Influence of Atomic Doping on Thermal Stability of Ferrite Nanoparticles—Structural and Magnetic Studies

Abstract

:1. Introduction

2. Experimental

2.1. Materials and Apparatus

2.2. Synthesis of Ferrite Nanoparticles

3. Results and Discussion

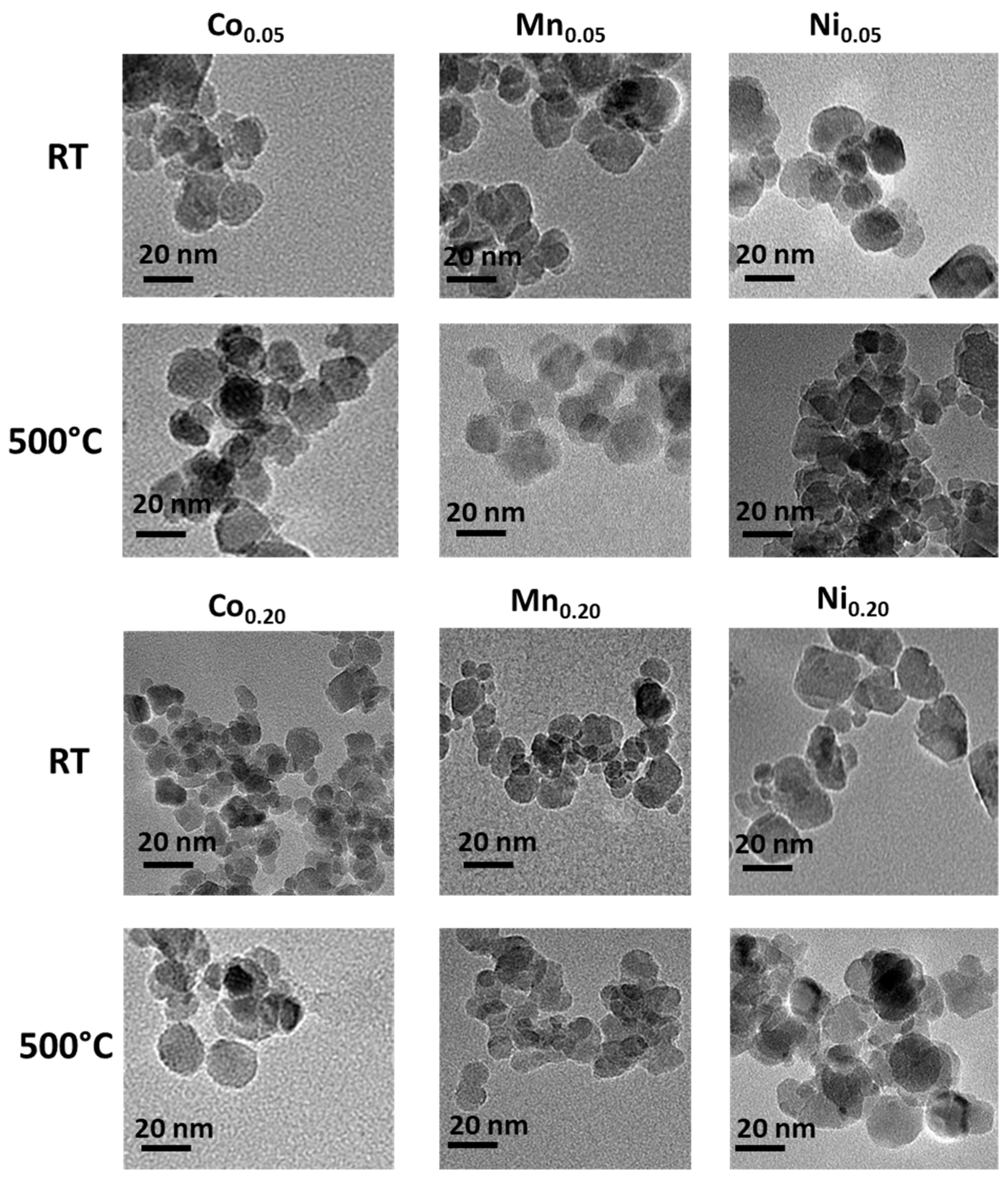

3.1. Transmission Electron Microscopy (TEM)

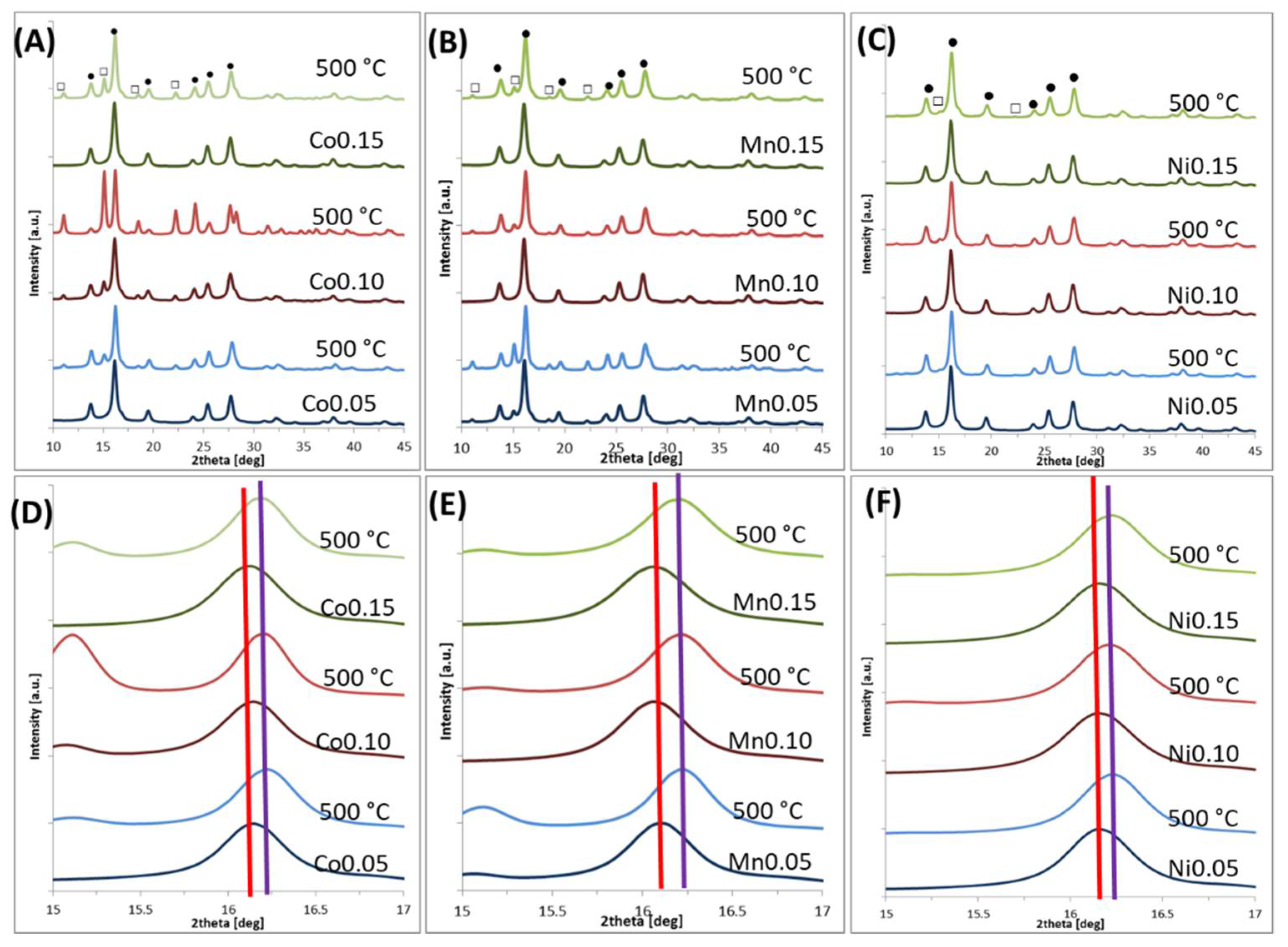

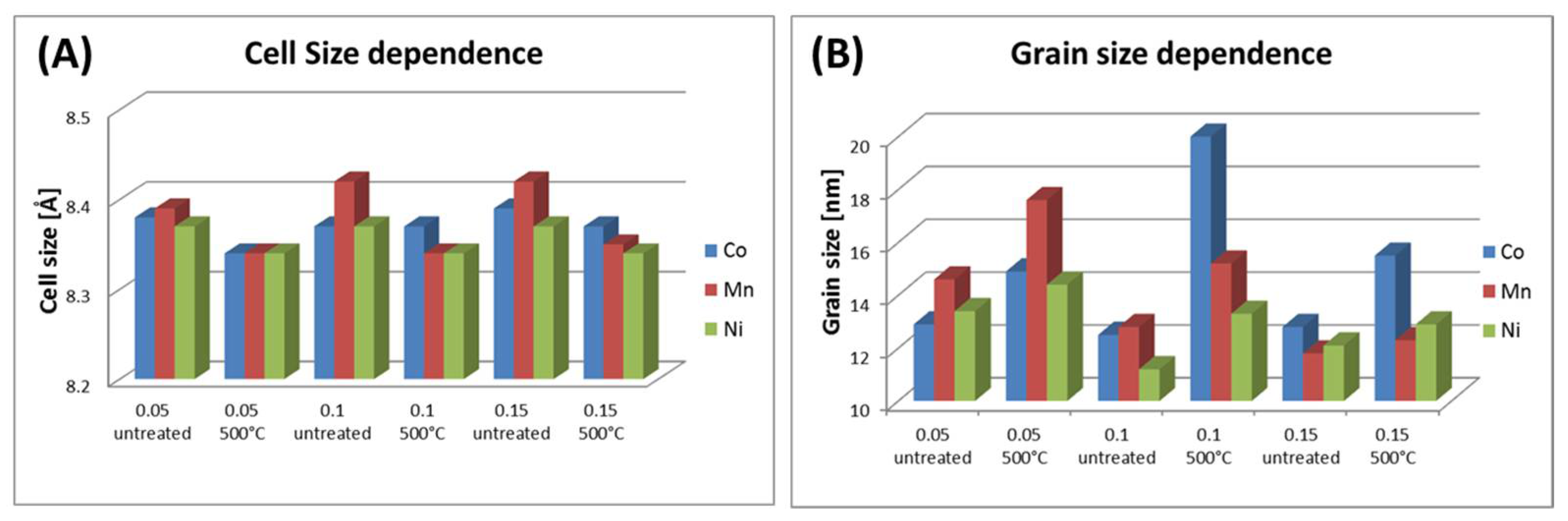

3.2. X-ray Diffraction (XRD)

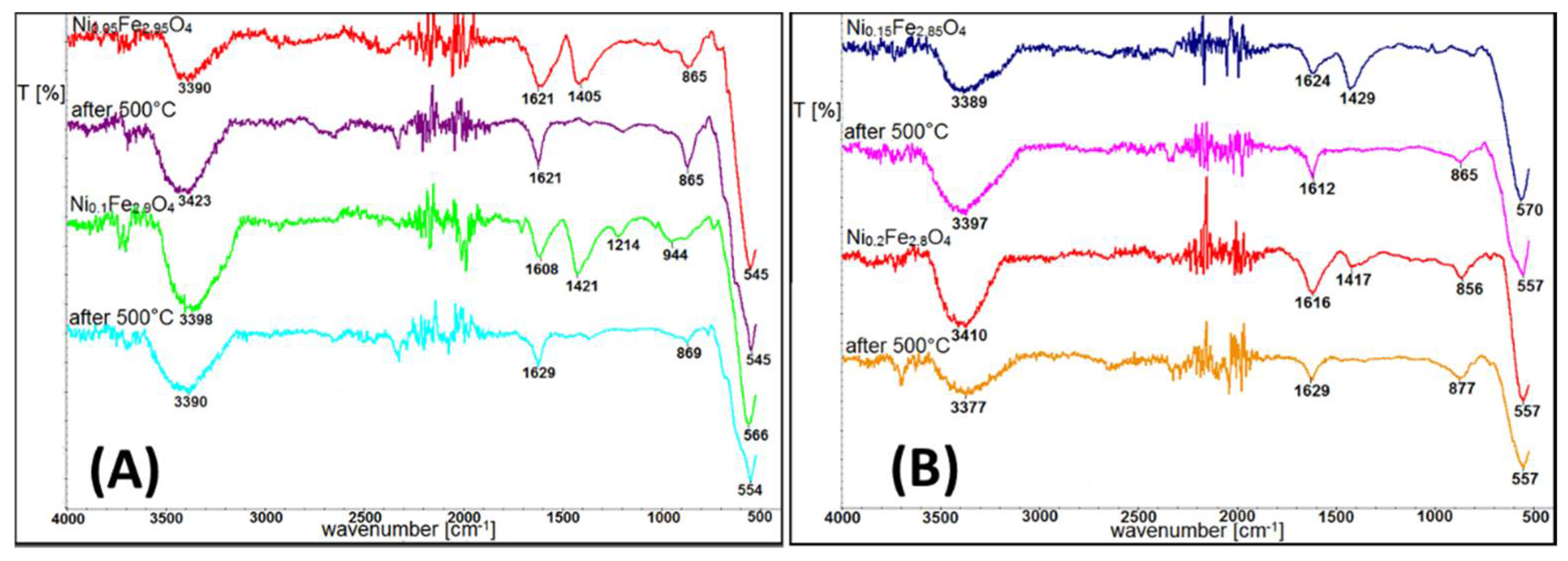

3.3. Infrared Spectroscopy (IR)

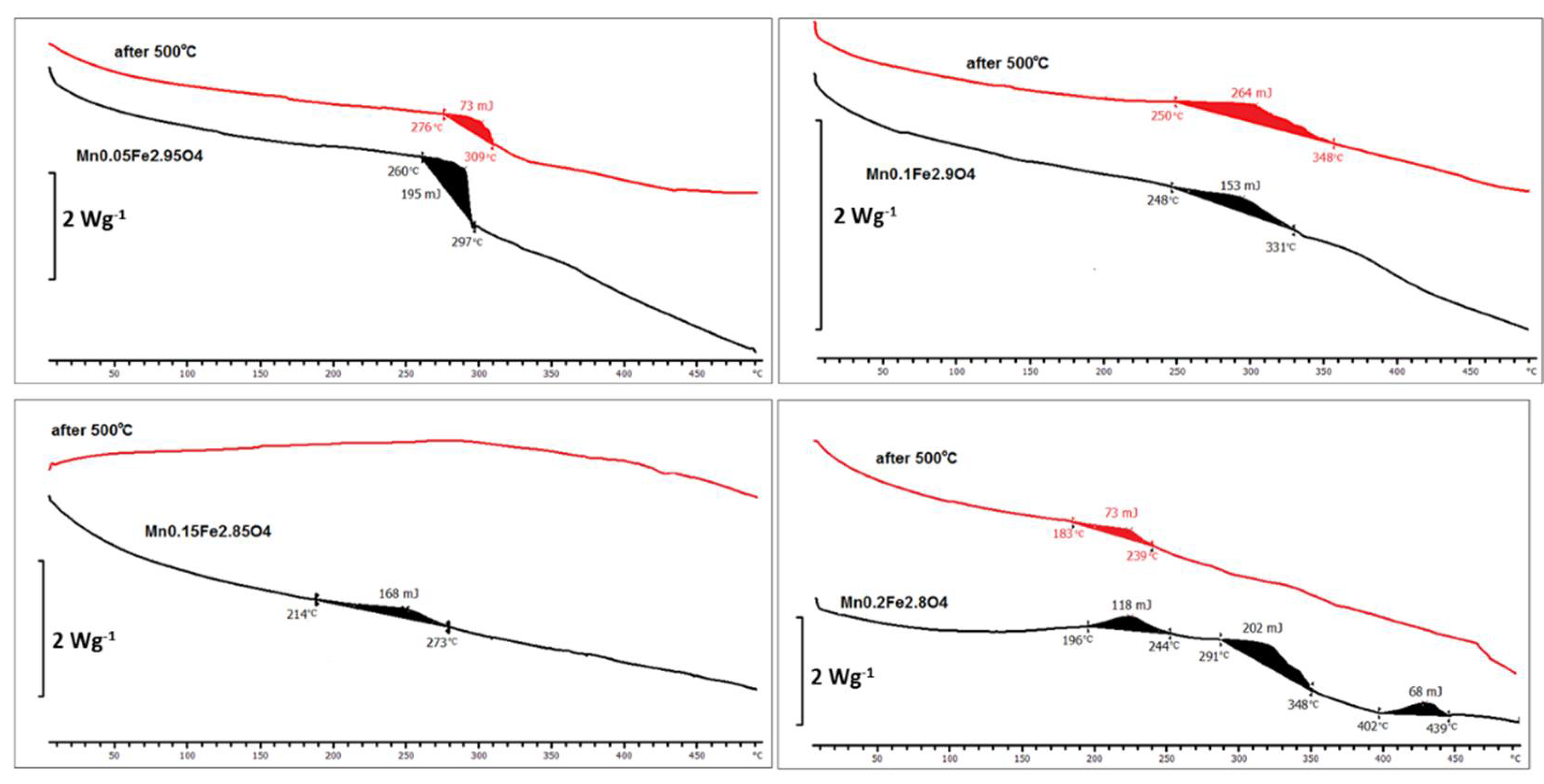

3.4. Differential Scanning Calorimetry (DSC)

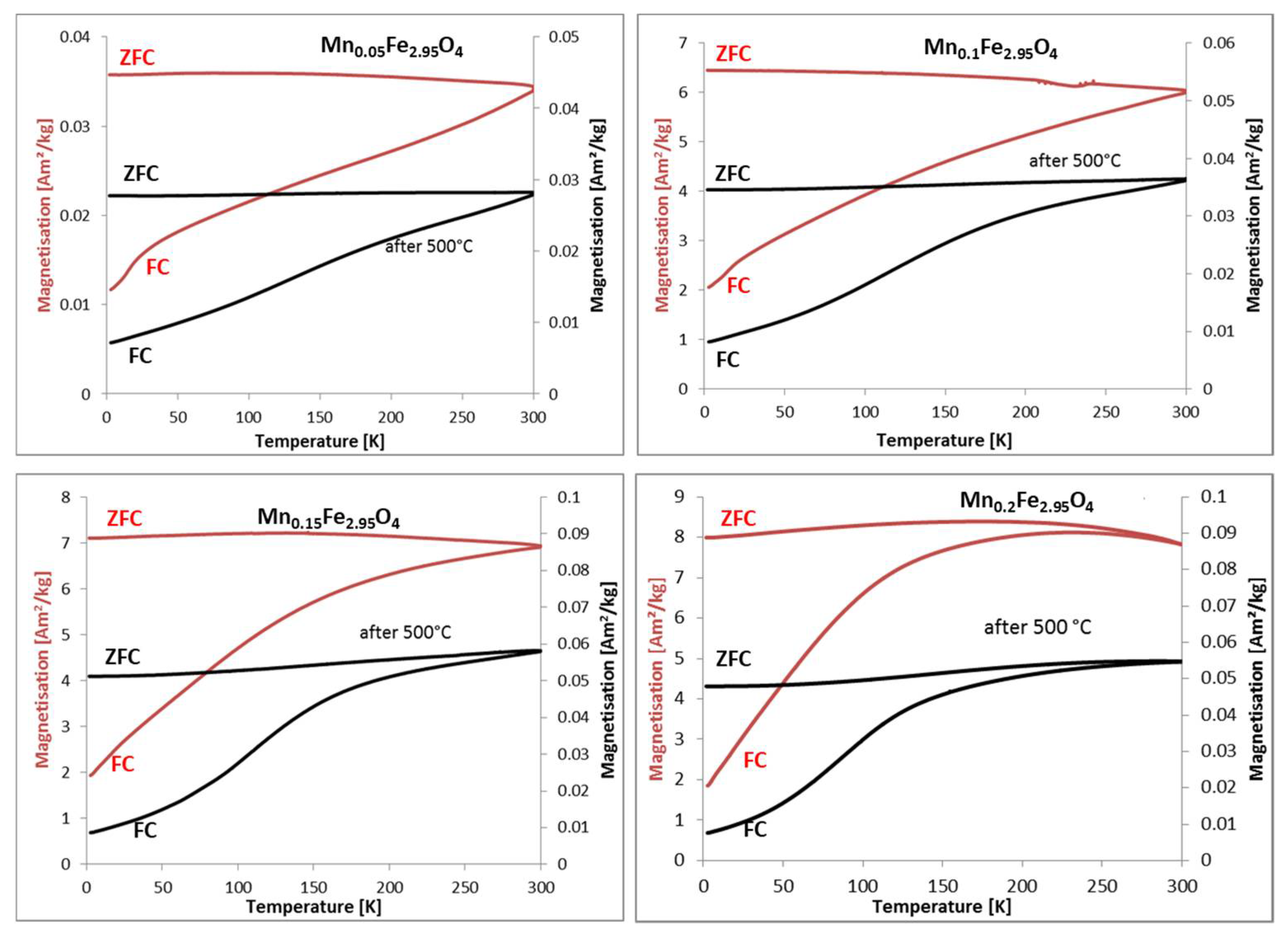

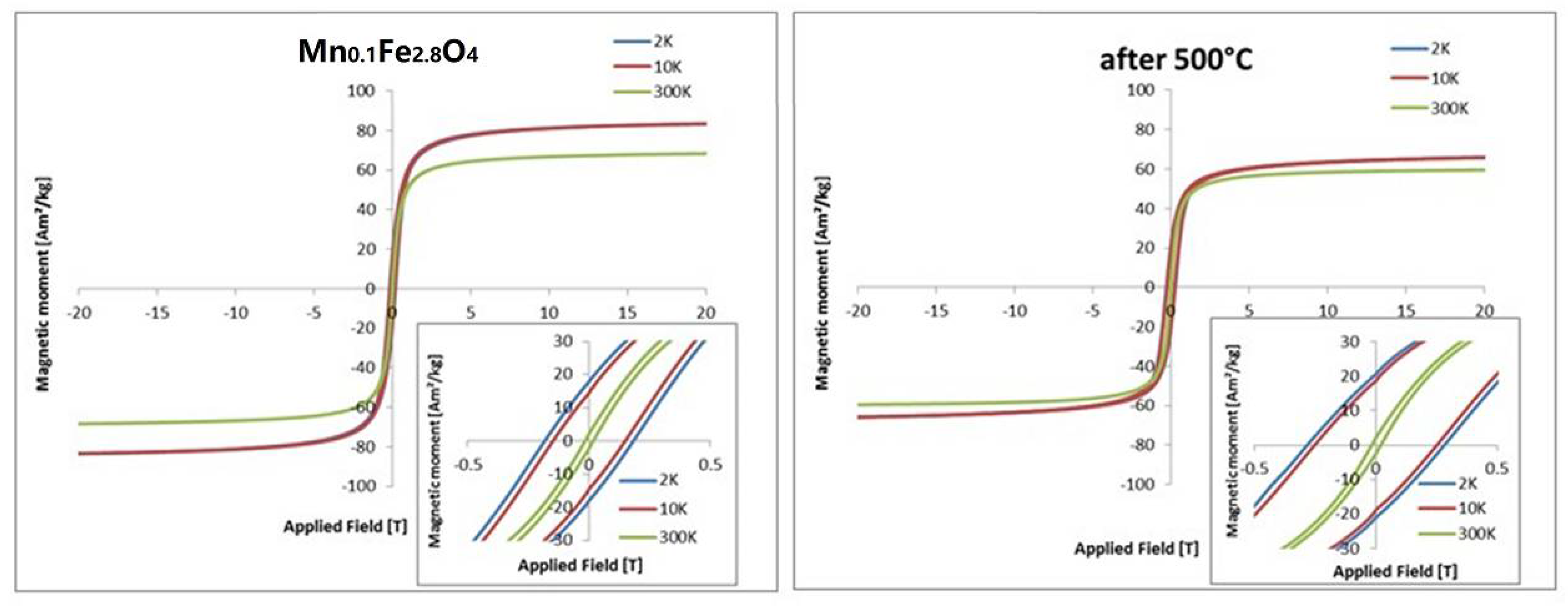

3.5. Vibrating Sample Magnetometry (VSM)

