Effects of Aging on the Physical and Rheological Properties of Trinidad Lake Asphalt Modified Bitumen

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Properties

2.2. Preparation of the TLA-Modified Binders

2.3. Aging Procedure

2.4. Physical Properties Tests

2.5. Rheological Properties Tests

2.5.1. Frequency Sweep Test

- is the complex viscosity;

- is the ZSV;

- is the limiting viscosity in the second Newtonian region;

- is the angular frequency (rad/s);

- K and m are constants.

2.5.2. Creep Test

- is the steady-state viscosity (SSV) (Pa·s);

- is the observation period (s);

- is the compliance difference over the last 15 min (1/Pa);

- is the compliance measured at the end of the creep test (1/Pa);

- is the compliance 15 min before the load is removed (1/Pa).

2.6. Aging Indices

3. Results and Discussion

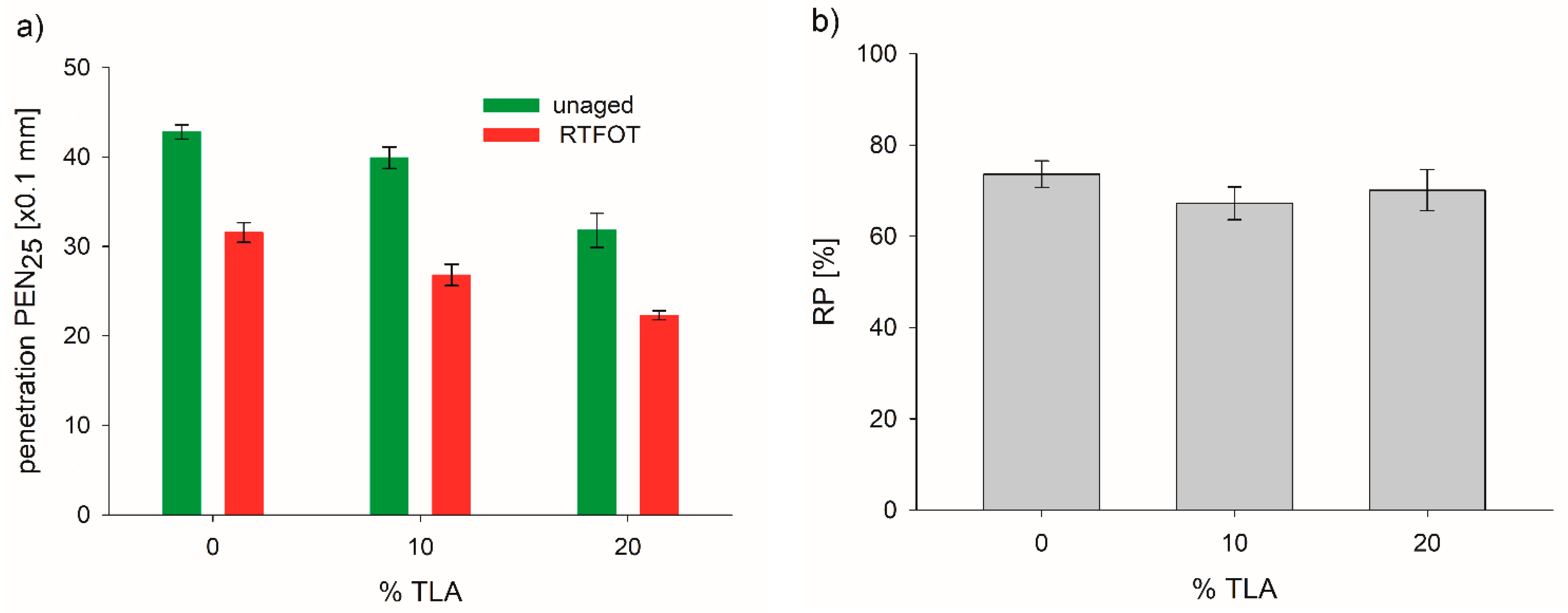

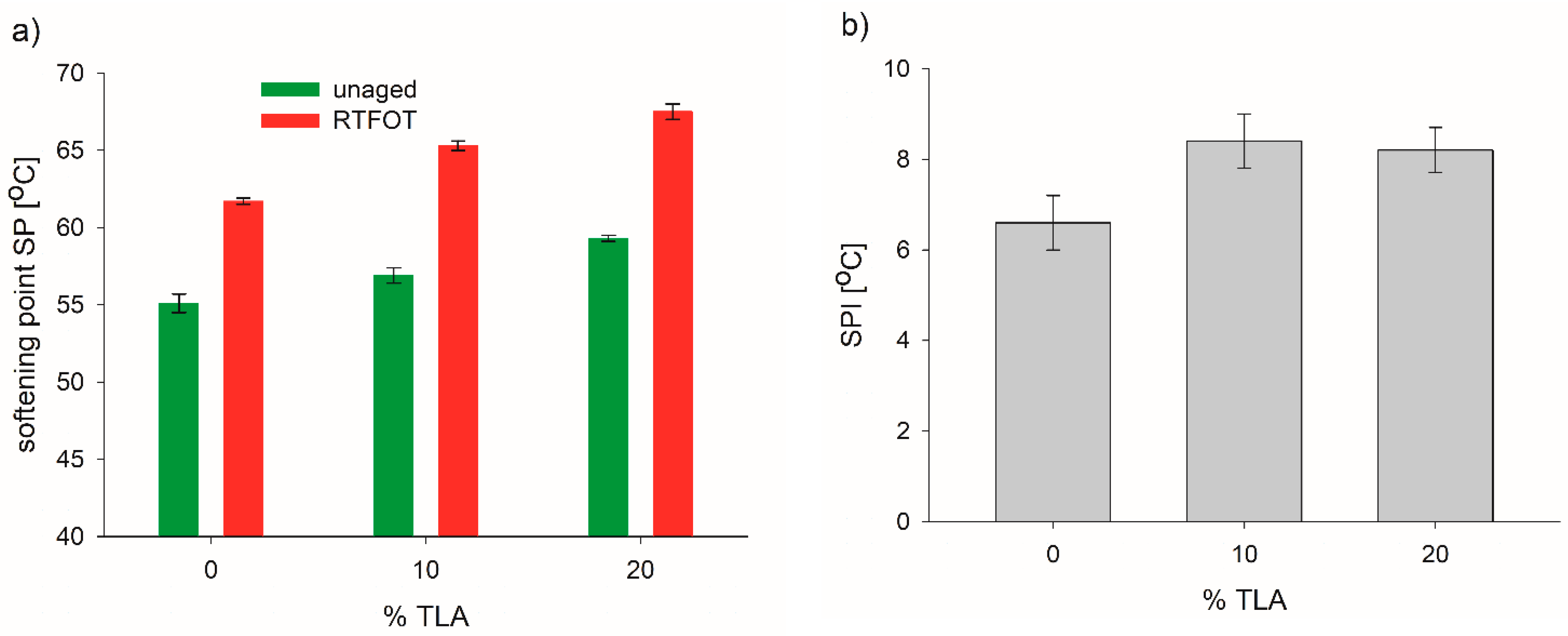

