Phase Transformation in 316L Austenitic Steel Induced by Fracture at Cryogenic Temperatures: Experiment and Modelling

Abstract

1. Introduction

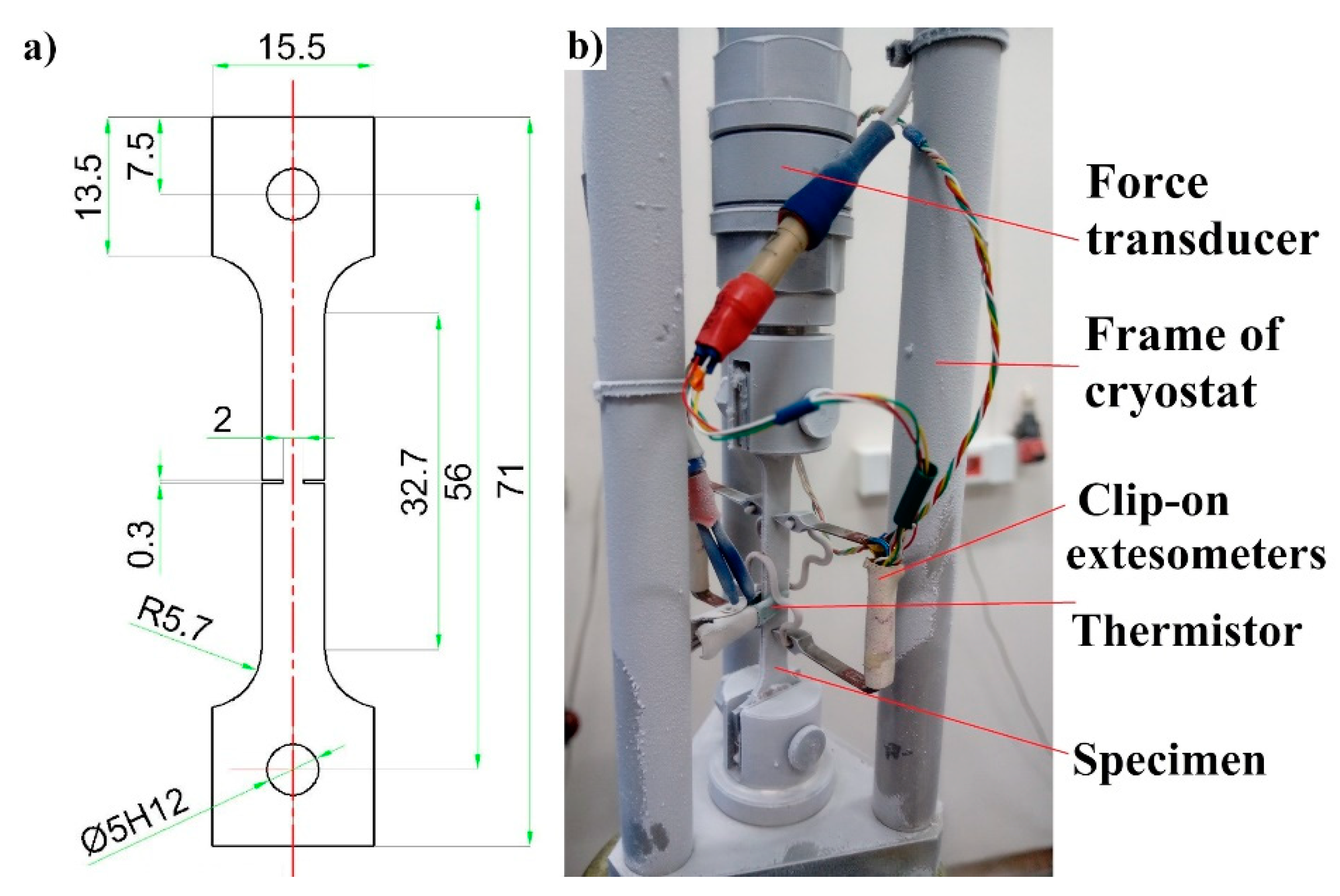

2. Materials and Methods

3. Experimental Results

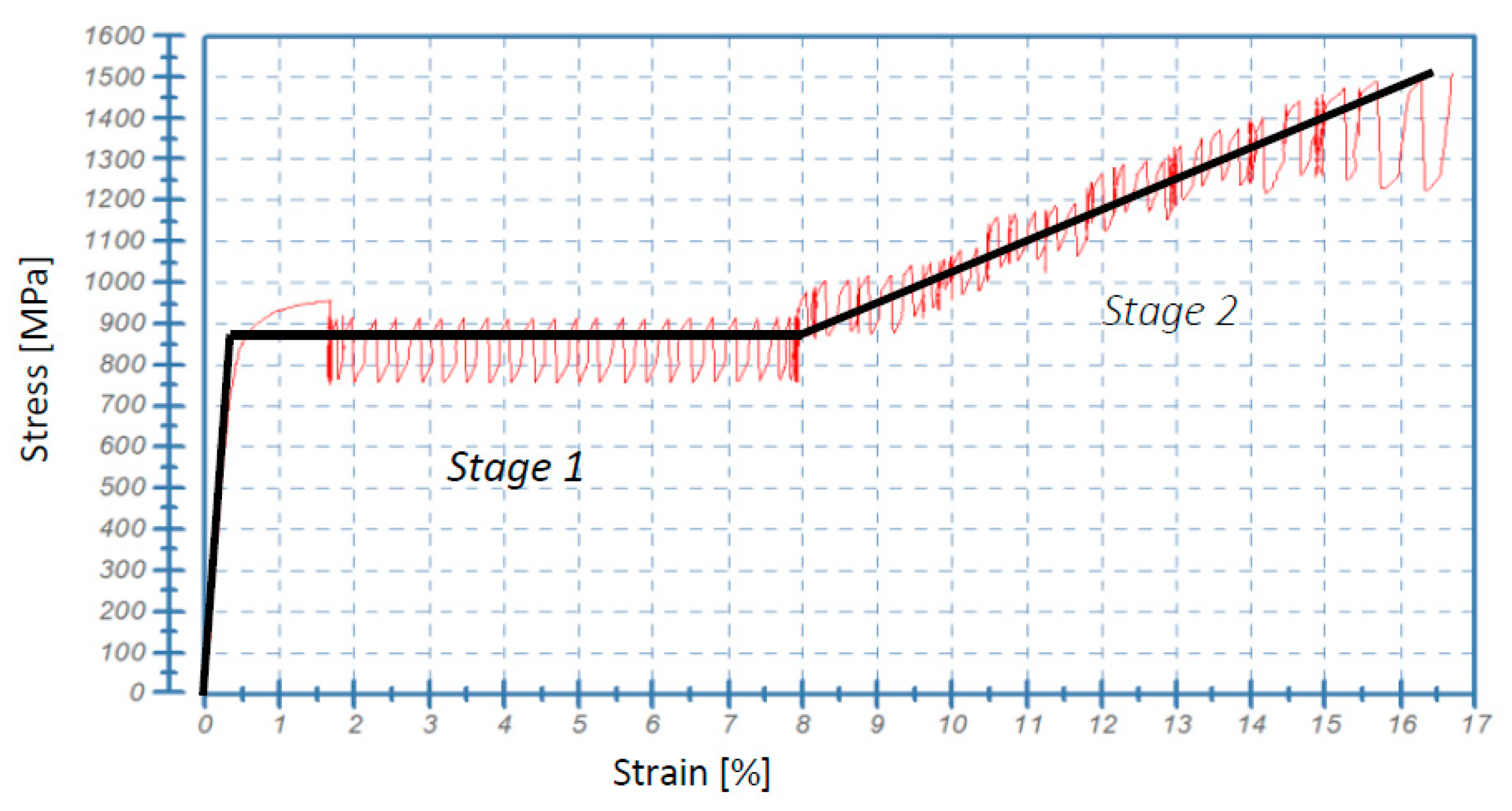

3.1. Mechanical Response at Different Temperatures

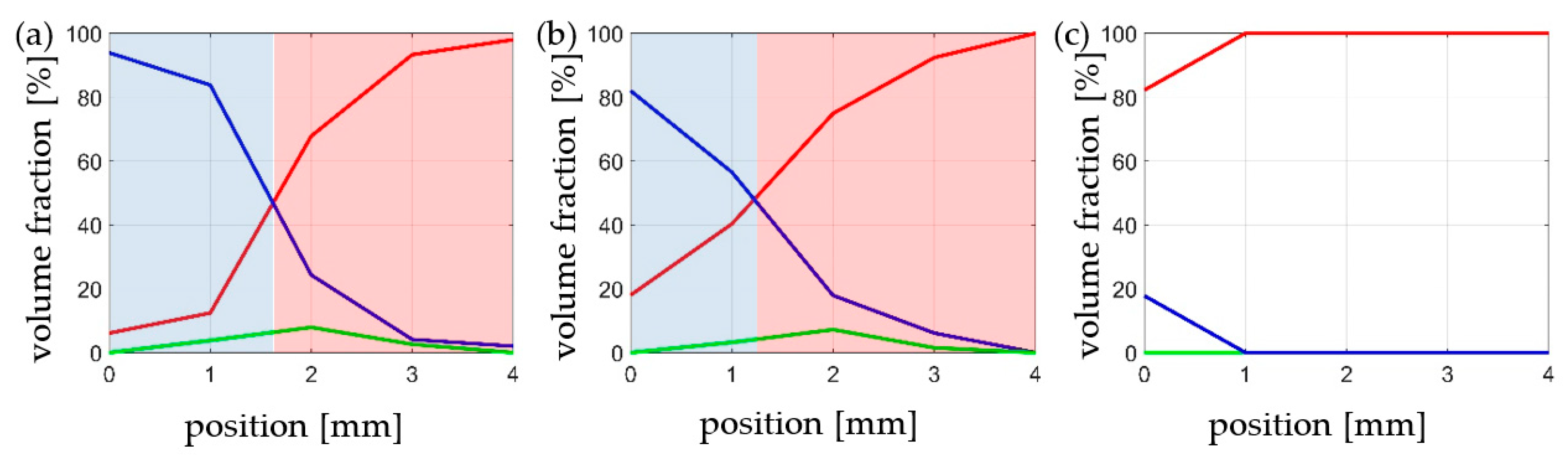

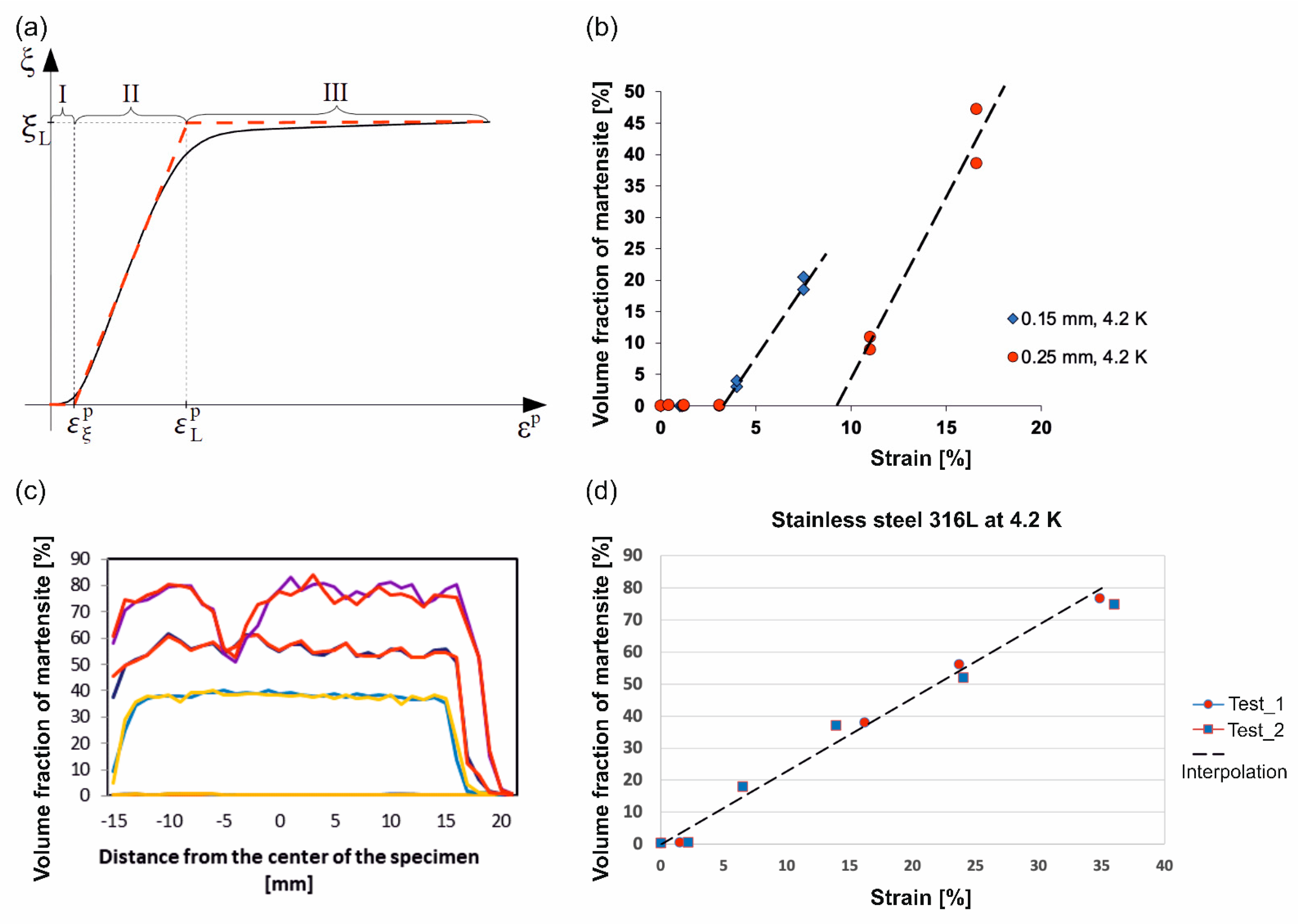

3.2. Phase Evolution

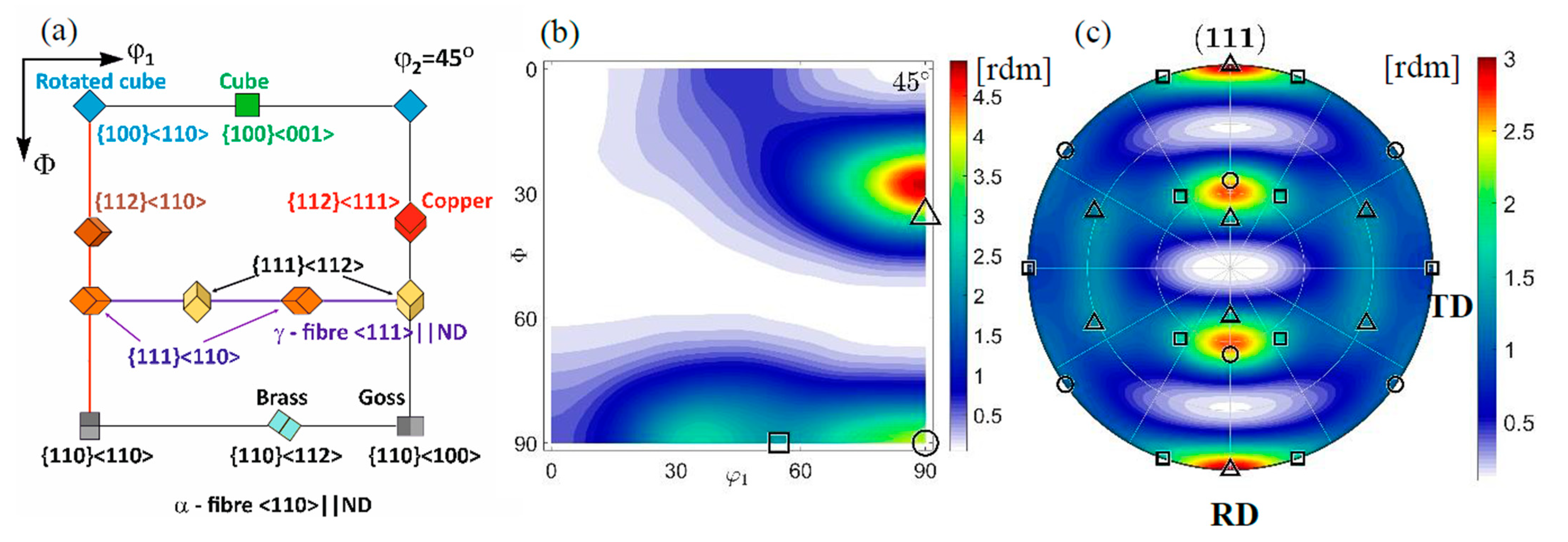

