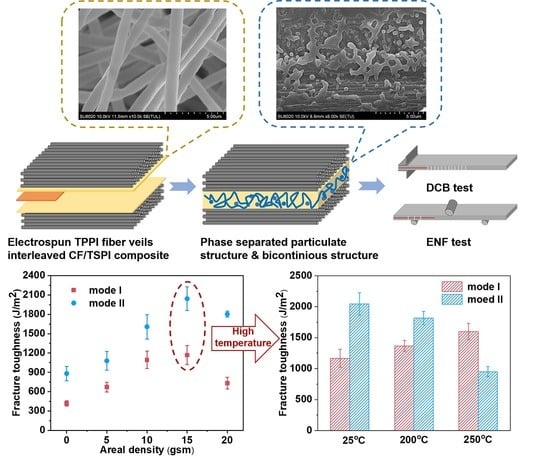

Interlaminar Fracture Behavior of Carbon Fiber/Polyimide Composites Toughened by Interleaving Thermoplastic Polyimide Fiber Veils

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Unidirectional CF/TSPI Prepreg

2.3. Preparation of Electrospun Thermoplastic Polyimide Fiber Veils

2.4. Preparation of TPPI Fiber Veils Interleaved Composites

2.5. Characterization

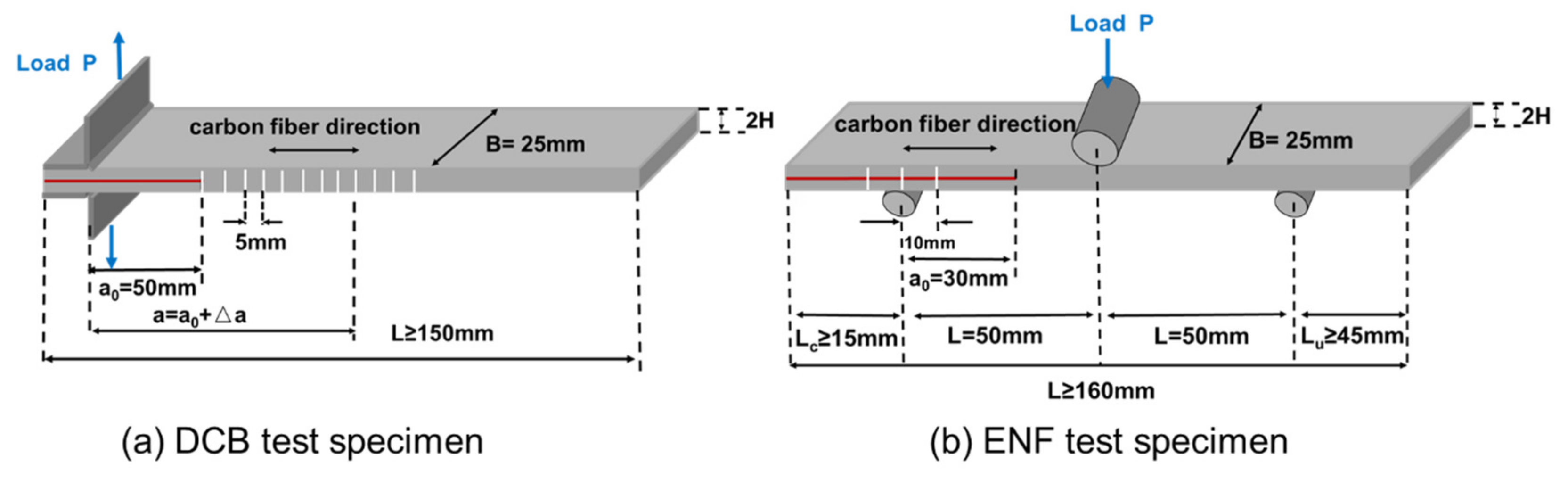

2.5.1. Mode I and Mode II Interlaminar Fracture Properties

2.5.2. Morphology Observation

2.5.3. Thermal Properties

3. Results

3.1. Characterization of Electrospun TPPI Fiber Veils

3.2. Mode I and Mode II Fracture Toughness of Laminates

3.3. Fracture Morphology Analysis

