Experimental Study on the Efficacy of a Novel Personal Cooling Vest Incorporated with Phase Change Materials and Fans

Abstract

1. Introduction

2. Mathematical Models

3. Experiments

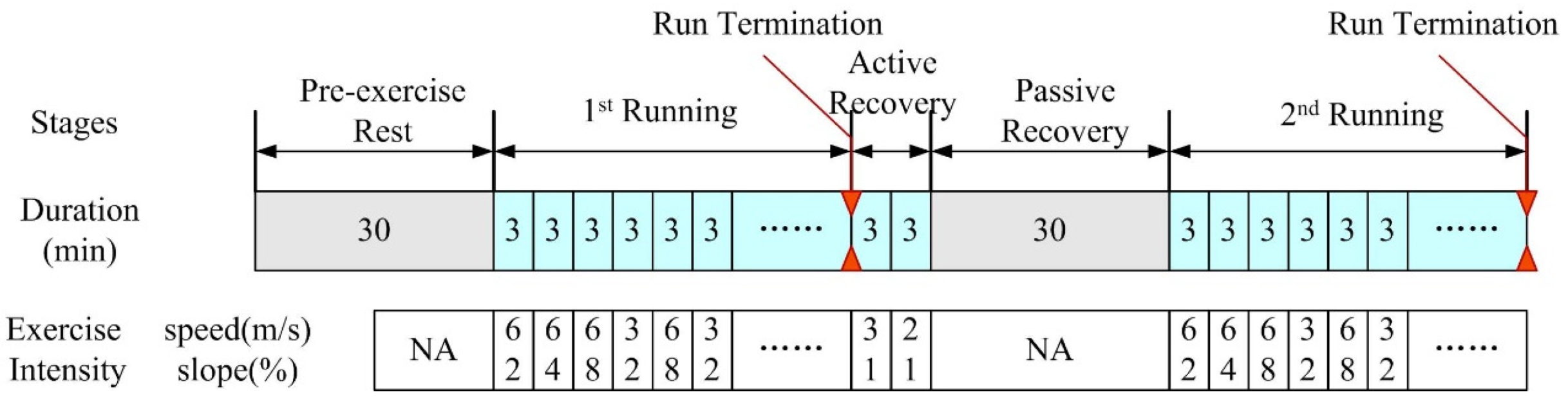

3.1. Experimental Design

3.2. Measurements and Calculations

4. Results

4.1. Physiological Responses

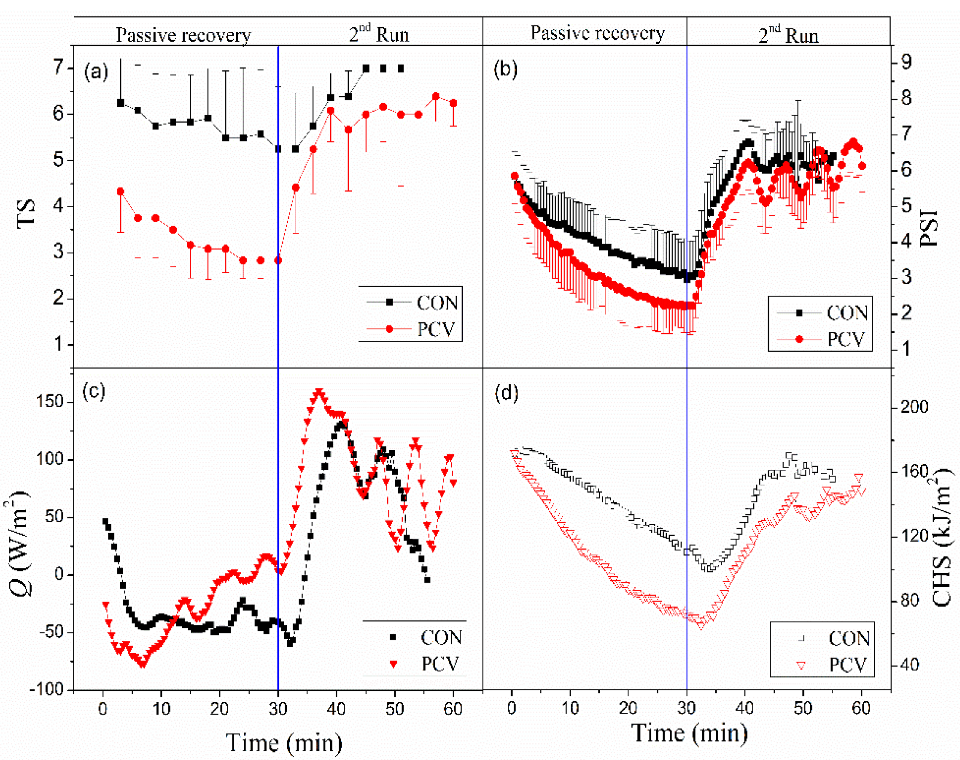

4.2. TS, PSI, Q, and CHS

5. Discussions

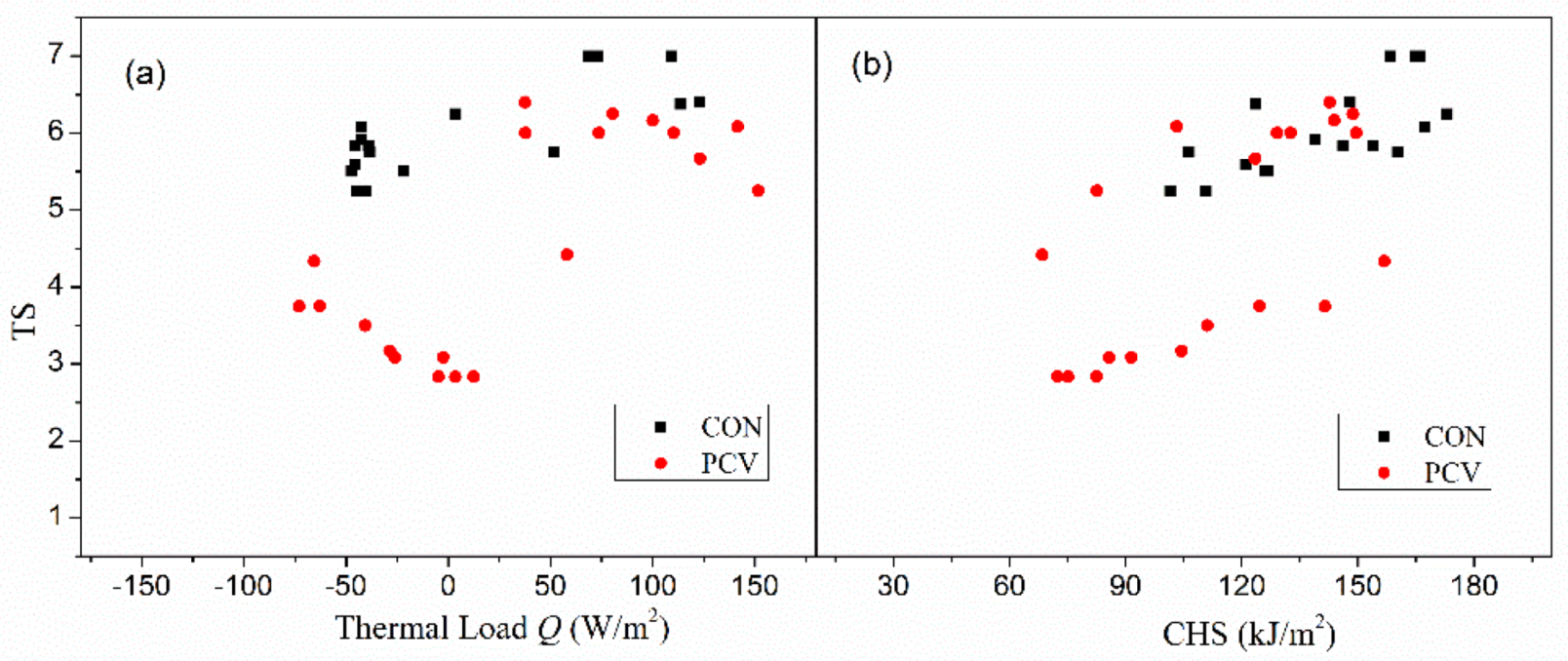

5.1. Relationships between TS with Q and CHS

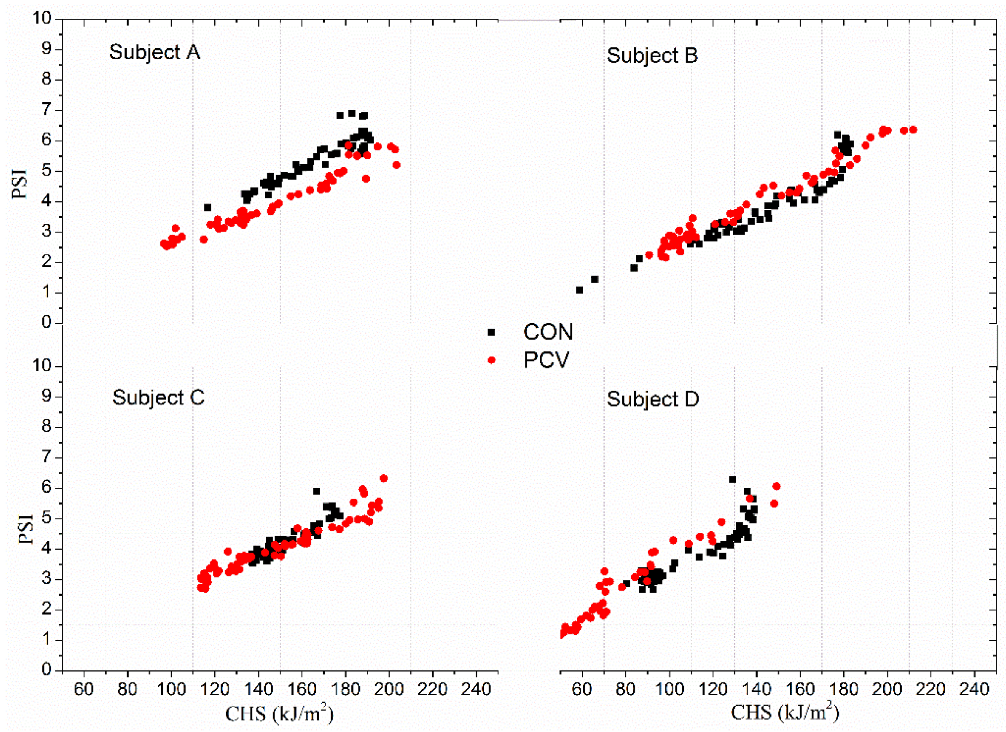

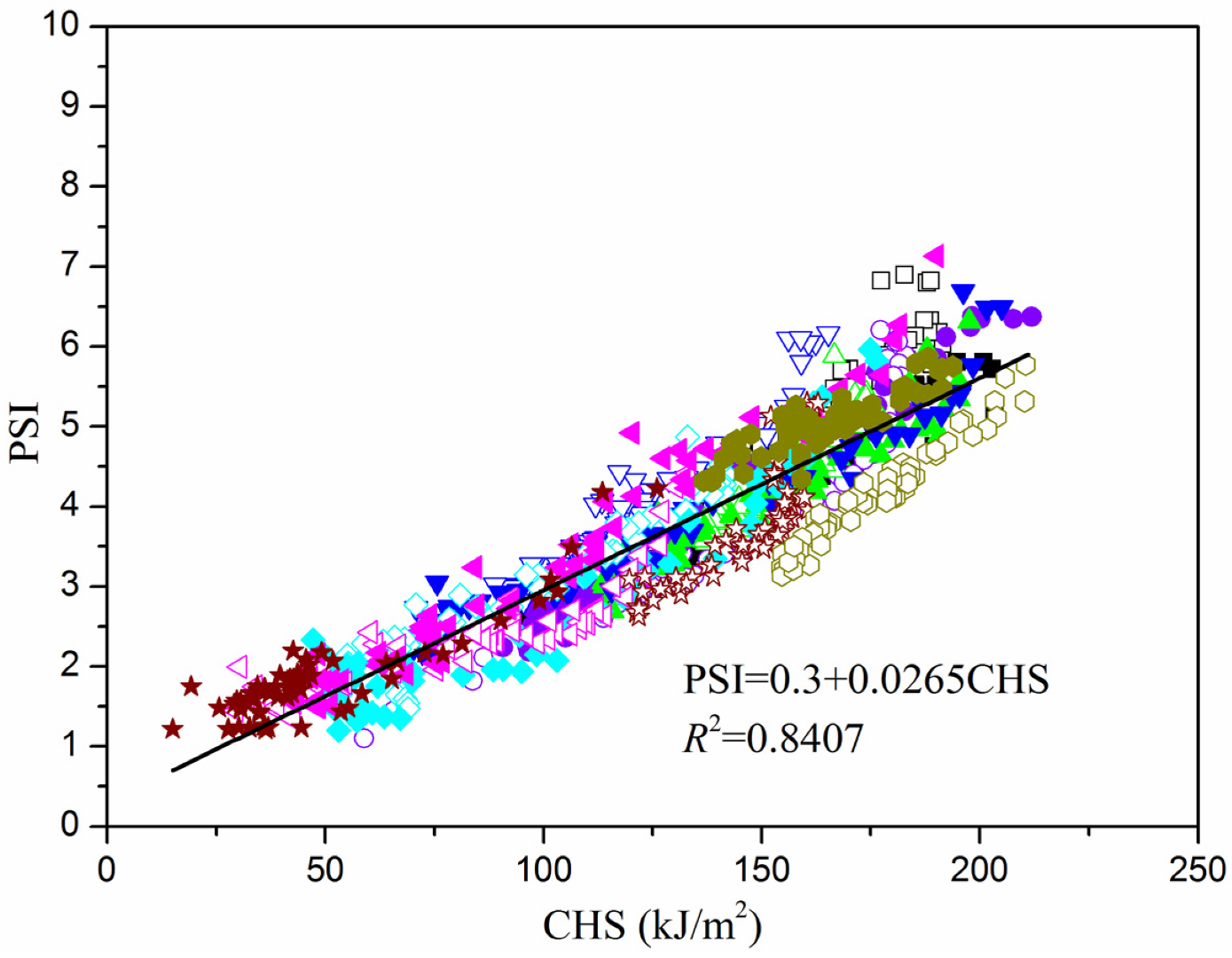