3.1. Physical Properties

3.2. Rheological Properties

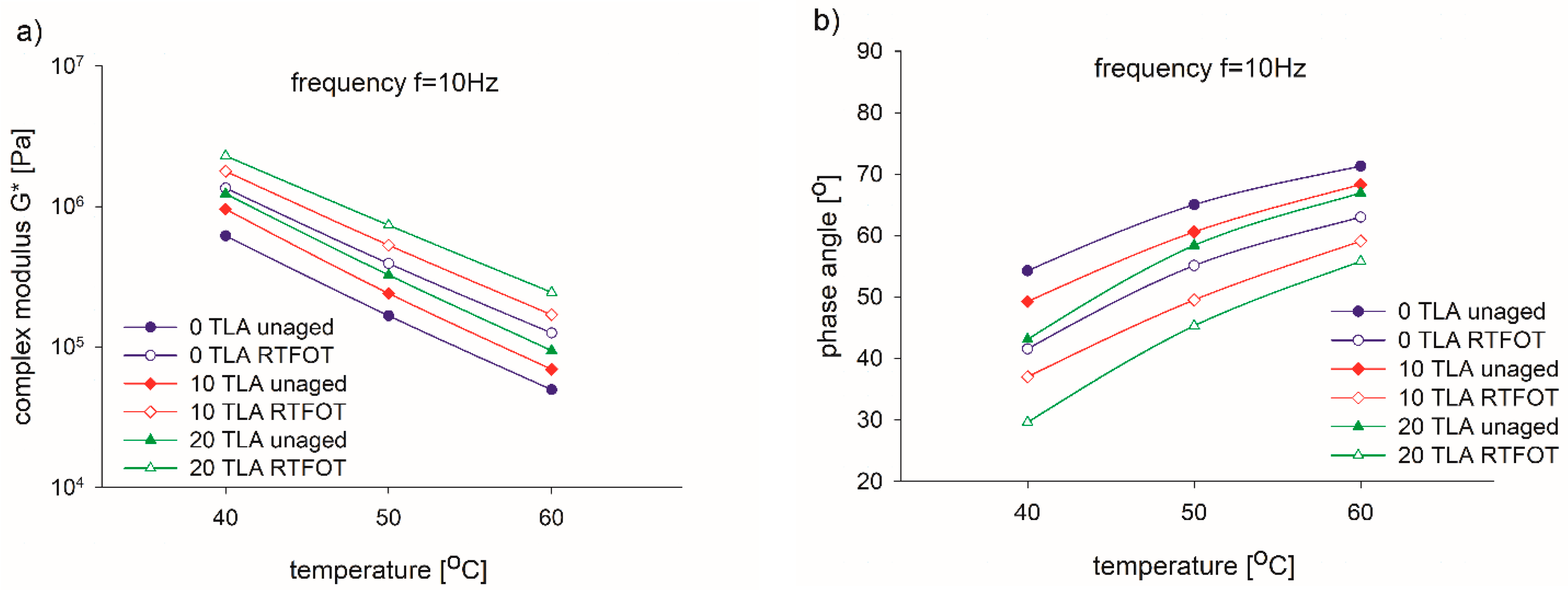

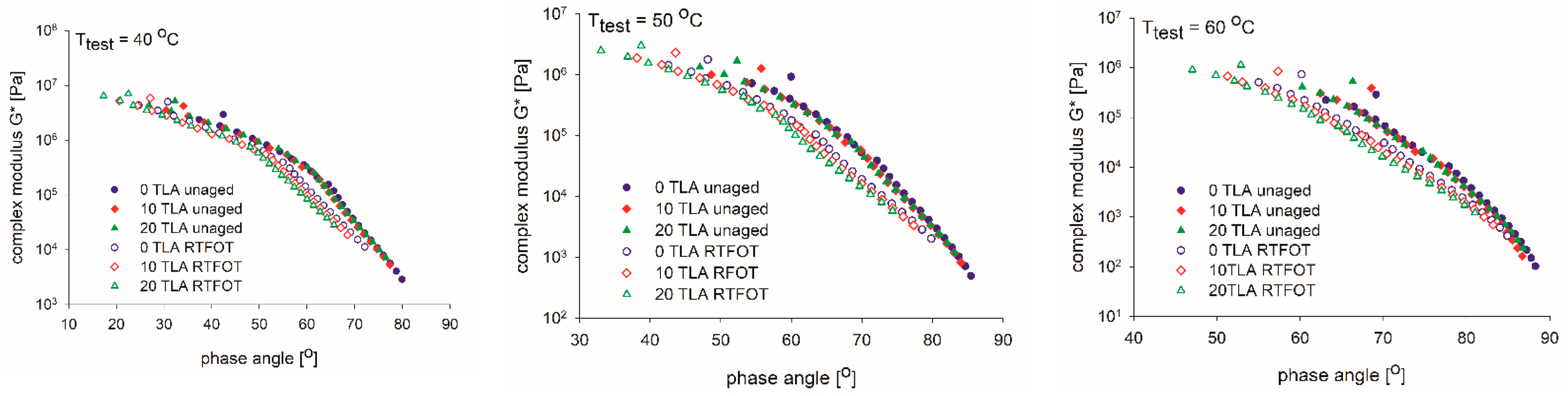

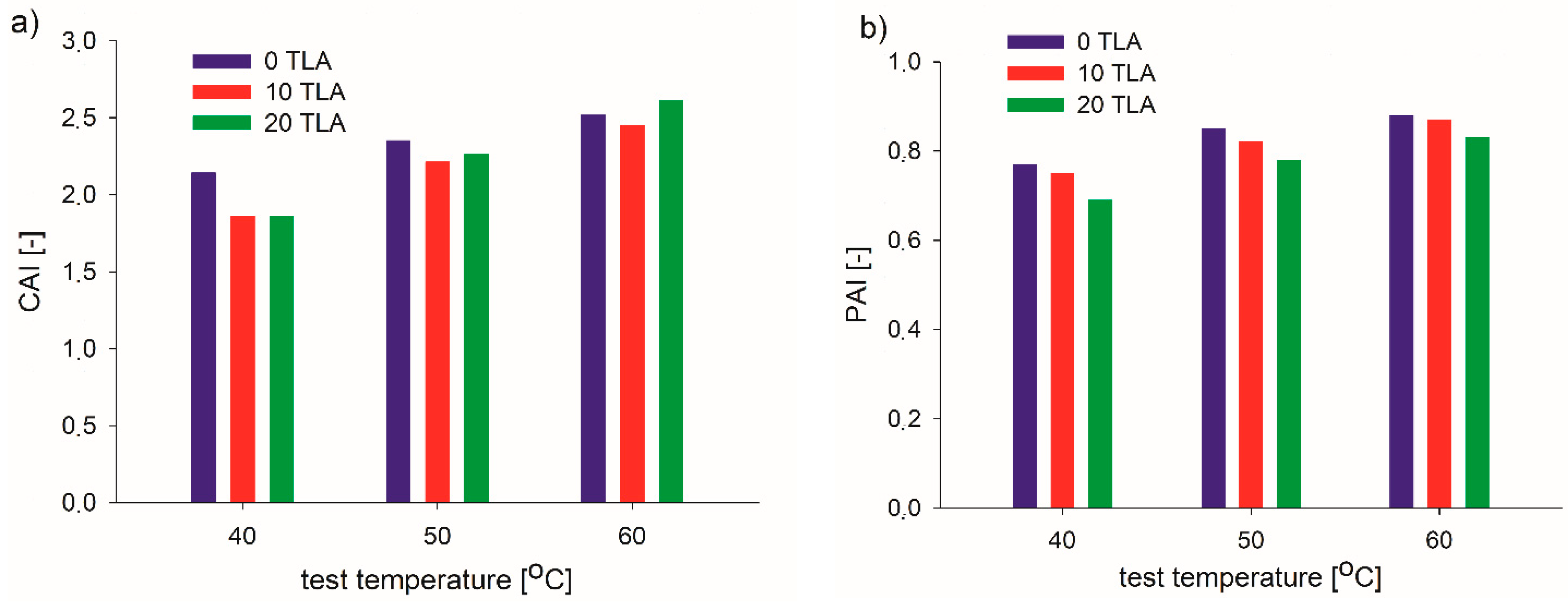

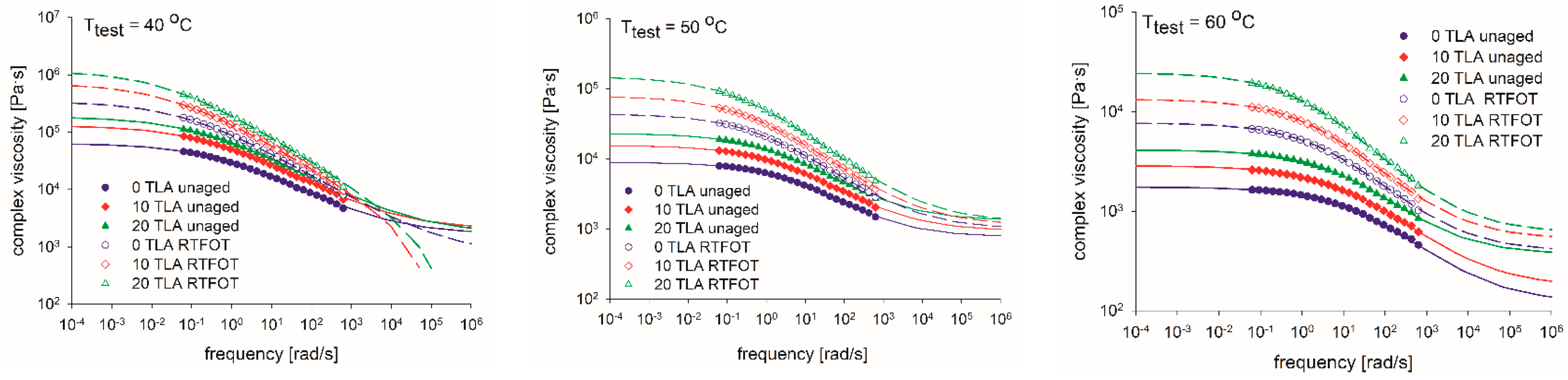

3.2.1. Complex Modulus and Phase Angle

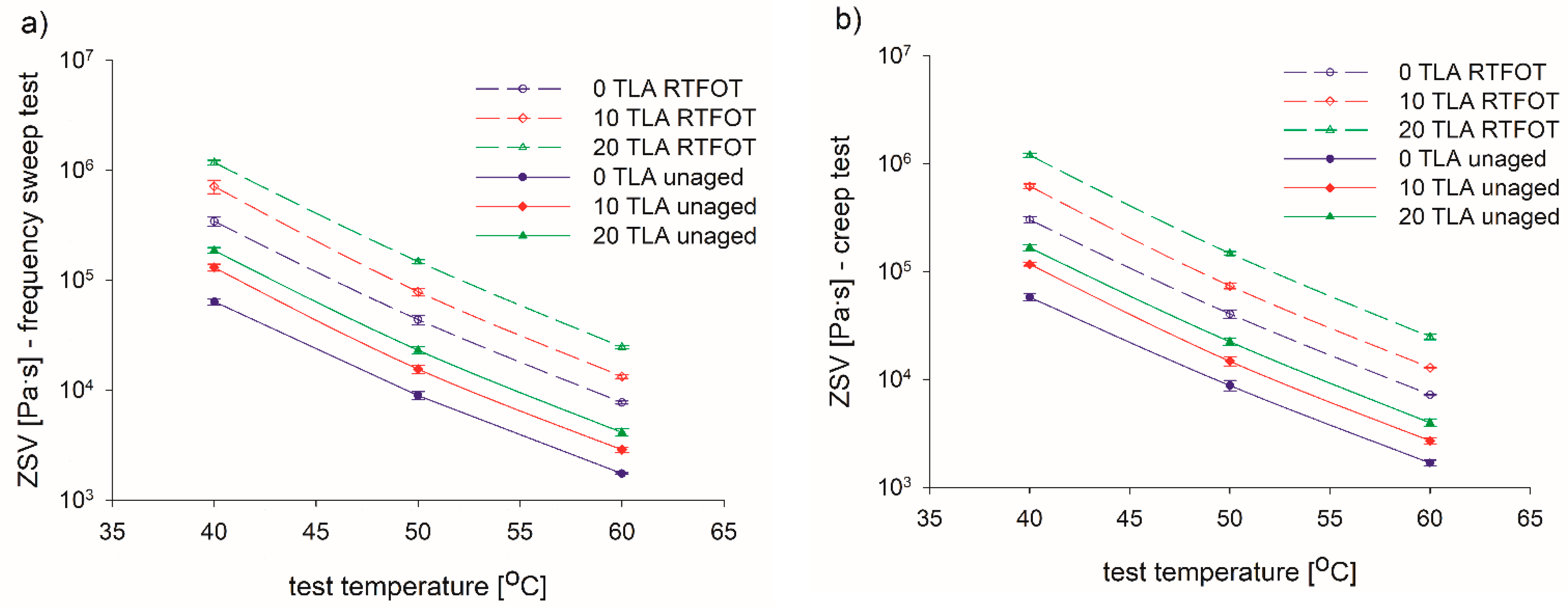

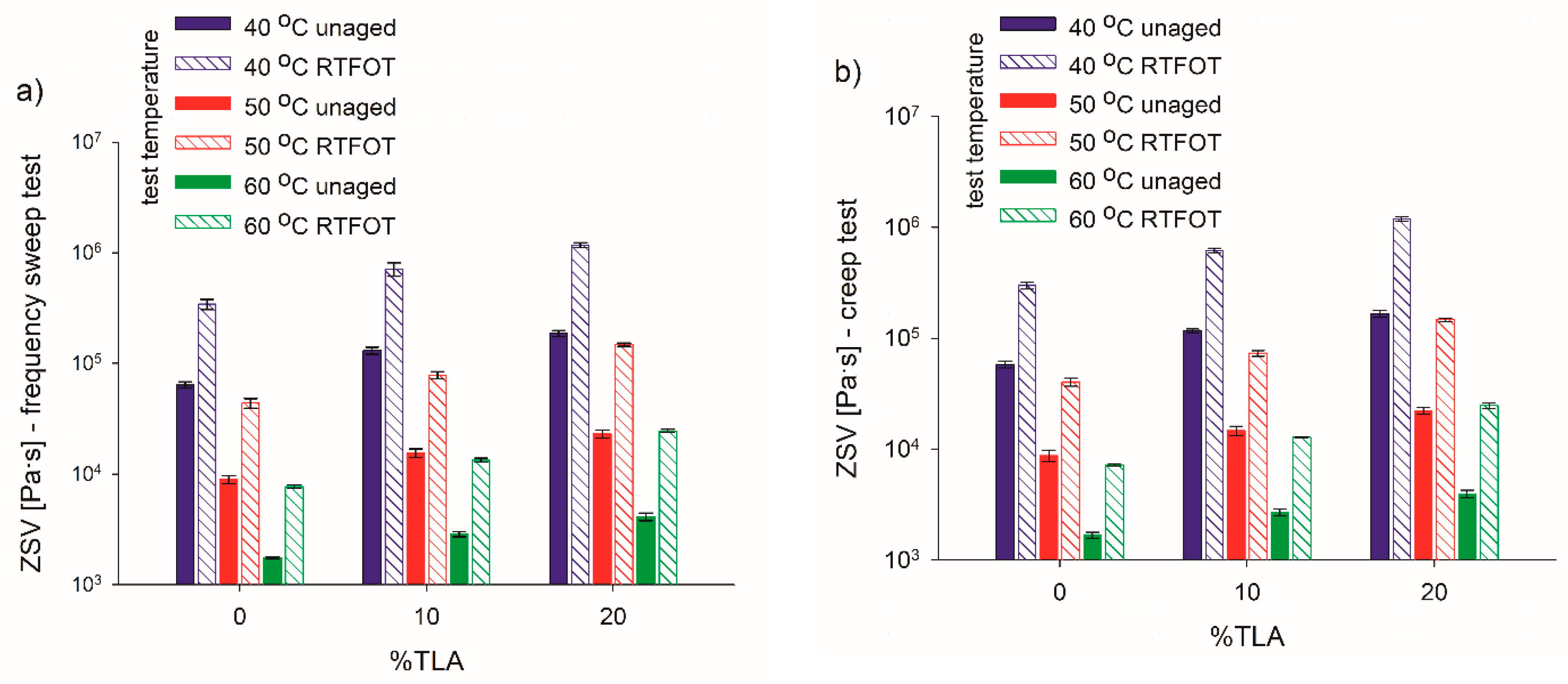

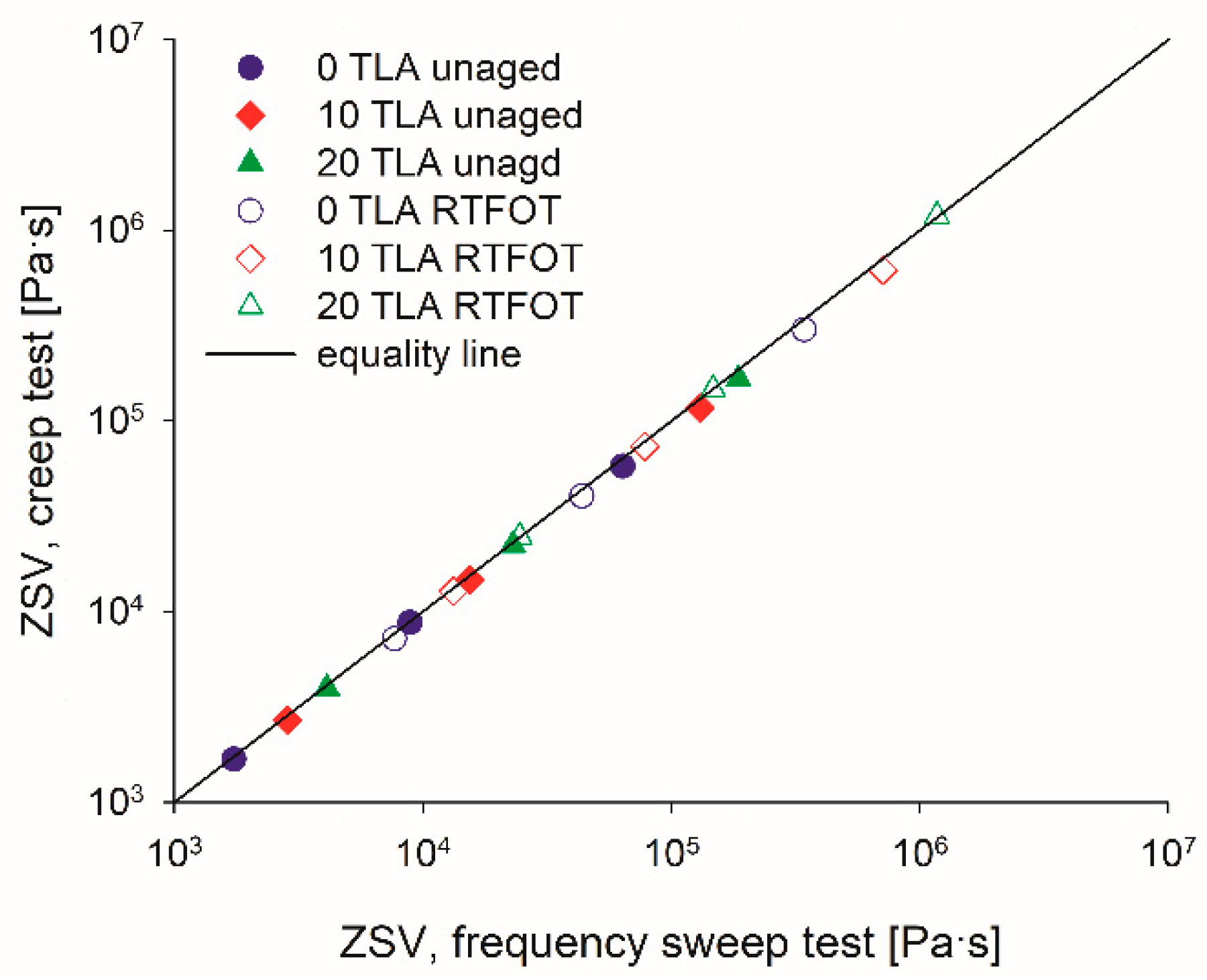

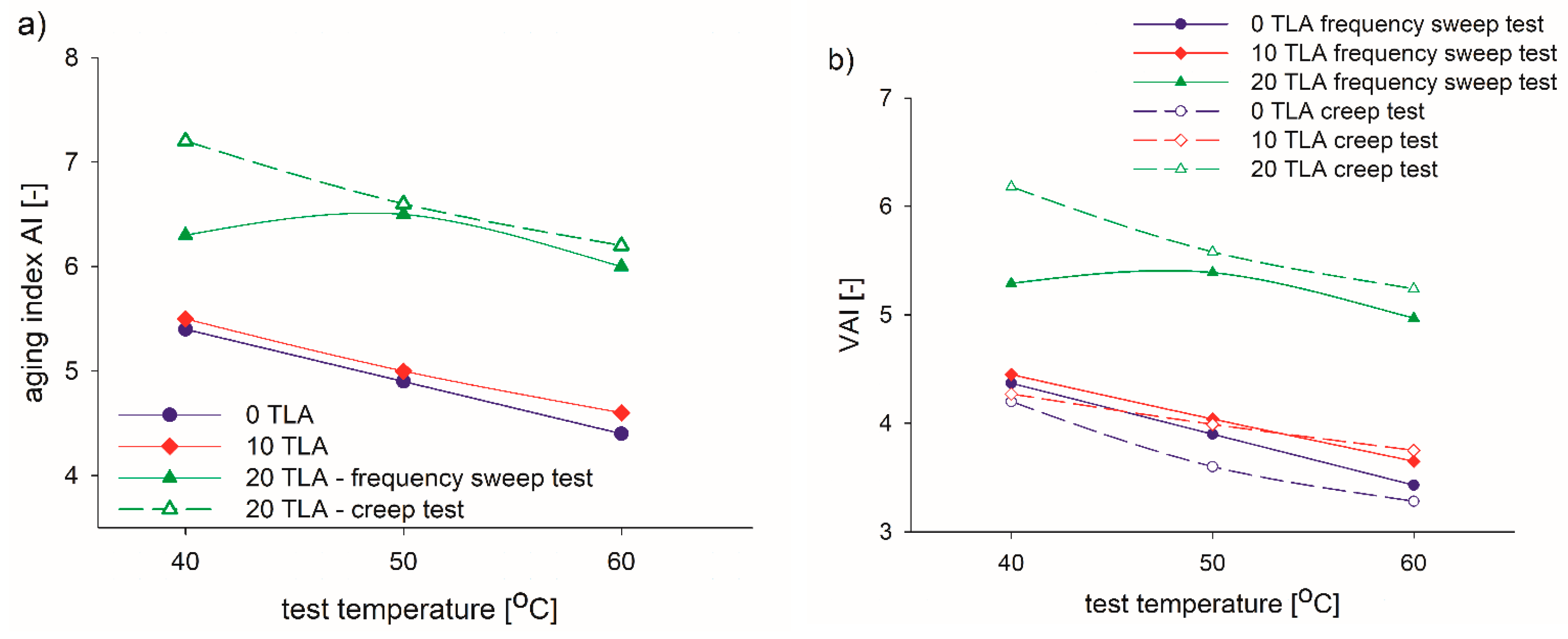

3.2.2. Zero Shear Viscosity

4. Conclusions

- A substantial reduction in penetration value (RP = ~68.5%) and a substantial increase in softening point temperature (SPI = ~8.3 °C) were obtained after the RTFOT aging of both TLA-modified binders. The 20% TLA content is recommended regarding the aging performance of base bitumen.