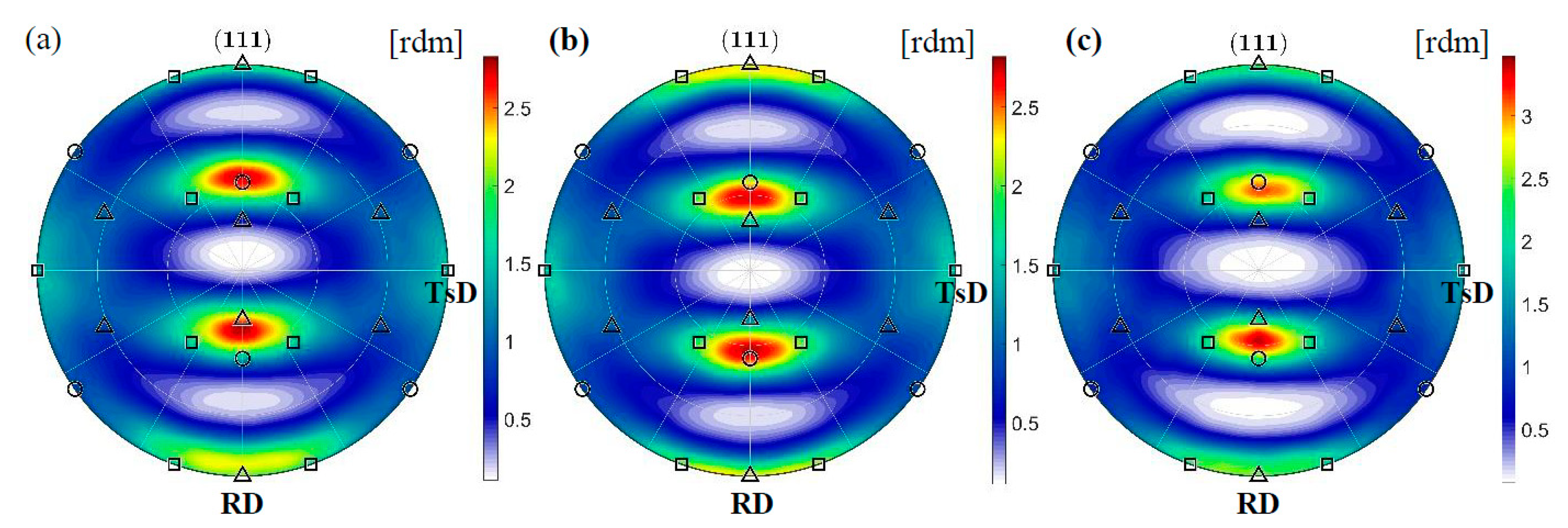

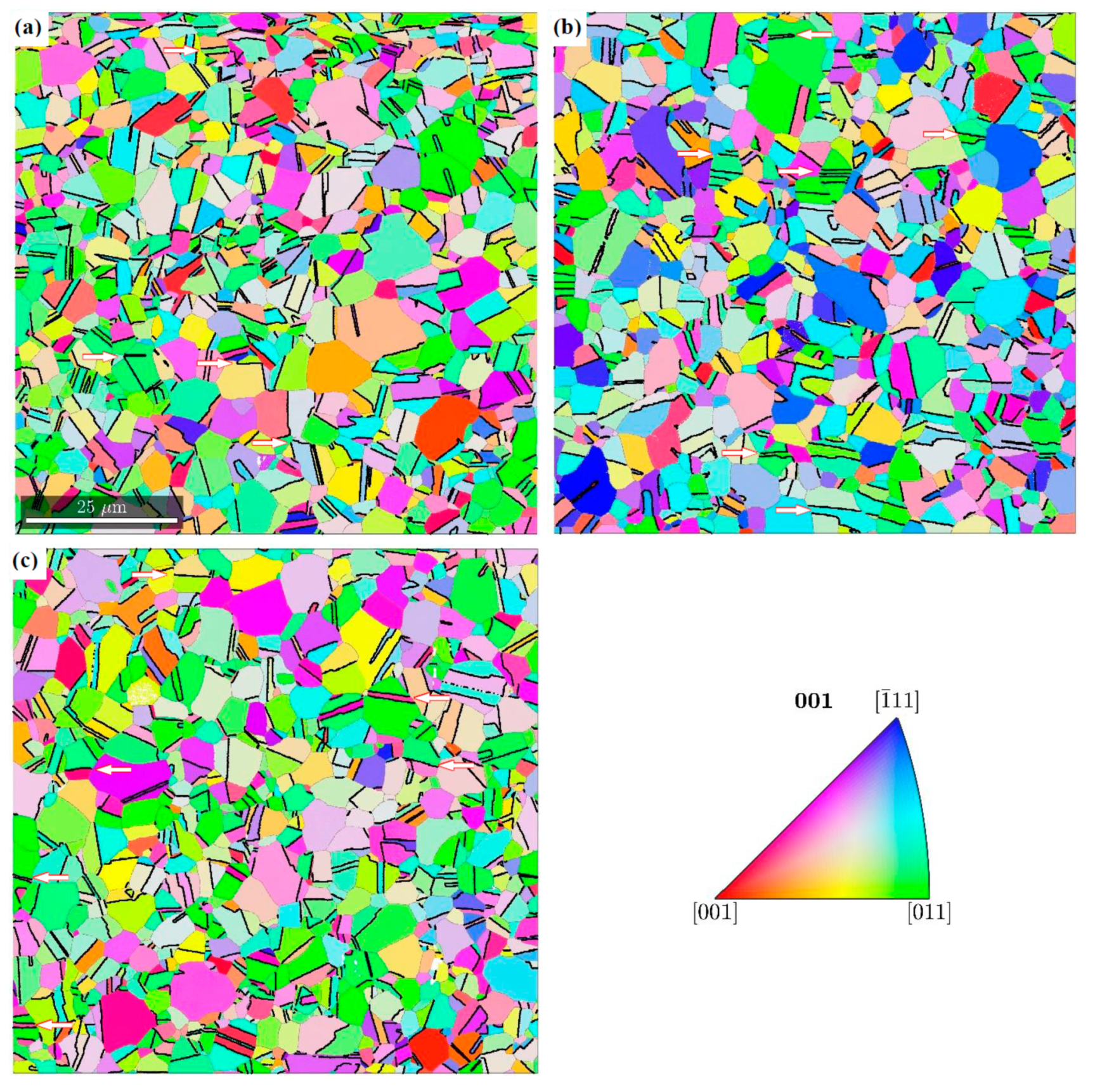

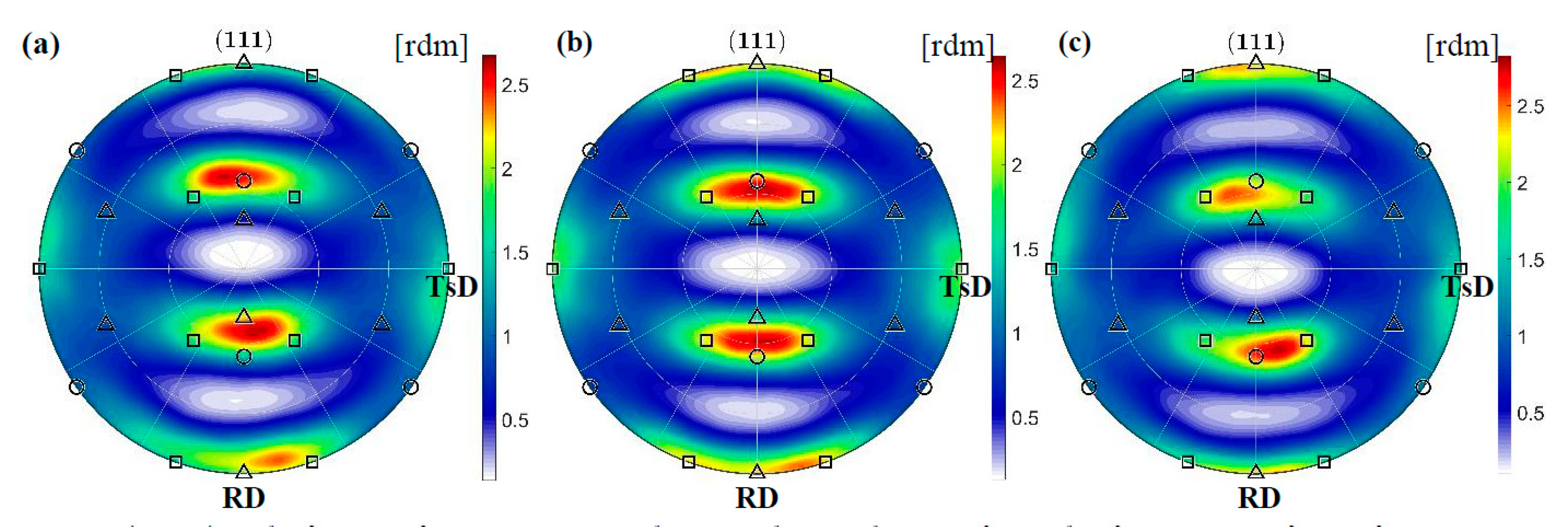

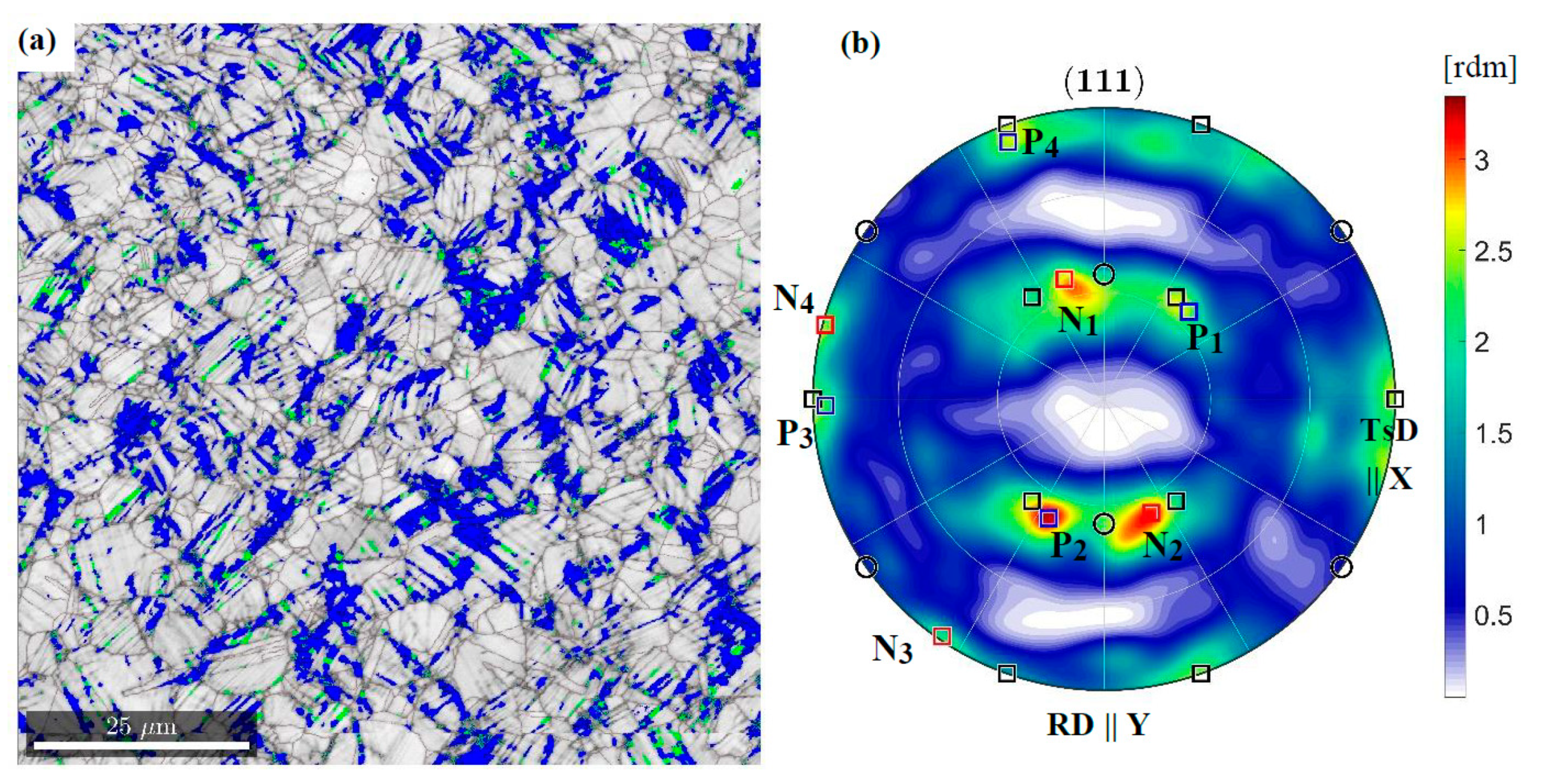

3.3. Austenite Texture

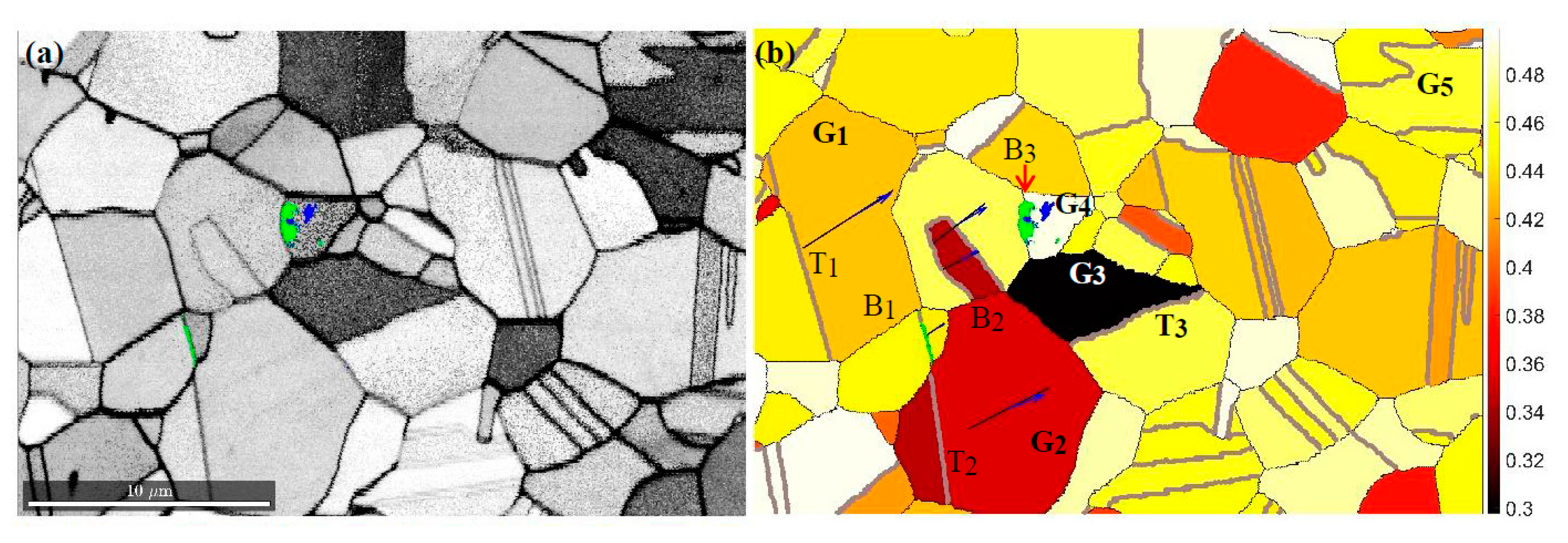

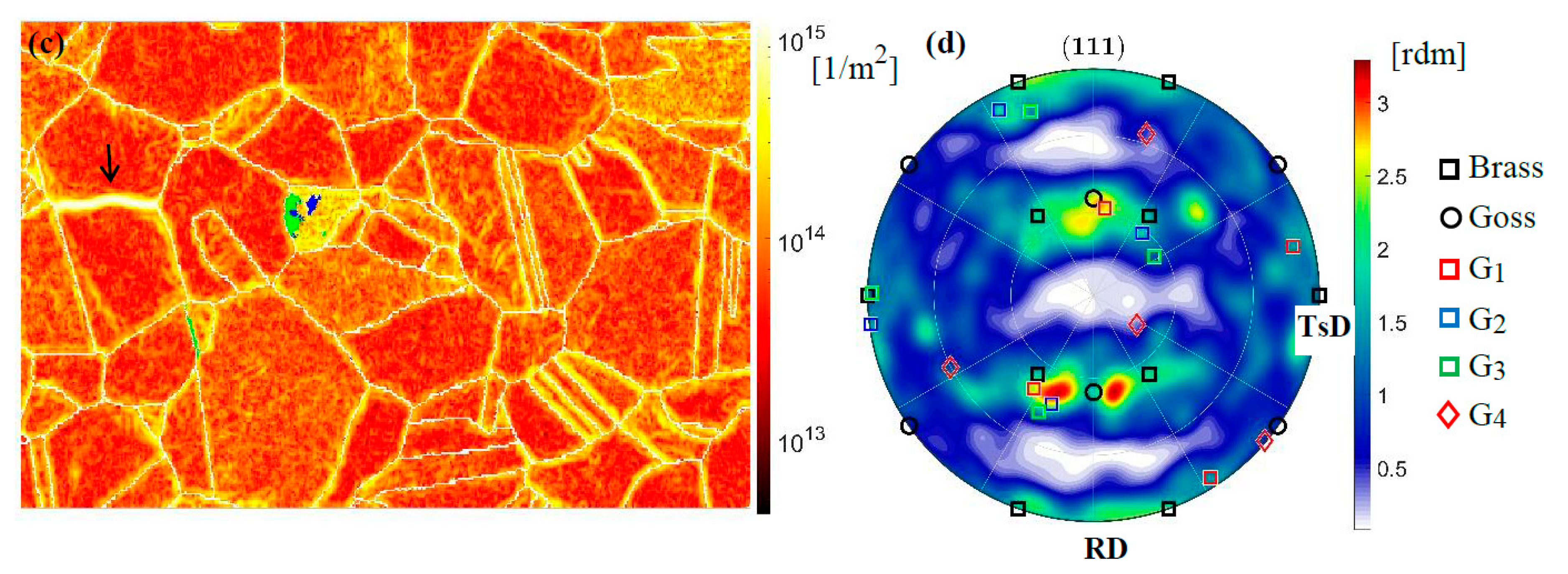

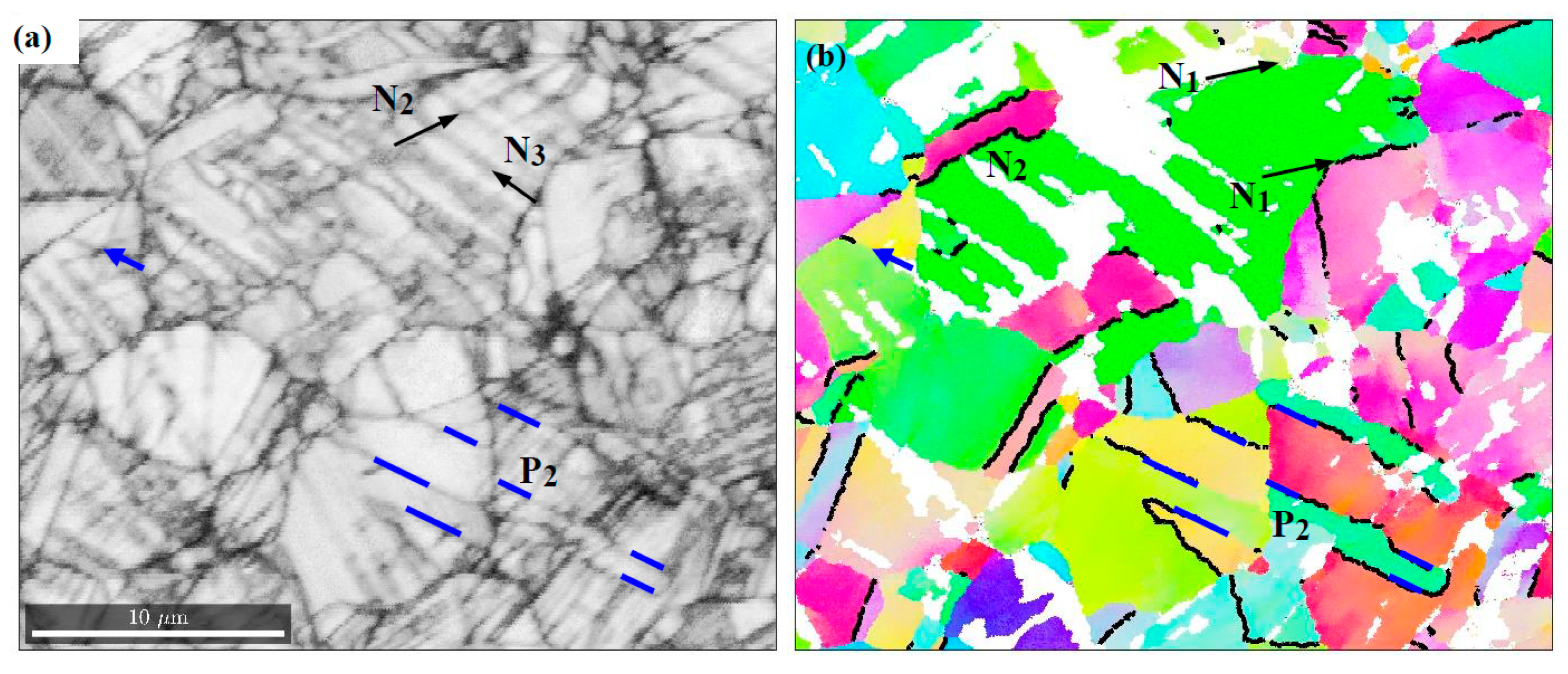

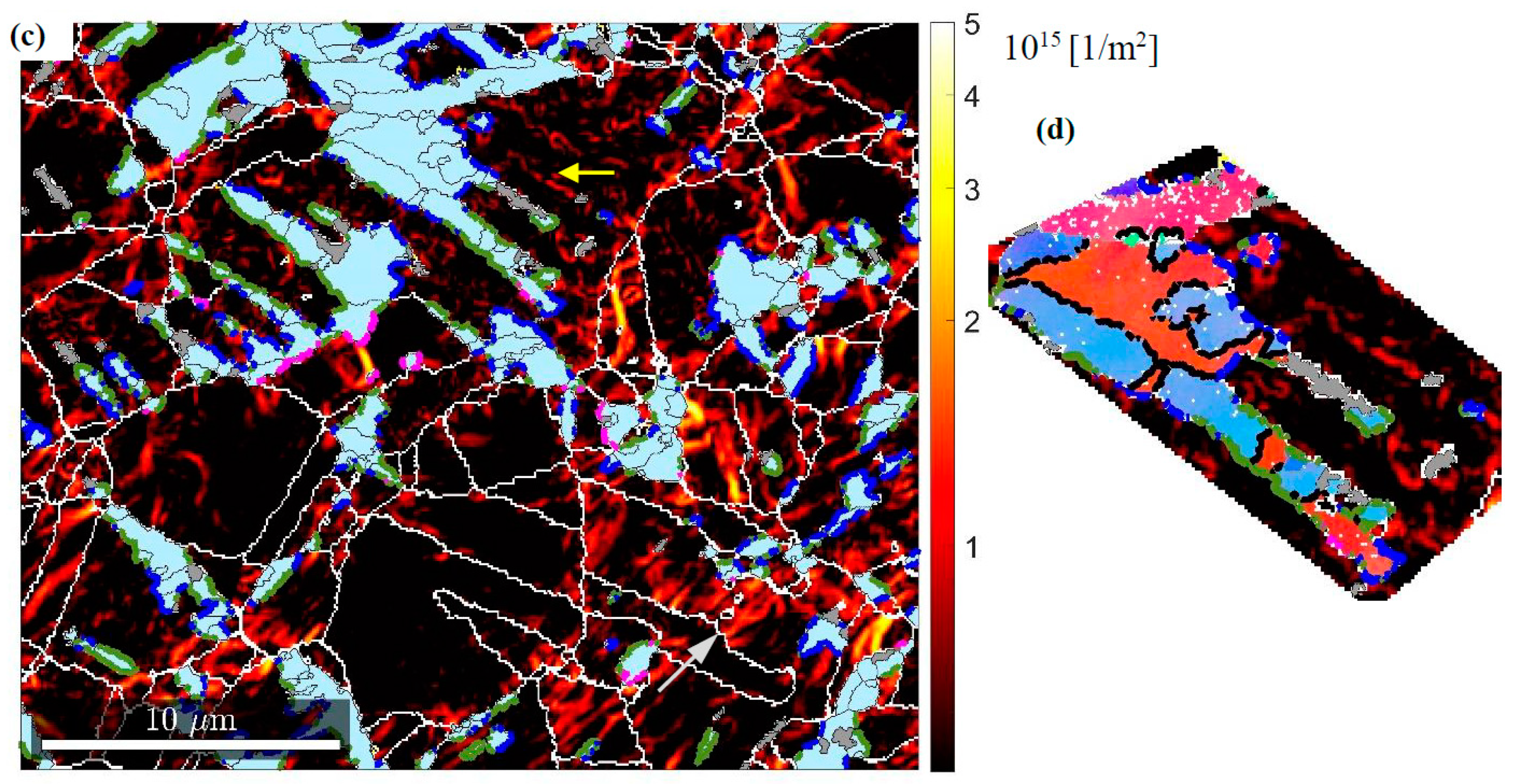

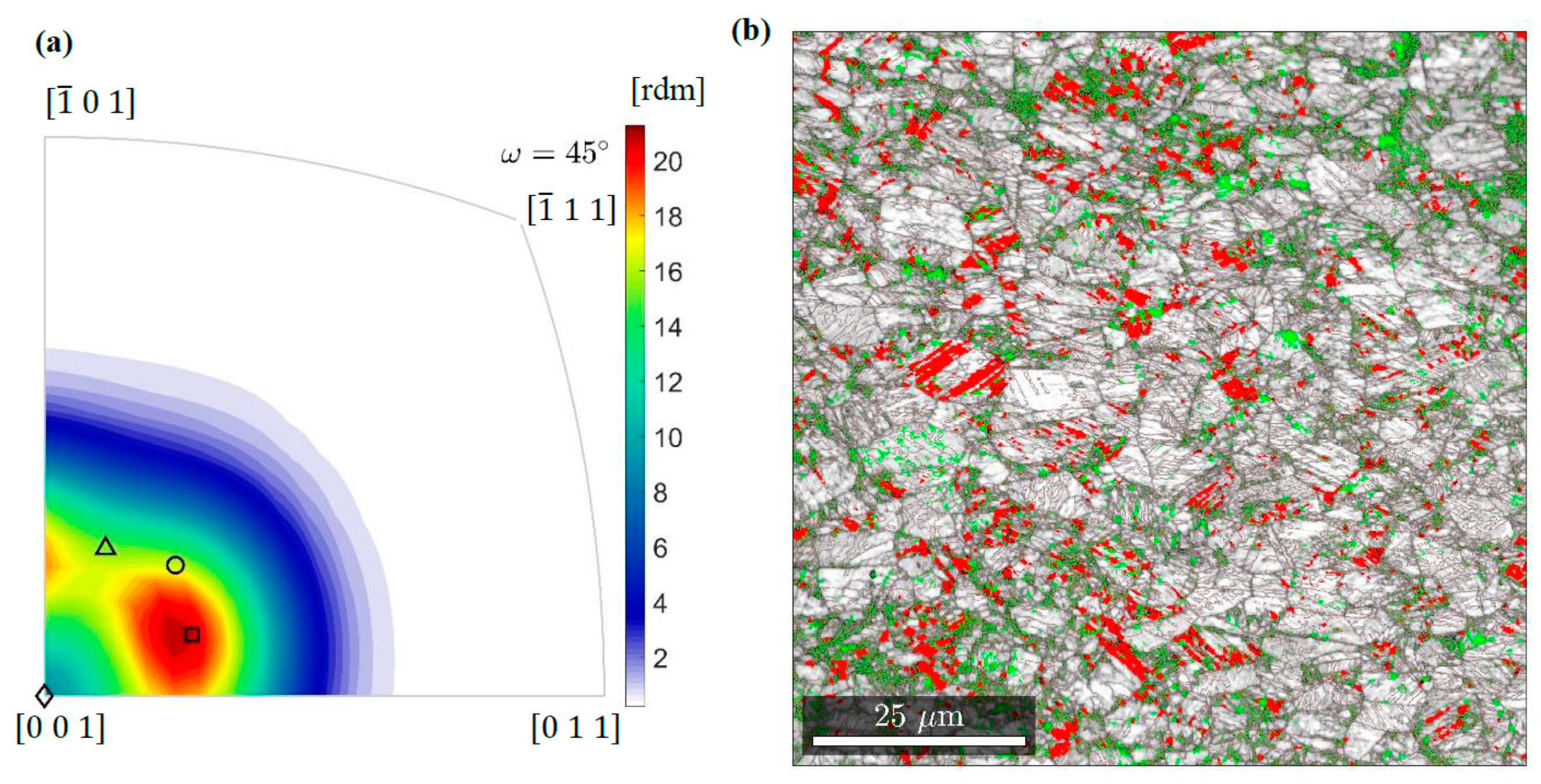

3.4. Phase Transformation Controlled by Austenite

4. FEM Analysis of Fracture in Two-Phase Continuum

