Effect of Martensite Volume Fraction on Oxidative and Adhesive Wear

Abstract

:1. Introduction

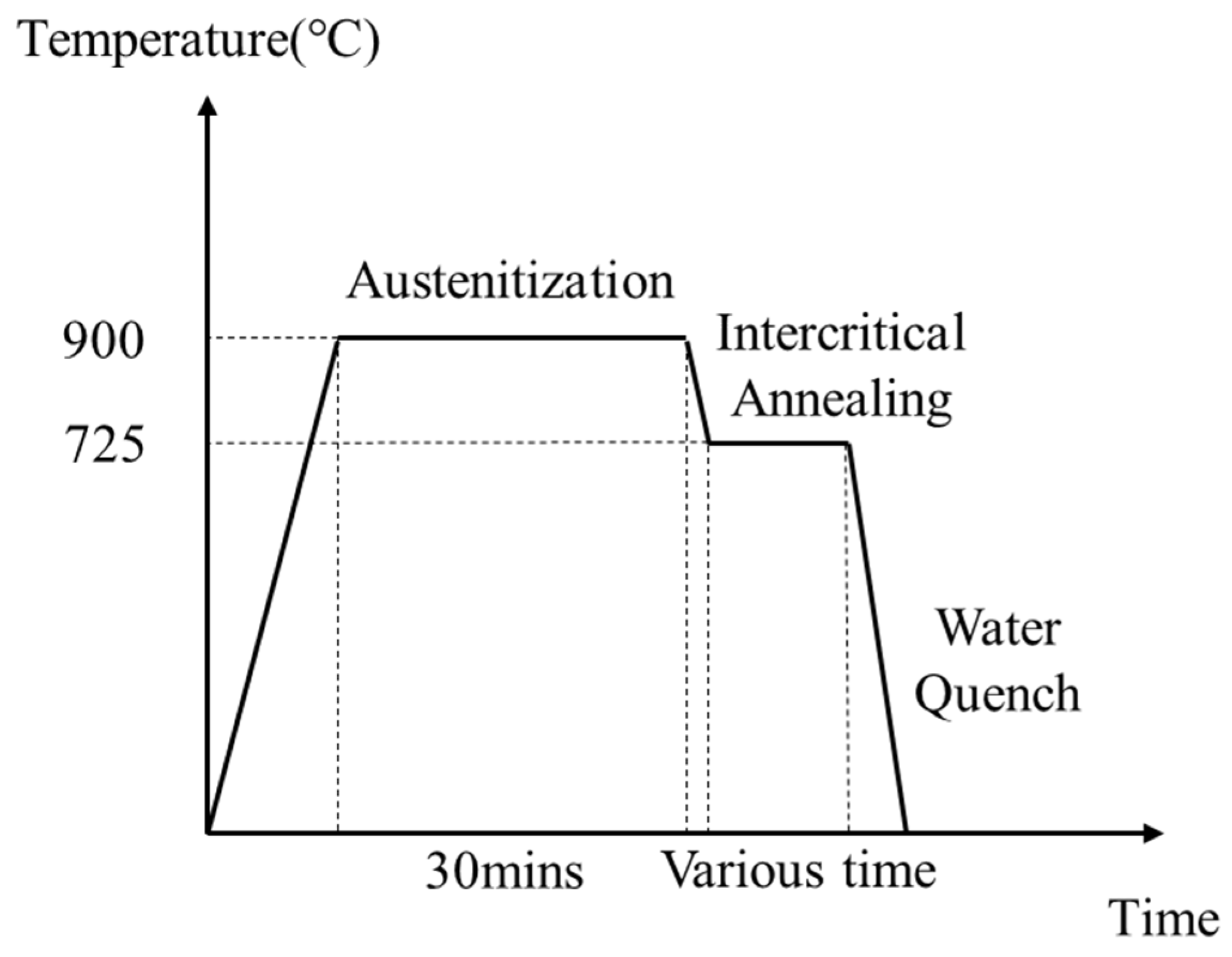

