1. Introduction

Additive manufacturing (AM) technologies are increasingly used for a wide range of new applications that require complex and multifunctional products. The commonly known AM technique is fused filament fabrication (FFF), which is part of the polymer material extrusion process family. FFF uses a solid polymer filament that is introduced and melted through a heated capillary and then deposited on a temperature-controlled bed. A 3D geometry is generated through the deposition of successive layers [

1,

2,

3]. Different advantages have allowed the growth of this technology compared to traditional manufacturing processes. This technique offers the possibility of printing complex structures, the fabrication of objects already assembled, and the production of personalized products. Importantly, FFF enables the use of less materials compared to conventional manufacturing methods and has lower distribution emissions, which renders this technique an attractive environmentally sustainable manufacturing process [

4,

5].

In recent years, AM has found applications in the fields of agriculture, particularly in the advanced design and development of agricultural equipment [

6,

7,

8]. The use of AM could be adopted for applications related to the context of precision agriculture. More specifically, the precision agriculture concept considers the use of technologies that are able to customize systems to gain higher efficiency, thus paying attention to ensuring a low environmental impact [

9,

10,

11,

12,

13,

14]. One interesting domain of precision agriculture is precision irrigation; in this domain, systems are used that control the required quantity of water to be supplied to the plants to function in the environmental condition and type of plant, which avoids water waste [

9,

10,

11,

12,

13,

14,

15,

16]. Another example of precision agriculture is the use of anti-UV polymer films widely adopted in the horticulture field. Researchers have been paying attention to the impacts of UV-B radiation (280–315 nm) on plants, since UV-B radiation has been recognized as a potential damaging factor for living organisms by modifying plant morphology, biochemistry, and development. This type of radiation induces growth retardation, macroscopic injuries, and oxidative damage for the plants [

17,

18,

19,

20,

21]. Although there is strong interest in precision agriculture applications, there is a lack of scientific studies regarding the use of the material extrusion process in 3D printing in the horticulture field. Concurrently, the extensive use of polymeric materials for agricultural applications and the consequent generation of large quantities of waste, stresses the need for the sustainable development of agricultural systems. A promising method to reduce the amount of polymeric waste is the use of polymer composites charged with fillers [

22,

23]. Nevertheless, the processes of making solid filler are unsustainable and require significant amounts of non-renewable resources such as fossil fuels [

24]. Considering the significant use of fillers in composite polymers, much attention has been paid to find more sustainable alternatives. A possible solution to decrease the environmental impact of the fillers is the direct use of unwanted by-products from industrial processes such as quarry waste. This valorization of waste offers additional benefits such as a reduction in CO

2 emissions, increased profitability (increased income and reduced disposal costs), efficient use of resources, and improved sustainability for local communities [

25].

In literature that has been developed for the field of new applications, new composite materials are available for the material extrusion process feedstock. For example, polymer composites have been formulated with carbon black, basaltic fibers, and Lecce stone. Moreover, the development of complex structures through AM technologies have mostly been studied in the field of construction using reinforced composite cement. However, studies on the effect of quarry waste fillers on the properties of polymeric composites for 3D printing is limited [

26,

27,

28,

29,

30,

31,

32,

33].

A quarry waste that has not yet been studied as a polymer filler is pozzolan. Pozzolan is a pyroclastic rock that is derived from mining, industrial, and agro-waste and is either in the form of clays or shales. [

34,

35]. It is an inorganic, poorly crystalline material that can be used directly from its natural origins or in artificial manufacturing. Natural pozzolan is rich in silicon dioxide and aluminum oxide and has a porous form and high thermal stability [

36]. Pozzolan materials have been used for applications such as in construction building and roads, sanitation, and agriculture. In agriculture, it is used for drainage, soil amendments, substrate crops, and the restoration of soil [

37,

38,

39,

40]. In France, there are several quarries that produce pozzolan from volcanic origin with a large generation of pozzolan waste. Particularly in the Puy de Dôme and Haute-Loire regions, the pozzolan materials consist essentially of scoria and well stratified pumice stones. Its color varies from red to black, suggesting a relatively complex volcanological history. The chemical composition is divided between basaltic and trashy-andesitic pyroclastics [

41,

42,

43].

