Literature Review of the In-Plane Behavior of Masonry Walls: Theoretical vs. Experimental Results

Abstract

1. Introduction

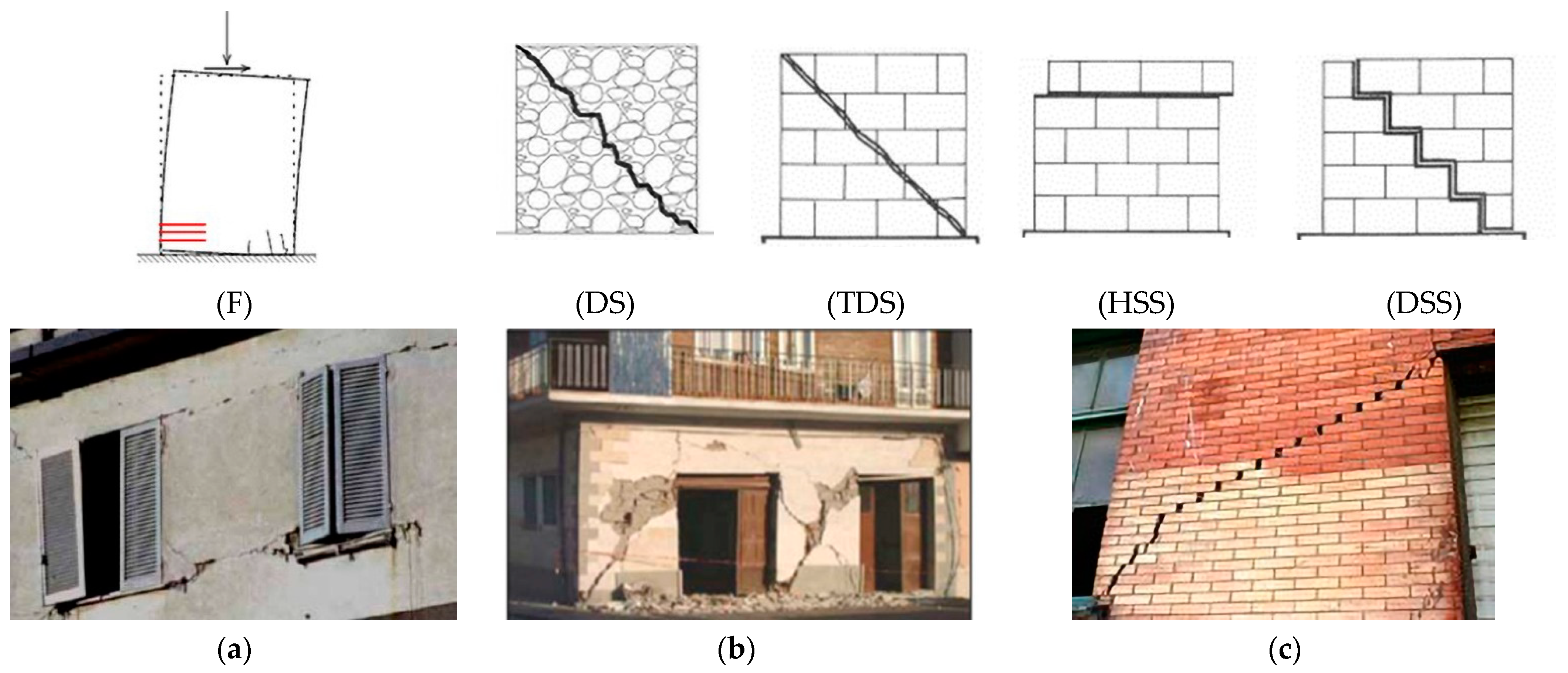

- flexural failure (rocking or toe crushing, named F in Figure 1a): failure due to the achievement of the tensile or compressive strength along the cross end-sections of the wall and characterized by nearly horizontal or vertical cracks, respectively;

- diagonal shear failure (Figure 1b): failure related to the achievement of the tensile strength of masonry along the principal direction and characterized by diagonal cracks along the wall. This kind of failure generally occurs in irregular/rubble masonry (DS), or in regular masonry (TDS) with strong mortar/weak units and good bond behavior at the mortar-masonry interfaces;

- sliding shear failure (Figure 1c): failure occurs along the mortar joints according to horizontal (HSS) or stepped diagonal cracks (DSS) because of the low bond strength at the mortar-masonry interface or in case of reduced values of the compressive stresses acting in the wall.

- diagonal compression test;

- shear-compression test.

2. Literature Review of Theoretical Formulations

2.1. Flexural Failure

2.2. Shear Failure

2.2.1. Regular Masonry

2.2.2. Irregular/Rubble Masonry

3. Sensitivity Analysis of the Theoretical Formulations

3.1. Flexural Failure

3.2. Shear Failure of Regular Masonry

3.3. Shear Failure in Irregular/Rubble Masonry

4. Theoretical vs. Experimental In-Plane Shear Capacity

4.1. The Experimental Database on Regular Masonry Walls

4.2. Theoretical vs. Experimental Shear Capacities for Regular Masonry Walls

4.3. The Experimental Database on Irregular/Rubble Masonry Walls

4.4. Theoretical vs. Experimental Capacities for Irregular/Rubble Masonry Walls

4.5. Reliability of Diagonal Shear Design Formulations for Regular Masonry Walls

A Proposal for Correcting the Shape Factor b

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lourenço, P.B.; Mendes, N.; Ramos, L.F.; Oliveira, D.V. Analysis of masonry structures without box behavior. Int. J. Archit. Herit. 2011, 5, 369–382. [Google Scholar] [CrossRef]

- Valluzzi, M.; da Porto, F.; Garbin, E.; Panizza, M. Out-of-plane behaviour of infill masonry panels strengthened with composite materials. Mater. Struct. 2014, 47, 2131–2145. [Google Scholar] [CrossRef]

- Giresini, L.; Stochino, F.; Sassu, M. Economic vs environmental isocost and isoperformance curves for the seismic and energy improvement of buildings considering Life Cycle Assessment. Eng. Struct. 2021, 233, 111923. [Google Scholar] [CrossRef]

- Giresini, L.; Solarino, F.; Paganelli, O.; Oliveira, D.V.; Froli, M. One-Sided rocking analysis of corner mechanisms in masonry structures: Influence of geometry, energy dissipation, boundary conditions. Soil Dyn. Earthq. Eng. 2019, 123, 357–370. [Google Scholar] [CrossRef]

- Casapulla, C.; Argiento, L.U.; Maione, A.; Speranza, E. Upgraded formulations for the onset of local mechanisms in multi-storey masonry buildings using limit analysis. Structures 2021, 31, 380–394. [Google Scholar] [CrossRef]

- Solarino, F.; Oliveira, D.V.; Giresini, L. Wall-to-horizontal diaphragm connections in historical buildings: A state-of-the-art review. Eng. Struct. 2019, 199, 109559. [Google Scholar] [CrossRef]

- Giresini, L. Design strategy for the rocking stability of horizontally restrained masonry walls. In Proceedings of the 6th ECCOMAS Thematic Conference on Computational Methods in Structural Dynamics and Earthquake Engineering, Rhodes Island, Greece, 15–17 June 2017; pp. 2963–2979. [Google Scholar]

- Giuffrè, A. Safety and Conservation of Historical Centres: The Ortigia Case (in Italian). In Guide to the Seismic Retrofit Project; Editori Laterza: Bari, Italy, 1993; pp. 151–188. [Google Scholar]

- Haach, V.G.; Vasconcelos, G.; Lourenço, P.B. Parametrical study of masonry walls subjected to in-plane loading through numerical modeling. Eng. Struct. 2011, 33, 1377–1389. [Google Scholar] [CrossRef]

- Vasconcelos, G.; Lourenço, P.B. In-plane experimental behavior of stone masonry walls under cyclic loading. J. Struct. Eng. 2009, 135, 1269–1277. [Google Scholar] [CrossRef]

- Anthoine, A.; Magonette, G.; Magenes, G. Shear-Compression Testing and Analysis of Brick Masonry Walls. In Proceedings of the 10th European Conference on Earthquake Engineering, Vienna, Austria, 28 August–2 September 1994; GERALDDUMA, Ed.; Central lnstitute for Meteorology and Geodynamics: Vienna, Austria, 1995. [Google Scholar]

- Tomaževič, M.; Lutman, M.; Petković, L. Seismic behavior of masonry walls: Experimental simulation. J. Struct. Eng. 1996, 122, 1040–1047. [Google Scholar] [CrossRef]

- Calderini, C.; Cattari, S.; Lagomarsino, S. In-plane strength of unreinforced masonry piers. Earthq. Eng. Struct. Dyn. 2009, 38, 243–267. [Google Scholar] [CrossRef]

- Turnšek, V.; Čačovič, F. Some experimental results on the strength of brick masonry walls. In Proceeding of the 2nd International Brick Masonry Conference, Stoke-on-Trent, UK, 12–15 April 1970; pp. 149–156. [Google Scholar]

- Petry, S.; Beyer, K. Limit states of modern unreinforced clay brick masonry walls subjected to in-plane loading. Bull. Earthq. Eng. 2015, 13, 1073–1095. [Google Scholar] [CrossRef]

- Casapulla, C.; Argiento, L.U. In-plane frictional resistances in dry block masonry walls and rocking-sliding failure modes revisited and experimentally validated. Compos. Part B Eng. 2018, 132, 197–213. [Google Scholar] [CrossRef]

- Mayes, R.L.; Clough, R.W. State-of-the-Art in Seismic Shear Strength of Masonry-An Evaluation and Review; Report No. EERC 75-21; Earthquake Engineering Research Center-University of California: Berkeley, CA, USA, 1975. [Google Scholar]

- Tomazevic, M.; Weiss, P. A rational, experimentally based method for the verification of earthquake resistance of masonry buildings. In Proceedings of the 4th U.S. National Conference on Earthquake Engineering, Palm Springs, CA, USA, 20–24 May 1990; pp. 349–359. [Google Scholar]

- Benedetti, D.; Carydis, P.; Limongelli, M.P. Evaluation of the seismic response of masonry buildings based on energy functions. Earthq. Eng. Struct. Dyn. 2001, 30, 1061–1081. [Google Scholar] [CrossRef]

- Yokel, F.Y.; Fattal, S.G. Failure hypothesis for masonry shear walls. J. Struct. Div. 1976, 102, 515–532. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Bridgeman, D.O. Seismic resistance of brick masonry walls. Bull. N.Z. Nat. Soc. Earthq. Eng. 1974, 7, 167–187. [Google Scholar] [CrossRef]

- Calderini, C.; Cattari, S.; Lagomarsino, S. The use of the diagonal compression test to identify the shear mechanical parameters of masonry. Constr. Build. Mater. 2010, 24, 677–685. [Google Scholar] [CrossRef]

- ASTM E 519-07. Standard Test Method for Diagonal Tension (Shear) in Masonry Assemblages. In Annual Book of ASTM Standard; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007. [Google Scholar]

- RILEM TC 76-LUM, Diagonal Tensile Strength Tests of Small Wall Specimens; RILEM Publications SARL: London, UK, 1994.