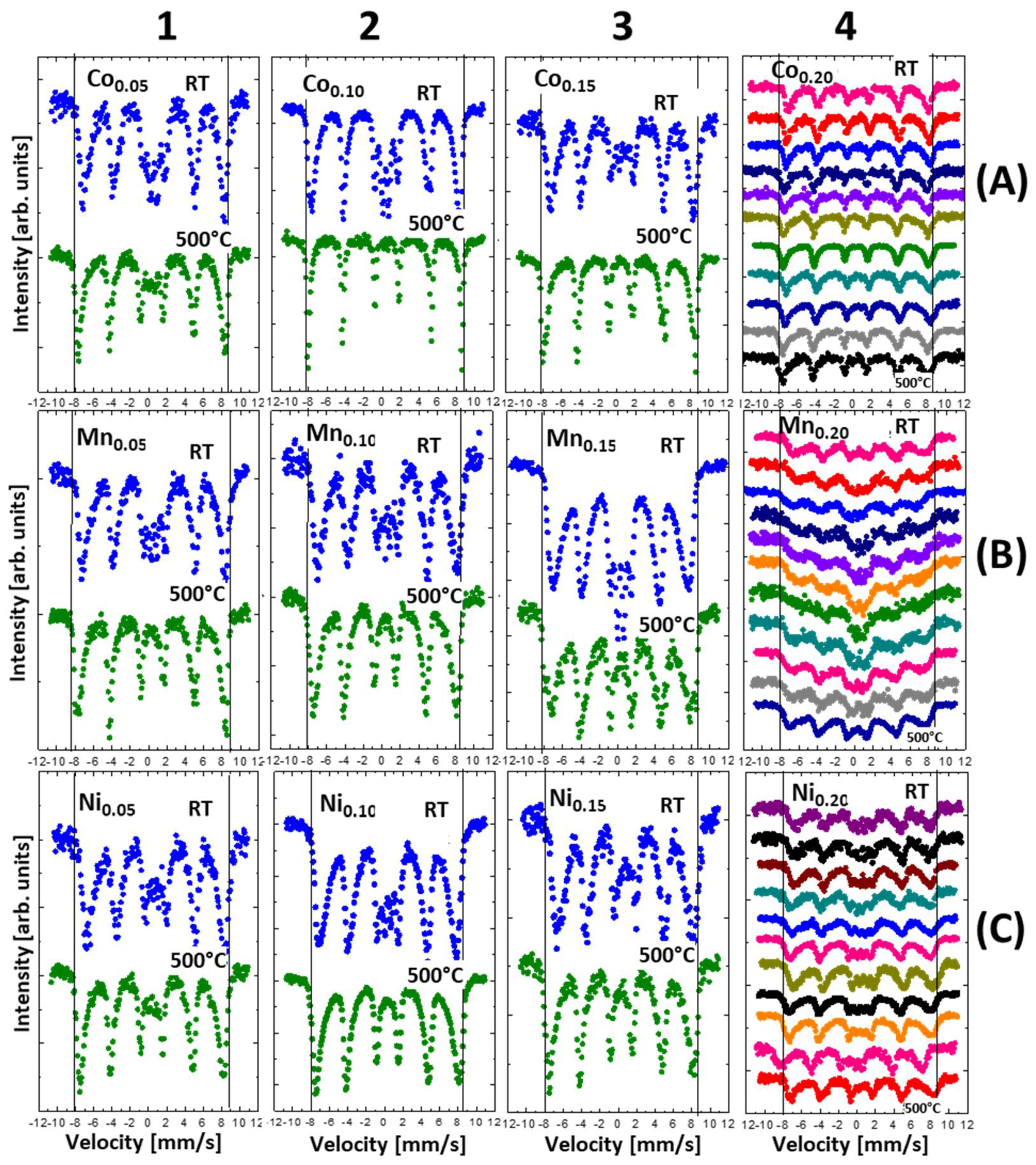

3.6. Mössbauer Spectroscopy

4. Conclusions

- -

- For the application of nanoparticles in an environment where rising temperature is expected, doping of the inorganic core by Co, Mn, and Ni is useful. Doping prevents the spontaneous oxidation induced by high temperatures. The results reveal that Ni doping can even suppress the oxidation process.

- -

- Particles exposed regularly or for a long period of time to high temperatures should be tested for their magnetic properties before and after heat treatment. It was observed that slow transformation from one oxide to another causes significant magnetic property changes, particularly saturation magnetization.

- -

