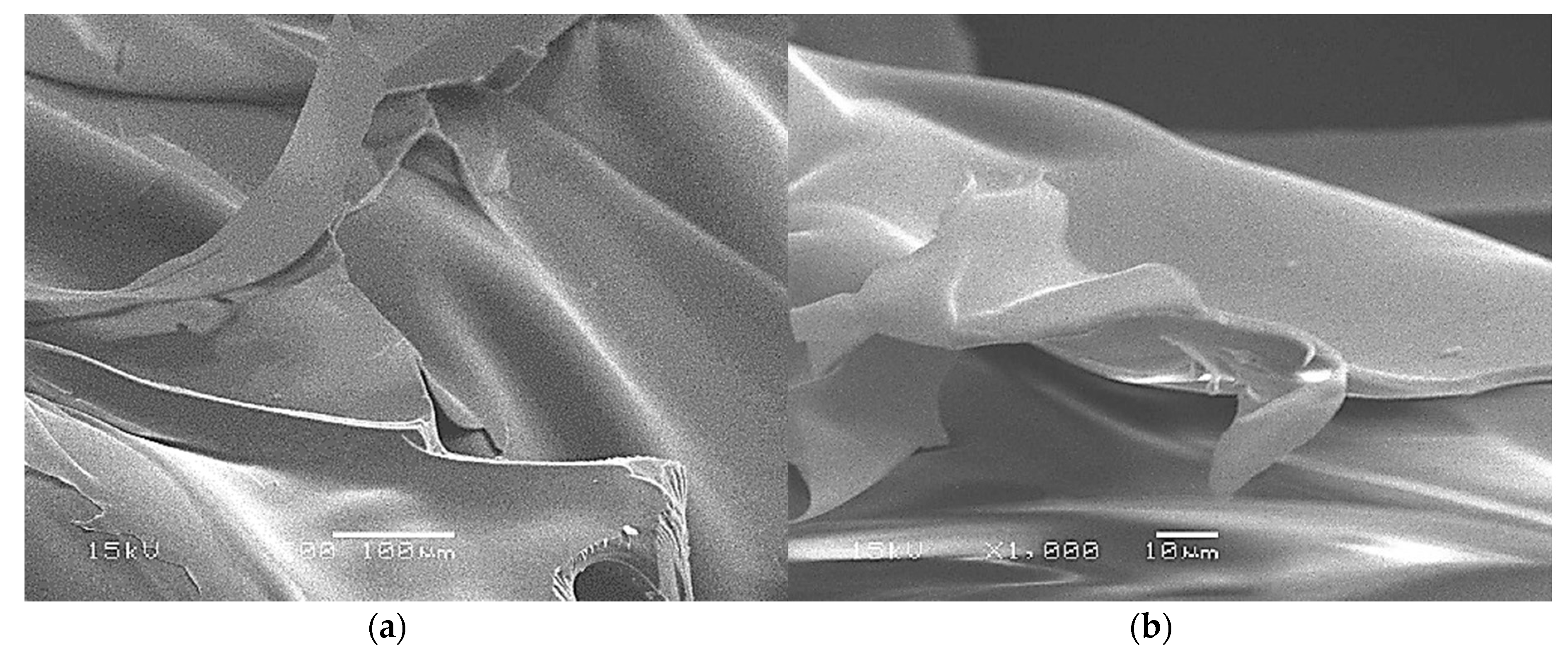

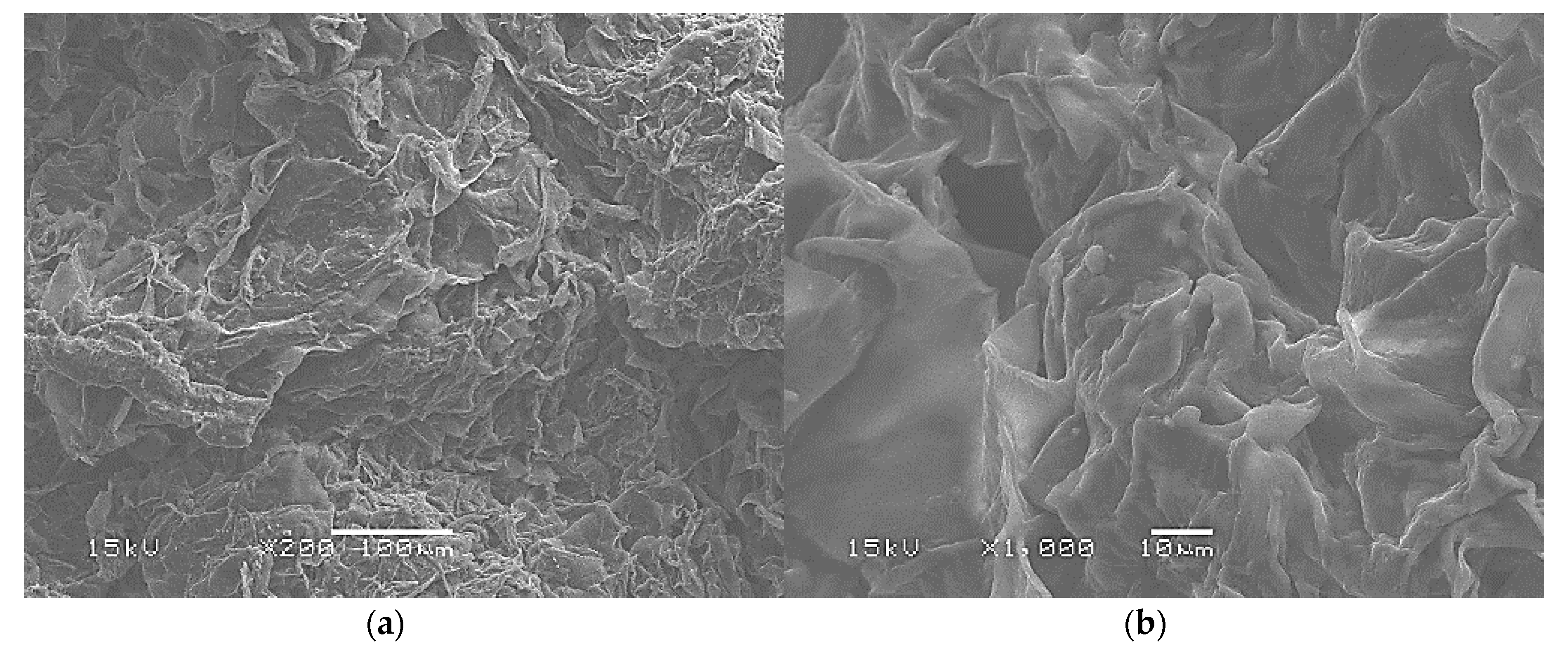

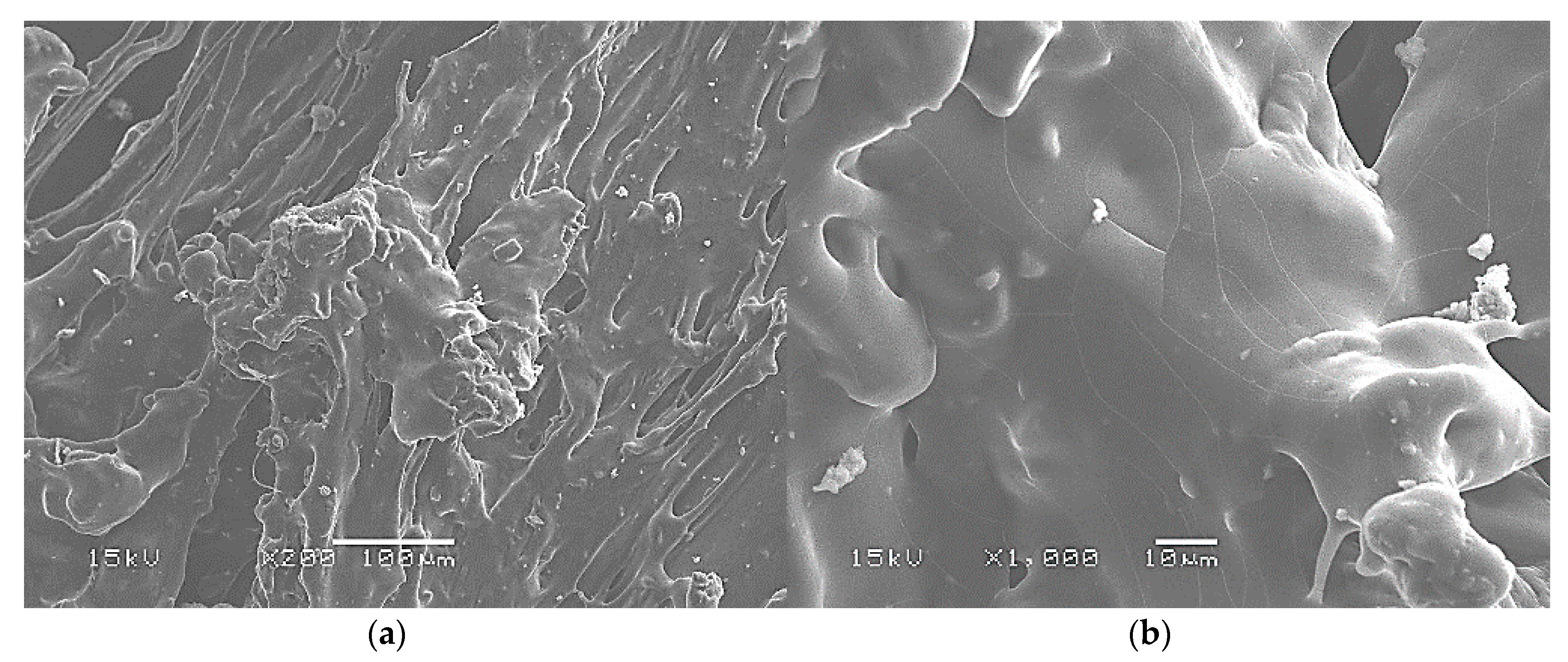