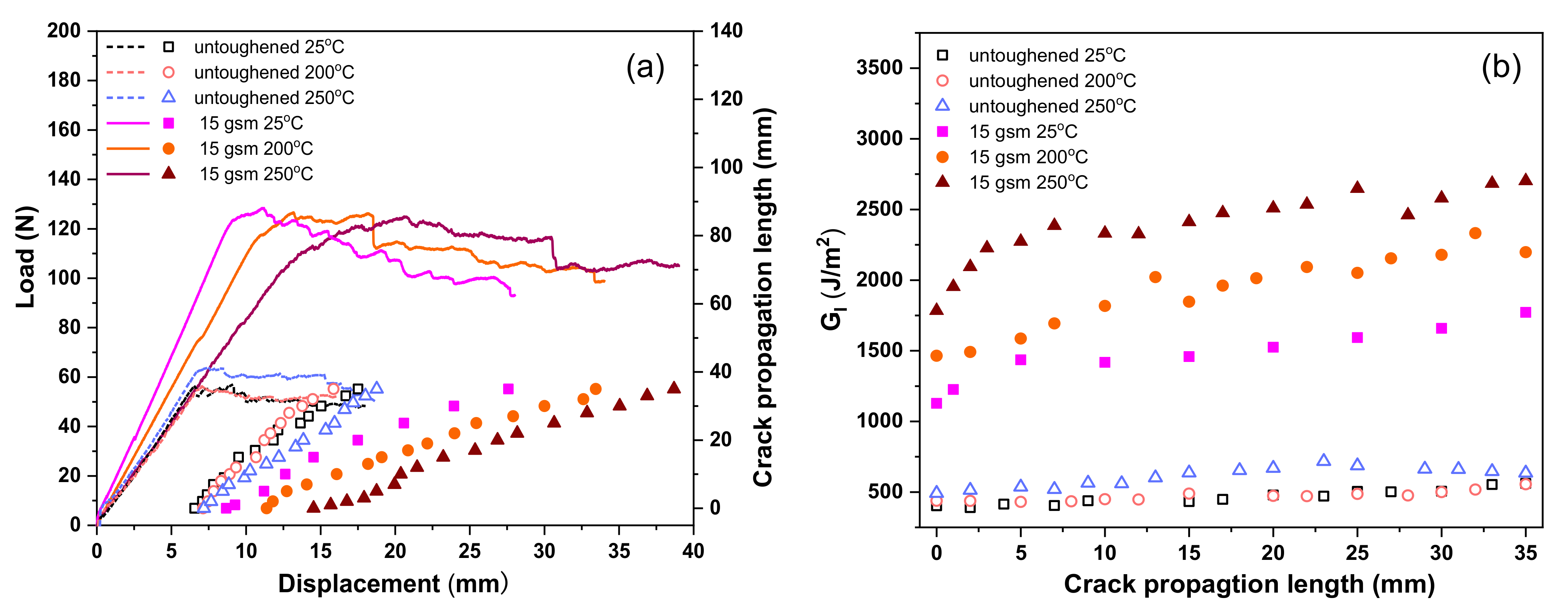

3.4. Interlaminar Fracture Behavior at Elevated Temperature

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meador, M.A. Recent advances in the development of processable high-temperature polymers. Annu. Rev. Mater. Res. 1998, 28, 599–630. [Google Scholar] [CrossRef]

- Liaw, D.-J.; Wang, K.-L.; Huang, Y.-C.; Lee, K.-R.; Lai, J.-Y.; Ha, C.-S. Advanced polyimide materials: Syntheses, physical properties and applications. Prog. Polym. Sci. 2012, 37, 907–974. [Google Scholar] [CrossRef]

- Hutapea, P.; Yuan, F. The effect of thermal aging on the Mode-I interlaminar fracture behavior of a high-temperature IM7/LaRC-RP46 composite. Compos. Sci. Technol. 1999, 59, 1271–1286. [Google Scholar] [CrossRef]