- Mann, W.; Koenig, G.; Oetes, A. Tests of masonry walls subjected to seismic forces. In Proceedings of the 8th International Brick/Block Masonry Conference, Dublin, Ireland, 19–21 September 1988; pp. 764–773. [Google Scholar]

- Godio, M.; Vanin, F.; Zhang, S.; Beyer, K. Quasi-static shear-compression tests on stone masonry walls with plaster: Influence of load history and axial load ratio. Eng. Struct. 2019, 192, 264–278. [Google Scholar] [CrossRef]

- Borri, A.; Castori, G.; Corradi, M. Determination of Shear Strength of Masonry Panels Through Different Tests. Int. J. Archit. Herit. 2015, 9, 913–927. [Google Scholar] [CrossRef]

- Dialer, C. Some remarks on the strength and deformation behaviour of shear stressed masonry panels under static monotonic loading. In Proceedings of the 9th International Brick/Block Masonry Conference, Berlin, Germany, 13–16 October 1991; pp. 276–283. [Google Scholar]

- Borchelt, J.G. Analysis of Brick Walls Subject to Axial Compression and In-Plane Shear. In Proceedings of the 2nd International Brick Masonry Conference, Stoke-on-Trent, UK, 12–15 April 1970. [Google Scholar]

- Vasconcelos, G.; Lourenço, P.B. Assessment of the in-plane shear strength of stone masonry walls by simplified models. In Proceedings of the 5th International Conference on Structural Analysis of Historical Constructions, New Delhi, India, 6–8 November 2006; pp. 843–850. [Google Scholar]

- Mahmoud, A.D.; Hamid, A.A.; El Magd, S.A. Lateral Response of Unreinforced Solid Masonry Shear Walls: An Experimental Study. In Proceedings of the 7th Canadian Masonry Symposium, Hamilton, ON, USA, 5–7 June 1995; pp. 110–125. [Google Scholar]

- Shah, N.; Abrams, D.P. Cyclic Load Testing of Unreinforced Masonry Walls; Report No. 92-26-10; Advanced Construction Technology Center-University of Illinois: Urbana, IL, USA, 1992. [Google Scholar]

- Page, A.W. The strength of brick masonry under biaxial tension-compression. Int. J. Mason. Constr. 1983, 3, 26–31. [Google Scholar]

- Dhanasekar, M.; Page, A.W.; Kleeman, P.W. The Failure of Brick Masonry Under Biaxial Stresses. Inst. Civ. Eng. 1985, 79, 295–313. [Google Scholar] [CrossRef]

- Benedetti, D.; Carydis, P.; Pezzoli, P. Shaking table tests on 24 masonry buildings. Earthq. Eng. Struct. Dyn. 1998, 27, 67–90. [Google Scholar] [CrossRef]

- Brencich, A.; Corradi, C.; Gambarotta, L. Eccentrically loaded brickwork: Theoretical and experimental results. Eng. Struct. 2008, 30, 3269–3643. [Google Scholar] [CrossRef]

- Corradi, M.; Tedeschi, C.; Binda, L.; Borri, A. Experimental evaluation of shear and compression strength of masonry wall before and after reinforcement: Deep repointing. Constr. Build. Mater. 2008, 22, 463–472. [Google Scholar] [CrossRef]

- Prota, A.; Marcari, G.; Fabbrocino, G.; Manfredi, G.; Aldea, C. Experimental in-plane behavior of tuff masonry strengthened with cementitious matrix-grid composites. J. Compos. Constr. 2006, 10. [Google Scholar] [CrossRef]

- Marcari, G.; Basili, M.; Vestroni, F. Experimental investigation of tuff masonry panels reinforced with surface bonded basalt textile-reinforced mortar. Compos. Part B 2017, 108, 131–142. [Google Scholar] [CrossRef]

- da Porto, F.; Mosele, F.; Modena, C. In-plane cyclic behaviour of a new reinforced masonry system: Experimental results. Eng. Struct. 2011, 33, 2584–2596. [Google Scholar] [CrossRef]

- Marcari, G.; Manfredi, G.; Prota, A.; Pecce, M. In-plane shear performance of masonry panels strengthened with FRP. Compos. Part B 2007, 38, 887–901. [Google Scholar] [CrossRef]

- Magenes, G.; Calvi, G.M. In-plane seismic response of brick masonry walls. Earthq. Eng. Struct. Dyn. 1997, 26, 1091–1112. [Google Scholar] [CrossRef]

- Grando, S.; Valluzzi, M.R.; Tumialan, J.C.; Nanni, A. Shear strengthening of UMR clay walls with FRP systems. In Fiber Reinforced Polymer Reinforcement for Concrete Structures-6; Tan, K.H., Ed.; World Scientific Publishing Company: Singapore; Shanghai, China, 8–10 July 2003. [Google Scholar] [CrossRef]

- Balsamo, A.; Di Ludovico, M.; Prota, A.; Manfredi, G. Masonry walls strengthened with innovative composites. ACI Spec. Pub. 2011, 275, 1–18. [Google Scholar]

- Almeida, J.; Pereira, E.; Barros, J. Assessment of overlay masonry strengthening systems under in-plane monotonic and cyclic loading using the diagonal tensile test. Constr. Build. Mater. 2015, 94, 851–865. [Google Scholar] [CrossRef]

- Augenti, N.; Parisi, F.; Prota, A.; Manfredi, G. In-plane lateral response of a full-scale masonry sub-assemblage with and without an inorganic matrix-grid strengthening system. J. Compos. Constr. 2011, 15, 578–590. [Google Scholar] [CrossRef]

- Lignola, G.P.; Prota, A.; Manfredi, G. Nonlinear analyses of tuff masonry walls strengthened with cementitious matrix-grid composites. J. Compos. Constr. 2009, 13, 243–251. [Google Scholar] [CrossRef]

- Garofano, A.; Ceroni, F.; Pecce, M. Modelling of the in-plane behaviour of masonry walls strengthened with FRP grid reinforced mortar layers. Compos. Part B 2016, 85, 243–258. [Google Scholar] [CrossRef]

- Papanicolaou, C.; Triantafillou, T.; Lekka, M. Externally bonded grids as strengthening and seismic retrofitting materials of masonry panels. Constr. Build. Mater. 2011, 25, 504–514. [Google Scholar] [CrossRef]

- Tomazevic, M.; Lutman, M. Seismic resistance of reinforced masonry walls. In Proceedings of the 9th World Conference on Earthquake Engineering, Tokyo-Kyoto, Japan, 2–6 August 1988; pp. 97–102. [Google Scholar]

- Abrams, D.P. Performance-based engineering concepts for unreinforced masonry building structures. Prog. Struct. Eng. Mater. 2001, 3, 48–56. [Google Scholar] [CrossRef]

- Eurocode 8. In Design of Structures for Earthquake Resistance—Part 3: Assessment and retrofitting of buildings (UNI EN 1998-3: 2005); European Committee for Standardization: Brussels, Belgium, 2005; ICS 91.120.25.

- Ministero delle Infrastrutture e dei Trasporti. Aggiornamento delle Norme tecniche per le costruzioni. Gazz. Uffic. Rep. Ita. 2018. Available online: https://www.gazzettaufficiale.it/eli/id/2018/02/20/18A00716/sg (accessed on 1 May 2021).

- Ministero delle Infrastrutture e dei Trasporti. Istruzioni per l’applicazione dell’ Aggiornamento delle ‘Norme Tecniche per le costruzioni’ di cui al decreto ministeriale 17 gennaio 2018. Gazz. Uffic. Rep. Ita. 2019. [Google Scholar]

- Eurocode 6. In Design of Masonry Structures–Part 1–1: General Rules for Reinforced and Unreinforced Masonry Structures (UNI EN 1996-1-1: 2006); European Committee for Standardization: Brussels, Belgium, 2006; ICS 91.010.30.

- Augenti, N.; Parisi, F. Constitutive modelling of tuff masonry in direct shear. Constr. Mater. 2011, 25, 1612–1620. [Google Scholar] [CrossRef]

- Grimm, T.C. Strength and Related Properties of Brick Masonry. ASCE J. Struct. Div. 1975, 101, 217–232. [Google Scholar] [CrossRef]

- Mann, W.; Muller, H. Failure of Shear-Stressed Masonry-An Enlarged Theory, Tests and Application to Shear-Walls. In Proceedings of the International Symposium on Load Bearing Brickwork, London, UK; 1980; pp. 1–13. [Google Scholar]

- Betti, M.; Galano, L.; Petracchi, M.; Vignoli, A. Diagonal cracking shear strength of unreinforced masonry panels: A correction proposal of the b shape factor. Bull. Eartq. Eng. 2011, 13, 3151–3186. [Google Scholar] [CrossRef]

- Celano, T.; Ceroni, F.; Lignola, G.P. Modelling of in-plane behaviour of masonry walls strengthened with FRCM materials. Eng. Comput. Mech. 2021. accepted. [Google Scholar]

- Corradi, M.; Borri, A.; Vignoli, A. Experimental study on the determination of strength of masonry walls. Constr. Build. Mater. 2003, 17, 325–337. [Google Scholar] [CrossRef]

- Vasconcelos, G.; Lourenço, P.B. Experimental characterization of stone masonry in shear and compression. Constr. Build. Mater. 2009, 23, 3337–3345. [Google Scholar] [CrossRef]

- Sheppard, P.F. In-situ test of the shear strength and deformability of an 18th century stone-and-brick masonry wall. In Proceedings of the 7th International Brick/Block Masonry Conference, Melbourne, Australia, 17–20 February 1985; pp. 149–160. [Google Scholar]

- Magenes, G.; Morandi, P.; Penna, A.; Ferrata, V. D7.1c Test Results on the Behaviour of Masonry under Static Cyclic in Plane Lateral Loads; ESECMaSE: Padua, Italy, 2008. [Google Scholar]

- Messali, F.; Esposito, R.; Ravenshorst, G.J.P.; Rots, J.G. Experimental investigation of the in-plane cyclic behaviour of calcium silicate brick masonry walls. Bull. Earthq. Eng. 2020, 18, 3963–3994. [Google Scholar] [CrossRef]

- Morandi, P.; Magenes, G.; Albanesi, L. Prove Sperimentali per la Valutazione della Risposta Sismica nel Piano di Pareti Murarie in Blocchi di Laterizio a Setti Sottili. In Proceedings of the XV Convegno Nazionale ANIDIS–“L’ingegneria sismica Italiana”, Padua, Italy, 30 June–4 July 2013. [Google Scholar]

- Tomaževič, M. Shear resistance of masonry walls and Eurocode 6: Shear versus tensile strength of masonry. Mater. Struct. 2009. [Google Scholar] [CrossRef]

- Churilov, S.; Dumova-Jovanoska, E. In-plane shear behaviour of unreinforced and jacketed brick masonry walls. Soil Dyn. Earthq. Eng. 2013, 50, 85–105. [Google Scholar] [CrossRef]

- Salmanpour, A.H.; Mojsilović, N.; Schwartz, J. Displacement capacity of contemporary unreinforced masonry walls: An experimental study. Eng. Struct. 2015, 80, 1–16. [Google Scholar] [CrossRef]

- Petry, S.; Beyer, K. Cyclic test data of six unreinforced masonry walls with different boundary conditions. Earthq. Spect. 2015, 31, 2459–2484. [Google Scholar] [CrossRef]

- Morandi, P.; Albanesi, L.; Magenes, G. URM walls with thin shell/web clay units and unfilled head-joints: Cyclic in-plane tests. In Proceedings of the 2nd European Conference on Earthquake Engineering and Seismology, Instanbul, Turkey, 25–29 August 2014. [Google Scholar]