2. Materials and Methods

2.1. Material and Heat Treatments

2.2. Microstructure Characterization

2.3. Friction Tests

3. Results and Discussion

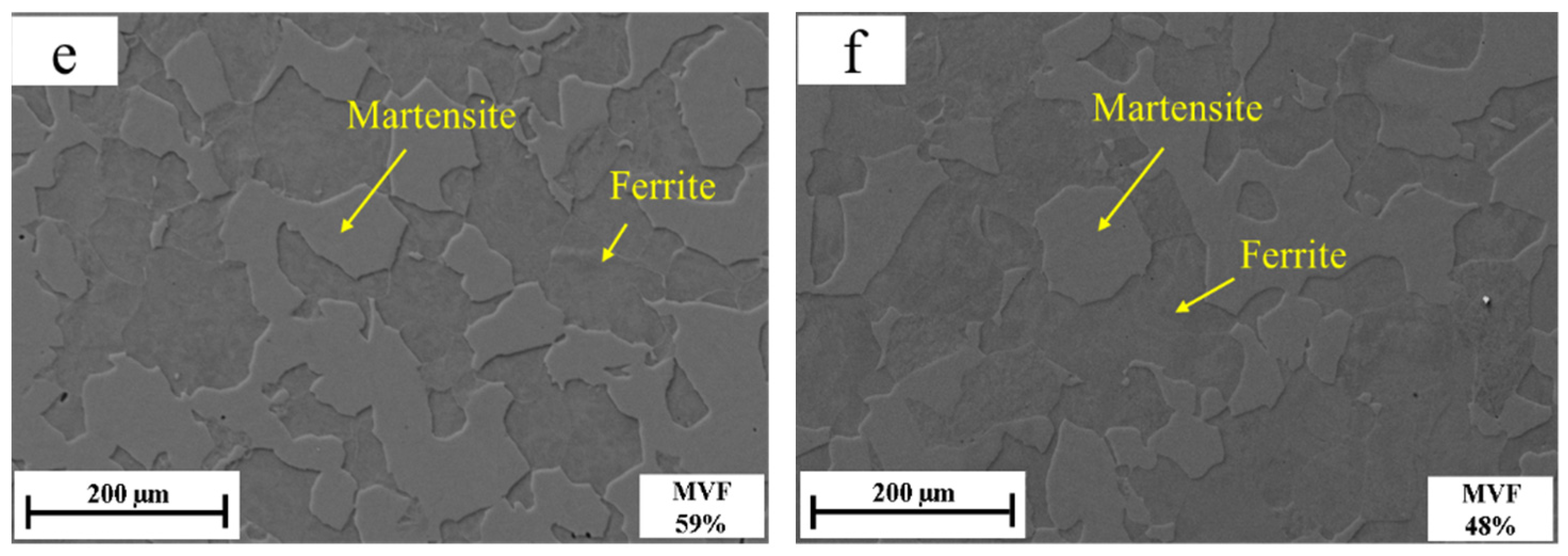

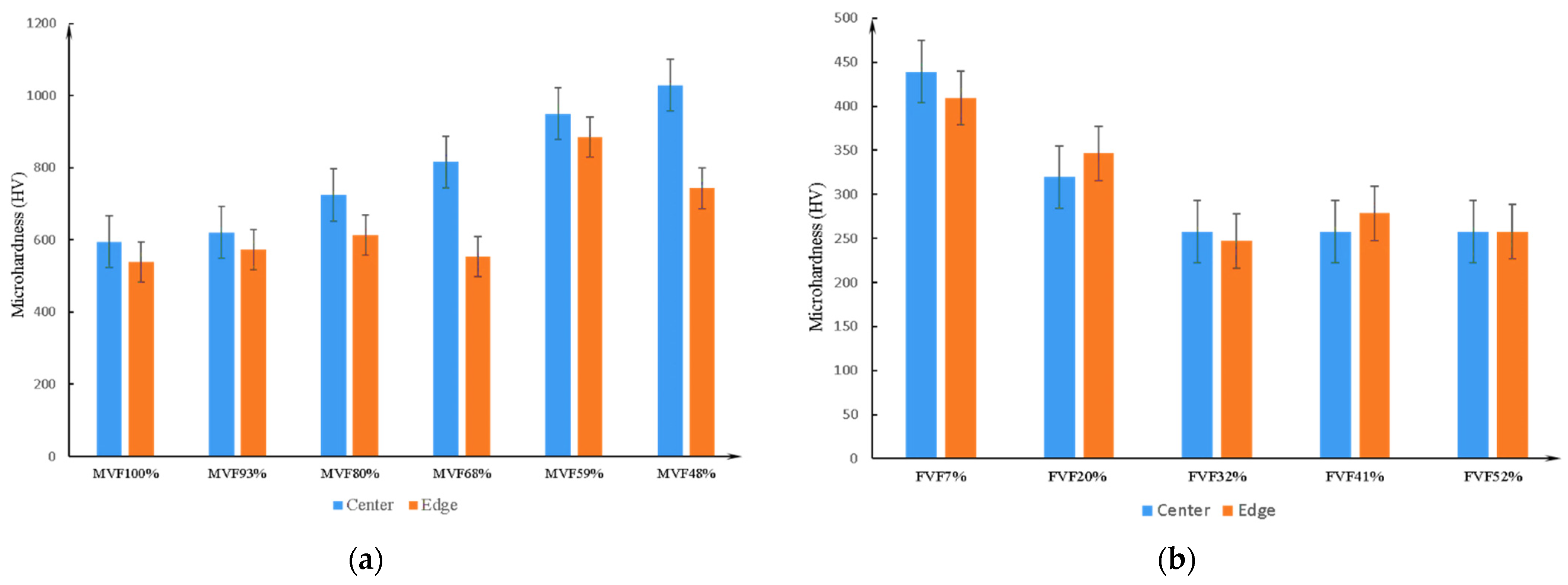

3.1. Microstructure and Hardness Analyses

3.2. Friction Coefficient

