High Functionality Bio-Polyols from Tall Oil and Rigid Polyurethane Foams Formulated Solely Using Bio-Polyols

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

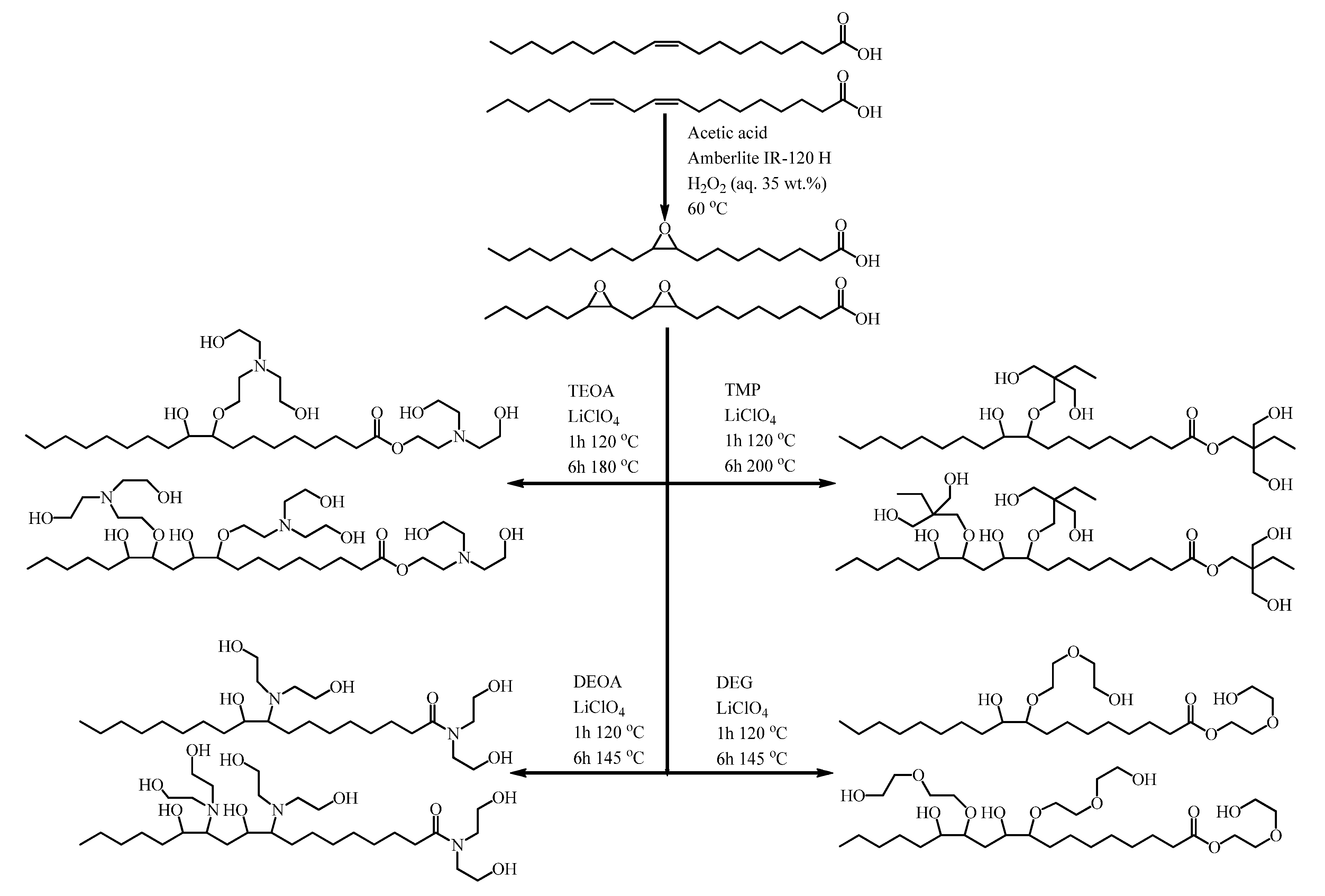

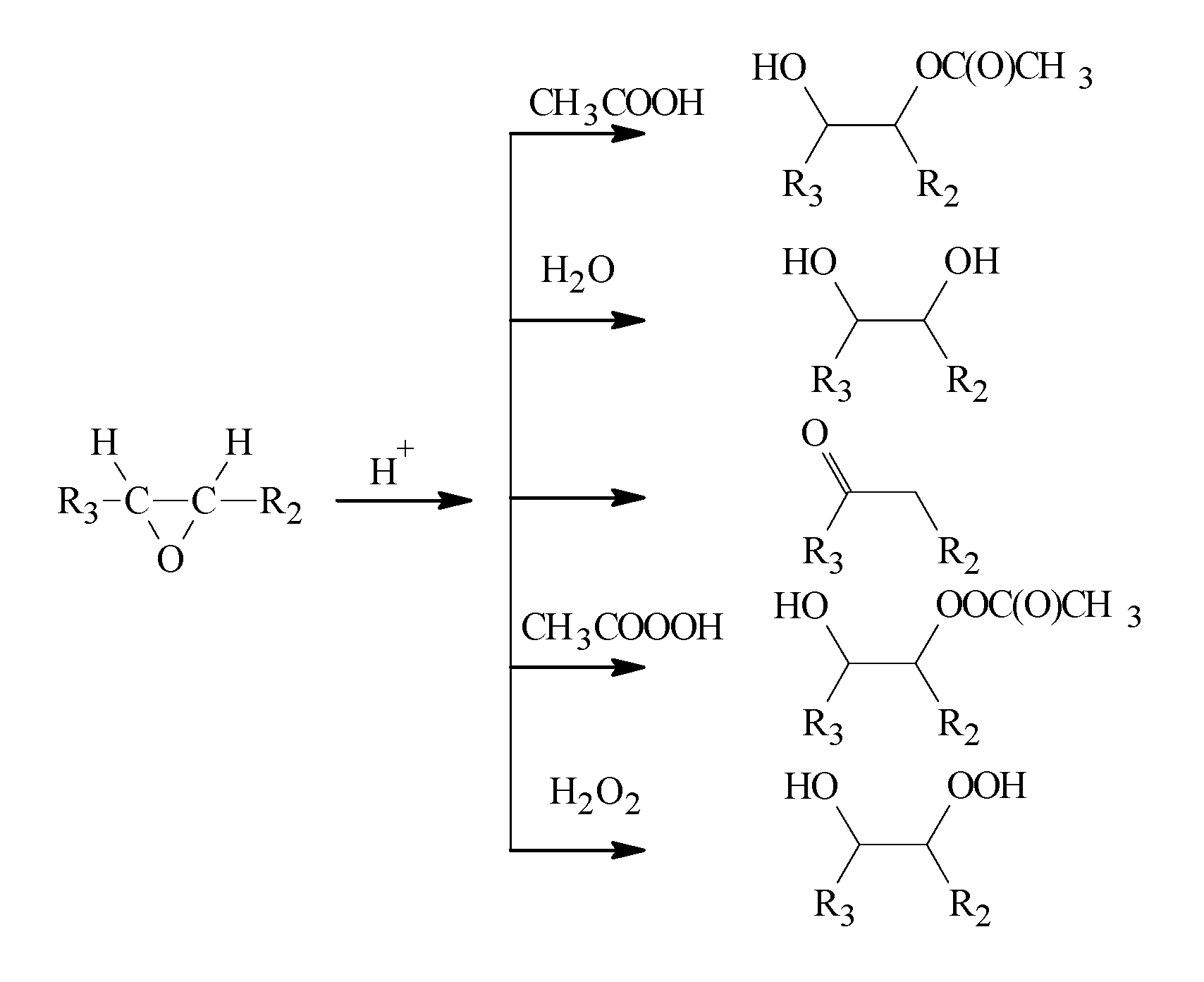

2.2. Epoxidation of Tall Oil Fatty Acids

2.3. Synthesis of Polyols

2.4. Characterization of Polyols and Their Precursors

2.5. Rigid PU Foam Development and Formulation Optimization

3. Results and Discussion

3.1. Characterization of Synthesized TOFA-Based Bio-Polyols

3.2. Characterization of the Chemical Structure of Synthesized Bio-Polyols Using FTIR

3.3. Development of ETOFA_TMP Polyol Based Rigid PU Foam

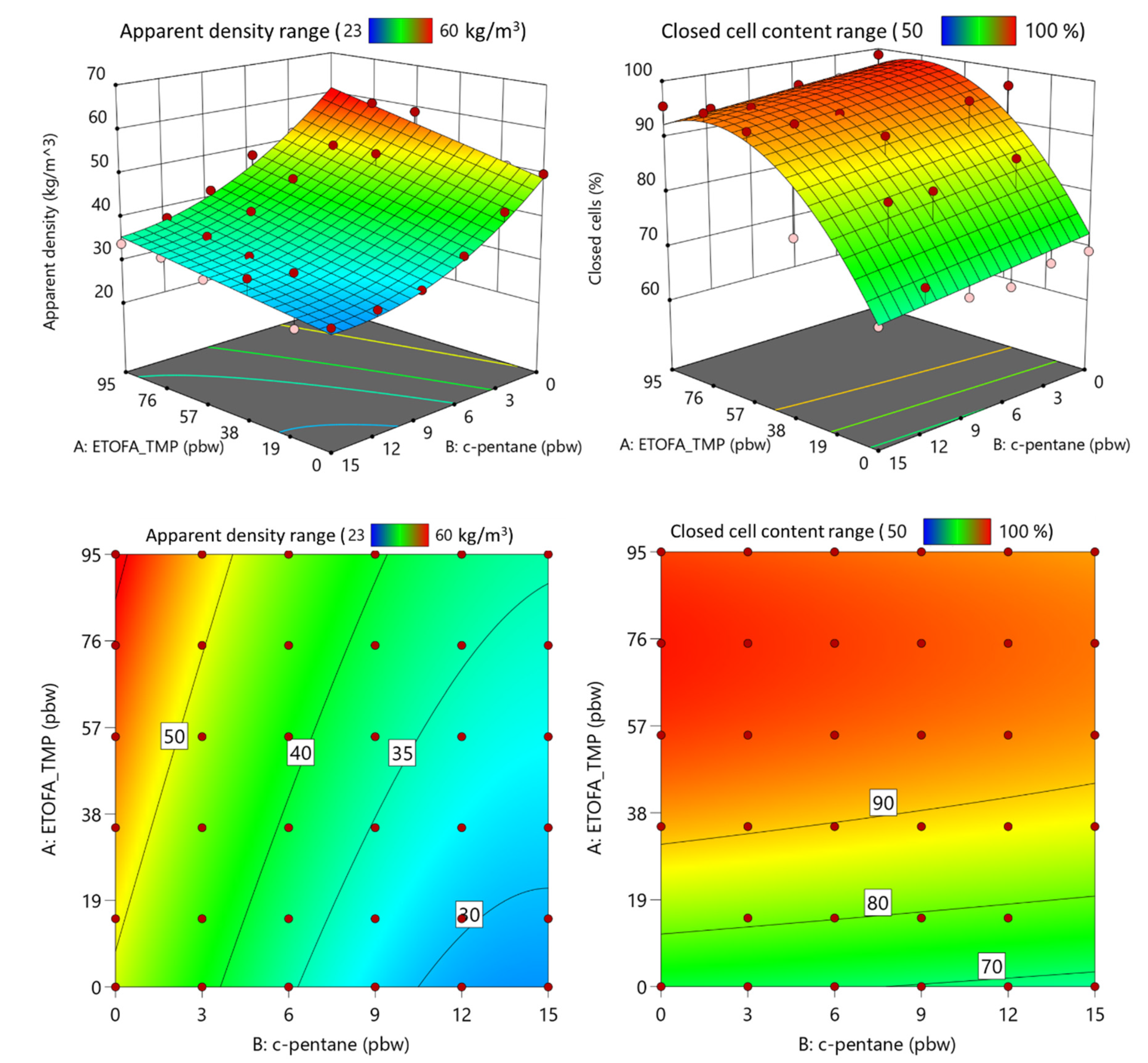

3.4. Optimization of Developed Rigid PU Foam Formulations

3.5. Development of Rigid PU Foam Thermal Insulation Using Optimized Formulations