3.1. Microscopic Structure of the Extruded Foams

3.2. Density Analysis

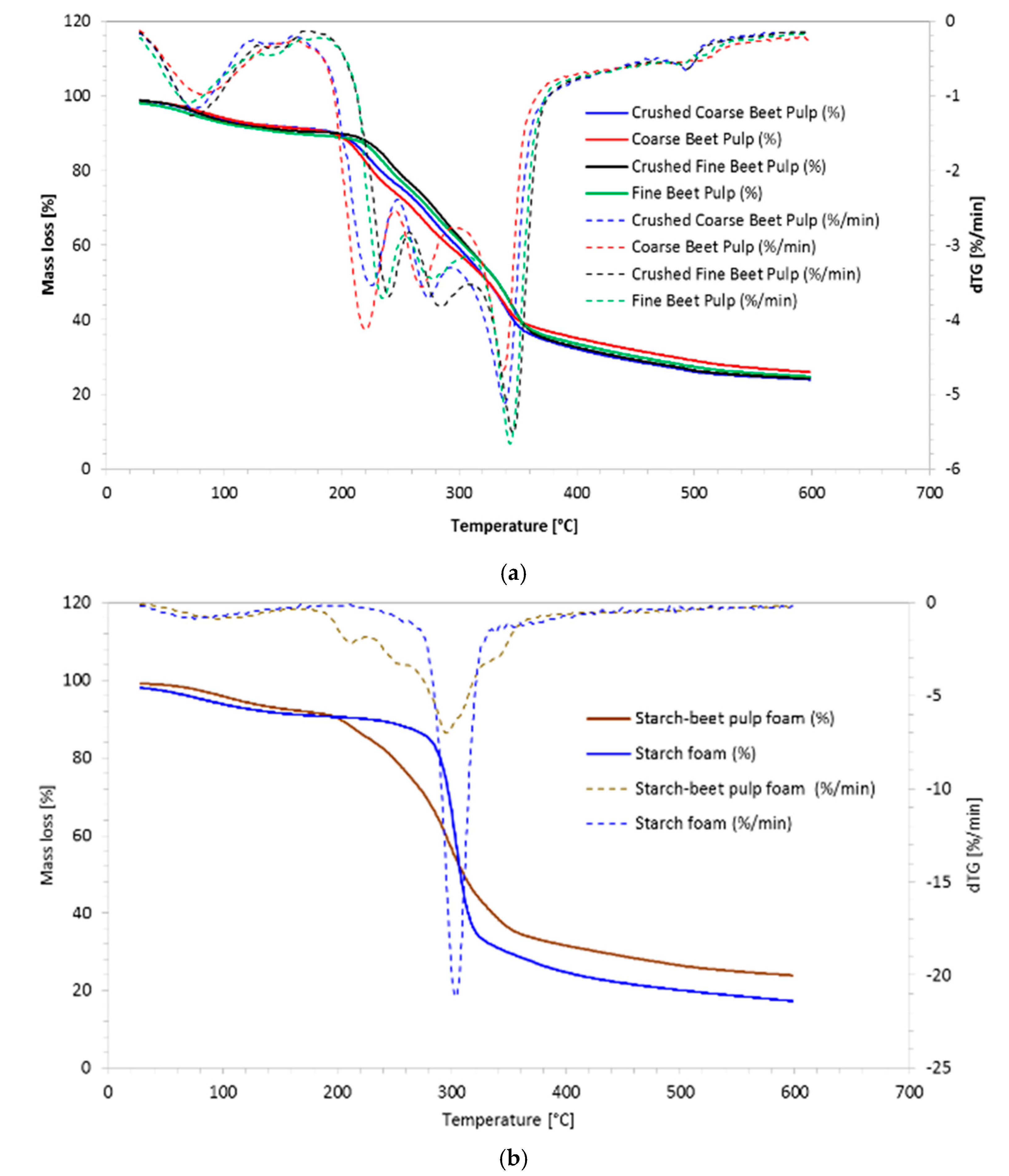

3.3. Thermogravimetric Analysis Results

