Decade of Twist Channel Angular Pressing: A Review

Abstract

:1. The Principles of Severe Plastic Deformation

2. Severe Plastic Deformation Processes

3. Twist Channel Angular Pressing

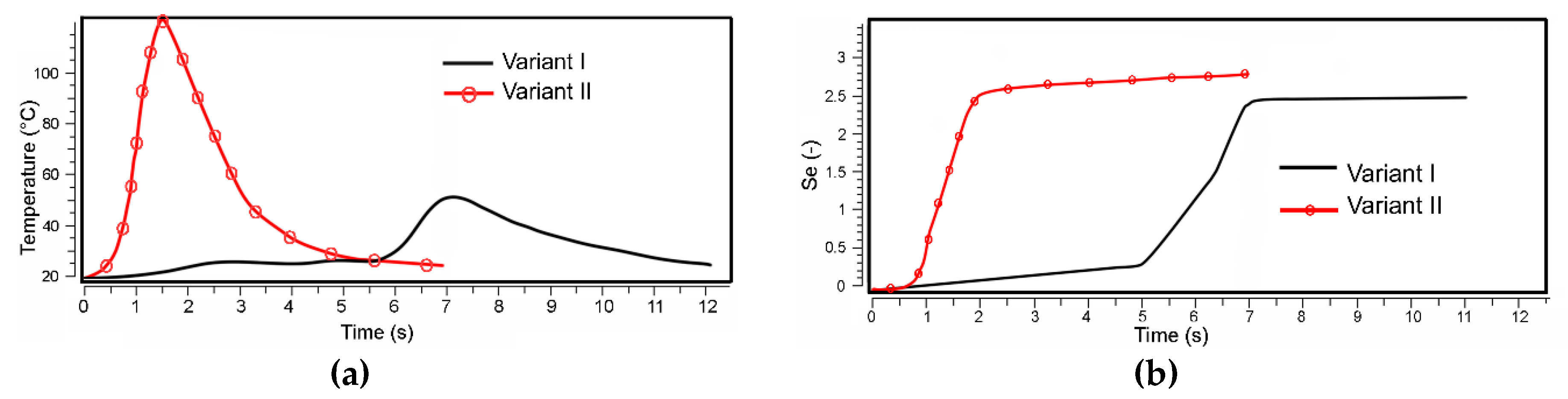

