3D-Printed Hermetic Alumina Housings

Abstract

1. Introduction

2. Materials and Methods

2.1. Ceramic Printing with Fused Filament Fabrication

2.2. Surface Preparation, Metal Deposition and Assembly

2.3. Testing Procedures

3. Results and Discussion

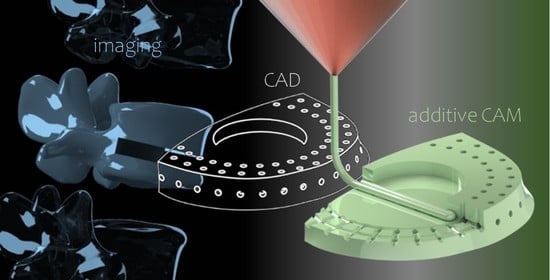

3.1. Bulk Structures and Geometric Properties

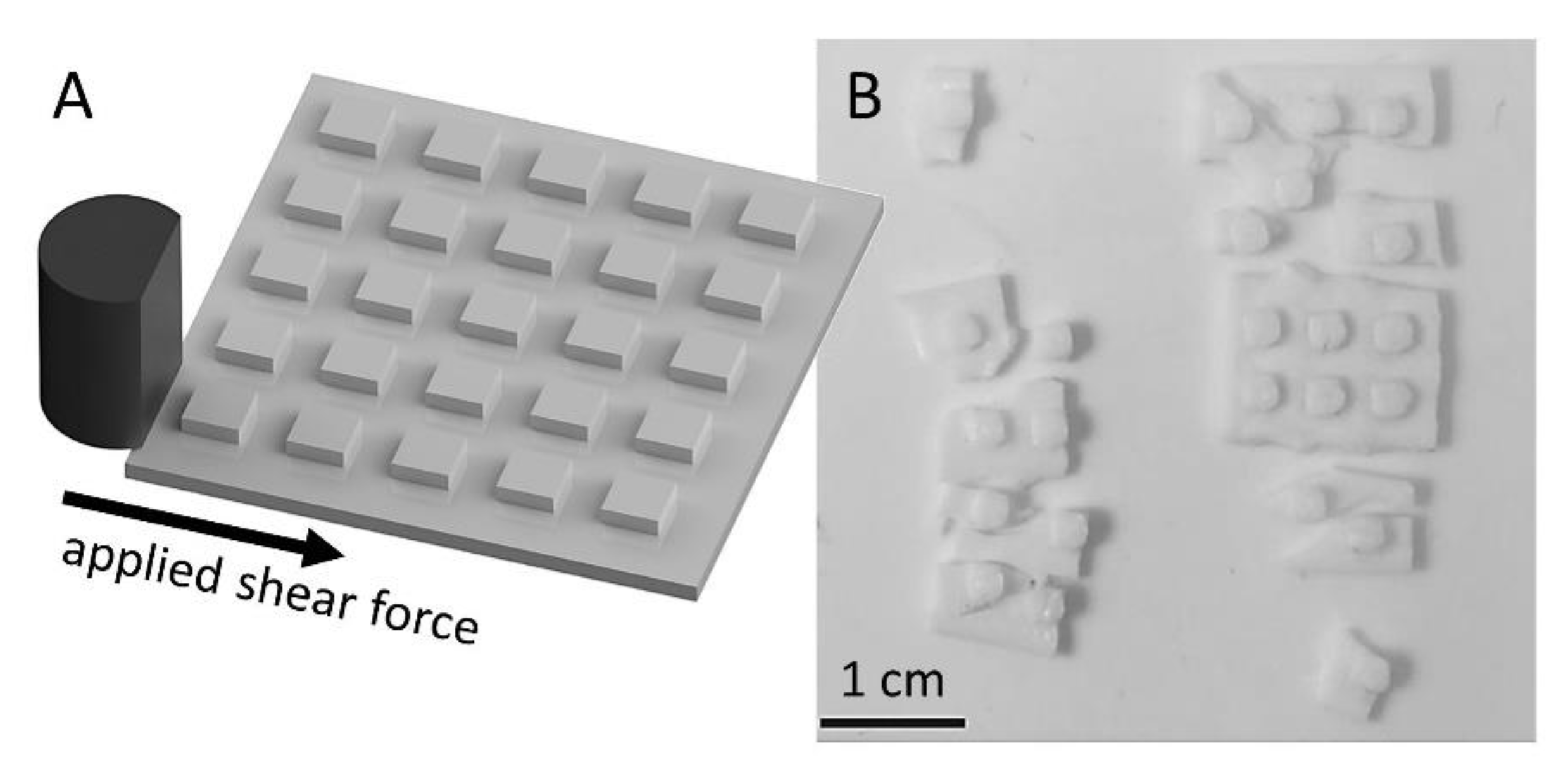

3.2. Mechanical Properties

3.3. Hermeticity

3.4. Surface Metallization

3.5. Realization of Complex Structures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chowdhry, U.; Sleight, A.W. Ceramic Substrates for Microelectronic Packaging. Annu. Rev. Mater. Sci. 1987, 17, 323–340. [Google Scholar] [CrossRef]

