Quasi-Static Tensile Properties of Unalloyed Copper Produced by Electron Beam Powder Bed Fusion Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methods

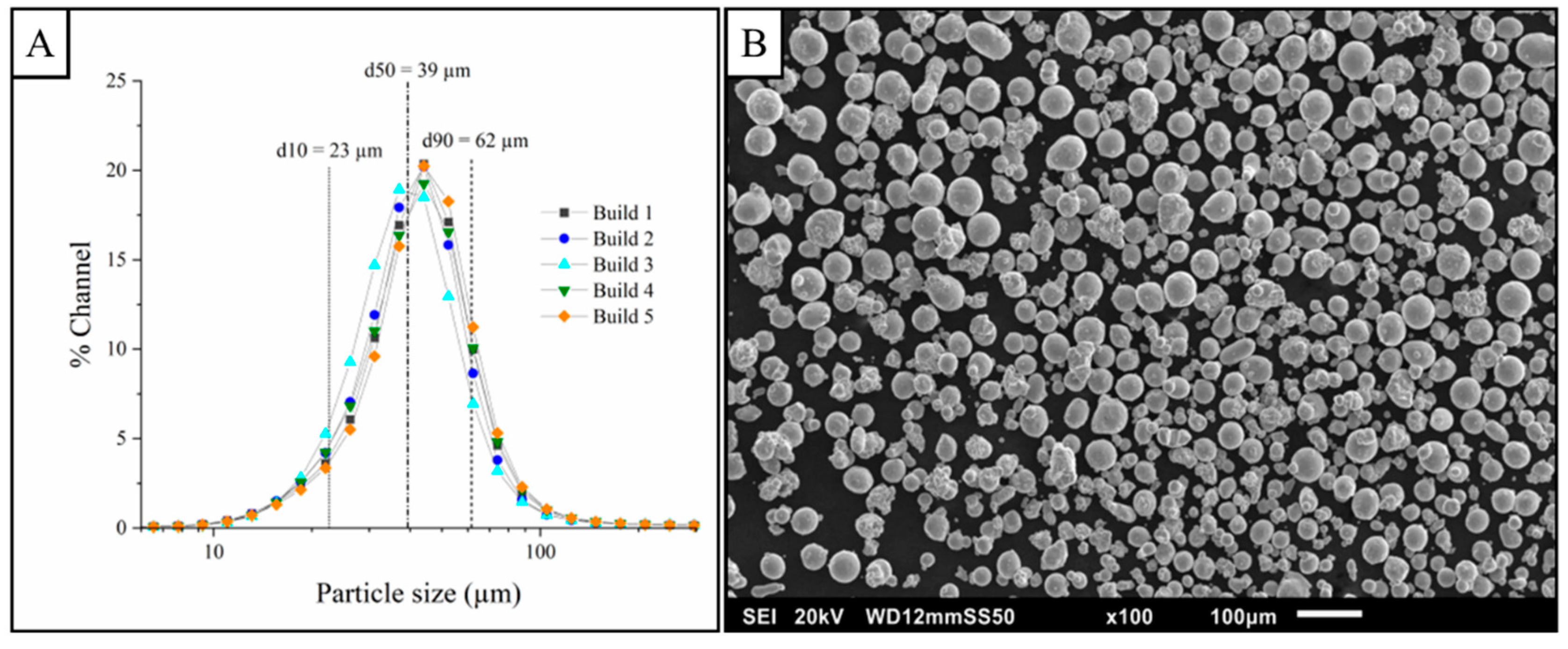

2.1. Powder Feedstock

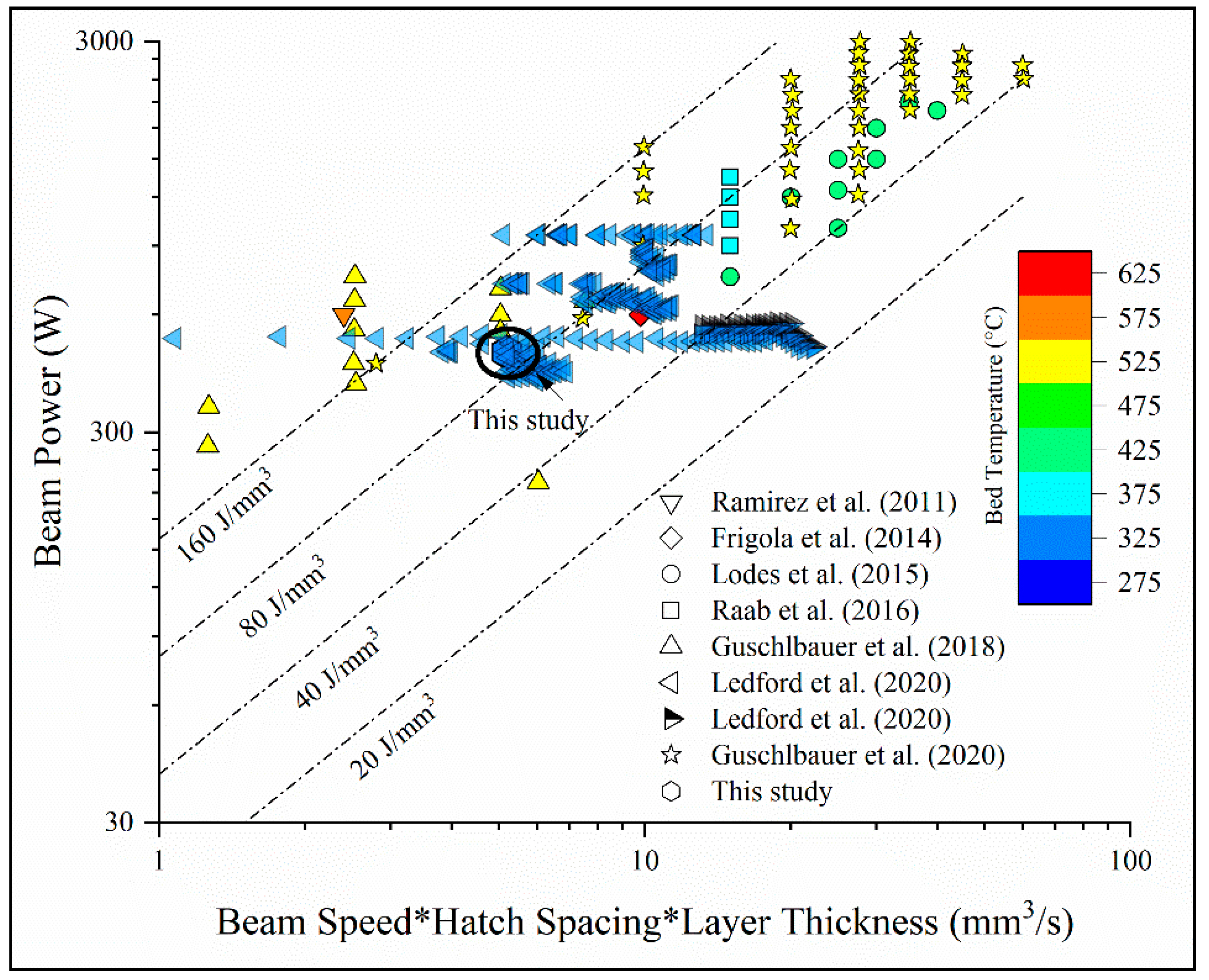

2.2. Sample Fabrication

2.3. Quasi-Static Uniaxial Tensile Test Procedure

2.4. Metallographic Analyses and Microhardness Measurements

3. Results and Discussion

3.1. Powder Characterization

3.2. Processing Space of Copper in EB-PBF

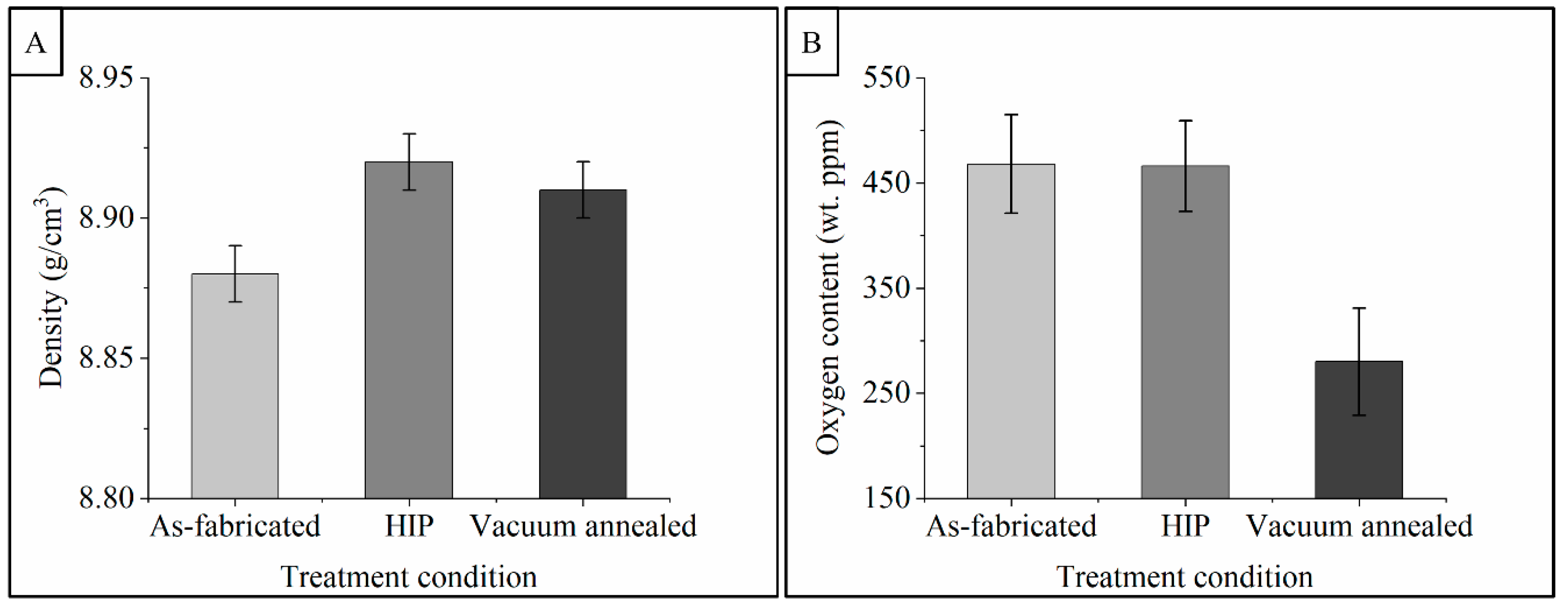

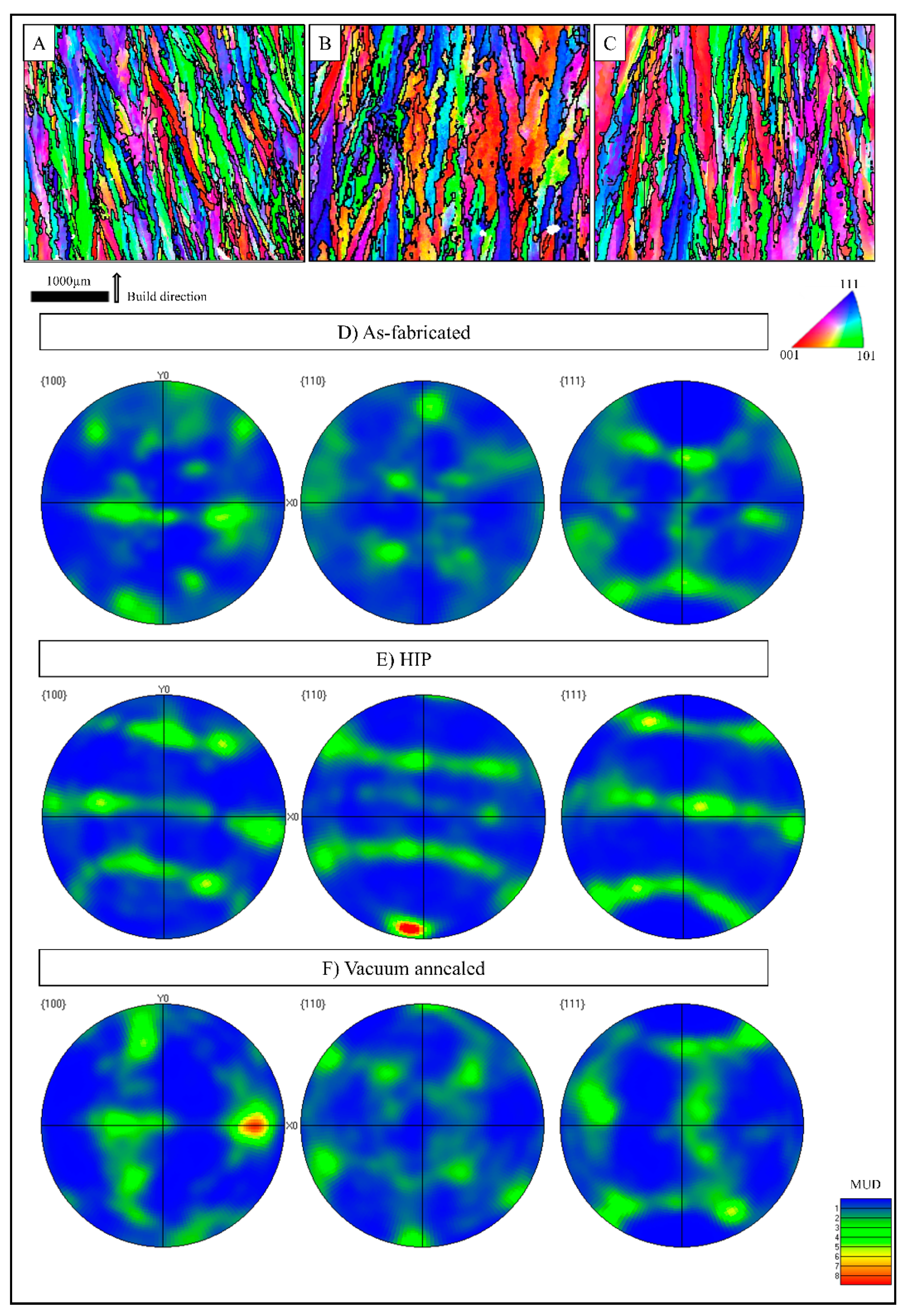

3.3. Material Characterization

4. Conclusions

- Mechanical properties of the as-fabricated specimens are observed to be similar to unalloyed annealed copper. X-oriented specimens have higher tensile strength values across post-processes than the Z-oriented samples with an average UTS of 211.2, 195.7 and 195.5 MPa in as-fabricated, HIP, and vacuum-annealing conditions, respectively. Maximum elongation to failure is recorded for Z-oriented vacuum-annealed and HIP specimens that showed average values of ~63%, as opposed to ~54% in as-fabricated samples.

- With the density values reaching close to the theoretical density, the observed differences in UTS and elongation are proposed to be controlled by orientation anisotropy and interdependencies between the grain morphology and dislocation movement. Difference in yield strength is more pronounced between treatment conditions than the specimen orientation (e.g., 101.4, 87.3 and 56.7 MPa for X-oriented samples in as-fabricated, HIP, and vacuum-annealing condition, respectively) and is assumed to be affected by the differences in residual stress as a function of treatment conditions.

