In Situ Characterization of Damage Development in Cottonid Due to Quasi-Static Tensile Loading

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

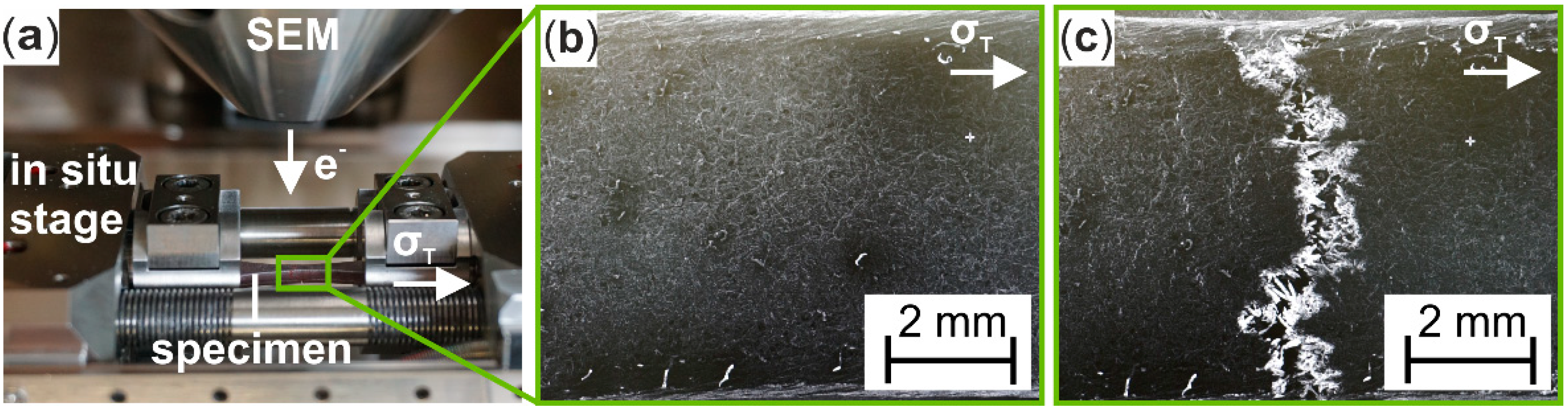

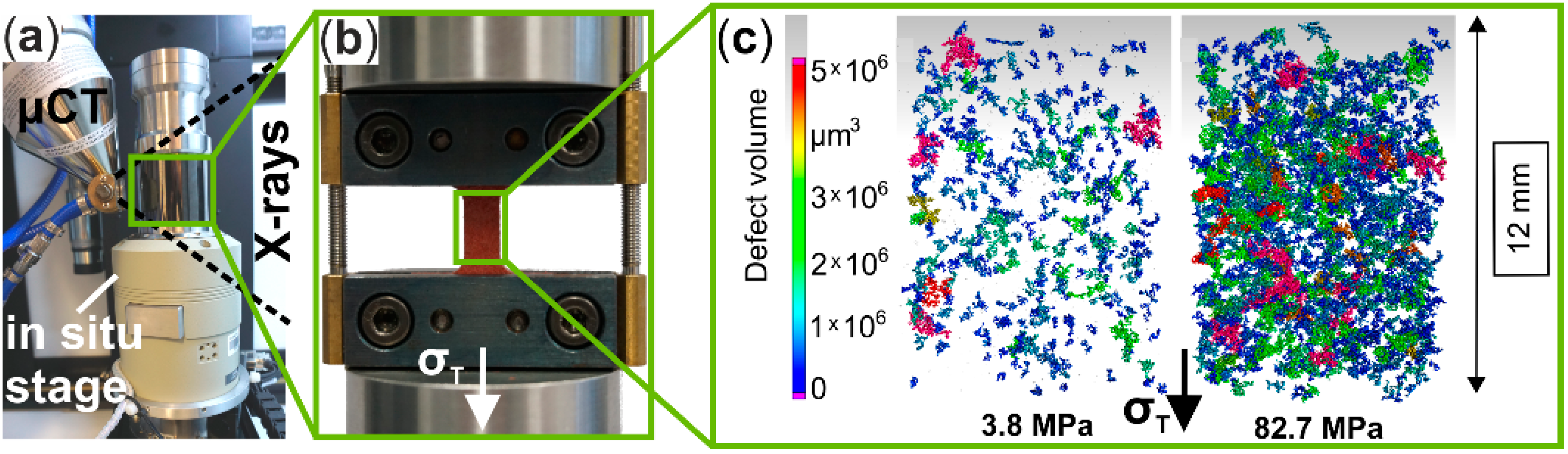

2.2. Test Setup for Microstructural In Situ Investigations

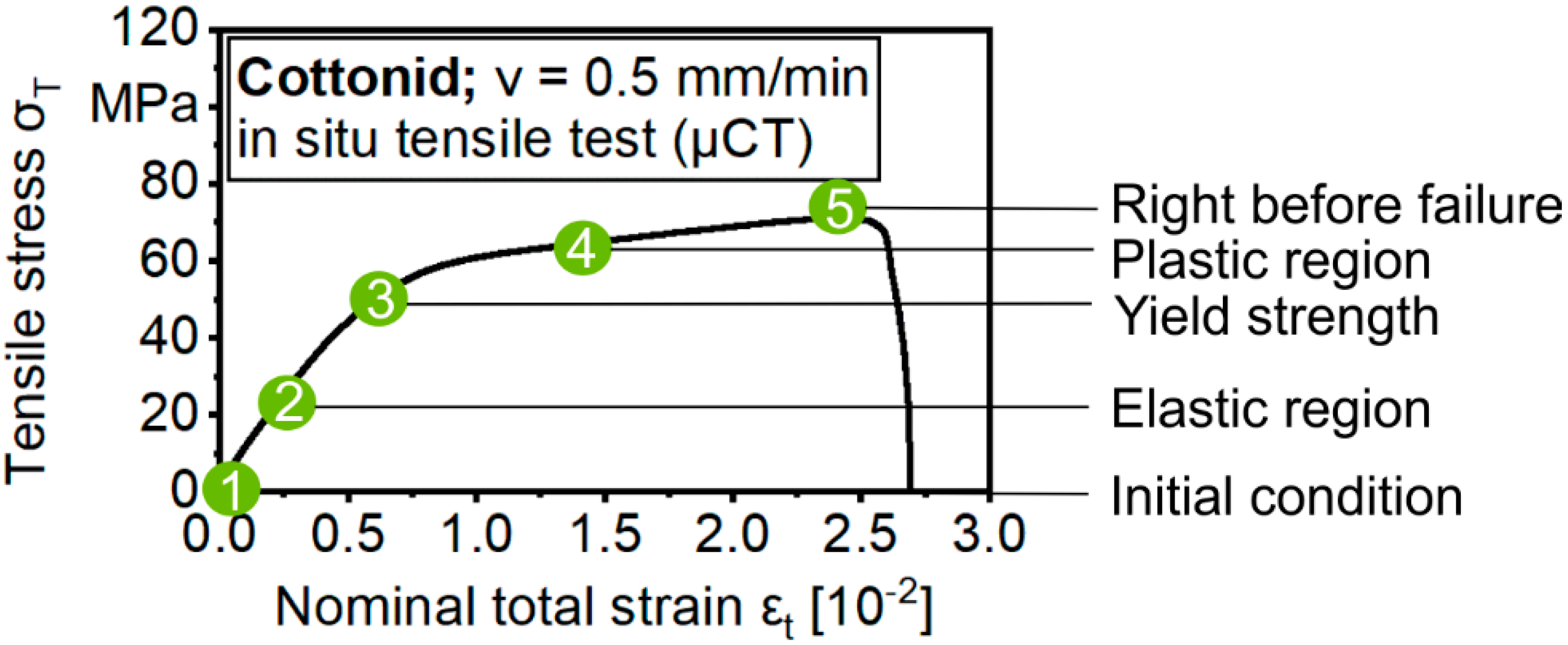

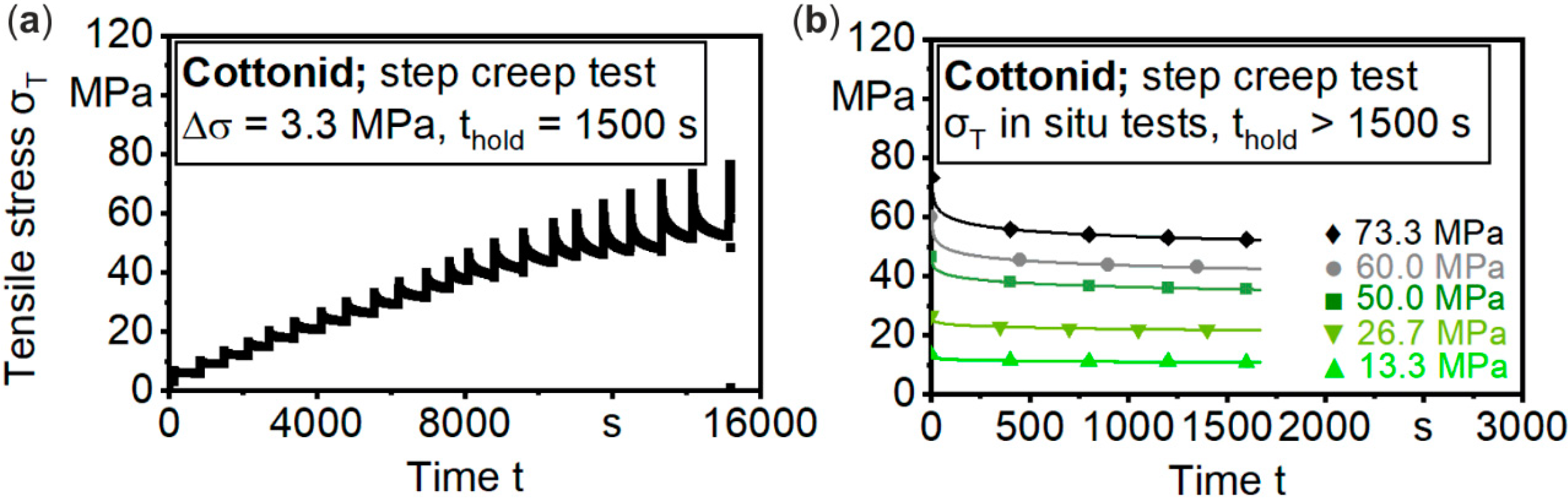

2.3. Test Strategy for Characterization of Damage Development on the Surface and in the Volume

3. Results