5.2. Relationship between PSI and CHS

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chan, A.P.C.; Yi, W.; Zhao, Y.; Yang, Y.; Wong, F.K.W.; Yam, M.C.H.; Chan, D.W.M.; Lam, E.W.M.; Li, Y.; Guo, Y. Developing a Personal Cooling System (PCS) for Construction Workers―An Experimental Approach. In Proceedings of the 8th International Conference on Construction in the 21st Century (CITC-VIII), Thessaloniki, Greece, 27–30 May 2015. [Google Scholar]

- Chan, A.P.; Zhang, Y.; Wang, F.; Wong, F.F.; Chan, D.W. A field study of the effectiveness and practicality of a novel hybrid personal cooling vest worn during rest in Hong Kong construction industry. J. Therm. Biol. 2017, 70, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Ramsey, J.D.; Burford, C.L.; Beshir, M.Y.; Jensen, R.C. Effects of workplace thermal conditions on safe work behavior. J. Saf. Res. 1983, 14, 105–114. [Google Scholar] [CrossRef]

- Ouahrani, D.; Itani, M.; Ghaddar, N.; Ghali, K.; Khater, B. Experimental study on using PCMs of different melting temperatures in one cooling vest to reduce its weight and improve comfort. Energy Build. 2017, 155, 533–545. [Google Scholar] [CrossRef]

- Gao, C.; Kuklane, K.; Holmér, I. Cooling vests with phase change materials: The effects of melting temperature on heat strain alleviation in an extremely hot environment. Eur. Appl. Physiol. 2011, 111, 1207–1216. [Google Scholar] [CrossRef]

- Hamdan, H.; Ghaddar, N.; Ouahrani, D.; Ghali, K.; Itani, M. PCM cooling vest for improving thermal comfort in hot environment. Int. J. Therm. Sci. 2016, 102, 154–167. [Google Scholar] [CrossRef]

- Itani, M.; Ouahrani, D.; Ghaddar, N.; Ghali, K.; Chakroun, W. The effect of PCM placement on torso cooling vest for an active human in hot environment. Build. Environ. 2016, 107, 29–42. [Google Scholar] [CrossRef]

