3.1. DC Conductivity

Electrical conductivity is one of the requisites for the sensing material to be used as a membrane in potentiometric sensors. According to the previous work, lignin-based polyurethanes are insulating with conductivity of nearly 10

−8 S·m

−1, which can be increased several orders of magnitude by doping with carbon nanotubes [

15,

16]. Lignin is considered to be an excellent dispersant of carbon nanotubes in the polymeric matrix [

14]. As phenolic hydroxyls are much less reactive to isocyanates than aliphatic ones [

17], the redox properties of lignin involved in copolymerization may not change significantly. The advantage of this approach is a percolation effect observed in lignin-based polymers doped with MWCNTs, e.g., drastic increase of conductivity in the presence of small amounts of carbon nanotubes. Thus, conducting polymers can be obtained in a cost-effective manner and without changing other properties of the material. A similar approach was adopted in this work to increase the conductivity of the eucalyptus LignoBoost

® kraft lignin and ellagic acid-based polyurethanes. Ellagic acid was used in this study as the main eucalyptus kraft lignin contaminant of polyphenolic origin [

18]. This tannin contributes substantially to the phenolic functionalities of the isolated lignin.

Firstly, polymers doped with 0.8 and 1.4% (w/w) of MWCNTs were synthesized. DC electrical conductivity (σ

DC) of both polymers, as a function of the MWCNTs’ concentration at 293 K, is plotted in the

Figure 1. The conductivity of both undoped polymers was very low: 1.80 × 10

−10 and 7.68 × 10

−10 S·m

−1 for LignoBoost

® kraft lignin and ellagic acid-based polymers, respectively (

Figure 1). Higher conductivity of polyurethane (PU) based on undoped ellagic acid, when compared to that of based on kraft-lignin, could be explained by the better dispersion of low molecular weight polyphenolic molecules in PPGDI copolymer than the larger lignin oligomers. Incompletely dissolved highly swollen aggregated lignin was previously detected in PU obtained by copolymerization of conventional acid-precipitated eucalyptus kraft lignin and PPGDI [

14]. In addition, conjugated aromatic rings of flat ellagic acid structure could positively contribute to the conductivity of the final PU more than kraft lignin, whose structural units are predominantly linked by alkyl–alkyl, alkyl–aryl, and aryl–ether bonds, i.e., having less conjugated aromatic structures [

18].

Addition of carbon nanotubes led to a significant increase in the conductivity of the LignoBoost

® kraft lignin-based polymer, reaching 5.37 × 10

−4 S·m

−1 after the addition of 1.4% (w/w) of MWCNTs. Despite the fact that conductivity of undoped ellagic acid-based polyurethane was higher compared to lignin-based one, the effect of the MWCNT addition on conductivity was less accentuated. The conductivity of only 1.12 × 10

−7 S·m

−1 was observed at 1.4% (w/w) of MWCNTs (

Figure 1).

LignoBoost

® kraft lignin-based polymers doped with intermediate concentrations of MWCNTs were synthetized with the aim to confirm that conductivity of this polymer follows percolation scaling law and to determine percolation threshold (

Figure 1). Percolation threshold x

c and critical exponent t were calculated by fitting experimental data to the Equation (1)

where σ

DC is the DC conductivity,

x the volume fraction of the conductive phase,

xc the critical concentration and

t the critical exponent.

Critical concentration was found to be 0.77% (w/w) of MWCNTs and critical exponent 1.54.

All lignin-polyurethane compositions with MWCNTs’ concentration above the percolation threshold have sufficiently high conductivity for electrochemical sensor applications. The percolation threshold for composites with high aspect ratio fillers, such as CNTs, can be calculated using 3D statistical percolation model proposed in a previous study [

19]. Nanotubes used in this work had a length of 1–5 µm and a diameter of 5–19 nm, which means that their aspect ratio could vary between 52 and 260 and predicted critical concentration between 0.18% and 1.46%. It is important to point out that statistical model does not account for interactions between filler and polymer matrix, effect of the processing conditions or curved shape of nanotubes. Nevertheless, experimental value of the critical concentration for LignoBoost

® kraft lignin-based polyurethane is within the predicted range. Critical concentrations between 0.5 to 4.5% (w/w) of CNTs were reported in the literature for the thermoplastic polymers [

20]. Critical concentration obtained for LignoBoost

® kraft lignin-based polyurethane is higher compared to the value of 0.18% (w/w) previously reported for the conventional technical kraft lignin doped with MWCNTs with the same characteristics as the ones used in this work [

16]. This disparity can be related to the differences in the two lignins’ structure and, consequently, the difference in the interaction between nanotubes and polymer matrix.