- Similar to the physical tests, the rheological tests (G*, δ) confirmed that in the RTFOT-aged condition, the TLA-modified binders were stiffer than in the unaged condition over the entire frequency range. The stiffness of the binders was directly proportional to the TLA content, both in the unaged and RTFOT-aged conditions. Considering the G* and δ values obtained in the tests, both the TLA modification and RTFOT aging procedures increased the binders’ ability to resist deformation in the temperature range of 40–60 °C and enhance the elastic response of the binders, which corresponded to the changes in physical properties.

- The zero shear viscosity (ZSV) was used to evaluate the partial contribution of the binder to the rutting resistance of bitumen pavement. The bigger the ZSV, the better the elasticity of the binder and the smaller the permanent plastic deformation. The short-term aging increased the ZSV values for all binders and decreased the creep deformation of the binders, regardless of the TLA content level. The 20% TLA-modified binder showed the largest ZSV value. The Cross model fit the data very well and was reliably used to estimate ZSV, both in the unaged and RTFOT-aged conditions.

- Considering all the analyzed properties (RP, SPI, CAI, PAI, and ZSV) in the rutting resistance context, it was observed that for a 20% TLA addition, four of the five properties were better than for the 10% addition, but the test results suggested that the binder with 20% TLA was the most susceptible to short-term aging.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Cholewińska, M.; Iwański, M. Modification of petroleum road bitumen 50/70 with natural asphalt Gilsonite. Struct. Environ. 2011, 3, 5–10. [Google Scholar]

- Shen, J.; Li, B.; Xie, Z. Interaction between crumb rubber modifier (CRM) and asphalt binder in dry process. Constr. Build. Mater. 2017, 149, 202–206. [Google Scholar] [CrossRef]

- Fernandes, S.; Peralta, J.; Oliveira, J.R.M.; Williams, R.C.; Silva, H.M.R.D. Improving asphalt mixture performance by partially replacing bitumen with waste motor oil and elastomer modifiers. Appl. Sci. 2017, 7, 794. [Google Scholar] [CrossRef] [Green Version]

- Kowalski, K.J.; Król, J.B.; Bańkowski, W.; Radziszewski, P.; Sarnowski, M. Thermal and fatigue evaluation of asphalt mixtures containing RAP treated with a bio-agent. Appl. Sci. 2017, 7, 216. [Google Scholar] [CrossRef] [Green Version]

- Brasileiro, L.; Moreno-Navarro, F.; Taste-Martínez, R.; Matos, J.; Rubio-Gámez, M. Reclaimed polymers as asphalt binder modifiers for more sustainable roads: A review. Sustainability 2019, 11, 646. [Google Scholar] [CrossRef] [Green Version]

- Maharaj, R. A comparison of the composition and rheology of Trinidad lake asphalt and Trinidad petroleum bitumen. Int. J. Appl. Chem. 2009, 5, 169–179. [Google Scholar]