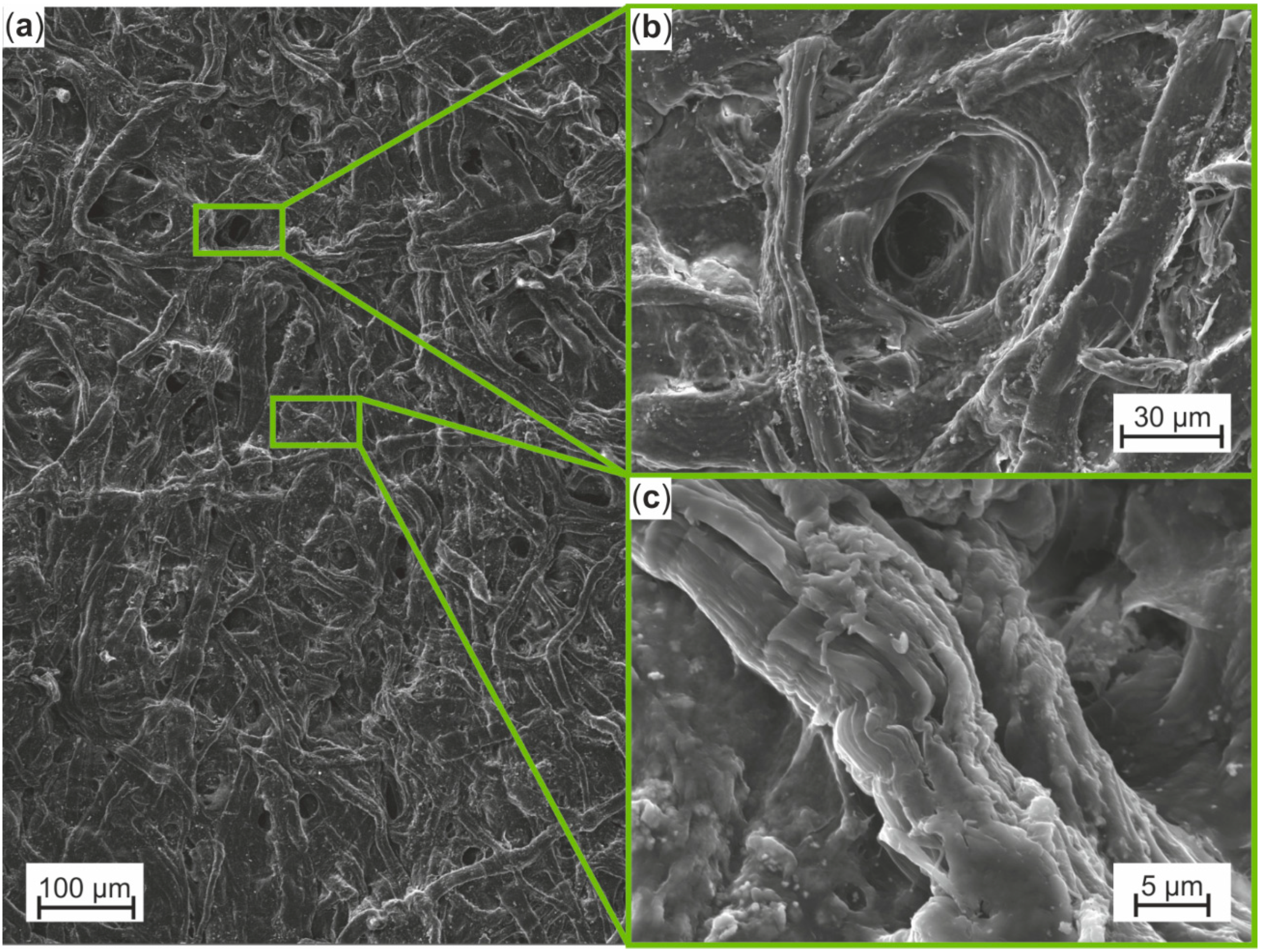

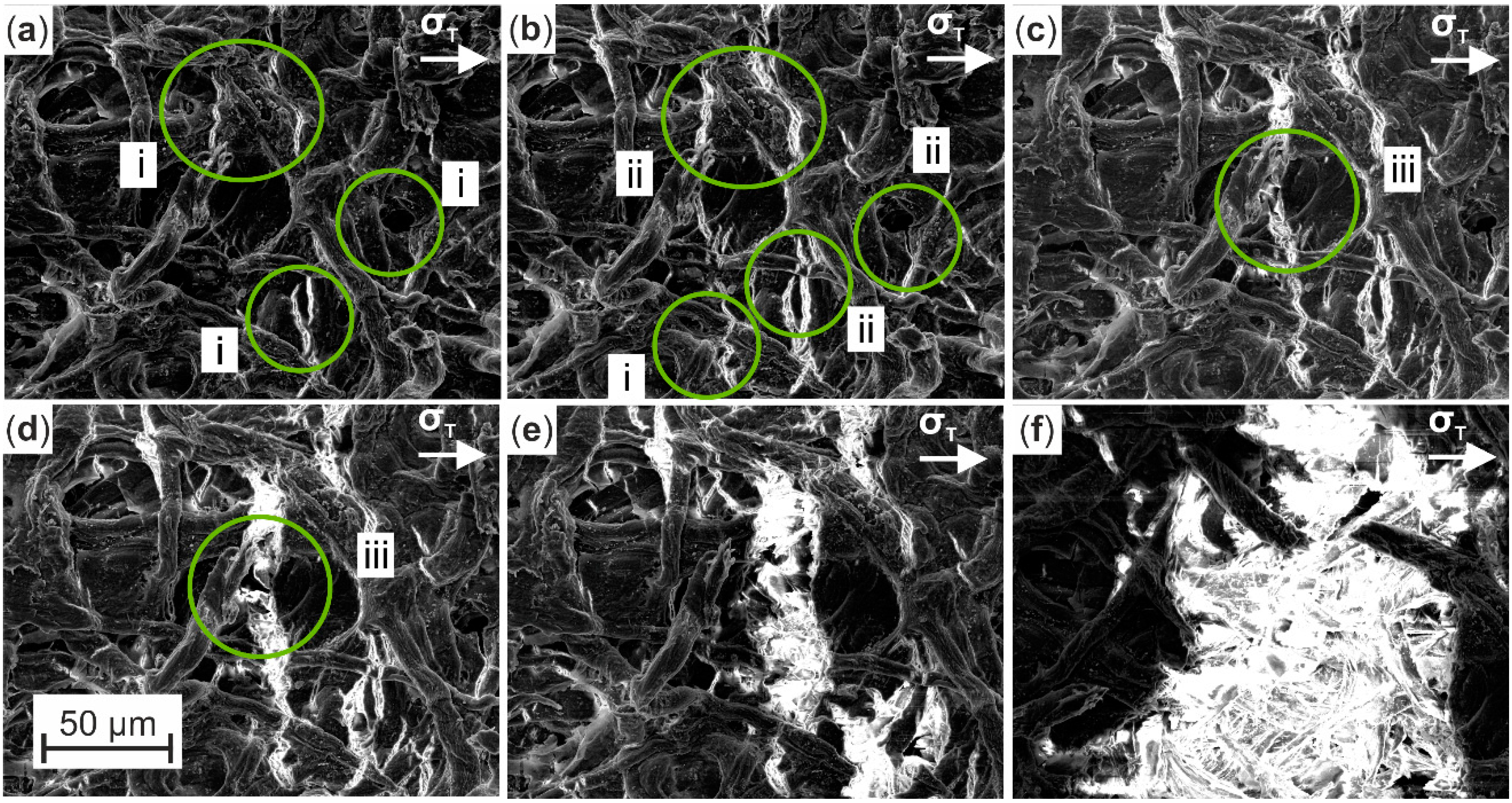

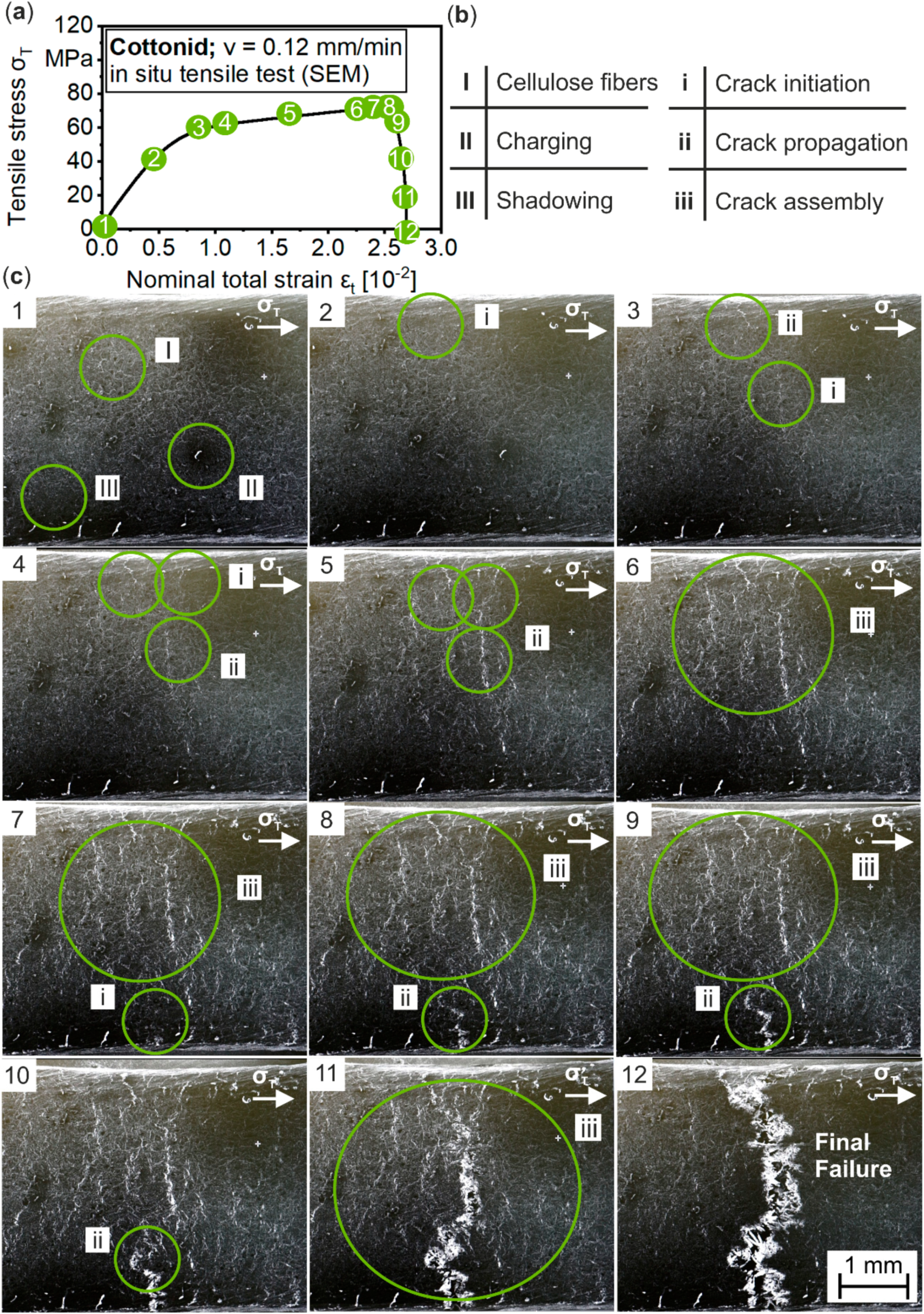

3.1. In Situ Quasi-Static Tensile Tests in SEM

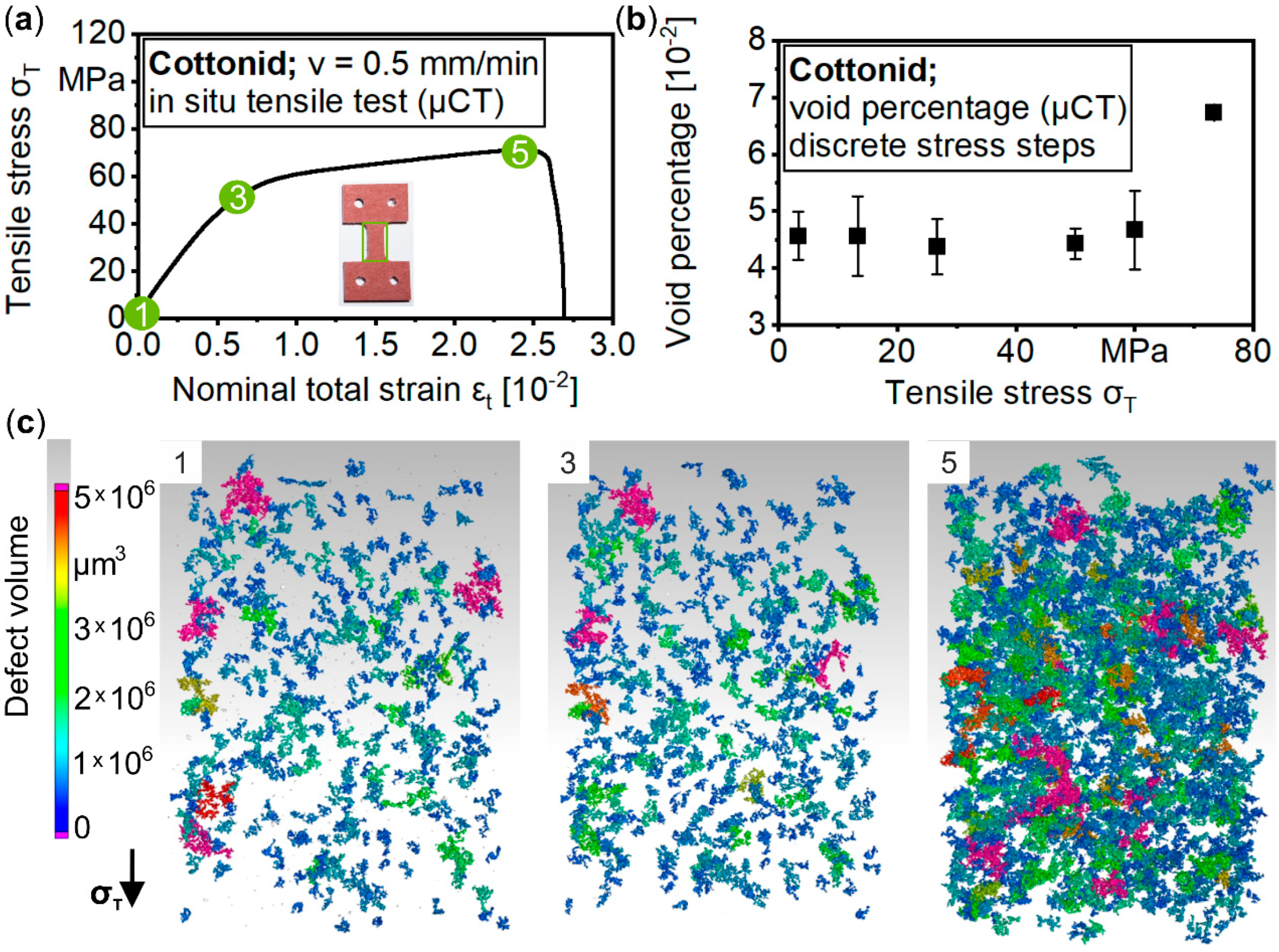

3.2. In Situ Quasi-Static Tensile Tests in µCT

4. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Taylor, T. Improvement in the Treatment of Paper and Paper-Pulp. U.S. Patent 114,880, 16 March 1871. [Google Scholar]

- Schoenen, F. 3: Cellulose als Ausgangsstoff. In Kunststoff Handbuch Band 3 Abgewandelte