Influence of Crimped Steel Fibre on Properties of Concrete Based on an Aggregate Mix of Waste and Natural Aggregates

Abstract

:1. Introduction

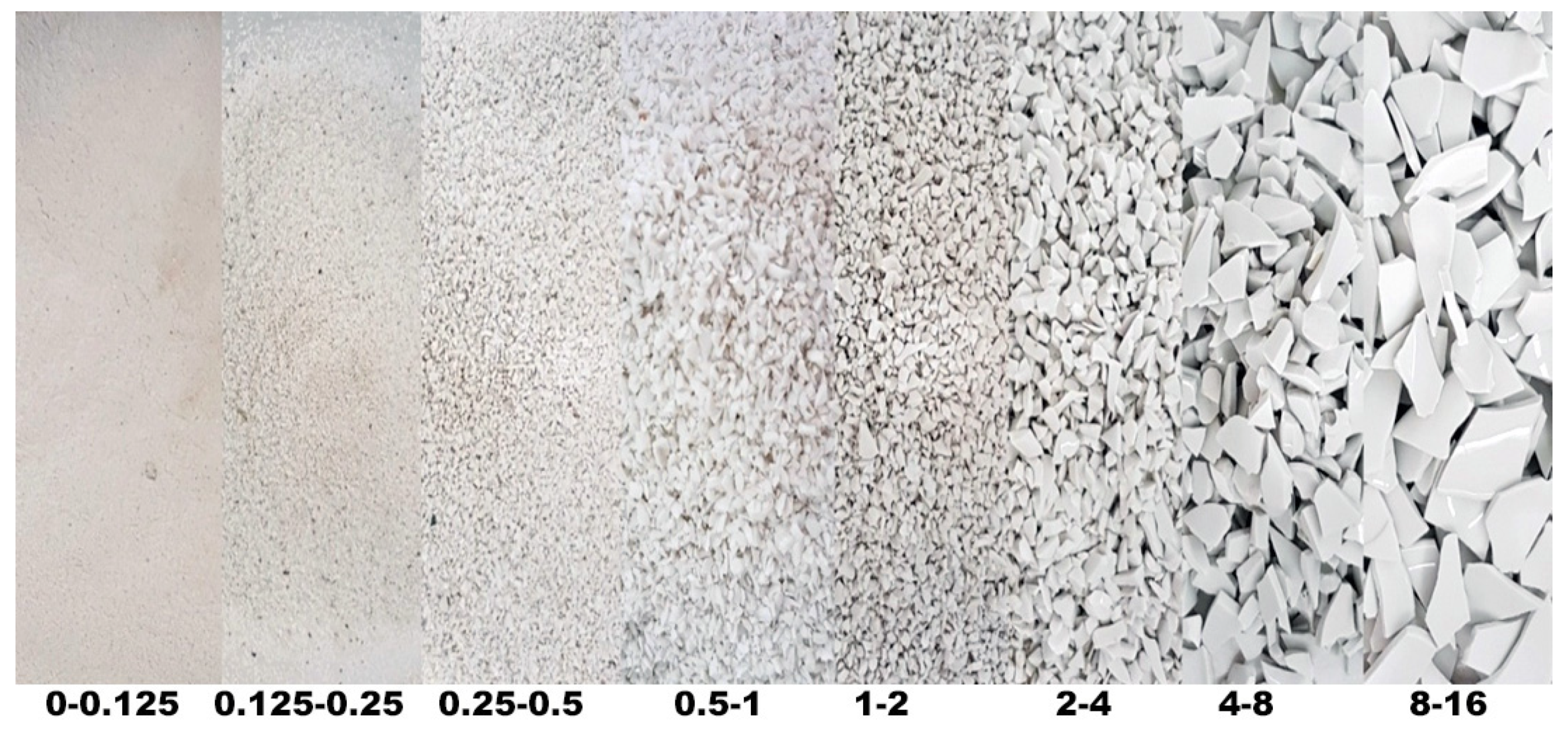

2. Materials

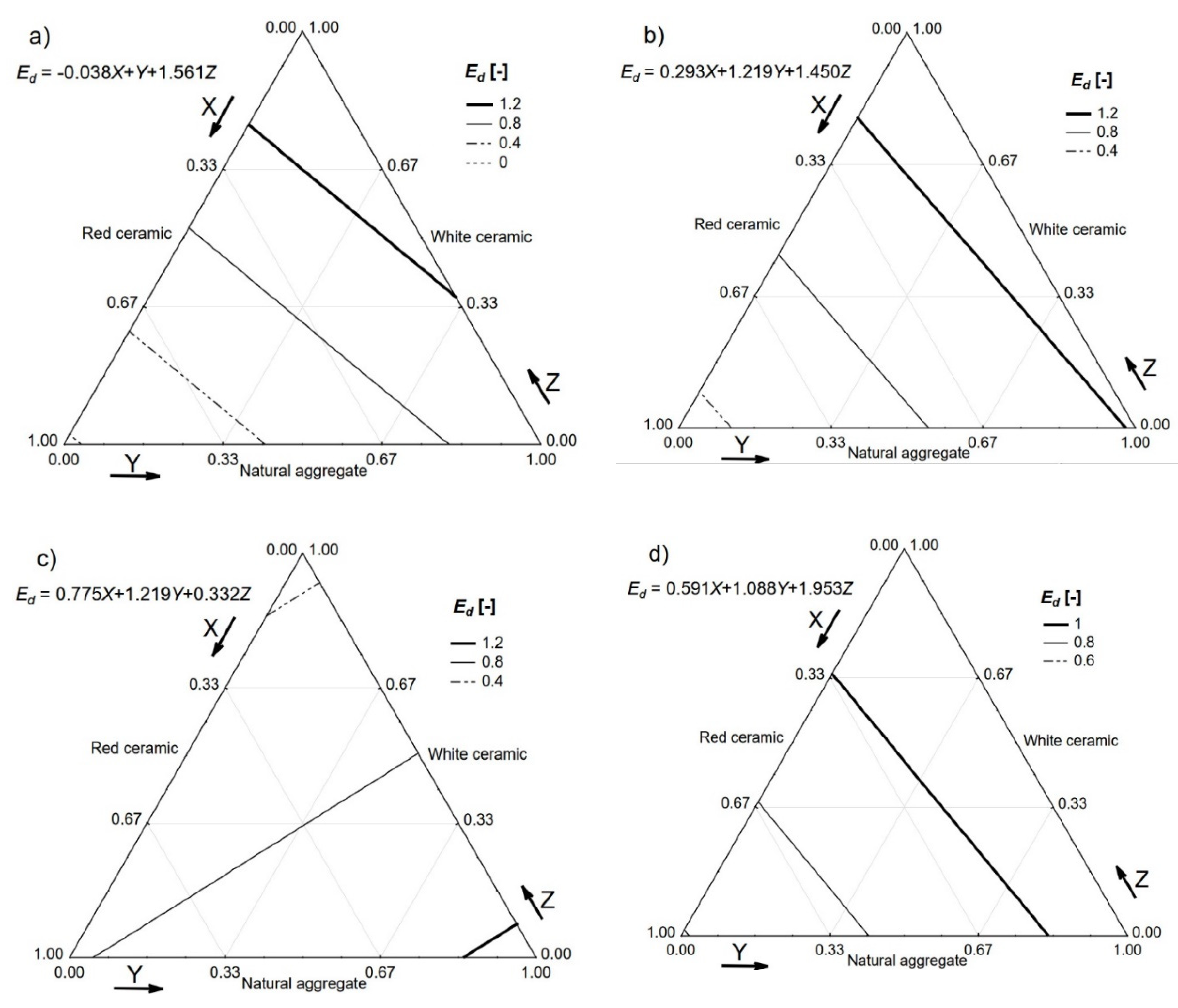

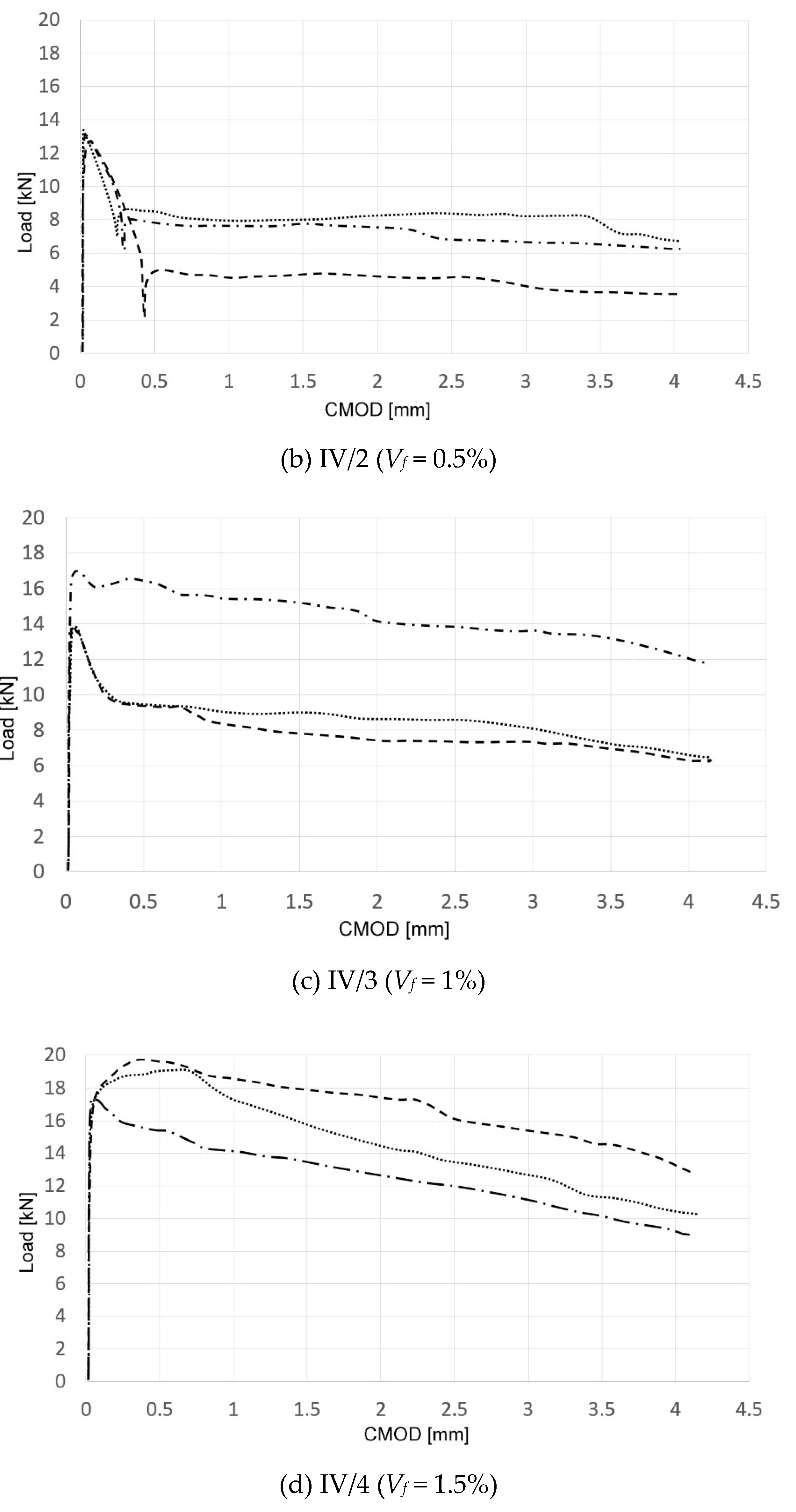

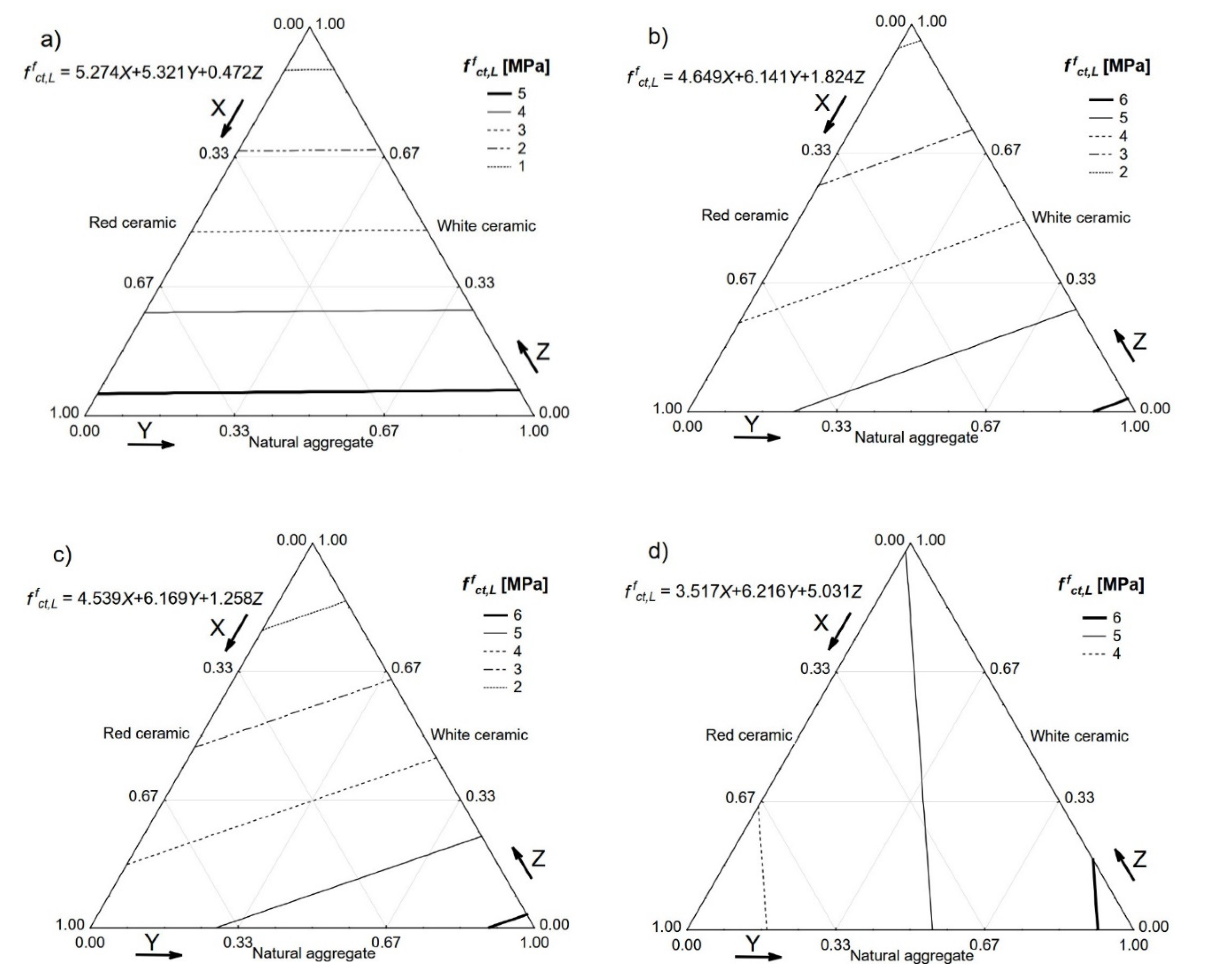

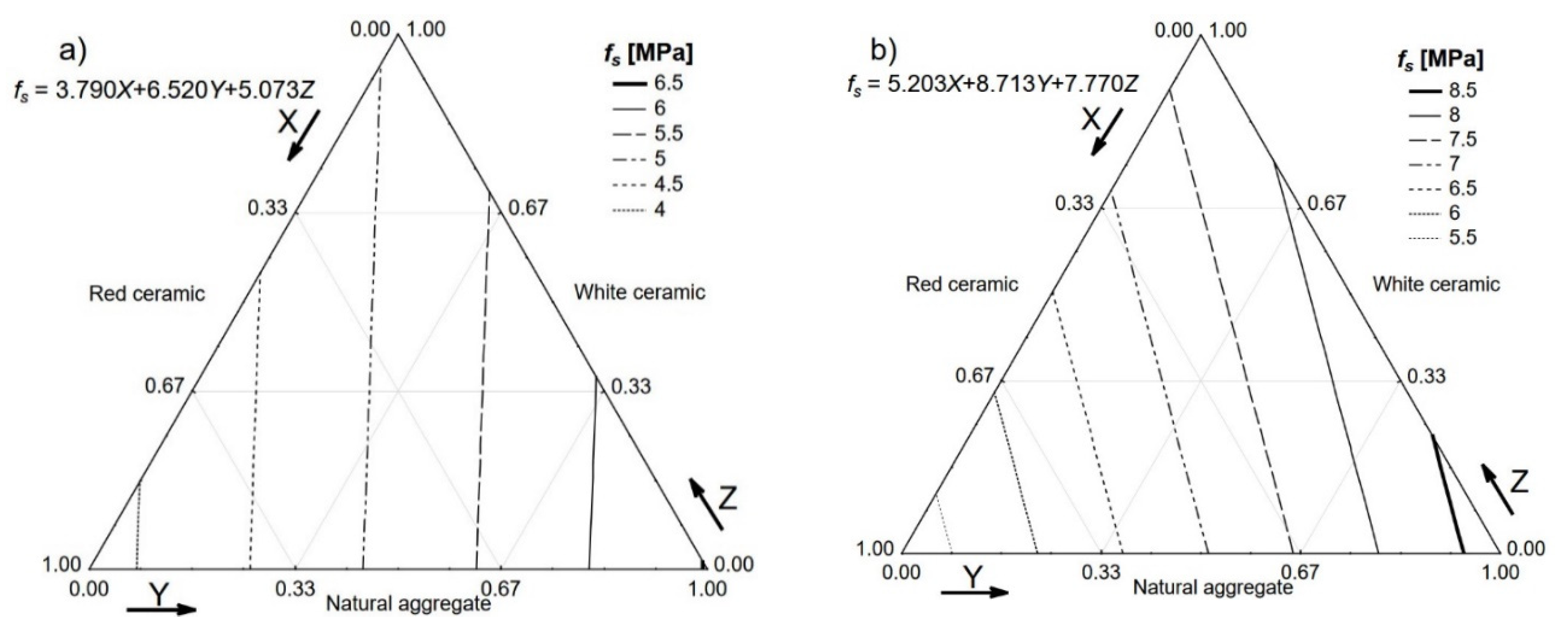

3. Experimental Design

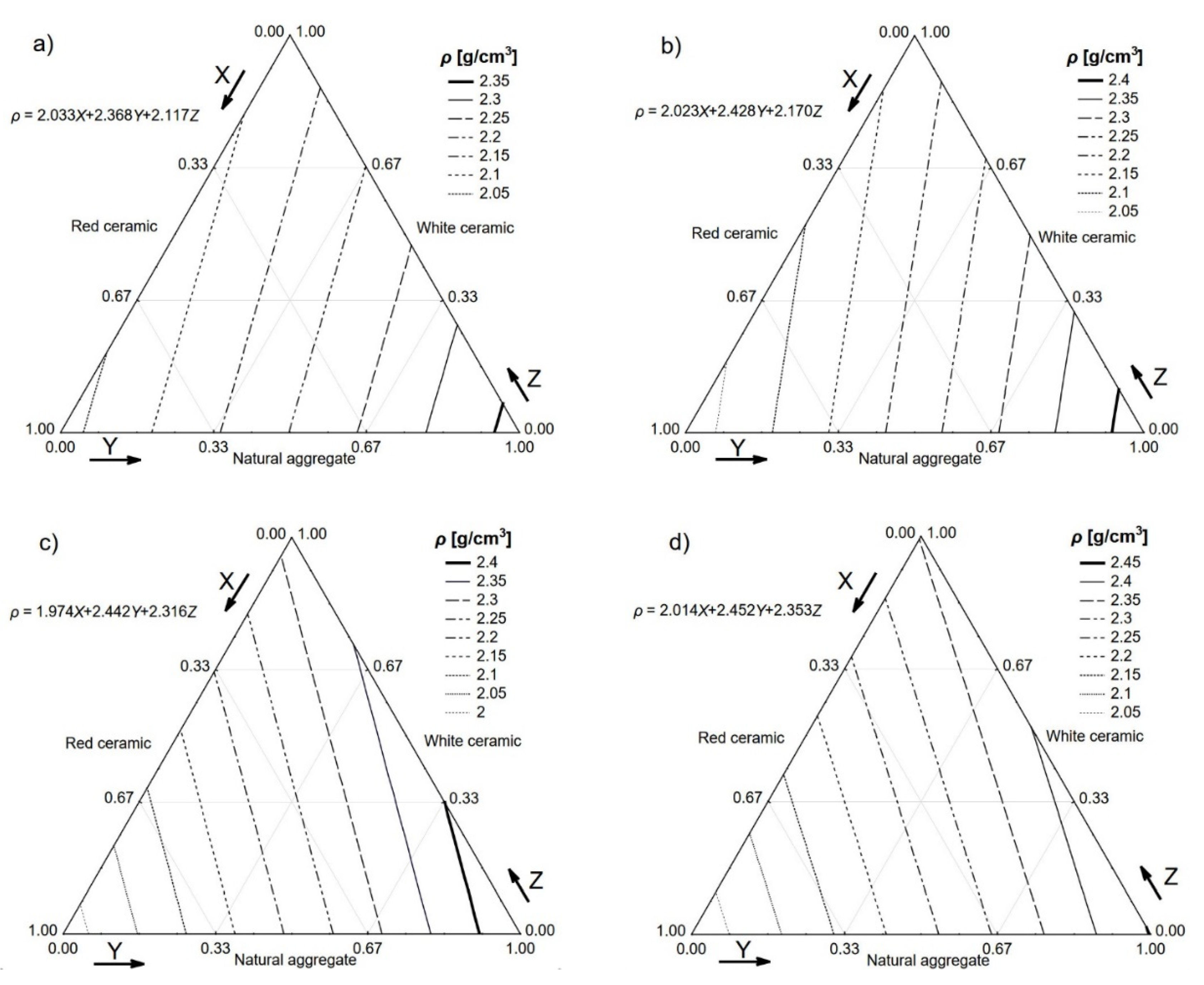

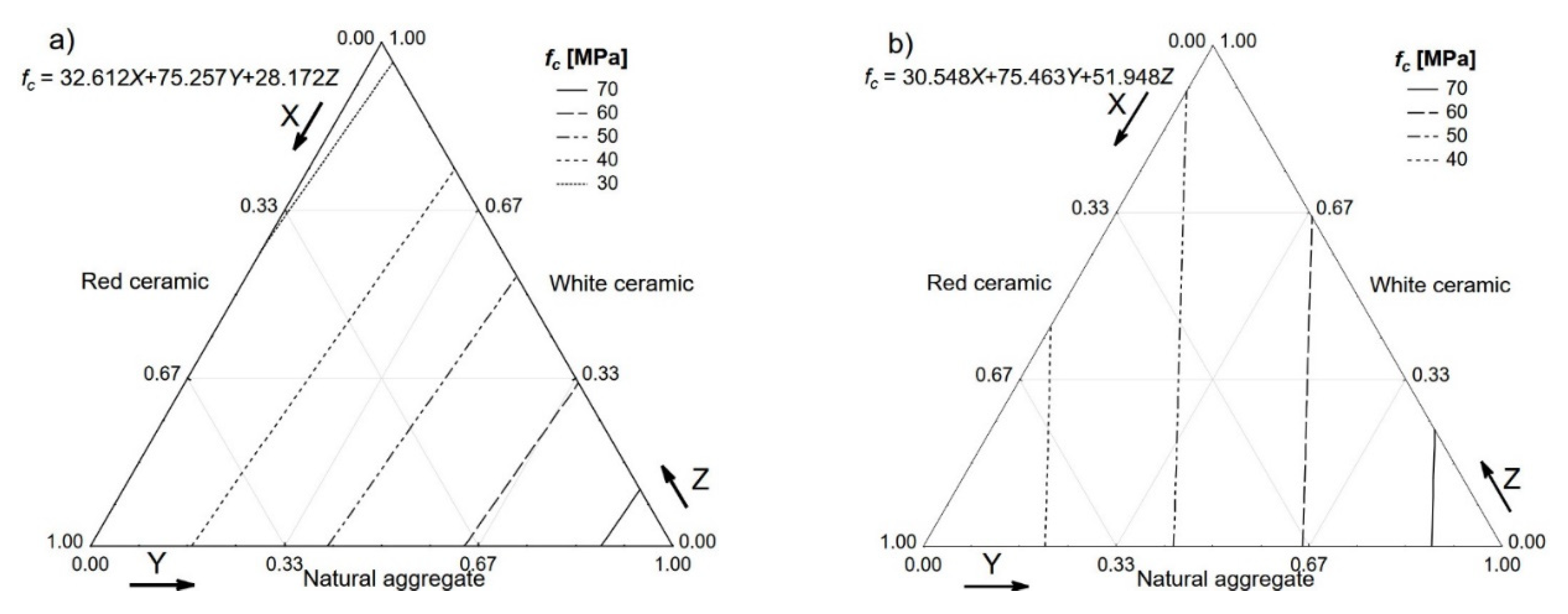

4. Results

5. Discussion

6. Conclusions

- It is possible to cast composites based on multiple waste aggregates;