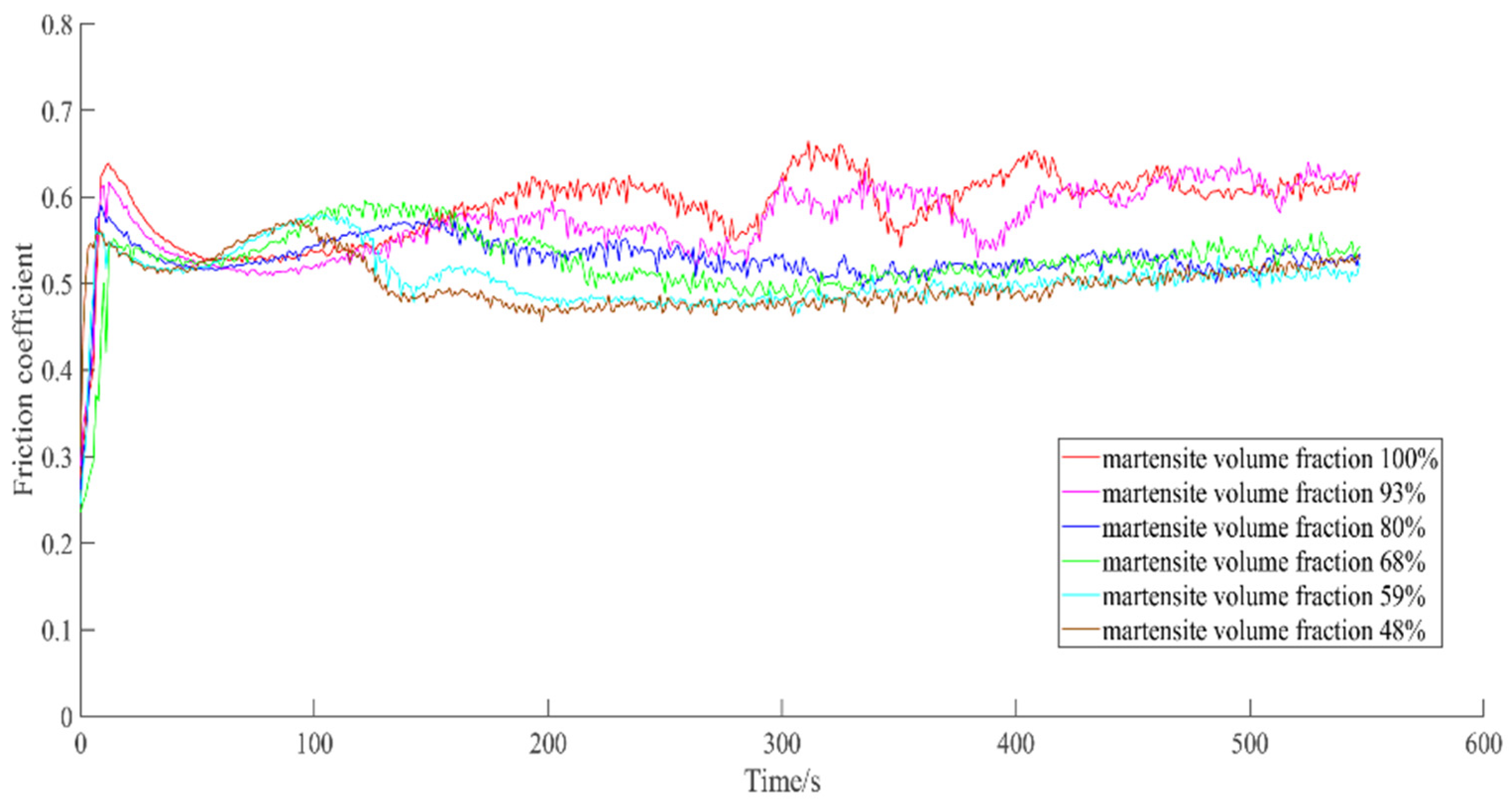

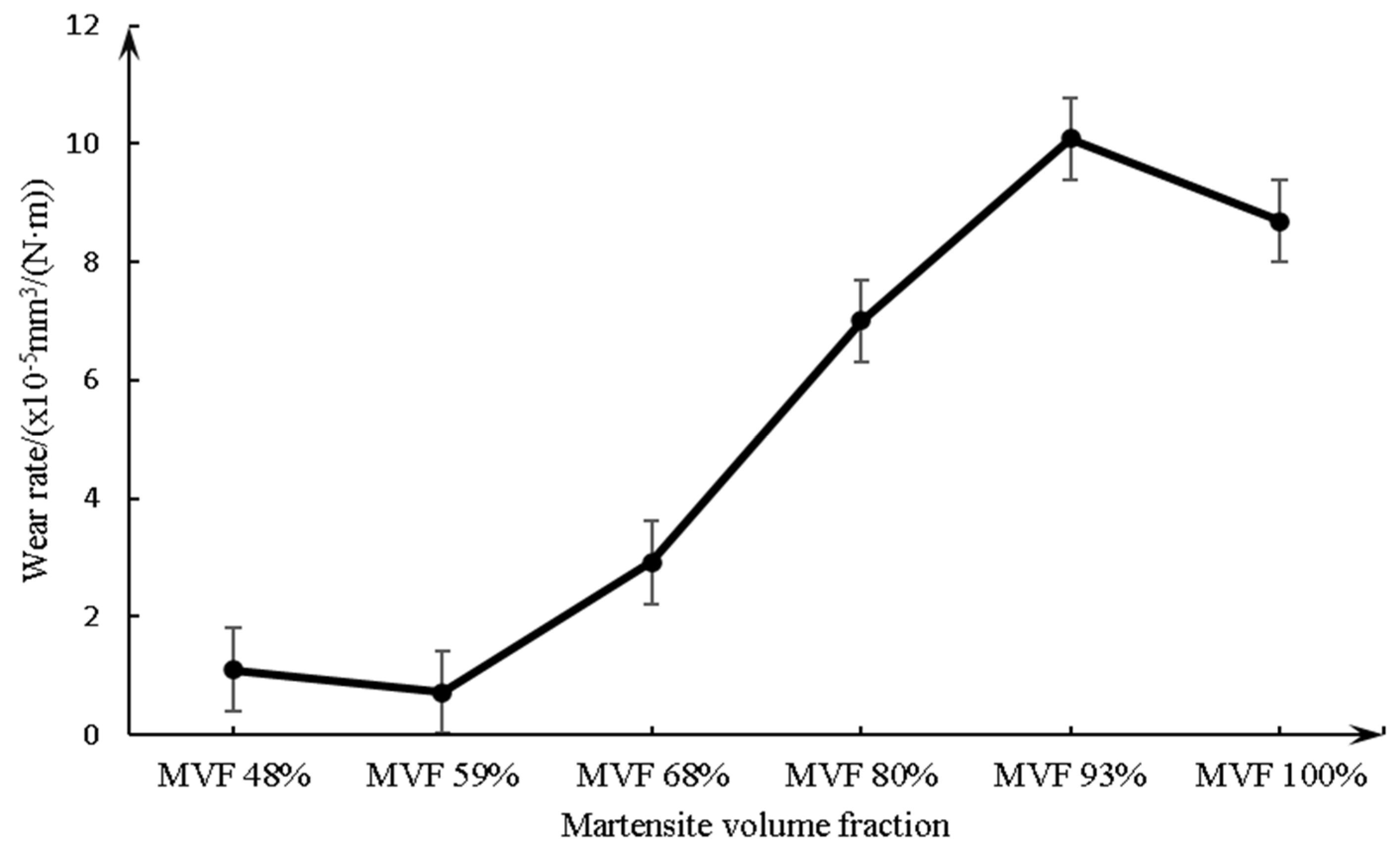

3.3. Wear Rate

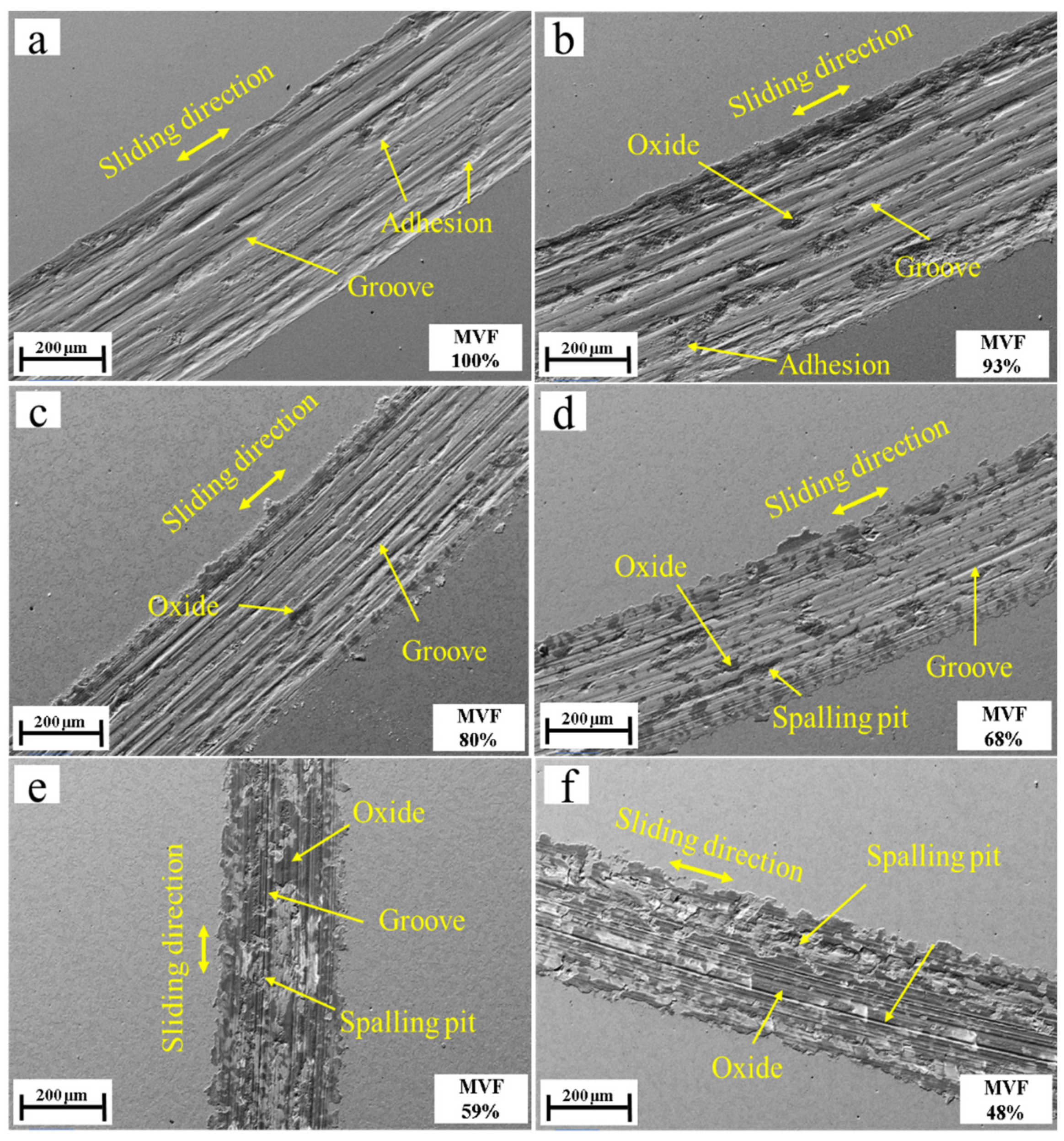