Naturstoffe Herstellung, Eigenschaften, Verarbeitung und Anwendungen; Vieweg, R., Becker, E., Eds.; Carl Hanser Verlag: München, Germany, 1965. [Google Scholar]

- Ernst Krueger GmbH. & Co. KG. Available online: https://www.hornex.de/ (accessed on 2 April 2020).

- Sachsenroeder GmbH. & Co. KG. Available online: https://sachsenroeder.com/ (accessed on 2 April 2020).

- Scholz, R.; Mittendorf, R.-M.; Engels, J.K.; Hartmaier, A.; Kuenne, B.; Walther, F. Direction-dependent mechanical characterization of cellulose-based composite vulcanized fiber. Mater. Test. 2016, 58, 813–817. [Google Scholar] [CrossRef] [Green Version]

- Scholz, R.; Delp, A.; Kaplan, A.; Walther, F. Vergleichende Bewertung der temperaturabhängigen mechanischen Eigenschaften von Vulkanfiber und technischen Kunststoffen. In Werkstoffprüfung 2016-Fortschritte in der Werkstoffprüfung für Forschung und Praxis; Christ, H.-J., Ed.; Stahleisen: Düsseldorf, Germany, 2016; pp. 245–250. ISBN 978-3-514-00830-4. [Google Scholar]