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Sikdar, S. Circular economy: Is there anything new in this concept? Clean Technol. Environ. Policy 2019, 21, 1173–1175. [Google Scholar] [CrossRef]

- Alagi, P.; Hong, S.C. Vegetable oil-based polyols for sustainable polyurethanes. Macromol. Res. 2015, 23, 1079–1086. [Google Scholar] [CrossRef]

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes; Rapra Technology: Shropshire, UK, 2005; ISBN 9781859575017. [Google Scholar]

- Li, Y.Y.; Luo, X.; Hu, S. Bio-Based Polyols and Polyurethanes; Sharma, S.K., Ed.; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 9783319215396. [Google Scholar]

- Noreen, A.; Zia, K.M.; Zuber, M.; Tabasum, S.; Zahoor, A.F. Bio-based polyurethane: An efficient and environment friendly coating systems: A review. Prog. Org. Coatings 2016, 91, 25–32. [Google Scholar] [CrossRef]

- Lomège, J.; Negrell, C.; Robin, J.J.; Lapinte, V.; Caillol, S. Oleic acid-based poly(alkyl methacrylate) as bio-based viscosity control additive for mineral and vegetable oils. Polym. Eng. Sci. 2019, 59, E164–E170. [Google Scholar] [CrossRef]

- Foreign Agricultural Service. United States Department of Agriculture Report: Oilseeds: World Markets and Trade; Foreign Agricultural Service: Washington, DC, USA, 2019.

- Lawson, H.; Lawson, H. The Basic Chemistry of Oils and Fats. In Food Oils and Fats: Technology, Utilization, and Nutrition; Springer: Boston, MA, USA, 1995; pp. 3–14. ISBN 978-1-4757-2351-9. [Google Scholar]

- Hubertus, G. OECD-FAO Agricultural Outlook 2019–2028; OECD Publishing: Paris, France, 2019; pp. 1–326. [Google Scholar]

- Poku, A.-G. Governance of Emerging Biomass-Based Value Webs in Africa: Case Studies from Ghana. Ph.D. Thesis, University of Hohenheim, Stuttgart, Germany.