- Density of the specimens increased slightly after the HIP treatment with an associated increase in ductility and decrease in strength. As expected, the vacuum-annealing process reduced the oxygen content within the specimen, also resulting in the lowest strength among all treatment conditions.

- The EBSD maps show no apparent texture in the as-fabricated specimens, and a slight amount of texture in HIP and vacuum-annealed specimens. However, the effect of such texture in the mechanical properties is outweighed by morphological anisotropy due to the epitaxial columnar microstructure formed during the fabrication process.

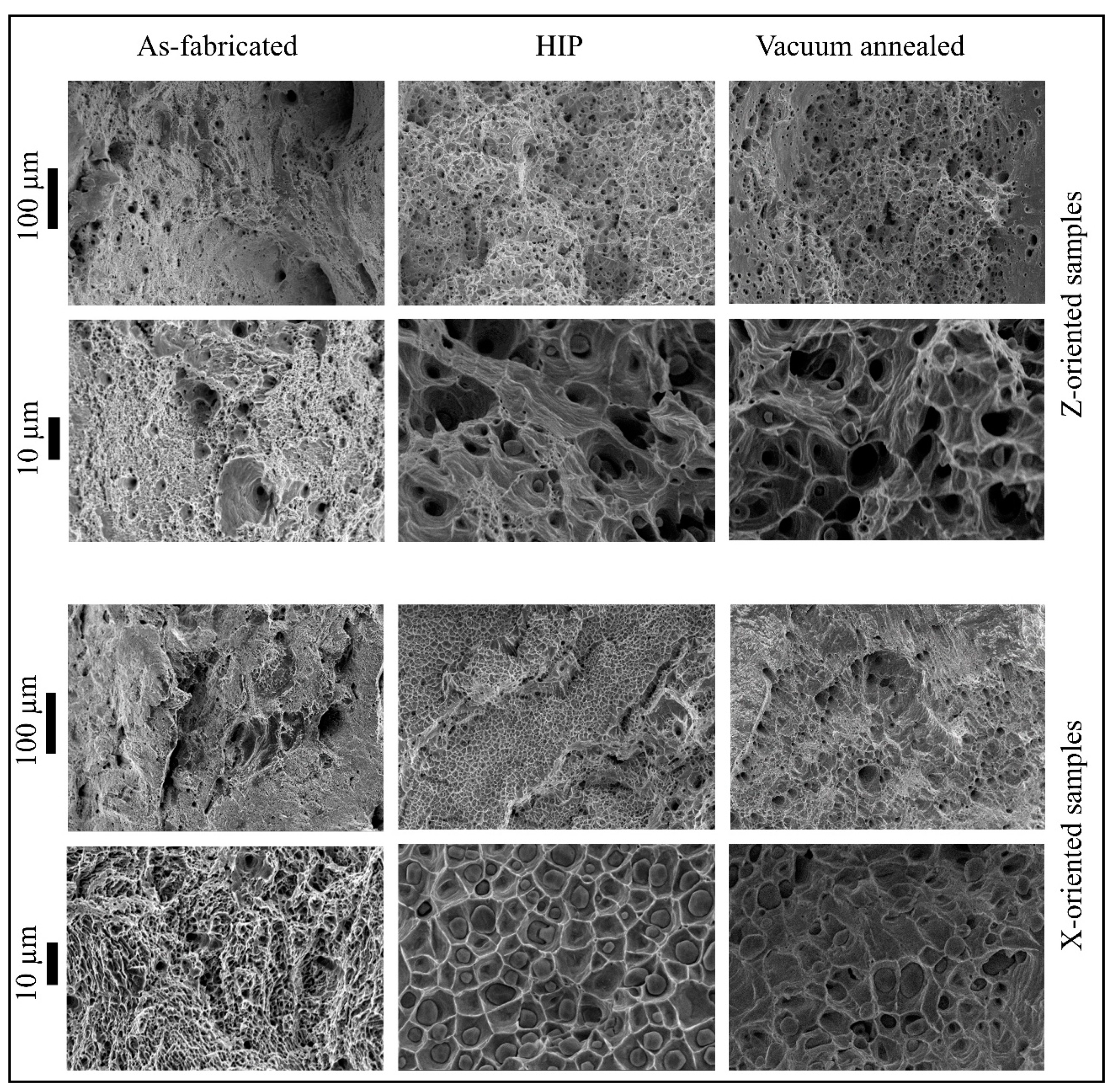

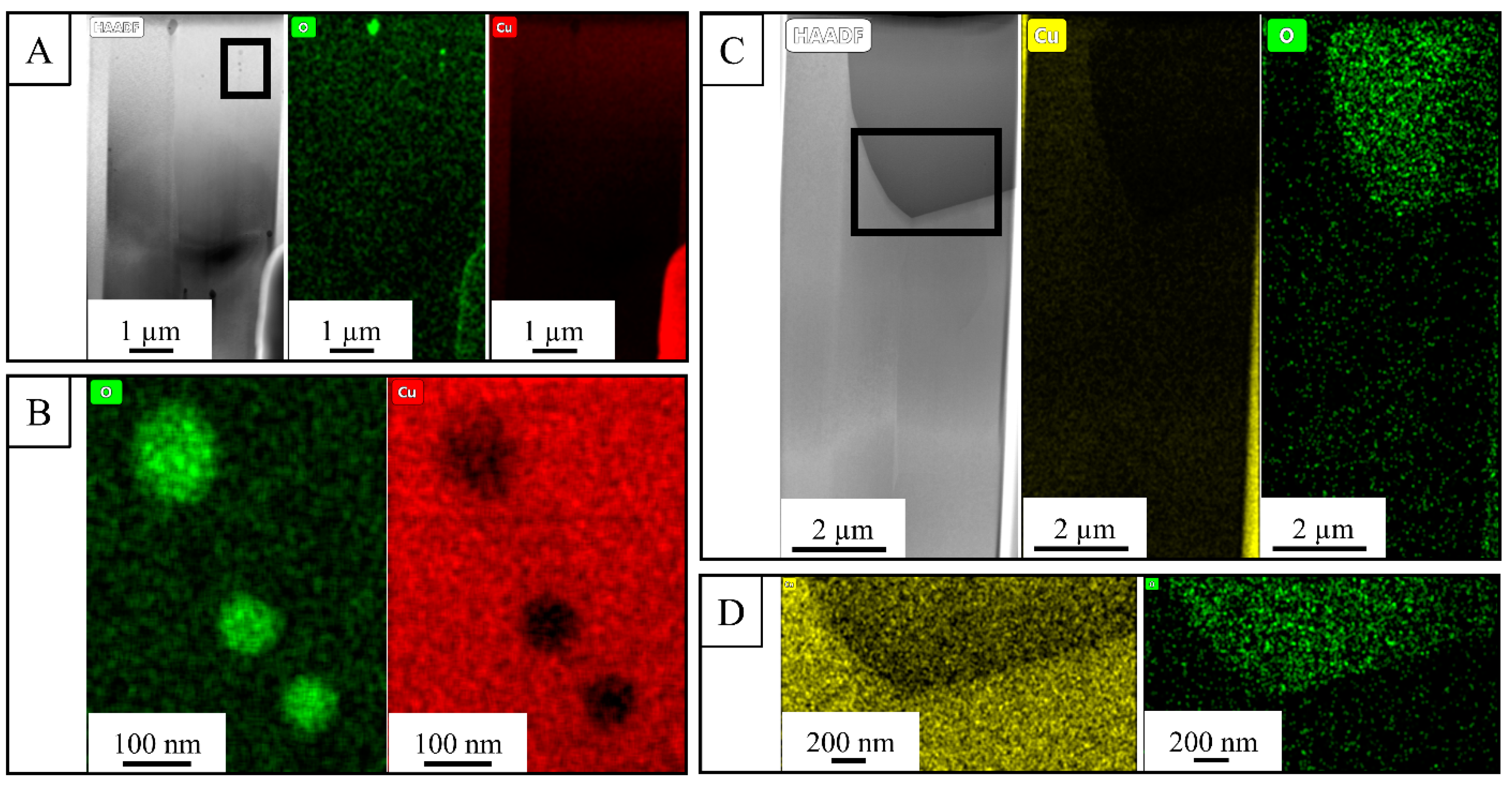

- While all treatment conditions show a ductile failure mode irrespective of the sample harvesting direction, HIP and vacuum-annealed specimens are noticeably different due to the presence of large micron-scale oxide particles within the dimples. It is suggested that the high temperature used in these post-processes promoted the coalescence and growth of grain boundary oxides which are mostly in