- Martinelli, E.; Perri, F.; Sguazzo, C.; Faella, C. Cyclic shear-compression tests on masonry walls strengthened with alternative configurations of CFRP strips. Bull. Earthq. Eng. 2016, 14, 1695–1720. [Google Scholar] [CrossRef]

- Fehling, E.; Stuerz, J. Test Results on the Behaviour of Masonry Under Static (Monotonic and Cyclic) in Plane Lateral Loads; ESECMaSE: Padua, Italy, 2007. [Google Scholar]

- Faella, G.; Manfredi, G.; Realfonzo, R. Cyclic behaviour of tuff masonry walls under horizontal loadings. In Proceedings of the 6th Canadian Masonry Symposium, Saskatoon, SK, Canada, 15–17 June 1992. [Google Scholar]

- Lourenço, P.B.; Oliveira, D.V.; Roca, P.; Orduña, A. Dry Joint Stone Masonry Walls Subjected to In-Plane Combined Loading. J. Struct. Eng. 2005, 131, 1665–1673. [Google Scholar] [CrossRef]

- Magenes, G.; Penna, A.; Galasco, A.; da Paré, M. In-plane cyclic shear tests of undressed double leaf stone masonry panels. In Proceedings of the 8th International Masonry Conference, Dresden, Germany, 4–7 July 2010. [Google Scholar]

- Silva, B.; Dalla Benetta, M.; Da Porto, F.; Modena, C. Experimental assessment of in-plane behaviour of three-leaf stone masonry walls. Constr. Build. Mater. 2014, 53, 149–161. [Google Scholar] [CrossRef]

- Gattesco, N.; Amadio, C.; Bedon, C. Experimental and numerical study on the shear behavior of stone masonry walls strengthened with GFRP reinforced mortar coating and steel-cord reinforced repointing. Eng. Struct. 2015, 90, 143–157. [Google Scholar] [CrossRef]

| Authors | Formula | Compressive Strength | Aspect Ratio | |

|---|---|---|---|---|

| Tomaževič and Lutman [50] | Equation (1) | fc,d | = 1 for cantilever; = 0.5 for double-fixed constraint. | |

| Magenes and Calvi [42] | Equation (2) | 0.85 fc,av | ||

| Abrams [51] | Equation (3) | 0.70 fc,av | For Heff see Figure 2 Heff = H for cantilever; Heff = 0.5 H for double-fixed constraint. | |

| Eurocode 8-Part 3 [52] | Equation (4) | 0.87 fc,d | ||

| NTC 2018 [53] | Equation (5) | 0.85 fc,d | ||

| Parameters | Authors | Formula | Failure | |

|---|---|---|---|---|

| Local for masonry fv0 and µ | Grimm [57] | Equation (7) | Sliding shear along horizontal cracks (HSS) | |

| Eurocode 6 [55] NTC 2018 [53] | Equation (8) | |||

| Global for masonry | Mann and Muller [58] | Equation (9) | Sliding shear along diagonal stepped cracks (DSS) | |

| Magenes and Calvi [42] | Equation (10) | = 1 for cantilever; = 0.5 for double-fixed constraint. | ||

| Commentary to the Italian code [54] | Equation (11) | |||

| Single units | Commentary to the Italian code [54] | Equation (12) | Diagonal shear for tensile cracking of units (TDS) | |

| Authors | Formula | Tensile Strength | Shape Factor | |

|---|---|---|---|---|

| Turnšek and Čačovič [14] | Equation (13) | |||

| Tomaževič and Lutman [50] | Equation (14) | |||

| Abrams [51] | Equation (15) | For Heff see Figure 2 Heff = H for cantilever; Heff = 0.5 H for double-fixed constrain. | ||

| Commentary to the Italian code [54] | Equation (16) | |||

| B | H | λ | s | bb | hb | σ0 | ft | fc | fv0 | μ |

|---|---|---|---|---|---|---|---|---|---|---|

| (m) | (m) | (−) | (m) | (m) | (m) | (MPa) | (MPa) | (MPa) | (MPa) | (−) |

| 1.00 | 1.00 | 1.0 | 0.25 | 0.15 | 0.15 | 0.60 | 0.50 | 5.00 | 0.25 | 0.58 |

| Case | Authors | Type of Masonry | B | H | λ | s | bb | hb | hb/bb | φ | Ф | σ0 | ft | fc | fv0 | μ | fbc | Failure Mode | Vexp | τav |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (−) | (mm) | (mm) | (mm) | (−) | (−) | (%) | (MPa) | (MPa) | (MPa) | (MPa) | (−) | (MPa) | (kN) | (MPa) | ||||

| 1-R | Anthoine et al., 1994 [11] | Clay brick | 1000 | 1350 | 1.35 | 250 | 300 | 125 | 0.42 | 0.83 | 0 | 0.60 | 0.25 | 6.20 | 0.23 | 0.58 | 24.40 | DSS | 75.0 | 0.30 |

| 2-R | 1000 | 2000 | 2.00 | 250 | 300 | 125 | 0.42 | 0.83 | 0 | 0.60 | 0.25 | 6.20 | 0.23 | 0.58 | 24.40 | F | 65.0 | 0.26 | ||

| 3-R | Magenes et al., 2008 [64] | Calcium silicate | 1250 | 2500 | 2.00 | 175 | 248 | 248 | 1.00 | 2.00 | 0 | 1.00 | 0.27 | 24.00 | 0.60 | 0.54 | 15.10 | DSS | 75.0 | 0.34 |

| 4-R | 1250 | 2500 | 2.00 | 175 | 248 | 248 | 1.00 | 2.00 | 0 | 0.50 | 0.27 | 24.00 | 0.60 | 0.54 | 15.10 | DSS | 50.0 | 0.23 | ||

| 5-R | 1250 | 2500 | 2.00 | 175 | 248 | 248 | 1.00 | 2.00 | 0 | 2.00 | 0.27 | 24.00 | 0.60 | 0.54 | 15.10 | DSS | 140.0 | 0.64 | ||

| 6-R | 1250 | 2500 | 2.00 | 175 | 248 | 248 | 1.00 | 2.00 | 0 | 1.00 | 0.27 | 24.00 | 0.60 | 0.54 | 15.10 | DSS | 100.0 | 0.46 | ||

| 7-R | Magenes et al., 2008 [64] | Hollow clay brick | 2500 | 2600 | 1.04 | 300 | 250 | 190 | 0.76 | 1.52 | 45 | 0.68 | 0.28 | 9.50 | 0.60 | 0.54 | 26.50 | DSS | 309.0 | 0.41 |

| 8-R | 2500 | 2600 | 1.04 | 300 | 250 | 190 | 0.76 | 1.52 | 45 | 0.68 | 0.28 | 9.50 | 0.60 | 0.54 | 26.50 | DSS | 340.0 | 0.45 | ||

| 9-R | 1250 | 2600 | 2.08 | 300 | 250 | 190 | 0.76 | 1.52 | 45 | 0.50 | 0.28 | 9.50 | 0.60 | 0.54 | 26.50 | F | 86.0 | 0.23 | ||

| 10-R | 1250 | 2600 | 2.08 | 300 | 250 | 190 | 0.76 | 1.52 | 45 | 0.50 | 0.28 | 9.50 | 0.60 | 0.54 | 26.50 | F | 72.0 | 0.19 | ||

| 11-R | Messali et al., 2020 [65] | Calcium silicate | 1100 | 2700 | 2.45 | 102 | 434 | 476 | 1.10 | 2.19 | 0 | 0.70 | 0.21 | 5.93 | 0.14 | 0.43 | 27.40 | DSS | 27.7 | 0.25 |

| 12-R | 1100 | 2700 | 2.45 | 102 | 434 | 476 | 1.10 | 2.19 | 0 | 0.40 | 0.21 | 5.93 | 0.14 | 0.43 | 27.40 | DSS | 15.0 | 0.13 | ||

| 13-R | 4000 | 2700 | 0.68 | 102 | 434 | 476 | 1.10 | 2.19 | 0 | 0.50 | 0.21 | 5.93 | 0.14 | 0.43 | 27.40 | HSS | 119.0 | 0.29 | ||

| 14-R | 4000 | 2700 | 0.68 | 102 | 434 | 476 | 1.10 | 2.19 | 0 | 0.30 | 0.21 | 5.93 | 0.14 | 0.43 | 27.40 | HSS | 102.0 | 0.25 | ||

| 15-R | Morandi et al., 2013 [66] | Hollow clay brick | 1250 | 2000 | 1.60 | 350 | 250 | 190 | 0.76 | 1.52 | 45 | 0.50 | 0.41 | 9.50 | 0.69 | 0.77 | 19.20 | TDS | 130.0 | 0.30 |

| 16-R | 1250 | 2000 | 1.60 | 350 | 250 | 190 | 0.76 | 1.52 | 45 | 0.70 | 0.41 | 9.50 | 0.69 | 0.77 | 19.20 | TDS | 166.0 | 0.38 | ||

| 17-R | 1250 | 2000 | 1.60 | 350 | 250 | 190 | 0.76 | 1.52 | 45 | 1.00 | 0.41 | 9.50 | 0.69 | 0.77 | 19.20 | TDS | 198.0 | 0.45 | ||

| 18-R | 2500 | 2000 | 0.80 | 350 | 250 | 190 | 0.76 | 1.52 | 45 | 0.50 | 0.41 | 9.50 | 0.69 | 0.77 | 19.20 | TDS | 401.0 | 0.46 | ||

| 19-R | 2500 | 2000 | 0.80 | 350 | 250 | 190 | 0.76 | 1.52 | 45 | 0.70 | 0.41 | 9.50 | 0.69 | 0.77 | 19.20 | TDS | 500.0 | 0.57 | ||

| 20-R | Tomaževič, 2009 [67] | Hollow clay brick | 1000 | 1430 | 1.43 | 280 | 188 | 189 | 1.01 | 2.01 | 58 | 1.92 | 0.23 | 4.88 | 0.27 | 0.40 | 20.70 | TDS | 140.6 | 0.50 |

| 21-R | 1000 | 1430 | 1.43 | 280 | 188 | 189 | 1.01 | 2.01 | 58 | 0.96 | 0.23 | 4.88 | 0.27 | 0.40 | 20.70 | TDS | 92.0 | 0.33 | ||

| 22-R | 1020 | 1510 | 1.48 | 280 | 238 | 234 | 0.98 | 1.97 | 55 | 1.71 | 0.24 | 4.89 | 0.26 | 0.40 | 13.00 | TDS | 133.7 | 0.47 | ||

| 23-R | 1020 | 1510 | 1.48 | 280 | 238 | 234 | 0.98 | 1.97 | 55 | 0.94 | 0.24 | 4.89 | 0.26 | 0.40 | 13.00 | TDS | 90.9 | 0.32 | ||

| 24-R | 1020 | 1510 | 1.48 | 280 | 238 | 234 | 0.98 | 1.97 | 55 | 1.37 | 0.24 | 4.89 | 0.26 | 0.40 | 13.00 | TDS | 118.0 | 0.41 | ||

| 25-R | 1010 | 1420 | 1.41 | 290 | 189 | 188 | 0.99 | 1.99 | 53 | 1.67 | 0.20 | 4.51 | 0.20 | 0.40 | 14.60 | TDS | 128.7 | 0.44 | ||

| 26-R | 1010 | 1420 | 1.41 | 290 | 189 | 188 | 0.99 | 1.99 | 53 | 0.89 | 0.20 | 4.51 | 0.20 | 0.40 | 14.60 | TDS | 84.2 | 0.29 | ||