3.1. Imposed Strain

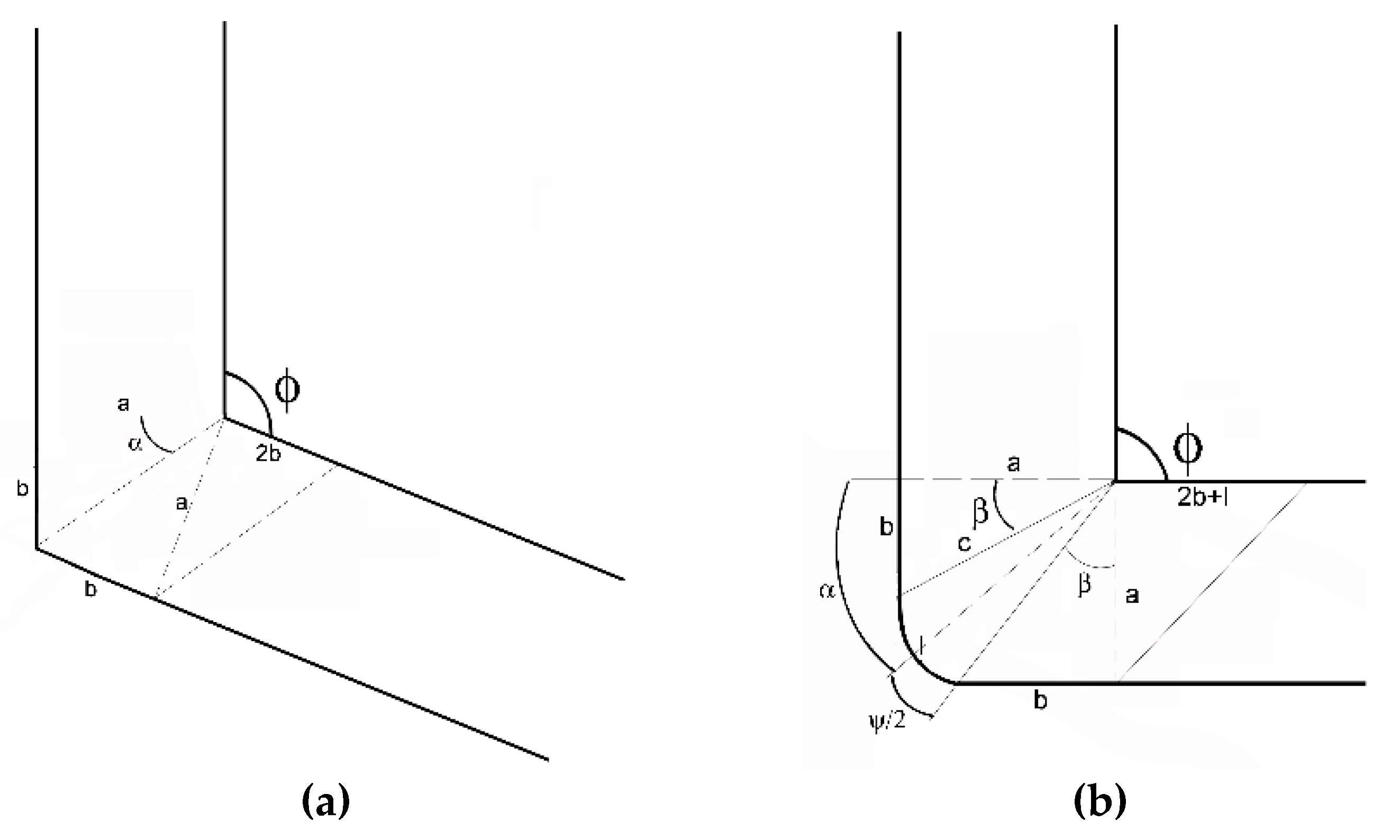

3.1.1. Channel Bending Part

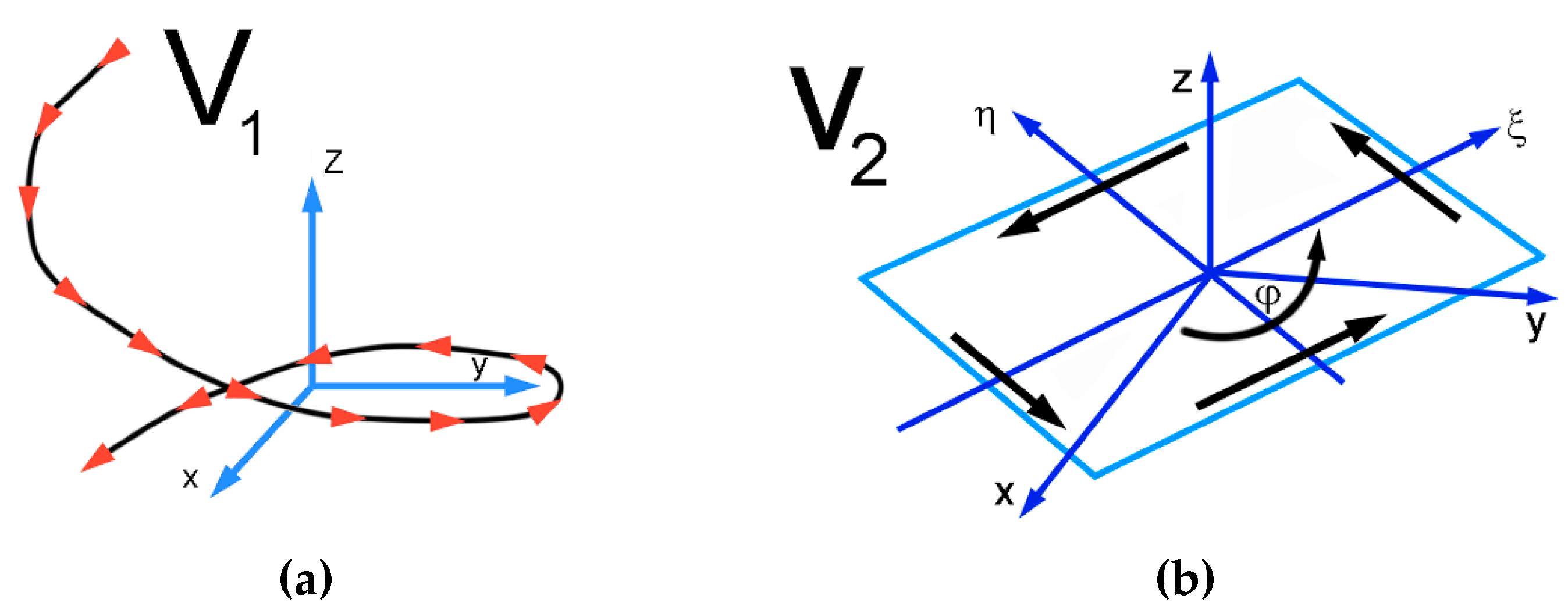

3.1.2. Channel Twist Part

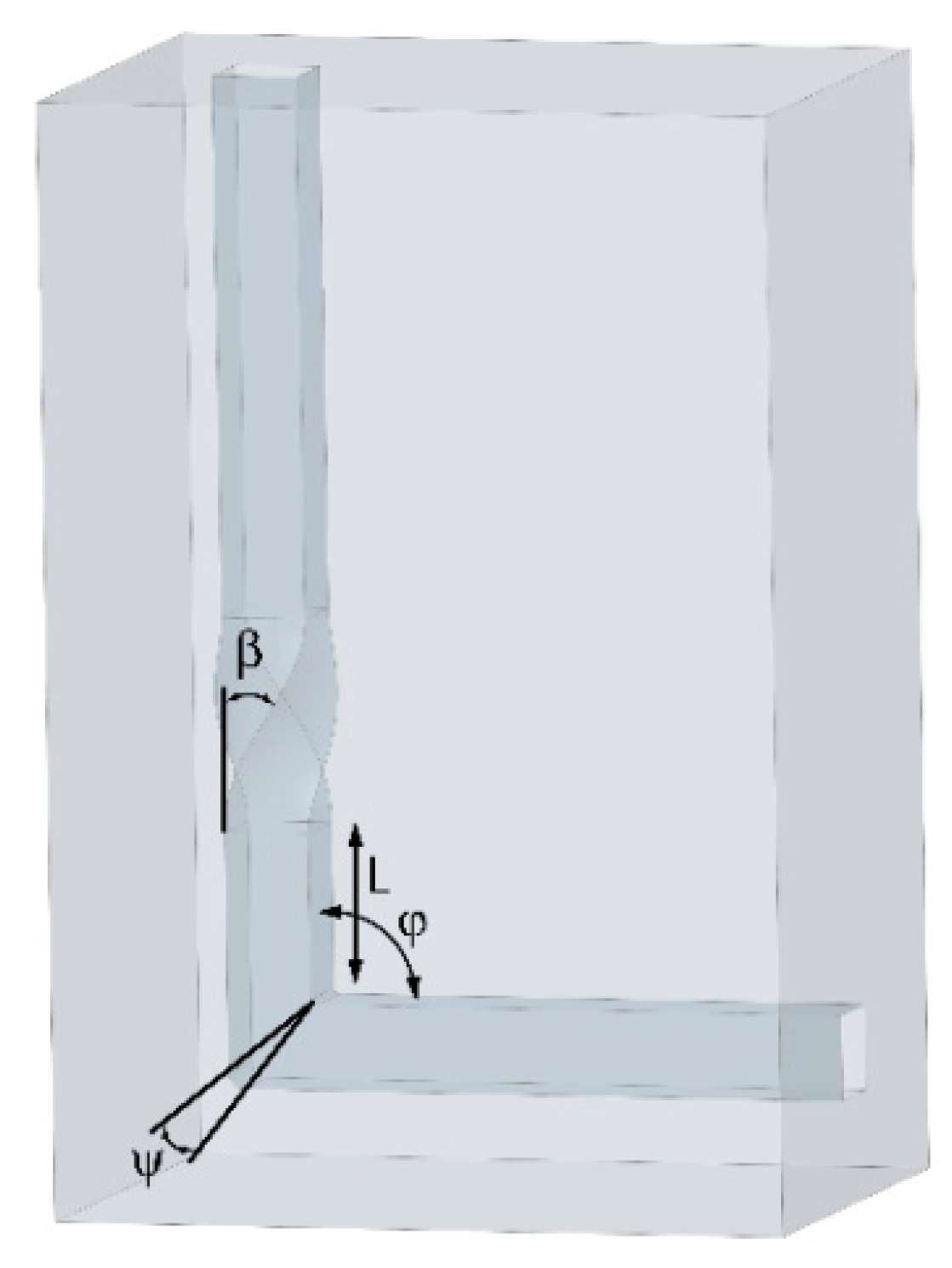

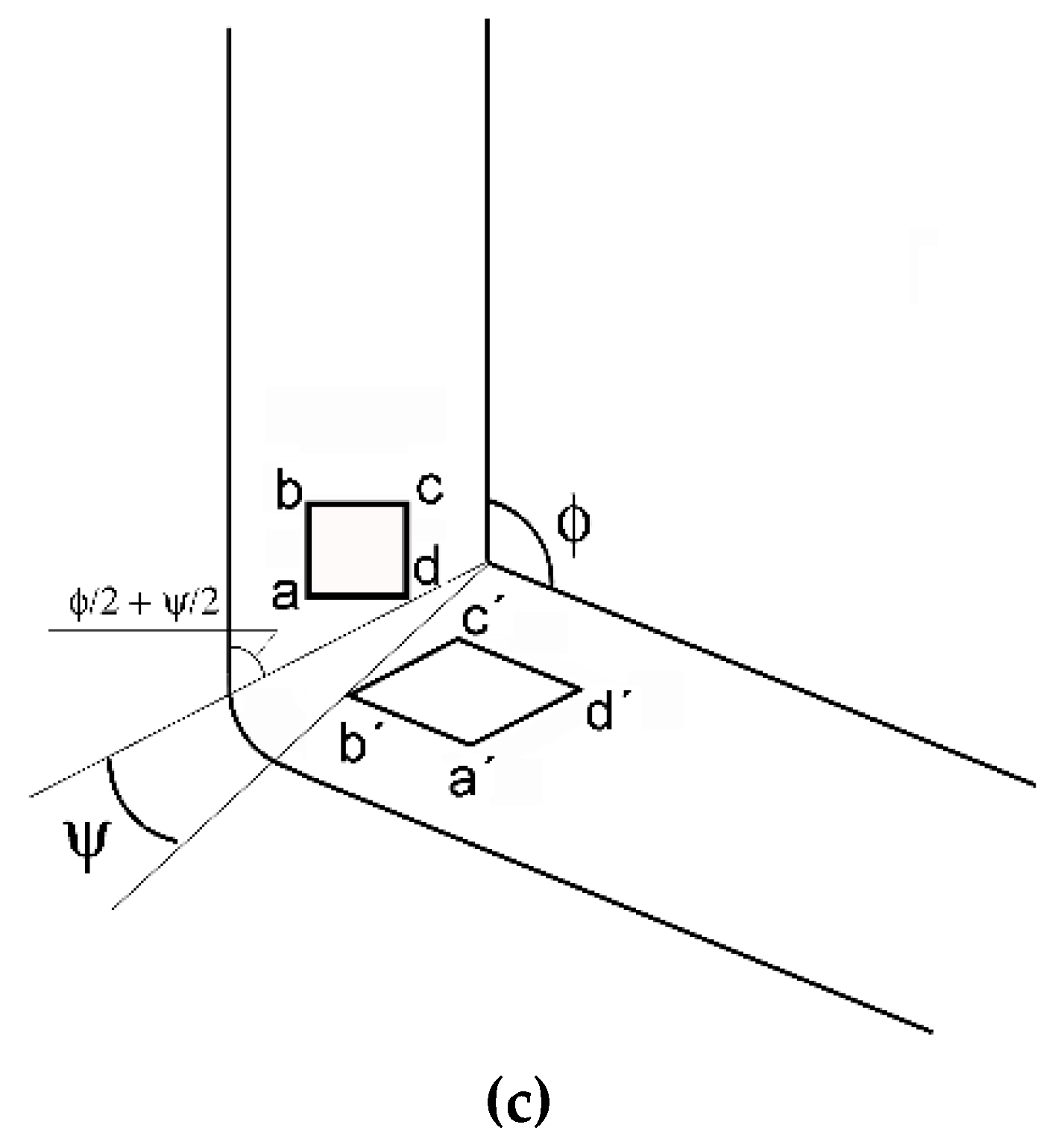