the nano-scale size in the as-fabricated condition. This bigger oxide size led to larger interparticle distances and resulted in increased void spacing that, in turn, increased ductility in the HIP and vacuum-annealed condition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ledford, C.; Rock, C.; Tung, M.; Wang, H.; Schroth, J.; Horn, T. Evaluation of Electron Beam Powder Bed Fusion Additive Manufacturing of High Purity Copper for Overhang Structures Using In-Situ Real Time Backscatter Electron Monitoring. Procedia Manuf. 2020, 48, 828–838. [Google Scholar] [CrossRef]

- Frigola, P.; Harrysson, O.A.; Horn, T.J.; West, H.; Aman, R.L.; Rigsbee, J.M.; Ramirez, D.A.; Murr, L.E.; Medina, F.; Wicker, R.B.; et al. Fabricating Copper Components with Electron Beam Melting. Adv. Mater. Process. 2014, 172, 5. [Google Scholar]

- Frigola, P.; Agustsson, R.B.; Boucher, S.; Murokh, A.; Rosenzweig, J.; Travish, G.; Faillace, L.; Cormier, D.; Mahale, T. A Novel Fabrication Technique for the Production of RF Photoinjectors. In Proceedings of the EPAC08, Genoa, Italy, 23–27 June 2008; p. 3. [Google Scholar]

