Mechanical Properties and Water Stability of High Ductility Magnesium Phosphate Cement-Based Composites (HDMC)

Abstract

1. Introduction

2. Materials and Methods

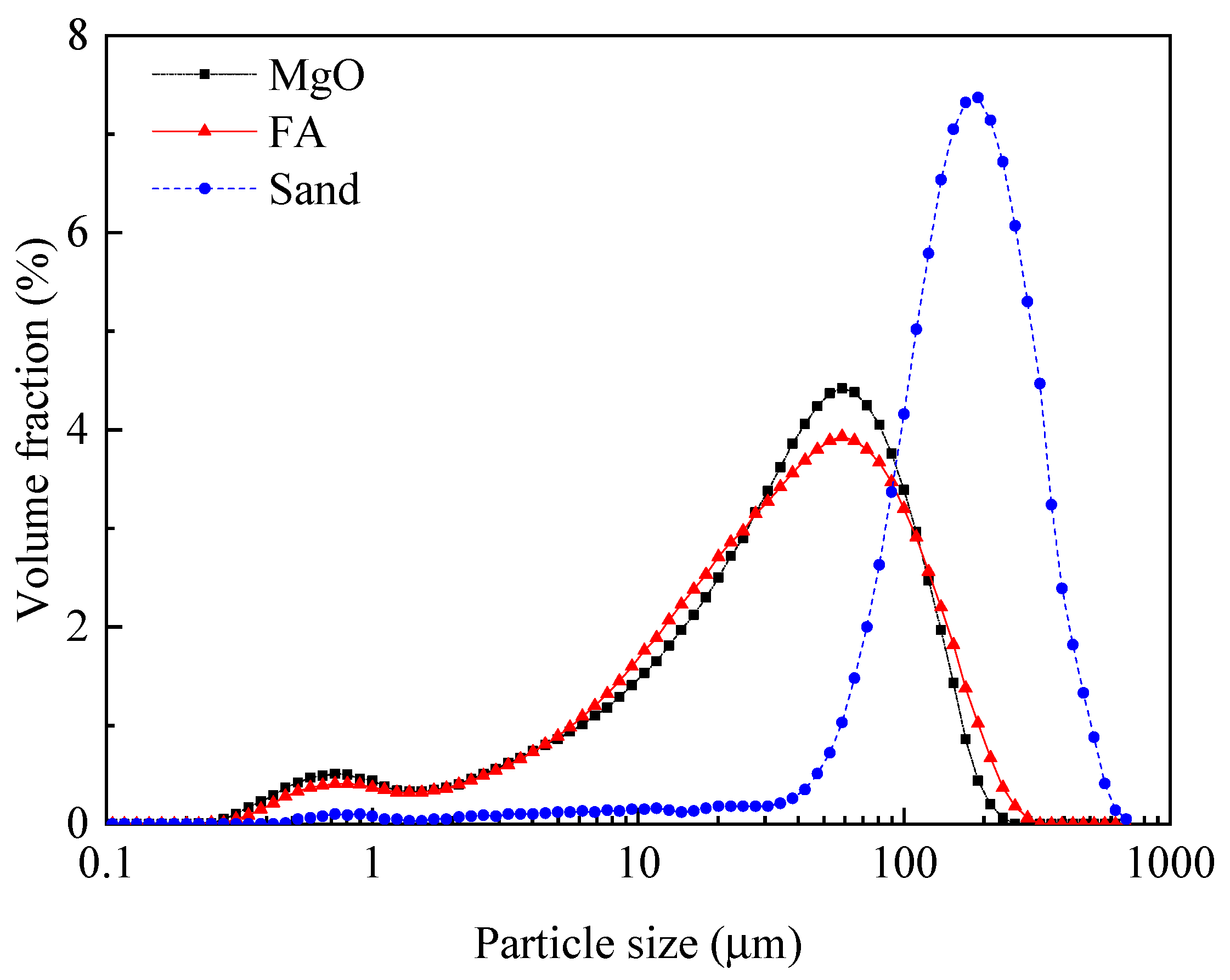

2.1. Raw Materials

2.2. Mix Proportion

2.3. Specimen Preparation

2.4. Test Methods

2.4.1. Compressive Test

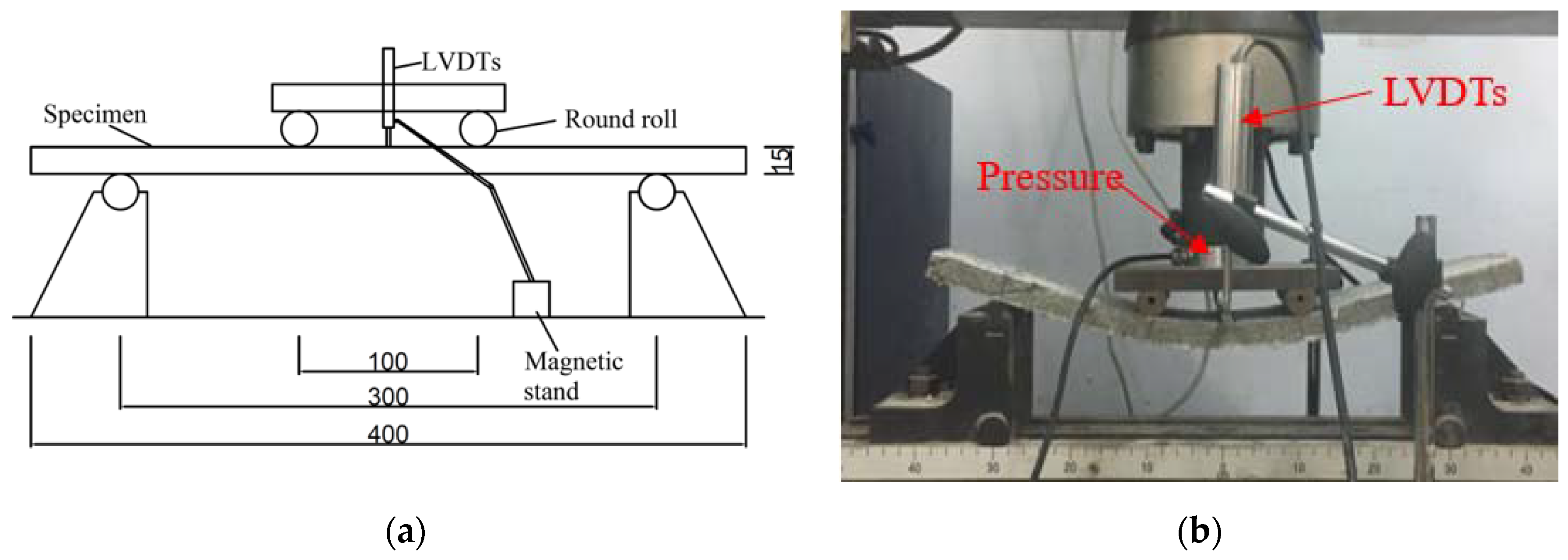

2.4.2. Four-Point Flexural Test

2.4.3. Scanning Electron Microscopy (SEM) Test

2.5. Flexural Performance Evaluation

- (1)

- Strength index

- (2)

- Ductility index

- (3)