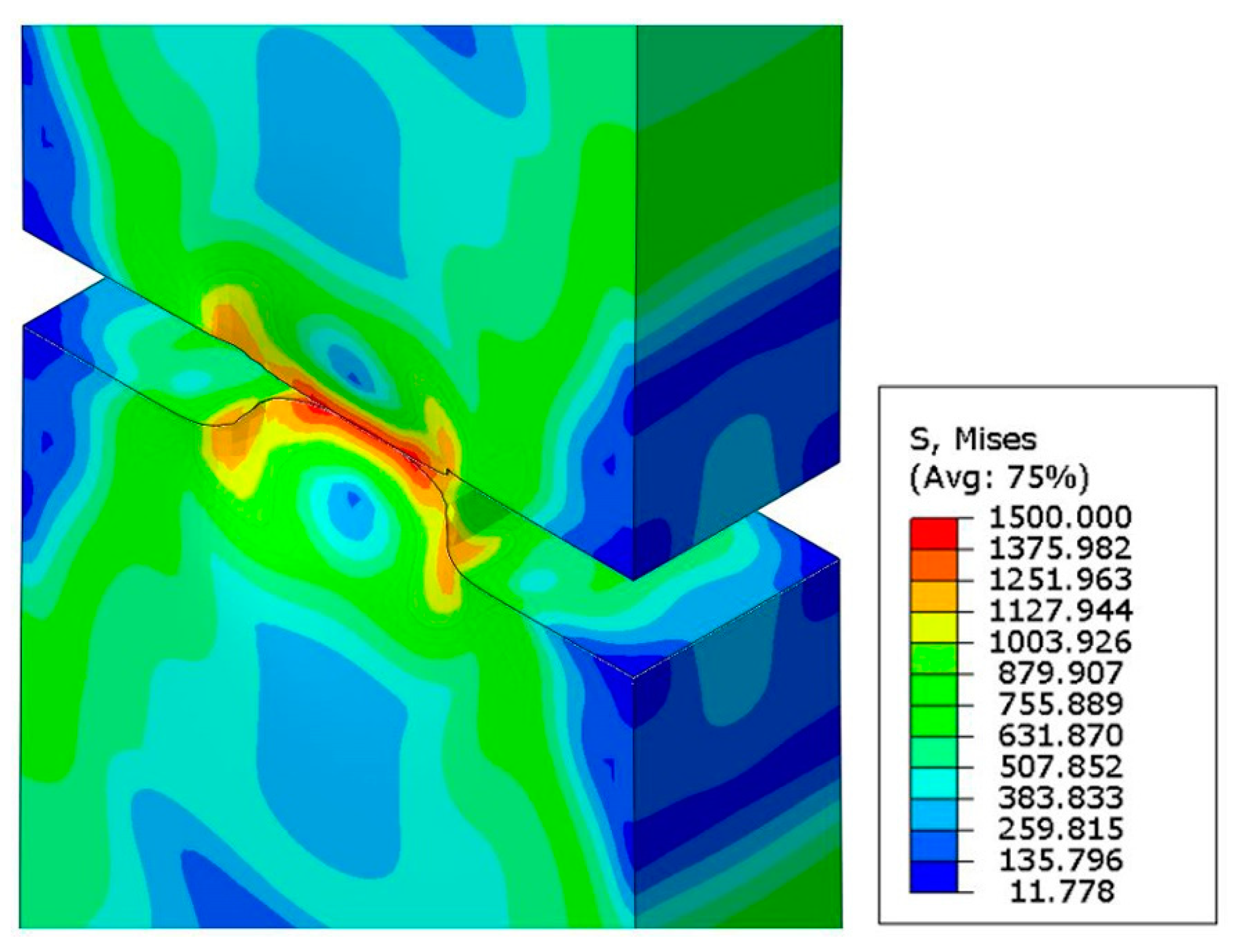

4.1. XFEM Method

4.2. Kinetics of Phase Transformation

4.3. Constitutive Model

4.4. Numerical Model

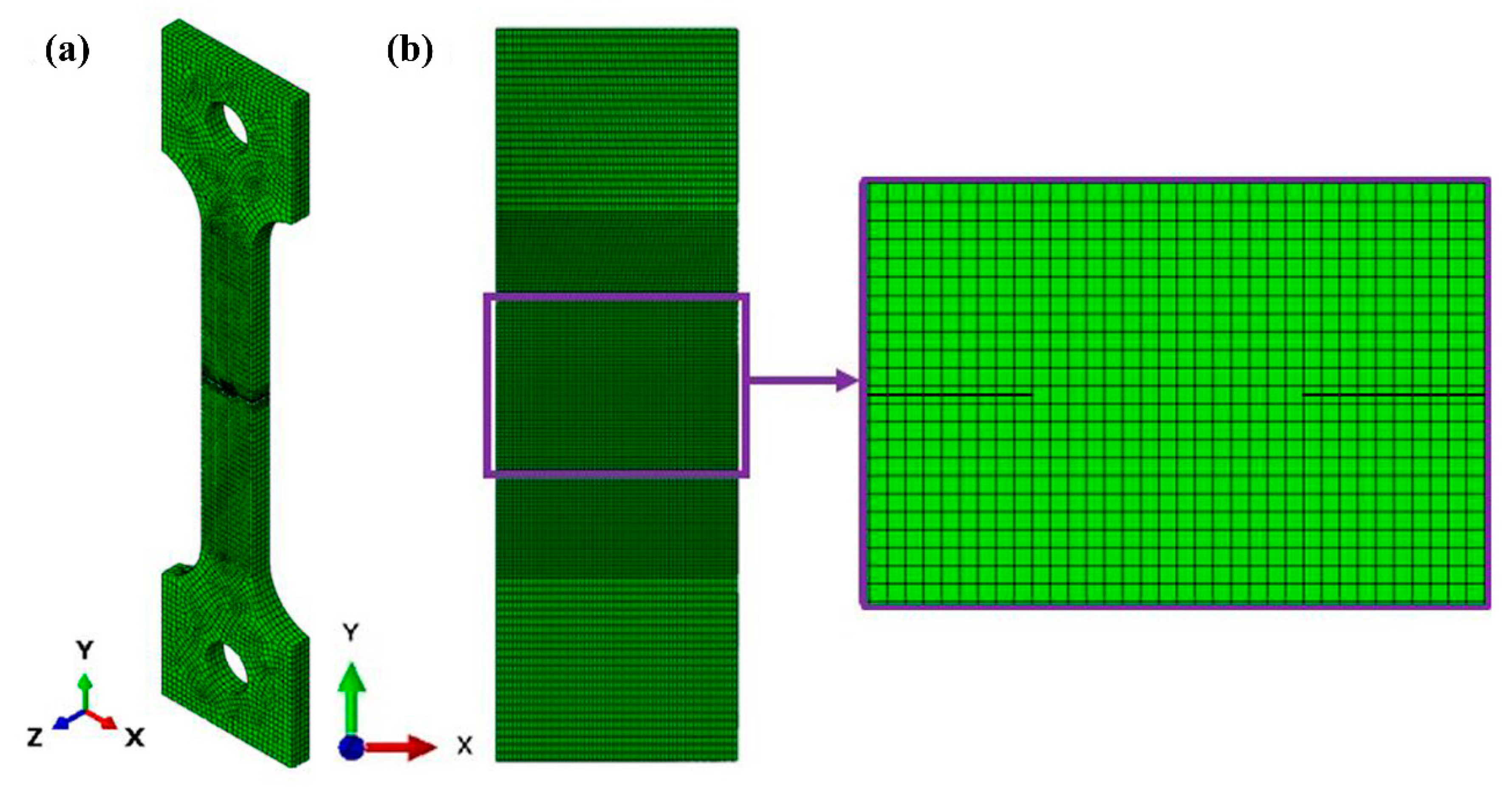

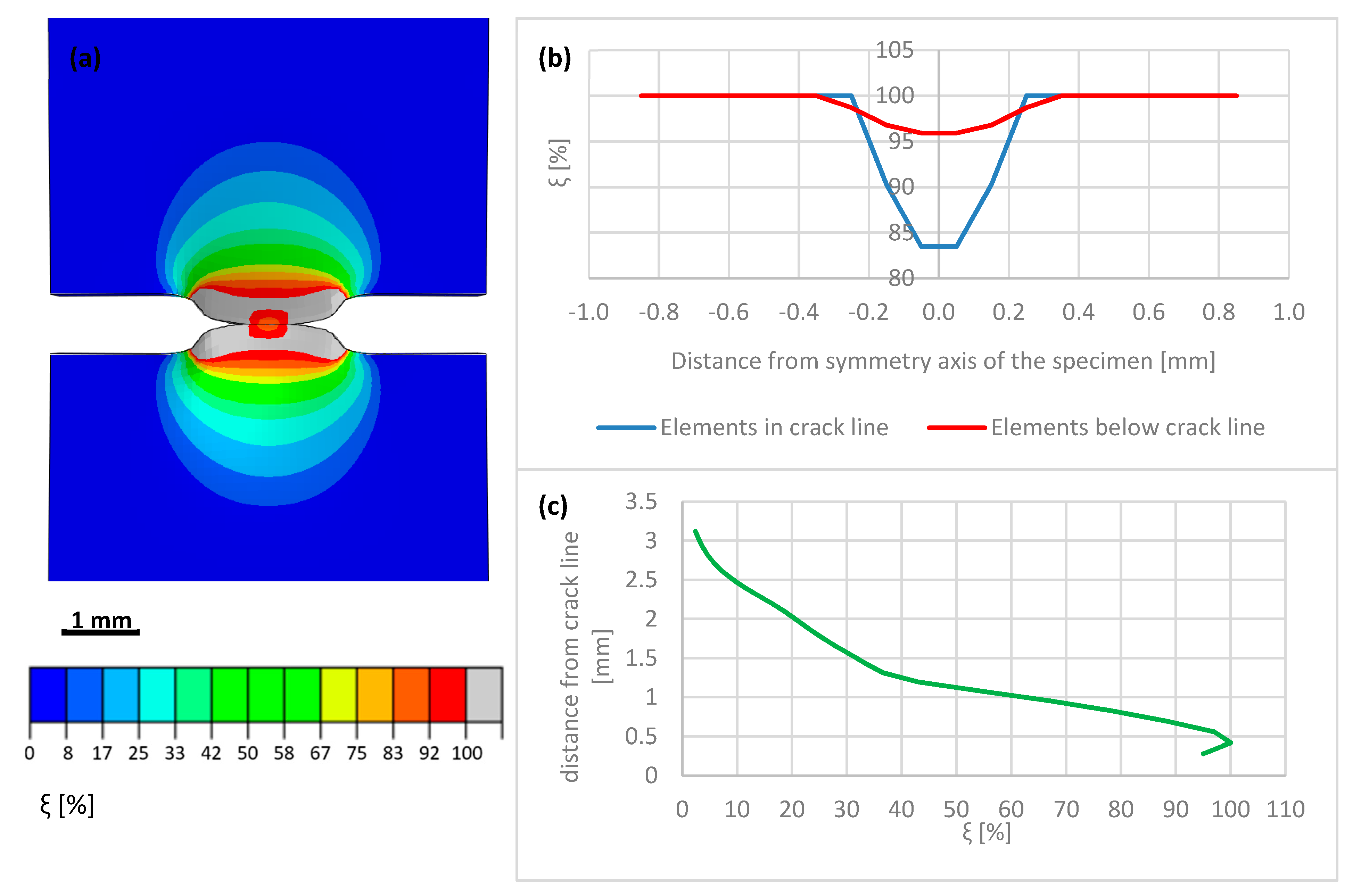

4.5. Numerical Results

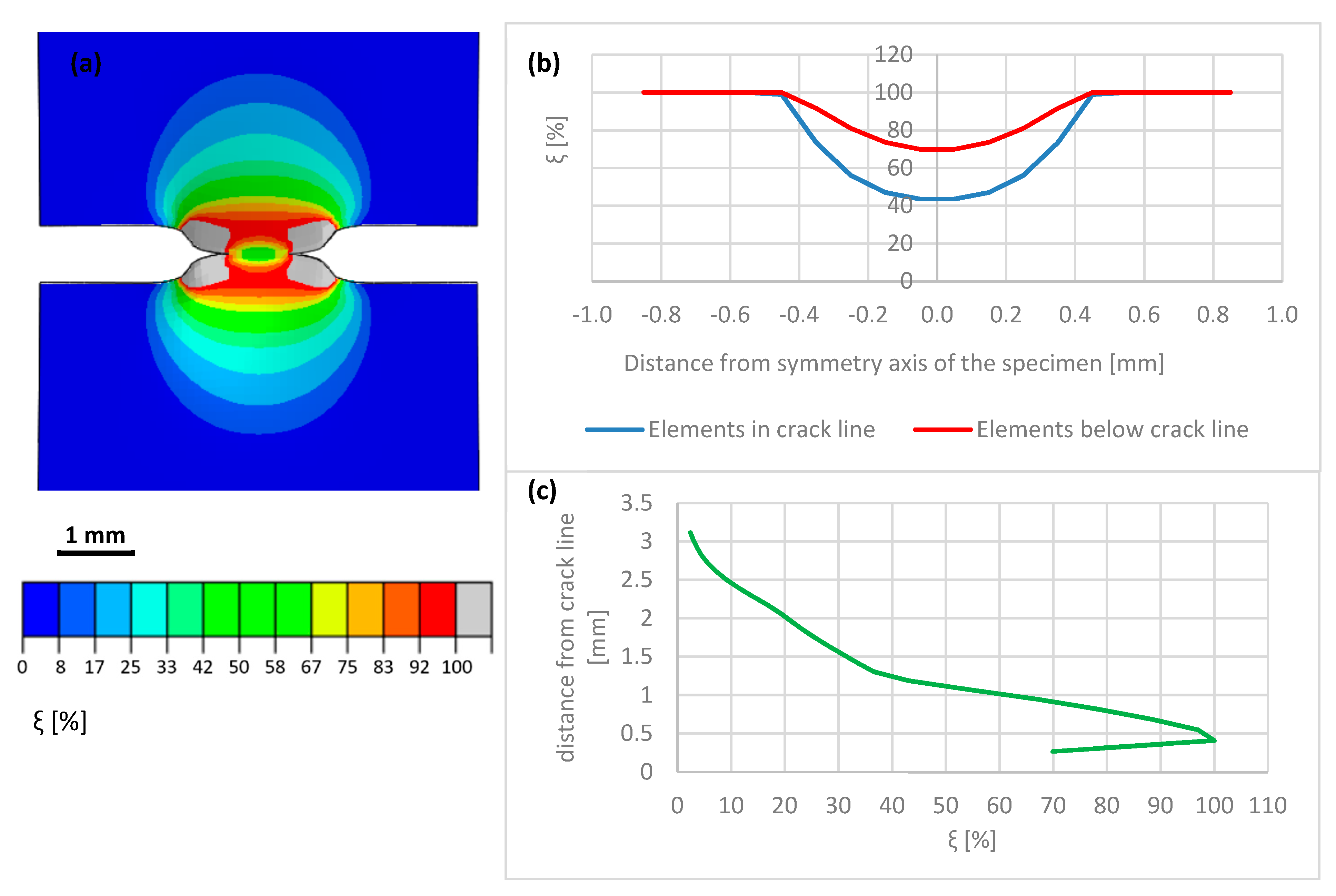

5. Comparison of Experimental and Numerical Results

5.1. Distribution of the Secondary Phase in the Macro-Crack Proximity

5.2. Microstructure Evolution during Fracture