- Zhou, D.; Jiang, G. (Eds.) Technology Advances and Challenges in Hermetic Packaging for Implantable Medical Devices; Springer: New York, NY, USA, 2009. [Google Scholar]

- Stieglitz, T. Manufacturing, assembling and packaging of miniaturized neural implants. Microsyst. Technol. 2010, 16, 723–734. [Google Scholar] [CrossRef]

- Schuettler, M.; Kohler, F.; Ordonez, J.S.; Stieglitz, T. Hermetic electronic packaging of an implantable brain-machine-interface with transcutaneous optical data communication. In Proceedings of the 2012 34th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), San Diego, CA, USA, 28 August–1 September 2012; IEEE: New York, NY, USA, 2012; pp. 3886–3889, ISBN 978-1-4577-1787-1. [Google Scholar]

- Conrad, H.J.; Seong, W.-J.; Pesun, I.J. Current ceramic materials and systems with clinical recommendations: A systematic review. J. Prosthet. Dent. 2007, 98, 389–404. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Li, R.W.K.; Chow, T.W.; Matinlinna, J.P. Ceramic dental biomaterials and CAD/CAM technology: State of the art. J. Prosthodont. Res. 2014, 58, 208–216. [Google Scholar] [CrossRef]

- Espera, A.H.; Dizon, J.R.C.; Chen, Q.; Advincula, R.C. 3D-printing and advanced manufacturing for electronics. Prog. Addit. Manuf. 2019, 4, 245–267. [Google Scholar] [CrossRef]

- Gongora-Rubio, M.R.; Espinoza-Vallejos, P.; Sola-Laguna, L.; Santiago-Avilés, J.J. Overview of low temperature co-fired ceramics tape technology for meso-system technology (MsST). Sens. Actuators A Phys. 2001, 89, 222–241. [Google Scholar] [CrossRef]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive manufacturing of advanced ceramic materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Conti, L.; Bienenstein, D.; Borlaf, M.; Graule, T. Effects of the Layer Height and Exposure Energy on the Lateral Resolution of Zirconia Parts Printed by Lithography-Based Additive Manufacturing. Materials 2020, 13, 1317. [Google Scholar] [CrossRef]

- Wu, H.; Liu, W.; He, R.; Wu, Z.; Jiang, Q.; Song, X.; Chen, Y.; Cheng, L.; Wu, S. Fabrication of dense zirconia-toughened alumina ceramics through a stereolithography-based additive manufacturing. Ceram. Int. 2017, 43, 968–972. [Google Scholar] [CrossRef]

- Nötzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. Materials 2018, 11, 1463. [Google Scholar] [CrossRef] [PubMed]

- Kiele, P.; Cvancara, P.; Mueller, M.; Stieglitz, T. Design of experiment evaluation of sputtered thin film platinum surface metallization on alumina substrate for implantable conductive structures. Conf. Proc. IEEE Eng. Med. Biol. Soc. 2017, 2017, 1066–1069. [Google Scholar] [CrossRef]

- Carnicer-Lombarte, A.; Lancashire, H.T.; Vanhoestenberghe, A. In vitro biocompatibility and electrical stability of thick-film platinum/gold alloy electrodes printed on alumina. J. Neural Eng. 2017, 14, 36012. [Google Scholar] [CrossRef] [PubMed]

- Parra-Cabrera, C.; Achille, C.; Kuhn, S.; Ameloot, R. 3D printing in chemical engineering and catalytic technology: Structured catalysts, mixers and reactors. Chem. Soc. Rev. 2018, 47, 209–230. [Google Scholar] [CrossRef] [PubMed]

- Nötzel, D.; Hanemann, T. New Feedstock System for Fused Filament Fabrication of Sintered Alumina Parts. Materials 2020, 13, 4461. [Google Scholar] [CrossRef]

- Fiedler, E.; Ordonez, J.S.; Stieglitz, T. Laser-structured ceramic adapters for reliable assembly of flexible thin-film electrodes. Biomed. Eng. Biomed. Tech. 2013. [Google Scholar] [CrossRef]