- Toughness index

2.6. Water Stability Evaluation

3. Results and Discussion

3.1. Effect of Ambient Curing Age and Water Immersion Age

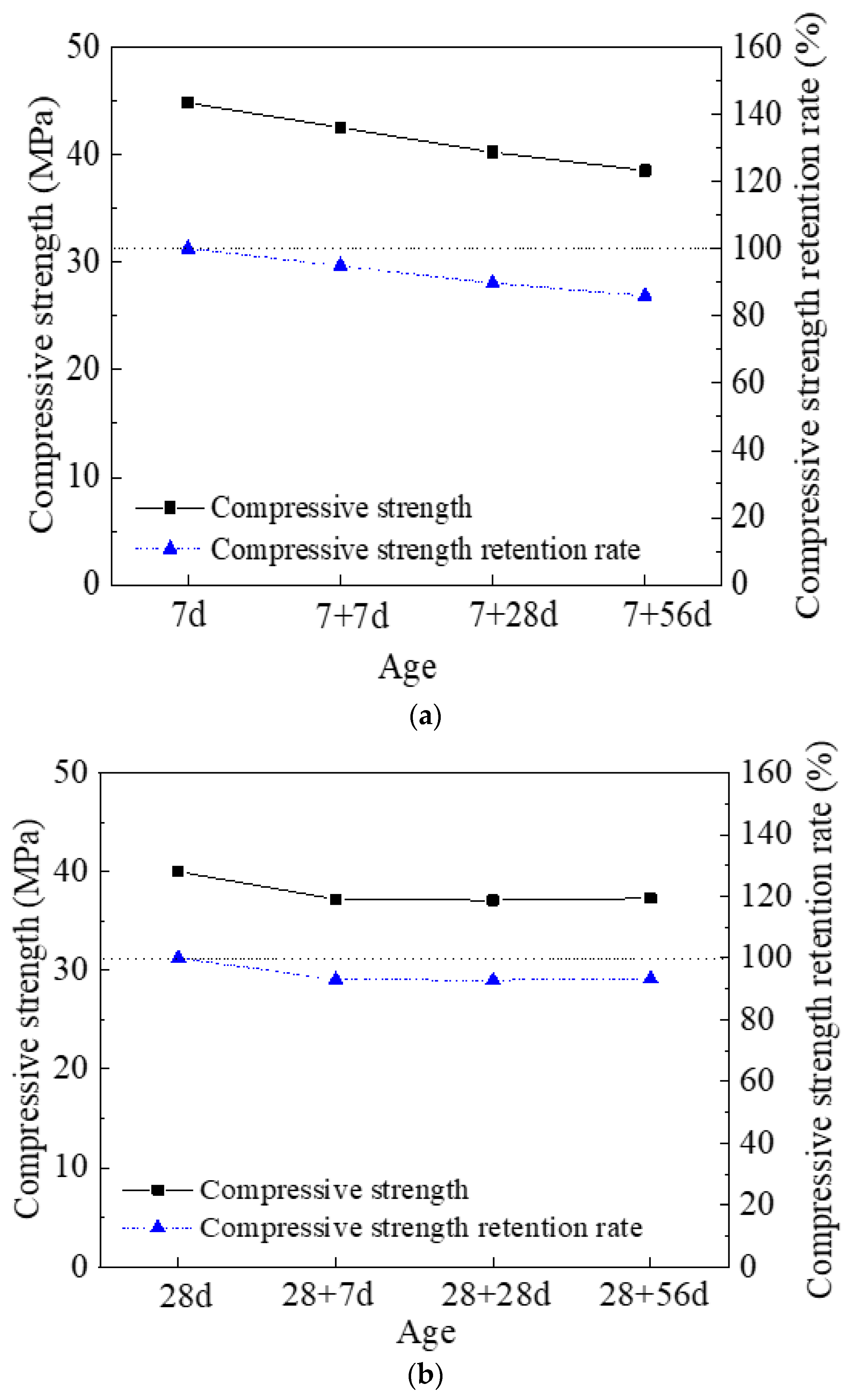

3.1.1. Compressive Strength and Its Retention Rate

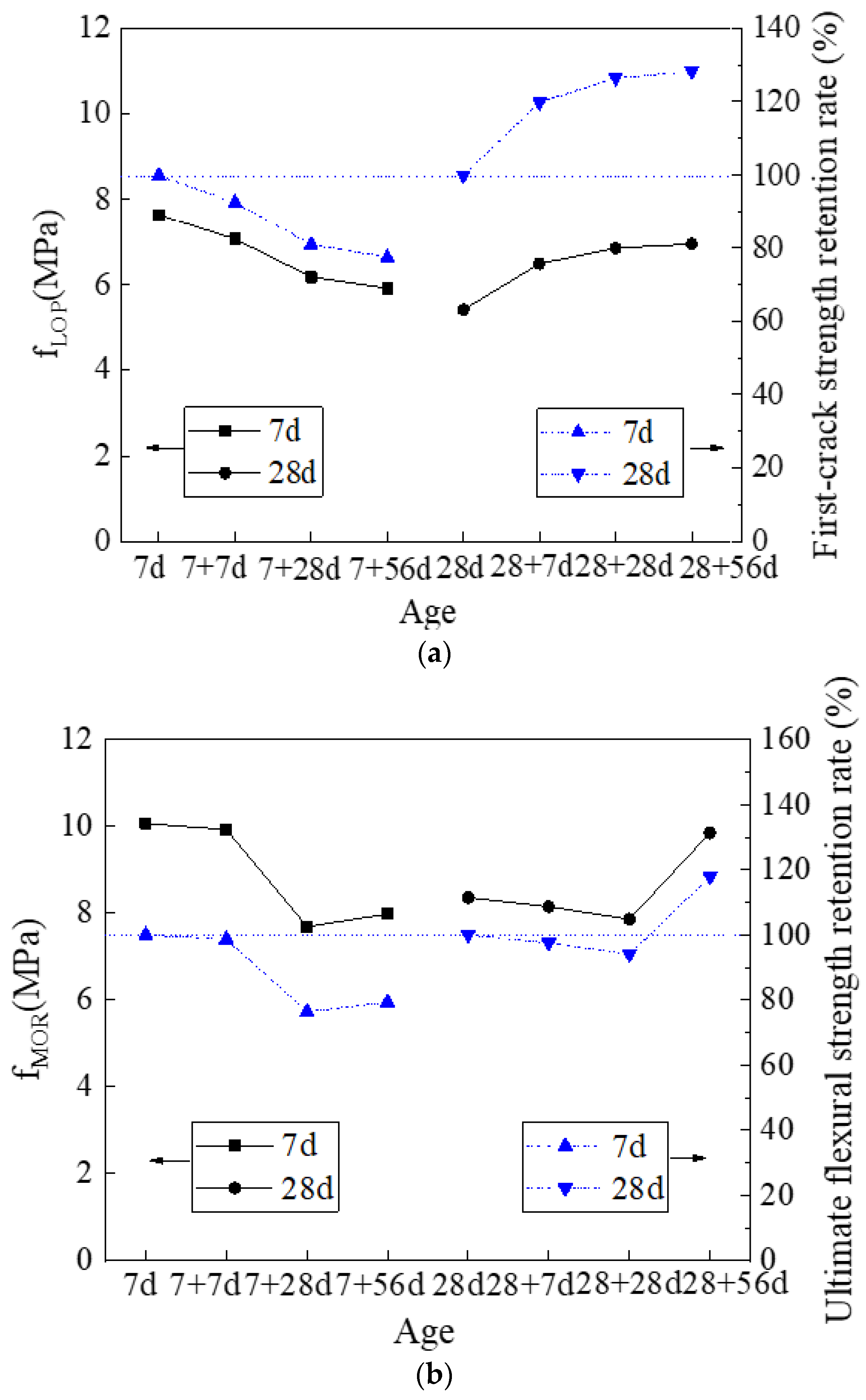

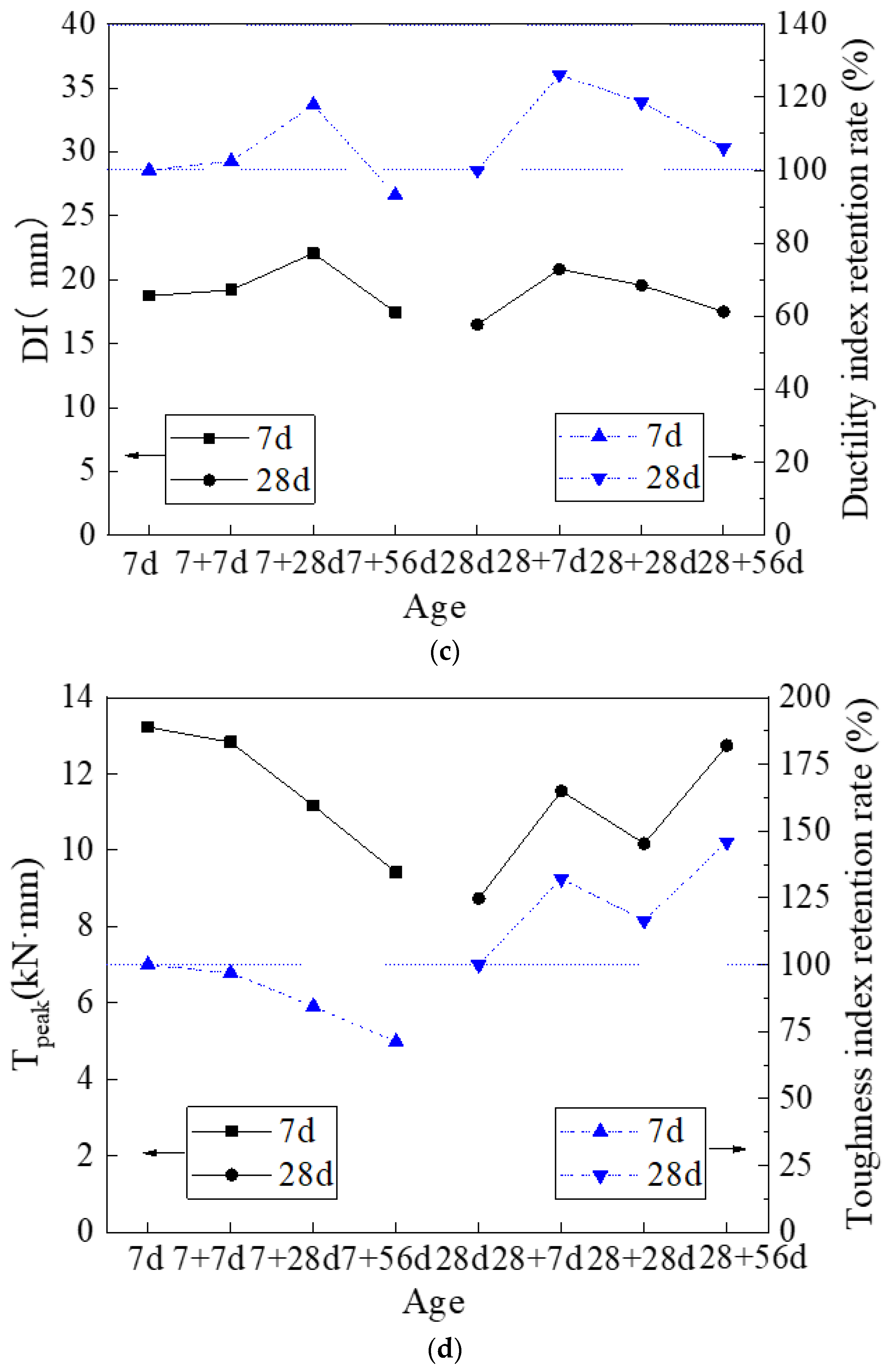

3.1.2. Strength Index, Ductility Index, and Toughness Index and Corresponding Retention Rates

3.2. Effect of Water/Binder (W/B) Ratio

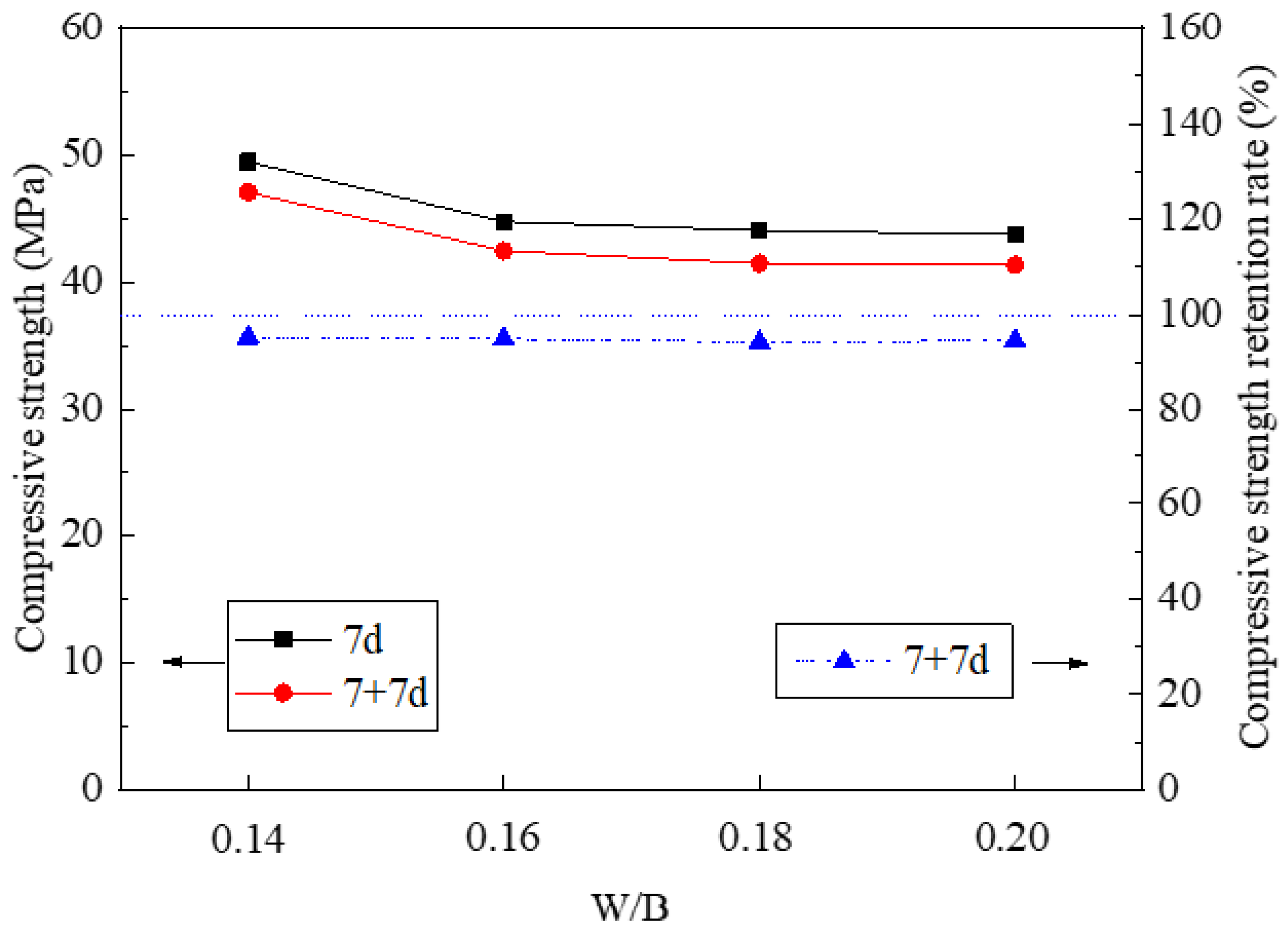

3.2.1. Compressive Strength and Its Retention Rate

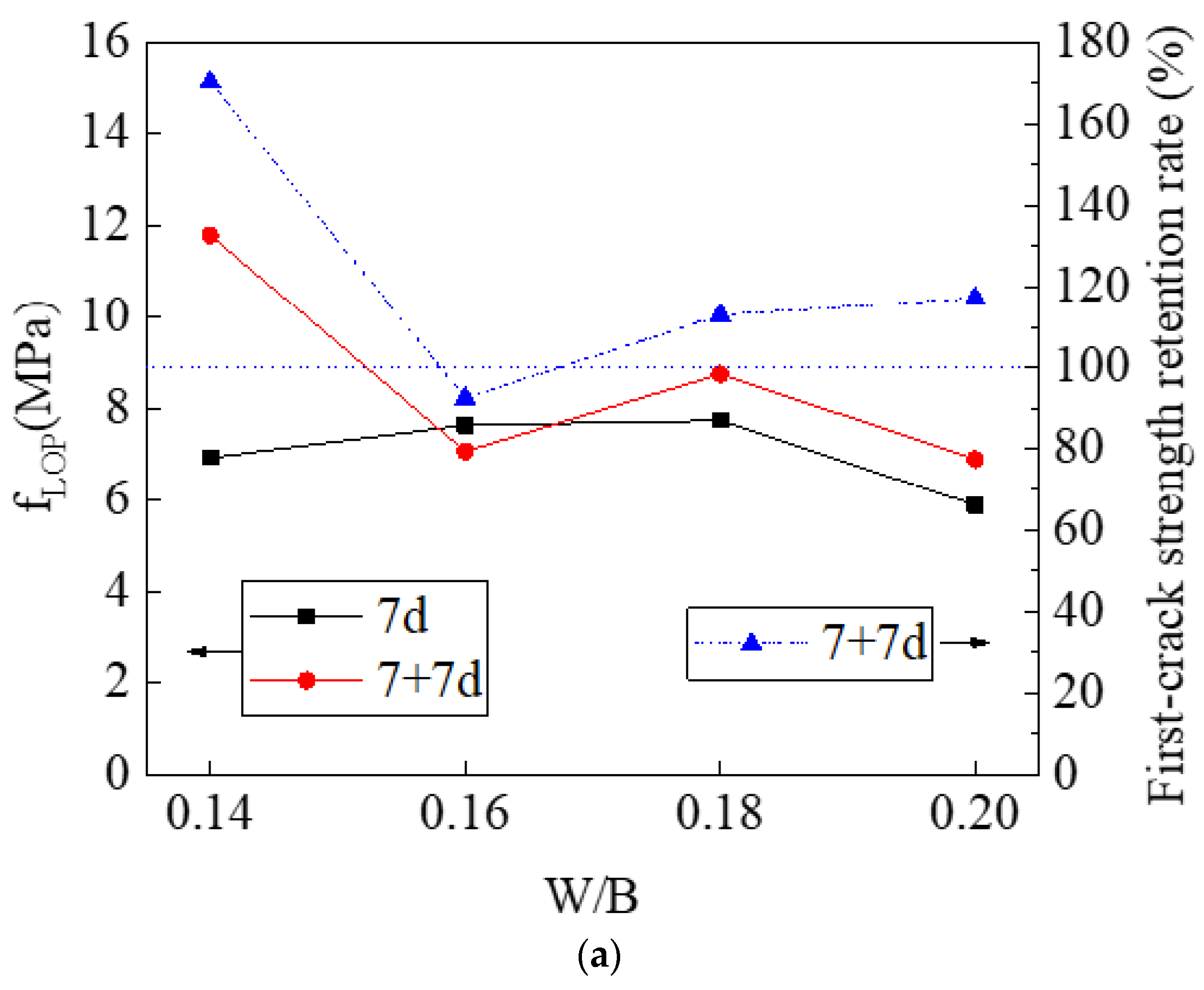

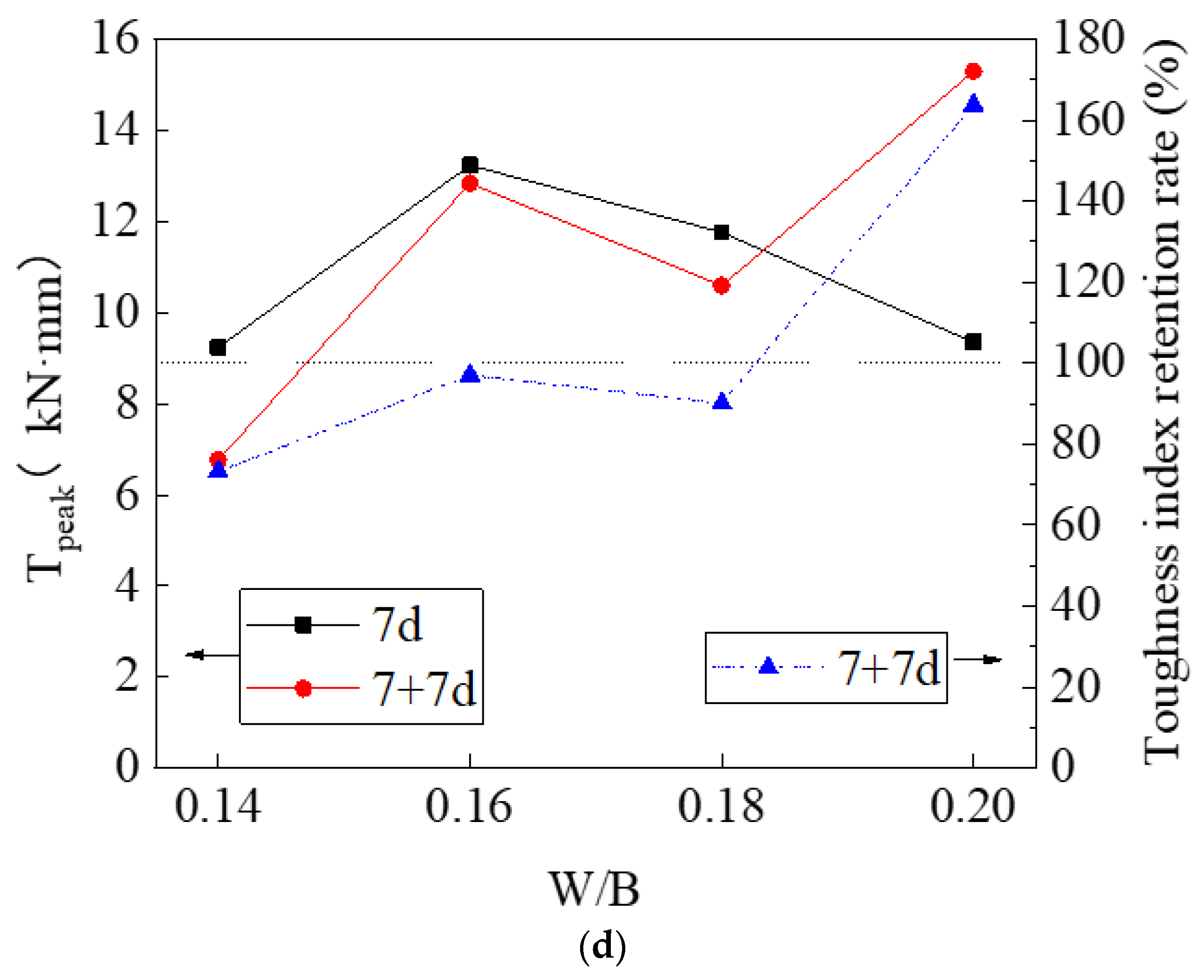

3.2.2. Strength Index, Ductility Index, and Toughness Index and Corresponding Retention Rates

3.3. Effect of M/P Ratio