The LignoBoost

® kraft lignin possesses higher molecular weight than the conventional kraft lignin and higher content of phenolic groups [

18], two factors favoring the association of lignin molecules in solution with copolymer (PPGDI). This negatively affects the dispersion of lignin in the polymeric matrix and, therefore, the dispersion of associated nanotubes in bulk. As such, the expected threshold occurred at a higher concentration of CNTs in the composite than that observed with conventional lignin kraft. According to previous findings, lignin interacts with CNTs via π-π stacking between aromatic ring and carbon nanotubes side wall, leading to the increase of the electron delocalization and eventual change in lignin chain conformation, thus allowing better π—overlap along the chain of lignin and giving rise to increased electric conductivity [

16]. Oriented by lignin, CNTs interact with each other, forming conductive assembles, which are incorporated into the polymeric matrix.

The critical exponent reflects the dimensionality of the system and usually takes values between 1.3 and 1.9, corresponding to two- and three-dimensional percolating systems, respectively [

21,

22]. Calculated value of the critical exponent for the doped LignoBoost

® kraft lignin-based polyurethane was lower than theoretical values, which is often observed for CNTs/polymer composites [

20]. Such apparent reduction of system dimensionality was interpreted as a consequence of mutual attraction and realignment of carbon nanotubes during polymer curing. Strong nanotube–nanotube, lignin–nanotube, and nanotube–polymer matrix interactions are a prerequisite for such realignment to take place. Thus, the formation of the conducting network in the polymer is not a true statistical percolation process based on random distribution.

A DC conductivity of both lignin and ellagic acid-based polymers increases exponentially with temperature, as shown in the

Figure 2. This behavior, which is typical for polymer composites, indicates that the conductivity is a thermally activated process and can be described by the well-known Arrhenius relation as follows

where

Ea is the activation energy (J mol

−1 K

−1),

T is the absolute temperature (K) and

k is the Boltzmann constant, 1.380649 × 10

−23 J·K

−1 [

23].

Activation energy can be calculated using plots of lnσ

DC. vs. the inversed temperature (

Figure 2). Values of the activation energy for the undoped LignoBoost

® kraft lignin and ellagic acid-based polymers were 0.76 eV and 1.05 eV, respectively. After addition of 1.4%(w/w) of MWCNTs, activation energy decreased to 0.08 eV and 0.39 eV for LignoBoost

® kraft lignin and ellagic acid-based polymers, respectively. Accordingly, the addition of MWCNTs resulted in a significant decrease of activation energy and increase of DC conductivity in both polymers, being more pronounced in lignin-based polyurethane, indicating active interaction between carbon nanotubes and lignin.

Ellagic acid-based polyurethanes had low conductivity even after doping with 1.4% (w/w) of MWCNTs, indicating that either no percolation occurs in this material or it occurs at relatively high concentrations of carbon nanotubes, making synthesis of such polymer costly and unpractical. Moreover, higher concentrations of a filler could alter thermoplastic properties of the polymer, which would be undesirable. Though both ellagic acid and lignin have aromatic groups in their structure, that were suggested to be involved in the interaction with carbon nanotubes, in the case of ellagic acid this interaction is certainly insufficient to effectively realign carbon nanotubes. This can be related to the significantly smaller size of the ellagic acid molecule compared to lignin, which prevents effective re-orientation of the carbon nanotubes. Hence, ellagic acid itself does not provide enough performance to be used in conducting blends with MWCNTs. Thus, only LignoBoost® lignin-based polyurethanes were considered a perspective sensing material and studied in more detail.