| 27-R | 990 | 1420 | 1.43 | 290 | 331 | 189 | 0.57 | 1.14 | 54 | 1.62 | 0.26 | 4.76 | 0.38 | 0.40 | 12.20 | TDS | 141.7 | 0.49 | ||

| 28-R | 990 | 1420 | 1.43 | 290 | 331 | 189 | 0.57 | 1.14 | 54 | 1.00 | 0.26 | 4.76 | 0.38 | 0.40 | 12.20 | TDS | 93.9 | 0.33 | ||

| 29-R | 1070 | 1470 | 1.37 | 250 | 254 | 121 | 0.48 | 0.95 | 25 | 1.96 | 0.23 | 5.44 | 0.33 | 0.40 | 30.30 | TDS | 131.0 | 0.49 | ||

| 30-R | 1070 | 1470 | 1.37 | 250 | 254 | 121 | 0.48 | 0.95 | 25 | 1.10 | 0.23 | 5.44 | 0.33 | 0.40 | 30.30 | TDS | 91.6 | 0.34 | ||

| 31-R | Churilov et al., 2013 [68] | Clay brick | 2600 | 1800 | 0.69 | 250 | 250 | 65 | 0.26 | 0.52 | 0 | 1.00 | 0.10 | 3.60 | 0.00 | 0.66 | 6.80 | TDS | 213.2 | 0.33 |

| 32-R | 1500 | 1800 | 1.20 | 250 | 250 | 65 | 0.26 | 0.52 | 0 | 1.00 | 0.10 | 3.60 | 0.00 | 0.66 | 6.80 | TDS | 99.1 | 0.26 | ||

| 33-R | 2600 | 1800 | 0.69 | 250 | 250 | 65 | 0.26 | 0.52 | 0 | 0.50 | 0.10 | 3.60 | 0.00 | 0.66 | 6.80 | TDS | 157.4 | 0.24 | ||

| 34-R | 1500 | 1800 | 1.20 | 250 | 250 | 65 | 0.26 | 0.52 | 0 | 0.50 | 0.10 | 3.60 | 0.00 | 0.66 | 6.80 | DSS | 65.5 | 0.17 | ||

| 35-R | Salmanpour et al., 2015 [69] | Hollow clay brick | 1500 | 1600 | 1.07 | 150 | 290 | 190 | 0.66 | 1.31 | 42 | 0.64 | 0.25 | 6.40 | 0.26 | 0.48 | 26.30 | TDS | 91.0 | 0.40 |

| 36-R | 1500 | 1600 | 1.07 | 150 | 290 | 190 | 0.66 | 1.31 | 42 | 0.96 | 0.25 | 6.40 | 0.26 | 0.48 | 26.30 | TDS | 103.0 | 0.46 | ||

| 37-R | Salmanpour et al., 2015 [69] | Calcium silicate | 1550 | 1600 | 1.03 | 150 | 250 | 190 | 0.76 | 1.52 | 25 | 0.77 | 0.26 | 7.70 | 0.26 | 0.48 | 22.20 | TDS | 131.0 | 0.56 |

| 38-R | 1550 | 1600 | 1.03 | 150 | 250 | 190 | 0.76 | 1.52 | 25 | 1.16 | 0.26 | 7.70 | 0.26 | 0.48 | 22.20 | TDS | 148.0 | 0.64 | ||

| 39-R | Salmanpour et al., 2015 [69] | Hollow clay brick | 2700 | 2600 | 0.96 | 150 | 290 | 190 | 0.66 | 1.31 | 42 | 0.58 | 0.25 | 6.40 | 0.26 | 0.48 | 26.30 | TDS | 141.0 | 0.35 |

| 40-R | 2700 | 2600 | 0.96 | 150 | 290 | 190 | 0.66 | 1.31 | 42 | 0.29 | 0.25 | 6.40 | 0.26 | 0.48 | 26.30 | DSS | 88.0 | 0.22 | ||

| 41-R | 2700 | 2600 | 0.96 | 150 | 290 | 190 | 0.66 | 1.31 | 42 | 0.42 | 0.25 | 6.40 | 0.26 | 0.48 | 26.30 | TDS | 181.0 | 0.45 | ||

| 42-R | 1800 | 2600 | 1.44 | 150 | 290 | 190 | 0.66 | 1.31 | 42 | 0.58 | 0.25 | 6.40 | 0.26 | 0.48 | 26.30 | TDS | 67.0 | 0.25 | ||

| 43-R | 3600 | 2600 | 0.72 | 150 | 290 | 190 | 0.66 | 1.31 | 42 | 0.58 | 0.25 | 6.40 | 0.26 | 0.48 | 26.30 | DSS | 223.0 | 0.41 | ||

| 44-R | Petry and Beyer, 2015 [70] | Hollow clay brick | 2010 | 2250 | 1.12 | 200 | 300 | 190 | 0.63 | 1.27 | - | 1.06 | 0.50 | 5.87 | 0.27 | 0.94 | 35.00 | TDS | 187.0 | 0.47 |

| 45-R | 2010 | 2250 | 1.12 | 200 | 300 | 190 | 0.63 | 1.27 | - | 1.06 | 0.50 | 5.87 | 0.27 | 0.94 | 35.00 | TDS | 178.0 | 0.44 | ||

| 46-R | 2010 | 2250 | 1.12 | 200 | 300 | 190 | 0.63 | 1.27 | - | 1.53 | 0.50 | 5.87 | 0.27 | 0.94 | 35.00 | TDS | 145.0 | 0.36 | ||

| 47-R | 2010 | 2250 | 1.12 | 200 | 300 | 190 | 0.63 | 1.27 | - | 0.53 | 0.50 | 5.87 | 0.27 | 0.94 | 35.00 | TDS | 135.0 | 0.34 | ||

| 48-R | 2010 | 2250 | 1.12 | 200 | 300 | 190 | 0.63 | 1.27 | - | 0.53 | 0.50 | 5.87 | 0.27 | 0.94 | 35.00 | TDS | 154.0 | 0.38 | ||

| 49-R | Morandi et al., 2014 [71] | Hollow clay Brick | 1350 | 2140 | 1.59 | 350 | 225 | 230 | 1.02 | 2.04 | 55 | 0.15 | 0.60 | 6.20 | 0.49 | 1.04 | 10.50 | DSS | 48.0 | 0.10 |

| 50-R | 1350 | 2140 | 1.59 | 350 | 225 | 230 | 1.02 | 2.04 | 55 | 0.45 | 0.60 | 6.20 | 0.49 | 1.04 | 10.50 | DSS | 119.0 | 0.25 | ||

| 51-R | 1350 | 2140 | 1.59 | 350 | 225 | 230 | 1.02 | 2.04 | 55 | 0.65 | 0.60 | 6.20 | 0.49 | 1.04 | 10.50 | TDS | 164.0 | 0.35 | ||

| 52-R | 2700 | 2140 | 0.79 | 350 | 225 | 230 | 1.02 | 2.04 | 55 | 0.45 | 0.60 | 6.20 | 0.49 | 1.04 | 10.50 | DSS | 263.0 | 0.28 | ||

| 53-R | 2700 | 2140 | 0.79 | 350 | 225 | 230 | 1.02 | 2.04 | 55 | 0.65 | 0.60 | 6.20 | 0.49 | 1.04 | 10.50 | TDS | 341.0 | 0.36 | ||

| 54-R | Martinelli et al., 2016 [72] | Clay brick | 1160 | 1160 | 1.00 | 250 | 250 | 55 | 0.22 | 0.44 | 0 | 0.52 | 0.13 | 12.31 | - | - | 30.32 | TDS | 124.0 | 0.43 |

| 55-R | 1160 | 1160 | 1.00 | 250 | 250 | 55 | 0.22 | 0.44 | 0 | 0.52 | 0.13 | 12.31 | - | - | 30.32 | TDS | 68.0 | 0.23 | ||

| 56-R | 1160 | 1160 | 1.00 | 250 | 250 | 55 | 0.22 | 0.44 | 0 | 0.52 | 0.13 | 12.31 | - | - | 30.32 | TDS | 104.0 | 0.36 | ||

| 57-R | Fehling and Stuerz, 2007 [73] | Hollow clay brick | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 160.0 | 0.42 |

| 58-R | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | DSS | 140.0 | 0.36 | ||

| 59-R | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 118.0 | 0.31 | ||

| 60-R | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 147.0 | 0.38 | ||

| 61-R | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 120.0 | 0.31 | ||

| 62-R | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 149.0 | 0.39 | ||

| 63-R | 1100 | 1900 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 60.0 | 0.31 | ||

| 64-R | 1100 | 1900 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 56.0 | 0.29 | ||

| 65-R | 2200 | 950 | 0.43 | 175 | 250 | 240 | 0.96 | 1.92 | - | 0.25 | 0.28 | 10.30 | - | - | 10.30 | DSS | 72.0 | 0.19 | ||

| 66-R | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 150.0 | 0.39 | ||

| 67-R | 2200 | 3800 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 162.0 | 0.42 | ||

| 68-R | 1100 | 1900 | 1.73 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.28 | 10.30 | - | - | 10.30 | TDS | 70.0 | 0.36 | ||

| 69-R | Fehling and Stuerz, 2007 [73] | Calcium silicate | 1250 | 2200 | 1.76 | 175 | 175 | 249 | 1.42 | 2.85 | - | 1.00 | 0.27 | 5.93 | - | - | 24.00 | DSS | 91.0 | 0.42 |

| 70-R | 1250 | 2200 | 1.76 | 175 | 175 | 249 | 1.42 | 2.85 | - | 1.00 | 0.27 | 5.93 | - | - | 24.00 | TDS | 86.0 | 0.39 | ||

| 71-R | Fehling and Stuerz, 2007 [73] | Lightweight Aerated Concrete | 1250 | 2200 | 1.76 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.25 | 2.40 | - | - | 3.31 | DSS | 90.0 | 0.41 |

| 72-R | 1250 | 2200 | 1.76 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.25 | 2.40 | - | - | 3.31 | DSS | 98.0 | 0.45 | ||

| 73-R | 1250 | 1100 | 0.88 | 175 | 250 | 240 | 0.96 | 1.92 | - | 0.50 | 0.25 | 2.40 | - | - | 3.31 | DSS | 65.0 | 0.30 | ||

| 74-R | 1250 | 1100 | 0.88 | 175 | 250 | 240 | 0.96 | 1.92 | - | 0.50 | 0.25 | 2.40 | - | - | 3.31 | DSS | 61.0 | 0.28 | ||

| 75-R | 1250 | 2200 | 1.76 | 175 | 250 | 240 | 0.96 | 1.92 | - | 1.00 | 0.25 | 2.40 | - | - | 3.31 | DSS | 49.0 | 0.22 | ||

| 76-R | Magenes et al., 2008 [64] | Lightweight Aerated Concrete | 2500 | 2500 | 1.00 | 175 | 247 | 240 | 0.97 | 1.94 | 0 | 0.50 | 0.25 | 2.40 | - | - | 3.31 | DSS | 125.0 | 0.29 |

| 77-R | 2500 | 2500 | 1.00 | 175 | 247 | 240 | 0.97 | 1.94 | 0 | 0.50 | 0.25 | 2.40 | - | - | 3.31 | DSS | 140.0 | 0.32 | ||

| 78-R | 2500 | 2500 | 1.00 | 175 | 247 | 240 | 0.97 | 1.94 | 0 | 1.00 | 0.25 | 2.40 | - | - | 3.31 | DSS | 230.0 | 0.53 | ||