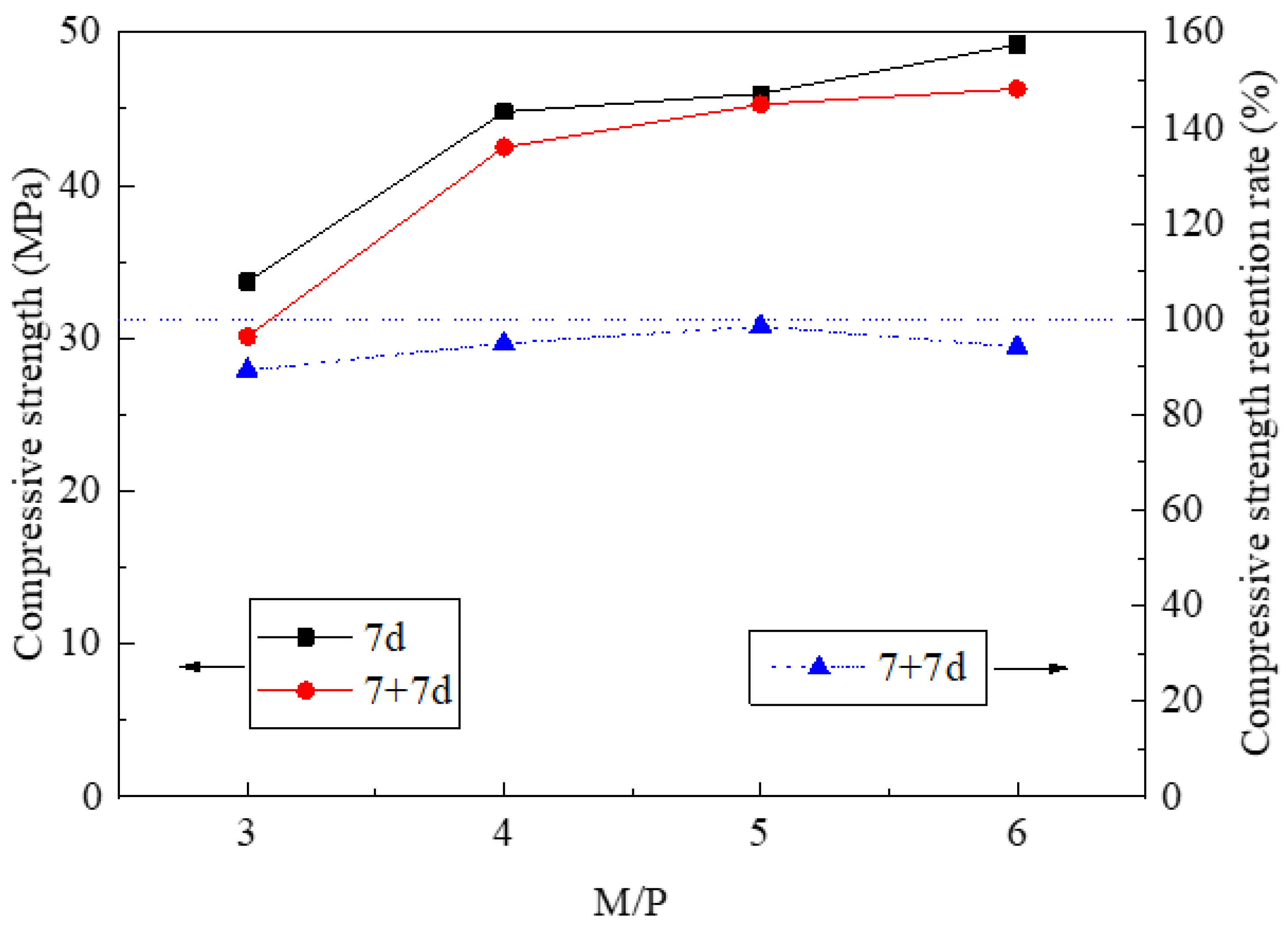

3.3.1. Compressive Strength and Its Retention Rate

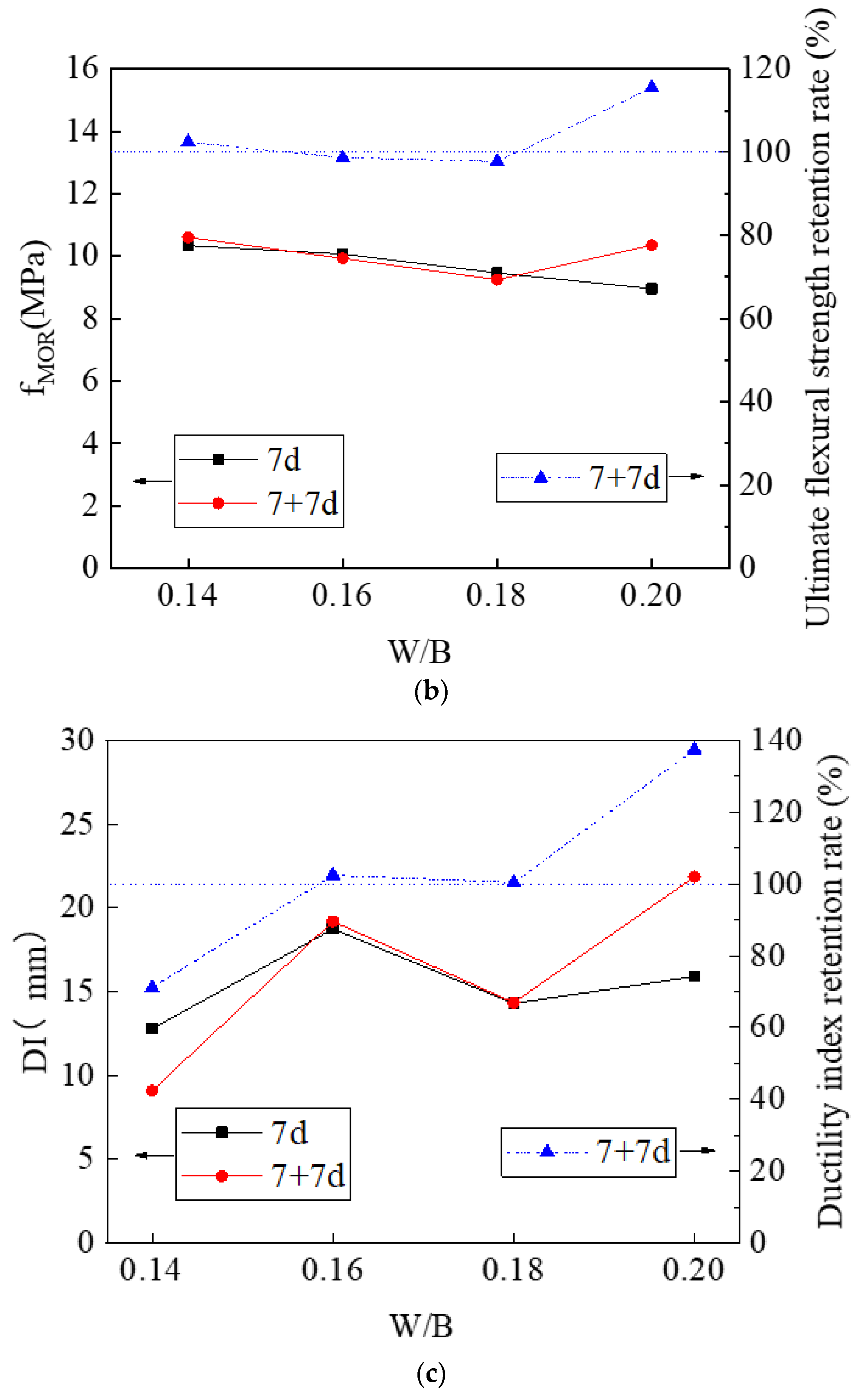

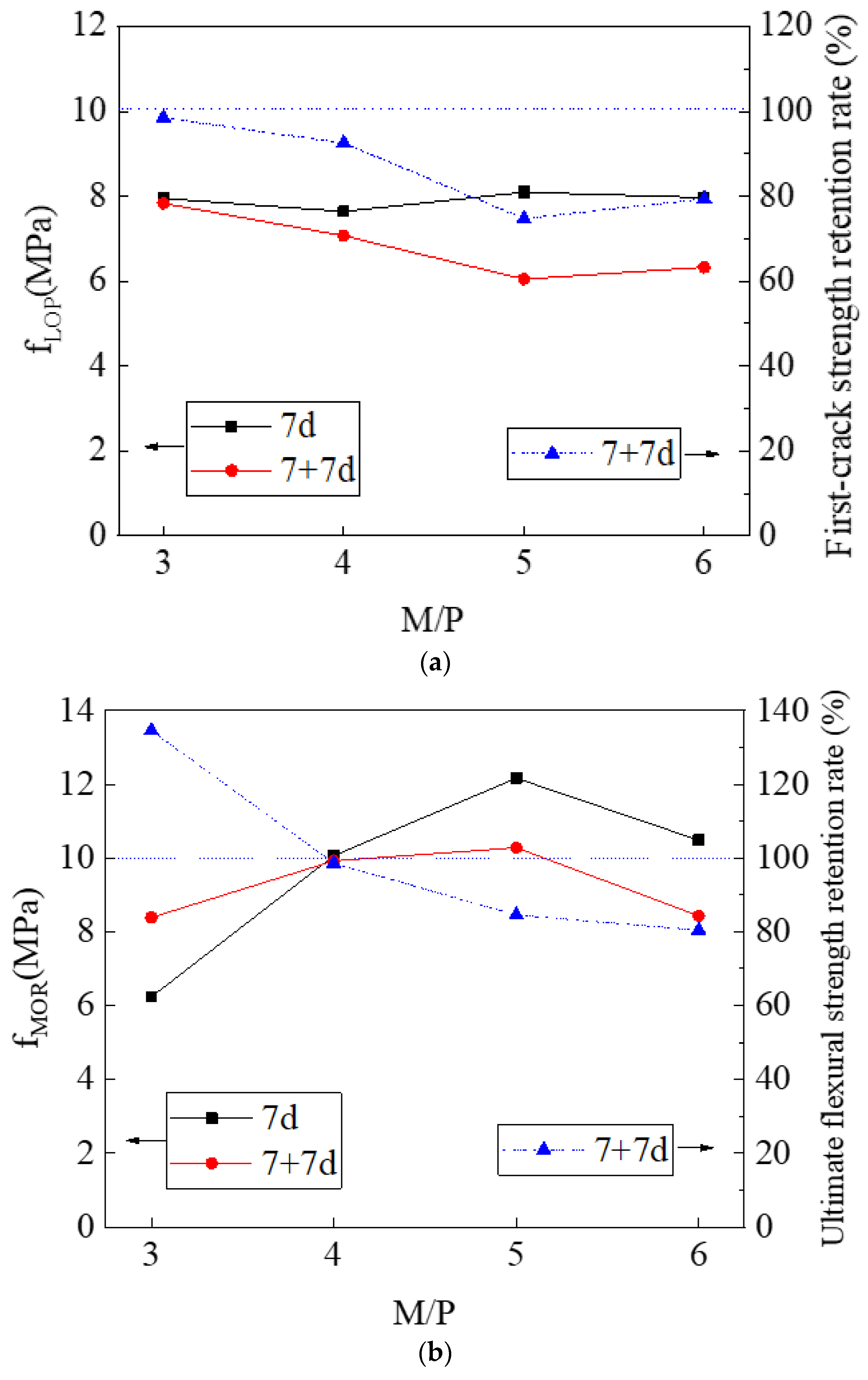

3.3.2. Strength Index, Ductility Index, and Toughness Index and Corresponding Retention Rates

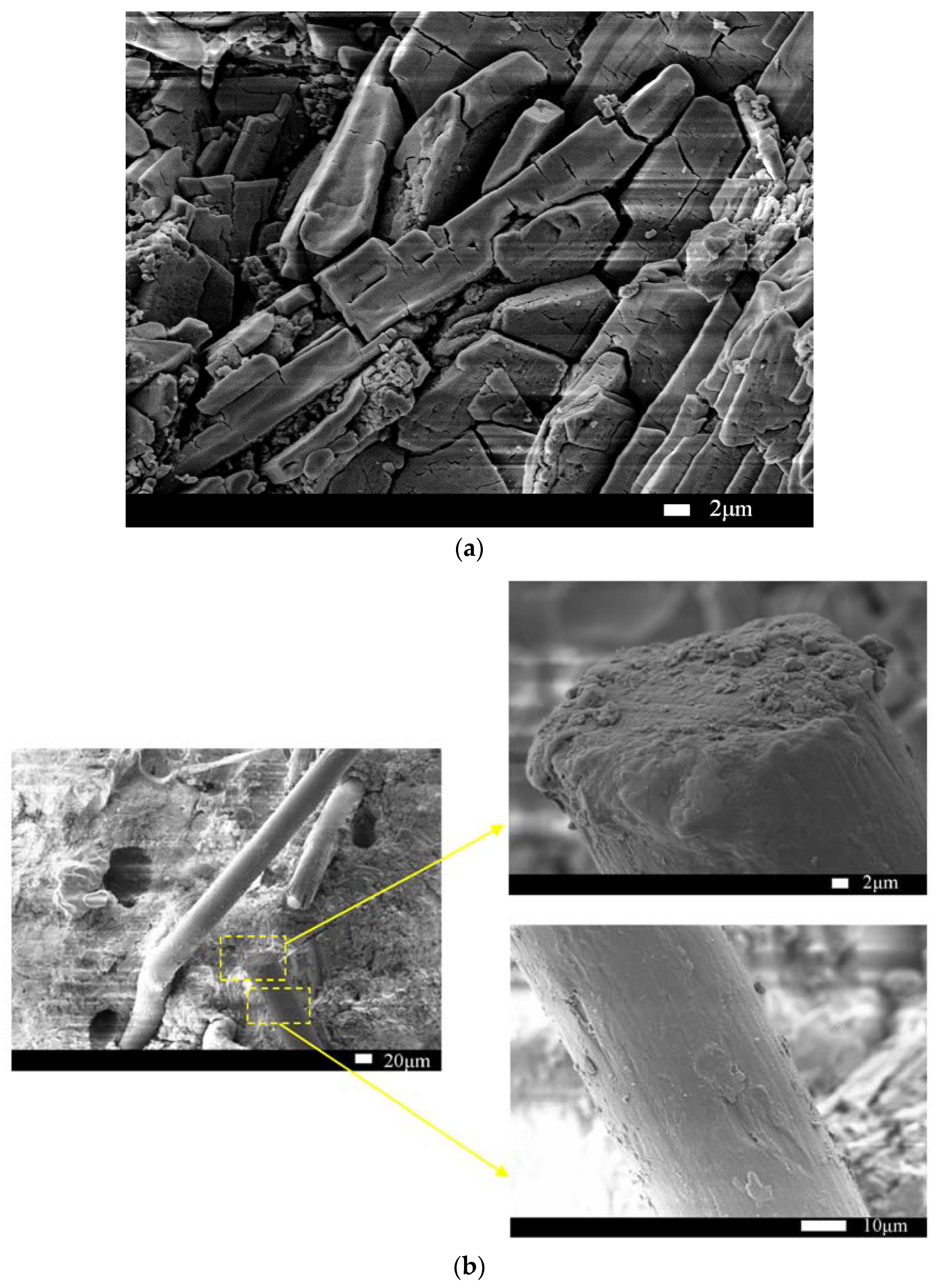

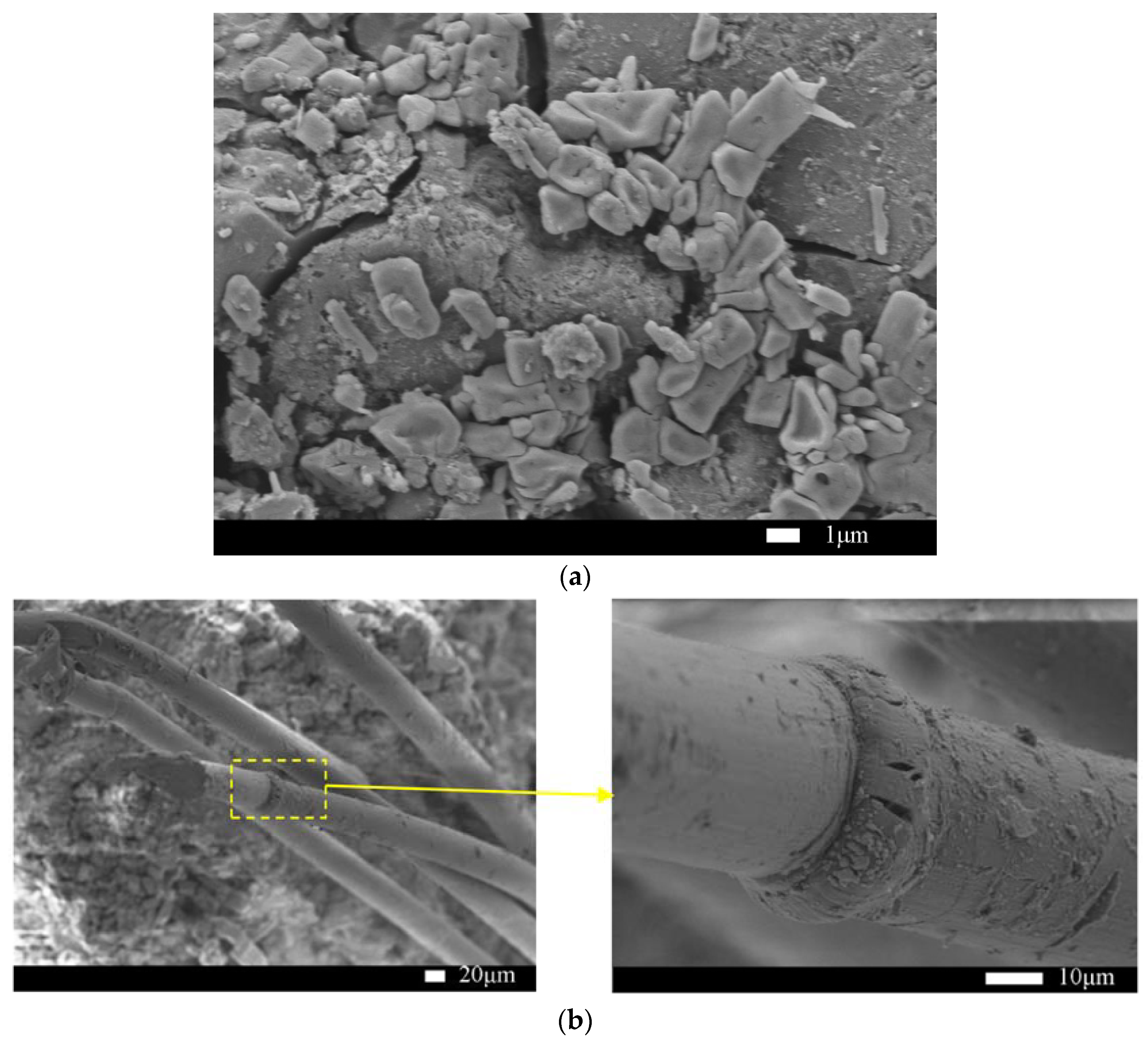

3.4. Microstructure of HDMC

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Buj, I.; Torras, J.; Casellas, D.; Rovira, M.; de Pablo, J. Effect of heavy metals and water content on the strength of magnesium phosphate cements. J. Hazard. Mater. 2009, 170, 345–350. [Google Scholar] [CrossRef]

- Yang, G.; Liu, J.; Li, F.; Pan, Z.; Ni, X.; Shen, Y.; Xu, H.; Huang, Q. Bioactive Calcium Sulfate/Magnesium Phosphate Cement for Bone Substitute Applications. Mater. Sci. Eng. C 2014, 35, 70–76. [Google Scholar] [CrossRef] [PubMed]