- Fengler, Z.R.; Osmari, P.H.; Leite, L.F.M.; Herrmann do Nascimento, L.A.; Fritzen, M.A.; Aragão, F.T.S. Impact of the addition of Trinidad Lake Asphalt (TLA) on the rheological and mechanical behavior of two asphalt binders. Road Mater. Pavement 2019, 20, 827–840. [Google Scholar] [CrossRef]

- Widyatmoko, I.; Elliott, R. Characteristics of elastomeric and plastomeric binders in contact with natural asphalts. Constr. Build. Mater. 2008, 22, 239–249. [Google Scholar] [CrossRef]

- Feng, X.; Zha, X.; Hao, P. Research on design technology of TLA modified asphalt mixture. Open Mater. Sci. J. 2011, 5, 140–146. [Google Scholar] [CrossRef] [Green Version]

- Widyatmoko, I.; Elliott, R.C.; Read, J.M. Development of heavy-duty mastic asphalt bridge surfacing, incorporating Trinidad lake asphalt and polymer modified binders. Road Mater. Pavement 2005, 6, 469–483. [Google Scholar] [CrossRef]

- Russel, M.; Uhlmeyer, J.S.; Anderson, K.; Weston, J. Evaluation of Trinidad Lake Asphalt Overlay Performance; Washington State Department of Transportation: Olympia, DC, USA, 2008. [Google Scholar]

- Cao, W.; Yao, Z.; Liu, S.; Cui, Z. Performance of modified asphalt with Trinidad Lake Asphalt used as a waterproofing material for bridge deck pavement. J. Test. Eval. 2009, 37, 463–467. [Google Scholar]

- Zou, G.; Xu, X.; Li, J.; Yu, H.; Wang, C.; Sun, J. The effects of bituminous binder on the performance of gussasphalt concrete for bridge deck pavement. Materials 2020, 13, 364. [Google Scholar] [CrossRef] [Green Version]

- Yang, E.; Zhang, X. The study of high temperature performance of asphalt modified by Trinidad Lake Asphalt. Adv. Mat. Res. 2013, 831, 387–392. [Google Scholar] [CrossRef]

- Liu, J.; Yan, K.; Liu, J.; Guo, D. Evaluation of the characteristics of Trinidad Lake Asphalt and Styrene—Butadiene—Rubber compound modified binder. Constr. Build. Mater. 2019, 202, 614–621. [Google Scholar] [CrossRef]

- He, R.; Zheng, S.; Chen, H.; Kuang, D. Investigation of the physical and rheological properties of Trinidad lake asphalt modified bitumen. Constr. Build. Mater. 2019, 203, 734–739. [Google Scholar] [CrossRef]

- Gilsonite vs. TLA in Mastic Asphalt Mixtures. Available online: https://www.americangilsonite.com/wp-content/uploads/2018/09/Asphalt-Mastic-WP.pdf (accessed on 4 April 2021).

- Hongyu, Y.; Xuancang, W.; Naren, F.; Ziyuan, S. Low-Temperature Performance and Evaluation Index of Gussasphalt for Steel Bridge Decks. Adv. Mater. Sci. Eng. 2019, 2019, 1–11. [Google Scholar]

- Liao, M.; Chen, J.; Airey, G.D.; Wang, S. Rheological behavior of bitumen mixed with Trinidad lake asphalt. Constr. Build. Mater. 2014, 66, 361–367. [Google Scholar] [CrossRef]

- Xu, S.; Hu, C.; Yu, J.; Liu, R.; Zhou, X. Influence of Trinidad Lake Asphalt on the physical and anti-aging properties of petroleum asphalt. Pet. Sci Technol. 2017, 35, 2194–2200. [Google Scholar] [CrossRef]

- Ni, F.J.; Lai, Y.M.; Zhan, H. Research on pavement performance of composite modified asphalt mixture with Trinidad Lake Asphalt (TLA). J. Highw. Transp. Res. Dev. 2005, 22, 13–16. [Google Scholar]

- Iwański, M.; Cholewińska, M.; Mazurek, G. The properties of bitumen with different modifiers after a short-term aging process. Budownictwo i Architektura 2014, 13, 15–27. (In Polish) [Google Scholar] [CrossRef]

- Li, R.; Wang, P.Z.; Xue, B.; Pei, J.Z. Experimental study on aging properties and modification mechanism of Trinidad lake asphalt modified bitumen. Constr. Build. Mater. 2015, 101, 878–883. [Google Scholar] [CrossRef]

- Słowik, M.; Bilski, M. An experimental study of the impact of aging on Gilsonite and Trinidad Epuré modified asphalt binders properties. Balt. J. Road Bridge Eng. 2017, 12, 71–81. [Google Scholar] [CrossRef]

- Bin, Y.; Jianhui, W.; Jianbo, X.; Zheng, Z. Aging Kinetic Equation of Pure Asphalt and Trinidad-Lake-Asphalt-Modified Asphalt. Sci. Adv. Mater. 2017, 9, 1081–1086. [Google Scholar]

- Kołodziej, K.; Bichajło, L. Effect of natural asphalt TLA on mastic asphalt ageing. J. Civ. Eng. Environ. Archit. JCEEA 2016, 33, 233–241. (In Polish) [Google Scholar]

- EN 12591: 2010. Bitumen and Bituminous Binders—Specification for Paving Grade Bitumens; European Committee for Standardization: Brussels, Belgium, 2010.

- EN 1426: 2015-08. Bitumen and Bituminous Binders—Determination of Needle Penetration; European Committee for Standardization: Brussels, Belgium, 2015.

- EN 1427: 2015-08. Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method; European Committee for Standardization: Brussels, Belgium, 2015.

- EN 12593: 2015-08. Bitumen and Bituminous Binders—Determination of the Fraass Breaking Point; European Committee for Standardization: Brussels, Belgium, 2015.

- EN 15326: 2010. Bitumen and Bituminous Binders—Measurement of Density and SPECIFIC gravity—Capillary-Stoppered Pyknometer Method; European Committee for Standardization: Brussels, Belgium, 2010.

- EN 13108-4: 2016-07. Bituminous Mixtures—Material Specifications—Part. 4: Hot Rolled Asphalt; European Committee for Standardization: Brussels, Belgium, 2016.

- EN 12592: 2010. Bitumen and Bituminous Binders—Determination of Solubility; European Committee for Standardization: Brussels, Belgium, 2010.

- EN 12607-1: 2014-12. Bitumen and Bituminous Binders—Determination of the Resistance to Hardening under the Influence of Heat and Air—Part. 1: RTFOT Method; European Committee for Standardization: Brussels, Belgium, 2014.