| 79-R | 2500 | 2500 | 1.00 | 175 | 247 | 240 | 0.97 | 1.94 | 0 | 1.00 | 0.25 | 2.40 | - | - | 3.31 | DSS | 230.0 | 0.53 | ||

| 80-R | Borri et al., 2015 [27] | Clay brick | 890 | 905 | 1.02 | 250 | 240 | 55 | 0.23 | 0.46 | 0 | 0.48 | 0.10 | 6.00 | - | - | 20.99 | TDS | 84.1 | 0.38 |

| 81-R | 900 | 895 | 0.99 | 250 | 240 | 55 | 0.23 | 0.46 | 0 | 0.40 | 0.10 | 6.00 | - | - | 20.99 | TDS | 61.3 | 0.27 | ||

| 82-R | 930 | 900 | 0.97 | 250 | 240 | 55 | 0.23 | 0.46 | 0 | 0.39 | 0.10 | 6.00 | - | - | 20.99 | TDS | 70.8 | 0.30 | ||

| 83-R | Marcari et al., 2007 [41] | Tuff stone (‘a sacco’) | 1480 | 1570 | 1.06 | 530 | - | - | - | - | 0 | 0.50 | 0.06 | 1.40 | - | - | 2.00 | TDS | 132.0 | 0.17 |

| 84-R | Faella et al., 1992 [74] | Tuff stone (‘a sacco’) | 1300 | 1250 | 0.96 | 500 | - | - | - | - | 0 | 0.21 | 0.06 | 2.00 | - | - | 3.00 | TDS | 82.4 | 0.13 |

| 85-R | 1300 | 1250 | 0.96 | 500 | - | - | - | - | 0 | 0.21 | 0.06 | 2.00 | - | - | 3.00 | TDS | 83.0 | 0.13 | ||

| 86-R | 1300 | 1250 | 0.96 | 500 | - | - | - | - | 0 | 0.52 | 0.06 | 2.00 | - | - | 3.00 | TDS | 107.7 | 0.17 | ||

| 87-R | 1300 | 1250 | 0.96 | 500 | - | - | - | - | 0 | 0.52 | 0.06 | 2.00 | - | - | 3.00 | TDS | 124.4 | 0.19 | ||

| 88-R | Faella et al., 1992 [74] | Tuff stone | 1300 | 1250 | 0.96 | 500 | - | - | - | - | 0 | 0.21 | 0.12 | 3.50 | - | - | 3.50 | TDS | 102.4 | 0.16 |

| 89-R | 1300 | 1250 | 0.96 | 500 | - | - | - | - | 0 | 0.52 | 0.12 | 3.50 | - | - | 3.50 | TDS | 165.7 | 0.25 | ||

| 90-R | Lourenço et al., 2005 [75] | Dry Stone | 1000 | 1000 | 1.00 | 200 | 200 | 100 | 0.50 | 1.00 | 0 | 0.15 | 0.06 | 50.00 | - | - | 82.70 | HSS | 22.0 | 0.11 |

| 91-R | 1000 | 1000 | 1.00 | 200 | 200 | 100 | 0.50 | 1.00 | 0 | 0.15 | 0.06 | 50.00 | - | - | 82.70 | HSS | 23.0 | 0.12 | ||

| 92-R | 1000 | 1000 | 1.00 | 200 | 200 | 100 | 0.50 | 1.00 | 0 | 0.50 | 0.07 | 50.00 | - | - | 82.70 | TDS | 42.0 | 0.21 | ||

| 93-R | 1000 | 1000 | 1.00 | 200 | 200 | 100 | 0.50 | 1.00 | 0 | 0.50 | 0.07 | 50.00 | - | - | 82.70 | TDS | 49.0 | 0.25 |

| Experimental Result | Theoretical Results | Theoretical vs. Experimental Results | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flexural Failure (F), Vth,F | Sliding Failure | Tensile Failure of Units (TDS) Vth,TDS | |||||||||||||

| ‘local’ (HSS) Vth,HSS | ‘global’ (DSS) Vth,DSS | ||||||||||||||

| CASE | Vexp | Failure Mode | Equation (1) | Equations (2) and (5) | Equation (3) | Equation (4) | Equation (7) | Equation (8) | Equations (9) and (11) | Equation (10) | Equation (12) | Vth,min,exp | ρmin,exp | Vth,min | ρmin |

| (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (kN) | (−) | (kN) | (−) | ||

| 1-R | 75.0 | DSS | 100.4 | 98.5 | 95.8 | 98.7 | 83.8 | 72.3 | 72.2 | 76.7 | 79.5 | 72.2 | 0.96 | 72.2 | 0.96 (DSS) |

| 2-R | 65.0 | F | 67.7 | 66.5 | 64.6 | 66.7 | 83.8 | 72.3 | 64.9 | 65.8 | 71.6 | 64.6 | 0.99 | 64.6 | 0.99 (F) |

| 3-R | 75.0 | DSS | 104.8 | 104.0 | 102.9 | 104.1 | 150.9 | 124.7 | 79.9 | 81.2 | 51.4 | 79.9 | 1.07 | 51.4 | 0.69 (TDS) |

| 4-R | 50.0 | DSS | 53.5 | 53.3 | 53.1 | 53.4 | 121.4 | 95.2 | 61.0 | 78.0 | 41.7 | 61.0 | 1.22 | 41.7 | 0.83 (TDS) |

| 5-R | 140.0 | DSS | 200.5 | 197.3 | 192.7 | 197.8 | 210.0 | 183.8 | 117.8 | 145.3 | 66.8 | 117.8 | 0.84 | 66.8 | 0.48 (TDS) |

| 6-R | 100.0 | DSS | 104.8 | 104.0 | 102.9 | 104.1 | 150.9 | 124.7 | 79.9 | 81.2 | 51.4 | 79.9 | 0.80 | 51.4 | 0.51 (TDS) |

| 7-R | 309.0 | DSS | 455.3 | 449.1 | 440.2 | 450.0 | 452.7 | 362.7 | 383.1 | 416.9 | 339.5 | 383.1 | 1.24 | 339.5 | 1.10 (TDS) |

| 8-R | 340.0 | DSS | 455.3 | 449.1 | 440.2 | 450.0 | 452.7 | 362.7 | 383.1 | 416.9 | 339.5 | 383.1 | 1.13 | 339.5 | 1.00 (TDS) |

| 9-R | 86.0 | F | 85.4 | 84.6 | 83.4 | 84.7 | 208.1 | 163.1 | 119.5 | 143.0 | 110.3 | 83.4 | 0.97 | 83.4 | 0.97 (F) |

| 10-R | 72.0 | F | 85.4 | 84.6 | 83.4 | 84.7 | 208.1 | 163.1 | 119.5 | 143.0 | 110.3 | 83.4 | 1.16 | 83.4 | 1.16 (F) |

| 11-R | 27.7 | DSS | 28.2 | 27.6 | 26.6 | 27.7 | 27.9 | 24.7 | 17.0 | 21.4 | 36.4 | 17.0 | 0.61 | 17.0 | 0.61 (DSS) |

| 12-R | 15.0 | DSS | 17.1 | 16.8 | 16.5 | 16.9 | 20.6 | 17.5 | 12.0 | 13.3 | 32.6 | 12.0 | 0.80 | 12.0 | 0.80 (DSS) |

| 13-R | 119.0 | HSS | 276.7 | 272.2 | 265.8 | 272.9 | 83.8 | 72.4 | 74.5 | 77.9 | 184.9 | 72.4 | 0.61 | 72.4 | 0.61 (HSS) |

| 14-R | 102.0 | HSS | 172.2 | 170.5 | 168.2 | 170.8 | 66.3 | 54.9 | 56.5 | 57.3 | 170.4 | 54.9 | 0.54 | 54.9 | 0.54 (HSS) |

| 15-R | 130.0 | TDS | 129.5 | 128.3 | 126.4 | 128.4 | 295.5 | 235.2 | 144.5 | 189.7 | 99.8 | 99.8 | 0.77 | 99.8 | 0.77 (TDS) |

| 16-R | 166.0 | TDS | 177.3 | 174.8 | 171.3 | 175.2 | 329.2 | 268.8 | 165.2 | 232.7 | 108.7 | 108.7 | 0.65 | 108.7 | 0.65 (TDS) |

| 17-R | 198.0 | TDS | 244.7 | 239.6 | 232.3 | 240.3 | 379.8 | 319.4 | 196.2 | 206.4 | 120.8 | 120.8 | 0.61 | 120.8 | 0.61 (TDS) |

| 18-R | 401.0 | TDS | 518.1 | 513.0 | 505.8 | 513.8 | 591.1 | 470.3 | 433.4 | 456.4 | 299.5 | 299.5 | 0.75 | 299.5 | 0.75 (TDS) |

| 19-R | 500.0 | TDS | 709.2 | 699.3 | 685.0 | 700.7 | 658.4 | 537.7 | 495.5 | 537.0 | 326.1 | 326.1 | 0.65 | 326.1 | 0.65 (TDS) |

| 20-R | 140.6 | TDS | 228.0 | 201.9 | 164.6 | 205.8 | 160.4 | 145.3 | 112.6 | 156.0 | 106.9 | 106.9 | 0.76 | 106.9 | 0.76 (TDS) |

| 21-R | 92.0 | TDS | 151.0 | 144.5 | 135.1 | 145.4 | 106.7 | 91.6 | 71.0 | 91.8 | 84.4 | 84.4 | 0.92 | 71.0 | 0.77 (DSS) |

| 22-R | 133.7 | TDS | 214.5 | 194.2 | 165.1 | 197.2 | 149.7 | 134.8 | 101.9 | 144.4 | 75.9 | 75.9 | 0.57 | 75.9 | 0.57 (TDS) |

| 23-R | 90.9 | TDS | 146.5 | 140.3 | 131.5 | 141.3 | 105.7 | 90.8 | 68.7 | 91.1 | 60.4 | 60.4 | 0.66 | 60.4 | 0.66 (TDS) |

| 24-R | 118.0 | TDS | 190.3 | 177.2 | 158.5 | 179.1 | 130.2 | 115.4 | 87.3 | 121.3 | 69.5 | 69.5 | 0.59 | 69.5 | 0.59 (TDS) |

| 25-R | 128.7 | TDS | 219.1 | 196.3 | 163.9 | 199.8 | 138.8 | 127.1 | 100.7 | 138.4 | 87.0 | 87.0 | 0.68 | 87.0 | 0.68 (TDS) |

| 26-R | 84.2 | TDS | 148.8 | 142.4 | 133.1 | 143.3 | 93.1 | 81.4 | 64.5 | 84.7 | 69.1 | 69.1 | 0.82 | 64.5 | 0.77 (DSS) |

| 27-R | 141.7 | TDS | 213.9 | 194.4 | 166.6 | 197.3 | 169.4 | 147.6 | 141.2 | 178.3 | 74.2 | 74.2 | 0.52 | 74.2 | 0.52 (TDS) |

| 28-R | 93.9 | TDS | 158.1 | 150.7 | 140.1 | 151.8 | 133.8 | 112.0 | 107.2 | 122.4 | 61.5 | 61.5 | 0.66 | 61.5 | 0.66 (TDS) |

| 29-R | 131.0 | TDS | 244.1 | 219.9 | 185.2 | 223.5 | 166.7 | 149.0 | 157.1 | 198.0 | 136.7 | 136.7 | 1.04 | 136.7 | 1.04 (TDS) |