- Wagh, A.S.; Jeong, S.Y. Chemically Bonded Phosphate Ceramics: I, A Dissolution Model of Formation. J. Am. Ceram. Soc. 2003, 86, 1838–1844. [Google Scholar] [CrossRef]

- Chau, C.K.; Qiao, F.; Li, Z. Microstructure of magnesium potassium phosphate cement. Constr. Build. Mater. 2011, 25, 2911–2917. [Google Scholar] [CrossRef]

- Qiao, F.; Chau, C.K.; Li, Z. Property evaluation of magnesium phosphate cement mortar as patch repair material. Constr. Build. Mater. 2010, 24, 695–700. [Google Scholar] [CrossRef]

- Buj, I.; Torras, J.; Rovira, M.; de Pablo, J. Leaching behaviour of magnesium phosphate cements containing high quantities of heavy metals. J. Hazard. Mater. 2010, 175, 789–794. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, S.; Ding, J.; Qi, Z. Study on the influent factors of magnesium phosphate cement repair materials abrasion resistance. J. Funct. Mater. 2015, 46, 20068–20072. [Google Scholar]

- Zhang, L.; Zhang, A.; Wang, Q.; Han, Y.; Li, K.; Gao, X.; Tang, Z. Corrosion resistance of wollastonite modified magnesium phosphate cement paste exposed to freeze-thaw cycles and acid-base corrosion. Case Stud. Constr. Mater. 2020, 13, e00421. [Google Scholar] [CrossRef]

- Li, Y.; Shi, T.; Chen, B.; Li, Y. Performance of magnesium phosphate cement at elevated temperatures. Constr. Build. Mater. 2015, 91, 126–132. [Google Scholar] [CrossRef]

