Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement

Abstract

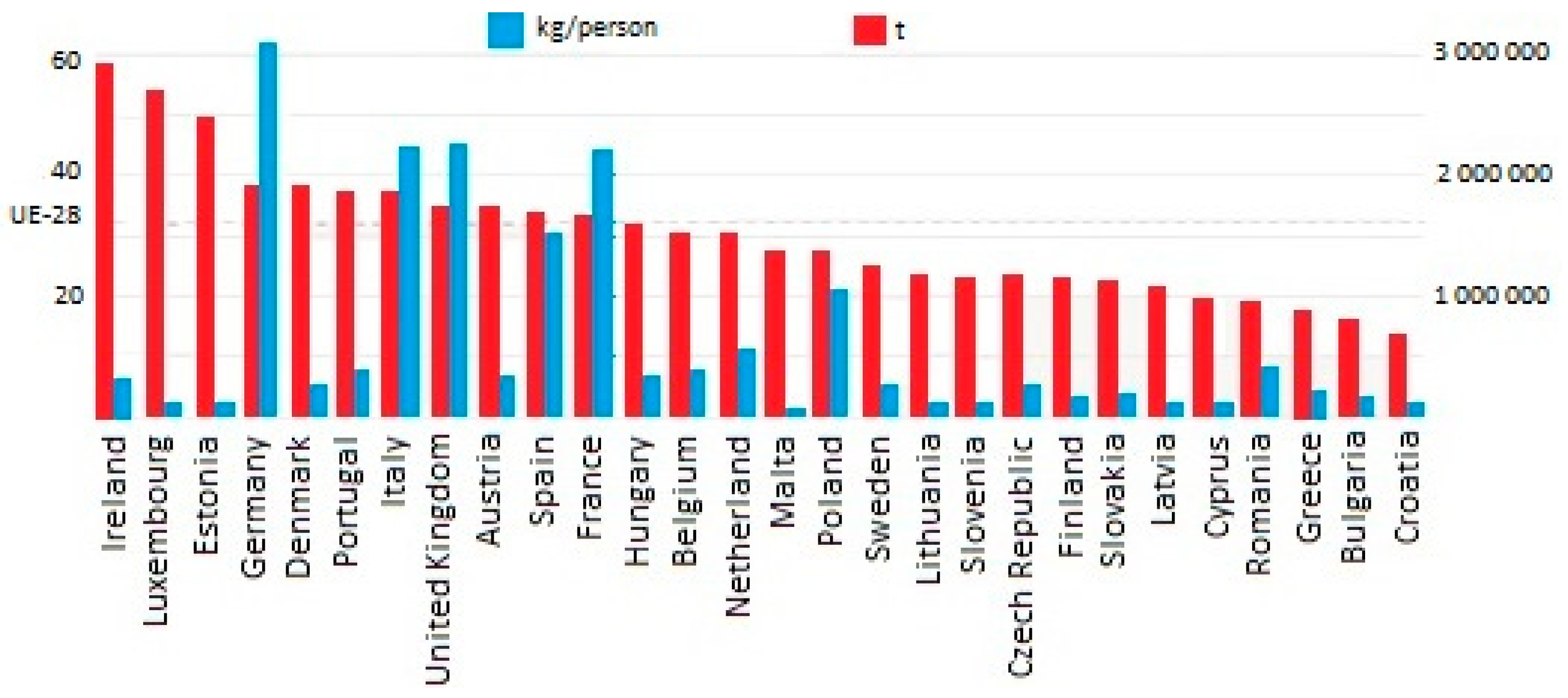

:1. Introduction

2. Materials

2.1. Specimen Preparation

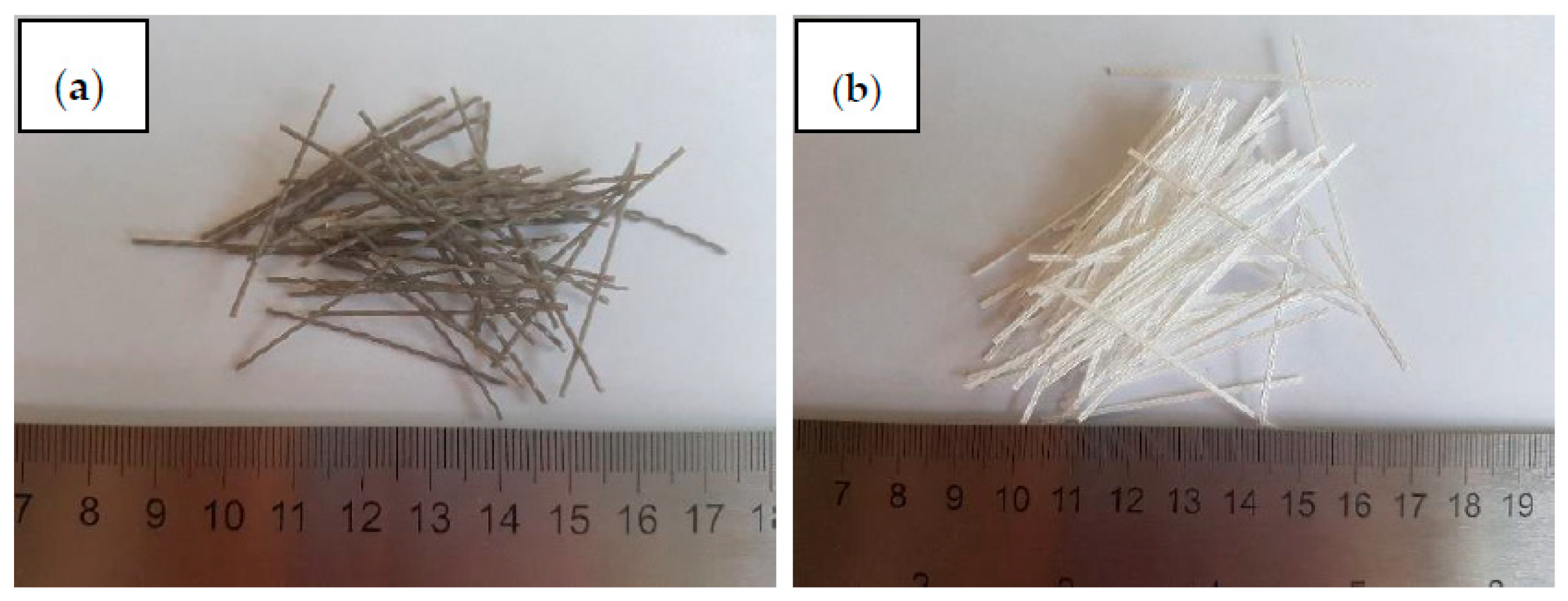

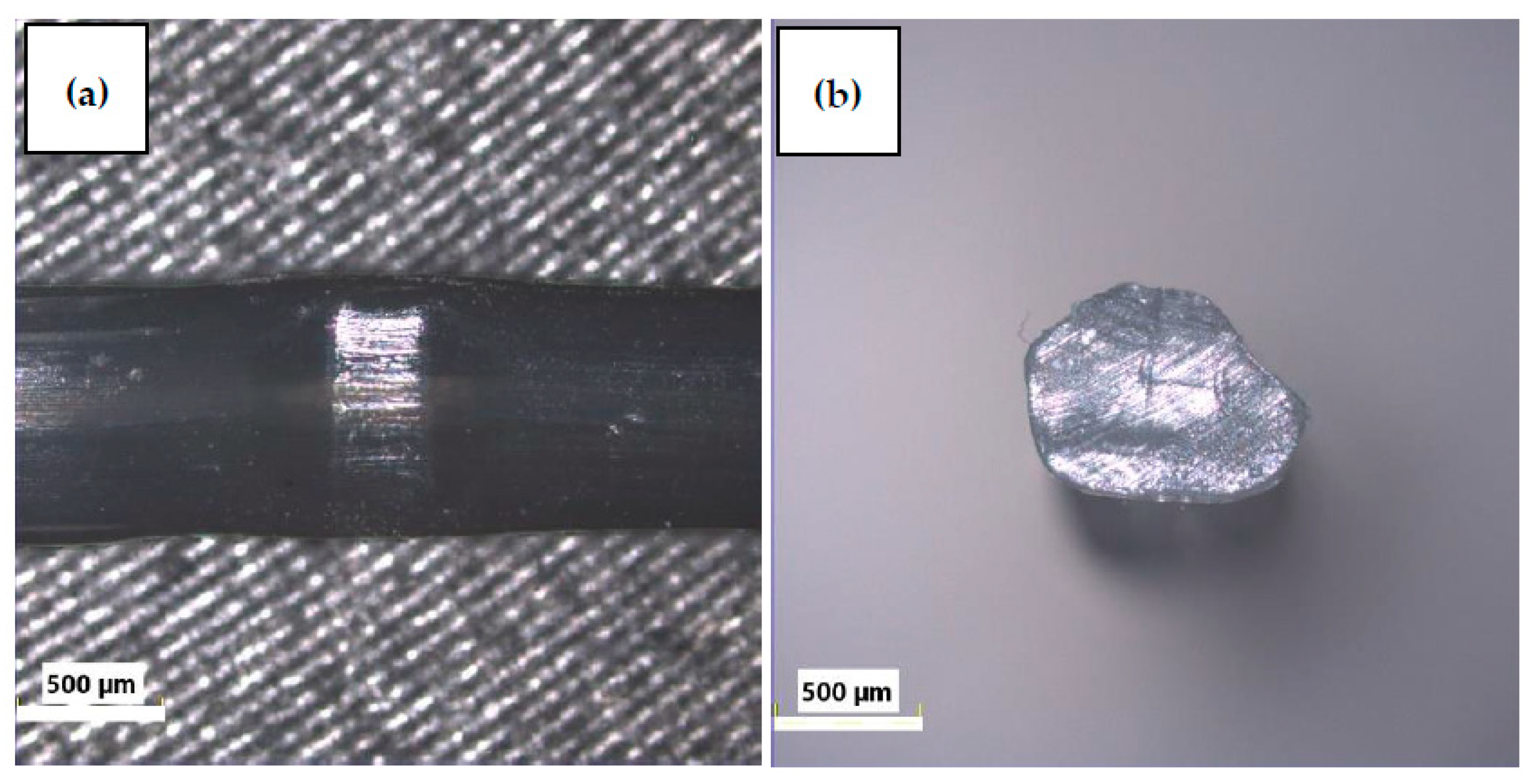

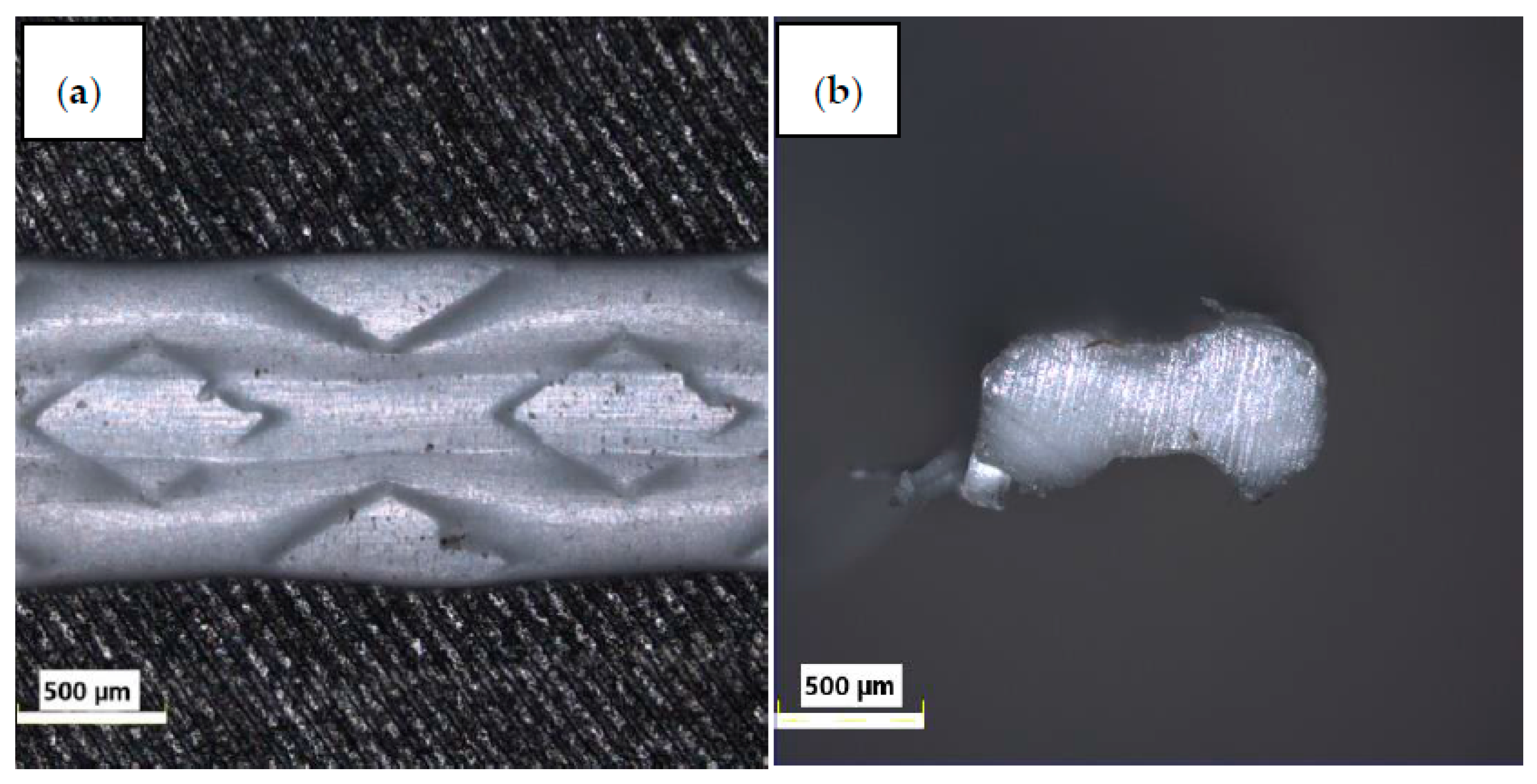

2.2. Polypropylene Fibers

2.3. Mix Composition

2.4. Mix Production

3. Methodology

3.1. Test on Mix

3.2. Test on Hardened Concrete