- Gamzina, D.; Luhmann, N.C.; Ledford, C.; Horn, T.; Karakaut, I.; Lin, L.; Frigola, P. Additive vacuum electronics: Electron beam melting of copper. In Proceedings of the 2017 Eighteenth International Vacuum Electronics Conference (IVEC), London, UK, 24–26 April 2017; pp. 1–2. [Google Scholar]

- Horn, T.J.; Gamzina, D. Additive Manufacturing of Copper and Copper Alloys. In Additive Manufacturing Processes; Bourell, D.L., Frazier, W., Kuhn, H., Seifi, M., Eds.; ASM International: Novelty, OH, USA, 2020; pp. 388–418. ISBN 978-1-62708-290-7. [Google Scholar]

- Horn, T.; Karakurt, I.; Ledford, C.; Gonzalez, M.; Gamzina, D.; Luhmann, N.C.; Lin, L. Additively manufactured WR-10 copper waveguide. In Proceedings of the 2018 IEEE International Vacuum Electronics Conference (IVEC), Monterey, CA, USA, 24–26 April 2018; pp. 409–410. [Google Scholar]

- Singer, F.; Deisenroth, D.C.; Hymas, D.M.; Ohadi, M.M. Additively manufactured copper components and composite structures for thermal management applications. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2017; pp. 174–183. [Google Scholar]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Wang, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D Printing of Highly Pure Copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef] [Green Version]

- Lykov, P.A.; Safonov, E.V.; Akhmedianov, A.M. Selective Laser Melting of Copper. Mater. Sci. Forum 2016, 843, 284–288. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Guschlbauer, R.; Burkhardt, A.K.; Fu, Z.; Körner, C. Effect of the oxygen content of pure copper powder on selective electron beam melting. Mater. Sci. Eng. A 2020, 779, 1–8. [Google Scholar] [CrossRef]

- Guschlbauer, R.; Momeni, S.; Osmanlic, F.; Körner, C. Process development of 99.95% pure copper processed via selective electron beam melting and its mechanical and physical properties. Mater. Charact. 2018, 143, 163–170. [Google Scholar] [CrossRef]

- Kumar, A.Y.; Wang, J.; Bai, Y.; Huxtable, S.T.; Williams, C.B. Impacts of process-induced porosity on material properties of copper made by binder jetting additive manufacturing. Mater. Des. 2019, 182, 1–12. [Google Scholar]

- Jadhav, S.D.; Goossens, L.R.; Kinds, Y.; Hooreweder, B.V.; Vanmeensel, K. Laser-based powder bed fusion additive manufacturing of pure copper. Addit. Manuf. 2021, 42, 101990. [Google Scholar]

- El-Wardany, T.I.; She, Y.; Jagdale, V.N.; Garofano, J.K.; Liou, J.J.; Schmidt, W.R. Challenges in Three-Dimensional Printing of High-Conductivity Copper. J. Electron. Packag. 2018, 140, 1–14. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.-P.; Van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Colopi, M.; Caprio, L.; Demir, A.G.; Previtali, B. Selective laser melting of pure Cu with a 1 kW single mode fiber laser. Procedia CIRP 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Ikeshoji, T.-T.; Nakamura, K.; Yonehara, M.; Imai, K.; Kyogoku, H. Selective Laser Melting of Pure Copper. JOM 2018, 70, 396–400. [Google Scholar] [CrossRef]

- Pelaprat, J.-M.; Finuf, M.; Fritz, R.; Zediker, M. Seeing Things in a New Light. Laser Tech. J. 2018, 15, 39–41. [Google Scholar] [CrossRef] [Green Version]

- Masuno, S.; Tsukamoto, M.; Tojo, K.; Asano, K.; Asuka, K.; Funada, Y.; Sakon, Y. Metal powder bed fusion additive manufacturing with 100W blue diode laser. Int. Congr. Appl. Lasers ElectroOpt. 2017, 2017, P130. [Google Scholar]

- Shibata, T.; Tsukamoto, M.; Sato, Y.; Masuno, S. Effect of input energy on densification for pure copper fabricated by SLM with blue diode laser. In Proceedings of the Laser 3D Manufacturing VI, San Francisco, CA, USA, 4 March 2019; Volume 10909, p. 109090Z. [Google Scholar]

- Suwa, M.; Wakabayashi, N.; Hiroki, T.; Tojo, K.; Masuno, S.; Higashino, R.; Tsukamoto, M. Development of BLUE IMPACT, a 450nm-wavelength light source for laser processing. In Proceedings of the High-Power Diode Laser Technology XVII, International Society for Optics and Photonics, San Francisco, CA, USA, 4 March 2019; Volume 10900, p. 109000A. [Google Scholar]

- Tiberto, D.; Klotz, U.E.; Held, F.; Wolf, G. Additive manufacturing of copper alloys: influence of process parameters and alloying elements. Mater. Sci. Technol. 2019, 35, 969–977. [Google Scholar] [CrossRef]

- Lu, W.; Zhai, W.; Wang, J.; Liu, X.; Zhou, L.; Ibrahim, A.M.M.; Li, X.; Lin, D.; Wang, Y.M. Additive manufacturing of isotropic-grained, high-strength and high-ductility copper alloys. Addit. Manuf. 2021, 38, 101751. [Google Scholar]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Ledford, C.; Tung, M.; Rock, C.; Horn, T. Real Time Monitoring of Electron Emissions during Electron Beam Powder Bed Fusion for Arbitrary Geometries and Toolpaths. Addit. Manuf. 2020, 34, 101365. [Google Scholar] [CrossRef]