- Gao, X.; Zhang, A.; Li, S.; Sun, B.; Zhang, L. The resistance to high temperature of magnesia phosphate cement paste containing wollastonite. Mater. Struct. 2016, 49, 3423–3434. [Google Scholar] [CrossRef]

- Klammert, U.; Vorndran, E.; Reuther, T.; Muller, F.A.; Zorn, K.; Gbureck, U. Low temperature fabrication of magnesium phosphate cement scaffolds by 3D powder printing. J. Mater. Sci.-Mater. Med. 2010, 21, 2947–2953. [Google Scholar] [CrossRef]

- Mestres, G.; Ginebra, M.P. Novel magnesium phosphate cements with high early strength and antibacterial properties. Acta Biomater. 2011, 7, 1853–1861. [Google Scholar] [CrossRef]

- Ding, Z.; Dai, J.; Muner, S. Study on an Improved Phosphate Cement Binder for the Development of Fiber-Reinforced Inorganic Polymer Composites. Polymers 2014, 6, 2819–2831. [Google Scholar] [CrossRef]

- Feng, H.; Sheikh, M.N.; Hadi, M.N.S.; Gao, D.; Zhao, J. Mechanical properties of micro-steel fibre reinforced magnesium potassium phosphate cement composite, mechanical properties of micro-steel fibre reinforced magnesium potassium phosphate cement composite. Constr. Build. Mater. 2018, 185, 423–435. [Google Scholar] [CrossRef]

- Frantzis, P.; Baggott, R. Transition points in steel fiber pullout tests from magnesium phosphate and accelerated calcium aluminates binders. Cem. Concr. Compos. 2003, 25, 11–17. [Google Scholar] [CrossRef]

- Frantzis, P.; Baggott, R. Bond between reinforcing steel fibres and magnesium phosphate/calcium aluminate binders. Cem. Concr. Compos. 2000, 22, 187–192. [Google Scholar] [CrossRef]