- Kiele, P.; Cvancara, P.; Langenmair, M.; Mueller, M.; Stieglitz, T. Thin Film Metallization Stacks Serve as Reliable Conductors on Ceramic-Based Substrates for Active Implants. IEEE Trans. Compon. Packag. Manufact. Technol. 2020, 10, 1803–1813. [Google Scholar] [CrossRef]

- Nötzel, D.; Hanemann, T.; Eickhoff, R. Charakterisierung additiv gefertigter keramischer Bauteile via FFF-Verfahren. Keram. Z. 2019, 71, 56–61. [Google Scholar] [CrossRef]

- Orlovská, M.; Chlup, Z.; Bača, Ľ.; Janek, M.; Kitzmantel, M. Fracture and mechanical properties of lightweight alumina ceramics prepared by fused filament fabrication. J. Eur. Ceram. Soc. 2020, 40, 4837–4843. [Google Scholar] [CrossRef]

- Mamatha, S.; Biswas, P.; Ramavath, P.; Das, D.; Johnson, R. 3D printing of complex shaped alumina parts. Ceram. Int. 2018, 44, 19278–19281. [Google Scholar] [CrossRef]

- Arnesano, A.; Padmanabhan, S.K.; Notarangelo, A.; Montagna, F.; Licciulli, A. Fused deposition modeling shaping of glass infiltrated alumina for dental restoration. Ceram. Int. 2020, 46, 2206–2212. [Google Scholar] [CrossRef]

- Serdeczny, M.P.; Comminal, R.; Pedersen, D.B.; Spangenberg, J. Numerical simulations of the mesostructure formation in material extrusion additive manufacturing. Addit. Manuf. 2019, 28, 419–429. [Google Scholar] [CrossRef]

- Boretius, T.; Mintri, A.; Suaning, G.J. Exploring the limits of helium spray tests. In Proceedings of the 2013 6th International IEEE/EMBS Conference on Neural Engineering (NER), San Diego, CA, USA, 6–8 November 2013; IEEE: New York, NY, USA, 2013; pp. 868–871, ISBN 978-1-4673-1969-0. [Google Scholar]

- Boeser, F.; Ordonez, J.S.; Schuettler, M.; Stieglitz, T.; Plachta, D.T.T. Non-hermetic encapsulation for implantable electronic devices based on epoxy. In Proceedings of the 2015 37th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Milan, Italy, 25–29 August 2015; IEEE: New York, NY, USA, 2015; pp. 809–812, ISBN 978-1-4244-9271-8. [Google Scholar]

- Guenther, T.; Dodds, C.W.D.; Lovell, N.H.; Suaning, G.J. Chip-scale hermetic feedthroughs for implantable bionics. IEEE EMBC 2011, 6717–6720. [Google Scholar] [CrossRef]

- Goeke, R.S.; Grubbs, R.K.; Yazzie, D.; Casias, A.L.; Peterson, K.A. Gas Permeation Measurements on Low Temperature Cofired Ceramics. Addit. Conf. Device Packag. HiTEC HiTEN CICMT 2012, 2012, 323–327. [Google Scholar] [CrossRef]

- Green, R.A.; Guenther, T.; Jeschke, C.; Jaillon, A.; Yu, J.F.; Dueck, W.F.; Lim, W.W.; Henderson, W.C.; Vanhoestenberghe, A.; Lovell, N.H.; et al. Integrated electrode and high density feedthrough system for chip-scale implantable devices. Biomaterials 2013, 34, 6109–6118. [Google Scholar] [CrossRef]

- Gunther, T.; Schwenck, A.; Matteucci, P.; Leigh, R.; Svehla, M.; Zimmermann, A.; Suaning, G.J. Practical Aspects and Limitations of Hermeticity Testing of Microencapsulations Using Cumulative Helium Leak Detection for Miniaturized Implantable Medical Devices. IEEE Trans. Compon. Packag. Manufact. Technol. 2020, 10, 351–359. [Google Scholar] [CrossRef]

- Rudmann, L.; Langenmair, M.; Hahn, B.; Ordonez, J.S.; Stieglitz, T. Novel desiccant-based very low humidity indicator for condition monitoring in miniaturized hermetic packages of active implants. Sens. Actuator B Chem. 2020, 322, 128555. [Google Scholar] [CrossRef]

- Meyer, J.; Schmidt, H.; Kowalsky, W.; Riedl, T.; Kahn, A. The origin of low water vapor transmission rates through Al2O3/ZrO2 nanolaminate gas-diffusion barriers grown by atomic layer deposition. Appl. Phys. Lett. 2010, 96, 243308. [Google Scholar] [CrossRef]