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Read, D.T.; Reed, R.P. Fracture and Strength Properties of Selected Austenitic Stainless Steels at Cryogenic Temperatures. Cryogenics 1981, 21, 415–417. [Google Scholar] [CrossRef]

- Simon, N.J.; Reed, R.P. Strength and Toughness of AISI 304 and 316 at 4 K. J. Nucl. Mater. 1986, 141–143, 44–48. [Google Scholar] [CrossRef]

- Skoczeń, B.; Bielski, J.; Tabin, J. Multiaxial constitutive model of discontinuous plastic flow at cryogenic temperatures. Int. J. Plast. 2014, 55, 198–218. [Google Scholar]

- Sitko, M.; Skoczeń, B.; Wróblewski, A. FCC-BCC phase transformation in rectangular beams subjected to plastic straining at cryogenic temperatures. Int. J. Mech. Sci. 2010, 52, 993–1007. [Google Scholar] [CrossRef]

- Ryś, M.; Skoczeń, B. Coupled constitutive model of damage affected two-phase continuum. Mech. Mater. 2017, 115, 1–15. [Google Scholar]

- Olson, G.B.; Cohen, M. A perspective on martensitic nucleation. Annu. Rev. Mater. Sci. 1982, 11, 1–30. [Google Scholar] [CrossRef]

- Yang, X.-S.; Sun, S.; Zhang, T.-Y. The mechanism of bcc ‘nucleation in single hcp ε laths in the fcc → hcp ε → bcc’ martensitic phase transformation. Acta Mater. 2015, 95, 264–273. [Google Scholar] [CrossRef]

- Staudhammer, K.P.; Murr, E.; Hecker, S.S. Nucleation and evolution of strain-induced martensitic (b.c.c.) embryos and substructure in stainless steel: A transmission electron microscope study. Acta Metall. 1983, 31, 267–274. [Google Scholar] [CrossRef]

- Han, W.; Liu, Y.; Wan, F.; Liu, P.; Yi, X.; Zhan, Q.; Morrall, D.; Ohnuki, S. Deformation behavior of austenitic stainless steel at deep cryogenic temperatures. J. Nucl. Mater. 2018, 504, 29–32. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Narutani, T.; Olson, G.; Cohen, M. Constitutive flow relations for austenitic steels during strain induced martensitic transformation. J. Phys. 1982, 43, 429–434. [Google Scholar]