- Raab, S.J.; Guschlbauer, R.; Lodes, M.A.; Körner, C. Thermal and Electrical Conductivity of 99.9% Pure Copper Processed via Selective Electron Beam Melting. Adv. Eng. Mater. 2016, 18, 1661–1666. [Google Scholar] [CrossRef]

- Lodes, M.A.; Guschlbauer, R.; Körner, C. Process development for the manufacturing of 99.94% pure copper via selective electron beam melting. Mater. Lett. 2015, 143, 298–301. [Google Scholar] [CrossRef]

- Myers, M.; Blythe, E.A. Effects of oxygen, sulphur, and porosity on mechanical properties of cast high-purity copper at 950 °C. Met. Technol. 1981, 8, 165–170. [Google Scholar] [CrossRef]

- Nieh, T.G.; Nix, W.D. Embrittlement of copper due to segregation of oxygen to grain boundaries. Metall. Trans. A 1981, 12, 893–901. [Google Scholar] [CrossRef]

- Ledford, C.; Rock, C.; Carriere, P.; Frigola, P.; Gamzina, D.; Horn, T. Characteristics and Processing of Hydrogen-Treated Copper Powders for EB-PBF Additive Manufacturing. Appl. Sci. 2019, 9, 3993. [Google Scholar] [CrossRef] [Green Version]

- UNE-EN ISO/ASTM 52921:2017 Standard Terminology for Additive Manufacturing—Coordinate Systems and Test Methodologies (ISO/ASTM 52921:2013). 2017. Available online: https://www.astm.org/cgi-bin/resolver.cgi?3PC+UNE+UNE-ENISO/ASTM52921:2017+en-US (accessed on 29 May 2021).

- ASTM International. E8/E8M-21 Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar] [CrossRef]

- ASTM International. B923-20 Standard Test Method for Metal Powder Skeletal Density by Helium or Nitrogen Pycnometry; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- ASTM International. B170-99 (2020) Standard Specification for Oxygen-Free Electrolytic Copper—Refinery Shapes; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- Ramirez, D.A.; Murr, L.E.; Martinez, E.; Hernandez, D.H.; Martinez, J.L.; Machado, B.I.; Medina, F.; Frigola, P.; Wicker, R.B. Novel precipitate-microstructural architecture developed in the fabrication of solid copper components by additive manufacturing using electron beam melting. Acta Mater. 2011, 59, 4088–4099. [Google Scholar] [CrossRef]

- Cordero, Z.C.; Meyer, H.M.; Nandwana, P.; Dehoff, R.R. Powder bed charging during electron-beam additive manufacturing. Acta Mater. 2017, 124, 437–445. [Google Scholar] [CrossRef] [Green Version]

- Magnusson, H.; Frisk, K. Self-Diffusion and Impurity Diffusion of Hydrogen, Oxygen, Sulphur and Phosphorus in Copper; Swedish Nuclear Fueland Waste Management C: Stockholm, Sweden, 2013; p. 33. [Google Scholar]

- Davis, J.R. (Ed.) Copper and Copper Alloys; ASM Specialty Handbook; ASM International: Materials Park, OH, USA, 2001; ISBN 978-0-87170-726-0. [Google Scholar]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Yang, K.V.; Rometsch, P.; Davies, C.H.J.; Huang, A.; Wu, X. Effect of heat treatment on the microstructure and anisotropy in mechanical properties of A357 alloy produced by selective laser melting. Mater. Des. 2018, 154, 275–290. [Google Scholar] [CrossRef]

- Dieter, G.E. Mechanical Metallurgy, 2nd ed.; Materials Science and Engineering Series; McGraw Hill: New York, NY, USA, 1976. [Google Scholar]

- Reed-Hill, R.E. Physical Metallurgy Principles, 2nd ed.; University Series in Basic Engineering; PWS-KENT: Boston, MA, USA, 1973. [Google Scholar]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef] [Green Version]

- Mooney, B.; Kourousis, K.I.; Raghavendra, R.; Agius, D. Process phenomena influencing the tensile and anisotropic characteristics of additively manufactured maraging steel. Mater. Sci. Eng. A 2019, 745, 115–125. [Google Scholar] [CrossRef]

- Shamsujjoha, M.; Agnew, S.R.; Fitz-Gerald, J.M.; Moore, W.R.; Newman, T.A. High Strength and Ductility of Additively Manufactured 316L Stainless Steel Explained. Metall. Mater. Trans. A 2018, 49, 3011–3027. [Google Scholar] [CrossRef]

- Barkia, B.; Aubry, P.; Haghi-Ashtiani, P.; Auger, T.; Gosmain, L.; Schuster, F.; Maskrot, H. On the origin of the high tensile strength and ductility of additively manufactured 316L stainless steel: Multiscale investigation. J. Mater. Sci. Technol. 2020, 41, 209–218. [Google Scholar] [CrossRef]