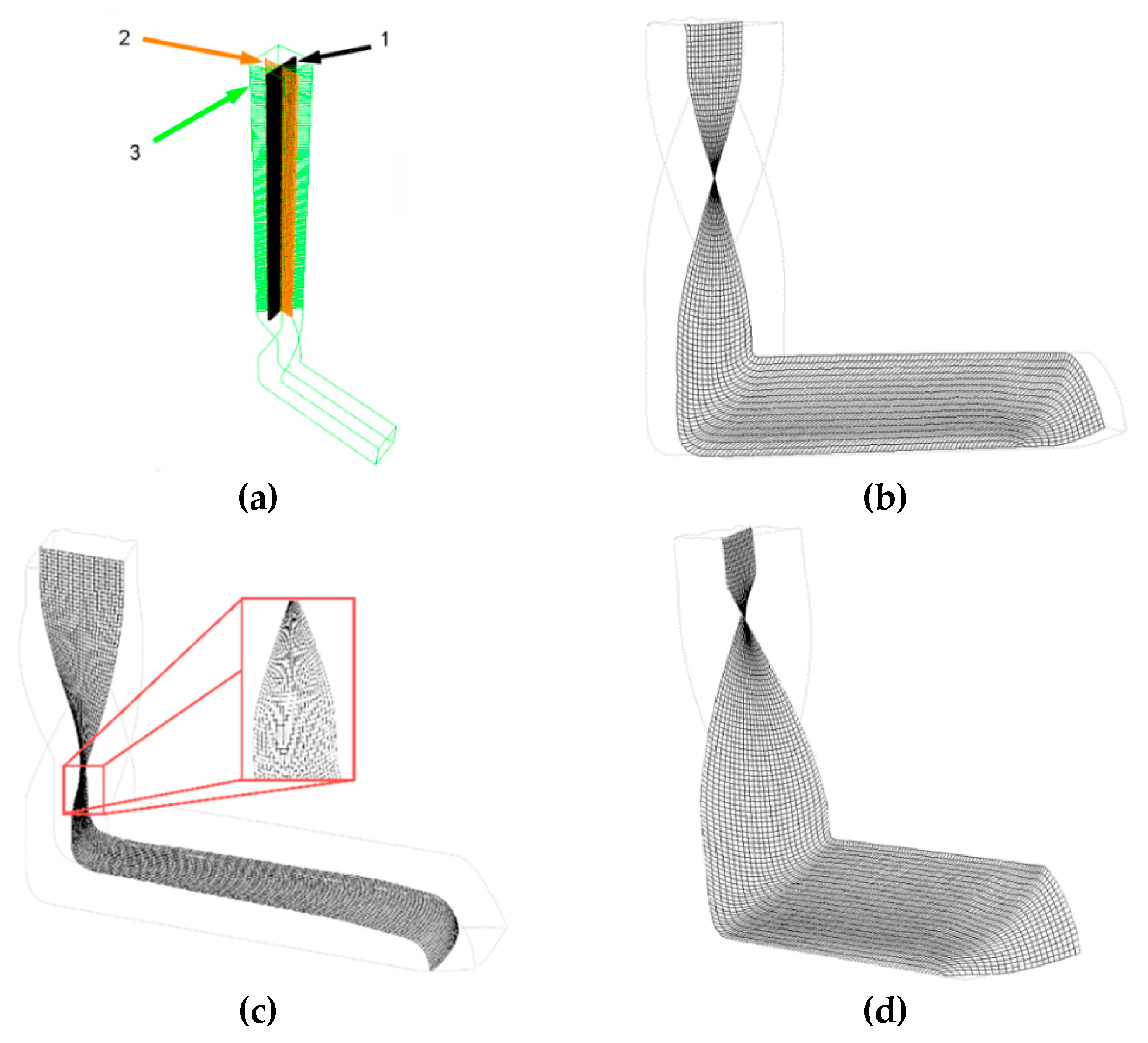

3.2. Die Geometry

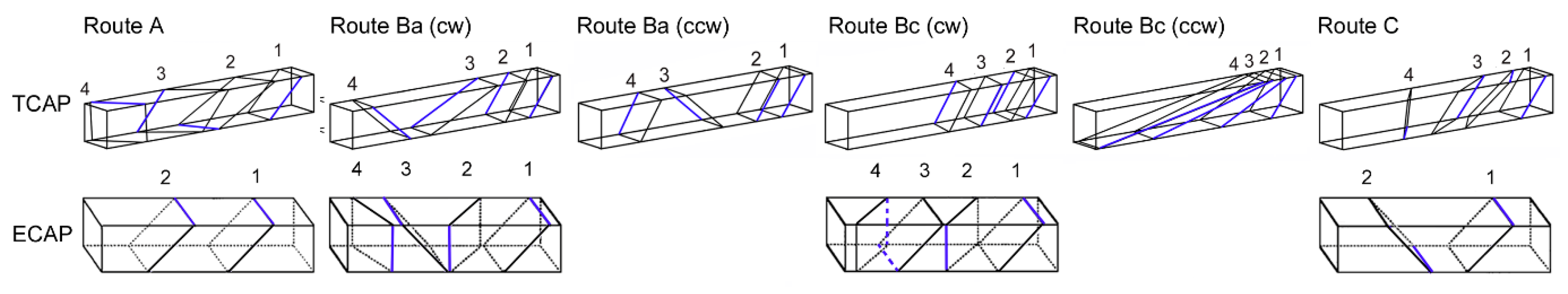

3.3. Strain Path

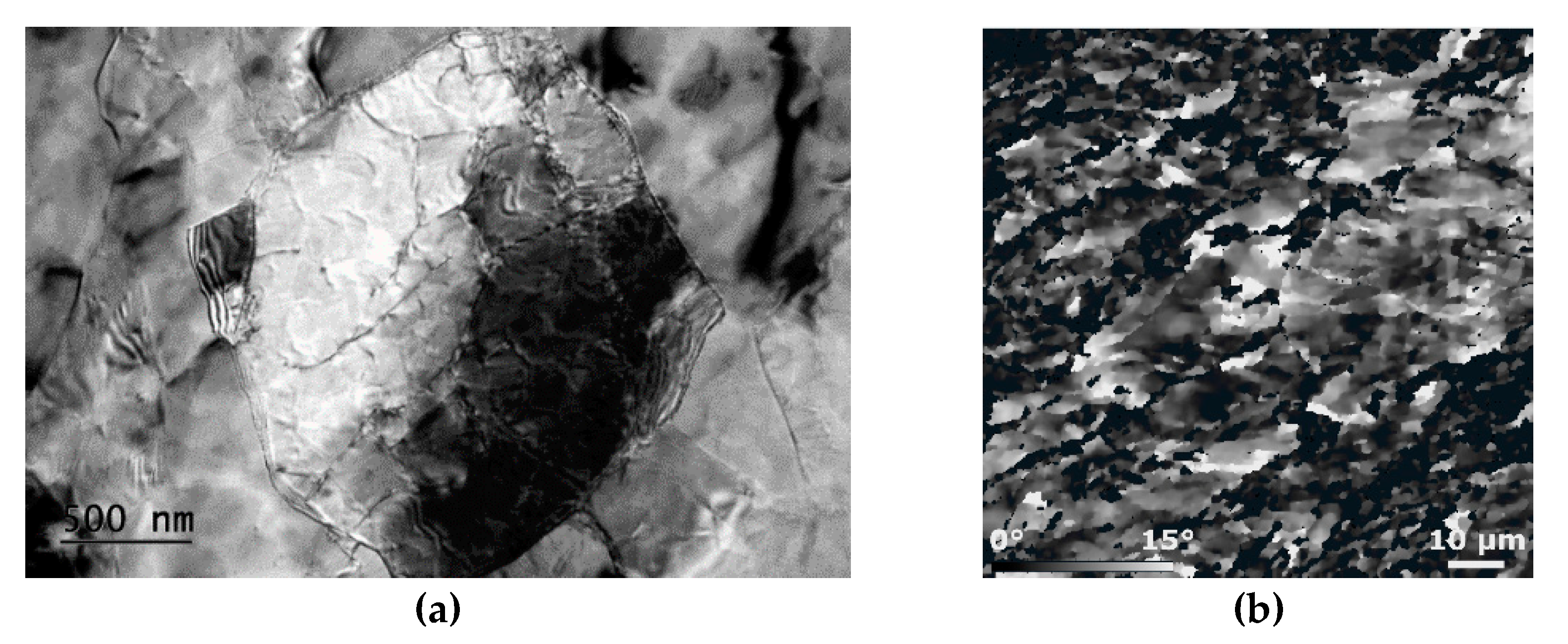

3.4. Structure and Properties

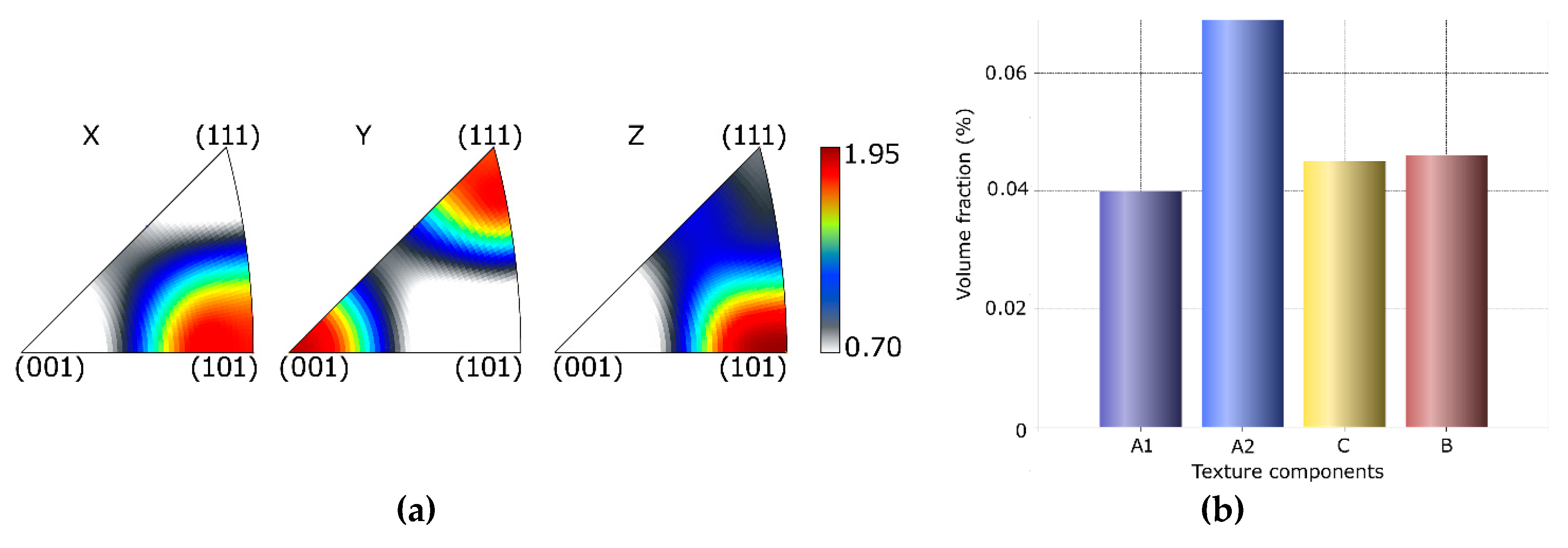

3.5. Texture

4. Twist Channel Multi Angular Pressing

5. Twisted Multi Channel Angular Pressing

6. Planar Twist Channel Angular Extrusion

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hansen, N. Hall–Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Verlinden, B.; Driver, J.; Samajdar, I.; Doherty, R.D. Thermo-Mechanical Processing of Metallic Materials; Elsevier: Amsterdam, The Netherlands, 2007; ISBN 9780080444970. [Google Scholar]