- Stringfellow, R.G.; Parks, D.M.; Olson, G.B. Constitutive model for transformation plasticity accompanying strain-induced martensitic transformations in metastable austenitic steels. Acta Metall. 1992, 40, 1703–1716. [Google Scholar] [CrossRef]

- Leblond, J.B.; Devaux, J.; Devaux, J.C. Mathematical modelling of transformation plasticity in steels—1: Case of ideal-plastic phases. Int. J. Plast. 1989, 5, 551–572. [Google Scholar] [CrossRef]

- Fischer, F.D.; Oberaigner, E.R.; Tanaka, K.; Nishimura, F. Transformation induced plasticity revised an updated formulation. Int. J. Solids Struct. 1998, 35, 2209–2227. [Google Scholar] [CrossRef]

- Diani, J.M.; Parks, D.M. Effects of strain state on the kinetics of strain induced martensite in steels. J. Mech. Phys. Solids 1998, 46, 1613–1635. [Google Scholar] [CrossRef]

- Levitas, V.I.; Idesman, A.V.; Olson, G.B. Continuum modeling of strain-induced martensitic transformation at shear band intersections. Acta Mater. 1999, 47, 219–233. [Google Scholar] [CrossRef]

- Fischer, F.D.; Reisner, G.; Werner, E.; Tanaka, K.; Cailletaud, G.; Antretter, T. A new view on transformation induced plasticity (TRIP). Int. J. Plast. 2000, 16, 723–748. [Google Scholar] [CrossRef]

- Cherkaoui, M.; Berveiller, M.; Lemoine, X. Couplings between plasticity and martensitic phase transformation: Overall behavior of polycrystalline TRIP steels. Int. J. Plast. 2000, 16, 1215–1241. [Google Scholar] [CrossRef]

- Kubler, J.; Schindler, H.J.; Muster, W.J. Influence of Aging on the Fracture Toughness of Cryogenic Austenitic Materials Evaluated by a Simple Test Method. Adv. Cryog. Eng. (Mater.) 1992, 38, 191–198. [Google Scholar]

- Dolgin, A.M.; Natsik, V.D. Criteria of Instability and Kinetics of Jumps under Unstable Low Temperature Plastic Flow. Acta Univ. Carol. Math. Phys. 1991, 32, 77–88. [Google Scholar]

- Zaiser, M.; Hähner, P. Oscillatory Modes of Plastic Deformation: Theoretical Concepts. Phys. Status Solidi B 1997, 199, 267–330. [Google Scholar] [CrossRef]

- Tabin, J.; Prącik, M. Methods for identifying dynamic parameters of clip-on extensometer-specimen structure in tensile tests. Measurement 2015, 63, 176–186. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef]

- Pantleon, W. Resolving the geometrically necessary dislocation content by conventional electron backscatteing diffraction. Scr. Mater. 2008, 58, 994–997. [Google Scholar] [CrossRef]

- Nye, J.F. Physical Properties of Crystals by Tensors and Matrices; Oxford University Press: Oxford, UK, 1985. [Google Scholar]

- Pagounis, E.; Chulist, R.; Lippmann, T.; Laufenberg, M.; Skrotzki, W. Structural modification and twinning stress reduction in a high-temperature Ni-Mn-Ga magnetic shape memory alloy. Appl. Phys. Lett. 2013, 103, 111911. [Google Scholar] [CrossRef]

- Chulist, R.; Straka, L.; Seiner, H.; Sozinov, A.; Schell, N.; Tokarski, T. Branching of {110) twin boundaries in five-layered Ni-Mn-Ga bent single crystals. Mater. Des. 2019, 171, 107703. [Google Scholar] [CrossRef]

- Randau, C.; Garbe, U.; Brokmeier, H.-G. StressTextureCalculator: A software tool to extract texture, strain and microstructure information from area-detector measurements. J. Appl. Crystallogr. 2011, 44, 641. [Google Scholar] [CrossRef]

- Pustovalov, V.V. Serrated deformation of metals and alloys at low temperatures (Review). Low Temp. Phys. 2008, 34, 683–723. [Google Scholar] [CrossRef]

- Donadille, C.; Valle, R.; Dervin, P.; Penelle, R. Development of texture and microstructure during cold-rolling and annealing of F.C.C. alloys: Example of an Austenitic stainless steel. Acta Metall. 1989, 37, 1547–1571. [Google Scholar] [CrossRef]

- Nazekat, M.; Akhiani, H.; Hoseini, M.; Szpunar, J. Effect of thermo-mechanical processing on texture evolution in austenitic stainless steel 316L. Mater. Charact. 2014, 98, 10–17. [Google Scholar] [CrossRef]

- Pawlik, K.; Ozga, P. Gottinger, LaboTex: The Texture Analysis Software. Arb. Geol. Palaont. 1999, SB4, 146–147. [Google Scholar]

- Venables, J.A. The martensite transformation in stainless steel. Philos. Mag. 1962, 7, 35–44. [Google Scholar] [CrossRef]

- Belytschko, T.; Black, T. Elastic crack growth in finite elements with minimal remeshing. Int. J. Numer. Meth. Engng. 1999, 45, 601–620. [Google Scholar] [CrossRef]

- ABAQUS. Analysis User’s Guide; Version 6.10; Dassault Systemes Simulia, Inc.: Johnston, RI, USA, 2010. [Google Scholar]

- Shin, H.C.; Ha, T.K.; Chang, Y.W. Kinetics of deformation induced martensitic transformation in a 304 stainless steel. Scr. Mater. 2001, 45, 823–829. [Google Scholar] [CrossRef]

- Das, A.; Tarafder, S. Experimental investigation on martensitic transformation and fracture morphologies of austenitic stainless steel. Int. J. Plast. 2009, 25, 2222–2247. [Google Scholar] [CrossRef]

- Tabin, J.; Skoczeń, B.; Bielski, J. Discontinuous plastic flow coupled with strain induced fcc–bcc phase transformation at extremely low temperatures. Mech. Mater. 2019, 129, 23–40. [Google Scholar] [CrossRef]

- Tabin, J.; Skoczeń, B.; Bielski, J. Damage affected discontinuous plastic flow (DPF). Mech. Mater. 2017, 110, 44–58. [Google Scholar] [CrossRef]

- Garion, C.; Skoczeń, B.; Sgobba, S. Constitutive modelling and identification of parameters of the plastic strain-induced martensitic transformation in 316L stainless steel at cryogenic temperatures. Int. J. Plast. 2006, 22, 1234–1264. [Google Scholar] [CrossRef]

- Zienkiewicz, O.C.; Taylor, R.L. Finite Element Method. Volume 2: Solid Mechanics, 5th ed.; Solid Mechanics; Butterworth-Heinemann: Oxford, UK, 2000. [Google Scholar]

| Element | C | Si | Mn | P | S | Cr | Ni | N |

|---|---|---|---|---|---|---|---|---|

| Content [%] | 0.030 | 1.00 | 2.00 | 0.045 | 0.015 | 18.200 | 11.500 | - |

| Temperature | 4.2 K | 77 K | RT | |||

|---|---|---|---|---|---|---|

| Distance from the fracture surface | 4 mm | 2 mm | 4 mm | 2 mm | 4 mm | 2 mm |

| The Brass orientation | 8.1% | 8.8% | 9.5% | 10.6% | 9.8% | 10.0% |

| The Goss orientation | 6.9% | 6.9% | 7.5% | 6.8% | 8.4% | 8.1% |

| The Cu orientation | 4.2% | 3.9% | 5.9% | 5.8% | 6.4% | 6.0% |

| Material Constant | E [MPa] | σ0 [MPa] | CR [MPa] |

|---|---|---|---|

| sample 1 | 220.000 | 880 | 7750 |

| sample 2 | 210.000 | 880 | 7890 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nalepka, K.; Skoczeń, B.; Ciepielowska, M.; Schmidt, R.; Tabin, J.; Schmidt, E.; Zwolińska-Faryj, W.; Chulist, R. Phase Transformation in 316L Austenitic Steel Induced by Fracture at Cryogenic Temperatures: Experiment and Modelling. Materials 2021, 14, 127. https://doi.org/10.3390/ma14010127

Nalepka K, Skoczeń B, Ciepielowska M, Schmidt R, Tabin J, Schmidt E, Zwolińska-Faryj W, Chulist R. Phase Transformation in 316L Austenitic Steel Induced by Fracture at Cryogenic Temperatures: Experiment and Modelling. Materials. 2021; 14(1):127. https://doi.org/10.3390/ma14010127

Chicago/Turabian StyleNalepka, Kinga, Błażej Skoczeń, Marlena Ciepielowska, Rafał Schmidt, Jakub Tabin, Elwira Schmidt, Weronika Zwolińska-Faryj, and Robert Chulist. 2021. "Phase Transformation in 316L Austenitic Steel Induced by Fracture at Cryogenic Temperatures: Experiment and Modelling" Materials 14, no. 1: 127. https://doi.org/10.3390/ma14010127

APA StyleNalepka, K., Skoczeń, B., Ciepielowska, M., Schmidt, R., Tabin, J., Schmidt, E., Zwolińska-Faryj, W., & Chulist, R. (2021). Phase Transformation in 316L Austenitic Steel Induced by Fracture at Cryogenic Temperatures: Experiment and Modelling. Materials, 14(1), 127. https://doi.org/10.3390/ma14010127