Nonconventional Ca(OH)2 Treatment of Bamboo for the Reinforcement of Cement Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

- Chips: the culm internodes were cut into small samples (60 mm × 10 mm × 15 mm);

- Barkless: the barks and internal layers of the chips were removed with a scalpel;

- Crushed: the chips were crushed in a blade mill and sieved with a 16 mesh (1.18 mm).

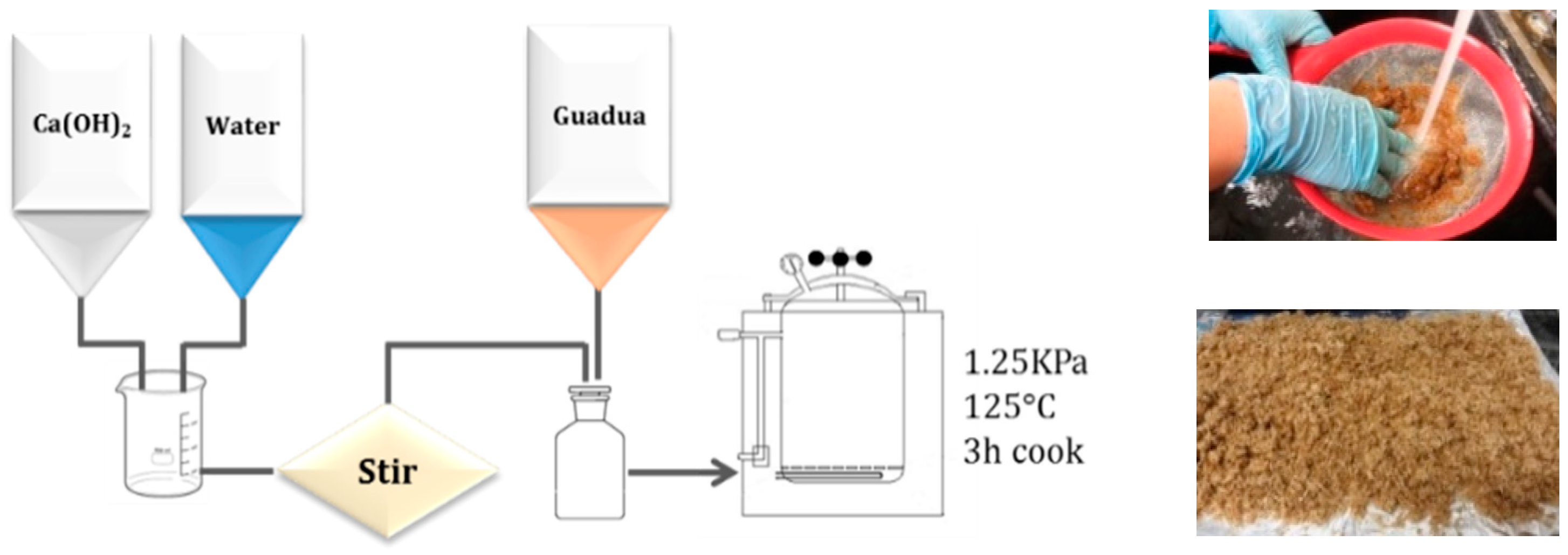

2.3. Ca(OH)2 Treatment

2.4. Fiber Surface Characterization

2.5. Fourier Transform Infrared Spectroscopy (FTIR)

2.6. X-Ray Difraction

2.7. CCB Manufacturing

2.8. Water Cement Ratio of CCBs

2.9. Flexural Strength of CCBs

2.10. Toughness of CCBs

2.11. Fracture Surface of CCBs

3. Results and Discussion

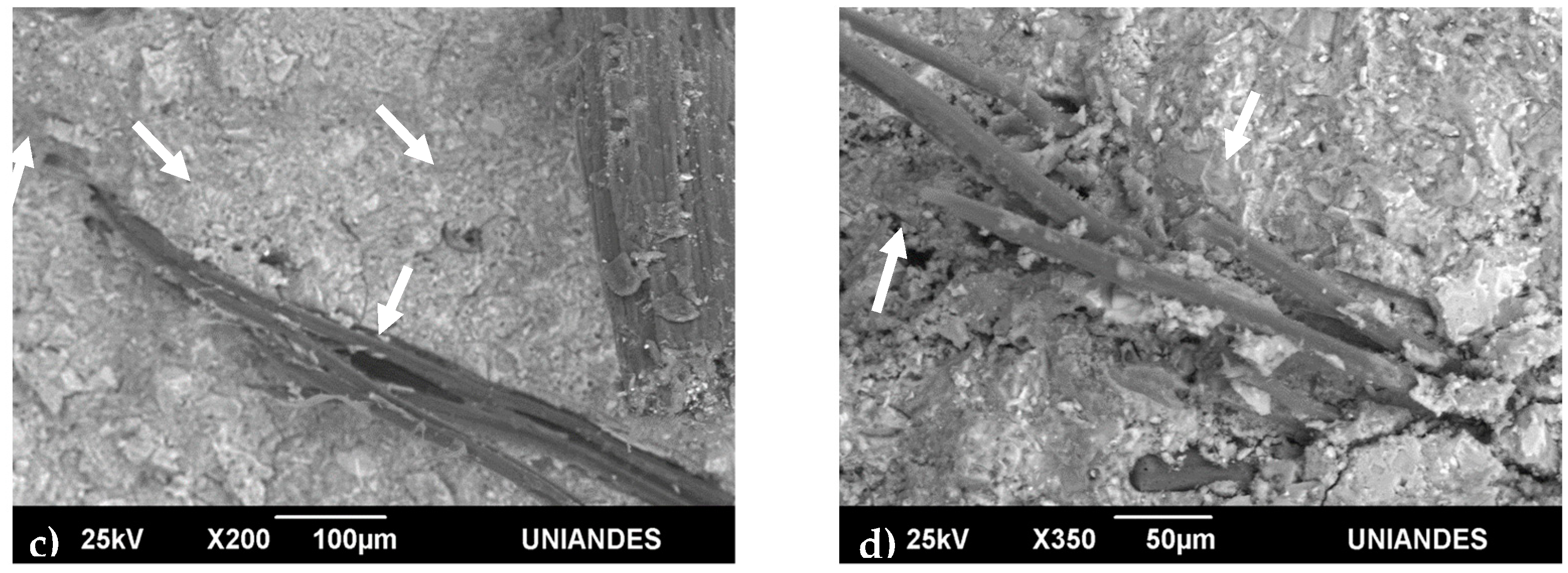

3.1. Ca(OH)2 Treatment Effect on the Bamboo Fiber Surface Morphology

3.2. FTIR Analysis of Untreated and Ca(OH)2-Treated Bamboo Fibers

3.3. XRD Analysis of Untreated and Ca(OH)2-Treated Bamboo Fibers

3.4. W/C of CCBs

3.5. Mechanical Properties of CCBs

3.6. Fracture Surface of CCBs

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Santos, S.F.; Tonoli, G.H.D.; Mejia, J.E.B.; Fiorelli, J.; Savastano, H., Jr. Non-conventional cement-based composites reinforced with vegetable fibers: A review of strategies to improve durability. Mater Constr. 2015, 65, 1–20. [Google Scholar]

- Johnston, C. Fiber—Reinforced Cements and Concrets; CRC Press-Taylor & Francis Group: New York, NY, USA, 2010; p. 370. [Google Scholar]