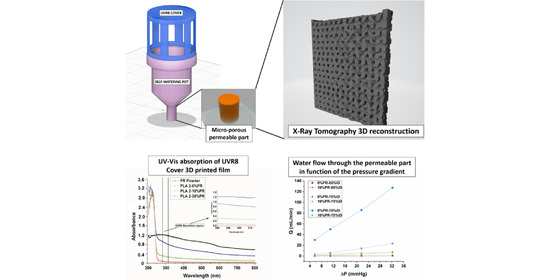

In this work, we produced and analyzed a new eco-composite based on natural waste for 3D printing. We studied the effect of adding pozzolan waste to different PLA grades and its impact on the composite filaments for 3D printing. The pozzolan powder was obtained from the separation of the finer fraction following the extraction process from the quarry. Three PLA grades with different percentages of enantiomers have been used to produce six mixtures with varying pozzolan content. The thermal and rheological properties were analyzed by means of differential scanning calorimetry and rotational rheometry, respectively. The composite with the optimum properties was then selected to produce the filaments for 3D printing and generating pellets. Mechanical tensile and impact tests were conducted on the 3D printed and injected specimens. The morphological properties of the samples were analyzed with scanning electron microscopy and X-ray tomography. Finally, a smart irrigation pot with a porous structure controlling the water flow and a UV-B barrier film was designed and printed.

2. Materials and Methods

2.1. Raw Materials

Pozzolan powder waste (PPW) was obtained from Pouzzolanes des domes S.A.S (Saint-Ours, France). The powder waste was a part of the storage on the quarry site and was obtained by a separation process after heating for 15 min at a temperature of 600 °C to remove the present moisture. It has a red color, and the chemical composition, according to the TAS (Total Alkali Silica) classification, is placed at the lower limit of trachybasalts.

Commercial poly(lactic acid) resins (NatureWorks PLA Polymer 4042D, Natureplast PLE 005, NatureWorks PLA Polymer 4032D) (Minnetonka, MN, USA) were studied in this work. For simplicity, the PLA 4042D, PLE 005, and PLA 4032D are called PLA 1, PLA 2, and PLA 3, respectively, in this work. A summary of their properties as provided by the resin manufacturers is presented in

Table 1.

2.2. Laser Granulometry Measurement

Laser granulometry is a technique based on light diffraction using Fraunhofer’s theory. This test allows for particle size measurement with a radius between 0.05 and 900 μm and determines the size polydispersity in a sample [

44]. In this study, the measures were carried out using a Malvern Mastersizer 3000 system. The particles are circulated and sonicated in water to carry out the analysis in liquid balk without particle agglomeration. The results were analyzed using the Mastersizer software to obtain the particle size and the cumulative volume distribution.

2.3. Preparation of Composite Pellets and the Filaments for 3D Printing

The preparation of composite pellets at different amounts of PPW (10%, 30%) was done with a twin screw extruder Thermo Fisher Scientific Pharma (Waltham, MA, USA) 11. Before the feeding of the materials in the extruder, the PLA and pozzolan were dried in an oven for 24 h at 60 °C. The process conditions were reported in

Table 2. Each single PLA 1, PLA 2, or PLA 3 was mixed with 10% and 30% weight mass fraction of pozzolan powder. The sample codes were reported as follows: resin type-%PR, where %PR is the value of the pozzolan mass percentage. Composite pellets made with PLA 2 and PPW were chosen to produce the 3D printing filaments. The filaments obtained had a diameter of 2.85 mm.

2.4. Rheological Measurement

Shear dynamic measurements were carried out with an ARES rheometer (Rheometric Scientific) manufactured by TA Instruments (New Castle, DE, USA). The shear dynamic measurements with a frequency sweep method were conducted using parallel plate geometry with a diameter of 8 mm. The temperature used for the test was 190 °C and the gap was set to 1 mm. The frequency sweep was set to 0.1100 rad/s, and a strain of 5% was used. From the data, the loss viscosity (η′) and storage viscosity (η″) were calculated as a function of the frequencies. The zero shear viscosity η

0 was determined from the experimental points since they can be obtained from the intersection of the arc of a circle with the abscissa, characteristic for a Cole–Cole distribution [

45].