- Maisonneuve, L.; Chollet, G.; Grau, E.; Cramail, H. Vegetable oils: A source of polyols for polyurethane materials. OCL—Oilseeds Fats Crop. Lipids 2016, 23, 10. [Google Scholar] [CrossRef]

- Hachemi, I.; Kumar, N.; Mäki-Arvela, P.; Roine, J.; Peurla, M.; Hemming, J.; Salonen, J.; Murzin, D.Y. Sulfur-free Ni catalyst for production of green diesel by hydrodeoxygenation. J. Catal. 2017, 347, 205–221. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Tall oil production from black liquor: Challenges and opportunities. Sep. Purif. Technol. 2017, 175, 469–480. [Google Scholar] [CrossRef]

- Ren, H.; Xin, D.; Omori, S. Preparation of Biodiesel and Separation of Hemicellulose from Soap Skimmings. Cellul. Chem. Technol. 2016, 50, 247–255. [Google Scholar]

- Himadri Panda. Handbook on Tall Oil Rosin Production, Processing and Utilization; Asia Pacific Business Press: Delhi, India, 2013. [Google Scholar]

- Lubguban, A.A.; Ruda, R.J.G.; Aquiatan, R.H.; Paclijan, S.; Magadan, K.O.; Balangao, J.K.B.; Escalera, S.T.; Bayron, R.R.; Debalucos, B.; Lubguban, A.A.; et al. Soy-Based Polyols and Polyurethanes. KIMIKA 2017, 28, 1–19. [Google Scholar] [CrossRef]

- Omrani, I.; Farhadian, A.; Babanejad, N.; Shendi, H.K.; Ahmadi, A.; Nabid, M.R. Synthesis of novel high primary hydroxyl functionality polyol from sunflower oil using thiol-yne reaction and their application in polyurethane coating. Eur. Polym. J. 2016, 82, 220–231. [Google Scholar] [CrossRef]

- Fridrihsone-Girone, A.; Stirna, U.; Misane, M.; Lazdiņa, B.; Deme, L. Spray-applied 100% volatile organic compounds free two component polyurethane coatings based on rapeseed oil polyols. Prog. Org. Coatings 2016, 94, 90–97. [Google Scholar] [CrossRef]

- Alagi, P.; Ghorpade, R.; Jang, J.H.; Patil, C.; Jirimali, H.; Gite, V.; Hong, S.C. Functional soybean oil-based polyols as sustainable feedstocks for polyurethane coatings. Ind. Crops Prod. 2018, 113, 249–258. [Google Scholar] [CrossRef]

- Pfister, D.P.; Xia, Y.; Larock, R.C. Recent advances in vegetable oil-based polyurethanes. ChemSusChem 2011, 4, 703–717. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.D.H.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications-a review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Furtwengler, P.; Avérous, L. Renewable polyols for advanced polyurethane foams from diverse biomass resources. Polym. Chem. 2018, 9, 4258–4287. [Google Scholar] [CrossRef]

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes; Rapra Technology: Shropshire, UK, 2007; Volume 56, ISBN 9781847350350. [Google Scholar]

- Cornille, A.; Auvergne, R.; Figovsky, O.; Boutevin, B.; Caillol, S. A perspective approach to sustainable routes for non-isocyanate polyurethanes. Eur. Polym. J. 2017, 87, 535–552. [Google Scholar] [CrossRef]

- Zhang, C.; Ding, R.; Kessler, M.R. Reduction of epoxidized vegetable oils: A novel method to prepare bio-based polyols for polyurethanes. Macromol. Rapid Commun. 2014, 35, 1068–1074. [Google Scholar] [CrossRef]

- Kirpluks, M.; Kalnbunde, D.; Walterova, Z.; Cabulis, U. Rapeseed Oil as Feedstock for High Functionality Polyol Synthesis. J. Renew. Mater. 2017, 5, 1–23. [Google Scholar] [CrossRef]

- Zhou, W.; Jia, P.; Zhou, Y.; Zhang, M. Preparation and characterization of tung oil-based flame retardant polyols. Chin. J. Chem. Eng. 2018, 26, 2664–2671. [Google Scholar] [CrossRef]

- Kirpluks, M.; Kalnbunde, D.; Benes, H.; Cabulis, U. Natural oil based highly functional polyols as feedstock for rigid polyurethane foam thermal insulation. Ind. Crops Prod. 2018, 122, 627–636. [Google Scholar] [CrossRef]

- Kirpluks, M.; Vanags, E.; Abolins, A.; Fridrihsone, A.; Cabulis, U. Chemo-enzymatic oxidation of tall oil fatty acids as a precursor for further polyol production. J. Clean. Prod. 2019, 215, 390–398. [Google Scholar] [CrossRef]

- Fang, Z.; Qiu, C.; Ji, D.; Yang, Z.; Zhu, N.; Meng, J.; Hu, X.; Guo, K. Development of High-Performance Biodegradable Rigid Polyurethane Foams Using Full Modified Soy-Based Polyols. J. Agric. Food Chem. 2019, 67, 2220–2226. [Google Scholar] [CrossRef] [PubMed]

- Prociak, A.; Malewska, E.; Kurańska, M.; Bąk, S.; Budny, P. Flexible polyurethane foams synthesized with palm oil-based bio-polyols obtained with the use of different oxirane ring opener. Ind. Crops Prod. 2018, 115, 69–77. [Google Scholar] [CrossRef]