- Bahia, H.U. Critical evaluation of asphalt modification using Strategic Highway Research Program concepts. Transp. Res. Rec. 1995, 1488, 82–88. [Google Scholar]

- Philips, M.; Robertus, C. Binder rheology and asphaltic pavement permanent deformation: The zero-shear-viscosity. In Proceedings of the Eurasphalt & Eurobitume Congress, Strasbourg, France, 7–10 May 1996; European Asphalt Pavement Association: Brussels, Belgium, 1996; p. 12. [Google Scholar]

- Desmazes, C.; Lecompte, M.; Lesueur, D.; Philips, M. A protocol for reliable measurement of zero-shear viscosity in order to evaluate the anti-rutting performance of binders. In Proceedings of the 2nd Eurasphalt and Eurobitume Congress, Barcelona, Spain, 20–22 September 2000; Foundation Eurasphalt: Ermelo, The Netherlands, 2000; pp. 203–211. [Google Scholar]

- De Visscher, J.; Vanelstraete, A. Practical test methods for measuring the zero shear viscosity of bituminous binders. Mater. Struct. 2004, 37, 360–364. [Google Scholar] [CrossRef]

- Delgadillo, R.; Nam, K.; Bahia, H. Why do we need to change G*/sinδ and how? Road Mater. Pavement 2006, 7, 7–27. [Google Scholar] [CrossRef]

- Abdullah, N.H.; Hamzah, M.O.; Yusoff, N.I.; Valentin, J. Determination of the zero shear viscosity of binder-filler mastic using Cross and Carreau models. Asian Transp. Stud. 2018, 5, 165–176. [Google Scholar]

- Sybilski, D. Zero-shear viscosity of bituminous binder and its relation to bituminous mixture’s rutting resistance. Transp. Res. Rec. 1996, 1535, 15–21. [Google Scholar] [CrossRef]

- Binard, C.; Anderson, D.; Lapalu, L.; Plache, J.-P. Zero shear viscosity of modified and unmodified binders. In Proceedings of the 3rd Eurasphalt and Eurobitume Congress, Vienna, Austria, 12–14 May 2004; European Asphalt Pavement Association: Brussels, Belgium, 2004; pp. 1721–1733. [Google Scholar]

- Marasteanu, M.; Clyne, T.; McGraw, J.; Li, X.; Velasquez, R. High-temperature rheological properties of asphalt binders. Transp. Res. Rec. 2005, 1901, 52–59. [Google Scholar] [CrossRef]

- Mazurek, G.; Iwański, M. Estimation of zero shear viscosity versus rutting resistance parameters of asphalt concrete. Procedia Eng. 2016, 161, 30–35. [Google Scholar] [CrossRef] [Green Version]

- EN 14770: 2009. Bitumen and Bituminous Binders—Determination of Complex Shear Modulus and PHASE Angle—Dynamic Shear Rheometer (DSR); European Committee for Standardization: Brussels, Belgium, 2009.

- Cross, M.M. Rheology of non-Newtonian fluids: A new flow equation for pseudoplastic systems. J. Coll. Sci. 1965, 20, 417–437. [Google Scholar] [CrossRef]

- Saboo, N.; Mudgal, A. Modelling creep and recovery response of asphalt binders using generalized Burgers model. Pet. Sci. Technol. 2018, 36, 1627–1634. [Google Scholar] [CrossRef]

- CEN/TS 15325: 2008. Bitumen and Bituminous Binders—Determination of Zero-Shear Viscosity (ZSV) Using a Shear Stress Rheometer in Creep Mode; Comite Europeen de Normalisation: Brussels, Belgium, 2008.

| Properties | Unit | Test Methods | Test Results | Requirements According to [28] |

|---|---|---|---|---|

| Penetration | ×0.1 mm | [29] | 42.8 ± 0.6 | 35.0–50.0 |

| Softening point | °C | [30] | 55.1 ± 0.6 | 50.0–58.0 |

| Fraass breaking point | °C | [31] | −13 ± 1.5 | ≤−5 |

| Density at 25 °C | kg/m3 | [32] | 1020 ± 6 | No requirements |

| Properties | Unit | Test Methods | Test Results | Requirements According to [33] |

|---|---|---|---|---|

| Penetration | ×0.1 mm | [29] | 4.0 ± 0.5 | 0.0–4.0 |

| Softening point | °C | [30] | 101.2 ± 1.0 | 93.0–99.0 |

| Solubility | % (m/m) | [34] | 57.6 ± 1.0 | 52.0–55.0 |

| Density at 25 °C | kg/m3 | [32] | 1380 ± 8 | 1390–1420 |

| Properties | Unit | 35/50 (Base Bitumen) | 35/50 +10% TLA | 35/50 +20% TLA |

|---|---|---|---|---|

| Before aging | ||||

| Penetration at 25 °C | (×0.1 mm) | 42.8 ± 0.8 | 39.9 ± 1.2 | 31.8 ± 1.9 |

| Softening point | (°C) | 55.1 ± 0.6 | 56.9 ± 0.5 | 59.3 ± 0.2 |

| After aging | ||||

| Penetration at 25 °C | (×0.1 mm) | 31.5 ± 1.1 | 26.8 ± 1.2 | 22.3 ± 0.5 |

| Softening point | (°C) | 61.7 ± 0.2 | 65.3 ± 0.3 | 67.5 ± 0.5 |

| Aging indices | ||||

| Retained penetration (RP) | (%) | 73.6 ± 2.9 | 67.2 ± 3.6 | 70.1 ± 4.5 |

| Softening point increment (SPI) | (°C) | 6.6 ± 0.6 | 8.4 ± 0.6 | 8.2 ± 0.5 |

| TLA Addition | Complex Modulus G* (MPa) | Phase Angle δ (°) | ||||

|---|---|---|---|---|---|---|

| Test Temperature (°C) | Test Temperature (°C) | |||||

| 40 | 50 | 60 | 40 | 50 | 60 | |

| Before aging | ||||||

| 0% TLA | 0.618 ± 0.036 | 0.167 ± 0.015 | 0.050 ± 0.001 | 54.3 ± 0.3 | 65.0 ± 0.2 | 71.3 ± 0.3 |

| 10% TLA | 0.958 ± 0.060 | 0.240 ± 0.010 | 0.069 ± 0.002 | 49.3 ± 0.5 | 60.6 ± 0.5 | 68.3 ± 0.3 |

| 20% TLA | 1.231 ± 0.043 | 0.325 ± 0.021 | 0.094 ± 0.007 | 43.1 ± 0.4 | 58.4 ± 0.4 | 66.9 ± 0.2 |

| After aging | ||||||

| 0% TLA | 1.321 ± 0.072 | 0.392 ± 0.032 | 0.126 ± 0.003 | 41.6 ± 0.8 | 55.1 ± 0.4 | 63.0 ± 0.6 |

| 10% TLA | 1.780 ± 0.137 | 0.530 ± 0.031 | 0.169 ± 0.006 | 37.0 ± 0.9 | 49.5 ± 0.4 | 59.1 ± 0.2 |

| 20% TLA | 2.292 ± 0.055 | 0.735 ± 0.017 | 0.245 ± 0.006 | 29.6 ± 0.2 | 45.3 ± 0.3 | 55.8 ± 0.2 |

| Complex modulus aging index (CAI) | Phase angle aging index (PAI) | |||||

| 0% TLA | 2.14 ± 0.17 | 2.35 ± 0.28 | 2.52 ± 0.08 | 0.77 ± 0.02 | 0.85 ± 0.01 | 0.88 ± 0.01 |

| 10% TLA | 1.86 ± 0.18 | 2.21 ± 0.16 | 2.45 ± 0.11 | 0.75 ± 0.02 | 0.82 ± 0.01 | 0.87 ± 0.005 |

| 20% TLA | 1.86 ± 0.08 | 2.26 ± 0.16 | 2.61 ± 0.20 | 0.69 ± 0.01 | 0.78 ± 0.01 | 0.83 ± 0.004 |

| TLA Addition | ZSV (Pa·s) from Frequency Sweep Test | ZSV (Pa·s) from Creep Test | ||||