- Frey, M.; Widner, D.; Segmehl, J.S.; Casdorff, K.; Keplinger, T.; Burgert, I. Delignified and densified cellulose bulk materials with excellent tensile properties for sustainable engineering. ACS AMI 2018, 10, 5030–5037. [Google Scholar] [CrossRef] [PubMed]

- Scholz, R.; Langhansl, M.; Zollfrank, C.; Walther, F. Cottonid-Ein effizienter Funktionswerkstoff für feuchtegetriebene Aktuatoren. In Smarte Strukturen und Systeme-Tagungsband des 4 Smarts-Symposiums; Wiedemann, M., Melz, T., Eds.; Shaker: Düren, Germany, 2019; pp. 63–75. ISBN 978-3-8440-6425-4. [Google Scholar]

- Scholz, R.; Langhansl, M.; Zollfrank, C.; Walther, F. Experimental study on the actuation and fatigue behavior of the biopolymeric material Cottonid. Mater. Today Proc. 2019, 7, 476–483. [Google Scholar] [CrossRef]

- Poppinga, S.; Zollfrank, C.; Prucker, O.; Rühe, J.; Menges, A.; Cheng, T.; Speck, T. Toward a new generation of smart biomimetic actuators for architecture. Adv. Mater. 2018, 30, 1–10. [Google Scholar] [CrossRef]