- Saalah, S.; Abdullah, L.C.; Aung, M.M.; Salleh, M.Z.; Biak, D.R.A.; Basri, M.; Jusoh, E.R.; Mamat, S. Physicochemical Properties of jatropha oil-based polyol produced by a two steps method. Molecules 2017, 22, 551. [Google Scholar] [CrossRef] [PubMed]

- Kurańska, M.; Prociak, A.; Kirpluks, M.; Cabulis, U. Polyurethane-polyisocyanurate foams modified with hydroxyl derivatives of rapeseed oil. Ind. Crops Prod. 2015, 74, 849–857. [Google Scholar] [CrossRef]

- Saalah, S.; Abdullah, L.C.; Aung, M.M.; Salleh, M.Z.; Awang Biak, D.R.; Basri, M.; Jusoh, E.R. Waterborne polyurethane dispersions synthesized from jatropha oil. Ind. Crops Prod. 2015, 64, 194–200. [Google Scholar] [CrossRef]

- Abril-Milán, D.; Valdés, O.; Mirabal-Gallardo, Y.; de la Torre, A.F.; Bustamante, C.; Contreras, J. Preparation of renewable bio-polyols from two species of Colliguaja for Rigid polyurethane foams. Materials 2018, 11, 2244. [Google Scholar] [CrossRef]

- Sawpan, M.A. Polyurethanes from vegetable oils and applications: A review. J. Polym. Res. 2018, 25, 184. [Google Scholar] [CrossRef]

- Ghasemlou, M.; Daver, F.; Ivanova, E.P.; Adhikari, B. Polyurethanes from seed oil-based polyols: A review of synthesis, mechanical and thermal properties. Ind. Crops Prod. 2019, 142, 111841. [Google Scholar] [CrossRef]

- Arniza, M.Z.; Hoong, S.S.; Idris, Z.; Yeong, S.K.; Hassan, H.A.; Din, A.K.; Choo, Y.M. Synthesis of transesterified palm olein-based Polyol and rigid polyurethanes from this polyol. JAOCS J. Am. Oil Chem. Soc. 2015, 92, 243–255. [Google Scholar] [CrossRef]

- Hong, J.; Radojčić, D.; Yang, X.; Wan, X.; Petrović, Z.S. Tough thermosetting polyurethanes and adhesives from rubber seed oil by hydroformylation. J. Appl. Polym. Sci. 2020, 137, 48509. [Google Scholar] [CrossRef]

- Ourique, P.A.; Gril, J.M.L.; Guillaume, G.W.; Wanke, C.H.; Echeverrigaray, S.G.; Bianchi, O. Synthesis and characterization of the polyols by air oxidation of soybean oil and its effect on the morphology and dynamic mechanical properties of poly(vinyl chloride) blends. J. Appl. Polym. Sci. 2015, 132, 1–8. [Google Scholar] [CrossRef]

- Elbers, N.; Ranaweera, C.K.; Ionescu, M.; Wan, X.; Kahol, P.K.; Gupta, R.K. Synthesis of Novel Biobased Polyol via Thiol-Ene Chemistry for Rigid Polyurethane Foams. J. Renew. Mater. 2017, 5, 74–83. [Google Scholar] [CrossRef]

- Alagi, P.; Choi, Y.J.; Seog, J.; Hong, S.C. Efficient and quantitative chemical transformation of vegetable oils to polyols through a thiol-ene reaction for thermoplastic polyurethanes. Ind. Crops Prod. 2016, 87, 78–88. [Google Scholar] [CrossRef]

- Yang, Z.; Feng, Y.; Liang, H.; Yang, Z.; Yuan, T.; Luo, Y.; Li, P.; Zhang, C. A Solvent-Free and Scalable Method to Prepare Soybean-Oil-Based Polyols by Thiol-Ene Photo-Click Reaction and Biobased Polyurethanes Therefrom. ACS Sustain. Chem. Eng. 2017, 5, 7365–7373. [Google Scholar]

- Tahir, S.M.; Norfirdaus, W.; Salleh, W.; Syahamatun, N.; Hadid, N.; Enderus, N.F. Synthesis of Waste Cooking Oil-Based Polyol Using Sugarcane Bagasse Activated Carbon and Transesterification Reaction for Rigid Polyurethane Foam. Mater. Sci. 2016, 846, 690–696. [Google Scholar]

- Gaidukova, G.; Ivdre, A.; Fridrihsone, A.; Verovkins, A.; Cabulis, U.; Gaidukovs, S. Polyurethane rigid foams obtained from polyols containing bio-based and recycled components and functional additives. Ind. Crops Prod. 2017, 102, 133–143. [Google Scholar] [CrossRef]

- Unverferth, M.; Meier, M.A.R. A sustainable tandem catalysis approach to plant oil based polyols via Schenck-Ene reaction and epoxidation. Eur. J. Lipid Sci. Technol. 2018, 120, 1800015. [Google Scholar] [CrossRef]

