Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Equipment and Method

2.3. Experimental Design

3. Results

3.1. Main Effects of Processing Parameters

3.2. Analysis of Variance

4. Discussion

5. Conclusions

- For the main effects of single factor, the influences of different processing parameters on the RD and the SR of 316L stainless steel are similar. The effects of P and V on RD and SR of parts are highly significant, but that of S is weak.

- For interaction effects between two factors, there are some differences between the RD and the SR. All of the interaction influences containing P*V, P*S, V*S on the RD behave significantly, whereas for the SR only the V*S has a significant influence.

- Based on the RSM and the ANOVA, the mathematical relationship model between the RD/SR and processing parameters have been built, and can be used to effectively predict the processing parameters set or the target response.

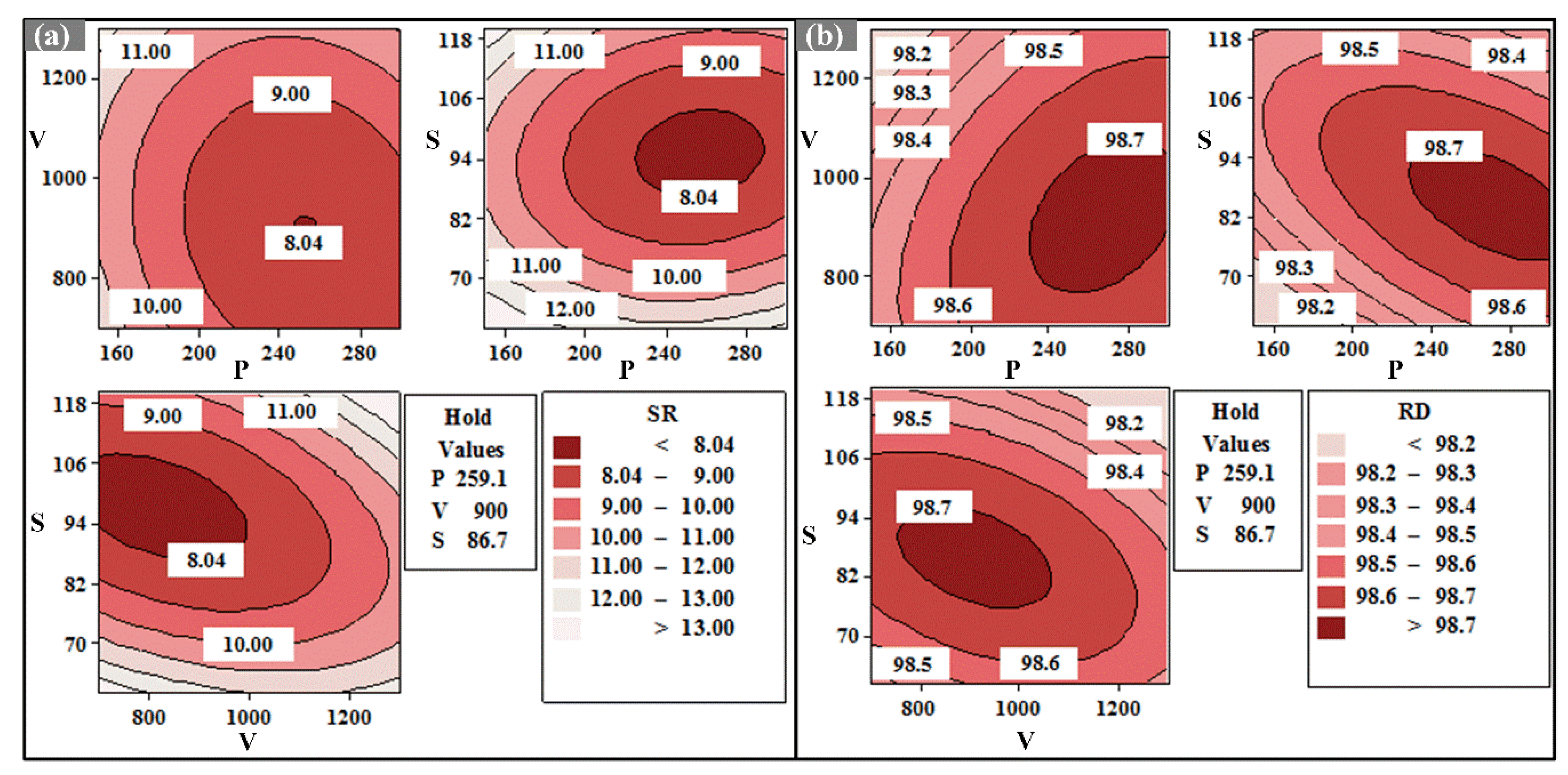

- According to multi-objective optimization, an optimal processing parameters set with (P, V, S) values of (259.1 W, 900 mm/s, 86.7 μm) has been obtained. A resultant high RD of 98.7% and excellent SR of 8.04 μm can be achieved simultaneously using these values, which can further improve fatigue properties of SLMed 316L stainless steel products.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.P. A study of the micro structural evolution during selective laser melting of ti-6al-4v. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Li, Z.H.; Kucukkoc, I.; Zhang, D.Z.; Liu, F. Optimising the process parameters of selective laser melting for the fabrication of Ti6Al4V alloy. Rapid Prototyp. J. 2018, 24, 150–159. [Google Scholar] [CrossRef]

- Simmons, J.C.; Chen, X.; Azizi, A.; Daeumer, M.A.; Zavalij, P.Y.; Zhou, G.; Schiffres, S.N. Influence of Processing and Microstructure on the Local and Bulk Thermal Conductivity of Selective Laser Melted 316L Stainless Steel. Addit. Manuf. 2020, 32, 100996. [Google Scholar] [CrossRef]

- Badrossamay, M.; Childs, T.H.C. Further studies in selective laser melting of stainless and tool steel powders. Int. J. Mach. Tools Manuf. 2007, 47, 779–784. [Google Scholar] [CrossRef]

- Meier, C.; Weissbach, R.; Weinberg, J.; Wall, W.A.; Hart, A.J. Critical influences of particle size and adhesion on the powder layer uniformity in metal additive manufacturing. J. Mater. Process. Tech. 2019, 266, 484–501. [Google Scholar] [CrossRef] [Green Version]