- Qu, X.; Ji, M.; Fan, L.; Yang, S. Thermoset polyimide matrix resins with improved toughness and high Tg for high temperature carbon fiber composites. High Perform. Polym. 2011, 23, 281–289. [Google Scholar] [CrossRef]

- Xiao, T.J.; Gao, S.Q.; Hu, A.J.; Wang, X.C.; Yang, S.Y. Thermosetting polyimides with improved impact toughness and excellent thermal and thermo-oxidative stability. High Perform. Polym. 2001, 13, 287–299. [Google Scholar] [CrossRef]

- Liu, B.; Ji, M.; Lin, F.; Yang, S. Phenylethynyl-endcapped polymerizable monomer reactants poly (amic ester) resins for high impact-toughened carbon fiber composites. High Perform. Polym. 2013, 25, 225–235. [Google Scholar] [CrossRef]

- Tang, H.; Dong, L.; Zhang, J.; Ding, M.; Feng, Z. Miscibility, crystallization, and morphology studies of thermosetting polyimide PMR-15/PEK-C blends. J. Appl. Polym. Sci. 1996, 60, 725–730. [Google Scholar] [CrossRef]

- Tai, H.J.; Jang, B.Z.; Wang, J.B. Synthesis and processing of PMR-15/LaRC-TPI semi-IPN systems. J. Appl. Polym. Sci. 1995, 58, 2293–2306. [Google Scholar] [CrossRef]

- Scott, J.M.; Phillips, D.C. Carbon fibre composites with rubber toughened matrices. J. Mater. Sci. 1975, 10, 551–562. [Google Scholar] [CrossRef]

- Maccaferri, E.; Mazzocchetti, L.; Benelli, T.; Brugo, T.M.; Zucchelli, A.; Giorgini, L. Rubbery nanofibrous interleaves enhance fracture toughness and damping of CFRP laminates. Mater. Des. 2020, 195, 109049. [Google Scholar] [CrossRef]

- El Assami, Y.; Habti, M.D.; Raman, V. Stiffening offshore composite wind-blades bonding joints by carbon nanotubes reinforced resin—A new concept. J. Struct. Integr. Maint. 2020, 5, 87–103. [Google Scholar] [CrossRef]

- García-Rodríguez, S.; Costa, J.; Rankin, K.; Boardman, R.; Singery, V.; Mayugo, J. Interleaving light veils to minimise the trade-off between mode-I interlaminar fracture toughness and in-plane properties. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105659. [Google Scholar] [CrossRef]

- Li, X.; Lei, X.I.; Ma, H.; Li, H.; Xiao-Su, Y. Toughness improvement of PMR-type polyimide and laminated graphite systems by ex-situ concept. J. Mater. Sci. 2005, 40, 5067–5070. [Google Scholar] [CrossRef]

- Davidson, B.; Kumar, M.; Soffa, M. Influence of mode ratio and hygrothermal condition on the delamination toughness of a thermoplastic particulate interlayered carbon/epoxy composite. Compos. Part A Appl. Sci. Manuf. 2009, 40, 67–79. [Google Scholar] [CrossRef]

- Tang, Y.; Ye, L.; Zhang, Z.; Friedrich, K. Interlaminar fracture toughness and CAI strength of fibre-reinforced composites with nanoparticles—A review. Compos. Sci. Technol. 2013, 86, 26–37. [Google Scholar] [CrossRef]

- Pegoretti, A.; Cristelli, I.; Migliaresi, C. Experimental optimization of the impact energy absorption of epoxy-carbon laminates through controlled delamination. Compos. Sci. Technol. 2008, 68, 2653–2662. [Google Scholar] [CrossRef] [Green Version]

- Guo, M.; Liu, L. Structuring the thermoplastic interleaf with lotus-leaf-like structure and its interlaminar toughening for CFRPs. Compos. Sci. Technol. 2019, 183, 107825. [Google Scholar] [CrossRef]

