Two-Step Sintering of Partially Stabilized Zirconia for Applications in Ceramic Crowns

Abstract

:1. Introduction

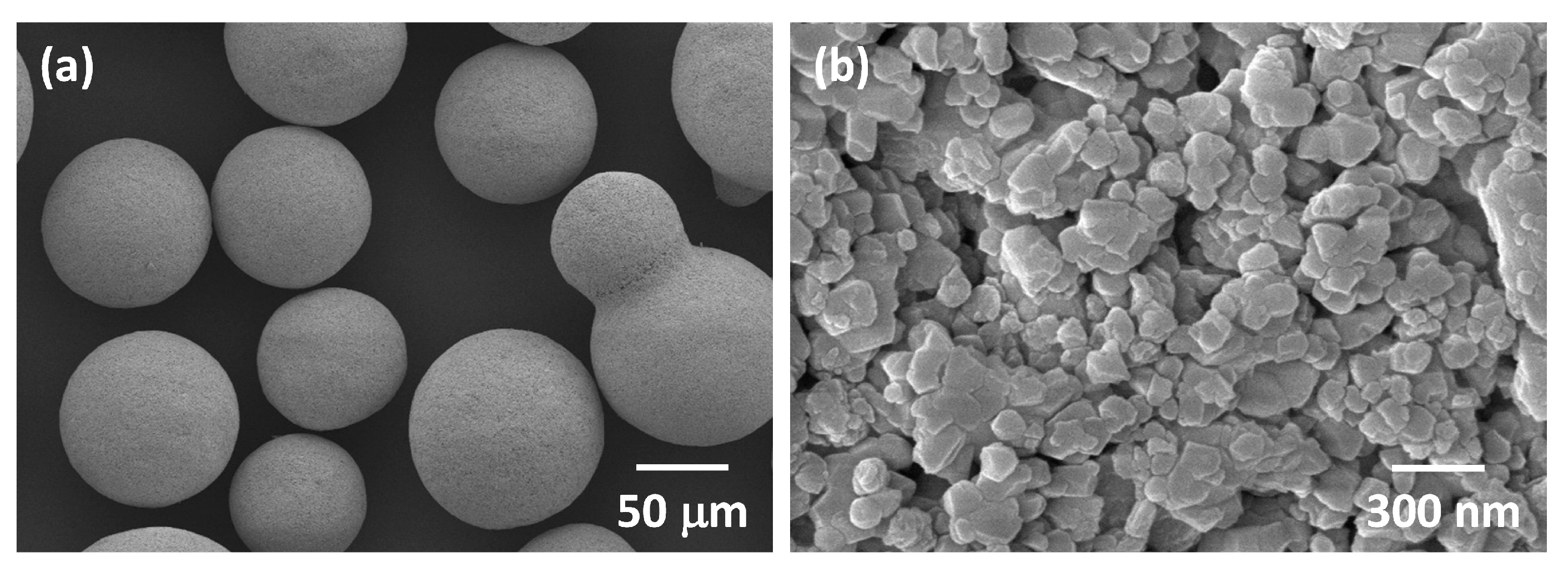

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergmann, C.P.; Stumpf, A. Ceramic Materials for Prosthetic and Restoration Use. In Dental Ceramics: Microstructure, Properties and Degradation; Springer: Berlin/Heidelberg, Germany, 2013; pp. 15–22. [Google Scholar]

- Johansson, C.; Kmet, G.; Rivera, J.; Larsson, C.; Vult Von Steyern, P. Fracture strength of monolithic all-ceramic crowns made of high translucent yttrium oxide-stabilized zirconium dioxide compared to porcelain-veneered crowns and lithium disilicate crowns. Acta Odontol. Scand. 2014, 72, 145–153. [Google Scholar] [CrossRef] [PubMed]

- Heffernan, M.J.; Aquilino, S.A.; Diaz-Arnold, A.M.; Haselton, D.R.; Stanford, C.M.; Vargas, M.A. Relative translucency of six all-ceramic systems. Part I: Core materials. J. Prosthet. Dent. 2002, 88, 4–9. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.-M.; Smales, R.J.; Yip, K.H.K.; Sung, W.-J. Translucency and biaxial flexural strength of four ceramic core materials. Dent. Mater. 2008, 24, 1506–1511. [Google Scholar] [CrossRef] [PubMed]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef] [PubMed]