- Xue, G.; Ke, L.D.; Zhu, H.H.; Liao, H.L.; Zhu, J.J.; Zeng, X.Y. Influence of processing parameters on selective laser melted SiCp/AlSi10Mg composites: Densifification, microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 764, 138155. [Google Scholar] [CrossRef]

- Majeed, A.; Ahmed, A.; Salam, A.; Sheikh, M.Z. Surface quality improvement by parameters analysis, optimization and heat treatment of AlSi10Mg parts manufactured by SLM additive manufacturing. Int. J. Lightweight Mater. Manuf. 2019, 2, 288–295. [Google Scholar] [CrossRef]

- Mumtaz, K.; Hopkinson, N. Top surface and side roughness of Inconel 625 parts processed using selective laser melting. Rapid Prototyp. J. 2009, 15, 96–103. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.J.; Zhang, B.C.; Liao, H.L.; Coddet, C. The Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater. Des. 2012, 35, 120–125. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Hao, L.; Jerrard, P.G.E.; Zhang, D.Z. Experimental study on selective laser melting behaviour and processing Windows of the in situ reacted Al/Fe2O3 powder mixture. Powder Technol. 2012, 231, 112–121. [Google Scholar] [CrossRef]

- Han, X.; Zhu, H.; Nie, X.; Wang, G.; Zeng, X. Investigation on selective laser melting AlSi10Mg cellular lattice strut: Molten pool morphology, surface roughness and dimensional accuracy. Materials 2018, 11, 392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Larimian, T.; Kannan, M.; Grzesiak, D.; AlMangour, B.; Borkar, T. Effect of energy density and scanning strategy on densification, microstructure and mechanical properties of 316L stainless steel processed via selective laser melting. Mater. Sci. Eng. A 2020, 770, 138455. [Google Scholar] [CrossRef]

- Ni, X.Q.; Kong, D.C.; Zhang, L.; Dong, C.F.; Song, J.; Wu, W.H. Effect of process parameters on the mechanical properties of hastelloy X alloy fabricated by selective laser melting. J. Mater. Eng. Perform. 2019, 28, 5533–5540. [Google Scholar] [CrossRef]

- Wang, J.J.; Wu, W.J.; Jing, W.; Tan, X.P.; Bi, G.J.; Tor, S.B.; Leong, K.F.; Chua, C.K.; Liu, E. Improvement of densification and microstructure of ASTM A131 EH36 steel samples additively manufactured via selective laser melting with varying laser scanning speed and hatch spacing. Mater. Sci. Eng. A 2019, 746, 300–313. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.J.; Liao, H.L.; Coddet, C. Process parameter selection for selective laser melting of Ti6Al4V based on temperature distribution simulation and experimental sintering. Int. J. Adv. Manuf. Technol. 2012, 61, 967–974. [Google Scholar] [CrossRef]