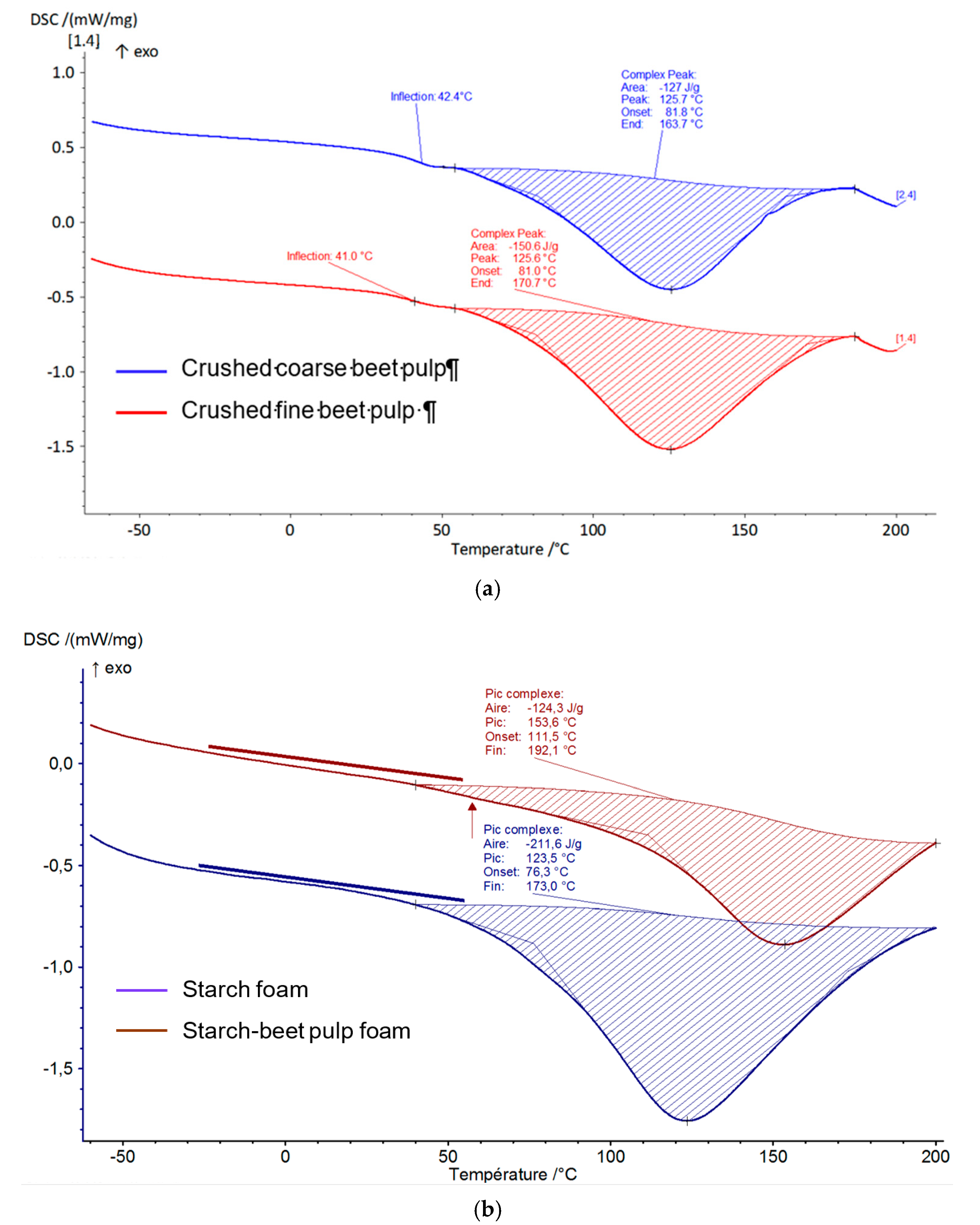

3.4. Differential Scanning Calorimetry (DSC) Results

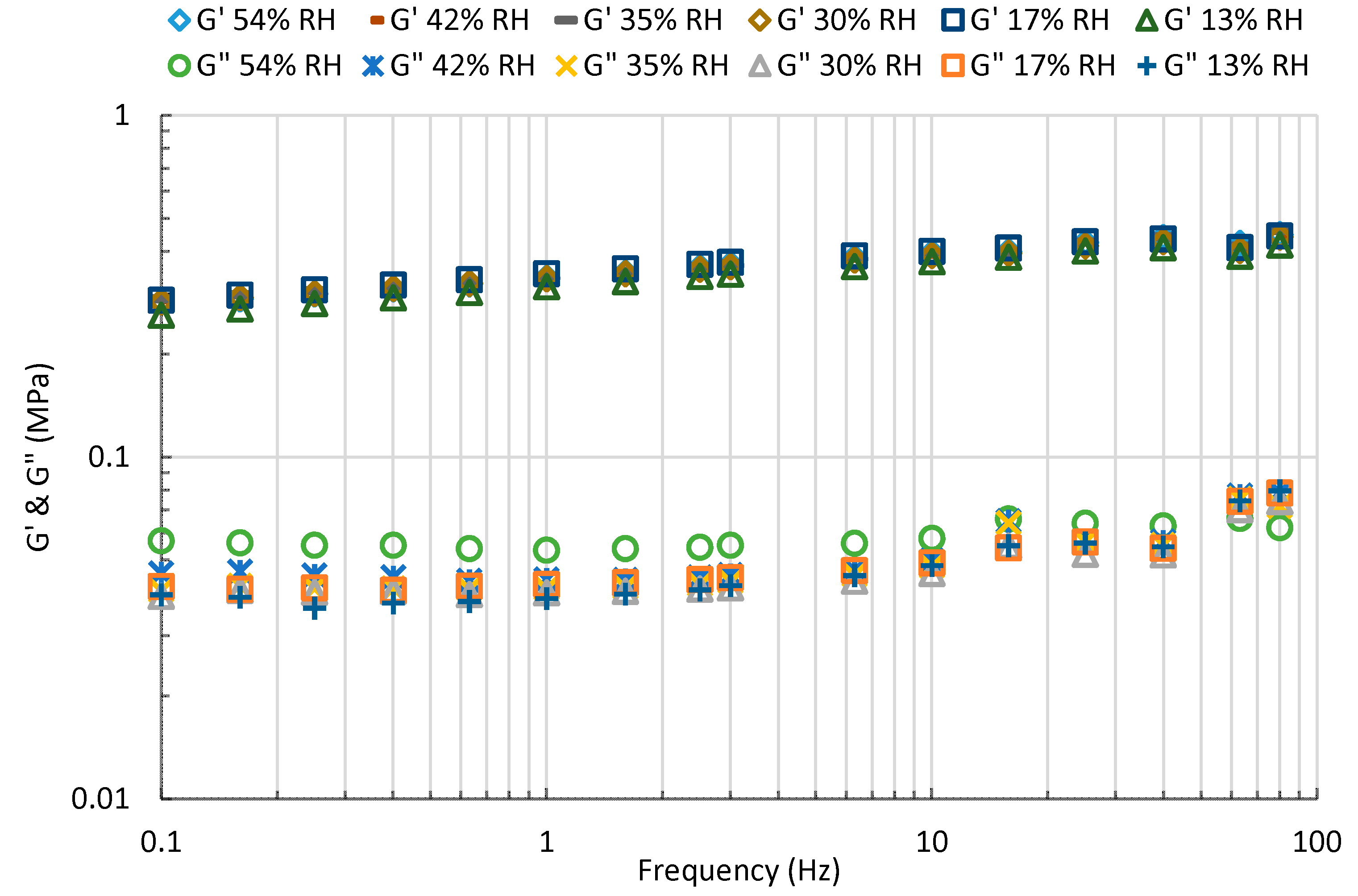