- Fang, Y.; Chen, X.; Madigan, B.; Cao, H.; Konovalov, S. Effects of strain rate on the hot deformation behavior and dynamic recrystallization in China low activation martensitic steel. Fusion Eng. Des. 2016, 103, 21–30. [Google Scholar] [CrossRef]

- Glezer, A.M.; Metlov, L.S. Physics of megaplastic (Severe) deformation in solids. Phys. Solid State 2010, 52, 1162–1169. [Google Scholar] [CrossRef]

- Bagherpour, E.; Pardis, N.; Reihanian, M.; Ebrahimi, R. An overview on severe plastic deformation: Research status, techniques classification, microstructure evolution, and applications. Int. J. Adv. Manuf. Technol. 2019, 100, 1647–1694. [Google Scholar] [CrossRef] [Green Version]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Qian, C.; He, Z.; Liang, C.; Cha, Y.; Ji, W. Superior intracluster conductivity of metallic lithium-ion battery anode achieved by high-pressure torsion. Mater. Lett. 2020, 260, 126933. [Google Scholar] [CrossRef]

- Voronova, L.M.; Chashchukhina, T.I.; Gapontseva, T.M.; Krasnoperova, Y.G.; Degtyarev, M.V.; Pilyugin, V.P. Effect of the deformation temperature on the structural refinement of BCC metals with a high stacking fault energy during high pressure torsion. Russ. Metall. 2016, 2016, 960–965. [Google Scholar] [CrossRef]

- Kunčická, L.; Lowe, T.C.; Davis, C.F.; Kocich, R.; Pohludka, M. Synthesis of an Al/Al2O3 composite by severe plastic deformation. Mater. Sci. Eng. A 2015, 646, 234–241. [Google Scholar] [CrossRef]

- Kocich, R.; Greger, M.; Macháčková, A. Finite element investigation of influence of selected factors on ECAP process. In Proceedings of the METAL 2010: 19th International Metallurgical and Materials Conference, Roznov pod Radhostem, Czech Republic, 20–22 May 2010; Tanger Ltd.: Ostrava, Czech Republic, 2010; pp. 166–171. [Google Scholar]

- Elhefnawey, M.; Shuai, G.L.; Li, Z.; Nemat-Alla, M.; Zhang, D.T.; Li, L. On achieving superior strength for Al–Mg–Zn alloy adopting cold ECAP. Vacuum 2020, 174, 109191. [Google Scholar] [CrossRef]

- Hlaváč, L.M.; Kocich, R.; Gembalová, L.; Jonšta, P.; Hlaváčová, I.M. AWJ cutting of copper processed by ECAP. Int. J. Adv. Manuf. Technol. 2016, 86, 885–894. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Tang, Y.; Sumikawa, K.; Takizawa, Y.; Yumoto, M.; Otagiri, Y.; Horita, Z. Multi-pass high-pressure sliding (MP-HPS) for grain refinement and superplasticity in metallic round rods. Mater. Sci. Eng. A 2019, 748, 108–118. [Google Scholar] [CrossRef]

- Tóth, L.S.; Arzaghi, M.; Fundenberger, J.J.; Beausir, B.; Bouaziz, O.; Arruffat-Massion, R. Severe plastic deformation of metals by high-pressure tube twisting. Scr. Mater. 2009, 60, 175–177. [Google Scholar] [CrossRef]

- Kunčická, L.; Král, P.; Dvořák, J.; Kocich, R. Texture evolution in biocompatible mg-y-re alloy after friction stir processing. Metals 2019, 9, 1181. [Google Scholar] [CrossRef] [Green Version]

- Zisman, A.A.; Rybin, V.V.; Van Boxel, S.; Seefeldt, M.; Verlinden, B. Equal channel angular drawing of aluminium sheet. Mater. Sci. Eng. A 2006, 427, 123–129. [Google Scholar] [CrossRef]

- Kocich, R.; Macháčková, A.; Andreyachshenko, V.A. A study of plastic deformation behaviour of Ti alloy during equal channel angular pressing with partial back pressure. Comput. Mater. Sci. 2015, 101, 233–241. [Google Scholar] [CrossRef]

- Fatemi-Varzaneh, S.M.; Zarei-Hanzaki, A.; Izadi, S. Shear deformation and grain refinement during accumulative back extrusion of AZ31 magnesium alloy. J. Mater. Sci. 2010, 46, 1937–1944. [Google Scholar] [CrossRef]

- Kocich, R.; Macháčková, A.; Fojtík, F. Comparison of strain and stress conditions in conventional and ARB rolling processes. Int. J. Mech. Sci. 2012, 64, 54–61. [Google Scholar] [CrossRef]

- Mohebbi, M.S.; Akbarzadeh, A. Accumulative spin-bonding (ASB) as a novel SPD process for fabrication of nanostructured tubes. Mater. Sci. Eng. A 2010, 528, 180–188. [Google Scholar] [CrossRef]

- Gupta, A.K.; Maddukuri, T.S.; Singh, S.K. Constrained groove pressing for sheet metal processing. Prog. Mater. Sci. 2016, 84, 403–462. [Google Scholar] [CrossRef]

- Torkestani, A.; Dashtbayazi, M.R. A new method for severe plastic deformation of the copper sheets. Mater. Sci. Eng. A 2018, 737, 236–244. [Google Scholar] [CrossRef]

- Abdolvand, H.; Sohrabi, H.; Faraji, G.; Yusof, F. A novel combined severe plastic deformation method for producing thin-walled ultrafine grained cylindrical tubes. Mater. Lett. 2015, 143, 167–171. [Google Scholar] [CrossRef]

- Zangiabadi, A.; Kazeminezhad, M. Development of a novel severe plastic deformation method for tubular materials: Tube Channel Pressing (TCP). Mater. Sci. Eng. A 2011, 528, 5066–5072. [Google Scholar] [CrossRef]