- Bayer, P.; Pérez-Ruiz, R.; Von Wangelin, A. Stereoselective Photooxidations by the Schenck Ene Reaction. ChemPhotoChem 2018, 2, 559–570. [Google Scholar] [CrossRef]

- Llevot, A.; Dannecker, P.K.; von Czapiewski, M.; Over, L.C.; Söyler, Z.; Meier, M.A.R. Renewability is not Enough: Recent Advances in the Sustainable Synthesis of Biomass-Derived Monomers and Polymers. Chem.-A Eur. J. 2016, 22, 11510–11521. [Google Scholar] [CrossRef]

- Szycher, M. Szycher’s Handbook of Polyurethanes, 1st ed.; CRC Press: Boca Raton, FL, USA, 1999; ISBN 9780849306020. [Google Scholar]

- Marcovich, N.E.; Kurańska, M.; Prociak, A.; Malewska, E.; Kulpa, K. Open cell semi-rigid polyurethane foams synthesized using palm oil-based bio-polyol. Ind. Crops Prod. 2017, 102, 88–96. [Google Scholar] [CrossRef]

- Rojek, P.; Prociak, A. Effect of different rapeseed-oil-based polyols on mechanical properties of flexible polyurethane foams. J. Appl. Polym. Sci. 2012, 125, 2936–2945. [Google Scholar] [CrossRef]

- Kurańska, M.; Prociak, A. The influence of rapeseed oil-based polyols on the foaming process of rigid polyurethane foams. Ind. Crops Prod. 2016, 89, 182–187. [Google Scholar] [CrossRef]

- Kairytė, A.; Kremensas, A.; Balčiūnas, G.; Członka, S.; Strąkowska, A. Closed Cell Rigid Polyurethane Foams Based on Low Functionality Polyols: Research of Dimensional Stability and Standardised Performance Properties. Materials 2020, 13, 1438. [Google Scholar] [CrossRef] [PubMed]

- Leng, W.; Pan, B. Thermal Insulating and Mechanical Properties of Cellulose Nanofibrils Modified Polyurethane Foam Composite as Structural Insulated Material. Forests 2019, 10, 200. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Kuranska, M.; Prociak, A. Porous polyurethane composites with natural fibres. Compos. Sci. Technol. 2012, 72, 299–304. [Google Scholar] [CrossRef]

- Tan, S.; Abraham, T.; Ference, D.; Macosko, C.W. Rigid polyurethane foams from a soybean oil-based Polyol. Polymer 2011, 52, 2840–2846. [Google Scholar] [CrossRef]

- Zhang, X.; Kim, Y.; Eberhardt, T.L.; Shmulsky, R. Lab-scale structural insulated panels with lignin-incorporated rigid polyurethane foams as core. Ind. Crops Prod. 2019, 132, 292–300. [Google Scholar] [CrossRef]

- Ivdre, A.; Abolins, A.; Sevastyanova, I.; Kirpluks, M.; Cabulis, U. Rigid Polyurethane Foams with Various Isocyanate Indices Based on Polyols from Rapeseed Oil and PET waste. Polymers 2020, 12, 738. [Google Scholar] [CrossRef]

- Kurańska, M.; Cabulis, U.; Auguścik, M.; Prociak, A.; Ryszkowska, J.; Kirpluks, M. Bio-Based Polyurethane-Polyisocyanurate Composites with an Intumescent Flame Retardant. Polym. Degrad. Stab. 2016, 127, 11–19. [Google Scholar] [CrossRef]

- Cabulis, U.; Kirpluks, M.; Stirna, U.; Lopez, M.J.J.; Vargas-Garcia, M.C.D.C.D.C.; Suarez-Estrella, F.; Moreno, J.; Del Carmen Vargas-Garcia, M.; Suárez-Estrella, F.; Moreno, J.; et al. Rigid polyurethane foams obtained from tall oil and filled with natural fibers: Application as a support for immobilization of lignin-degrading microorganisms. J. Cell. Plast. 2012, 48, 500–515. [Google Scholar] [CrossRef]

- Kirpluks, M.; Cabulis, U.; Zeltins, V.; Stiebra, L.; Avots, A. Rigid polyurethane foam thermal insulation protected with mineral intumescent mat. Autex Res. J. 2014, 14, 259–269. [Google Scholar] [CrossRef]

- Hejna, A.; Kirpluks, M.; Kosmela, P.; Cabulis, U.; Haponiuk, J.; Piszczyk, Ł. The influence of crude glycerol and castor oil-based polyol on the structure and performance of rigid polyurethane-polyisocyanurate foams. Ind. Crops Prod. 2017, 95, 113–125. [Google Scholar] [CrossRef]

- Vanags, E.; Kirpluks, M.; Cabulis, U.; Walterova, Z. Highly functional polyol synthesis from epoxidized tall oil fatty acids. J. Renew. Mater. 2018, 6, 764–771. [Google Scholar] [CrossRef]

- BASF Technical Data Sheet; Lupranol 3422; BASF Polyurethanes GmbH: Lemförde, Germany, 17 July 2019.