4. Results and Discussion

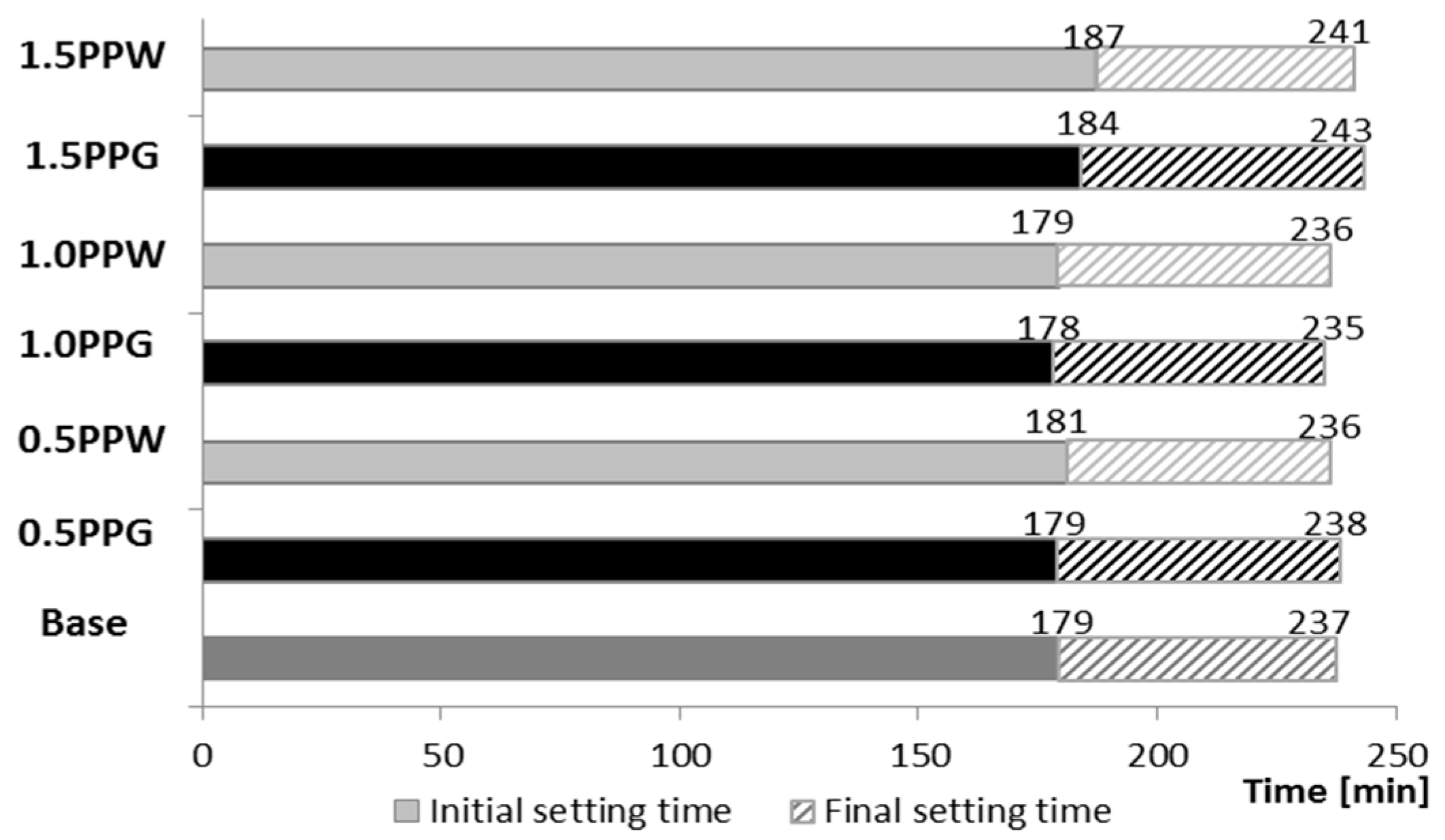

4.1. The Initial and Final Setting Time

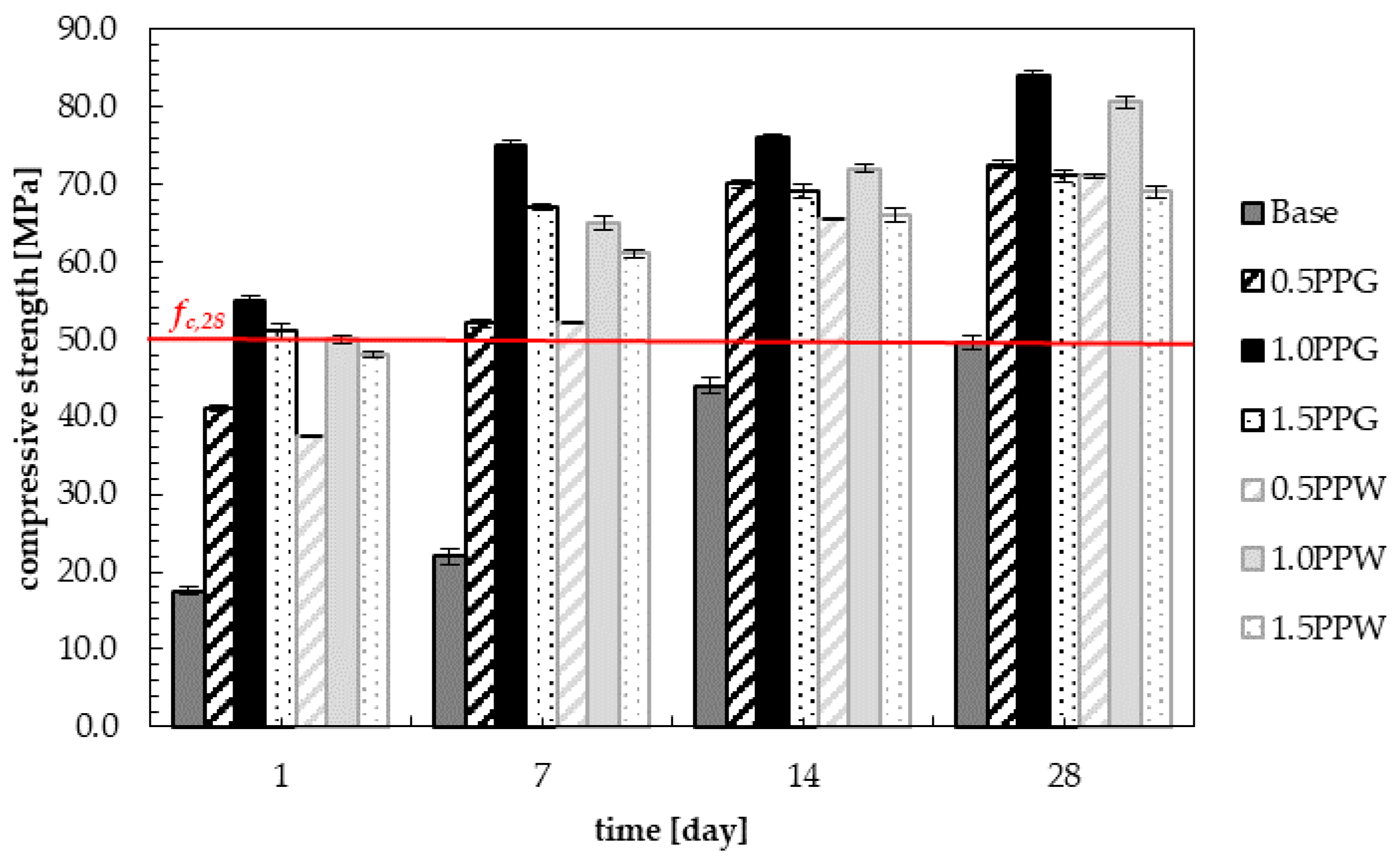

4.2. Compressive Strength

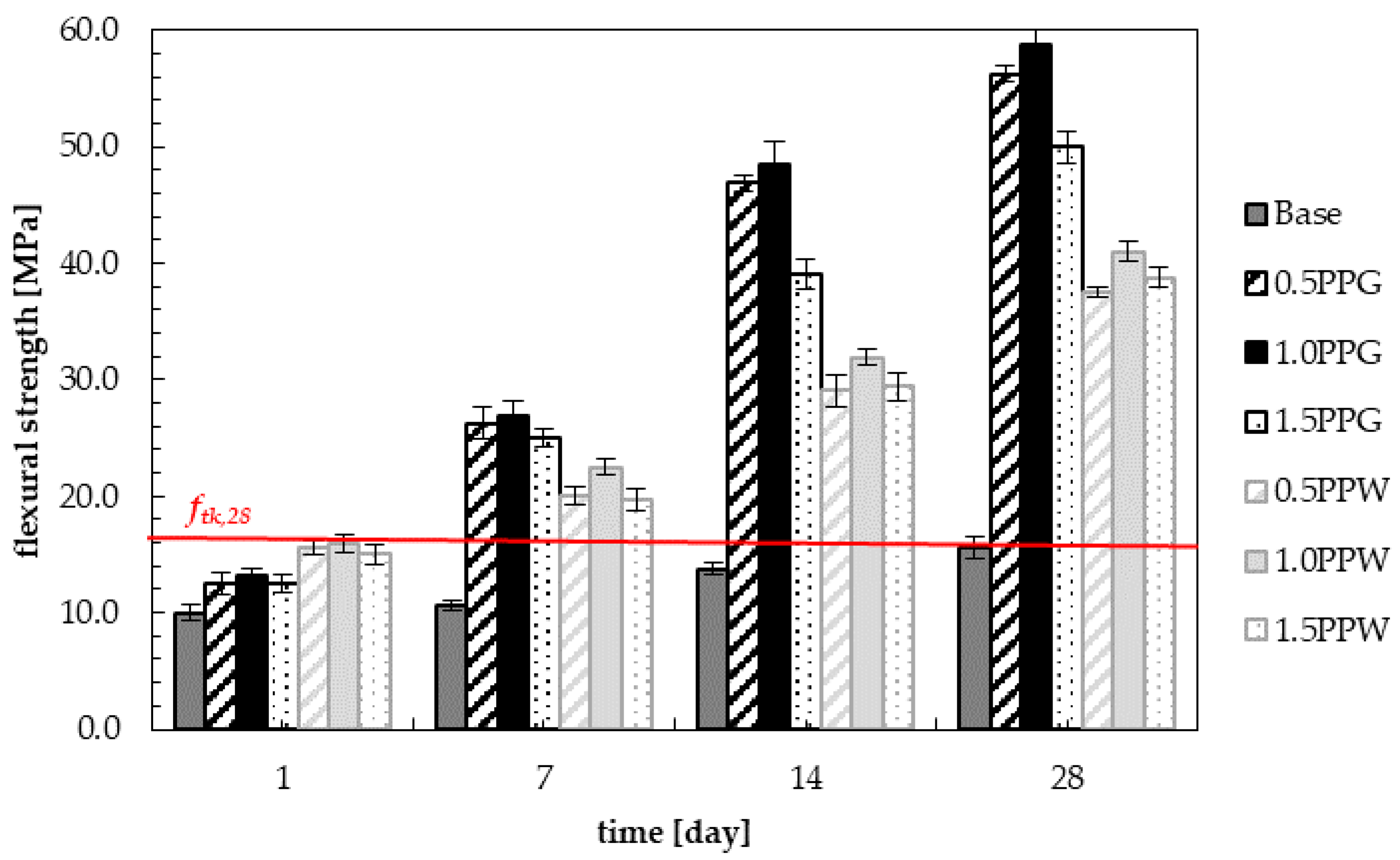

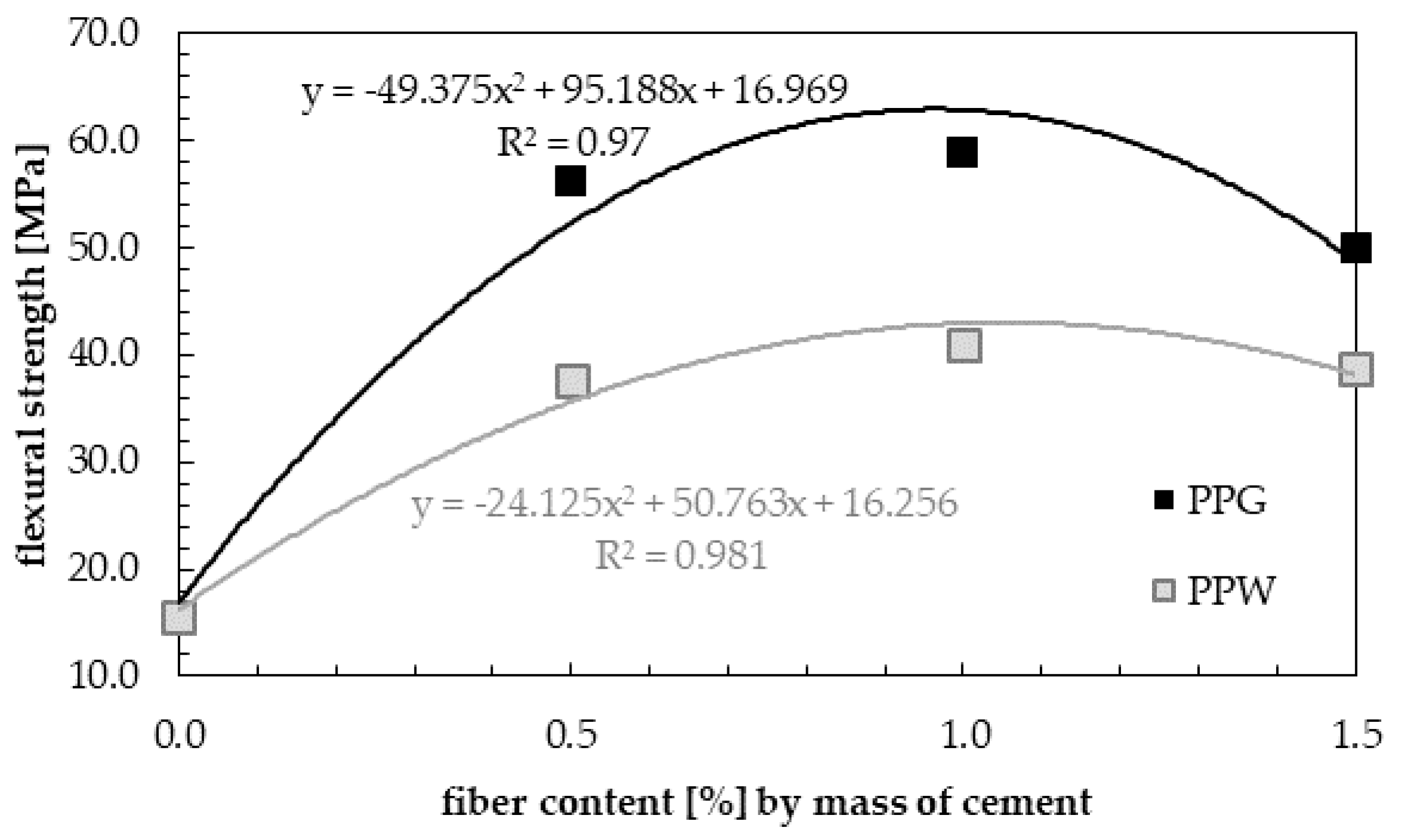

4.3. Flexural Strength

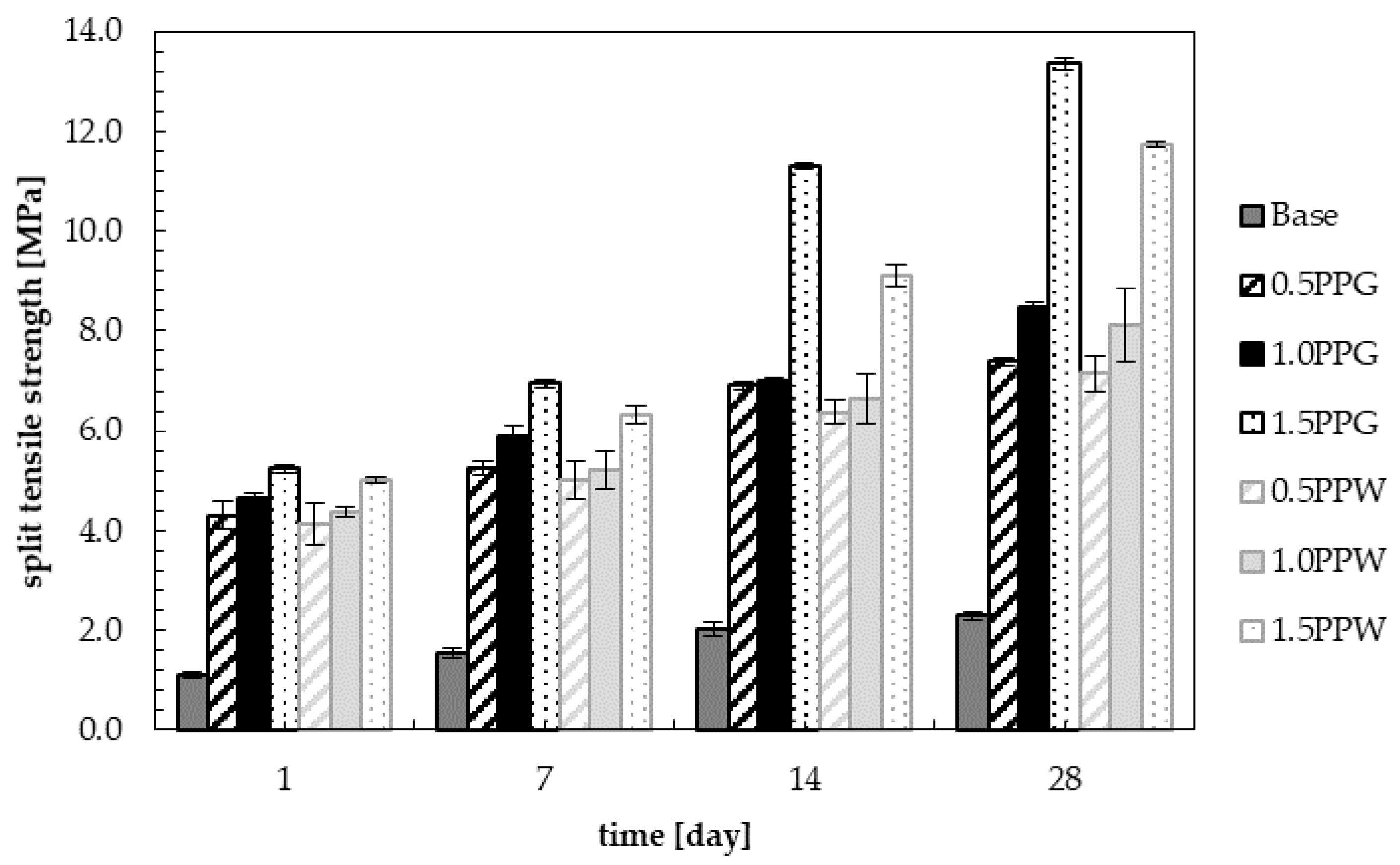

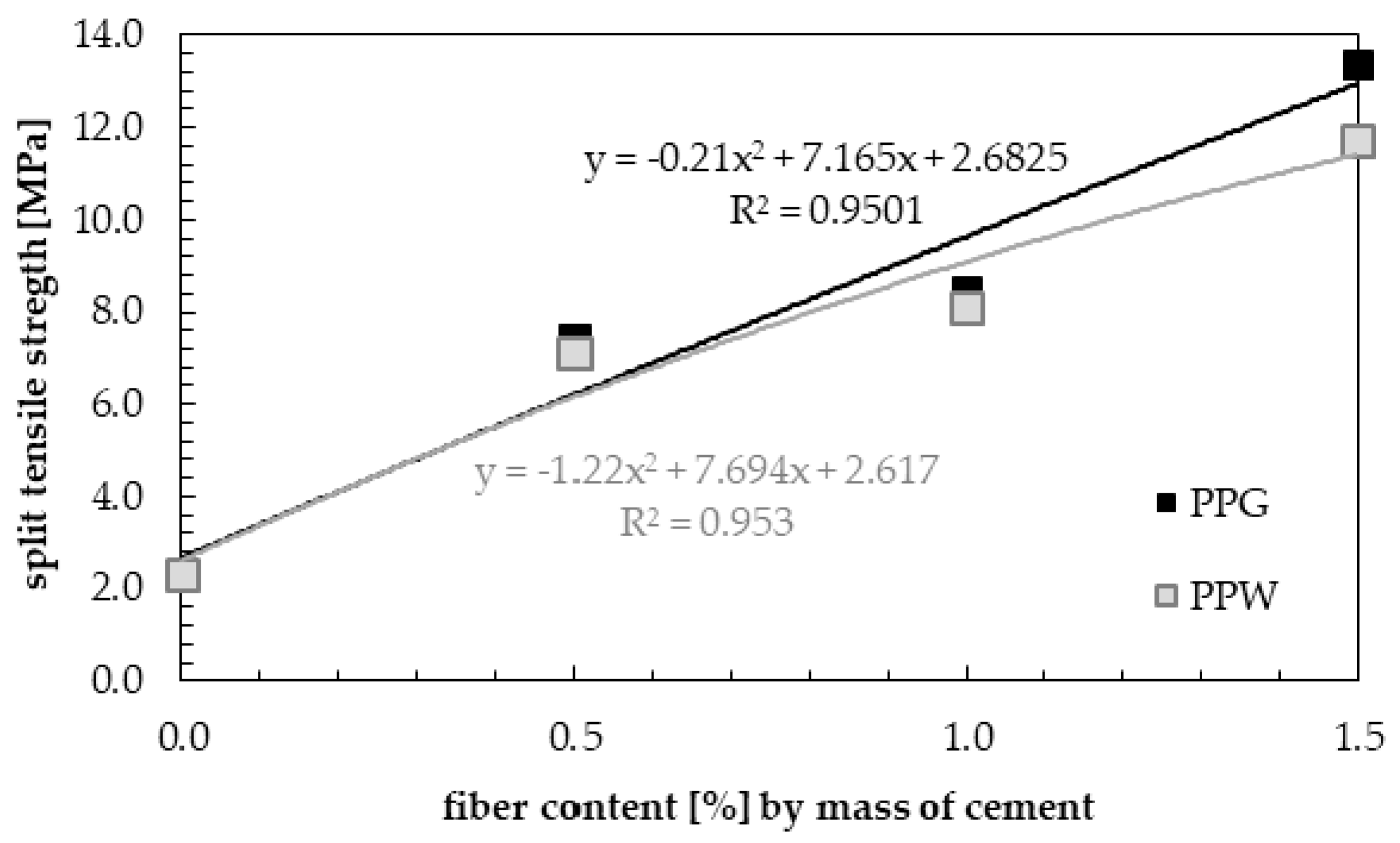

4.4. Split Tensile Strength

5. Conclusions

- (1)

- The decrease in the slump flow with addition of PP fibers was observed, but all mixes were within slump flow class SF1;

- (2)

- The obtained 28 days compressive strengths of reinforced concrete were from 69.0 to 84.0 MPa for different content of fibers, what meet the requirements for high-strength concrete;

- (3)

- The increase in mechanical properties as an effect of the addition of recycled polypropylene fibers compared to unreinforced concrete is unexpected and unparalleled (69.7% and 39.4% increase in compressive strength, 276.0% and 162.4% increase in flexural strength and 269.4% and 254.2% increase in split tensile strength were obtained for PPG and PPW respectively);

- (4)

- The highest values of mechanical properties were obtained for concrete with 1.0 wt.% of polypropylene fibers for each type of fiber;

- (5)

- The higher values for all tested properties were determined for PPG fibers;

- (6)

- The nature of the recycled fiber-reinforced concrete curing process is faster than for the reference concrete (without fibers);

- (7)

- For all fiber-reinforced concrete samples the required compressive strength was achieved earlier than for normal concrete (between 1 and 7 days) which allows it to be used in places where high strength is required fast.