- A blend of waste ceramic aggregates achieved a greater flexural strength of a cement composite than ordinary natural sand;

- The highest compressive strength was achieved using only natural aggregates;

- The compressive strength of the tested concretes was significantly influenced by the composition of the aggregate mix, as evidenced by the concrete with 1.5% fibre composition, whereby the values ranged from 17.5 MPa to 85.3 MPa;

- It is possible to partially or fully substitute natural aggregates with white or red ceramic wastes;

- The composites created on the basis of the white and red ceramic wastes are characterised by satisfactory mechanical properties, allowing for the assignment of standard strength classes according to both the EN and fib Model Code 2010;

- The research programme should be continued using greater specimens, focusing on more complicated mechanical characteristics (e.g., dynamic properties) of composites to enable full-scale modelling.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Awoyera, P.O.; Ndambuki, J.M.; Akinmusuru, J.O.; Omole, D.O. Characterization of ceramic waste aggregate concrete. HBRC J. 2018, 14, 282–287. [Google Scholar] [CrossRef] [Green Version]

- García-González, J.; Rodríguez-Robles, D.; Juan-Valdés, A.; Morán-Del Pozo, J.M.; Guerra-Romero, M.I. Ceramic ware waste as coarse aggregate for structural concrete production. Environ. Technol. 2015, 36, 3050–3059. [Google Scholar] [CrossRef] [PubMed]

- Rashid, K.; Razzaq, A.; Ahmad, M.; Rashid, T.; Tariq, S. Experimental and analytical selection of sustainable recycled concrete with ceramic waste aggregate. Constr. Build. Mater. 2017, 154, 829–840. [Google Scholar] [CrossRef]

- Katzer, J. Strength performance comparison of mortars made with waste fine aggregate and ceramic fume. Constr. Build. Mater. 2013, 47, 1–6. [Google Scholar] [CrossRef]