- Stirna, U.; Fridrihsone, A.; Misane, M.; Vilsone, D.; State, L.; Chemistry, W. Rapeseed Oil as Renewable Resource for Polyol Synthesis. Environ. Clim. Technol. 2011, 6, 85–90. [Google Scholar] [CrossRef]

- Myers, R.H.; Monthgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments, 4th ed.; Taylor Francis Group: Hoboken, NJ, USA, 2016; ISBN 9781118916018. [Google Scholar]

- Kairytė, A.; Kirpluks, M.; Ivdre, A.; Cabulis, U.; Vaitkus, S.; Pundienė, I. Cleaner production of polyurethane foam: Replacement of conventional raw materials, assessment of fire resistance and environmental impact. J. Clean. Prod. 2018, 183, 760–771. [Google Scholar] [CrossRef]

- Septevani, A.A.; Evans, D.A.C.; Annamalai, P.K.; Martin, D.J. The use of cellulose nanocrystals to enhance the thermal insulation properties and sustainability of rigid polyurethane foam. Ind. Crops Prod. 2017, 107, 114–121. [Google Scholar] [CrossRef]

- BASF—Technical Data Sheet TDS; Elastospray 1622/6; BASF Polyurethanes GmbH: Lemförde, Germany, 5 April 2012.

- Członka, S.; Strąkowska, A.; Strzelec, K.; Kairytė, A.; Kremensas, A. Bio-Based Polyurethane Composite Foams with Improved Mechanical, Thermal, and Antibacterial Properties. Materials 2020, 13, 1108. [Google Scholar] [CrossRef]

| Multifunctional Alcohol for Oxirane Ring-Opening and Esterification of TOFA 1 | Mass, g | Esterification/Amidation Temperature, °C | TOFA Content in Bio-Polyol, % |

|---|---|---|---|

| TMP 1 | 90.9 | 200 | 62.2 |

| DEG 1 | 71.9 | 200 | 67.9 |

| TEOA 1 | 101.1 | 180 | 59.5 |

| DEOA 1 | 71.2 | 145 | 68.1 |

| Components | Different Reagents, pbw | ||||

|---|---|---|---|---|---|

| ETOFA_TMP | ETOFA_DEG | ETOFA_TEOA | ETOFA_DEOA | ||

| Polyols | ETOFA_TMP * | 95–0 | − | − | − |

| ETOFA_DEG * | − | 95–0 | − | − | |

| ETOFA_TEOA * | − | − | 95–0 | − | |

| ETOFA_DEOA * | − | − | − | 95–0 | |

| TO_TEOA * | 0–95 | 0–95 | 0–95 | 0–95 | |

| Glycerol * | 5 | 5 | 5 | 5 | |

| Blowing agents | Water * | 2.0 | 2.0 | 2.0 | 2.0 |

| c-pentane | 0–15 | 0–15 | 0–15 | 0–15 | |

| Catalysts | Amine Catalysts | 4.0 | 2.5 | 4.0 | 4.0 |

| PC CAT TKA 30 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Surfactant | L6915 | 2.5 | 2.5 | 2.5 | 2.5 |

| Flame retardant | TCPP | 8 wt.% | 8 wt.% | 8 wt.% | 8 wt.% |

| Isocyanate | pMDI | 155–183 | 138–155 | 163–209 | 156–197 |

| Green carbon content in % | 18.1–26.4 | 24.4–26.5 | 16.7–26.5 | 18.7–26.2 | |

| Sustainable material content in % | 15.8–23.2 | 20.8–23.7 | 15.1–23.5 | 16.3–23.1 | |

| Changed Factor | Weight Ratios of Changed Factors, pbw | |||||

|---|---|---|---|---|---|---|

| New TOFA-based bio-polyols | 95 | 75 | 55 | 35 | 15 | 0 |

| TO_TEOA | 0 | 20 | 40 | 60 | 80 | 95 |

| c-pentane | 0–15 | 0–15 | 0–15 | 0–15 | 0–15 | 0–15 |

| Polyol | OH val., mg KOH/g | Viscosity (25 °C), mPa⋅s | Acid val., mg KOH/g | Moisture, % | Density (20 °C), g/cm3 | fn | Mn | pd |

|---|---|---|---|---|---|---|---|---|

| ETOFA/TMP | 390 ± 15 | 77,000 ± 1000 | 7 ± 2 | <0.1 | 1.056 | 9.3 | 1264 | 1.59 |

| ETOFA/DEG | 260 ± 10 | 1060 ± 40 | 5 ± 2 | <0.1 | 1.039 | 5.8 | 1215 | 1.53 |

| ETOFA/TEOA | 500 ± 15 | 7400 ± 100 | 3 ± 2 | <0.5 | 1.047 | 7.9 | 888 | 1.71 |

| ETOFA/DEOA | 480 ± 15 | 104,000 ± 2000 | 2 ± 2 | <0.2 | 1.070 | 5.0 | 569 | 1.28 |

| Response | X1 | X2 | X3 | X4 | X5 | X6 | R2 |

|---|---|---|---|---|---|---|---|

| Apparent density | +48.98633 | +0.129410 | −2.82320 | −0.003643 | 0 | +0.096614 | 0.9665 |