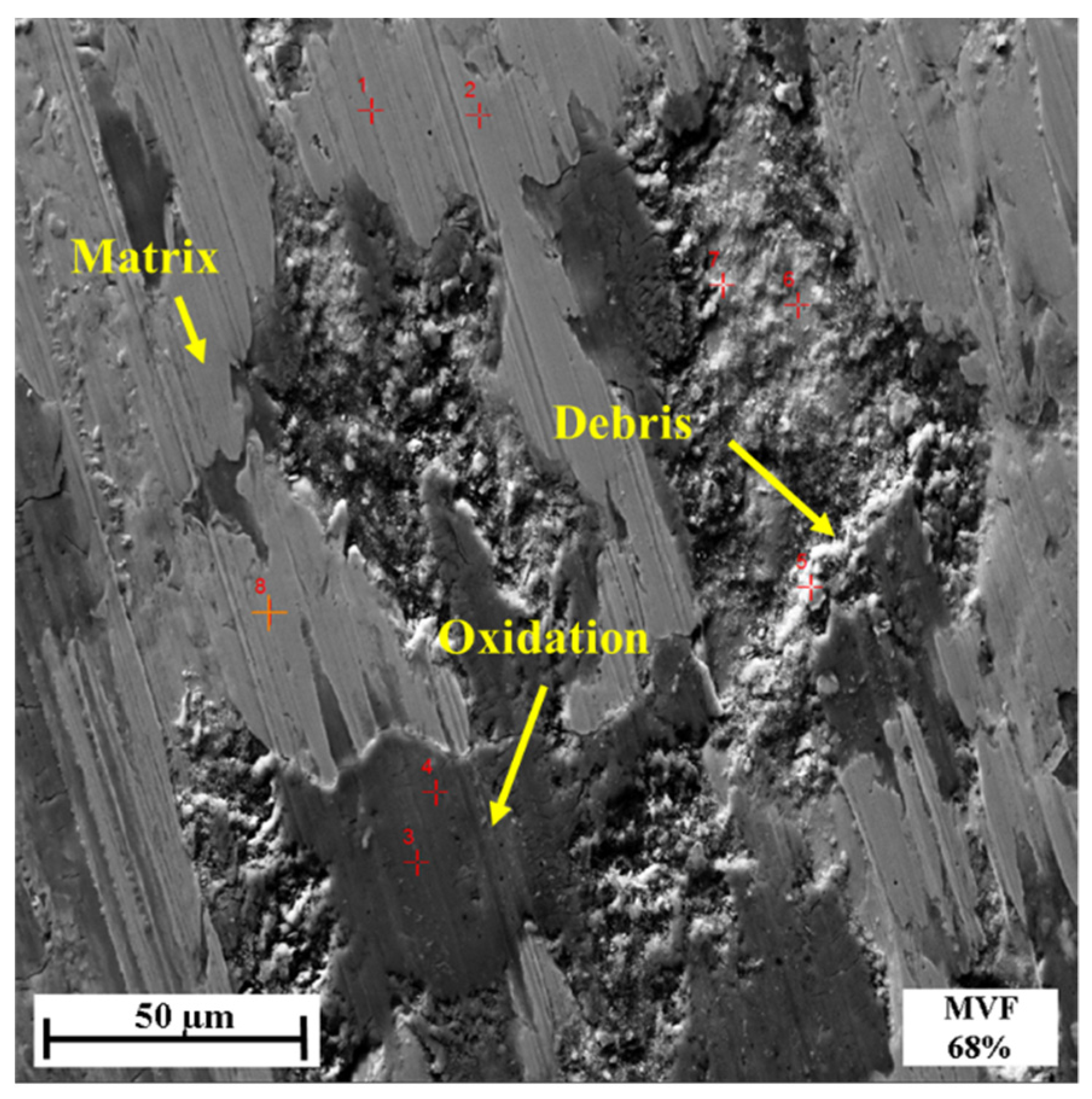

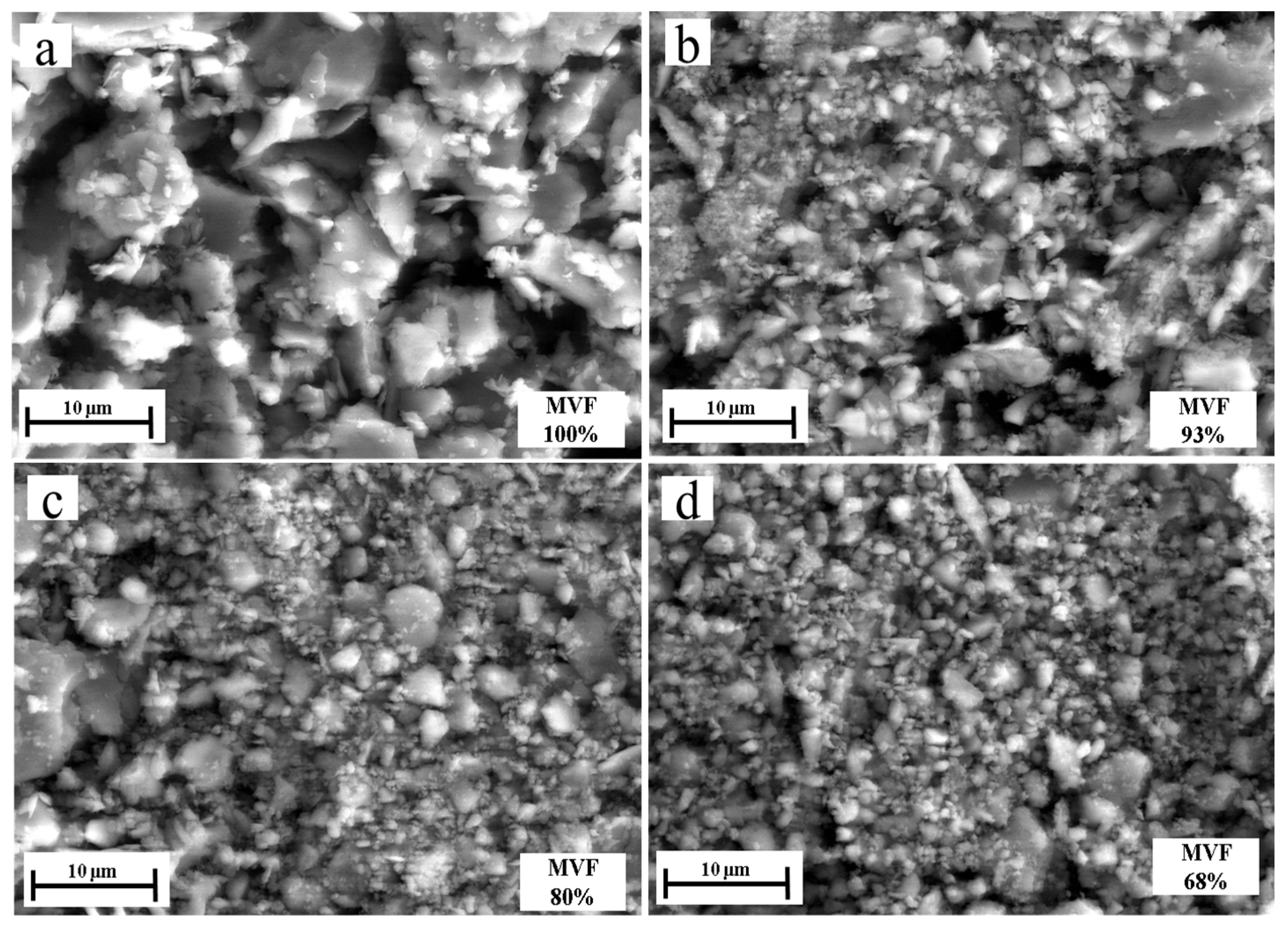

3.4. Wear Mechanisms

4. Conclusions

- (1)