| 30-R | 91.6 | TDS | 170.9 | 163.2 | 152.3 | 164.4 | 120.6 | 113.0 | 108.6 | 125.1 | 114.4 | 114.4 | 1.25 | 108.6 | 1.19 (DSS) |

| 31-R | 213.2 | TDS | 678.1 | 632.1 | 566.3 | 639.0 | 429.0 | 429.0 | 319.4 | 319.4 | 208.1 | 208.1 | 0.98 | 208.1 | 0.98 (TDS) |

| 32-R | 99.1 | TDS | 225.7 | 210.4 | 188.5 | 212.7 | 247.5 | 247.5 | 153.6 | 184.3 | 100.0 | 100.0 | 1.01 | 100.0 | 1.01 (TDS) |

| 33-R | 157.4 | TDS | 404.2 | 392.7 | 376.3 | 394.5 | 214.5 | 214.5 | 159.7 | 159.7 | 166.5 | 166.5 | 1.06 | 159.7 | 1.01 (DSS) |

| 34-R | 65.5 | DSS | 134.5 | 130.7 | 125.2 | 131.3 | 123.8 | 123.8 | 76.8 | 92.1 | 80.0 | 76.8 | 1.17 | 76.8 | 1.17 (DSS) |

| 35-R | 91.0 | TDS | 121.5 | 119.1 | 115.7 | 119.5 | 151.0 | 127.6 | 73.4 | 85.0 | 97.4 | 97.4 | 1.07 | 73.4 | 0.81 (DSS) |

| 36-R | 103.0 | TDS | 172.1 | 166.8 | 159.1 | 167.6 | 185.6 | 162.2 | 93.3 | 107.9 | 107.7 | 107.7 | 1.05 | 93.3 | 0.91 (DSS) |

| 37-R | 131.0 | TDS | 156.1 | 153.0 | 148.6 | 153.5 | 170.6 | 146.4 | 82.0 | 92.8 | 95.8 | 95.8 | 0.73 | 82.0 | 0.63 (DSS) |

| 38-R | 148.0 | TDS | 221.4 | 214.5 | 204.7 | 215.6 | 213.8 | 189.6 | 106.2 | 119.1 | 107.9 | 107.9 | 0.73 | 106.2 | 0.72 (DSS) |

| 39-R | 141.0 | TDS | 221.9 | 218.0 | 212.4 | 218.6 | 260.2 | 218.1 | 133.9 | 146.8 | 183.0 | 183.0 | 1.30 | 133.9 | 0.95 (DSS) |

| 40-R | 88.0 | DSS | 116.0 | 115.0 | 113.7 | 115.2 | 203.6 | 161.5 | 99.1 | 103.8 | 162.4 | 99.1 | 1.13 | 99.1 | 1.13 (DSS) |

| 41-R | 181.0 | TDS | 165.0 | 162.9 | 160.0 | 163.2 | 229.0 | 186.9 | 114.7 | 124.3 | 172.0 | 172.0 | 0.95 | 114.7 | 0.63 (DSS) |

| 42-R | 67.0 | TDS | 98.8 | 97.1 | 94.6 | 97.3 | 173.6 | 145.6 | 61.9 | 92.6 | 84.5 | 84.5 | 1.26 | 61.9 | 0.92 (DSS) |

| 43-R | 223.0 | DSS | 394.1 | 387.2 | 377.3 | 388.2 | 346.8 | 290.6 | 178.4 | 201.5 | 244.0 | 178.4 | 0.80 | 178.4 | 0.80 (DSS) |

| 44-R | 187.0 | TDS | 311.1 | 299.1 | 281.9 | 300.9 | 275.6 | 253.9 | 207.1 | 214.6 | 232.2 | 232.2 | 1.24 | 207.1 | 1.11 (DSS) |

| 45-R | 178.0 | TDS | 311.1 | 299.1 | 281.9 | 300.9 | 275.6 | 253.9 | 207.1 | 214.6 | 232.2 | 232.2 | 1.30 | 207.1 | 1.16 (DSS) |

| 46-R | 145.0 | TDS | 405.6 | 380.4 | 344.5 | 384.2 | 364.3 | 342.6 | 279.4 | 297.3 | 256.8 | 256.8 | 1.77 | 256.8 | 1.77 (TDS) |

| 47-R | 135.0 | TDS | 172.6 | 169.6 | 165.3 | 170.1 | 175.8 | 154.1 | 125.7 | 146.3 | 201.0 | 201.0 | 1.49 | 125.7 | 0.93 (DSS) |

| 48-R | 154.0 | TDS | 172.6 | 169.6 | 165.3 | 170.1 | 175.8 | 154.1 | 125.7 | 146.3 | 201.0 | 201.0 | 1.31 | 125.7 | 0.82 (DSS) |

| 49-R | 48.0 | DSS | 43.6 | 43.4 | 43.2 | 43.5 | 198.9 | 152.6 | 65.1 | 73.7 | 52.4 | 65.1 | 1.36 | 43.2 | 0.90 (DSS) |

| 50-R | 119.0 | DSS | 124.4 | 122.7 | 120.2 | 122.9 | 272.6 | 226.3 | 96.5 | 142.5 | 67.2 | 96.5 | 0.81 | 67.2 | 0.56 (TDS) |

| 51-R | 164.0 | TDS | 173.4 | 169.9 | 164.7 | 170.4 | 321.8 | 275.5 | 117.5 | 179.0 | 75.5 | 75.5 | 0.46 | 75.5 | 0.46 (TDS) |

| 52-R | 263.0 | DSS | 497.6 | 490.7 | 480.9 | 491.7 | 545.3 | 452.7 | 289.6 | 319.5 | 201.7 | 289.6 | 1.10 | 201.7 | 0.77 (TDS) |

| 53-R | 341.0 | TDS | 693.7 | 679.4 | 658.9 | 681.6 | 643.5 | 550.9 | 352.5 | 389.3 | 226.5 | 226.5 | 0.66 | 226.5 | 0.66 (TDS) |

| Statistical Values | ρmin,exp | ρmin |

|---|---|---|

| Mean (−) | 0.94 | 0.82 |

| Stand. Dev. (−) | 0.28 | 0.24 |

| CoV (%) | 30.4% | 29.4% |

| Case | Authors | Type of Masonry | B | H | λ | s | σ0 | ft | fc | fbc | Failure Mode | Vexp | τav |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (−) | (mm) | (MPa) | (MPa) | (MPa) | (MPa) | (kN) | (MPa) | ||||

| 94-R | Borri et al., 2015 [27] | Double-leaf stone | 860 | 910 | 1.06 | 480 | 0.15 | 0.05 | 20.99 | 36.00 | DS | 34.3 | 0.08 |

| 95-R | 860 | 900 | 1.05 | 480 | 0.18 | 0.05 | 20.99 | 36.00 | DS | 37.0 | 0.09 | ||

| 96-R | 900 | 900 | 1.00 | 480 | 0.18 | 0.05 | 20.99 | 36.00 | DS | 62.5 | 0.14 | ||

| 97-IR | 880 | 915 | 1.04 | 480 | 0.31 | 0.07 | 20.99 | 36.00 | DS | 88.3 | 0.21 | ||

| 98-IR | 930 | 915 | 0.98 | 480 | 0.29 | 0.10 | 20.99 | 36.00 | DS | 100.5 | 0.23 | ||

| 99-IR | 880 | 910 | 1.03 | 480 | 0.12 | 0.06 | 20.99 | 36.00 | DS | 74.4 | 0.18 | ||

| 100-IR | Borri et al., 2015 [27] | Double-leaf stone | 900 | 903 | 1.00 | 510 | 0.21 | 0.04 | 20.99 | 36.00 | DS | 109.3 | 0.24 |

| 101-IR | 900 | 905 | 1.01 | 490 | 0.21 | 0.04 | 20.99 | 36.00 | DS | 52.0 | 0.12 | ||

| 102-IR | 900 | 903 | 1.00 | 510 | 0.19 | 0.04 | 20.99 | 36.00 | DS | 80.7 | 0.18 | ||

| 103-IR | 900 | 950 | 1.06 | 490 | 0.21 | 0.04 | 20.99 | 36.00 | DS | 87.6 | 0.20 | ||

| 104-IR | Vasconcelos and Lourenço, 2009 [10] | Irregular stone | 1000 | 1200 | 1.20 | 200 | 0.88 | 0.12 | 18.40 | 18.40 | DS | 55.7 | 0.28 |

| 105-IR | 1000 | 1200 | 1.20 | 200 | 1.25 | 0.12 | 18.40 | 18.40 | DS | 83.0 | 0.41 | ||

| 106-IR | Vasconcelos and Lourenço, 2009 [10] | Rubble stone | 1000 | 1200 | 1.20 | 200 | 0.88 | 0.12 | 18.40 | 18.40 | DS | 63.8 | 0.32 |

| 107-IR | 1000 | 1200 | 1.20 | 200 | 1.25 | 0.12 | 18.40 | 18.40 | DS | 66.0 | 0.33 | ||

| 108-IR | Magenes et al., 2010 [76] | Double-leaf stone | 1250 | 2500 | 2.00 | 320 | 0.20 | 0.14 | 3.28 | 165.00 | DS | 48.0 | 0.12 |

| 109-IR | 2500 | 2500 | 1.00 | 320 | 0.50 | 0.14 | 3.28 | 165.00 | DS | 234.0 | 0.29 | ||

| 110-IR | 2500 | 2500 | 1.00 | 320 | 0.20 | 0.14 | 3.28 | 165.00 | DS | 154.0 | 0.19 | ||

| 111-IR | Silva et al., 2014 [77] | Three-leaf stone | 1000 | 1200 | 1.20 | 500 | 0.50 | 0.05 | 2.50 | 93.40 | DS | 64.7 | 0.13 |

| 112-IR | 1000 | 1200 | 1.20 | 500 | 0.75 | 0.05 | 2.50 | 93.40 | DS | 84.5 | 0.17 | ||

| 113-IR | 1000 | 1200 | 1.20 | 500 | 1.00 | 0.05 | 2.50 | 93.40 | DS | 93.5 | 0.19 | ||

| 114-IR | Godio et al., 2019 [26] | Irregular stone | 900 | 900 | 1.00 | 200 | 0.74 | 0.25 | 10.34 | 65.60 | DS | 76.0 | 0.42 |

| 115-IR | 900 | 900 | 1.00 | 200 | 0.99 | 0.25 | 10.34 | 65.60 | DS | 90.0 | 0.50 | ||

| 116-R | 900 | 900 | 1.00 | 200 | 1.52 | 0.25 | 10.34 | 65.60 | DS | 138.0 | 0.77 | ||

| 117-R | 900 | 900 | 1.00 | 200 | 1.15 | 0.25 | 10.34 | 65.60 | DS | 110.0 | 0.61 | ||

| 118-R | 900 | 900 | 1.00 | 200 | 1.15 | 0.25 | 10.34 | 65.60 | DS | 108.0 | 0.60 | ||

| 119-R | 900 | 900 | 1.00 | 200 | 1.15 | 0.25 | 10.34 | 65.60 | DS | 103.0 | 0.57 | ||

| 120-R | Gattesco et al., 2015 [78] | Double-leaf stone | 1500 | 2000 | 1.33 | 350 | 0.90 | 0.13 | 4.50 | 7.50 | DS | 155.0 | 0.30 |