- Nasser, J.; Zhang, L.; Sodano, H. Aramid nanofiber interlayer for improved interlaminar properties of carbon fiber/epoxy composites. Compos. Part B Eng. 2020, 197, 108130. [Google Scholar] [CrossRef]

- Liu, Z.; Guo, E.; Xing, J.; Li, H.; Yi, X.; Wang, Z.; Yu, Y. Application of carbon fiber/RTMable polyimide composites by ex-situ toughness method. Acta Mater. Compos. Sin. 2010, 27, 1–8. [Google Scholar] [CrossRef]

- Taheri, H.; Oliaei, M.; Ipakchi, H.; Saghafi, H. Toughening phenolic composite laminates by interleaving hybrid pyrolytic carbon/polyvinyl butyral nanomat. Compos. Part B Eng. 2020, 191, 107981. [Google Scholar] [CrossRef]

- Saghafi, H.; Palazzetti, R.; Heidary, H.; Brugo, T.M.; Zucchelli, A.; Minak, G. Toughening behavior of carbon/epoxy laminates interleaved by PSF/PVDF composite nanofibers. Appl. Sci. 2020, 10, 5618. [Google Scholar] [CrossRef]

- Han, Y.; Xu, Y.; Zhang, S.; Li, T.; Ramakrishna, S.; Liu, Y. Progress of improving mechanical strength of electrospun nanofibrous membranes. Macromol. Mater. Eng. 2020, 305. [Google Scholar] [CrossRef]

- Li, G.; Li, P.; Zhang, C.; Yu, Y.; Liu, H.; Jia, X.; Yang, X.; Xue, Z.; Ryu, S. Inhomogeneous toughening of carbon fiber/epoxy composite using electrospun polysulfone nanofibrous membranes by in situ phase separation. Compos. Sci. Technol. 2008, 68, 987–994. [Google Scholar] [CrossRef]

- Zhang, J.; Yang, T.; Lin, T.; Wang, C.H. Phase morphology of nanofibre interlayers: Critical factor for toughening carbon/epoxy composites. Compos. Sci. Technol. 2012, 72, 256–262. [Google Scholar] [CrossRef]

- Pater, R.H. Interpenetrating polymer network approach to tough and microcracking resistant high temperature polymers. Part II. LaRC-RP41. Polym. Eng. Sci. 1991, 31, 20–27. [Google Scholar] [CrossRef]

- Singh, J.J.; Pater, R.H.; Eftekhari, A. Microstructural characterization of semi-interpenetrating polymer networks by positron lifetime spectroscopy. Nucl. Instrum. Methods Phys. Res. Sect. B 1998, 134, 113–120. [Google Scholar] [CrossRef]

- Yokota, R.; Yamamoto, S.; Yano, S.; Sawaguchi, T.; Hasegawa, M.; Yamaguchi, H.; Ozawa, H.; Sato, R. Molecular design of heat resistant polyimides having excellent processability and high glass transition temperature. High Perform. Polym. 2001, 13, S61–S72. [Google Scholar] [CrossRef]

- Ogasawara, T.; Ishikawa, T.; Yokota, R.; Ozawa, H.; Taguchi, M.; Sato, R.; Shigenari, Y.; Miyagawa, K. Processing and properties of carbon fiber reinforced triple-A polyimide (Tri-A PI) matrix composites. Adv. Compos. Mater. 2002, 11, 277–286. [Google Scholar] [CrossRef]

- Liu, Y.; Mo, S.; He, M.; Zhai, L.; Xu, C.; Fan, L. Phenylethynyl-terminated oligoimides based on bis(p-aminophenoxy) dimethyl silane: Effect of siloxane structure on processability and thermal stability. High Perform. Polym. 2018, 31, 651–661. [Google Scholar] [CrossRef]

- Liu, Y.; Fan, L.; Xu, X.; Mo, S.; Peng, D.; Mu, Q.; Zhu, C.; Li, C.; Xu, J. Melt fluidity and thermal property of thermosetting siloxane-containing polyimide resins and their organic/inorganic hybrid characteristics. Mater. Today Commun. 2020, 25, 101443. [Google Scholar] [CrossRef]