Author Contributions

Funding

Conflicts of Interest

References

- Brusselse Association of Plastics Manufacturers. Plastics-the Facts; Plastics Europe: Brussels, Belgium, 2017; Available online: https://www.plasticseurope.org/download_file/force/1055/181 (accessed on 20 February 2020).

- Gu, L.; Ozbakkaloglu, T. Use of recycled plastics in concrete: A critical review. Waste Manag. 2016, 51, 19–42. [Google Scholar] [CrossRef]

- Nikbin, I.M.; Rahimi, S.; Allahyari, H.; Fallah, F. Feasibility study of waste Poly Ethylene Terephthalate (PET) particles as aggregate replacement for acid erosion of sustainable structural normal and lightweight concrete. J. Clean. Prod. 2016, 126, 108–117. [Google Scholar] [CrossRef]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.H.J.; Song, Y.C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Wei, R.; Zimmermann, W. Biocatalysis as a green route for recycling the recalcitrant plastic polyethylene terephthalate. Microbiol. Biotechnol. 2017, 10, 1302–1307. [Google Scholar] [CrossRef]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef]

- Akꞔaözoğlu, S. Evaluation of waste plastics as recycled plastic composite materials. Edorium J. Waste Manag. 2015, 1, 16–19. [Google Scholar] [CrossRef]

- Huysman, S.; De Schaepmeester, J.; Ragaert, K.; Dewulf, J.; De Meester, S. Performance indicators for a circular economy: A case study on post-industrial plastic waste. Resour. Conserv. Recycl. 2017, 120, 46–54. [Google Scholar] [CrossRef]

- Wahab, D.A.; Abidin, A.; Azhari, C.H. Recycling trends in the plastics manufacturing and recycling companies in Malaysia. J. Appl. Sci. 2007, 7, 1030–1035. [Google Scholar] [CrossRef]

- Haward, M. Plastic pollution of the world’s seas and oceans as a contemporary challenge in ocean governance. Nat. Commun. 2018, 9, 1–3. [Google Scholar] [CrossRef] [Green Version]

- Daana, K.K.L.; Gårdfeldt, K.; Lyashevska, O.; Hassellöv, M.; Thompson, R.C.; O’Connor, I. Microplastics in sub-surface waters of the Arctic Central Basin. Mar. Pollut. Bull. 2018, 130, 8–18. [Google Scholar] [CrossRef]

- European Parliament. Plastic Waste and Recycling in the Europe: Facts and Figures. Available online: https://www.europarl.europa.eu/news/pl/headlines/society/20181212STO21610/odpady z tworzyw sztucznych i recykling w ue fakty i liczby (accessed on 20 February 2020).

- Gayer, A.; Adamkiewicz, Ł.; Mucha, D.; Badyda, A. Air quality health indices-review. In Proceedings of the MATEC Web of Conferences, FESE 2018, Lviv, Ukraine, 7–8 November 2018; pp. 1–8. [Google Scholar] [CrossRef] [Green Version]

- Mohammadhosseini, H.; Tahir, M.M. Durability performance of concrete incorporating waste metalized plastic fibres and palm oil fuel ash. Constr. Build. Mater. 2008, 180, 92–102. [Google Scholar] [CrossRef]

- COM(2018)35 Final. Report of the European Parliament and Counsel; European Parliament: Belgium, Brussels, 2018; Available online: https://ec.europa.eu/transparency/regdoc/rep/1/2018/PL/COM-2018-35-F1-PL-MAIN-PART-1.PDF (accessed on 20 February 2020).

- Watts, N.; Amann, M.; Arnell, N.; Ayeb-Karlsson, S.; Belesova, K.; Boykoff, M.; Byass, P.; Cai, W.; Campbell-Lendrum, D.; Capstick, S.; et al. The 2019 report of The Lancet Countdown on health and climate change: Ensuring that the health of a child born today is not defined by a changing climate. Lancet 2019, 394, 1836–1878. [Google Scholar] [CrossRef] [Green Version]

- Cooper, D.R.; Gutowski, T.G. The environmental impacts of reuse: A review. J. Ind. Ecol. 2017, 21, 38–56. [Google Scholar] [CrossRef]

- Lavers, J.L.; Dicks, L.; Dicks, M.R.; Finger, A. Significant plastic accumulation on the Cocos (Keeling) Islands, Australia. Sci. Rep. 2019, 9, 1–9. [Google Scholar] [CrossRef]

- COM 614. Closing the Loop-An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- European Parliament. Plastic Waste and Recycling in the Europe: Production of plastic waste on the world, 2019. Available online: https://www.europarl.europa.eu/resources/library/images/20190108PHT22905/20190108PHT22905_original.jpg (accessed on 20 February 2020).

- Kozłowski, M.; Kadela, M. Mechanical Characterization of Lightweight Foamed Concrete. Adv. Mater. Sci. Eng. 2018, 2018, 6801258. [Google Scholar] [CrossRef] [Green Version]

- Kadela, M.; Kukiełka, A. Influence of foaming agent content in fresh concrete on elasticity modulus of hard foam concrete. In Proceedings of the Brittle Matrix Composites 11—Proceedings of the 11th International Symposium on Brittle Matrix Composites BMC 2015, Warsaw, Poland, 12–14 October 2015; pp. 489–496. [Google Scholar]

- Kadela, M.; Kozłowski, M.; Kukiełka, A. Application of foamed concrete in road pavement–weak soil system. In Proceedings of the Procedia Engineering, International Conference on Analytical Models and New Concepts in Concrete and Masonry Structures AMCM’2017, Gliwice, Poland, 5–7 June 2017; pp. 439–446. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Khatib, J.; Colangelo, F.; Tuladhar, R. Use of Recycled Plastics in Eco-Efficient Concrete; Elsevier: Asterdam, The Netherlands, 2019. [Google Scholar]

- Zalegowski, K.; Piotrowski, T.; Garbacz, A. Influence of polymer modification on the microstructure of shielding concrete. Materials 2020, 13, 498. [Google Scholar] [CrossRef] [Green Version]

- Czarnecki, L. Book review: Would recycled plastics be a driving force in concrete technology? J. Zhejiang Univ. Sci. A 2019, 20, 384–388. [Google Scholar] [CrossRef]

- Balaguru, P.N.; Shah, S.P. Fiber Reinforced Cement Composite; MSGraw-Hill: New York, NY, USA, 1992. [Google Scholar]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites; Taylor&Francis Group: Oxfordshire, UK, 2006. [Google Scholar]