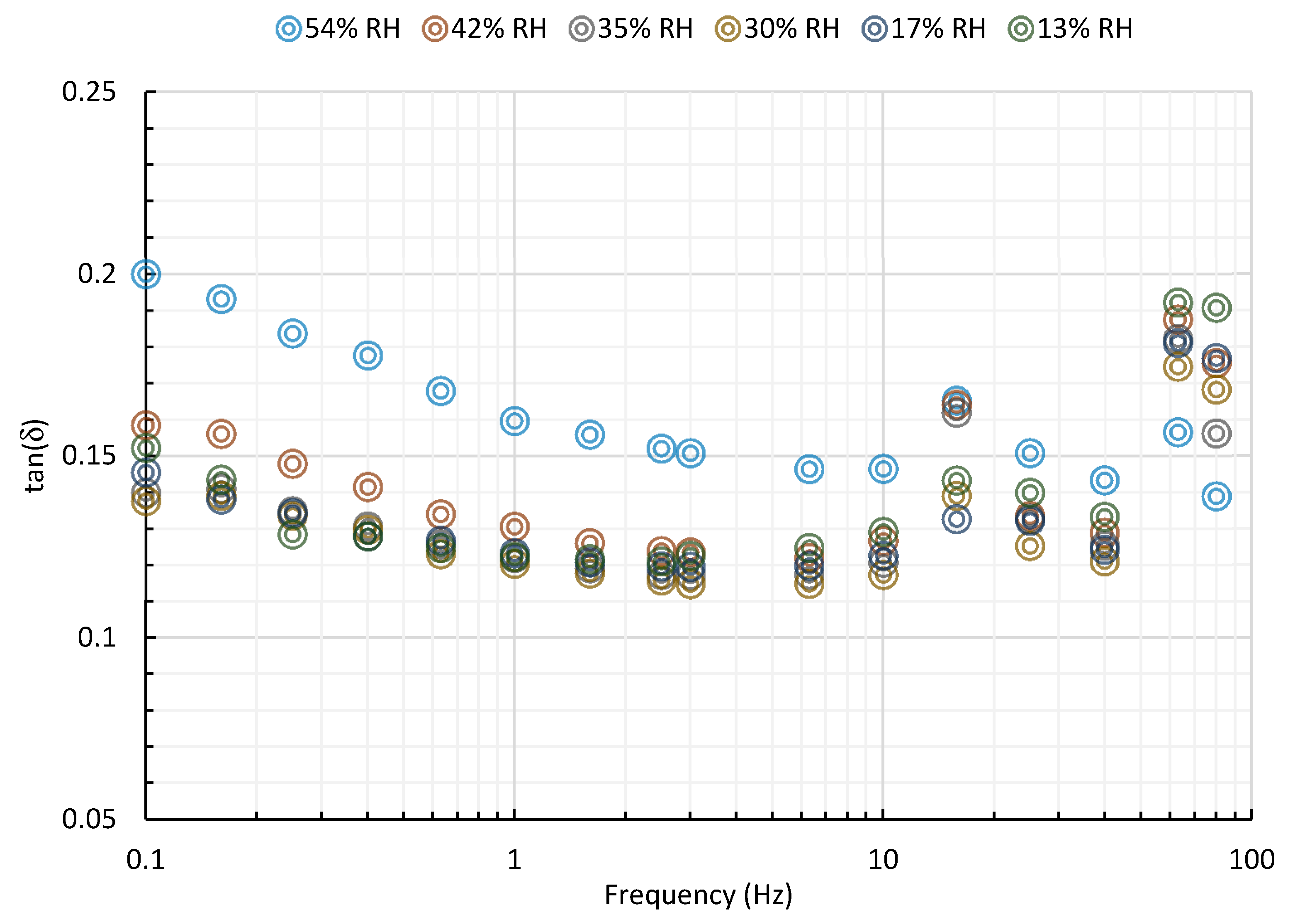

3.5. Dynamic Mechanical Analysis (DMA) Results

3.5.1. Storage and Loss Moduli

3.5.2. Creep-Recovery Response

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Best in Packaging. Bioplastics: From Hot to Cold. 2010. Available online: http://bestinpackaging.com/2010/09/12/bio-plastics-from-hot-to-cold/ (accessed on 2 February 2020).