- Farr, I.V.; Kratzner, D.; Glass, T.E.; Dunson, D.; Ji, Q.; McGrath, J.E. The synthesis and characterization of polyimide homo-polymers based on 5(6)-amino-1-(4-aminophenyl)-1,3,3-trimethylindane. J. Polym. Sci. Part A Polym. Chem. 2000, 38, 2840–2854. [Google Scholar] [CrossRef]

- Li, H.; Wang, W.; Chen, G.; Liu, Y.; Fang, X. Highly soluble phenylethynyl terminated oligoimides derived from 5(6)-amino-1-(4-aminophenyl)-1,3,3-trimethylindane, 4,4′-oxydianiline and mixed thioetherdiphthalic anhydride isomers. J. Polym. Res. 2018, 25, 32. [Google Scholar] [CrossRef]

- Beckermann, G.W.; Pickering, K.L. Mode I and Mode II interlaminar fracture toughness of composite laminates interleaved with electrospun nanofibre veils. Compos. Part A Appl. Sci. Manuf. 2015, 72, 11–21. [Google Scholar] [CrossRef]

- Liu, H.; Nie, H.; Zhang, C.; Li, Y. Loading rate dependency of Mode I interlaminar fracture toughness for unidirectional composite laminates. Compos. Sci. Technol. 2018, 167, 215–223. [Google Scholar] [CrossRef]

- May, M. Measuring the rate-dependent mode I fracture toughness of composites—A review. Compos. Part A Appl. Sci. Manuf. 2016, 81, 1–12. [Google Scholar] [CrossRef]

- Mohammadi, R.; Najafabadi, M.A.; Saghafi, H.; Zarouchas, D. Mode-II fatigue response of AS4/8552 carbon /epoxy composite laminates interleaved by electrospun nanofibers. Thin-Walled Struct. 2020, 154, 106811. [Google Scholar] [CrossRef]

- Quan, D.; Bologna, F.; Scarselli, G.; Ivankovic, A.; Murphy, N. Interlaminar fracture toughness of aerospace-grade carbon fibre reinforced plastics interleaved with thermoplastic veils. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105642. [Google Scholar] [CrossRef]

- Van Der Heijden, S.; Daelemans, L.; De Schoenmaker, B.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Interlaminar toughening of resin transfer moulded glass fibre epoxy laminates by polycaprolactone electrospun nanofibres. Compos. Sci. Technol. 2014, 104, 66–73. [Google Scholar] [CrossRef] [Green Version]

- Cheng, C.; Chen, Z.; Huang, Z.; Zhang, C.; Tusiime, R.; Zhou, J.; Sun, Z.; Liu, Y.; Yu, M.; Zhang, H. Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105696. [Google Scholar] [CrossRef]

- Cheng, C.; Zhang, C.; Zhou, J.; Jiang, M.; Sun, Z.; Zhou, S.; Liu, Y.; Chen, Z.; Xu, L.; Zhang, H.; et al. Improving the interlaminar toughness of the carbon fiber/epoxy composites via interleaved with polyethersulfone porous films. Compos. Sci. Technol. 2019, 183, 107827. [Google Scholar] [CrossRef]

- Magniez, K.; Chaffraix, T.; Fox, B. Toughening of a carbon-fibre composite using electrospun poly (hydroxyether of bisphenol A) nanofibrous membranes through inverse phase separation and inter-domain etherification. Materials 2011, 4, 1967–1984. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Daelemans, L.; Van Der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Damage-resistant composites using electrospun nanofibers: A multiscale analysis of the toughening mechanisms. ACS Appl. Mater. Interfaces 2016, 8, 11806–11818. [Google Scholar] [CrossRef] [PubMed]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Using aligned nanofibres for identifying the toughening micromechanisms in nanofibre interleaved laminates. Compos. Sci. Technol. 2016, 124, 17–26. [Google Scholar] [CrossRef]