| Case | Vexp(kN) | Fail. Mode | Flexural Failure (F), Vth,F (kN) | Diagonal Shear (DS), Vth,DS (kN) | ρF = Vth,F/Vexp(−) | ρDS = Vth,DS/Vexp(−) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Equation (3) | Equations (13) and (16) | Equation (14) | Equation (15) | Equation (3) | Equations (13) and (16) | Equation (14) | Equation (15) | |||

| 94-R | 34.3 | DS | 56.77 | 37.0 | 33.3 | 37.0 | 1.66 | 1.08 | 0.97 | 1.08 |

| 95-R | 37.0 | DS | 71.67 | 40.8 | 36.8 | 40.8 | 1.94 | 1.10 | 0.99 | 1.10 |

| 96-R | 62.5 | DS | 78.07 | 44.6 | 40.2 | 44.6 | 1.25 | 0.71 | 0.64 | 0.71 |

| 97-IR | 88.3 | DS | 122.50 | 67.2 | 60.5 | 67.2 | 1.39 | 0.76 | 0.68 | 0.76 |

| 98-IR | 100.5 | DS | 127.67 | 87.8 | 79.0 | 89.3 | 1.27 | 0.87 | 0.79 | 0.89 |

| 99-IR | 74.4 | DS | 49.42 | 42.2 | 38.0 | 42.2 | 0.66 | 0.57 | 0.51 | 0.57 |

| 100-IR | 109.3 | DS | 93.86 | 48.2 | 43.4 | 48.2 | 0.86 | 0.44 | 0.40 | 0.44 |

| 101-IR | 52.0 | DS | 89.93 | 46.2 | 41.6 | 46.2 | 1.73 | 0.89 | 0.80 | 0.89 |

| 102-IR | 80.7 | DS | 84.95 | 46.2 | 41.6 | 46.2 | 1.05 | 0.57 | 0.52 | 0.57 |

| 103-IR | 87.6 | DS | 86.08 | 44.1 | 39.7 | 44.1 | 0.98 | 0.50 | 0.45 | 0.50 |

| 104-IR | 55.7 | DS | 135.93 | 57.6 | 51.8 | 57.6 | 2.44 | 1.03 | 0.93 | 1.03 |

| 105-IR | 83.0 | DS | 188.11 | 67.6 | 60.8 | 67.6 | 2.27 | 0.81 | 0.73 | 0.81 |

| 106-IR | 63.8 | DS | 135.93 | 57.6 | 51.8 | 57.6 | 2.13 | 0.90 | 0.81 | 0.90 |

| 107-IR | 66.0 | DS | 188.11 | 67.6 | 60.8 | 67.6 | 2.85 | 1.02 | 0.92 | 1.02 |

| 108-IR | 48.0 | DS | 76.52 | 57.3 | 51.6 | 43.0 | 1.59 | 1.19 | 1.07 | 0.90 |

| 109-IR | 234.0 | DS | 312.89 | 236.3 | 212.7 | 236.3 | 1.34 | 1.01 | 0.91 | 1.01 |

| 110-IR | 154.0 | DS | 196.06 | 171.9 | 154.7 | 171.9 | 1.27 | 1.12 | 1.00 | 1.12 |

| 111-IR | 64.7 | DS | 148.81 | 69.1 | 62.2 | 69.1 | 2.30 | 1.07 | 0.96 | 1.07 |

| 112-IR | 84.5 | DS | 178.57 | 83.3 | 75.0 | 83.3 | 2.11 | 0.99 | 0.89 | 0.99 |

| 113-IR | 93.5 | DS | 178.57 | 95.5 | 85.9 | 95.5 | 1.91 | 1.02 | 0.92 | 1.02 |

| 114-IR | 76.0 | DS | 120.22 | 89.7 | 80.8 | 89.7 | 1.58 | 1.18 | 1.06 | 1.18 |

| 115-IR | 90.0 | DS | 153.68 | 100.2 | 90.2 | 100.2 | 1.71 | 1.11 | 1.00 | 1.11 |

| 116-R | 138.0 | DS | 215.79 | 119.6 | 107.7 | 119.6 | 1.56 | 0.87 | 0.78 | 0.87 |

| 117-R | 110.0 | DS | 174.11 | 106.5 | 95.8 | 106.5 | 1.58 | 0.97 | 0.87 | 0.97 |

| 118-R | 108.0 | DS | 174.11 | 106.5 | 95.8 | 106.5 | 1.61 | 0.99 | 0.89 | 0.99 |

| 119-R | 103.0 | DS | 174.11 | 106.5 | 95.8 | 106.5 | 1.69 | 1.03 | 0.93 | 1.03 |

| 120-R | 155.0 | DS | 253.13 | 144.1 | 129.7 | 144.1 | 1.63 | 0.93 | 0.84 | 0.93 |

| Case | λ (−) | Vexp (kN) | Failure Mode | Diagonal Shear (DS), Vth,DS (kN) | ρDS =Vth,DS/Vexp(−) | ρmin =Vth,min/Vexp(−) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Equations (13) and (16) | Equation (14) | Equation (15) | Equations (13) and (16) | Equation (14) | Equation (15) | Min | ||||