|---|---|---|---|---|---|---|

| Test Temperature (°C) | Test Temperature (°C) | |||||

| 40 | 50 | 60 | 40 | 50 | 60 | |

| Before aging | ||||||

| 0% TLA | 63,840 ± 4210 | 8916 ± 763 | 1740 ± 36 | 57,832 ± 4089 | 8769 ± 1009 | 1682 ± 105 |

| 10% TLA | 130,367 ± 9649 | 15,510 ± 1376 | 2865 ± 165 | 117,026 ± 4216 | 14,711 ± 1400 | 2698 ± 172 |

| 20% TLA | 186,383 ± 11,031 | 23,063 ± 1903 | 4118 ± 318 | 166,109 ± 11,294 | 22,312 ± 1597 | 3965 ± 295 |

| After aging | ||||||

| 0% TLA | 342,650 ± 35,413 | 43,690 ± 4314 | 7703 ± 239 | 300,743 ± 20,527 | 40,381 ± 3619 | 7198 ± 125 |

| 10% TLA | 710,933 ± 99,477 | 78,232 ± 5870 | 13,312 ± 568 | 616,827 ± 29,599 | 73,351 ± 4283 | 12,817 ± 79 |

| 20% TLA | 1172,167 ± 60,001 | 147,400 ± 5247 | 24,572 ± 747 | 1192,585 ± 54,268 | 146,889 ± 6059 | 24,749 ± 1378 |

| Viscosity aging index (VAI) | ||||||

| 0% TLA | 4.37 | 3.90 | 3.43 | 4.20 | 3.60 | 3.28 |

| 10% TLA | 4.45 | 4.04 | 3.65 | 4.27 | 3.99 | 3.75 |

| 20% TLA | 5.29 | 5.39 | 4.97 | 6.18 | 5.58 | 5.24 |

| Aging index (AI) | ||||||

| 0% TLA | 5.37 | 4.90 | 4.43 | 5.20 | 4.60 | 4.28 |

| 10% TLA | 5.45 | 5.04 | 4.65 | 5.27 | 4.99 | 4.75 |

| 20% TLA | 6.29 | 6.39 | 5.97 | 7.18 | 6.58 | 6.24 |

| TLA Addition | Test Temperature (°C) | Cross Parameters | |||

|---|---|---|---|---|---|

| K (s) | m (-) | ||||

| Before aging | |||||

| 0% TLA | 40 | 63,840 ± 4210 | 1675 ± 172 | 1.657 ± 0.162 | 0.405 ± 0.016 |

| 50 | 8916 ± 763 | 773.2 ± 157.0 | 0.209 ± 0.007 | 0.462 ± 0.010 | |

| 60 | 1740 ± 36 | 177.6 ± 84.7 | 0.041 ± 0.005 | 0.459 ± 0.043 | |

| 10% TLA | 40 | 130,367 ± 9649 | 2035 ± 418 | 3.542 ± 0.348 | 0.405 ± 0.009 |

| 50 | 15,510 ± 1376 | 939.1 ± 42.0 | 0.383 ± 0.053 | 0.440 ± 0.005 | |

| 60 | 2865 ± 165 | 174.6 ± 72.8 | 0.068 ± 0.007 | 0.427 ± 0.026 | |

| 20% TLA | 40 | 186,383 ± 11,031 | 1703 ± 486 | 5.148 ± 0.527 | 0.393 ± 0.011 |

| 50 | 23,063 ± 1903 | 1310 ± 120 | 0.537 ± 0.055 | 0.439 ± 0.005 | |

| 60 | 4118 ± 318 | 368.3 ± 68.8 | 0.099 ± 0.004 | 0.455 ± 0.009 | |

| After aging | |||||

| 0% TLA | 40 | 342,650 ± 35,413 | 735.0 ± 204.4 | 13.676 ± 2.532 | 0.411 ± 0.012 |

| 50 | 43,690 ± 4314 | 995.6 ± 70.7 | 1.484 ± 0.121 | 0.436 ± 0.004 | |

| 60 | 7703 ± 239 | 396.0 ± 21.5 | 0.255 ± 0.018 | 0.454 ± 0.003 | |

| 10% TLA | 40 | 710,933 ± 99,477 | −1474 ± 820 | 34.439 ± 8.327 | 0.412 ± 0.012 |

| 50 | 78,232 ± 5870 | 1132 ± 73 | 2.831 ± 0.185 | 0.438 ± 0.005 | |

| 60 | 13,312 ± 568 | 523.4 ± 14.0 | 0.479 ± 0.027 | 0.456 ± 0.004 | |

| 20% TLA | 40 | 1172,167 ± 60,001 | −1243 ± 614 | 46.226 ± 7.841 | 0.427 ± 0.006 |

| 50 | 147,400 ± 5247 | 1263 ± 206 | 5.237 ± 0.321 | 0.445 ± 0.004 | |

| 60 | 24,572 ± 747 | 607.5 ± 47.5 | 0.928 ± 0.040 | 0.457 ± 0.004 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kołodziej, K.; Bichajło, L.; Siwowski, T. Effects of Aging on the Physical and Rheological Properties of Trinidad Lake Asphalt Modified Bitumen. Materials 2021, 14, 2532. https://doi.org/10.3390/ma14102532

Kołodziej K, Bichajło L, Siwowski T. Effects of Aging on the Physical and Rheological Properties of Trinidad Lake Asphalt Modified Bitumen. Materials. 2021; 14(10):2532. https://doi.org/10.3390/ma14102532

Chicago/Turabian StyleKołodziej, Krzysztof, Lesław Bichajło, and Tomasz Siwowski. 2021. "Effects of Aging on the Physical and Rheological Properties of Trinidad Lake Asphalt Modified Bitumen" Materials 14, no. 10: 2532. https://doi.org/10.3390/ma14102532

APA StyleKołodziej, K., Bichajło, L., & Siwowski, T. (2021). Effects of Aging on the Physical and Rheological Properties of Trinidad Lake Asphalt Modified Bitumen. Materials, 14(10), 2532. https://doi.org/10.3390/ma14102532