- Anderson, D.J.; Smith, S.T.; Au, F.T.K. Mechanical properties of concrete utilising waste ceramic as coarse aggregate. Constr. Build. Mater. 2016, 117, 20–28. [Google Scholar] [CrossRef]

- Elçi, H. Utilisation of crushed floor and wall tile wastes as aggregate in concrete production. J. Clean. Prod. 2016, 112, 742–752. [Google Scholar] [CrossRef]

- Shakir, A.A. The Use of Crushed Brick Waste for the Internal Curing In Cement Mortar. Muthanna J. Eng. Technol. 2017, 5, 16–21. [Google Scholar]

- De Brito, J.; Pereira, A.S.; Correia, J.R. Mechanical behaviour of non-structural concrete made with recycled ceramic aggregates. Cem. Concr. Compos. 2005, 27, 429–433. [Google Scholar] [CrossRef]

- Katzer, J.; Kobaka, J. The assessment of fine aggregate pit deposits for concrete production. Kuwait J. Sci. Eng. 2006, 33, 165–174. [Google Scholar]

- Bentz, D.P.; Ardani, A.; Barrett, T.; Jones, S.Z.; Lootens, D.; Peltz, M.A.; Sato, T.; Stutzman, P.E.; Tanesi, J.; Weiss, W.J. Multi-scale investigation of the performance of limestone in concrete. Constr. Build. Mater. 2015, 75, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Bektas, F.; Wang, X. Statistical mixture design of ternary blends for controlling ASR. Mag. Concr. Res. 2015, 67, 63–70. [Google Scholar] [CrossRef]