- Al-Amleh, B.; Lyons, K.; Swain, M. Clinical trials in zirconia: A systematic review. J. Oral Rehab. 2010, 37, 641–652. [Google Scholar] [CrossRef] [PubMed]

- Benetti, P.; Kelly, J.R.; Sanchez, M.; Della Bona, A. Influence of thermal gradients on stress state of veneered restorations. Dent. Mater. 2014, 30, 554–563. [Google Scholar] [CrossRef]

- Sen, N.; Sermet, I.B.; Cinar, S. Effect of coloring and sintering on the translucency and biaxial strength of monolithic zirconia. J. Prosthet. Dent. 2018, 119, 308. [Google Scholar] [CrossRef]

- Stawarczyk, B.; Özcan, M.; Hallmann, L.; Ender, A.; Mehl, A.; Hämmerlet, C.H.F. The effect of zirconia sintering temperature on flexural strength, grain size, and contrast ratio. Clin. Oral Investig. 2013, 17, 269–274. [Google Scholar] [CrossRef] [Green Version]

- Peelen, J.G.J.; Metselaar, R. Light scattering by pores in polycrystalline materials: Transmission properties of alumina. J. Appl. Phys. 1974, 45, 216–220. [Google Scholar] [CrossRef]

- Apetz, R.; Bruggen, M.P.B. Transparent Alumina: A Light-Scattering Model. J. Am. Ceram. Soc. 2003, 86, 480–486. [Google Scholar] [CrossRef]

- Krell, A.; Klimke, J.; Hutzler, T. Transparent compact ceramics: Inherent physical issues. Opt. Mater. 2009, 31, 1144–1150. [Google Scholar] [CrossRef]

- Pecharromán, C.; Mata-Osoro, G.; Antonio Díaz, L.; Torrecillas, R.; Moya, J.S. On the transparency of nanostructured alumina: Rayleigh-Gans model for anisotropic spheres. Opt. Express 2009, 17, 6899–6912. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamashita, I.; Tsukuma, K. Light scattering by residual pores in transparent zirconia ceramics. J. Ceram. Soc. Jpn. 2011, 119, 133–135. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.F.; Zhang, J.; Luo, D.W.; Gu, F.; Tang, D.Y.; Dong, Z.L.; Tan, G.E.B.; Que, W.X.; Zhang, T.S.; Li, S.; et al. Transparent ceramics: Processing, materials and applications. Progress Solid State Chem. 2013, 41, 20–54. [Google Scholar] [CrossRef]

- Penilla, E.H.; Hardin, C.L.; Kodera, Y.; Basun, S.A.; Evans, D.R.; Garay, J.E. The role of scattering and absorption on the optical properties of birefringent polycrystalline ceramics: Modeling and experiments on ruby (Cr:Al2O3). J. Appl. Phys. 2016, 119, 023106. [Google Scholar] [CrossRef]

- Zhang, Y. Making yttria-stabilized tetragonal zirconia translucent. Dent. Mater. 2014, 30, 1195–1203. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Srdić, V.V.; Winterer, M.; Hahn, H. Sintering Behavior of Nanocrystalline Zirconia Prepared by Chemical Vapor Synthesis. J. Am. Ceram. Soc. 2000, 83, 729–736. [Google Scholar] [CrossRef]

- Ross, I.M.; Rainforth, W.M.; McComb, D.W.; Scott, A.J.; Brydson, R. The role of trace additions of alumina to yttria-tetragonal zirconia polycrystals (Y–TZP). Scripta Mater. 2001, 45, 653–660. [Google Scholar] [CrossRef]

- Tsubakino, H.; Nozato, R.; Hamamoto, M. Effect of Alumina Addition on the Tetragonal-to-Monoclinic Phase Transformation in Zirconia-3 mol% Yttria. J. Am. Ceram. Soc. 1991, 74, 440–443. [Google Scholar] [CrossRef]