- Brandt, A.M. Cement Based Composites: Materials, Mechanical Properties and Performance; Taylor&Francis Group: Oxfordshire, UK, 2009. [Google Scholar]

- Kozlowski, M.; Kadela, M. Experimental and Numerical Investigation of Fracture Behavior of Foamed Concrete Based on Three-Point Bending Test of Beams with Initial Notch. In Proceedings of the ICMCME 2015: International Conference on Mechanical, Civil and Material Engineering, Barcelona, Spain, 21–23 May 2015; p. 943. [Google Scholar] [CrossRef] [Green Version]

- Kozłowski, M.; Kadela, M.; Kukiełka, A. Fracture energy of foamed concrete based on three-point bending test on notched beams. In Proceedings of the Procedia Engineering, 7th Scientific-Technical Conference Material Problems in Civil Engineering (MATBUD’2015), Cracow, Poland, 22–24 June 2015; pp. 349–354. [Google Scholar] [CrossRef] [Green Version]

- Zollo, R.F. Fiber-reinforced concrete: An overview after 30 years of development. Cem. Concr. Compos. 1997, 19, 107–122. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Mandegari, M.; Sanginabadi, K.; Mostofinejad, D.; Abtahi, S.M. The effect of concrete alkalinity on behavior of reinforcing polyester and polypropylene fibers with similar properties. Cem. Concr. Compos. 2019, 97, 118–124. [Google Scholar] [CrossRef]

- Li, J.; Niu, J.; Wan, C.H.; Liu, X.; Jin, Z. Comparison of flexural property between high performance polypropylene fiber reinforced lightweight aggregate concrete and steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 157, 729–736. [Google Scholar] [CrossRef]

- Szeląg, M. Evaluation of cracking patterns of cement paste containing polypropylene fibers. Compos. Struct. 2019, 220, 402–411. [Google Scholar] [CrossRef]

- Shafiulla, S.; Begum, S.S. Mechanical behavior of industrial waste admixed with polypropylene fiber in concrete. Int. J. Sci. Res. Sci. Technol. 2017, 3, 545–564. [Google Scholar]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Serrano, R.; Cobo, A.; Prieto, M.I.; Nieves González, M. Analysis of fire resistance of concrete with polypropylene or steel fibers. Constr. Build. Mater. 2016, 122, 302–309. [Google Scholar] [CrossRef] [Green Version]

- Badogiannis, E.G.; Christidis, Κ.I.; Tzanetatos, G.E. Evaluation of the mechanical behavior of pumice lightweight concrete reinforced with steel and polypropylene fibers. Constr. Build. Mater. 2019, 196, 443–456. [Google Scholar] [CrossRef]

- Li, Y.; Pimienta, P.; Pinoteau, N.; Tan, K.H. Effect of aggregate size and inclusion of polypropylene and steel fibers on explosive spalling and pore pressure in ultra-high-performance concrete (UHPC) at elevated temperature. Cem. Concr. Compos. 2019, 99, 62–71. [Google Scholar] [CrossRef]

- Li, Y.; Tan, K.H.; Yang, E. -H. Synergistic effects of hybrid polypropylene and steel fibers on explosive spalling prevention of ultra-high performance concrete at elevated temperature. Cem. Concr. Compos. 2019, 96, 174–181. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shanks, R.A.; Collister, T.; Combe, M.; Jacob, M.; Tian, M.; Sivakugan, N. Fiber preparation and mechanical properties of recycled polypropylene for reinforcing concrete. J. Appl. Polym. Sci. 2015, 132, 1–10. [Google Scholar] [CrossRef]

- Eidan, J.; Rasoolan, I.; Rezaeian, A.; Poorveis, D. Residual mechanical properties of polypropylene fiber-reinforced concrete after heating. Constr. Build. Mater. 2019, 198, 195–206. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, X.; Chai, J.; Xu, Z.; Li, S. Experimental study of compressive behavior of polypropylene-fiber reinforced and polypropylene-fiber-fabric-reinforced concrete. Constr. Build. Mater. 2019, 194, 216–225. [Google Scholar] [CrossRef]

- Akand, L.; Yang, M.; Wang, X. Effectiveness of chemical treatment on polypropylene fibers as reinforcement in pervious concrete. Constr. Build. Mater. 2018, 163, 32–39. [Google Scholar] [CrossRef]

- Fu, Q.; Niu, D.; Zhang, J.; Huang, D.; Wang, Y.; Hong, M.; Zhang, L. Dynamic compressive mechanical behaviour and modelling of basalt-polypropylene fibre-reinforced concrete. Arch. Civ. Mech. Eng. 2018, 18, 914–927. [Google Scholar] [CrossRef]

- Matar, P.; Assaad, J.J. Concurrent effects of recycled aggregates and polypropylene fibers on workability and key strength properties of self-consolidating concrete. Constr. Build. Mater. 2019, 199, 492–500. [Google Scholar] [CrossRef]

- Singh, V.K. Effect of polypropylene fiber on properties of concrete. Int. J. Eng. Sci. Res. Technol. 2014, 3, 312–317. [Google Scholar]

- Alsadey, S.; Salem, M. Influence of polypropylene fiber on strength of concrete. Am. J. Eng. Res. 2016, 5, 223–226. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Falliano, D.; Domenico, D.D.; Ricciardi, G.; Gugliandolo, E. Compressive and flexural strength of fiber-reinforced foamed concrete: Effect of fiber content, curing conditions and dry density. Constr. Build. Mater. 2019, 198, 479–493. [Google Scholar] [CrossRef]

- Górażdże Group: Cement, Concrete, Aggregate. Technical Data Sheet CEM I 42.5 R. Available online: http://www.gorazdze.pl (accessed on 20 February 2020).

- Das Ch, S.; Dey, T.; Dandapat, R.; Mukharjee, B.B.; Kumar, J. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Małek, M.; Życiński, W.; Jackowski, M.; Wachowski, M. Effect of polypropylene fiber addition on mechanical properties of concrete based on portland cement. Tech Sci. 2018, 21, 207–214. [Google Scholar] [CrossRef]

- Fadhil, S.; Yaseen, M. The production of economical precast concrete panels reinforced by waste plastics fibers. Am. J. Civ. Eng. Arch. 2015, 3, 80–85. [Google Scholar]

- Bhogayata, A.C.; Shah, K.D.; Vyas, B.A.; Arora, N.K. Performance of concrete by using non recyclable plastic wastes as concrete constituent. Mater. Sci. 2012, 1, 1–3. [Google Scholar]

- Bayasi, Z.; Zeng, J. Properties of polypropylene fiber reinforced concrete. ACI Mater. J. 1993, 90, 605–610. [Google Scholar]

- Neville, A.M. Właściwości Betonu [Concrete Properties]; Polski Cement: Cracov, Poland, 2000. [Google Scholar]

- Caldarone, M.A. High-Strength Concrete. A Practical Guide; Taylon&Francis Group: London, UK; New York, NY, USA, 2009. [Google Scholar]

- Meran, C.; Ozturk, O.; Yuksel, M. Examination of the possibility of recycling and utilizing recycled polyethylene and polypropylene. Mater. Des. 2008, 29, 701–705. [Google Scholar] [CrossRef]

- Naaman, A.E. Fiber Reinforced Cement and Concrete Composites; Techno Press 3000: Ann Arbor, MI, USA, 2018. [Google Scholar]

- Chawla, K.K. Fibrous Materials; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Hannant, D.J. Chapter 6—Fibre-reinforced concrete. In Advanced Concrete Technology; Elsevier: Asterdam, The Netherlands, 2003. [Google Scholar]