- Each of the studied oxides has its own magnetic characteristic; therefore, they cannot be expected to behave the same way when the application is considered.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, C.; Meyer, J.; Teichert, N.; Auge, A.; Rausch, E.; Balke, B.; Hütten, A.; Fecher, G.H.; Felser, C. Heusler nanoparticles for spintronics and ferromagnetic shape memory alloys. J. Vac. Sci. Technol. B 2014, 32, 020802. [Google Scholar] [CrossRef]

- Kefeni, K.K.; Msagati, T.A.M.; Mamba, B.B. Ferrite nanoparticles: Synthesis, characterisation and applications in electronic device. Mater. Sci. Eng. B 2017, 215, 37–55. [Google Scholar] [CrossRef]

- Wang, L.; Ma, W.; Xu, L.; Chen, W.; Zhu, Y.; Xu, C.; Kotov, N.A. Nanoparticle-based environmental sensors. Mater. Sci. Eng. R Rep. 2010, 70, 265–274. [Google Scholar] [CrossRef]

- Cowburn, R.P.; Welland, M.E. Room Temperature Magnetic Quantum Cellular Automata. Science 2000, 287, 1466–1468. [Google Scholar] [CrossRef]

- Patitsa, M.; Karathanou, K.; Kanaki, Z.; Tzioga, L.; Pippa, N.; Demetzos, C.; Verganelakis, D.A.; Cournia, Z.; Klinakis, A. Magnetic nanoparticles coated with polyarabic acid demonstrate enhanced drug delivery and imaging properties for cancer theranostic applications. Sci. Rep. 2017, 7, 775. [Google Scholar] [CrossRef] [Green Version]

- Amiri, M.; Akbari, A.; Ahmadi, M.; Pardakhti, A.; Salavati-Niasari, M. Synthesis and in vitro evaluation of a novel magnetic drug delivery system; proecological method for the preparation of CoFe2O4 nanostructures. J. Mol. Liq. 2018, 249, 1151–1160. [Google Scholar] [CrossRef]

- Naahidi, S.; Jafari, M.; Edalat, F.; Raymond, K.; Khademhosseini, A.; Chen, P. Biocompatibility of engineered nanoparticles for drug delivery. J. Control. Release 2013, 166, 182–194. [Google Scholar] [CrossRef]

- Haun, J.B.; Yoon, T.J.; Lee, H.; Weissleder, R. Magnetic nanoparticle biosensors. Wiley Interdiscip. Rev. Nanomed. Nanobiotechnol. 2010, 2, 291–304. [Google Scholar] [CrossRef]

- Hedayatnasab, Z.; Abnisa, F.; Daud, W.M.A.W. Review on magnetic nanoparticles for magnetic nanofluid hyperthermia application. Mater. Des. 2017, 123, 174–196. [Google Scholar] [CrossRef]