- Wang, D.; Song, C.H.; Yang, Y.Q.; Bai, Y.C. Investigation of crystal growth mechanism during selective laser melting and mechanical property characterization of 316L stainless steel parts. Mater. Des. 2016, 100, 291–299. [Google Scholar] [CrossRef]

- Kong, D.C.; Dong, C.F.; Ni, X.Q.; Zhang, L.; Luo, H.; Li, R.X.; Wang, L.; Man, C.; Li, X.G. The passivity of selective laser melted 316L stainless steel. Appl. Surf. Sci. 2020, 504, 144495. [Google Scholar] [CrossRef]

- Ma, Y.F.; Evans, T.M.; Philips, N.; Cunningham, N. Numerical simulation of theeffect of fine fraction on the flowability of powders in additive manufacturing. Powder Technol. 2020, 360, 608–621. [Google Scholar] [CrossRef]

- Jeong, H.S.; Ko, Y.C.; Kim, H.J. Effects of a stylus on the surface roughness determination in a contact method for paper and paperboard. Nord. Pulp Pap. Res. J. 2019, 34, 442–452. [Google Scholar] [CrossRef]

- Bai, S.G.; Perevoshchikova, N.; Sha, Y.; Wu, X.H. The Effects of selective laser melting process parameters on relative density of the AlSi10Mg parts and suitable procedures of the archimedes method. Appl. Sci. 2019, 9, 583. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, J.; Pang, Z.C.; Wu, W.H. Investigation into the influence of laser energy input on selective laser melted thin-walled parts by response surface method. Opt. Lasers Eng. 2018, 103, 34–45. [Google Scholar] [CrossRef]

- Yalçınkaya, Ö.; Bayhan, G.M. Modelling and optimization of average travel time for a metro line by simulation and response surface methodology. Eur. J. Oper. Res. 2009, 196, 225–233. [Google Scholar] [CrossRef]

- Ding, E.; Cao, C.; Hua, H.Q.; Chen, Y.X.; Lu, X.L. Application of central composite design to the optimization of fly ash-based geopolymers. Constr. Build. Mater. 2020, 230, 116960. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Machine | FS271M |

| Platform Dimension (L × W × H) | 275 mm × 275 mm × 320 mm |

| Laser Type | Fiber laser |

| Laser Diameter | 70~200 μm |

| Maximum Laser Power | 500 W |

| Maximum Scan Speed | 15.2 m/s |

| Layer Thickness | 0.02~0.1 mm |

| Volume Forming Rate | 20 cm3/h |

| Input Factors (Coded Values) | The Levels of Input Factors | ||||

|---|---|---|---|---|---|

| −1.682 | −1 | 0 | 1 | 1.682 | |

| Laser Power (W) | 150 | 180.4 | 225 | 269.6 | 300 |

| Scanning Speed (mm/s) | 700 | 821.6 | 1000 | 1178.4 | 1300 |

| Hatch Spacing (μm) | 60 | 72.2 | 80 | 107.8 | 120 |

| Standard Sequence | The Processing Parameters | Measured Value | Calculated Value | Measured Value | ||