- Itani, M.; Ghaddar, N.; Ghali, K.; Ouahrani, D.; Khater, B. Significance of PCM arrangement in cooling vest for enhancing comfort at varied working periods and climates: Modeling and experimentation. Appl. Therm. Eng. 2018, 145, 772–790. [Google Scholar] [CrossRef]

- Dhumane, R.; Qiao, Y.; Ling, J.; Muehlbauer, J.; Aute, V.; Hwang, Y. Reinhard Radermacher, Improving system performance of a personal conditioning system integrated with thermal storage. Appl. Therm. Eng. 2019, 147, 40–45. [Google Scholar] [CrossRef]

- Yang, Y.; Stapleton, J.; Diagne, B.; Kenny, G.; Lan, Q. Man-portable personal cooling garment based on vacuum desiccant cooling. Appl. Therm. Eng. 2012, 47, 18–24. [Google Scholar] [CrossRef]

- Gharbi, S.; Harmand, S.; Jabrallah, S. Experimental study of the cooling performance of phase change material with discrete heat sources-Continuous and intermittent regimes. Appl. Therm. Eng. 2017, 111, 103–111. [Google Scholar] [CrossRef]

- Bogerd, N.; Psikuta, A.; Daanen, H.A.M.; Rossi, R.M. How to measure thermal effects of personal cooling systems: Human, thermal manikin and human simulator study. Physiol. Meas. 2010, 31, 1161. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Gonzalez, J.A.; Berglund, L.G.; Kolka, M.A.; Endrusick, T.L. Forced ventilation of protective garments for hot industries. Therm. Manik. Model. 2006, 165–168. [Google Scholar]

- Li, L.N.; Qian, X.M.; Fan, J.T. Test and analysis of cooling performance of cooling garments. J. Tianjin Polytech. Univ. 2008, 27, 47–54. [Google Scholar]

- Psikuta, A.; Richards, M.; Fiala, D. Single-sector thermophysiological human simulator. Physiol. Meas. 2008, 29, 181. [Google Scholar] [CrossRef] [PubMed]

- Hou, J.; Yang, Z.; Xu, P.; Huang, G. Design and performance evaluation of novel personal cooling garment. Appl. Therm. Eng. 2019, 154, 131–139. [Google Scholar] [CrossRef]

- Ping, Z.X.G.; Jun, L.; Yingxin, Z. Experimental study on thermal comfort of medical phase change cooling garment. In Proceedings of the National Academic Conference on Heating, Ventilating, Air Conditioning and Refrigeration in 2004, Lanzhou, China, 11 August 2004; pp. 323–328. [Google Scholar]

- ISO. Ergonomics of The Thermal Environment―Analytical Determination and Interpretation of Heat Stress Using Calculation of the Predicted Heat Strain; Iso/Fdis 7933; ISO: Geneva, Switzerland, 2004; Volume 3, pp. 1–34. [Google Scholar]

- Chan, A.P.C.; Yang, Y.; Guo, Y.P.; Yam, M.C.H.; Song, W.F. Evaluating the physiological and perceptual responses of wearing a newly designed construction work uniform. Text. Res. J. 2016, 86, 659–673. [Google Scholar] [CrossRef]

- Yang, Y.; Chan, A.P.C. Perceptual strain index for heat strain assessment in an experimental study: An application to construction workers. J. Therm. Biol. 2015, 48, 21–27. [Google Scholar] [CrossRef] [PubMed]

- Moran, D.S.; Shitzer, A.; Pandolf, K.B. A physiological strain index to evaluate heat stress. Am. J. Physiol. 1998, 275, 129–134. [Google Scholar] [CrossRef]

- Moran, D.S.; Horowitz, M.; Meiri, U.; Laor, A.; Pandolf, K.B. The physiological strain index applied to heat-stressed rats. J. Appl. Physiol. 1999, 86, 895–901. [Google Scholar] [CrossRef]

- Moran, D.S.; Kenney, W.L.; Pierzga, J.M.; Pandolf, K.B. Aging and assessment of physiological strain during exercise-heat stress. Am. J. Physiol. Regul. Integr. Comp. Physiol. 2002, 282, R1063–R1069. [Google Scholar] [CrossRef]

- Lokeshbabu, D.S.; Jeyakumar, S.; Jitendra, P.; Sathiyabarathi, M.; Manimaran, A.; Kumaresan, A.; Kataktalware, M.A. Monitoring foot surface temperature using infrared thermal imaging for assessment of hoof health status in cattle: A review. J. Therm. Biol. 2018, 78, 10–21. [Google Scholar]