- Mody, V.V.; Cox, A.; Shah, S.; Singh, A.; Bevins, W.; Parihar, H. Magnetic nanoparticle drug delivery systems for targeting tumor. Appl. Nanosci. 2013, 4, 385–392. [Google Scholar] [CrossRef] [Green Version]

- Périgo, E.A.; Hemery, G.; Sandre, O.; Ortega, D.; Garaio, E.; Plazaola, F.; Teran, F.J. Fundamentals and advances in magnetic hyperthermia. Appl. Phys. Rev. 2015, 2, 041302. [Google Scholar] [CrossRef] [Green Version]

- Sahoo, Y.; Goodarzi, A.; Swihart, M.T.; Ohulchanskyy, T.Y.; Kaur, N.; Furlani, E.P.; Prasad, P.N. Aqueous ferrofluid of magnetite nanoparticles: Fluorescence labeling and magnetophoretic control. J. Phys. Chem. B 2005, 109, 3879–3885. [Google Scholar] [CrossRef] [PubMed]

- Zakharova, I.N.; Shipilin, M.A.; Alekseev, V.P.; Shipilin, A.M. Mössbauer study of maghemite nanoparticles. Tech. Phys. Lett. 2012, 38, 55–58. [Google Scholar] [CrossRef]

- Chourpa, I.; Douziech-Eyrolles, L.; Ngaboni-Okassa, L.; Fouquenet, J.-F.; Cohen-Jonathan, S.; Soucé, M.; Marchais, H.; Dubois, P. Molecular composition of iron oxide nanoparticles, precursors for magnetic drug targeting, as characterized by confocal Raman microspectroscopy. Analyst 2005, 130, 1395. [Google Scholar] [CrossRef]

- Issa, B.; Obaidat, I.M.; Albiss, B.A.; Haik, Y. Magnetic nanoparticles: Surface effects and properties related to biomedicine applications. Int. J. Mol. Sci. 2013, 14, 21266–21305. [Google Scholar] [CrossRef] [Green Version]

- Gossuin, Y.; Gillis, P.; Hocq, A.; Vuong, Q.L.; Roch, A. Magnetic resonance relaxation properties of superparamagnetic particles. Nanomed. Nanobiotechnol. 2009, 1, 299–310. [Google Scholar] [CrossRef]

- Amiri, M.; Pardakhti, A.; Ahmadi-Zeidabadi, M.; Akbari, A.; Salavati-Niasari, M. Magnetic nickel ferrite nanoparticles: Green synthesis by Urtica and therapeutic effect of frequency magnetic field on creating cytotoxic response in neural cell lines. Colloids Surf. B Biointerfaces 2018, 172, 244–253. [Google Scholar] [CrossRef]

- Ali, A.; Zafar, H.; Zia, M.; Haq, I.U.; Phull, A.R.; Ali, J.S.; Hussain, A. Synthesis, characterization, applications, and challenges of iron oxide nanoparticles. Nanotechnol. Sci. Appl. 2016, 9, 49–67. [Google Scholar] [CrossRef] [Green Version]

- Mamiya, H.; Ohnuma, M.; Nakatani, I.; Furubayashim, T. Extraction of blocking temperature distribution from zero-field-cooled and field-cooled magnetization curves. IEEE Trans. Magn. 2005, 41, 3394–3396. [Google Scholar] [CrossRef]

- Reddy, L.H.; Arias, J.L.; Nicolas, J.; Couvreur, P. Magnetic nanoparticles: Design and characterization, toxicity and biocompatibility, pharmaceutical and biomedical applications. Chem. Rev. 2012, 112, 5818–5878. [Google Scholar] [CrossRef]

- Petran, A.; Radu, T.; Borodi, G.; Nan, A.; Suciu, M.; Turcu, R. Effects of rare earth doping on multi-core iron oxide nanoparticles properties. Appl. Surf. Sci. 2018, 428, 492–499. [Google Scholar] [CrossRef]

- Kowalik, P.; Mikulski, J.; Borodziuk, A.; Duda, M.; Kamińska, I.; Zajdel, K.; Rybusinski, J.; Szczytko, J.; Wojciechowski, T.; Sobczak, K.; et al. Yttrium-Doped Iron Oxide Nanoparticles for Magnetic Hyperthermia Applications. J. Phys. Chem. C 2020, 124, 6871–6883. [Google Scholar] [CrossRef] [PubMed]

- Sivagurunathan, P.; Sathiyamurthy, K. Effect of Temperatures on Structural, Morphological and Magnetic Properties of Zinc Ferrite Nanoparticles. Can. Chem. Trans. Year 2016, 4, 244–254. [Google Scholar]

- Tuček, J.; Zbořil, R.; Namai, A.; Ohkoshi, S. ε-Fe2O3: An Advanced Nanomaterial Exhibiting Giant Coercive Field, Millimeter-Wave Ferromagnetic Resonance, and Magnetoelectric Coupling. Chem. Mater. 2010, 22, 6483–6505. [Google Scholar] [CrossRef]

- Kalska-Szostko, B.; Kropiewnicka, K. The influence of the transition metal substitution on chemically prepared ferrite nanoparticles—Mossbauer studies. Curr. Appl. Phys. 2012, 12, 896–902. [Google Scholar] [CrossRef]

- Colombo, M.; Carregal-Romero, S.; Casula, M.F.; Gutiérrez, L.; Morales, M.P.; Böhm, I.B.; Heverhagen, J.T.; Prosperi, D.; Parak, W.J. Biological applications of magnetic nanoparticles. Chem. Soc. Rev. 2012, 41, 4306–4334. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.K.; Ma, M.; Zhang, Y.; Gu, N. Synthesis of nanometer-size maghemite particles from magnetite. Colloids Surf. A Physicochem. Eng. Asp. 2004, 245, 15–19. [Google Scholar] [CrossRef]

- Kalska-Szostko, B.; Wykowska, U.; Satula, D.; Nordblad, P. Thermal treatment of magnetite nanoparticles. Beilstein J. Nanotechnol. 2015, 6, 1385–1396. [Google Scholar] [CrossRef] [Green Version]

- Mote, V.; Purushotham, Y.; Dole, B. Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J. Theor. Appl. Phys. 2012, 6, 6. [Google Scholar] [CrossRef] [Green Version]