- The friction coefficient decreases with decreasing MVF;

- (2)

- For samples with low MVF (59% or less), there is little wear compared with high MVF;

- (3)

- As the MVF decreases, the oxidative wear increases. The formation of a compact oxide film (glazed layer) can effectively reduce wear, especially adhesion wear. For low MVF, compact oxide layers are more likely to form and remain on worn surfaces;

- (4)

- For lower MVF, the main wear mechanism is mild oxidative wear. However, for higher MVF, severe adhesion wear is predominant;

- (5)

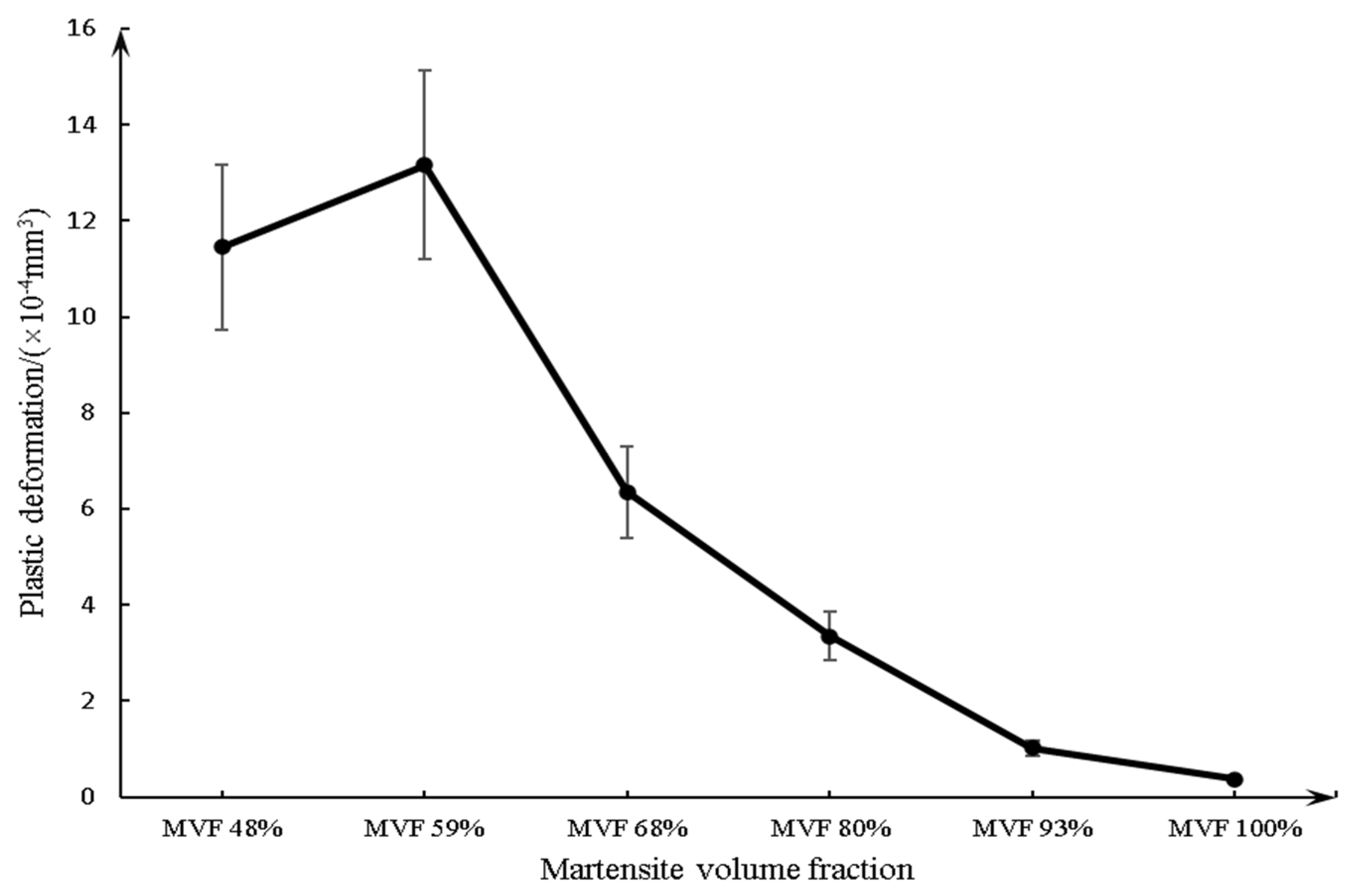

- The plastic deformation decreases with increasing MVF;

- (6)

- The size of the debris decreases with the MVF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Holmberg, K.; Erdemir, A. Global impact of friction on energy consumption, economy and environment. FME Trans. 2015, 43, 181–185. [Google Scholar]

- Karlsson, P.; Gåård, A.; Krakhmalev, P. Influence of tool steel microstructure on friction and initial material transfer. Wear 2014, 319, 12–18. [Google Scholar] [CrossRef]

- Cui, X.H.; Wang, S.Q.; Wei, M.X.; Yang, Z.R. Wear characteristics and mechanisms of H13 steel with various tempered structures. J. Mater. Eng. Perform. 2011, 20, 1055–1062. [Google Scholar] [CrossRef]

- Trevisiol, C.; Jourani, A.; Bouvier, S. Effect of hardness, microstructure, normal load and abrasive size on friction and on wear behaviour of 35NCD16 steel. Wear 2017, 388–389, 101–111. [Google Scholar] [CrossRef]