- Gloster, J.; Ebert, K.; Gubbins, S.; Bashiruddin, J.; Paton, D.J. Normal variation in thermal radiated temperature in cattle: Implications for foot-and-mouth disease detection. BMC Vet. Res. 2011, 7, 73. [Google Scholar] [CrossRef] [PubMed]

- Shimazaki, Y.; Yoshida, A.; Suzuki, R.; Kawabata, T.; Imai, D.; Kinoshita, S. Application of human thermal load into unsteady condition for improvement of outdoor thermal comfort. Build. Environ. 2011, 46, 1716–1724. [Google Scholar] [CrossRef]

- Gao, S.; Li, Y.; Wang, Y.A.; Meng, X.Z.; Zhang, L.Y.; Yang, C.; Jin, L.W. A human thermal balance based evaluation of thermal comfort subject to radiant cooling system and sedentary status. Appl. Therm. Eng. 2017, 122, 461–472. [Google Scholar] [CrossRef]

- ASHRAE. ASHRAE Handbook-Fundamentals; ASHRAE: Atlanta, GA, USA, 2009; pp. 21.1–21.67. [Google Scholar]

- Rappaport, S.M.; Goldberg, M.; Susi, P.; Herrick, R.F. Excessive exposure to silica in the US construction industry. Ann. Occup. Hyg. 2003, 47, 111–122. [Google Scholar]

- ASHRAE. Standard 55: Thermal Environmental Conditions for Human Occupancy; ASHRAE: Atlanta, GA, USA, 2004. [Google Scholar]

- Ramanathan, N.L. A new weighting system for mean surface temperature of the human body. J. Appl. Physiol. 1964, 19, 531–533. [Google Scholar] [CrossRef]

- Taniguchi, Y.; Aoki, H.; Fujikake, K.; Tanaka, H.; Kitada, M. Study on car air conditioning system controlled by car occupants’ skin temperatures-part 1: Research on a method of quantitative evaluation of car occupants’ thermal sensations by skin temperatures. Sae Tech. Pap. 1992. [Google Scholar] [CrossRef]

- Tanaka, H.; Kitada, M.; Taniguchi, Y.; Ohno, Y.; Shinagawa, T.; Aoki, H. Study on car air conditioning system controlled by car occupants’ skin temperatures-part 2: Development of a new air conditioning system. SAE Tech. Pap. 1992. [Google Scholar] [CrossRef]

- Wang, X. Thermal comfort and sensation under transient conditions. Ph.D. Thesis, Department of Energy Technology, Division of Heating and Ventilation, The Royal Institute of Technology, Stockholm, Sweden, 1994. [Google Scholar]

| Scale | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| TS | Cold | Cool | Slightly cool | Neutral | Slightlywarm | Warm | Hot |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, X.; Yao, T.; Zhang, Y.; Zhao, Y.; Hu, Q.; Chan, A.P.C. Experimental Study on the Efficacy of a Novel Personal Cooling Vest Incorporated with Phase Change Materials and Fans. Materials 2020, 13, 1801. https://doi.org/10.3390/ma13081801

Ni X, Yao T, Zhang Y, Zhao Y, Hu Q, Chan APC. Experimental Study on the Efficacy of a Novel Personal Cooling Vest Incorporated with Phase Change Materials and Fans. Materials. 2020; 13(8):1801. https://doi.org/10.3390/ma13081801

Chicago/Turabian StyleNi, Xiaoyang, Tianyu Yao, Ying Zhang, Yijie Zhao, Qin Hu, and Albert P.C. Chan. 2020. "Experimental Study on the Efficacy of a Novel Personal Cooling Vest Incorporated with Phase Change Materials and Fans" Materials 13, no. 8: 1801. https://doi.org/10.3390/ma13081801

APA StyleNi, X., Yao, T., Zhang, Y., Zhao, Y., Hu, Q., & Chan, A. P. C. (2020). Experimental Study on the Efficacy of a Novel Personal Cooling Vest Incorporated with Phase Change Materials and Fans. Materials, 13(8), 1801. https://doi.org/10.3390/ma13081801