- Mandal, M.; Kundu, S.; Ghosh, S.K.; Panigrahi, S.; Sau, T.K.; Yusuf, S.M.; Pal, T. Magnetite nanoparticles with tunable gold or silver shell. J. Colloid Interface Sci. 2005, 286, 187–194. [Google Scholar] [CrossRef]

- Kalska-Szostko, B.; Wykowska, U.; Satuła, D. Magnetic nanoparticles of core-shell structure. Colloids Surf. A Physicochem. Eng. Asp. 2015, 481, 527–536. [Google Scholar] [CrossRef]

- Panda, R.N.; Gajbhiye, N.S.; Balaji, G. Magnetic properties of interacting single domain Fe3O4 particles. J. Alloys Compd. 2001, 326, 50–53. [Google Scholar] [CrossRef]

- Tronc, E.; Ezzir, A.; Cherkaoui, R.; Chaneac, C.; Nogues, M.; Kachkachi, H.; Fiorani, D.; Testa, A.M.; Greneche, J.M.; Jolivet, J.P. Surface-related properties of gamma-Fe2O3 nanoparticles. J. Magn. Magn. Mater. 2000, 221, 63–79. [Google Scholar] [CrossRef]

- Chen, T.; Xu, H.; Xie, Q.; Chen, J.; Ji, J.; Lu, H. Characteristics and genesis of maghemite in Chinese loess and paleosols: Mechanism for magnetic susceptibility enhancement in paleosols. Earth Planet. Sci. Lett. 2005, 240, 790–802. [Google Scholar] [CrossRef]

- Singh, L.H.; Pati, S.S.; Sales, M.J.A.; Guimarães, E.M.; Oliveira, A.C.; Garg, V.K. Facile Method to Tune the Particle Size and Thermal Stability of Magnetite Nanoparticles. J. Braz. Chem. Soc. 2015, 26, 2214–2223. [Google Scholar] [CrossRef]

- Vujtek, M.; Zboril, R.; Kubinek, R.; Mashlan, M. Ultrafine Particles of Iron(III) Oxides by View of AFM—Novel Route for Study of Polymorphism in Nano-world. Sci. Technol. Educ. Microsc. 2003, 1, 1–8. [Google Scholar]

- Balasubramaniam, R.; Ramesh Kumar, A.V. Characterization of Delhi iron pillar rust by X-ray diffraction, Fourier transform infrared spectroscopy and Mossbauer spectroscopy. Corros. Sci. 2000, 42, 2085–2101. [Google Scholar] [CrossRef]

- Kalska-Szostko, B.; Wykowska, U.; Piekut, K.; Satuła, D. Stability of Fe3O4 nanoparticles in various model solutions. Colloids Surf. A Physicochem. Eng. Asp. 2014, 450, 15–24. [Google Scholar] [CrossRef]

- Hansen, M.F.; Mørup, S. Estimation of blocking temperatures from ZFC/FC curves. J. Magn. Magn. Mater. 1999, 203, 214–216. [Google Scholar] [CrossRef]

- Kalska-Szostko, B.; Cydzik, M.; Satuła, D.; Giersig, M. Mössbauer Studies of Core-Shell Nanoparticles. Acta Phys. Pol. A 2011, 119, 3–5. [Google Scholar] [CrossRef]

- Kalska-Szostko, B.; Satuła, D.; Olszewski, W. Mössbauer spectroscopy studies of the magnetic properties of ferrite nanoparticles. Curr. Appl. Phys. 2015, 15, 226–231. [Google Scholar] [CrossRef]

| Type of Nanoparticle | Abbreviation | %Fe | %M | ||

|---|---|---|---|---|---|

| Weight ± 2% | Theory | Weight ± 2% | Theory | ||

| Co0.05Fe2.95O4 | Co0.05 | 94 | 95 | 6 | 5 |

| Co0.1Fe2.9O4 | Co0.1 | 91 | 92 | 9 | 8 |

| Co0.15Fe2.85O4 | Co0.15 | 87 | 88 | 13 | 12 |

| Co0.2Fe2.8O4 | Co0.2 | 81 | 84 | 19 | 16 |

| Mn0.05Fe2.95O4 | Mn0.05 | 93 | 96 | 7 | 4 |

| Mn0.1Fe2.9O4 | Mn0.1 | 89 | 92 | 11 | 8 |

| Mn0.15Fe2.85O4 | Mn0.15 | 83 | 88 | 17 | 12 |

| Mn0.2Fe2.8O4 | Mn0.2 | 77 | 85 | 22 | 15 |

| Ni0.05Fe2.95O4 | Ni0.05 | 94 | 96 | 6 | 4 |

| Ni0.1Fe2.9O4 | Ni0.1 | 90 | 92 | 10 | 8 |

| Ni0.15Fe2.85O4 | Ni0.15 | 85 | 88 | 15 | 12 |

| Ni0.2Fe2.8O4 | Ni0.2 | 80 | 85 | 20 | 15 |

| Name | Size (nm) ± 1 | Strain [103] ± 0.5 | Fe3O4 Cell Size (Å) ± 0.02 | Fe2O3 Cell Size (Å) ± 0.02 | Fe3O4 (%) ± 1 | α-Fe2O3 (%) ± 1 |