- Ponikiewski, T.; Katzer, J. Properties of fresh SCC mix reinforced by different types of steel and polymer fibre. Constr. Build. Mater. 2014, 62, 96–101. [Google Scholar] [CrossRef]

- Katzer, J.; Kobaka, J. Influence of fine aggregate grading on properties of cement composite. Silic. Ind. 2009, 74, 9–14. [Google Scholar]

- Katzer, J.; Kobaka, J. Harnessing waste fine aggregate for sustainable production of concrete precast elements. Rocz. Ochr. Srodowiska 2011, 12, 33–45. [Google Scholar]

- Katzer, J. Median diameter as a grading characteristic for fine aggregate cement composite designing. Constr. Build. Mater. 2012, 35, 884–887. [Google Scholar] [CrossRef]

- Katzer, J.; Kuźmińska, E. Optimal composition of blended waste ceramic aggregate. In Proceedings of the Sustainable Construction Materials and Technologies, Las Vegas, NV, USA, 7–11 August 2016. [Google Scholar]

- Domski, J.; Katzer, J.; Zakrzewski, M.; Ponikiewski, T. Comparison of the mechanical characteristics of engineered and waste steel fiber used as reinforcement for concrete. J. Clean. Prod. 2017, 158. [Google Scholar] [CrossRef]

- Zarzycki, P.K.; Katzer, J.; Domski, J. Fast classification of fibres for concretebased on multivariate statistics. Comput. Concr. 2017, 20, 23–29. [Google Scholar]

- Hornakova, M.; Katzer, J.; Kobaka, J.; Konecny, P. Lightweight SFRC Benefitting from a Pre-Soaking and Internal Curing Process. Materials 2019, 12, 4152. [Google Scholar] [CrossRef] [Green Version]

- Naaman, A.E. Engineered Steel Fibers with Optimal Properties for Reinforcement of Cement Composites. J. Adv. Concr. Technol. 2003, 1, 241–252. [Google Scholar] [CrossRef] [Green Version]

- Bayramov, F.; Taşdemir, C.; Taşdemir, M.A. Optimisation of steel fibre reinforced concretes by means of statistical response surface method. Cem. Concr. Compos. 2004, 26, 665–675. [Google Scholar] [CrossRef]

- Mann, H.B. Analysis and Design of Experiments; Dover Publications Inc.: New York, NY, USA, 1949. [Google Scholar]

- Shenk, H. Theories of Engineering Experimentation; Third Edition, CRC Press: Cleveland, OH, USA, 1979. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education Limited: Harlow, UK, 2011; ISBN 978-0-273-75580-7. [Google Scholar]

- Katzer, J.; Kobaka, J. Combined non-destructive testing approach to waste fine aggregate cement composites. Sci. Eng. Compos. Mater. 2009, 16, 277–284. [Google Scholar] [CrossRef]

- Maidl, B. Steel Fibre Reinforced Concrete; Ernst & Sohn: Berlin, Germany, 1995; ISBN 978-3433012888. [Google Scholar]

- Bajgirani, A.G.; Moghadam, S.; Tafreshi, S.T.; Arbab, A.; Razeghi, H. The Influence of aspect ratio of steel fibers on the mechanical properties of concrete. In Proceedings of the 3rd International Conference on Research in Civil Engineering, Architecture, Urban Planning & Sustainable Environment, Istanbul, Turkey, 2 June 2016. [Google Scholar]

- Kheder, G.F. Two stage procedure for assessment of in situ concrete strength using combined non-destructive testing. Mater. Struct. Constr. 1999, 32, 410–417. [Google Scholar] [CrossRef]

- Qasrawi, H.Y. Concrete strength by combined nondestructive methods simply and reliably predicted. Cem. Concr. Res. 2000, 30, 739–746. [Google Scholar] [CrossRef]

- Hassan, M.; Burdet, O.; Favre, R. Ultrasonic measurements and static load tests in bridge evaluation. NDT E Int. 1995, 28, 331–337. [Google Scholar] [CrossRef]

- Komloš, K.; Popovics, S.; Nürnbergerová, T.; Babál, B.; Popovics, J.S. Ultrasonic pulse velocity test of concrete properties as specified in various standards. Cem. Concr. Compos. 1996, 18, 357–364. [Google Scholar] [CrossRef]

- Di Prisco, M.; Plizzari, G.; Vandewalle, L. Fibre reinforced concrete: New design perspectives. Mater. Struct. 2009, 42, 1261–1281. [Google Scholar] [CrossRef]

- Di Prisco, M.; Colombo, M.; Dozio, D. Fibre-reinforced concrete in fib Model Code 2010: Principles, models and test validation. Struct. Concr. 2013, 14, 342–361. [Google Scholar] [CrossRef]