- Trevisiol, C.; Jourani, A.; Bouvier, S. Effect of microstructures with the same chemical composition and similar hardness levels on tribological behavior of a low alloy steel. Tribol. Int. 2018, 127, 389–403. [Google Scholar] [CrossRef]

- Tuckart, W.; Iurman, L.; Forlerer, E. Influence of microstructure on tribologically mixed layers. Wear 2011, 271, 792–801. [Google Scholar] [CrossRef]

- Zambrano, O.; Gómez, J.; Coronado, J.; Rodríguez, S. The sliding wear behaviour of steels with the same hardness. Wear 2019, 418–419, 201–207. [Google Scholar] [CrossRef]

- Davies, R. Influence of martensite composition and content on the properties of dual phase steels. Metall. Trans. A 1978, 9, 671–679. [Google Scholar] [CrossRef]

- Jha, A.; Prasad, B.; Modi, O.; Das, S.; Yegneswaran, A. Correlating microstructural features and mechanical properties with abrasion resistance of a high strength low alloy steel. Wear 2003, 254, 120–128. [Google Scholar] [CrossRef]

- Nadlene, R.; Esah, H.; Norliana, S.; Irwan, M.M. Study on the effect of volume fraction of dual phase steel to corrosion behaviour and hardness. World Acad. Sci. Eng. Technol. 2011, 5, 564–567. [Google Scholar]

- Saai, A.; Hopperstad, O.; Granbom, Y.; Lademo, O.-G. Influence of volume fraction and distribution of martensite phase on the strain localization in dual phase steels. Procedia Mater. Sci. 2014, 3, 900–905. [Google Scholar] [CrossRef] [Green Version]

- Saghafian, H.; Kheirandish, S. Correlating microstructural features with wear resistance of dual phase steel. Mater. Lett. 2007, 61, 3059–3063. [Google Scholar] [CrossRef]

- Trevisiol, C.; Jourani, A.; Bouvier, S. Effect of martensite volume fraction and abrasive particles size on friction and wear behaviour of a low alloy steel. Tribol. Int. 2017, 113, 411–425. [Google Scholar] [CrossRef]

- Xu, X.; van der Zwaag, S.; Xu, W. The effect of Martensite volume fraction on the scratch and abrasion resistance of a ferrite–martensite dual phase steel. Wear 2016, 348–349, 80–88. [Google Scholar] [CrossRef]

- Xu, X.; Xu, W.; Ederveen, F.H.; van der Zwaag, S. Design of low hardness abrasion resistant steels. Wear 2013, 301, 89–93. [Google Scholar] [CrossRef]

- Abouei, V.; Saghafian, H.; Kheirandish, S. Effect of microstructure on the oxidative wear behavior of plain carbon steel. Wear 2007, 262, 1225–1231. [Google Scholar] [CrossRef]

- Tyagi, R.; Nath, S.K.; Ray, S. Effect of martensite content on friction and oxidative wear behavior of 0.42 Pct carbon dual-phase steel. Metall. Mater. Trans. A 2002, 33, 3479–3488. [Google Scholar] [CrossRef]

- Tyagi, R.; Nath, S.; Ray, S. Modelling of dry sliding oxidation-modified wear in two phase materials. Wear 2003, 255, 327–332. [Google Scholar] [CrossRef]

- Digital Surf. SensoMAP Premium, version:7.4.8164; Digital Surf: Besancon, France, 2017. [Google Scholar]

- Zhang, J.; Di, H.; Deng, Y.; Misra, R.D. Effect of martensite morphology and volume fraction on strain hardening and fracture behavior of martensite–ferrite dual phase steel. Mater. Sci. Eng. A 2015, 627, 230–240. [Google Scholar] [CrossRef]

- Mediratta, S.; Ramaswamy, V.; Rao, P. Influence of ferrite-martensite microstructural morphology on the low cycle fatigue of a dual-phase steel. Int. J. Fatigue 1985, 7, 107–115. [Google Scholar] [CrossRef]

- Hashmi, S. Comprehensive Materials Processing; Newnes: Oxford, UK, 2014. [Google Scholar]

- Xu, X.; van der Zwaag, S.; Xu, W. The effect of ferrite–martensite morphology on the scratch and abrasive wear behaviour of a dual phase construction steel. Wear 2016, 348, 148–157. [Google Scholar] [CrossRef]

- Fereiduni, E.; Banadkouki, S.G. Reliability/unreliability of mixture rule in a low alloy ferrite–martensite dual phase steel. J. Alloys Compd. 2013, 577, 351–359. [Google Scholar] [CrossRef]

- Valeria, L.; Lorusso, H.N.; Svoboda, H.G. Effect of carbon content on microstructure and mechanical properties of dual phase steels. Procedia Mater. Sci. 2015, 8, 1047–1056. [Google Scholar]

- Modi, O.; Pandit, P.; Mondal, D.; Prasad, B.; Yegneswaran, A.; Chrysanthou, A. High-stress abrasive wear response of 0.2% carbon dual phase steel: Effects of microstructural features and experimental conditions. Mater. Sci. Eng. A 2007, 458, 303–311. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Adachi, Y.; Ponge, D.; Raabe, D. Deformation and fracture mechanisms in fine-and ultrafine-grained ferrite/martensite dual-phase steels and the effect of aging. Acta Mater. 2011, 59, 658–670. [Google Scholar] [CrossRef]

- Movahed, P.; Kolahgar, S.; Marashi, S.P.; Pouranvari, M.; Parvin, N. The effect of intercritical heat treatment temperature on the tensile properties and work hardening behavior of ferrite–martensite dual phase steel sheets. Mater. Sci. Eng. A 2009, 518, 1–6. [Google Scholar] [CrossRef]