|---|---|---|---|---|---|---|

| Fe3O4 | 15 | 3.1 | 8.37 | - | 100 | 0 |

| Co0.05 a.p. | 13 | 3.7 | 8.38 | - | 100 | 0 |

| Co0.05 500 °C | 15 | 4.1 | 8.34 | 5.03 | 77 | 23 |

| Co0.10 a.p. | 13 | 4.1 | 8.37 | 5.03 | 78 | 22 |

| Co0.10 500 °C | 25 | 5.0 | 8.37 | 5.04 | 25 | 75 |

| Co0.15 a.p. | 13 | 3.1 | 8.39 | - | 100 | 0 |

| Co0.15 500 °C | 15 | 3.7 | 8.37 | 5.04 | 76 | 24 |

| Mn0.05 a.p. | 15 | 4.4 | 8.39 | - | 80 | 20 |

| Mn0.05 500 °C | 18 | 4.3 | 8.34 | 5.03 | 64 | 36 |

| Mn0.10 a.p. | 13 | 3.1 | 8.42 | - | 100 | 0 |

| Mn0.10 500 °C | 15 | 4.0 | 8.34 | 5.04 | 85 | 15 |

| Mn0.15 a.p. | 12 | 4.5 | 8.42 | - | 100 | 0 |

| Mn0.15 500 °C | 12 | 3.8 | 8.35 | 5.03 | 86 | 14 |

| Ni0.05 a.p. | 13 | 3.0 | 8.37 | - | 100 | 0 |

| Ni0.05 500 °C | 14 | 3.4 | 8.34 | 5.03 | 94 | 6 |

| Ni0.10 a.p. | 11 | 1.9 | 8.37 | - | 100 | 0 |

| Ni0.10 500 °C | 13 | 3.2 | 8.34 | 5.04 | 92 | 8 |

| Ni0.15 a.p. | 12 | 3.1 | 8.37 | - | 100 | 0 |

| Ni0.15 500 °C | 13 | 3.2 | 8.34 | 5.03 | 96 | 4 |

| Name | Size (nm) ± 1 | Strain [103] ± 0.5 | Fe3O4 Cell Size (Å) ± 0.02 |

|---|---|---|---|

| Co0.20 a.p. | 11 | 2.1 | 8.38 |

| Co0.20 50 °C | 12 | 2.1 | 8.39 |

| Co0.20 100 °C | 12 | 1.2 | 8.38 |

| Co0.20 150 °C | 13 | 3.2 | 8.38 |

| Co0.20 200 °C | 13 | 3.2 | 8.37 |

| Co0.20 250 °C | 12 | 2.8 | 8.37 |

| Co0.20 300 °C | 10 | 4.7 | 8.35 |

| Co0.20 350 °C | 11 | 1.7 | 8.34 |

| Co0.20 400 °C | 12 | 3.1 | 8.34 |

| Co0.20 450 °C | 12 | 2.5 | 8.36 |

| Co0.20 500 °C | 12 | 1.7 | 8.36 |

| Mn0.20 a.p. | 10 | 5.1 | 8.42 |

| Mn0.20 50 °C | 10 | 4.7 | 8.42 |

| Mn0.20 100 °C | 10 | 4.5 | 8.41 |

| Mn0.20 150 °C | 11 | 4.6 | 8.39 |

| Mn0.20 200 °C | 10 | 4.7 | 8.38 |

| Mn0.20 250 °C | 11 | 4.7 | 8.37 |

| Mn0.20 300 °C | 12 | 2.1 | 8.36 |

| Mn0.20 350 °C | 11 | 3.9 | 8.33 |

| Mn0.20 400 °C | 11 | 3.4 | 8.33 |

| Mn0.20 450 °C | 11 | 3.5 | 8.34 |

| Mn0.20 500 °C | 11 | 3.9 | 8.35 |

| Ni0.20 a.p. | 10 | 2.8 | 8.36 |

| Ni0.20 50 °C | 11 | 2.4 | 8.36 |

| Ni0.20 100 °C | 12 | 2.8 | 8.37 |

| Ni0.20 150 °C | 12 | 2.4 | 8.35 |

| Ni0.20 200 °C | 12 | 2.4 | 8.34 |

| Ni0.20 250 °C | 12 | 3.1 | 8.34 |

| Ni0.20 300 °C | 12 | 3.1 | 8.34 |

| Ni0.20 350 °C | 12 | 2.8 | 8.34 |

| Ni0.20 400 °C | 12 | 2.5 | 8.33 |

| Ni0.20 450 °C | 11 | 1.7 | 8.34 |

| Ni0.20 500 °C | 12 | 2.6 | 8.33 |

| Sample | MS | Tbm (K) ± 1 | Mrs (A·m2/kg) ± 0.5 | Ms (A·m2/kg) ± 0.5 | Hc (mT) ± 0.5 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| H-M | M | 2 K | 10 K | 300 K | 2 K | 10 K | 300 K | 2 K | 10 K | 300 K | ||

| Mn0.20 | >RT | 169 | 5.6 | 28.4 | 20.5 | 0.2 | 88.6 | 88.7 | 68.1 | 29.4 | 19.7 | 0.1 |

| Mn0.20 500 °C | >RT | 243 | 84.9 | 27.9 | 25.4 | 0.1 | 65.6 | 65.6 | 55.3 | 44.7 | 38.4 | 0.1 |

| Mn0.15 | >RT | >300 | 299 | 22.7 | 18.1 | 0.6 | 82.4 | 82.5 | 67.0 | 23.3 | 18.0 | 0.4 |

| Mn0.15 500 °C | >RT | >300 | 113 | 23.0 | 21.5 | 0.3 | 57.9 | 57.7 | 50.7 | 38.3 | 34.4 | 0.2 |

| Mn0.10 | >RT | >300 | 299 | 20.9 | 17.9 | 2.1 | 85.4 | 85.4 | 69.7 | 21.5 | 18.2 | 1.6 |

| Mn0.10 500 °C | >RT | >300 | 116 | 23.2 | 21.4 | 1.7 | 68.3 | 68.3 | 60.1 | 31.5 | 28.5 | 1.4 |

| Mn0.05 | >RT | >300 | 299 | 17.8 | 15.3 | 3.6 | 68.1 | 68.0 | 59.1 | 24.4 | 20.8 | 3.5 |

| Mn0.05 500 °C | >RT | >300 | 299 | 18.4 | 17.6 | 3.5 | 53.4 | 53.4 | 47.2 | 30.8 | 29.2 | 3.6 |

| Co0.05 | >RT | >300 | 299 | 50.8 | 49.5 | 11.3 | 70.3 | 70.2 | 59.7 | 512 | 480 | 23.0 |

| Ni0.05 | >RT | >300 | 299 | 22.7 | 19.9 | 2.8 | 76.5 | 76.9 | 70.1 | 24.2 | 21.1 | 2.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klekotka, U.; Satuła, D.; Spassov, S.; Kalska-Szostko, B. Influence of Atomic Doping on Thermal Stability of Ferrite Nanoparticles—Structural and Magnetic Studies. Materials 2021, 14, 100. https://doi.org/10.3390/ma14010100

Klekotka U, Satuła D, Spassov S, Kalska-Szostko B. Influence of Atomic Doping on Thermal Stability of Ferrite Nanoparticles—Structural and Magnetic Studies. Materials. 2021; 14(1):100. https://doi.org/10.3390/ma14010100

Chicago/Turabian StyleKlekotka, Urszula, Dariusz Satuła, Simo Spassov, and Beata Kalska-Szostko. 2021. "Influence of Atomic Doping on Thermal Stability of Ferrite Nanoparticles—Structural and Magnetic Studies" Materials 14, no. 1: 100. https://doi.org/10.3390/ma14010100