- Bergel, B.F.; da Luz, L.; Santana, R.M.C. Comparative study of the influence of chitosan as coating of thermoplastic starch foam from potato, cassava and corn starch. Prog. Org. Coat. 2017, 106, 27–32. [Google Scholar] [CrossRef]

- Albertson, A. Biodegradation of polymers in historical perspective versus modern polymer chemistry. In Handbook of Polymer Degradation, 2nd ed.; Hamid, S.H., Ed.; Marcel Dekker Inc.: New York, NY, USA, 2000; pp. 421–439. [Google Scholar]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Khalil, H.P.S.A.; Bhat, A.H.; Yusra, A.F.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Marsh, K.; Bugusu, B. Food packaging–Roles, materials, and environmental issues: Scientific status summary. J. Food Sci. 2007, 72, 39–55. [Google Scholar] [CrossRef]

- Plastics Europe. Plastics—the Facts: An Analysis of European Plastics Production, Demand and Waste Data; Plastics Europe: Brussels, Belgium, 2015; pp. 1–30. [Google Scholar]

- Lawton, J.W.; Shogren, R.L.; Tiefenbacher, K.F. Aspen fiber addition improves the mechanical properties of baked cornstarch foams. Ind. Crops Prod. 2004, 19, 41–48. [Google Scholar] [CrossRef]

- Zhou, J.; Song, J.; Parker, R. Microwave-assisted moulding using expandable extruded pellets from wheat flours and starch. Carbohyd. Polym. 2007, 69, 445–454. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Thanomsilp, C.; Suwantong, O. A review: Starch-based composite foams. Compos. Part A Appl. Sci. Manuf. 2015, 78, 246–263. [Google Scholar] [CrossRef]

- Singh, N.; Isono, N.; Srichuwong, S.; Nodad, T.; Nishinari, K. Structural, thermal and viscoelastic properties of potato starches. Food Hydrocoll. 2008, 22, 979–988. [Google Scholar] [CrossRef]

- Abinader, G.; Lacoste, C.; Le Baillif, M.; Erre, D.; Copinet, A. Effect of the formulation of starch-based foam cushions on the morphology and mechanical properties. J. Cell. Plast. 2015, 51, 31–44. [Google Scholar] [CrossRef]

- Abinader, G.; Lacoste, C.; Erre, D. Effect of formulation and process on the extrudability of starch-based foam cushions. Ind. Crops Prod. 2018, 115, 306–314. [Google Scholar]

- Glenn, G.M.; Orts, W.J. Properties of starch-based foam formed by compression/explosion processing. Ind. Crops Prod. 2001, 13, 135–143. [Google Scholar] [CrossRef]

- Lopez-Gil, A.; Silva-Bellucci, F.; Velaso, D.; Ardanuy, M.; Rodriguez-Perez, M.A. Cellular structure and mechanical properties of starch-based foamed blocks reinforced with natural fibers and produced by microwave heating. Ind. Crops Prod. 2015, 66, 194–205. [Google Scholar] [CrossRef]

- Svagen, A.J.; Azizi Samir, M.A.S.; Berglund, L.A. Biomimetic foams of high mechanical performance based on nanostructured cell walls reinforced by native cellulose nanofibrils. Adv. Mater. 2008, 20, 1263–1269. [Google Scholar] [CrossRef]

- Alavi, S.H.; Rizvi, S.S.H.; Harriott, P. Process dynamics of starch-based microcellular foams produced by supercritical fluid extrusion. I: Model development. Food Res. Int. 2003, 36, 309–319. [Google Scholar] [CrossRef]

- Shogren, R.; Lawton, J.; Doane, W.; Tiefenbacher, K. Structure and morphology of baked starch foams. Polymer 1998, 39, 6649–6655. [Google Scholar] [CrossRef]

- Karaky, H.; Maalouf, C.; Bliard, C.; Gacoin, A.; Lachi, M.; Wakil, N.; Polidori, G. Characterization of beet-pulp fiber reinforced potato starch biopolymer composites for building applications. Const. Build. Mat. 2019, 203, 711–721. [Google Scholar] [CrossRef]

- Liu, L.S.; Fishman, M.L.; Hicks, K.B.; Liu, C.-K. Biodegradable Composites from Sugar Beet Pulp and Poly(lactic acid). J. Agric. Food Chem. 2005, 53, 9017–9022. [Google Scholar] [CrossRef]

- Li, W.; Coffin, D.R.; Jin, T.Z.; Latona, N.; Liu, C.-K.; Liu, B.; Zhang, J.; Liu, L.S. Biodegradable Composites from Polyester and Sugar Beet Pulp with Antimicrobial Coating for Food Packaging. J. Appl. Polym. Sci. 2012, 126, 361–372. [Google Scholar] [CrossRef]

- Schiweck, H.; Clarke, M.; Pollach, G. Sugar. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley-VCH Verlag GmbH & Co, KGaA: Weinheim, Germany, 2007. [Google Scholar]