- Wang, C.; Li, F.; Li, Q.; Li, J.; Wang, L.; Dong, J. A novel severe plastic deformation method for fabricating ultrafine grained pure copper. Mater. Des. 2013, 43, 492–498. [Google Scholar] [CrossRef]

- Wang, Q.D.; Chen, Y.J.; Lin, J.B.; Zhang, L.J.; Zhai, C.Q. Microstructure and properties of magnesium alloy processed by a new severe plastic deformation method. Mater. Lett. 2007, 61, 4599–4602. [Google Scholar] [CrossRef]

- Kim, K.; Yoon, J. Evolution of the microstructure and mechanical properties of AZ61 alloy processed by half channel angular extrusion (HCAE), a novel severe plastic deformation process. Mater. Sci. Eng. A 2013, 578, 160–166. [Google Scholar] [CrossRef]

- Richert, M.; Liu, Q.; Hansen, N. Microstructural evolution over a large strain range in aluminium deformed by cyclic-extrusion–compression. Mater. Sci. Eng. A 1999, 260, 275–283. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Huang, W. Severe Deformation Based Process for Grain Subdivision and Resulting Microstructures. In Investigations and Applications of Severe Plastic Deformation; Springer: Dordrecht, The Netherlands, 2000; pp. 29–36. [Google Scholar]

- Pardis, N.; Talebanpour, B.; Ebrahimi, R.; Zomorodian, S. Cyclic expansion-extrusion (CEE): A modified counterpart of cyclic extrusion-compression (CEC). Mater. Sci. Eng. A 2011, 528, 7537–7540. [Google Scholar] [CrossRef]

- Ensafi, M.; Faraji, G.; Abdolvand, H. Cyclic extrusion compression angular pressing (CECAP) as a novel severe plastic deformation method for producing bulk ultrafine grained metals. Mater. Lett. 2017, 197, 12–16. [Google Scholar] [CrossRef] [Green Version]

- Khoddam, S.; Farhoumand, A.; Hodgson, P.D. Axi-symmetric forward spiral extrusion, a kinematic and experimental study. Mater. Sci. Eng. A 2011, 528, 1023–1029. [Google Scholar] [CrossRef]

- Farhoumand, A.; Hodgson, P.D.; Khoddam, S. Finite element analysis of plastic deformation in variable lead axisymmetric forward spiral extrusion. J. Mater. Sci. 2013, 48, 2454–2461. [Google Scholar] [CrossRef]

- Ebrahimi, G.R.; Barghamadi, A.; Ezatpour, H.R.; Amiri, A. A novel single pass severe plastic deformation method using combination of planar twist extrusion and conventional extrusion. J. Manuf. Process. 2019, 47, 427–436. [Google Scholar] [CrossRef]

- Yu, J.; Zhang, Z.; Wang, Q.; Hao, H.; Cui, J.; Li, L. Rotary extrusion as a novel severe plastic deformation method for cylindrical tubes. Mater. Lett. 2018, 215, 195–199. [Google Scholar] [CrossRef]

- Mizunuma, S. Large Straining Behavior and Microstructure Refinement of Several Metals by Torsion Extrusion Process. Mater. Sci. Forum 2006, 503–504, 185–192. [Google Scholar] [CrossRef]

- Noor, S.V.; Eivani, A.R.; Jafarian, H.R.; Mirzaei, M. Inhomogeneity in microstructure and mechanical properties during twist extrusion. Mater. Sci. Eng. A 2016, 652, 186–191. [Google Scholar] [CrossRef]

- Pardis, N.; Ebrahimi, R. Deformation behavior in Simple Shear Extrusion (SSE) as a new severe plastic deformation technique. Mater. Sci. Eng. A 2009, 527, 355–360. [Google Scholar] [CrossRef]

- Utsunomiya, H.; Hatsuda, K.; Sakai, T.; Saito, Y. Continuous grain refinement of aluminum strip by conshearing. Mater. Sci. Eng. A 2004, 372, 199–206. [Google Scholar] [CrossRef]

- Lee, J.-C.; Seok, H.-K.; Suh, J.-Y. Microstructural evolutions of the Al strip prepared by cold rolling and continuous equal channel angular pressing. Acta Mater. 2002, 50, 4005–4019. [Google Scholar] [CrossRef]

- Huang, Y.; Prangnell, P.B. Continuous frictional angular extrusion and its application in the production of ultrafine-grained sheet metals. Scr. Mater. 2007, 56, 333–336. [Google Scholar] [CrossRef]

- Huang, J.Y.; Zhu, Y.T.; Jiang, H.; Lowe, T.C. Microstructures and dislocation configurations in nanostructured Cu processed by repetitive corrugation and straightening. Acta Mater. 2001, 49, 1497–1505. [Google Scholar] [CrossRef]

- Nakamura, K.; Neishi, K.; Kaneko, K.; Nakagaki, M.; Horita, Z. Development of Severe Torsion Straining Process for Rapid Continuous Grain Refinement. Mater. Trans. 2004, 45, 3338–3342. [Google Scholar] [CrossRef] [Green Version]

- Kocich, R.; Lukáč, P. SPD Processes-Methods for Mechanical Nanostructuring. In Handbook of Mechanical Nanostructuring; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015; pp. 235–262. [Google Scholar]

- Semenova, I.P.; Polyakov, A.V.; Raab, G.I.; Lowe, T.C.; Valiev, R.Z. Enhanced fatigue properties of ultrafine-grained Ti rods processed by ECAP-Conform. J. Mater. Sci. 2012, 47, 7777–7781. [Google Scholar] [CrossRef]

- Kocich, R.; Greger, M.; Kursa, M.; Szurman, I.; Macháčková, A. Twist channel angular pressing (TCAP) as a method for increasing the efficiency of SPD. Mater. Sci. Eng. A 2010, 527, 6386–6392. [Google Scholar] [CrossRef]