Interaction between LignoBoost

® kraft lignin and MWCNTs was assessed by probing the effectiveness of the nanotube dispersion in lignin-based polyurethane. SEM images of the mixture of LignoBoost

® kraft lignin with MWCNTs (1.4% w/w) show an even distribution of disentangled carbon nanotubes, appearing as thin fibers on the surface of the larger lignin particles (

Figure 3a,b). SEM images of the transversal cuts of LignoBoost

® kraft lignin-based polyurethane and ellagic acid-based polyurethane films, with and without MWCNTs, all differed in their structure. Both undoped polymers are porous, however, while lignin-based polyurethane has several evenly distributed air bubbles of varying sizes (

Figure 3c), ellagic acid-based polyurethane is denser with fewer air bubbles in its structure (

Figure 3e). Addition of the MWCNTs results in appearance of irregularly shaped pores in lignin-based polyurethane (

Figure 3d) and numerous round shaped pores in ellagic acid-based polyurethane (

Figure 3f). The structural dissimilarities between undoped and doped polymers confirm interaction between carbon nanotubes and lignin or ellagic acid. Differences in properties of ellagic acid and lignin, the size of the molecule probably being the most important, results in different interaction between these compounds and carbon nanotubes, thus leading to different structure of the respective polyurethanes. Further insights into the interactions between LignoBoost® lignin and carbon nanotubes in the polyurethane matrix were gained using dielectric spectroscopy.

3.2. AC Conductivity

Alternating current (AC) conductivity of LignoBoost

® kraft lignin-based copolymers undoped and doped with different amounts of MWCNTs is depicted in the

Figure 4a. The effect of the temperature on the AC conductivity variation as a function of frequency for LignoBoost

® kraft lignin based polyurethane, doped with 1.4% (w/w) of MWCNTs, is shown in the

Figure 4b. Real and imaginary parts of the complex permittivity, ε*(f) = ε′(f) − iε″(f), and calculated AC electrical conductivity as a function of frequency for the lignin-based copolymer, with 1.4% (w/w) and without MWCNTs at T = 350 K, are shown in the

Figure 5a,b, respectively.

Increase of AC conductivity and decrease of both, real and imaginary parts of permittivity, with an increase of frequency was observed for both polymers (

Figure 5a,b). Two distinct domains can be identified in the AC conductivity dependence on frequency [

24]. AC conductivity is nearly independent of the frequency at low frequencies (below 1000 Hz), with its value approaching the DC conductivity (

Figure 5a,b). This phenomenon, called the anomalous low frequency dispersion, is commonly observed in the disordered low-dimensional materials such as polymer matrices. Anomalous low-frequency dispersion arises from the restricted effective charge transport when charge motions are limited to one- or two-dimensional pathways. At frequencies above the crossover frequency fc, AC conductivity increases to different levels, depending on the material. Both ε’ and ε´´ decrease in all measured frequency intervals, which also corresponds to anomalous frequency dispersion.

Substantial increase of critical frequency, at which an increase in conductivity occurs, was observed in polymers doped with 0.8% (w/w) and higher concentrations of MWCNTs (

Figure 4a). The critical frequency increased concomitantly with MWCNTs’ concentration in the polymer, which is common behavior for the polymers doped with conducting particles [

25,

26]. The effect of the temperature on the AC conductivity dependence of the frequency for lignin based polyurethane doped with 1.4% (w/w) of MWCNTs is shown in the

Figure 4b. Concomitantly dependent on applied frequency, with only a small increase observed at high frequencies. At lower temperatures, the increase in conductivity is more pronounced as the frequency increases.

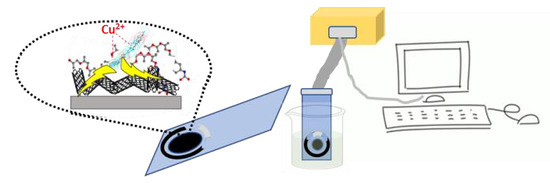

3.4. Sensor Properties

LignoBoost

® kraft lignin-based polyurethane doped with 1.4% (w/w) of MWCNTs was used for the preparation of the membrane of potentiometric chemical sensor. Slopes of the electrode function (S) of the sensor in the individual solutions of transition metal salts are depicted in the

Figure 6. The sensor displayed no response to sodium, calcium and iron (III), very low response to cadmium, lead, and chromium (VI), and low redox response in the solutions of redox pair Fe(CN)

6/Fe(CN)

6−3/−4. Sensor displayed theoretical response of 32 (±1) mV·pM

−1 to copper (II) with detection limit of 6(±1) × 10

−6 mol·L

−1. Sensor response to mercury (II) decreased with each consecutive calibration from 32 mV·pM

−1 in the first calibration to 18 mV·pM

−1 in the third. After exposure to the solutions of mercury (II), the sensor no longer responded to copper (II) ions. This behavior may be associated with irreversible complexation of mercury (II) ions by the polymeric membrane similar to the reported for several copper-sensitive organic ionophores [

28]. Thus, mercury must be avoided in the solutions analyzed by the sensor. Sensor displayed high selectivity towards copper in the presence of other transition metals except for mercury (II), to which it was not selective (

Table 1). Parameters of the sensor are close to the values reported in the literature for the copper-selective electrodes based on organic ligands (

Table S1).