- Nasielski, S. Le bon usage de la pulpe surpressée; Institut français d’analyse transactionnelle: Tienen (Tirlemont), Belgium, 2009; p. 132. [Google Scholar] [CrossRef]

- Asadi, M. Beet-Sugar Handbook; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Monreal, P.; Mboumba-Mamboundou, L.B.; Dheilly, R.M.; Quéneudec, M. Effects of aggregate coating on the hygral properties of lignocellulosic composites. Cem. Concr. Compos. 2011, 33, 301–308. [Google Scholar] [CrossRef]

- Bourdot, A.; Moussa, T.; Gacoin, A.; Maalouf, C.; Vazquez, P.; Thomachot-Schneider, C.; Bliard, C.; Merabtine, A.; Lachi, M.; Douzane, O.; et al. Characterization of a hemp-based agro-material: Influence of starch ratio and hemp shive size on physical, mechanical, and hygrothermal properties. Energy Build. 2017, 153, 501–512. [Google Scholar] [CrossRef]

- Sidi-Yacoub, B.; Oudghiri, F.; Belkadi, M.; Rodriguez-Barroso, R. Characterization of lignocellulosic components in exhausted sugar beet pulp waste by TG/FTIR analysis. J. Therm. Anal. Calorim. 2019, 138, 1801–1809. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, L.; Ma, C.; Zhang, Y. Thermal Behavior of Sweet Potato Starch by Non-Isothermal Thermogravimetric Analysis. Materials 2019, 12, 699. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yu, L.; Christie, G. Measurement of starch thermal transitions using differential scanning calorimetry. Carbohydr. Polym. 2001, 46, 179–184. [Google Scholar] [CrossRef]

- Rouilly, A.; Jorda, J.; Rigal, L. Thermo-mechanical processing of sugar beet pulp. II. Thermal and rheological properties of thermoplastic SBP. Carbohydr. Polym. 2006, 66, 117–125. [Google Scholar] [CrossRef] [Green Version]

- Mitrus, M. TPS and Its Nature. In Thermoplastic Starch. A Green Material for Various Industries; Janssen, L.P.B.M., Moscicki, L., Eds.; Wiley-VCH Verlag GmbH&Co. KGaA: Weinheim, Germany, 2009; pp. 77–104. [Google Scholar]

| ESBP Foam Bulk Density (g/cm3) | Raw Starch Bulk Density (g/cm3) | BP Bulk Density [20] (g/cm3) |

|---|---|---|

| 0.686 ± 0.05 | 0.510 ± 0.05 | 0.194 ± 0.007 |

| SBP foam abs. density (g/cm3) | Raw Starch abs. density (g/cm3) | BP abs. density [20] (g/cm3) |

| 1.470 ± 0.005 | 1.510 ± 0.005 | 1.073 ± 0.005 |

| 30 | 0.50 | 2499.4 | 1.04 | 3671.6 | 0.00076 | 1366.9 | 1.085 |

| 41 | 0.29 | 2299.0 | 1.05 | 3751.6 | 0.00075 | 1115.4 | 0.732 |

| 52 | 0.01 | 1200.0 | 1.07 | 3881.4 | 0.00075 | 1291.0 | 0.674 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbès, B.; Lacoste, C.; Bliard, C.; Maalouf, C.; Simescu-Lazar, F.; Bogard, F.; Polidori, G. Novel Extruded Starch-Beet Pulp Composites for Packaging Foams. Materials 2020, 13, 1571. https://doi.org/10.3390/ma13071571

Abbès B, Lacoste C, Bliard C, Maalouf C, Simescu-Lazar F, Bogard F, Polidori G. Novel Extruded Starch-Beet Pulp Composites for Packaging Foams. Materials. 2020; 13(7):1571. https://doi.org/10.3390/ma13071571

Chicago/Turabian StyleAbbès, Boussad, Catherine Lacoste, Christophe Bliard, Chadi Maalouf, Florica Simescu-Lazar, Fabien Bogard, and Guillaume Polidori. 2020. "Novel Extruded Starch-Beet Pulp Composites for Packaging Foams" Materials 13, no. 7: 1571. https://doi.org/10.3390/ma13071571

APA StyleAbbès, B., Lacoste, C., Bliard, C., Maalouf, C., Simescu-Lazar, F., Bogard, F., & Polidori, G. (2020). Novel Extruded Starch-Beet Pulp Composites for Packaging Foams. Materials, 13(7), 1571. https://doi.org/10.3390/ma13071571