- Samodurova, A.; Kocjan, A.; Swain, M.V.; Kosmač, T. The combined effect of alumina and silica co-doping on the ageing resistance of 3Y-TZP bioceramics. Acta Biomater. 2015, 11, 477–487. [Google Scholar] [CrossRef]

- Zhang, F.; Vanmeensel, K.; Batuk, M.; Hadermann, J.; Inokoshi, M.; Van Meerbeek, B.; Naert, I.; Vleugels, J. Highly-translucent, strong and aging-resistant 3Y-TZP ceramics for dental restoration by grain boundary segregation. Acta Biomater. 2015, 16, 215–222. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Li, Z.; Kim, B.-N.; Morita, K.; Yoshida, H.; Hiraga, K.; Sakka, Y. Effect of Alumina Dopant on Transparency of Tetragonal Zirconia. J. Nanomater. 2012, 2012, 5. [Google Scholar] [CrossRef] [Green Version]

- Dash, A.; Kim, B.-N.; Klimke, J.; Vleugels, J. Transparent tetragonal-cubic zirconia composite ceramics densified by spark plasma sintering and hot isostatic pressing. J. Eur. Ceram. Soc. 2019, 39, 1428–1435. [Google Scholar] [CrossRef]

- Nassary Zadeh, P.; Lümkemann, N.; Sener, B.; Eichberger, M.; Stawarczyk, B. Flexural strength, fracture toughness, and translucency of cubic/tetragonal zirconia materials. J. Prosthet. Dent. 2018, 120, 948–954. [Google Scholar] [CrossRef] [Green Version]

- Chevalier, J.; Deville, S.; Münch, E.; Jullian, R.; Lair, F. Critical effect of cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for hip replacement prosthesis. Biomaterials 2004, 25, 5539–5545. [Google Scholar] [CrossRef] [Green Version]

- Matsui, K.; Horikoshi, H.; Ohmichi, N.; Ohgai, M.; Yoshida, H.; Ikuhara, Y. Cubic-Formation and Grain-Growth Mechanisms in Tetragonal Zirconia Polycrystal. J. Am. Ceram. Soc. 2003, 86, 1401–1408. [Google Scholar] [CrossRef]

- Abd El-Ghany, O.S.; Sherief, A.H. Zirconia based ceramics, some clinical and biological aspects: Review. Future Dent. J. 2016, 2, 55–64. [Google Scholar] [CrossRef]

- Zhao, J.; Ikuhara, Y.; Sakuma, T. Grain Growth of Silica-Added Zirconia Annealed in the Cubic/Tetragonal Two-Phase Region. J. Am. Ceram. Soc. 1998, 81, 2087–2092. [Google Scholar] [CrossRef]

- Lóh, N.J.; Simão, L.; Faller, C.A.; De Noni, A.; Montedo, O.R.K. A review of two-step sintering for ceramics. Ceram. Int. 2016, 42, 12556–12572. [Google Scholar] [CrossRef]

- Matsui, K.; Yoshida, H.; Ikuhara, Y. Review: Microstructure-development mechanism during sintering in polycrystalline zirconia. Int. Mater. Rev. 2018, 63, 375–406. [Google Scholar] [CrossRef]

- Kim, M.-S.; Go, S.-I.; Kim, J.-M.; Park, Y.-J.; Kim, H.-N.; Ko, J.-W.; Jung, S.-H.; Kim, J.-Y.; Yun, J.-D. Sinterability of Low-Cost 3Y-ZrO2 Powder and Mechanical Properties of the Sintered Body. J. Korean Ceram. Soc. 2017, 54, 285–291. [Google Scholar] [CrossRef] [Green Version]

- Han, Y.; Li, S.; Zhu, T.; Xie, Z. An oscillatory pressure sintering of zirconia powder: Rapid densification with limited grain growth. J. Am. Ceram. Soc. 2017, 100, 2774–2780. [Google Scholar] [CrossRef]