Sensing characteristics of the sensor with LignoBoost

® kraft lignin-based membrane differs from the ones with membranes prepared using other technical lignins, such as conventional kraft lignin precipitated by deep acidification of black liquor, lignosulfonate, and organosolv lignin, all of which responded selectively to Cr(VI) in acidic solutions [

16]. Mechanism of these sensors’ response to Cr(VI) was suggested to be mixed, redox, and ionic, as the sensitivity of sensors was correlated with the content of quinone structures, the dominant redox-active moieties of lignin [

29]. Contrary to these findings, LignoBoost

® kraft lignin-based sensor did not display redox sensitivity, showing a very low response to Cr(VI) and redox pair, but instead it showed a selective response to Cu(II).

This behavior can be explained by the differences in the composition of eucalyptus LignoBoost

® kraft lignin and other technical lignins [

30,

31,

32], most noticeably, lower content of redox quinone type moieties and significantly higher content of polyphenolic groups with vicinal hydroxyls originating from concomitant tannins in the former [

18]. In particular, the LignoBoost

® kraft lignin has a higher total content of total hydroxyl groups and higher relative content of phenolic hydroxyl groups compared to the technical kraft lignin obtained from the cooking of the same wood species, but isolated by the conventional procedure [

32]. Considering that sensors based on the polyurethanes, synthesized using kraft lignin isolated using conventional procedure, did not display sensitivity to Cu(II) [

16], response of the sensor developed in this work can be attributed to the capability of phenolic hydroxyl groups to complex transition metals with higher specificity towards copper and mercury. This proposition is further corroborated by the reported higher chelating capacity of tannins with vicinal phenolic groups towards Cu(II) when compared to other bivalent transition ions, such as Zn(II) and Fe(II) [

33]. However, studies on the exact mechanisms are still necessary for a better understanding of the observed phenomena.

Furthermore, characteristics of sensors with and without solid inner contact, as well as their stability in copper(II) solutions over a 4-week period were evaluated. Potentiometric chemical sensors require inner contact since ion-to-electron transduction between the sensing membrane with ionic conductivity and substrate with electronic conductivity ensures the stability of the sensor potential. In all-solid-state sensors, inner contact is commonly made from conducting polymers that have mixed ion-electronic conductivity [

1]. As lignin-based polyurethanes are conducting polymers with mixed ionic and electronic conductivity, it was expected that they could be used for fabrication of the all solid-state sensors without additional inner contact layer. Newly prepared sensors with lignin-based polyurethane membrane, both with and without solid inner contact, displayed responses close to the theoretical ones to copper (II) ions: 33 and 32 mV·pM

−1, respectively, being not statistically different for

p = 0.05 (

Figure 7). However, sensor without solid inner contact had higher detection limit than the one with solid inner contact: 2(±1) × 10

−5 and 6(±1) × 10

−6 mol·L

−1, respectively. After one week, the slope of the sensor with solid inner contact slightly decreased, from 33 to 29 mV·pM

−1 and remained constant over the next three weeks (slopes were not statistically different for

p = 0.05). The slope of the sensor without solid inner contact remained close to the theoretical value for two weeks, after which it started to decrease. After the fourth week, this decrease became abrupt, with sensor’s response to Cu(II) being only 8 mV·pM

−1 (statistically different for

p = 0.05). A slight increase of the detection limit was observed for both types of sensors during this period.

Deterioration of properties, such as long-term stability and detection limit, of the sensor without solid inner contact indicates that the interface between electrode and membrane is not well-defined [

34]. This may occur due to the poor adhesion of the lignin-based polyurethane to the gold working electrode, leading to the formation of the water layer. Therefore, despite the electronic conductivity of lignin-based polyurethane imparted by MWCNTs, an intermediate conductive polymer layer is required to ensure better temporal stability and a lower detection limit.