- Thijs, L.; Montero Sistiaga, M.L.; Wauthle, R.; Xie, Q.; Kruth, J.-P.; Van Humbeeck, J. Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Palmer, T.A.; Beese, A.M. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef] [Green Version]

- Ghahremaninezhad, A.; Ravi-Chandar, K. Ductile failure in polycrystalline OFHC copper. Int. J. Solids Struct. 2011, 48, 3299–3311. [Google Scholar] [CrossRef] [Green Version]

- Hutasoit, N.; Rashid, R.A.R.; Palanisamy, S.; Duguid, A. Effect of build orientation and post-build heat treatment on the mechanical properties of cold spray additively manufactured copper parts. Int. J. Adv. Manuf. Technol. 2020, 110, 2341–2357. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, G.J.; Ding, X.D.; Sun, J.; Chen, K.H. The influences of multiscale-sized second-phase particles on ductility of aged aluminum alloys. Metall. Mater. Trans. A 2004, 35, 1725–1734. [Google Scholar] [CrossRef]

| Process | UTS (MPa) | Yield Strength (MPa) | Elongation to Failure (%) | Relative Density (%) | Oxygen Content (wt. ppm) | Treatment Condition | Ref. |

|---|---|---|---|---|---|---|---|

| L-PBF | 149 | - | - | 88.1 | - | As-fabricated | [9] |

| L-PBF | 248 ± 8.5 | 187 ± 5.3 | 9.2 ± 2.12 | 99.1 ± 0.5 | 446 | As-fabricated | [10] |

| L-PBF | 215 ± 7.2 | 51 ± 8.2 | 30 ± 3.04 | - | 446 | Vacuum annealed | [10] |

| L-PBF | 211 ± 4 | 122 ± 1 | 43 ± 3 | 99.3 ± 0.2 | 54 | As-fabricated | [14] |

| EB-PBF | - | 76 | - | - | - | As-fabricated | [2] |

| EB-PBF | 231.6 ± 5.4 | 149.8 | 56.2 | >99.5 | 188 | As-fabricated (horizontal) | [11] |

| EB-PBF | 177 ± 3.3 | 78.1 ± 0.9 | 59.3 ± 7.5 | >99.5 | 188 | As-fabricated (vertical) | [12] |

| BJ | 176.4 ± 6.5 | N/A | 67.2 ± 2.2 | 97.3 ± 0.1 | N/A | Sintered, HIP | [13] |

| Melting Parameter | Value |

|---|---|

| Surface Temp (°C) | 600 |

| Power Analyze Max Current (mA) | 25 |

| Power Analyze Min Current (mA) | 8 |

| Beam Speed (mm/s) | 1000 |

| Beam Current (mA) | 8 |

| Max Current (mA) | 8 |

| Focus Offset (mA) | 18 |

| Speed Function | 20 |

| Line Offset (mm) | 0.13 |

| Change for Each Depth (mm) | 0.02 |

| Heating Enable | TRUE |

| Max Heat Time (s) | 5 |

| Melt Heating Use Process Power | TRUE |

| Heating Between Models | TRUE |

| Parameter | Value |

|---|---|

| Focus Value (mA) | 70 |

| Focus Value Heater (mA) | 150 |

| Box Enable | TRUE |

| Box Size (mm) | 85 |

| Offset to Part (mm) | 0.1 |

| Max Current for Box (mA) | 22.5 |

| Jump Safe Sweep Max Current (mA) | 13.5 |

| Jump Safe Sweep Min Current (mA) | 0.1 |

| Jump Safe Sweep Speed (mm/s) | 14600 |

| Jump Safe Sweep Total Repetitions of Sweep | 40 |

| Jump Safe Sweep Max Number of Sweeps | 40 |

| Heating Enable | TRUE |

| Max Heat Time (s) | 5 |

| Heating Between Models | TRUE |

| Ag | Cd | N | P | Pb | S | Sb | Sn | Zn |

|---|---|---|---|---|---|---|---|---|

| 10 | <1 | 2 | 5 | 2 | 8 | <1 | <1 | <1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarafder, P.; Rock, C.; Horn, T. Quasi-Static Tensile Properties of Unalloyed Copper Produced by Electron Beam Powder Bed Fusion Additive Manufacturing. Materials 2021, 14, 2932. https://doi.org/10.3390/ma14112932

Tarafder P, Rock C, Horn T. Quasi-Static Tensile Properties of Unalloyed Copper Produced by Electron Beam Powder Bed Fusion Additive Manufacturing. Materials. 2021; 14(11):2932. https://doi.org/10.3390/ma14112932

Chicago/Turabian StyleTarafder, Prithwish, Christopher Rock, and Timothy Horn. 2021. "Quasi-Static Tensile Properties of Unalloyed Copper Produced by Electron Beam Powder Bed Fusion Additive Manufacturing" Materials 14, no. 11: 2932. https://doi.org/10.3390/ma14112932

APA StyleTarafder, P., Rock, C., & Horn, T. (2021). Quasi-Static Tensile Properties of Unalloyed Copper Produced by Electron Beam Powder Bed Fusion Additive Manufacturing. Materials, 14(11), 2932. https://doi.org/10.3390/ma14112932