- Jamili, A.M.; Zarei-Hanzaki, A.; Abedi, H.R.; Mosayebi, M.; Kocich, R.; Kunčická, L. Development of fresh and fully recrystallized microstructures through friction stir processing of a rare earth bearing magnesium alloy. Mater. Sci. Eng. A 2019, 775, 138837. [Google Scholar] [CrossRef]

- Kocich, R.; Fiala, J.; Szurman, I.; Macháčková, A.; Mihola, M. Twist-channel angular pressing: Effect of the strain path on grain refinement and mechanical properties of copper. J. Mater. Sci. 2011, 46, 7865–7876. [Google Scholar] [CrossRef]

- Iqbal, U.M.; Muralidharan, S. Optimization of die design parameters and experimental validation on twist channel angular pressing process of AA6061-T6 aluminium alloy. Mater. Res. Express 2019, 6, 0865f2. [Google Scholar] [CrossRef]

- Segal, V.M. Slip line solutions, deformation mode and loading history during equal channel angular extrusion. Mater. Sci. Eng. A 2003, 345, 36–46. [Google Scholar] [CrossRef]

- Kim, H.S.; Seo, M.H.; Hong, S.I. On the die corner gap formation in equal channel angular pressing. Mater. Sci. Eng. A 2000, 291, 86–90. [Google Scholar] [CrossRef]

- Orlov, D.; Beygelzimer, Y.; Synkov, S.; Varyukhin, V.; Horita, Z. Evolution of Microstructure and Hardness in Pure Al by Twist Extrusion. Mater. Trans. 2008, 49, 2–6. [Google Scholar] [CrossRef]

- Latypov, M.I.; Lee, M.G.; Beygelzimer, Y.; Kulagin, R.; Kim, H.S. On the simple shear model of twist extrusion and its deviations. Met. Mater. Int. 2015, 21, 569–579. [Google Scholar] [CrossRef]

- Bahadori, S.R.; Dehghani, K.; Akbari Mousavi, S.A.A. Comparison of microstructure and mechanical properties of pure copper processed by twist extrusion and equal channel angular pressing. Mater. Lett. 2015, 152, 48–52. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Mihola, M.; Skotnicová, K. Numerical and experimental analysis of twist channel angular pressing (TCAP) as a SPD process. Mater. Sci. Eng. A 2013, 563, 86–94. [Google Scholar] [CrossRef]

- Glezer, A.M.; Sundeev, R.V. General view of severe plastic deformation in solid state. Mater. Lett. 2015, 139, 455–457. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Král, P.; Pohludka, M.; Marek, M. Effect of strain path on severely deformed aluminium. Mater. Lett. 2016, 180, 280–283. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Král, P.; Macháčková, A. Sub-structure and mechanical properties of twist channel angular pressed aluminium. Mater. Charact. 2016, 119, 75–83. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Alexandrov, I.V.; Lowe, T.C.; Valiev, R.Z. Influence of ECAP routes on the microstructure and properties of pure Ti. Mater. Sci. Eng. A 2001, 299, 59–67. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Structure Development after Twist Channel Angular Pressing. Acta Phys. Pol. A 2017, 134, 681–685. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Ryukhtin, V.; Cullen, J.C.T.; Lavery, N.P. Study of structure of naturally aged aluminium after twist channel angular pressing. Mater. Charact. 2019, 152, 94–100. [Google Scholar] [CrossRef] [Green Version]

- Beyerlein, I.J.; Tóth, L.S. Texture evolution in equal-channel angular extrusion. Prog. Mater. Sci. 2009, 54, 427–510. [Google Scholar] [CrossRef]

- Kocich, R.; Macháčková, A.; Kunčická, L. Twist channel multi-angular pressing (TCMAP) as a new SPD process: Numerical and experimental study. Mater. Sci. Eng. A 2014, 612, 445–455. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Macháčková, A. Twist Channel Multi-Angular Pressing ( TCMAP ) as a method for increasing the efficiency of SPD. IOP Conf. Ser. Mater. Sci. Eng. 2014, 63, 012006. [Google Scholar] [CrossRef]

- Alavizadeh, S.M.; Abrinia, K.; Parvizi, A. Twisted Multi Channel Angular Pressing (TMCAP) as a Novel Severe Plastic Deformation Method. Met. Mater. Int. 2020, 26, 260–271. [Google Scholar] [CrossRef]

- Shamsborhan, M.; Ebrahimi, M. Production of nanostructure copper by planar twist channel angular extrusion process. J. Alloys Compd. 2016, 682, 552–556. [Google Scholar] [CrossRef]

- Shokuhfar, A.; Shamsborhan, M. Finite element analysis of planar twist channel angular extrusion (PTCAE) as a novel severe plastic deformation method. J. Mech. Sci. Technol. 2014, 28, 1753–1757. [Google Scholar] [CrossRef]

- Shamsborhan, M.; Shokuhfar, A.; Nejadseyfi, O.; Kakemam, J.; Moradi, M. Experimental and numerical comparison of equal channel angular extrusion (ECAE) with planar twist channel angular extrusion (PTCAE). Proc. Inst. Mech. Eng. Part C 2015, 229, 3059–3067. [Google Scholar] [CrossRef]

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macháčková, A. Decade of Twist Channel Angular Pressing: A Review. Materials 2020, 13, 1725. https://doi.org/10.3390/ma13071725

Macháčková A. Decade of Twist Channel Angular Pressing: A Review. Materials. 2020; 13(7):1725. https://doi.org/10.3390/ma13071725

Chicago/Turabian StyleMacháčková, Adéla. 2020. "Decade of Twist Channel Angular Pressing: A Review" Materials 13, no. 7: 1725. https://doi.org/10.3390/ma13071725

APA StyleMacháčková, A. (2020). Decade of Twist Channel Angular Pressing: A Review. Materials, 13(7), 1725. https://doi.org/10.3390/ma13071725