- Liu, R.; Luo, S.; Cao, J.; Chen, Y. Mechanical properties of wood flour/poly (lactic acid) composites coupled with waterborne silane-polyacrylate copolymer emulsion. Holzforschung 2016, 70, 439–447. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E. Comparing flexural behaviour of fibre–cement composites reinforced bagasse: Wheat and eucalyptus. Constr. Build. Mater. 2011, 25, 3661–3667. [Google Scholar] [CrossRef]

- Khorami, M.; Ganjian, E. The effect of limestone powder, silica fume and fibre content on flexural behaviour of cement composite reinforced by waste Kraft pulp. Constr. Build. Mater. 2013, 46, 142–149. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; DaSilva, I.L.A.; DaCosta, L.L. Natural Lignocellulosic Fibers as Engineering Materials—An Overview. Metall. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef] [Green Version]

- Osorio, L.; Trujillo, E.; Van-Vuure, A.W.; Verpoest, I. Morphological aspects and mechanical properties of single bamboo fibers and flexural characterization of bamboo/ epoxy composites. J. Reinf. Plast. Comp. 2011, 30, 396–408. [Google Scholar] [CrossRef]

- Yu, Y.; Tian, G.; Wang, H.; Fei, B.; Wang, G. Mechanical characterization of single bamboo fibers with nanoindentation and microtensile technique. Holzforschung 2011, 65, 113–119. [Google Scholar] [CrossRef]

- Abdul Khalil, H.P.S.; Bhat, I.U.H.; Jawaid, M.; Zaidon, A.; Hermawan, D.; Hadi, Y.S. Bamboo fibre reinforced biocomposites: A review. Mater. Des. 2012, 42, 353–368. [Google Scholar] [CrossRef]