The study of the PPW effect on the volumetric contraction stress of the composites was analyzed with the force gap measurement as a function of the temperature and time with a force gap test in the sequence configuration. The gap was fixed at 1 mm and the temperature profile was characterized by a series of steps, each of 5 °C. The initial and final temperatures were 190 and 100 °C, respectively, and a duration of 2 min was set for each step [

46].

2.5. Thermal Characterization

The crystallinity and thermal behavior of the studied samples were investigated by a differential scanning calorimetry (METTLER TOLEDO DSC 3+, Columbus, OH, USA) under a nitrogen atmosphere. For each sample, 8–10 mg of material was tested under a heat–cool–heat cycle method. The temperatures and heating/cooling rate were set from room temperature to 210 °C at 10 °C min

−1. The percentage of crystallinity

Xc of the samples was calculated using the equation:

where Δ

Hm, Δ

Hc, and

are the melting enthalpy, the crystallization enthalpy, and the melting enthalpy of pure fully crystalline polymers, respectively; and (

w/

w)

p is the mass fraction of polymer in the matrix. The

was taken as 93 J/g for PLA. To evaluate the evolution of the crystallization kinetics at the isothermal condition for each composite, an Avrami analysis was performed, where the thermal cycle was as follows: heating from 30 °C to 210 °C at 40 °C/min, 3 min at 210 °C to uniform temperature in the sample, then cooling down to a defined crystallization temperature (105 °C) at 40 °C/min. The crystallization half-time (t

1/2) was calculated for each sample to compare the crystallization kinetics of the composites as a function of the PPW contents [

47].

2.6. D Specimens and Smart Irrigation System Prototype Preparation

An Ultimaker3 3D printer (Utrecht, Netherlands) was used to elaborate the specimens for mechanical tests and the prototypes of smart irrigation systems. The gcode files were elaborated through the CURA 4.1 software. The geometry of the specimens was selected according to ASTM D638 for the tensile test and ASTM D256 (West Conshohocken, PA, USA) for the Charpy impact test. All specimens were printed directly on the heating plate with a filling rate set to 100% and a linear infill pattern. All samples were printed in two different ways, the first way was simultaneous printing and the second was in sequence printing [

48]. The smart irrigation prototypes were printed starting from the models developed with the 3D CAD software Autodesk Fusion 360. The system was conceived by assembling two parts. The first part was a self-watering pot designed in a way that the base of the container was characterized by a permeable porous structure (

Figure 1). The porous structure was obtained by changing the infill density (ID) of the piece using a gyroid pattern geometry without walls. For the analysis of the porous structure effect on the liquid water flow, three print sets with different IDs were used: 70, 75, and 85%. The second part acted as a cover and was placed on the upper part of the container with the purpose of protecting the plant from UV-B radiation in the range of 280–315 nm. The geometry is shown in

Figure 1a. The cover was printed separately and the printing direction was set starting from the top of the piece, therefore the model was rotated 180° with respect to the x-axis. The summary of the parameters is shown in

Table 3. Furthermore, the specimens for mechanical studies were also produced with the injection molding process to compare the differences between the injected and 3D printed samples. The process conditions of the injection molding and 3D printing are reported in

Table 4 and

Table 5, respectively.

2.7. Mechanical Characterization

The tensile properties were evaluated according to ASTM D638 using a Lloyd EZ50 mechanical test machine (JLW Instruments, Chicago, IL, USA) at a crosshead speed of 30 mm/min. Tests were carried out at room temperature; at least five specimens were tested for each sample, and the results were averaged to obtain a mean value. The impact properties were also evaluated according to ASTM D256 using a Pendulum impact tester Zwick/Roell HIT (Ulm, Germany) with a pendulum of 50 J in Charpy configuration.