|---|---|---|---|---|---|---|

| P (w) | V (mm/s) | S (μm) | Density (g/cm3) | RD (%) | SR (μm) | |

| 1 | 180.4 | 821.6 | 72.2 | 7.845 | 98.31 | 11.57 |

| 2 | 269.6 | 821.6 | 72.2 | 7.870 | 98.62 | 10.38 |

| 3 | 180.4 | 1178.4 | 72.2 | 7.840 | 98.25 | 10.90 |

| 4 | 269.6 | 1178.4 | 72.2 | 7.871 | 98.63 | 10.35 |

| 5 | 180.4 | 821.6 | 107.8 | 7.869 | 98.61 | 10.25 |

| 6 | 269.6 | 821.6 | 107.8 | 7.863 | 98.53 | 8.47 |

| 7 | 180.4 | 1178.4 | 107.8 | 7.840 | 98.25 | 12.18 |

| 8 | 269.6 | 1178.4 | 107.8 | 7.851 | 98.38 | 10.73 |

| 9 | 150.0 | 1000.0 | 90.0 | 7.850 | 98.37 | 10.62 |

| 10 | 300.0 | 1000.0 | 90.0 | 7.877 | 98.71 | 8.35 |

| 11 | 225.0 | 700.0 | 90.0 | 7.879 | 98.73 | 8.11 |

| 12 | 225.0 | 1300.0 | 90.0 | 7.850 | 98.37 | 10.26 |

| 13 | 225.0 | 1000.0 | 60.0 | 7.855 | 98.43 | 11.73 |

| 14 | 225.0 | 1000.0 | 120.0 | 7.847 | 98.33 | 10.94 |

| 15 | 225.0 | 1000.0 | 90.0 | 7.872 | 98.65 | 8.73 |

| 16 | 225.0 | 1000.0 | 90.0 | 7.871 | 98.63 | 8.41 |

| 17 | 225.0 | 1000.0 | 90.0 | 7.870 | 98.62 | 8.06 |

| 18 | 225.0 | 1000.0 | 90.0 | 7.875 | 98.68 | 8.35 |

| 19 | 225.0 | 1000.0 | 90.0 | 7.877 | 98.71 | 8.04 |

| 20 | 225.0 | 1000.0 | 90.0 | 7.874 | 98.67 | 8.06 |

| Source | DOF | Sum of Squares | Mean Square | The F-Value | P-Values | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| RD | SR | RD | SR | RD | SR | RD | SR | |||

| Model | 9 | 0.513907 | 37.2364 | 0.057101 | 4.1374 | 31.42 | 31.07 | 0.000 | 0.000 | |

| Linear | 3 | 0.228636 | 9.9670 | 0.076212 | 3.3223 | 41.94 | 24.95 | 0.000 | 0.000 | |

| P | 1 | 0.126006 | 5.6545 | 0.126006 | 5.6545 | 69.34 | 42.47 | 0.000 | 0.000 | |

| V | 1 | 0.099457 | 3.6973 | 0.099457 | 3.6973 | 54.73 | 27.77 | 0.000 | 0.000 | |

| S | 1 | 0.003173 | 0.6152 | 0.003173 | 0.6152 | 1.75 | 4.62 | 0.216 | 0.057 | |

| Square | 3 | 0.197821 | 23.8852 | 0.06594 | 7.9617 | 36.28 | 59.80 | 0.000 | 0.000 | |

| P2 | 1 | 0.034911 | 4.0903 | 0.034911 | 4.0903 | 19.21 | 30.72 | 0.001 | 0.000 | |

| V2 | 1 | 0.030076 | 2.6237 | 0.030076 | 2.6237 | 16.55 | 19.71 | 0.002 | 0.001 | |

| S2 | 1 | 0.161276 | 20.2991 | 0.161276 | 20.2991 | 88.74 | 152.45 | 0.000 | 0.000 | |

| Two-Factor Interaction | 3 | 0.08745 | 3.3841 | 0.02915 | 1.1280 | 16.04 | 8.47 | 0.000 | 0.004 | |

| P*V | 1 | 0.0098 | 0.1176 | 0.0098 | 0.1176 | 5.39 | 0.88 | 0.043 | 0.369 | |

| P*S | 1 | 0.0512 | 0.2775 | 0.0512 | 0.2775 | 28.17 | 2.08 | 0.000 | 0.179 | |

| V*S | 1 | 0.02645 | 2.9890 | 0.02645 | 2.9890 | 14.55 | 22.45 | 0.003 | 0.001 | |

| Error | 10 | 0.018173 | 1.3315 | 0.001817 | 0.1331 | |||||

| Lack of Fit | 5 | 0.012573 | 0.9529 | 0.002515 | 0.1906 | 2.25 | 2.52 | 0.198 | 0.167 | |

| Pure Error | 5 | 0.0056 | 0.3785 | 0.00112 | 0.0757 | |||||

| Total | 19 | 0.53208 | 38.5679 | |||||||

| Summary of the Model | ||||||||||

| Standard Deviation | Determination Factor R2 | R2 (Calibration) | R2 (Prediction) | |||||||

| RD | SR | RD | SR | RD | SR | RD | SR | |||

| 0.0426299 | 0.364896 | 96.58% | 96.55% | 93.51% | 93.44% | 79.84% | 79.87% | |||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Y.; Mao, Z.; Yang, N.; Niu, X.; Lu, X. Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting. Materials 2020, 13, 1601. https://doi.org/10.3390/ma13071601

Deng Y, Mao Z, Yang N, Niu X, Lu X. Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting. Materials. 2020; 13(7):1601. https://doi.org/10.3390/ma13071601

Chicago/Turabian StyleDeng, Yong, Zhongfa Mao, Nan Yang, Xiaodong Niu, and Xiangdong Lu. 2020. "Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting" Materials 13, no. 7: 1601. https://doi.org/10.3390/ma13071601

APA StyleDeng, Y., Mao, Z., Yang, N., Niu, X., & Lu, X. (2020). Collaborative Optimization of Density and Surface Roughness of 316L Stainless Steel in Selective Laser Melting. Materials, 13(7), 1601. https://doi.org/10.3390/ma13071601