- Sykora, M.; Krejsa, J.; Mlcoch, J.; Prieto, M.; Tanner, P. Uncertainty in shear resistance models of reinforced concrete beams according to fib MC2010. Struct. Concr. 2018, 19, 284–295. [Google Scholar] [CrossRef] [Green Version]

| Sieves (mm) | Passing (%) | ||

|---|---|---|---|

| Natural | Red Ceramic | White Ceramic | |

| 0.000–0.125 | 1.0 | 7.0 | 3.0 |

| 0.125–0.250 | 6.0 | 17.0 | 10.0 |

| 0.250–0.500 | 18.5 | 25.5 | 16.0 |

| 0.500–1.000 | 27.0 | 32.0 | 25.0 |

| 1.000–2.000 | 36.0 | 40.0 | 39.0 |

| 2.000–4.000 | 55.0 | 52.0 | 55.5 |

| 4.000–8.000 | 77.0 | 70.0 | 77.0 |

| 8.000–16.00 | 100.0 | 100.0 | 100.0 |

| dm (mm) | 3.47 | 3.67 | 3.33 |

| mK (-) | 5.795 | 5.565 | 5.744 |

| mH (-) | 141.850 | 134.950 | 140.323 |

| mA (-) | 4.715 | 4.485 | 4.664 |

| ρ (kg/m3) | 2650 | 1690 | 2400 |

| Absorbability (%) | - | 16.8 | 0.0 |

| Freeze–thaw resistance (%) of mass loss | 0.06 | 0.17 | 0.01 |

| Abrasion resistance (%) of LA mass loss | 24 | 44 | 24.5 |

| Dimensions (mm) | FIER * | l/d | Density | Ultimate Tensile Strength | |

|---|---|---|---|---|---|

| Length (l) | Diameter (d) | (-) | (-) | (kg/m3) | (GPa) |

| 30.8 | 0.73 | 169.4 | 42.3 | 7800 | 1.7 ± 0.3 |

| Mix No. | Aggregate (%) | ||

|---|---|---|---|

| Natural Aggregate | White Ceramic Waste | Red Ceramic Waste | |

| I | 100 | 0 | 0 |

| II | 0 | 33 | 67 |

| III | 67 | 33 | 0 |

| IV | 34 | 33 | 33 |

| Type of Test | Specimen Shape (cm) | Number of Specimens | Standard | |

|---|---|---|---|---|

| In One Test | Total | |||

| Density | Cube 15 × 15 × 15 Beam 70 × 15 × 15 | 3 3 | 96 | EN 12390-7:2011 * |

| Compression strength | Cube 15 × 15 × 15 | 3 | 48 | EN 12390-3:2011 * |

| Shear strength | Beam 70 × 15 × 15 | 3 | 48 | JCI-SF6:1984 ** |

| Ultrasound propagation velocity | Beam 70 × 15 × 15 | 3 | 48 | EN 12504-4:2005 * |

| Dynamic modulus of elasticity *** | Beam 70 × 15 × 15 | 3 | 48 | EN 12504-4:2005 * |

| Flexural strength: LOP (limit of proportionality) | Beam 70 × 15 × 15 | 3 | 48 | EN 14651:2007 * |

| Concrete Symbol | fR3/fR1 | fR1/fLOP | fLOP (MPa) | Strength Class | Reinforcement Substitution |

|---|---|---|---|---|---|

| I | 0.783 | 0.978 | 6.216 | 6.0b | Enabled |

| II | 0.696 | 0.597 | 3.653 | 3.0a | Enabled |

| III | 0.788 | 1.005 | 5.452 | 5.0b | Enabled |

| IV | 0.761 | 1.027 | 5.658 | 5.0b | Enabled |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Katzer, J.; Kobaka, J.; Ponikiewski, T. Influence of Crimped Steel Fibre on Properties of Concrete Based on an Aggregate Mix of Waste and Natural Aggregates. Materials 2020, 13, 1906. https://doi.org/10.3390/ma13081906

Katzer J, Kobaka J, Ponikiewski T. Influence of Crimped Steel Fibre on Properties of Concrete Based on an Aggregate Mix of Waste and Natural Aggregates. Materials. 2020; 13(8):1906. https://doi.org/10.3390/ma13081906

Chicago/Turabian StyleKatzer, Jacek, Janusz Kobaka, and Tomasz Ponikiewski. 2020. "Influence of Crimped Steel Fibre on Properties of Concrete Based on an Aggregate Mix of Waste and Natural Aggregates" Materials 13, no. 8: 1906. https://doi.org/10.3390/ma13081906

APA StyleKatzer, J., Kobaka, J., & Ponikiewski, T. (2020). Influence of Crimped Steel Fibre on Properties of Concrete Based on an Aggregate Mix of Waste and Natural Aggregates. Materials, 13(8), 1906. https://doi.org/10.3390/ma13081906