- Afroughsabet, V.; Biolzi, L.; Ozbakkaloglu, T. High-performance fiber-reinforced concrete: A review. J. Mater. Sci. 2016, 51, 6517–6551. [Google Scholar] [CrossRef] [Green Version]

- Giurgiutiu, V. Chapter 5—Damage and Failure of Aerospace Composites. In Structural Health Monitoring of Aerospace Composites; Elsevier: Amsterdam, The Netherlands, 2016; pp. 125–175. [Google Scholar] [CrossRef]

- Kalifa, P.; Chene, G.; Galle, C. High-temperature behavior of HPC with polypropylene fibres. From spalling to microstructure. Cem. Concr. Res. 2001, 31, 1487–1499. [Google Scholar] [CrossRef]

- Kosmatka, S.; Kerkhoff, B.; Panarese, W. Design and Control of Concrete Mixtures; PCA: Warsaw, Poland, 2009. [Google Scholar]

- Naaman, A.E.; Reinhart, H.W. High Performance Fiber Reinforced Cement Composites 2; Taylor&Francis Group: Oxford, UK, 1996. [Google Scholar]

- Albano, C.; Camacho, N.; Hernandez, M.; Matheus, A.; Gutierrez, A. Influence of content and particle size of waste PET bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

- Dharan, D.S.; Lal, A. Study the effect of polypropylene fiber in concrete. Int. Res. J. Eng. Technol. 2016, 3, 616–619. [Google Scholar]

- Köksal, F.; Altun, F.; Yiğit, I.; Șahin, Y. Combined effect of silics fuma and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Raghatate, A.M. Use of plastic in a concrete to improve its properties. Int. J. Adv. Eng. Res. Technol. 2012, 1, 109–111. [Google Scholar]

- Najimi, M.; Farahani, F.M.; Pourkhorshidi, A.R. Effects of polypropylene fibers on physical and mechanical properties of concretes. In Proceedings of the 3rd International Conference on Concrete&Development, CD03-009, Tehran, Iran, 27–29 April 2009; pp. 1073–1081. Available online: https://www.irbnet.de/daten/iconda/CIB13842.pdf (accessed on 20 February 2020).

- Mohhammadi, Y.; Singh, S.P.; Kaushik, S.K. Properties of steel fibrous concrete containing mixed fibres in fresh and hardened state. Constr. Build. Mater. 2008, 22, 956–965. [Google Scholar] [CrossRef]

- Blunt, J.D.; Ostertag, C.P. Deflection hardening and workability of hybrid fiber composites. ACI Mater. J. 2009, 106, 265–272. [Google Scholar]

- Castoldi, R.S.; Souza, L.M.S.; Andrade Silva, F. Comparative study on the mechanical behavior and durability of polypropylene and sisal fiber reinforced concretes. Constr. Build. Mater. 2019, 211, 617–628. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. An experimental investigation on the integral waterproofing capacity of polypropylene fiber concrete with fly ash and slag powder. Constr. Build. Mater. 2019, 212, 675–686. [Google Scholar] [CrossRef]

- Kandasamy, R.; Murugesan, R. Fibre reinforced concrete using domestic waste plastics as fibres. ARPN J. Eng. Appl. Sci. 2011, 6, 75–82. [Google Scholar]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Akoi, A.O.M.; Mermerdaş, K. Combined effect of steel fiber and metakaolin incorporation on mechanical properties of concrete. Compos. Build. Eng. 2014, 56, 83–91. [Google Scholar] [CrossRef]

- Yazɪcɪ, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Sivakumar, A.; Santhanam, M. Mechanical properties of high strength concrete reinforced with metallic ans nonmetallic fibres. Cem. Concr. Compos. 2007, 29, 603–608. [Google Scholar] [CrossRef]

- Altun, F.; Haktanir, T.; Ari, K. Effects of steel fiber addition on mechanical properties of concrete ans RC beams. Constr. Build. Mater. 2007, 21, 654–661. [Google Scholar] [CrossRef]

- Gül, R.; Okuyucu, E.; Türkmen, İ.; Aydin, A.C. Thermomechanical properties of fiber reinforced raw perlite concrete. Mater. Lett. 2007, 61, 5145–5149. [Google Scholar] [CrossRef]

- Gao, J.; Sun, W.; Morino, K. Mechanical properties of steel fiber-reinforced, high-strength, lightweight concrete. Cem. Concr. Compos. 1997, 19, 307–313. [Google Scholar] [CrossRef]

- Yao, W.; Li, J.; Wu, K. Mechanical properties of hybrid fiber-reinforced concrete at low fiber volume fraction. Cem. Concr. Res. 2003, 33, 27–30. [Google Scholar] [CrossRef]

- Song, P.S.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Constr. Build. Mater. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, L.C. Experimental study on static and dynamic mechanical properties of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2013, 38, 1146–1151. [Google Scholar] [CrossRef]

- Eren, Ö.; Çelik, T. Effect of silica fume and steel fibers on some properties of high-strength concrete. Constr. Build. Mater. 1997, 11, 373–382. [Google Scholar] [CrossRef]

- Wafa, F.F.; Ashour, S.A. Mechanical properties of high-strength fiber reinforced concrete. ACI Mater. J. 1992, 89, 449–455. [Google Scholar]

| Compositions | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2O | K2O | Cl |

| Unit(vol.%) | 19.5 | 4.9 | 2.9 | 63.3 | 1.3 | 2.8 | 0.1 | 0.9 | 0.05 |

| Specific Surface Area [m2/kg] | Specific Gravity [kg/m3] | Compressive Strength after Days [MPa] | |

|---|---|---|---|

| 2 days | 28 days | ||

| 3840 | 3060 | 28.0 | 58.0 |

| Compositions | O | Na | S | K |

| Unit(vol.%) | 77.7 | 14.9 | 4.8 | 2.6 |

| Type of Fiber | Average Thickness [μm] | Average Circumference [μm] | Length [mm] |

|---|---|---|---|

| PPG | 904.9 ± 10.0 | 472.2 ± 0.5 | 29.7–33.2 |

| PPW | 1152.5 ± 10.0 | 538.2 ± 0.5 | 27.1–32.6 |

| Mix Symbol | Cement [kg] | Water [kg] | Type of Fiber | Fiber Content [wt.%] | Fiber [kg] |

|---|---|---|---|---|---|

| Base mix | 550 | 165 | – | 0.0 | 0.0 |

| PPG-0.5 | PPG | 0.5 | 2.75 | ||

| PPG-1.0 | 1.0 | 5.50 | |||

| PPG-1.5 | 1.5 | 8.25 | |||

| PPW-0.5 | PPW | 0.5 | 2.75 | ||

| PPW-1.0 | 1.0 | 5.50 | |||

| PPW-1.5 | 1.5 | 8.25 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Małek, M.; Jackowski, M.; Łasica, W.; Kadela, M. Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Materials 2020, 13, 1827. https://doi.org/10.3390/ma13081827

Małek M, Jackowski M, Łasica W, Kadela M. Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Materials. 2020; 13(8):1827. https://doi.org/10.3390/ma13081827

Chicago/Turabian StyleMałek, Marcin, Mateusz Jackowski, Waldemar Łasica, and Marta Kadela. 2020. "Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement" Materials 13, no. 8: 1827. https://doi.org/10.3390/ma13081827

APA StyleMałek, M., Jackowski, M., Łasica, W., & Kadela, M. (2020). Characteristics of Recycled Polypropylene Fibers as an Addition to Concrete Fabrication Based on Portland Cement. Materials, 13(8), 1827. https://doi.org/10.3390/ma13081827