- Wang, C.; Mao, X.; Peng, Y.-P.; Jiang, B.; Fan, J.; Xu, Y.; Zhang, L.; Zhao, J. Preparation and Optical Properties of Infrared Transparent 3Y-TZP Ceramics. Materials 2017, 10, 390. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hu, X.; Jiang, X.; Chen, S.; Zhu, Q.; Feng, M.; Zhang, P.; Fan, J.; Jiang, B.; Mao, X.; Zhang, L. Fabrication of infrared-transparent 3Y-TZP ceramics with small grain size by pre-sintering in an oxygen atmosphere and hot isostatic pressing. Ceram. Int. 2018, 44, 2093–2097. [Google Scholar] [CrossRef]

- Anselmi-Tamburini, U.; Woolman, J.N.; Munir, Z.A. Transparent Nanometric Cubic and Tetragonal Zirconia Obtained by High-Pressure Pulsed Electric Current Sintering. Adv. Funct. Mater. 2007, 17, 3267–3273. [Google Scholar] [CrossRef]

- Casolco, S.R.; Xu, J.; Garay, J.E. Transparent/translucent polycrystalline nanostructured yttria stabilized zirconia with varying colors. Scripta Mater. 2008, 58, 516–519. [Google Scholar] [CrossRef]

- Zhang, H.B.; Kim, B.N.; Morita, K.; Yoshida, H.; Lim, J.H.; Hiraga, K. Optimization of high-pressure sintering of transparent zirconia with nano-sized grains. J. Alloys Compd. 2010, 508, 196–199. [Google Scholar] [CrossRef]

- Zhang, H.; Kim, B.-N.; Morita, K.; Yoshida, H.; Lim, J.-H.; Hiraga, K. Optical Properties and Microstructure of Nanocrystalline Cubic Zirconia Prepared by High-Pressure Spark Plasma Sintering. J. Am. Ceram. Soc. 2011, 94, 2981–2986. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Z.; Kim, B.-N.; Morita, K.; Yoshida, H.; Hiraga, K.; Sakka, Y. Highly Infrared Transparent Nanometric Tetragonal Zirconia Prepared by High-Pressure Spark Plasma Sintering. J. Am. Ceram. Soc. 2011, 94, 2739–2741. [Google Scholar] [CrossRef]

- Hallmann, L.; Ulmer, P.; Reusser, E.; Louvel, M.; Hämmerle, C.H.F. Effect of dopants and sintering temperature on microstructure and low temperature degradation of dental Y-TZP-zirconia. J. Eur. Ceram. Soc. 2012, 32, 4091–4104. [Google Scholar] [CrossRef]

- Chu, M.-Y.; De Jonghe, L.C.; Lin, M.K.F.; Lin, F.J.T. Precoarsening to Improve Microstructure and Sintering of Powder Compacts. J. Am. Ceram. Soc. 1991, 74, 2902–2911. [Google Scholar] [CrossRef]

- Chen, I.W.; Wang, X.H. Sintering dense nanocrystalline ceramics without final-stage grain growth. Nature 2000, 404, 168. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.-I.; Kim, Y.-W.; Mitomo, M.; Kim, D.-Y. Fabrication of Dense Nanostructured Silicon Carbide Ceramics through Two-Step Sintering. J. Am. Ceram. Soc. 2003, 86, 1803–1805. [Google Scholar] [CrossRef]

- Wang, X.-H.; Deng, X.-Y.; Bai, H.-L.; Zhou, H.; Qu, W.-G.; Li, L.-T.; Chen, I.-W. Two-Step Sintering of Ceramics with Constant Grain-Size, II: BaTiO3 and Ni-Cu-Zn Ferrite. J. Am. Ceram. Soc. 2006, 89, 438–443. [Google Scholar] [CrossRef] [Green Version]

- Bodišová, K.; Šajgalík, P.; Galusek, D.; Švančárek, P. Two-Stage Sintering of Alumina with Submicrometer Grain Size. J. Am. Ceram. Soc. 2007, 90, 330–332. [Google Scholar] [CrossRef]

- Mazaheri, M.; Valefi, M.; Hesabi, Z.R.; Sadrnezhaad, S.K. Two-step sintering of nanocrystalline 8Y2O3 stabilized ZrO2 synthesized by glycine nitrate process. Ceram. Int. 2009, 35, 13–20. [Google Scholar] [CrossRef]