| Closed cell content | +72.43408 | +0.713941 | −0.312739 | 0 | −0.004800 | 0 | 0.9004 |

| Start time | +10.06081 | +0.090974 | +0.036797 | 0 | 0 | 0 | 0.8611 |

| String time | +15.89392 | +0.197703 | +0.390999 | 0 | 0 | 0 | 0.8743 |

| Tack-free time | +22.47031 | +0.090724 | +0.383783 | 0 | +0.001611 | 0 | 0.9200 |

| Optimized Responses | Targeted Value | Importance Level |

|---|---|---|

| Apparent free rise density | 40 ± 5 kg/m3 | 5 |

| Closed cell content | MAX (>90%) | 5 |

| Sustainable material content in the rigid PU foam | MAX | 3 |

| Start time | ~10–20 s | 0–1 |

| String time | ~20–40 s | 0–1 |

| Tack-free time | ~30–60 s | 0–1 |

| Flag Nr | ETOFA_TMP Polyol Content, pbw | c-pentane Content, pbw | TO_TEOA Polyol Content, pbw | Desirability |

| 1 | 35 | 5 | 60 | 0.20 |

| 2 | 49 | 6 | 44 | 0.60 |

| 3 | 55 | 7 | 40 | 0.68 |

| 4 | 65 | 7 | 30 | 0.74 |

| 5 | 75 | 8 | 20 | 0.77 |

| 6 | 85 | 9 | 10 | 0.71 |

| Flag Nr | ETOFA_DEG Polyol Content, pbw | c-pentane Content, pbw | TO_TEOA Polyol Content, pbw | Desirability |

| 1 | 35 | 6 | 60 | 0.40 |

| 2 | 55 | 6.5 | 40 | 0.63 |

| 3 | 84 | 7 | 11 | 0.62 |

| Flag Nr | ETOFA_TEOA Polyol Content, pbw | c-pentane Content, pbw | TO_TEOA Polyol Content, pbw | Desirability |

| 1 | 35 | 5 | 60 | 0.46 |

| 2 | 55 | 6 | 40 | 0.65 |

| 3 | 75 | 7.5 | 20 | 0.71 |

| 4 | 83 | 8 | 12 | 0.71 |

| Characteristics | ETOFA_TMP—85 c-pentane—9 | PPWS-0T 1 | RO/PET_150 2 | Rigid PU Foam F0 3 | Elastospray 1622/6 BASF System 4 | PU-0 5 |

|---|---|---|---|---|---|---|

| Apparent density, kg/m3 | 37.7 | 38.8 | 39.1 | 37.4 | 37.0 | 39.0 |

| Closed cell content, % | 94 | n.a. | 99 | 86 | 95 | 88 |

| Thermal conductivity, mW/(m·K) | 20.5 | 27.4 | 20.7 | 25.5 | 20.5 | n.a. |

| Compression strength, MPa | 0.32 | 0.22 | 0.35 | 0.21 | 0.22 | 0.25 |

| Compression modulus, MPa | 9.0 | 4.9 | 7.0 | 5.1 | n.a. | 6.4 |

| Sustainable mat. content, % | 19.4 | n.a. | ~12.5 | n.a. | n.a. | n.a. |

| Average cell size, μm | 240 ± 84 | 840 ± 50 | n.a. | 530 ± 170 | n.a. | 390 ± 9 |

| Isocyanate index | 150 | 150 | 150 | 110 | n.a. | 160 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirpluks, M.; Vanags, E.; Abolins, A.; Michalowski, S.; Fridrihsone, A.; Cabulis, U. High Functionality Bio-Polyols from Tall Oil and Rigid Polyurethane Foams Formulated Solely Using Bio-Polyols. Materials 2020, 13, 1985. https://doi.org/10.3390/ma13081985

Kirpluks M, Vanags E, Abolins A, Michalowski S, Fridrihsone A, Cabulis U. High Functionality Bio-Polyols from Tall Oil and Rigid Polyurethane Foams Formulated Solely Using Bio-Polyols. Materials. 2020; 13(8):1985. https://doi.org/10.3390/ma13081985

Chicago/Turabian StyleKirpluks, Mikelis, Edgars Vanags, Arnis Abolins, Slawomir Michalowski, Anda Fridrihsone, and Ugis Cabulis. 2020. "High Functionality Bio-Polyols from Tall Oil and Rigid Polyurethane Foams Formulated Solely Using Bio-Polyols" Materials 13, no. 8: 1985. https://doi.org/10.3390/ma13081985

APA StyleKirpluks, M., Vanags, E., Abolins, A., Michalowski, S., Fridrihsone, A., & Cabulis, U. (2020). High Functionality Bio-Polyols from Tall Oil and Rigid Polyurethane Foams Formulated Solely Using Bio-Polyols. Materials, 13(8), 1985. https://doi.org/10.3390/ma13081985