- Wang, S.Q.; Wei, M.X.; Wang, F.; Cui, X.H.; Chen, K.M. Effect of morphology of oxide scale on oxidation wear in hot working die steels. Mater. Sci. Eng. A 2009, 505, 20–26. [Google Scholar] [CrossRef]

- Buckley, D.H. Surface Effects in Adhesion, Friction, Wear, and Lubrication; Elsevier: Amsterdam, The Netherlands, 1981; Volume 5. [Google Scholar]

- Merstallinger, A.; Sales, M.; Semerad, E.; Dunn, B.D. Assessment of cold welding between separable contact surfaces due to impact and fretting under vacuum. ESA Sci. Tech. Memo. 2009, 279, 57. [Google Scholar]

- Bowden, F.P.; Young, J. Friction of clean metals and the influence of adsorbed films. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1951, 208, 311–325. [Google Scholar]

- Buckley, D.; Friction, W. Lubrication in Vacuum, NASA SP-277; National Aeronautics and Space Administration, Scientific and Technical Information Office: Washington, DC, USA, 1971. [Google Scholar]

- Mølgaard, J. A discussion of oxidation, oxide thickness and oxide transfer in wear. Wear 1976, 40, 277–291. [Google Scholar] [CrossRef]

- So, H.; Yu, D.; Chuang, C. Formation and wear mechanism of tribo-oxides and the regime of oxidational wear of steel. Wear 2002, 253, 1004–1015. [Google Scholar] [CrossRef]

- Wang, S.Q.; Wei, M.X.; Zhao, Y.T. Effects of the tribo-oxide and matrix on dry sliding wear characteristics and mechanisms of a cast steel. Wear 2010, 269, 424–434. [Google Scholar] [CrossRef]

- Wei, M.X.; Chen, K.M.; Wang, S.Q.; Cui, X.H. Analysis for Wear Behaviors of Oxidative Wear. Tribol. Lett. 2011, 42, 1–7. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, K.; Wang, L.; Cui, X.; Wang, S. Characteristics of oxidative wear and oxidative mildwear. Tribol. Int. 2013, 61, 214–223. [Google Scholar] [CrossRef]

- Wang, S.Q.; Wei, M.X.; Wang, F.; Cui, X.H.; Dong, C. Transition of mild wear to severe wear in oxidative wear of H21 steel. Tribol. Lett. 2008, 32, 67–72. [Google Scholar] [CrossRef]

- Wang, S.; Wei, M.; Wang, F.; Zhao, Y. Transition of elevated-temperature wear mechanisms and the oxidative delamination wear in hot-working die steels. Tribol. Int. 2010, 43, 577–584. [Google Scholar] [CrossRef]

- Quinn, T. Review of oxidational wear: Part I: The origins of oxidational wear. Tribol. Int. 1983, 16, 257–271. [Google Scholar] [CrossRef]

- Quinn, T. Review of oxidational wear part II: Recent developments and future trends in oxidational wear research. Tribol. Int. 1983, 16, 305–315. [Google Scholar] [CrossRef]

| C | Mn | Si | S | P | Cr | Ni | Mo |

|---|---|---|---|---|---|---|---|

| 0.25 | ≤0.90 | ≤0.40 | ≤0.035 | ≤0.035 | ≤1.20 | - | ≤0.25 |

| MVF | Test 1 (%) | Test 2 (%) | Test 3 (%) | Average (%) |

|---|---|---|---|---|

| MVF100% | 7.57 | 5.23 | 7.53 | 6.78 |

| MVF93% | 6.88 | 12.28 | 13.13 | 10.76 |

| MVF80% | 18.22 | 19.51 | 19.12 | 18.95 |

| MVF68% | 21.18 | 18.58 | 21.98 | 20.58 |

| MVF59% | 29.33 | 26.64 | 27.78 | 27.92 |

| MVF48% | 31.68 | 28.07 | 27.2 | 28.98 |

| Label | No | W% (C) | W% (O) | W% (Al) | W% (Si) | W% (Cr) | W% (Mn) | W% (Fe) | W% (Mo) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 0.45 | 6.77 | 0.05 | 0.24 | 0.97 | 0.85 | 90.22 | 0.46 |

| 2 | 2 | 1.00 | 2.84 | 0.00 | 0.15 | 0.97 | 0.83 | 94.00 | 0.22 |

| 3 | 3 | 0.88 | 35.02 | 0.32 | 0.18 | 0.58 | 0.30 | 62.34 | 0.37 |

| 4 | 4 | 0.80 | 35.39 | 0.40 | 0.20 | 0.60 | 0.49 | 61.79 | 0.33 |

| 5 | 5 | 1.44 | 44.00 | 0.61 | 0.22 | 0.41 | 0.42 | 52.81 | 0.08 |

| 6 | 6 | 1.24 | 3.09 | 0.05 | 0.20 | 1.12 | 0.76 | 93.23 | 0.30 |

| 7 | 7 | 1.43 | 23.33 | 0.21 | 0.23 | 0.80 | 0.56 | 73.30 | 0.14 |

| 8 | 8 | 1.02 | 3.97 | 0.00 | 0.18 | 0.94 | 0.76 | 92.78 | 0.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Jourani, A. Effect of Martensite Volume Fraction on Oxidative and Adhesive Wear. Materials 2021, 14, 2964. https://doi.org/10.3390/ma14112964

Zhang Y, Jourani A. Effect of Martensite Volume Fraction on Oxidative and Adhesive Wear. Materials. 2021; 14(11):2964. https://doi.org/10.3390/ma14112964

Chicago/Turabian StyleZhang, Yunbo, and Abdeljalil Jourani. 2021. "Effect of Martensite Volume Fraction on Oxidative and Adhesive Wear" Materials 14, no. 11: 2964. https://doi.org/10.3390/ma14112964