- Grosso, R.L.; Muccillo, E.N.S. Sintering, phase composition and ionic conductivity of zirconia–scandia–ceria. J. Power Sour. 2013, 233, 6–13. [Google Scholar] [CrossRef]

- Nadernezhad, A.; Moztarzadeh, F.; Hafezi, M.; Barzegar-Bafrooei, H. Two step sintering of a novel calcium magnesium silicate bioceramic: Sintering parameters and mechanical characterization. J. Eur. Ceram. Soc. 2014, 34, 4001–4009. [Google Scholar] [CrossRef]

- Hotza, D.; García, D.E.; Castro, R.H.R. Obtaining highly dense YSZ nanoceramics by pressureless, unassisted sintering. Int. Mater. Rev. 2015, 60, 353–375. [Google Scholar] [CrossRef]

- Ojaimi, C.L.; Ferreira, J.A.; dos Santos, F.A.; Chinelatto, A.L.; Pallone, E.M.; Chinelatto, A.S.A. Mechanical characterisation and hydrothermal degradation of Al2O3-15 vol% ZrO2 nanocomposites consolidated by two-step sintering. Ceram. Int. 2018, 44, 16128–16136. [Google Scholar] [CrossRef]

- Mazaheri, M.; Simchi, A.; Golestani-Fard, F. Densification and grain growth of nanocrystalline 3Y-TZP during two-step sintering. J. Eur. Ceram. Soc. 2008, 28, 2933–2939. [Google Scholar] [CrossRef]

- Rez, G.; Sakka, Y.; Suzuki, T.S.; Uchikoshi, T.; Aglietti, E.F. Effect of bead-milling treatment on the dispersion of tetragonal zirconia nanopowder and improvements of two-step sintering. J. Ceram. Soc. Jpn. 2009, 117, 470–474. [Google Scholar] [CrossRef] [Green Version]

- Paul, A.; Vaidhyanathan, B.; Binner, J.G.P. Hydrothermal Aging Behavior of Nanocrystalline Y-TZP Ceramics. J. Am. Ceram. Soc. 2011, 94, 2146–2152. [Google Scholar] [CrossRef]

- Sutharsini, U.; Thanihaichelvan, M.; Ting, C.H.; Ramesh, S.; Tan, C.Y.; Chandran, H.; Sarhan, A.A.D.; Ramesh, S.; Urriés, I. Effect of two-step sintering on the hydrothermal ageing resistance of tetragonal zirconia polycrystals. Ceram. Int. 2017, 43, 7594–7599. [Google Scholar] [CrossRef]

- Zhang, W.; Bao, J.; Jia, G.; Guo, W.; Song, X.; An, S. The effect of microstructure control on mechanical properties of 12Ce-TZP via two-step sintering method. J. Alloys Compd. 2017, 711, 686–692. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization. ISO 6872:1995 Dental Ceramic; International Organization for Standardization: Geneva, Switzerland, 1995. [Google Scholar]

- German, R.M. Solid-State Sintering Fundamentals. In Sintering Theory and Practice; Wiley: New York, NY, USA, 1996; pp. 67–141. [Google Scholar]

- Ohmichi, N.; Kamioka, K.; Ueda, K.; Matsui, K.; Ohgai, M. Phase Transformation of Zirconia Ceramics by Annealing in Hot Water. J. Ceram. Soc. Jpn. 1999, 107, 128–133. [Google Scholar] [CrossRef] [Green Version]

- Chen, P.-L.; Chen, I.-W. Sintering of Fine Oxide Powders: I, Microstructural Evolution. J. Am. Ceram. Soc. 1996, 79, 3129–3141. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.J.L. Normal Grain Growth and Second-Phase Particles. In Sintering: Densification, Grain Growth & Microstructure; Elsevier Butterworth Heinemann: Oxford, UK, 2005; pp. 91–96. [Google Scholar]