- Weinmann, M.; Nisch, W.; Stett, A.; Urban, G.; Bucher, V. Monitored Water Vapour Barrier Coatings for Flexible Micro-Implants. Biomed. Eng. Biomed. Tech. 2013. [Google Scholar] [CrossRef]

- Jiang, B.; Maeder, T.; Santis-Alvarez, A.J.; Poulikakos, D.; Muralt, P. A low-temperature co-fired ceramic micro-reactor system for high-efficiency on-site hydrogen production. J. Power Sources 2015, 273, 1202–1217. [Google Scholar] [CrossRef]

- Strietzel, R. Die Werkstoffkunde der Metall-Keramik-Systeme, 1. Aufl.; Verl. Neuer Merkur: München, Germnay, 2005; ISBN 3937346147. [Google Scholar]

- Huh, C.; Mason, S.G. Effects of surface roughness on wetting (theoretical). J. Colloid Interface Sci. 1977, 60, 11–38. [Google Scholar] [CrossRef]

- Mueller, M.; de La Oliva, N.; Del Valle, J.; Delgado-Martínez, I.; Navarro, X.; Stieglitz, T. Rapid prototyping of flexible intrafascicular electrode arrays by picosecond laser structuring. J. Neural Eng. 2017, 14, 66016. [Google Scholar] [CrossRef] [PubMed]

- Lenau, T.; Connolly, C. Miniature electronic modules for advanced health care. Sens. Rev. 2009, 29, 98–103. [Google Scholar] [CrossRef]

- de Wild, M.; Zimmermann, S.; Rüegg, J.; Schumacher, R.; Fleischmann, T.; Ghayor, C.; Weber, F.E. Influence of Microarchitecture on Osteoconduction and Mechanics of Porous Titanium Scaffolds Generated by Selective Laser Melting. 3D Print. Addit. Manuf. 2016, 3, 142–151. [Google Scholar] [CrossRef]

- Bose, S.; Darsell, J.; Hosick, H.L.; Yang, L.; Sarkar, D.K.; Bandyopadhyay, A. Processing and characterization of porous alumina scaffolds. J. Mater. Sci. Mater. Med. 2002, 13, 23–28. [Google Scholar] [CrossRef]

- Herdering, A.; Hubálková, J.; Abendroth, M.; Gehre, P.; Aneziris, C.G. Additive Manufactured Polymer Foams as Templates for Customized Ceramic Foams—Comparison of SLS and FFF Techniques. Interceram. Int. Ceram. Rev. 2019, 68, 30–37. [Google Scholar] [CrossRef]

- Schuettler, M.; Stieglitz, T. Implantable Sensor Systems for Medical Applications // Implantable Sensor Systems for Medical Applications. Microassembly and Micropackaging of Implantable Systems; Woodhead Publishing Limited: Cambridge, UK, 2013; ISBN 9780857096289. [Google Scholar]

| Sample | Printed | Grinded | Commercial Plate | |

|---|---|---|---|---|

| Ra/µm | bottom | 15.1 ± 4.0 (n = 19) | 1.24 ± 0.21 (n = 9) | 0.66 ± 0.08 (n = 6) |

| top | 20.9 ± 7.3 (n = 15) | 1.23 ± 0.47 (n = 7) | ||

| Rz/µm | bottom | 152.1 ± 20.1 | 13.04 ± 1.72 | 8.18 ± 2.91 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Eickenscheidt, M.; Langenmair, M.; Dbouk, A.; Nötzel, D.; Hanemann, T.; Stieglitz, T. 3D-Printed Hermetic Alumina Housings. Materials 2021, 14, 200. https://doi.org/10.3390/ma14010200

Eickenscheidt M, Langenmair M, Dbouk A, Nötzel D, Hanemann T, Stieglitz T. 3D-Printed Hermetic Alumina Housings. Materials. 2021; 14(1):200. https://doi.org/10.3390/ma14010200

Chicago/Turabian StyleEickenscheidt, Max, Michael Langenmair, Ahmad Dbouk, Dorit Nötzel, Thomas Hanemann, and Thomas Stieglitz. 2021. "3D-Printed Hermetic Alumina Housings" Materials 14, no. 1: 200. https://doi.org/10.3390/ma14010200

APA StyleEickenscheidt, M., Langenmair, M., Dbouk, A., Nötzel, D., Hanemann, T., & Stieglitz, T. (2021). 3D-Printed Hermetic Alumina Housings. Materials, 14(1), 200. https://doi.org/10.3390/ma14010200