- Tolosa, R.A.; Jimenez-Obando, G.; Arias, N.P.; Cardona, C.A.; Giraldo, O. Cementicious Materials Reinforcement Using Angustifolia kunth Bamboo Fiber Covered with Nanostructured Manganese Oxide. Ind. Eng. Chem. Res. 2014, 53, 8452–8463. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites; Taylor & Francis Group: New York, NY, USA, 2007; p. 595. [Google Scholar]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I.N. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos. Part A Appl. S 2016, 90, 589–597. [Google Scholar] [CrossRef]

- Alessandra, F.; Panthapulakkal, S.; Konar, S.; Sain, M.; Bufalino, L.; Raabe, J.; De Andrade, I.P.; Martins, M.A.; Tonolii, G.H.D. Improving cellulose nanofibrillation of non-wood fiber using alkaline and bleaching pre-treatments. Ind. Crop. Prod. 2019, 131, 203–212. [Google Scholar]

- Chen, H.; Yu, Y.; Zhong, T.; Wu, Y. Effect of alkali treatment on microstructure and mechanical properties of individual bamboo fibers. Cellulose 2016, 24, 333–347. [Google Scholar] [CrossRef]

- Bajpai, P. Pretreatment of Lignocellulosic Biomass. In Pretreatment of Lignocellulosic Biomass for Biofuel Production; Sharma, S., Ed.; Springer: Singapore, 2016; p. 87. [Google Scholar]

- Salmela, M.; Alén, R.; Vu, M.T.H.; Thi, A.; Vu, H. Description of kraft cooking and oxygen–alkali delignification of bamboo by pulp and dissolving material analysis. Ind. Crop. Prod. 2008, 28, 47–55. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef] [Green Version]

- Gierer, J. Chemical aspects of Kraft pulping. Wood Sci. Technol. 1980, 14, 241–266. [Google Scholar] [CrossRef]

- Anggono, J.; Sugondo, S.; Henrico, S.; Purwaningsih, H. Effect of Alkali Treatment Using Calcium Hydroxide and the Fiber Length on the Strength of Sugarcane Bagasse Fibers-Polypropylene Composites. Appl. Mech. Mater. 2015, 815, 106–110. [Google Scholar] [CrossRef] [Green Version]

- Sierra, R.; Granda, C.B.; Holtzapple, M.T. Lime Pretreatment. In Biofuels; Mielenz, J.R., Ed.; Humana Press: Totowa, NJ, USA, 2009; pp. 115–124. [Google Scholar]

- Chang, V.S.; Nagwani, M.; Kim, C.H.; Holtzapple, M.T. Oxidative Lime Pretreatment of High-Lignin Biomass. Appl. Biochem. Biotechnol. 2001, 94, 1–28. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J., Jr.; Martin, A.E.J.; Conrad, C.M. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Jarabo, R.; Fuente, E.; Monte, M.; Savastano, H., Jr.; Mujté, P.; Negro, C. Use of cellulose fibers from hemp core in fiber-cement production. Effect on flocculation, retention, drainage and product properties. Ind. Crop. Prod. 2012, 39, 89–96. [Google Scholar] [CrossRef] [Green Version]

- Rusu, M.; Mörseburg, K.; Gregersen, Ø.; Yamakawa, A.; Liukkonen, S. Relation Between Fibre Flexibility and Cross Sectional Properties. BioResources 2011, 6, 641–655. [Google Scholar]

- Rodrigues, J.; Faix, O.; Pereira, H. Determination of Lignin Content of Eucalyptus globulus Wood Using FTIR Spectroscopy. Holzforschung 1998, 52, 46–50. [Google Scholar] [CrossRef]

- Le Trodec, M.; Sedan, D.; Peyratout, C.; Bonnet, J.P.; Smith, A.; Guinebretiere, R.; Gloaguen, V.; Krauszc, P. Influence of various chemical treatments on the composition and structure of hemp fibres. Compos. Part A Appl. S 2008, 39, 514–522. [Google Scholar] [CrossRef]

- Yuan, Z.; Kapu, N.S.; Beatson, R.; Martinez, D.M.; Feng, X. Effect of alkaline pre-extraction of silica and hemicellulose on Kraft pulping of bamboo. Ind. Crop. Prod. 2016, 91, 1–41. [Google Scholar] [CrossRef]

- Gunasekaran, S.; Anbalagan, G. Spectroscopic characterization of natural calcite minerals. Spectrochim. Acta A 2007, 68, 656–664. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Hu, H. X-ray diffraction study of bamboo fibers treated with NaOH. Fiber Polym. 2008, 9, 735–739. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.D.A.; Lima, P.R.L.; Toledo Filho, R.D. Effect of fiber treatments on the sisal fiber properties and fiber-matrix bond in cement based systems. Constr. Build. Mater. 2015, 101, 730–740. [Google Scholar] [CrossRef]