- Chiang, Y.M.; Birnie, D.; Kingery, W.D. Microstructure. In Physical Ceramics: Principles for Ceramic Science and Engineering; Chapter 5; John Wiley & Sons: New York, NY, USA, 1997; pp. 351–513. [Google Scholar]

- Pouchly, V.; Maca, K.; Shen, Z. Two-stage master sintering curve applied to two-step sintering of oxide ceramics. J. Eur. Ceram. Soc. 2013, 33, 2275–2283. [Google Scholar] [CrossRef]

- Mazaheri, M.; Zahedi, A.M.; Sadrnezhaad, S.K. Two-Step Sintering of Nanocrystalline ZnO Compacts: Effect of Temperature on Densification and Grain Growth. J. Am. Ceram. Soc. 2008, 91, 56–63. [Google Scholar] [CrossRef]

- Czubayko, U.; Sursaeva, V.G.; Gottstein, G.; Shvindlerman, L.S. Influence of triple junctions on grain boundary motion. Acta Mater. 1998, 46, 5863–5871. [Google Scholar] [CrossRef]

- Gottstein, G.; King, A.H.; Shvindlerman, L.S. The effect of triple-junction drag on grain growth. Acta Mater. 2000, 48, 397–403. [Google Scholar] [CrossRef] [Green Version]

- Mattissen, D.; Molodov, D.A.; Shvindlerman, L.S.; Gottstein, G. Drag effect of triple junctions on grain boundary and grain growth kinetics in aluminium. Acta Mater. 2005, 53, 2049–2057. [Google Scholar] [CrossRef]

- Bernard-Granger, G.; Guizard, C. Apparent Activation Energy for the Densification of a Commercially Available Granulated Zirconia Powder. J. Am. Ceram. Soc. 2007, 90, 1246–1250. [Google Scholar] [CrossRef]

- Shao, W.Q.; Chen, S.O.; Li, D.; Cao, H.S.; Zhang, Y.C.; Zhang, S.S. Apparent activation energy for densification of α-Al2O3 powder at constant heating-rate sintering. Bull. Mater. Sci. 2009, 31, 903. [Google Scholar] [CrossRef]

- Song, X.; Lu, J.; Zhang, T.; Ma, J. Two-Stage Master Sintering Curve Approach to Sintering Kinetics of Undoped and Al2O3-Doped 8 Mol% Yttria-Stabilized Cubic Zirconia. J. Am. Ceram. Soc. 2011, 94, 1053–1059. [Google Scholar] [CrossRef]

- Gupta, T.K.; Bechtold, J.H.; Kuznicki, R.C.; Cadoff, L.H.; Rossing, B.R. Stabilization of tetragonal phase in polycrystalline zirconia. J. Mater. Sci. 1977, 12, 2421–2426. [Google Scholar] [CrossRef]

- Gupta, T.K.; Lange, F.F.; Bechtold, J.H. Effect of stress-induced phase transformation on the properties of polycrystalline zirconia containing metastable tetragonal phase. J. Mater. Sci. 1978, 13, 1464–1470. [Google Scholar] [CrossRef]

- Sakthiabirami, K.; Vu, V.T.; Kim, J.W.; Kang, J.H.; Jang, K.J.; Oh, G.J.; Fisher, J.G.; Yun, K.D.; Lim, H.P.; Park, S.W. Tailoring interfacial interaction through glass fusion in glass/zinc-hydroxyapatite composite coatings on glass-infiltrated zirconia. Ceram. Int. 2018, 44, 16181–16190. [Google Scholar] [CrossRef]

- Aboras, M.; Muchtar, A.; Azhari, C.H.; Yahaya, N.; Mah, J.C.W. Enhancement of the microstructural and mechanical properties of dental zirconia through combined optimized colloidal processing and cold isostatic pressing. Ceram. Int. 2019, 45, 1831–1836. [Google Scholar] [CrossRef]

- Zimmermann, A.; Hoffman, M.; Flinn, B.D.; Bordia, R.K.; Chuang, T.J.; Fuller, E.R.; Rödel, J. Fracture of Alumina with Controlled Pores. J. Am. Ceram. Soc. 1998, 81, 2449–2457. [Google Scholar] [CrossRef]