- Czabaj, M.W.; Davidson, B.D. Determination of the mode I, mode II, and mixed-mode I–II delamination toughness of a graphite/polyimide composite at room and elevated temperatures. J. Compos. Mater. 2015, 50, 2235–2253. [Google Scholar] [CrossRef]

- Boni, L.; Fanteria, D.; Lazzeri, L.; Panettieri, E.; Mariani, U.; Rigamonti, M. Influence of environment conditioning on the interlaminar fracture toughness of a graphite/epoxy unidirectional material. Compos. Part B Eng. 2018, 153, 97–107. [Google Scholar] [CrossRef]

- Kim, K.-Y.; Ye, L. Interlaminar fracture toughness of CF/PEI composites at elevated temperatures: Roles of matrix toughness and fibre/matrix adhesion. Compos. Part A Appl. Sci. Manuf. 2004, 35, 477–487. [Google Scholar] [CrossRef]

- Cowley, K.D.; Beaumont, P.W. The interlaminar and intralaminar fracture toughness of carbon-fibre/polymer composites: The effect of temperature. Compos. Sci. Technol. 1997, 57, 1433–1444. [Google Scholar] [CrossRef]

| Specimens | GIC (J/m2) | GIR (J/m2) | GIIC (J/m2) |

|---|---|---|---|

| untoughened | 418 ± 41 | 602 ± 51 | 881 ± 111 |

| 5 gsm | 671 ± 76 (61%) | 928 ± 33 (54%) | 1079 ± 144 (22%) |

| 10 gsm | 1094 ± 133 (162%) | 1334 ± 84 (122%) | 1607 ± 189 (82%) |

| 15 gsm | 1167 ± 148 (179%) | 1542 ± 105 (156%) | 2042 ± 183 (132%) |

| 20 gsm | 733 ± 90 (75%) | 1265 ± 26 (110%) | 1803 ± 44 (105%) |

| Specimens | Test Temperature (°C) | GIC (J/m2) | GIR (J/m2) | GIIC (J/m2) |

|---|---|---|---|---|

| untoughened | 25 | 418 ± 41 | 602 ± 51 | 881 ± 111 |

| 200 | 470 ± 30 | 640 ± 102 | 421 ± 21 | |

| 250 | 525 ± 25 | 699 ± 59 | 258 ± 21 | |

| 15 gsm | 25 | 1167 ± 148 (179%) | 1542 ± 105 (156%) | 2042 ± 183 (132%) |

| 200 | 1366 ± 92 (191%) | 1832 ± 149 (186%) | 1815 ± 109 (331%) | |

| 250 | 1599 ± 133(205%) | 2237 ± 188 (220%) | 950 ± 84 (268%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, B.; Liu, Y.; Mo, S.; He, M.; Zhai, L.; Fan, L. Interlaminar Fracture Behavior of Carbon Fiber/Polyimide Composites Toughened by Interleaving Thermoplastic Polyimide Fiber Veils. Materials 2021, 14, 2695. https://doi.org/10.3390/ma14102695

Lan B, Liu Y, Mo S, He M, Zhai L, Fan L. Interlaminar Fracture Behavior of Carbon Fiber/Polyimide Composites Toughened by Interleaving Thermoplastic Polyimide Fiber Veils. Materials. 2021; 14(10):2695. https://doi.org/10.3390/ma14102695

Chicago/Turabian StyleLan, Bangwei, Yi Liu, Song Mo, Minhui He, Lei Zhai, and Lin Fan. 2021. "Interlaminar Fracture Behavior of Carbon Fiber/Polyimide Composites Toughened by Interleaving Thermoplastic Polyimide Fiber Veils" Materials 14, no. 10: 2695. https://doi.org/10.3390/ma14102695

APA StyleLan, B., Liu, Y., Mo, S., He, M., Zhai, L., & Fan, L. (2021). Interlaminar Fracture Behavior of Carbon Fiber/Polyimide Composites Toughened by Interleaving Thermoplastic Polyimide Fiber Veils. Materials, 14(10), 2695. https://doi.org/10.3390/ma14102695