- Heise, K.; Rossberg, C.; Strätz, J.; Bäurich, C.; Brendler, E.; Keller, H.; Fischer, S. Impact of pre-treatments on properties of lignocelluloses and their accessibility for a subsequent carboxymethylation. Carbohydr. Polym. 2017, 161, 82–89. [Google Scholar] [CrossRef]

- Wang, X.; Chang, L.; Shi, X.; Wang, L. Effect of Hot-Alkali Treatment on the Structure Composition of Jute Fabrics and Mechanical Properties of Laminated Composites. Materials 2019, 12, 1386. [Google Scholar] [CrossRef] [Green Version]

- Faruk, O.; Bledzki, A.K.; Fink, H.; Sain, M. Progress in Polymer Science Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Boufi, S.; Chaker, A. Easy production of cellulose nanofibrils from corn stalk by a conventional high speed blender. Ind. Crop. Prod. 2016, 93, 39–47. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M.; Zhao, J. Mixture Proportion Design Method of Steel Fiber Reinforced Recycled Coarse Aggregate Concrete. Materials 2019, 12, 375. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saidani, M.; Saraireh, D.; Gerges, M. Behaviour of different types of fibre reinforced concrete without admixture. Eng. Struct. 2016, 113, 328–334. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Z.; Yan, Y. Flexural properties and impact behaviour analysis of bamboo cellulosic fibers filled cement based composites. Constr. Build. Mater. 2019, 241, 403–414. [Google Scholar] [CrossRef]

- Potential of bamboo organosolv pulp as a reinforcing element in fiber–cement materials in fiber–cement materials. Constr. Build. Mater. 2014, 72, 65–71. [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- CEN. BS EN 12467:2004 Fibre-Cement Flat Sheets—Product Specification and Test Methods. 2004. [Google Scholar]

- Klerk, M.D.; Kayondo, M.; Moelich, G.M.; De Villers, W.I.; Combrinck, R. Durability of chemically modified sisal fibre in cement-based composites. Constr. Build. Mater. 2020, 241, 117835. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Density (kg/m3) | 2937 |

| Specific surface (cm2/g) | 4589.6 |

| Unit mass (kg/m3) | 825.9 |

| Sample | I002 | Iam | Cellulose CI (%) |

|---|---|---|---|

| Untreated | 1557 | 829 | 46.8 |

| Guadua chips | 2419 | 1085 | 55.1 |

| Barkless Guadua | 1487 | 782.5 | 47.4 |

| Crushed Guadua | 2908 | 1009 | 65.3 |

| CCB type | W/C |

|---|---|

| Without fibers | 0.17 ± 0.01 |

| With untreated fibers | 0.23 ± 0.03 |

| With Ca(OH)2-treated fibers | 0.27 ± 0.01 |

| CCB Reinforcement | MOR (MPa) | Specific Energy (kJ/m2) | ||||

|---|---|---|---|---|---|---|

| 7 days | 28 days | 90 days | 7 days | 28 days | 90 days | |

| Unreinforced | 4.8 0.9 a | 5.2 0.6 a | 5.6 0.9 a | 0.19 0.02 a | 0.20 0.01 a | 0.25 0.02 a |

| Untreated fibers | 3.6 0.9 b | 5.0 0.9 a | 7.4 0.5 b | 0.63 0.03 b | 0.51 0.02 b | 0.61 0.02 b |

| Ca(OH)2-treated fibers | 5.2 0.8 a | 5.4 0.6 a | 8.2 0.9 b | 1.19 0.20 c | 0.99 0.09 c | 1.09 0.10 c |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanchez-Echeverri, L.A.; Medina-Perilla, J.A.; Ganjian, E. Nonconventional Ca(OH)2 Treatment of Bamboo for the Reinforcement of Cement Composites. Materials 2020, 13, 1892. https://doi.org/10.3390/ma13081892

Sanchez-Echeverri LA, Medina-Perilla JA, Ganjian E. Nonconventional Ca(OH)2 Treatment of Bamboo for the Reinforcement of Cement Composites. Materials. 2020; 13(8):1892. https://doi.org/10.3390/ma13081892

Chicago/Turabian StyleSanchez-Echeverri, Luz Adriana, Jorge Alberto Medina-Perilla, and Eshmaiel Ganjian. 2020. "Nonconventional Ca(OH)2 Treatment of Bamboo for the Reinforcement of Cement Composites" Materials 13, no. 8: 1892. https://doi.org/10.3390/ma13081892

APA StyleSanchez-Echeverri, L. A., Medina-Perilla, J. A., & Ganjian, E. (2020). Nonconventional Ca(OH)2 Treatment of Bamboo for the Reinforcement of Cement Composites. Materials, 13(8), 1892. https://doi.org/10.3390/ma13081892