- Zhang, F.; Inokoshi, M.; Batuk, M.; Hadermann, J.; Naert, I.; Van Meerbeek, B.; Vleugels, J. Strength, toughness and aging stability of highly-translucent Y-TZP ceramics for dental restorations. Dent. Mater. 2016, 32, e327–e337. [Google Scholar] [CrossRef] [PubMed]

- Yashima, M.; Kakihana, M.; Yoshimura, M. Metastable-stable phase diagrams in the zirconia-containing systems utilized in solid-oxide fuel cell application. Solid State Ionics 1996, 86, 1131–1149. [Google Scholar] [CrossRef]

- Stubican, V.S.; Hellmann, J.R.; Ray, S.P. Defects and Ordering in Zirconia Crystalline Solutions. Mater. Sci. Monogr. 1982, 10, 257–261. [Google Scholar]

- Pascual, C.; Durán, P. Subsolidus Phase Equilibria and Ordering in the System ZrO2-Y2O3. J. Am. Ceram. Soc. 1983, 66, 23–27. [Google Scholar] [CrossRef]

- Lawson, S. Environmental degradation of zirconia Ceramics. J. Eur. Ceram. Soc. 1995, 15, 485–502. [Google Scholar] [CrossRef]

- Klimke, J.; Trunec, M.; Krell, A. Transparent Tetragonal Yttria-Stabilized Zirconia Ceramics: Influence of Scattering Caused by Birefringence. J. Am. Ceram. Soc. 2011, 94, 1850–1858. [Google Scholar] [CrossRef]

| Schedule | Temperature 1 T1 (°C) | Holding Time 1 t1 (min) | Temperature 2 T2 (°C) | Holding Time 2 t2 (h) |

|---|---|---|---|---|

| 1 | 1300 | 5 | 1200 | 5–20 |

| 1250 | 5–20 | |||

| 1275 | 5–20 | |||

| 2 | 1375 | 5 | 1325 | 5–20 |

| 3 | 1400 | 5 | 1350 | 5–20 |

| Sample | Temperature (°C) | Dwell Time (h) | Hardness (GPa) | Flexural Strength (MPa) |

|---|---|---|---|---|

| CS | 1450 | 2 | 13.98 ± 0.54 a | 381.30 ± 54.66 d |

| TSS-5 | T1-1400; T2-1350 | 5 | 13.26 ± 0.47 c | 346.38 ± 41.94 d |

| TSS-10 | T1-1400; T2-1350 | 10 | 13.84 ± 0.48 abc | 345.12 ± 22.70 d |

| TSS-15 | T1-1400; T2-1350 | 15 | 13.59 ± 0.89 ab | 357.04 ± 49.00 d |

| TSS-20 | T1-1400; T2-1350 | 20 | 13.43 ± 0.57 c | 402.12 ± 45.36 d |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Darmawan, B.A.; Fisher, J.G.; Trung, D.T.; Sakthiabirami, K.; Park, S.-W. Two-Step Sintering of Partially Stabilized Zirconia for Applications in Ceramic Crowns. Materials 2020, 13, 1857. https://doi.org/10.3390/ma13081857

Darmawan BA, Fisher JG, Trung DT, Sakthiabirami K, Park S-W. Two-Step Sintering of Partially Stabilized Zirconia for Applications in Ceramic Crowns. Materials. 2020; 13(8):1857. https://doi.org/10.3390/ma13081857

Chicago/Turabian StyleDarmawan, Bobby Aditya, John G. Fisher, Doan Thanh Trung, Kumaresan Sakthiabirami, and Sang-Won Park. 2020. "Two-Step Sintering of Partially Stabilized Zirconia for Applications in Ceramic Crowns" Materials 13, no. 8: 1857. https://doi.org/10.3390/ma13081857

APA StyleDarmawan, B. A., Fisher, J. G., Trung, D. T., Sakthiabirami, K., & Park, S.-W. (2020). Two-Step Sintering of Partially Stabilized Zirconia for Applications in Ceramic Crowns. Materials, 13(8), 1857. https://doi.org/10.3390/ma13081857