- Awd, M.; Siddique, S.; Walther, F. Microstructural damage and fracture mechanisms of selective laser melted Al-Si alloys under fatigue loading. Theor. App. Fract. Mec. 2020, 106, 102483. [Google Scholar] [CrossRef]

- Backe, S.; Balle, F. A novel short-time concept for fatigue life estimation of carbon (CFRP) and metal/carbon fiber reinforced polymer (MCFRP). Int. J. Fatigue 2018, 116, 317–322. [Google Scholar] [CrossRef]

- Giovino, M.; Pribyl, J.; Benicewicz, B.; Bucinell, R.; Schadler, L. Mechanical properties of polymer grafted nanoparticle composites. Nanocomposites 2019, 9, 244–252. [Google Scholar] [CrossRef] [Green Version]

- Mammadi, Y.; Joseph, A.; Joulain, A.; Boneeville, J.; Tromas, C.; Hedan, S.; Valle, V. Nanometric metrology by FIB-SEM-DIC measuremtns of strain field and fracture separation on composite metallic material. Mater. Des. 2020. [Google Scholar] [CrossRef]

- Hülsbusch, D.; Kohl, A.; Striemann, P.; Niedermeier, M.; Strauch, J.; Walther, F. Development of an energy-based approach for optimized frequency selection for fatigue testing on polymers—Exemplified on polyamide 6. Polym. Test. 2020, 81, 106260. [Google Scholar] [CrossRef]

- Mao, H.; Xiao, X.Y.; Mao, H.; Tang, W.; Huang, Z.; Li, X.; Sun, L. Fatigue damage detection and location of metal materials by electrical impedance tomography. Results Phys. 2019, 15, 102664. [Google Scholar] [CrossRef]

- Tillmann, W.; Walther, F.; Luo, W.; Haack, M.; Nellesen, J.; Knyazeva, M. In Situ Acoustic Monitoring of Thermal Spray Process Using High-Frequency Impulse Measurements. J. Therm. Spray Technol. 2018, 27, 50–58. [Google Scholar] [CrossRef]

- Ivanov, S.G.; Gorbatikh, L.; Lomov, S.V.; Verpoest, I. Textile composites in tension: In situ observation of damage development. In Proceedings of the Composites Week @ Leuven and TexComp-11 Conference, Leuven, Belgium, 16–20 September 2013. [Google Scholar]

- Myslicki, S.; Ortlieb, M.; Frieling, G.; Walther, F. High-precision deformation and damage development assessment of composite materials by high-speed camera, high-frequency impulse and digital image correlation techniques. Mater. Test. 2015, 57, 933–941. [Google Scholar] [CrossRef] [Green Version]

- Gerbe, S.; Tenkamp, J.; Scherbring, S.; Bleicher, K.; Krupp, U.; Michels, W.; Walther, F. Microstructural influences on the fatigue crack initiation and propagation mechanisms in hypo-eutectic Al-Si cast alloys. Proc. Struct. Integ. 2019, 23, 511–516. [Google Scholar] [CrossRef]

- Kucharczyk, P.; Sharaf, M.; Münstermann, S. On the influence of steel microstructure on short crack growth under cyclic loading. Int. J. Fatigue 2012, 41, 83–89. [Google Scholar] [CrossRef]

- Niederberger, C.; Mook, W.M.; Maeder, X.; Michler, J. In situ electron backscatter diffraction (EBSD) during the compression of micropillars. Mater. Sci. Eng. A 2010, 527, 4306–4311. [Google Scholar] [CrossRef]

- Liu, Y.; Tanaka, Y. In situ characterization of tensile damage behavior of a plain-woven fiber-reinforced polymer-derived ceramic composite. Mater. Lett. 2003, 57, 1571–1578. [Google Scholar] [CrossRef]

- Scott, A.E.; Mavrogordato, M.; Wright, P.; Sinclair, I.; Spearing, S.M. In situ fibre fracture measurement in carbon-epoxy laminates using highresolution computed tomography. Compos. Sci. Technol. 2011, 71, 1471–1477. [Google Scholar] [CrossRef] [Green Version]

- Arif, M.F.; Meraghni, F.; Chemisky, Y.; Despringre, N.; Robert, G. In situ damage mechanisms investigation of PA66/GF30 composite: Effect of relative humidity. Compos. Part B Eng. 2014, 58, 487–495. [Google Scholar] [CrossRef] [Green Version]

- Hülsbusch, D.; Mrzljak, S.; Walther, F. In situ computed tomography for the characterization of the fatigue damage development in glass fiber-reinforced polyurethane. Mater. Test. 2019, 61, 821–828. [Google Scholar] [CrossRef]

- Schilling, P.J.; Karedla, B.P.R.; Tatiparthi, A.K.; Verges, M.A.; Herrington, P.D. X-ray computed microtomography of internal damage in fiber reinforced polymer matrix composites. Compos. Sci. Technol. 2005, 65, 2071–2078. [Google Scholar] [CrossRef]