| 1-R | 1.35 | 75.0 | DSS | 85.4 | 76.8 | 85.4 | 1.14 | 1.02 | 1.14 | 0.96 (DSS) |

| 3-R | 2.00 | 75.0 | DSS | 85.4 | 76.9 | 64.0 | 1.14 | 1.02 | 0.85 | 0.69 (TDS) |

| 4-R | 2.00 | 50.0 | DSS | 66.5 | 59.8 | 49.9 | 1.33 | 1.20 | 1.00 | 0.83 (TDS) |

| 5-R | 2.00 | 140.0 | DSS | 114.2 | 102.8 | 85.6 | 0.82 | 0.73 | 0.61 | 0.48 (TDS) |

| 6-R | 2.00 | 100.0 | DSS | 85.4 | 76.9 | 64.0 | 0.85 | 0.77 | 0.64 | 0.51 (TDS) |

| 7-R | 1.04 | 309.0 | DSS | 372.2 | 334.9 | 372.2 | 1.20 | 1.08 | 1.20 | 1.10 (TDS) |

| 8-R | 1.04 | 340.0 | DSS | 372.2 | 334.9 | 372.2 | 1.09 | 0.99 | 1.09 | 1.00 (TDS) |

| 11-R | 2.45 | 27.7 | DSS | 32.7 | 29.4 | 20.0 | 1.18 | 1.06 | 0.72 | 0.61 (DSS) |

| 12-R | 2.45 | 15.0 | DSS | 26.8 | 24.1 | 16.4 | 1.78 | 1.61 | 1.09 | 0.80 (DSS) |

| 13-R | 0.68 | 119.0 | HSS | 157.5 | 141.8 | 233.4 | 1.32 | 1.19 | 1.96 | 0.61 (HSS) |

| 14-R | 0.68 | 102.0 | HSS | 133.5 | 120.2 | 197.8 | 1.31 | 1.18 | 1.94 | 0.54 (HSS) |

| 15-R | 1.60 | 130.0 | TDS | 178.2 | 160.3 | 167.0 | 1.37 | 1.23 | 1.28 | 0.77 (TDS) |

| 16-R | 1.60 | 166.0 | TDS | 196.8 | 177.1 | 184.5 | 1.19 | 1.07 | 1.11 | 0.65 (TDS) |

| 17-R | 1.60 | 198.0 | TDS | 221.8 | 199.6 | 207.9 | 1.12 | 1.01 | 1.05 | 0.61 (TDS) |

| 18-R | 0.80 | 401.0 | TDS | 534.5 | 481.0 | 668.1 | 1.33 | 1.20 | 1.67 | 0.75 (TDS) |

| 19-R | 0.80 | 500.0 | TDS | 590.3 | 531.3 | 737.9 | 1.18 | 1.06 | 1.48 | 0.65 (TDS) |

| 20-R | 1.43 | 140.6 | TDS | 137.7 | 123.9 | 137.7 | 0.98 | 0.88 | 0.98 | 0.76 (TDS) |

| 21-R | 1.43 | 92.0 | TDS | 102.4 | 92.2 | 102.4 | 1.11 | 1.00 | 1.11 | 0.77 (DSS) |

| 22-R | 1.48 | 133.7 | TDS | 132.0 | 118.8 | 132.0 | 0.99 | 0.89 | 0.99 | 0.57 (TDS) |

| 23-R | 1.48 | 90.9 | TDS | 102.7 | 92.4 | 102.7 | 1.13 | 1.02 | 1.13 | 0.66 (TDS) |

| 24-R | 1.48 | 118.0 | TDS | 119.9 | 107.9 | 119.9 | 1.02 | 0.91 | 1.02 | 0.59 (TDS) |

| 25-R | 1.41 | 128.7 | TDS | 127.4 | 114.7 | 127.4 | 0.99 | 0.89 | 0.99 | 0.68 (TDS) |

| 26-R | 1.41 | 84.2 | TDS | 97.3 | 87.5 | 97.3 | 1.16 | 1.04 | 1.16 | 0.77 (DSS) |

| 27-R | 1.43 | 141.7 | TDS | 139.9 | 125.9 | 139.9 | 0.99 | 0.89 | 0.99 | 0.52 (TDS) |

| 28-R | 1.43 | 93.9 | TDS | 114.6 | 103.1 | 114.6 | 1.22 | 1.10 | 1.22 | 0.66 (TDS) |

| 29-R | 1.37 | 131.0 | TDS | 138.2 | 124.4 | 138.2 | 1.05 | 0.95 | 1.05 | 1.04 (TDS) |

| 30-R | 1.37 | 91.6 | TDS | 107.7 | 96.9 | 107.7 | 1.18 | 1.06 | 1.18 | 1.19 (DSS) |

| 31-R | 0.69 | 213.2 | TDS | 215.6 | 194.0 | 311.4 | 1.01 | 0.91 | 1.46 | 0.98 (TDS) |

| 32-R | 1.20 | 99.1 | TDS | 103.6 | 93.3 | 103.6 | 1.05 | 0.94 | 1.05 | 1.01 (TDS) |

| 33-R | 0.69 | 157.4 | TDS | 159.2 | 143.3 | 230.0 | 1.01 | 0.91 | 1.46 | 1.01 (DSS) |

| 34-R | 1.20 | 65.5 | DSS | 76.5 | 68.9 | 76.5 | 1.17 | 1.05 | 1.17 | 1.17 (DSS) |

| 35-R | 1.07 | 91.0 | TDS | 99.5 | 89.5 | 99.5 | 1.09 | 0.98 | 1.09 | 0.81 (DSS) |

| 36-R | 1.07 | 103.0 | TDS | 116.0 | 104.4 | 116.0 | 1.13 | 1.01 | 1.13 | 0.91 (DSS) |

| 37-R | 1.03 | 131.0 | TDS | 116.6 | 104.9 | 116.6 | 0.89 | 0.80 | 0.89 | 0.63 (DSS) |

| 38-R | 1.03 | 148.0 | TDS | 136.7 | 123.0 | 136.7 | 0.92 | 0.83 | 0.92 | 0.72 (DSS) |

| 39-R | 0.96 | 141.0 | TDS | 184.5 | 166.1 | 191.6 | 1.31 | 1.18 | 1.36 | 0.95 (DSS) |

| 40-R | 0.96 | 88.0 | DSS | 148.7 | 133.8 | 154.4 | 1.69 | 1.52 | 1.75 | 1.13 (DSS) |

| 41-R | 0.96 | 181.0 | TDS | 165.7 | 149.2 | 172.1 | 0.92 | 0.82 | 0.95 | 0.63 (DSS) |

| 42-R | 1.44 | 67.0 | TDS | 85.2 | 76.7 | 85.2 | 1.27 | 1.14 | 1.27 | 0.92 (DSS) |

| 43-R | 0.72 | 223.0 | DSS | 245.9 | 221.3 | 340.5 | 1.10 | 0.99 | 1.53 | 0.80 (DSS) |

| 44-R | 1.12 | 187.0 | TDS | 209.0 | 188.1 | 209.0 | 1.12 | 1.01 | 1.12 | 1.11 (DSS) |

| 45-R | 1.12 | 178.0 | TDS | 209.0 | 188.1 | 209.0 | 1.17 | 1.06 | 1.17 | 1.16 (DSS) |

| 46-R | 1.12 | 145.0 | TDS | 209.0 | 188.1 | 209.0 | 1.44 | 1.30 | 1.44 | 1.77 (TDS) |

| 47-R | 1.12 | 135.0 | TDS | 221.7 | 199.5 | 221.7 | 1.64 | 1.48 | 1.64 | 0.93 (DSS) |

| 48-R | 1.12 | 154.0 | TDS | 195.5 | 176.0 | 195.5 | 1.27 | 1.14 | 1.27 | 0.82 (DSS) |

| 49-R | 1.59 | 48.0 | DSS | 99.6 | 89.7 | 94.3 | 2.08 | 1.87 | 1.96 | 0.90 (DSS) |

| 50-R | 1.59 | 119.0 | DSS | 131.8 | 118.6 | 124.7 | 1.11 | 1.00 | 1.05 | 0.56 (TDS) |

| 51-R | 1.59 | 164.0 | TDS | 149.4 | 134.5 | 141.4 | 0.91 | 0.82 | 0.86 | 0.46 (TDS) |

| 52-R | 0.79 | 263.0 | DSS | 395.3 | 355.8 | 498.8 | 1.50 | 1.35 | 1.90 | 0.77 (TDS) |

| 53-R | 0.79 | 341.0 | TDS | 448.3 | 403.4 | 565.6 | 1.31 | 1.18 | 1.66 | 0.66 (TDS) |

| 54-R | 1.00 | 124.0 | DDS | 83.7 | 75.4 | 83.7 | 0.68 | 0.61 | 0.68 | - |

| 55-R | 1.00 | 68.0 | DDS | 83.7 | 75.4 | 83.7 | 1.23 | 1.11 | 1.23 | - |

| 56-R | 1.00 | 104.0 | DDS | 83.7 | 75.4 | 83.7 | 0.81 | 0.72 | 0.81 | - |

| 57-R | 1.73 | 160.0 | TDS | 153.7 | 138.3 | 133.4 | 0.96 | 0.86 | 0.83 | - |

| 58-R | 1.73 | 140.0 | DSS | 153.7 | 138.3 | 133.4 | 1.10 | 0.99 | 0.95 | - |

| 59-R | 1.73 | 118.0 | TDS | 153.7 | 138.3 | 133.4 | 1.30 | 1.17 | 1.13 | - |

| 60-R | 1.73 | 147.0 | TDS | 153.7 | 138.3 | 133.4 | 1.05 | 0.94 | 0.91 | - |

| 61-R | 1.73 | 120.0 | TDS | 153.7 | 138.3 | 133.4 | 1.28 | 1.15 | 1.11 | - |

| 62-R | 1.73 | 149.0 | TDS | 153.7 | 138.3 | 133.4 | 1.03 | 0.93 | 0.90 | - |

| 63-R | 1.73 | 60.0 | TDS | 76.8 | 69.1 | 66.7 | 1.28 | 1.15 | 1.11 | - |

| 64-R | 1.73 | 56.0 | TDS | 76.8 | 69.1 | 66.7 | 1.37 | 1.23 | 1.19 | - |

| 65-R | 0.43 | 72.0 | DSS | 148.3 | 133.5 | 171.7 | 2.06 | 1.85 | 2.39 | - |

| 66-R | 1.73 | 150.0 | TDS | 153.7 | 138.3 | 133.4 | 1.02 | 0.92 | 0.89 | - |

| 67-R | 1.73 | 162.0 | TDS | 153.7 | 138.3 | 133.4 | 0.95 | 0.85 | 0.82 | - |

| 68-R | 1.73 | 70.0 | TDS | 76.8 | 69.1 | 66.7 | 1.10 | 0.99 | 0.95 | - |

| 69-R | 1.76 | 91.0 | DSS | 85.4 | 76.9 | 72.8 | 0.94 | 0.84 | 0.80 | - |

| 70-R | 1.76 | 86.0 | TDS | 85.4 | 76.9 | 72.8 | 0.99 | 0.89 | 0.85 | - |

| 71-R | 1.76 | 90.0 | DSS | 81.5 | 73.4 | 69.5 | 0.91 | 0.82 | 0.77 | - |

| 72-R | 1.76 | 98.0 | DSS | 81.5 | 73.4 | 69.5 | 0.83 | 0.75 | 0.71 | - |

| 73-R | 0.88 | 65.0 | DSS | 94.7 | 85.2 | 107.6 | 1.46 | 1.31 | 1.66 | - |

| 74-R | 0.88 | 61.0 | DSS | 94.7 | 85.2 | 107.6 | 1.55 | 1.40 | 1.76 | - |

| 75-R | 1.76 | 49.0 | DSS | 81.5 | 73.4 | 69.5 | 1.66 | 1.50 | 1.42 | - |

| 76-R | 1.00 | 125.0 | DSS | 189.4 | 170.5 | 189.4 | 1.52 | 1.36 | 1.52 | - |

| 77-R | 1.00 | 140.0 | DSS | 189.4 | 170.5 | 189.4 | 1.35 | 1.22 | 1.35 | - |

| 78-R | 1.00 | 230.0 | DSS | 244.6 | 220.1 | 244.6 | 1.06 | 0.96 | 1.06 | - |

| 79-R | 1.00 | 230.0 | DSS | 244.6 | 220.1 | 244.6 | 1.06 | 0.96 | 1.06 | - |

| 80-R | 1.02 | 84.1 | TDS | 53.9 | 48.5 | 53.9 | 0.64 | 0.58 | 0.64 | - |

| 81-R | 0.99 | 61.3 | TDS | 51.2 | 46.1 | 51.5 | 0.84 | 0.75 | 0.84 | - |

| 82-R | 0.97 | 70.8 | TDS | 52.3 | 47.1 | 54.1 | 0.74 | 0.67 | 0.76 | - |

| 83-R | 1.06 | 132.0 | TDS | 139.3 | 125.3 | 139.3 | 1.05 | 0.95 | 1.05 | - |

| 84-R | 0.96 | 82.4 | TDS | 84.9 | 76.4 | 88.3 | 1.03 | 0.93 | 1.07 | - |

| 85-R | 0.96 | 83.0 | TDS | 84.9 | 76.4 | 88.3 | 1.02 | 0.92 | 1.06 | - |

| 86-R | 0.96 | 107.7 | TDS | 124.6 | 112.1 | 129.6 | 1.16 | 1.04 | 1.20 | - |

| 87-R | 0.96 | 124.4 | TDS | 124.6 | 112.1 | 129.6 | 1.00 | 0.90 | 1.04 | - |

| 88-R | 0.96 | 102.4 | TDS | 129.0 | 116.1 | 134.1 | 1.26 | 1.13 | 1.31 | - |

| 89-R | 0.96 | 165.7 | TDS | 180.1 | 162.1 | 187.3 | 1.09 | 0.98 | 1.13 | - |

| 90-R | 1.00 | 22.0 | HSS | 22.4 | 20.2 | 22.4 | 1.02 | 0.92 | 1.02 | - |

| 91-R | 1.00 | 23.0 | HSS | 22.4 | 20.2 | 22.4 | 0.98 | 0.88 | 0.98 | - |

| 92-R | 1.00 | 42.0 | TDS | 39.9 | 36.0 | 39.9 | 0.95 | 0.86 | 0.95 | - |

| 93-R | 1.00 | 49.0 | TDS | 39.9 | 36.0 | 39.9 | 0.82 | 0.73 | 0.82 | - |

| Slenderness | Statistical Values | ρDS Equations (13) and (16) | ρDS Equation (14) | ρDS Equation (15) |

|---|---|---|---|---|

| λ < 1 (23 data) | Mean (−) | 1.23 | 1.10 | 1.45 |

| Stand. Dev. (−) | 0.30 | 0.27 | 0.41 | |

| CoV (%) | 24.2% | 24.2% | 28.1% | |

| 1 ≤ λ ≤ 1.5 (39 data) | Mean (−) | 1.09 | 0.98 | 1.09 |

| Stand. Dev. (−) | 0.20 | 0.18 | 0.20 | |

| CoV (%) | 18.3% | 18.3% | 18.3% | |

| λ > 1.5 (28 data) | Mean (−) | 1.17 | 1.05 | 0.99 |

| Stand. Dev. (−) | 0.29 | 0.26 | 0.27 | |

| CoV (%) | 25.1% | 25.1% | 27.5% | |

| all tests (90 data) | Mean (−) | 1.15 | 1.03 | 1.15 |

| Stand. Dev. (−) | 0.26 | 0.23 | 0.34 | |

| CoV (%) | 22.7% | 22.7% | 29.3% |

| Slenderness | Statistical Values | ρDS Equations (13) and (16)* | ρDS Equation (14)* |

|---|---|---|---|

| λ < 1 (23 data) | Mean (−) | 0.82 | 0.74 |

| Stand. Dev. (−) | 0.20 | 0.18 | |

| CoV (%) | 24.2% | 24.2% | |

| 1 ≤ λ ≤ 1.5 (39 data) | Mean (−) | 0.86 | 0.77 |

| Stand. Dev. (−) | 0.21 | 0.19 | |

| CoV (%) | 24.0% | 24.0% | |

| λ > 1.5 (28 data) | Mean (−) | 1.17 | 1.05 |

| Stand. Dev. (−) | 0.29 | 0.26 | |

| CoV (%) | 25.1% | 25.1% | |

| all tests (90 data) | Mean (−) | 0.94 | 0.85 |

| Stand. Dev. (−) | 0.28 | 0.25 | |

| CoV (%) | 29.3% | 29.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Celano, T.; Argiento, L.U.; Ceroni, F.; Casapulla, C. Literature Review of the In-Plane Behavior of Masonry Walls: Theoretical vs. Experimental Results. Materials 2021, 14, 3063. https://doi.org/10.3390/ma14113063

Celano T, Argiento LU, Ceroni F, Casapulla C. Literature Review of the In-Plane Behavior of Masonry Walls: Theoretical vs. Experimental Results. Materials. 2021; 14(11):3063. https://doi.org/10.3390/ma14113063

Chicago/Turabian StyleCelano, Thomas, Luca Umberto Argiento, Francesca Ceroni, and Claudia Casapulla. 2021. "Literature Review of the In-Plane Behavior of Masonry Walls: Theoretical vs. Experimental Results" Materials 14, no. 11: 3063. https://doi.org/10.3390/ma14113063

APA StyleCelano, T., Argiento, L. U., Ceroni, F., & Casapulla, C. (2021). Literature Review of the In-Plane Behavior of Masonry Walls: Theoretical vs. Experimental Results. Materials, 14(11), 3063. https://doi.org/10.3390/ma14113063