2.8. Morphology Characterization

The fractured cross-section from the tensile test printed samples was analyzed using a HIROX SH4000M scanning electron microscope (SEM) (Hirox Europe, Limonest, France). The coated samples were left to dry at room temperature before SEM could be performed. The SEM analyses were done at 20 kV and magnification equal to X41.

To analyze the morphological and porosity structure of the printed samples, a Skycan 1174 (Bruker, Billerica, MA, USA) X-ray radiography and tomography was used. Each sample was placed on a rotating plate while the X-ray beam passed through. The images were recorded by a CCD camera with a resolution of 1024 × 1024 pixels, which revealed different levels of X-ray absorption of the sample. The total exposure time for each sample was 450 s and the pixel size was 29.7 µm. Two images were taken per angular position and were averaged. After the reconstruction of the 3D structure part, the CT analysis software was used to measure the open/close porosity, specific surface of the voids, and to create a 3D model for the internal section of the permeable part of the pot. Furthermore, the isometric projections of the permeable part of the pot were obtained using DataViewer software 2.5.

2.9. Characterization of the Prototype System Functionalities

2.9.1. Water Flow Measurement

The measurement of the water flow rate of the self-watering pot was carried out by measuring the volumetric flow rate of liquid as the hydrostatic pressure of the water in the container changes. The hydrostatic pressure was calculated starting from the measurement of the height of the liquid inside the container, in accordance with Stevin’s law. To keep the liquid level constant, the addition of water was made continuously to ensure minimum perturbation of the liquid bulk [

49].

2.9.2. UV–Vis Characterization

Ultraviolet-visible (UV–Vis) spectroscopy measurements were performed on the film part cuts by the 3D printed UVR8 cover where a Shimadzu UV-2600 spectrophotometer (Kyoto, Tokyo) was used. All measurements were done at room temperature.

4. Conclusions

A new eco-composite based on natural pozzolan waste was studied. Three different PLA grades named PLA1, PLA2, and PLA3 were used as a polymer matrix to produce the composites. The obtained sample was subjected to thermal and rheological characterization. The results showed that the composites produced with PLA2 (5% D-lactide content) had intermediate properties among the different studied composites. In particular, the thermal behavior did not show significant variations following the addition of the pozzolan, retaining its crystallization kinetics. Instead, for PLA1, the pozzolan did not significantly affect the thermal behavior of the pure matrix, while for PLA3, the pozzolan acted as a nucleating agent. Concerning the rheological behavior, the viscosity of the composites increased with the increase in the pozzolan content, and the normal force increased during the crystallization phenomenon. However, PLA2 showed intermediate behavior in the evolution of the normal force and viscosity. The highest increase in the normal force was observed for the PLA3/PPW composites; in contrast, the PLA1/PPW did not show a significant increase. Consequently, given its optimum properties, the composite based on PLA2 was chosen to produce a filament for material extrusion fabrication. Mechanical tensile and impact tests were conducted on the 3D printed and injected specimens. The results showed that the pozzolan acts as a reinforcement for the composites for both the printed and injected samples. However, in the case of 3D printed pieces, the 30% pozzolan composite involved less cohesion between the layers in comparison to the 10% pozzolan one, as depicted by X-ray tomography and SEM analysis. Consequently, the mechanical properties were highest for the composite with 10% of pozzolan. Finally, a smart irrigation pot with a porous structure for the control of the water flow and a UV-B barrier film was designed and printed. The effect of the pores on the passage of water was measured by evaluating the water flow rate as a function of the pressure gradient along the permeable part. The measurements showed that the presence of the pozzolan reduced the passage of water. The porosity of the permeable part was analyzed with X-ray tomography showing a radial distribution of pores on the cross-section of the considered part. Regarding the barrier film, the analysis of UV–Vis spectroscopy showed that the presence of the pozzolan can play a role as a UV-B absorber in the range of 280–315 nm, consequently, the results confirm the possibility of printing a complex piece with a thin film with specific functionalities.