- Little, J.E.; Yuan, X.; Jones, M.I. Characterisation of voids in fibre reinforced composite materials. NDT&E Int. 2012, 46, 122–127. [Google Scholar]

- Yu, B.; Bradley, R.; Soutis, C.; Hogg, P.; Withers, P. 2D and 3D imaging of fatigue failure mechanisms of 3D woven composites. Compos. Part A 2015, 77, 37–49. [Google Scholar] [CrossRef]

- Patera, A.; Derome, D.; Griffa, M.; Carmeliet, J. Hysteresis in swelling and in sorption of wood tissue. J. Struct. Biol. 2013, 182, 226–234. [Google Scholar] [CrossRef] [PubMed]

- Hamad, W.H.; Provan, J.W. Microstructural cumulative material degradation and fatigue-failure micromechanisms in wodd-pulp fibres. Cellulose 1995, 2, 159–177. [Google Scholar] [CrossRef]

- Adey-Johnson, R.; Mclean, J.P.; Van den Bulcke, J.; Van Acker, J.; McDonald, P.J. Micro-CT measurements of within-ring variability in longitudinal hydraulic pathways in Norway spruce. IAWA J. 2020, 1, 12–29. [Google Scholar] [CrossRef]

- Barbero, E.J.; Cosso, F.A.; Campo, F.A. Benchmark solution for degradation of elastic properties due to transverse matrix cracking in laminated composites. Comp. Struct. 2013, 98, 242–252. [Google Scholar] [CrossRef]

- Carraro, P.A.; Quaresimin, M. A stiffness degradation model for cracked multidirectional laminates with cracks in multiple layers. Int. J. Solids Struct. 2015, 58, 34–51. [Google Scholar] [CrossRef]

- Reifsnider, K.; Raihan, M.R.; Vadlamudi, V. Heterogeneous fracture mechanics for multi defect analysis. Compos. Struct. 2016, 156, 20–28. [Google Scholar] [CrossRef] [Green Version]

- G’sell, C.; Dahoun, A. Evolution of microstructure in semi-crystalline polymers under large plastic deformation. Mater. Sci. Eng. A 1994, 175, 183–199. [Google Scholar] [CrossRef]

- Landis, E.N.; Vasic, S.; Davids, W.G.; Parrod, P. Coupled experiments and simulations of microstructural damage in wood. Exp. Mech. 2002, 42, 389–394. [Google Scholar] [CrossRef]

- Qing, H.; Mishnaevsky, L.J. A 3D multilevel model of damage and strength of wood: Analysis of microstructural effects. Mech. Mater. 2011, 43, 487–495. [Google Scholar] [CrossRef]

- Chaboche, J.L.; Girard, R.; Levasseur, P. On the interface deponding models. Int. J. Damage Mech. 1997, 6, 220–257. [Google Scholar] [CrossRef]

| Tensile Stress σT [MPa] | Lead Time ts before µCT Scan [s] |

|---|---|

| 13.3 | 57 |

| 26.6 | 60 |

| 50.0 | 1080 |

| 60.0 | 1580 |

| 73.3 | 2300 |

| Defect Volume [µm3] | Development of Void Volume in Relation to Initial Condition [%] | ||||

|---|---|---|---|---|---|

| >1,000,000 | −7 ± 37 | −16 ± 25 | −9 ± 25 | +2 ± 35 | +418 ± 127 |

| 1,000,000–500,000 | +3 ± 26 | −5 ± 21 | +2 ± 21 | +10 ± 18 | +169 ± 63 |

| 499,999–100,000 | −1 ± 15 | −5 ± 10 | −2 ± 10 | +4 ± 12 | +56 ± 22 |

| 99,999–10,000 | 0 ± 8 | −2 ± 7 | −2 ± 7 | −1 ± 5 | +10 ± 8 |

| <10,000 | 0 ± 11 | −4 ± 9 | −5 ± 10 | −3 ± 7 | +12 ± 5 |

| Tensile stress σT [MPa] | 13.3 | 26.7 | 50.0 | 60.0 | 73.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scholz, R.; Delp, A.; Walther, F. In Situ Characterization of Damage Development in Cottonid Due to Quasi-Static Tensile Loading. Materials 2020, 13, 2180. https://doi.org/10.3390/ma13092180

Scholz R, Delp A, Walther F. In Situ Characterization of Damage Development in Cottonid Due to Quasi-Static Tensile Loading. Materials. 2020; 13(9):2180. https://doi.org/10.3390/ma13092180

Chicago/Turabian StyleScholz, Ronja, Alexander Delp, and Frank Walther. 2020. "In Situ Characterization of Damage Development in Cottonid Due to Quasi-Static Tensile Loading" Materials 13, no. 9: 2180. https://doi.org/10.3390/ma13092180

APA StyleScholz, R., Delp, A., & Walther, F. (2020). In Situ Characterization of Damage Development in Cottonid Due to Quasi-Static Tensile Loading. Materials, 13(9), 2180. https://doi.org/10.3390/ma13092180