- Fang, Y.; Chen, B.; Oderji, S.Y. Experimental research on magnesium phosphate cement mortar reinforced by glass fiber. Constr. Build. Mater. 2018, 188, 729–736. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Shafiq, N.; Ayub, T.; Khan, S.U. Investigating the performance of PVA and basalt fibre reinforced beams subjected to flexural action. Compos. Struct. 2016, 153, 30–41. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B.; Ahmad, M.R.; Shah, S.F.A. Evaluating the physical and strength properties of fibre reinforced magnesium phosphate cement mortar considering mass loss. Constr. Build. Mater. 2019, 217, 427–440. [Google Scholar] [CrossRef]

- Ahmad, M.R.; Chen, B. Effect of silica fume and basalt fiber on the mechanical properties and microstructure of magnesium phosphate cement (MPC) mortar. Constr. Build. Mater. 2018, 190, 466–478. [Google Scholar] [CrossRef]

- Qin, J.; Qian, J.; Li, Z.; You, C.; Dai, X.; Yue, Y.; Fan, Y. Mechanical properties of basalt fiber reinforced magnesium phosphate cement composites. Constr. Build. Mater. 2018, 188, 946–955. [Google Scholar] [CrossRef]

- Pera, J.; Ambroise, J. Fiber-reinforced Magnesia-phosphate Cement Composites for Rapid Repair. Cem. Concr. Compos. 1998, 20, 31–39. [Google Scholar] [CrossRef]

- Meng, D.; Huang, T.; Zhang, Y.X.; Lee, C.K. Mechanical behaviour of a polyvinyl alcohol fibre reinforced engineered cementitious composite (PVA-ECC) using local ingredients. Constr. Build. Mater. 2017, 141, 259–270. [Google Scholar] [CrossRef]

- Yang, E.H.; Wang, S.X.; Yang, Y.Z.; Li, V.C. Fiber-bridging constitutive law of engineered cementitious composites. J. Adv. Concr. Technol. 2008, 6, 181–193. [Google Scholar] [CrossRef]

- Noushini, A.; Samali, B.; Vessalas, K. Effect of polyvinyl alcohol (PVA) fibre on dynamic and material properties of fibre reinforced concrete. Constr. Build. Mater. 2013, 49, 374–383. [Google Scholar] [CrossRef]

- Thong, C.C.; Teo, D.C.L.; Ng, C.K. Application of polyvinyl alcohol (PVA) in cement-based composite materials: A review of its engineering properties and microstructure behavior. Constr. Build. Mater. 2016, 107, 172–180. [Google Scholar] [CrossRef]

- Lee, H.; Lee, I.; Lee, J.; Oh, H. A experimental study on the hardening and shrinkage characteristics at early age of fiber reinforced MPC mortar. J. Korean Soc. Hazard Mitig. 2017, 17, 225–234. [Google Scholar] [CrossRef]

- Wang, L.; Yu, I.K.M.; Tsang, D.C.W.; Yu, K.; Li, S.; Poon, C.S.; Dai, J. Upcycling wood waste into fibre-reinforced magnesium phosphate cement particleboards. Constr. Build. Mater. 2018, 159, 54–63. [Google Scholar] [CrossRef]

- Li, Y.; Chen, B. Factors that affect the properties of magnesium phosphate cement. Constr. Build. Mater. 2013, 47, 977–983. [Google Scholar] [CrossRef]

- Li, D.; Li, P.; Feng, C. Research on water resistance of magnesium phosphate cement. J. Build. Mater. 2009, 12, 505–510. [Google Scholar]

- Liu, K.; Jiang, F.; Zhang, C.; Zhang, B.; Li, D. Failure mechanism of dipotassium hydrogen phosphate modified magnesia—Phosphate cements under water curing condition. J. Chin. Ceram. Soc. 2012, 40, 1693–1698. [Google Scholar]

- Chong, L.; Yang, J.; Shi, C. Effect of curing regime on water resistance of magnesium-potassium phosphate cement. Constr. Build. Mater. 2017, 151, 43–51. [Google Scholar] [CrossRef]

- Wang, H. Study on the High Performance Magnesia-Phosphate Cement Based Composites; Chongqing University: Chongqing, China, 2006. [Google Scholar]

- Hou, D.; Yan, H.; Zhang, J.; Wang, P.; Li, Z. Experimental and computational investigation of magnesium phosphate cement mortar. Constr. Build. Mater. 2016, 112, 331–342. [Google Scholar] [CrossRef]

- Ma, H.; Xu, B.; Liu, J.; Pei, H.; Li, Z. Effects of water content, magnesia-to-phosphate molar ratio and age on pore structure, strength and permeability of magnesium potassium phosphate cement paste. Mater. Des. 2014, 64, 497–502. [Google Scholar] [CrossRef]

- Ding, Z.; Li, Z. Effect of aggregates and water contents on the properties of magnesium phospho-silicate cement. Cem. Concr. Compos. 2005, 27, 11–18. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, J.; Li, J.; Ma, A.; Liu, L. Effect of liquid-to-solid ratios on the properties of magnesium phosphate chemically bonded ceramics. Mater. Sci. Eng. C 2013, 33, 2508–2512. [Google Scholar] [CrossRef]

- Zheng, D.; Ji, T.; Wang, C.; Sun, C.; Lin, X.; Hossain, K.M.A. Effect of the combination of fly ash and silica fume on water resistance of Magnesium–Potassium Phosphate Cement. Constr. Build. Mater. 2016, 106, 415–421. [Google Scholar] [CrossRef]

- Huanai Magnesium Industry Co., Ltd of Yancheng, Jiangsu, China. Available online: http://2528445.b2b.liebiao.com/ (accessed on 13 November 2019). (In Chinese).

- Dingshengxin Chemical Co., Ltd of Tianjin, China. Available online: http://www.dsxhg.com/ (accessed on 13 November 2019). (In Chinese).

- Weitong Chemical Co., Ltd of Wujiang, Jiangsu, China. Available online: https://wjwthg1818.1688.com/ (accessed on 13 November 2019). (In Chinese).

- Banda Technology Co., Ltd. of Liaoning, China. Available online: http://www.lnpdkj.com/ (accessed on 13 November 2019). (In Chinese).

- ASTM C109. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Xu, S.; Cai, X. Experimental study on mechanical properties of ultra-high toughness fiber reinforced cementitious composite. J. Hydraul. Eng. 2009, 40, 1055–1063. [Google Scholar]

- ASTM C1018-97. Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Sun, C.; Lin, X.; Ji, T. Influence of the ratio of KH2PO4 to MgO, ratio of water to bind, content change of borax on water resistance of magnesium-potassium phosphate cement. J. Fuzhou Univ. (Nat. Sci. Ed.) 2016, 44, 856–862. [Google Scholar]

- Yang, J. Control on Setting Time and Water Stability of Magnesium-Potassium Phosphate Cement and Mechanism; Southeast University: Nanjing, China, 2011. [Google Scholar]

| Chemical Composition | Mass Percent (%) |

|---|---|

| MgO | ≧96 |

| Fe2O3 | ≦0.18 |

| SiO2 | ≦1.4 |

| CaO | ≦1.4 |

| Al2O3 | ≦0.3 |

| Raw Materials | Particle Size (μm) | Specific Surface Area (m2/kg) | Appearance | Purity | Manufacturer |

|---|---|---|---|---|---|

| M | - | 315.7 | Light yellow powder | ≥96% | Huanai [40] |

| Coarse P | 425–600 | - | White crystal | ≥99% | Dingshengxin [41] |

| Fine P | 180–315 | - | White crystal | ≥99% | Weitong [42] |

| B | - | - | White powder | ≥99.5% | Banda [43] |

| SiO2 Percent | Bulk Density | Mohs Hardness | Porosity | Specific Gravity |

|---|---|---|---|---|

| 99.3% | 1.8 g/cm3 | 7.5 | 43% | 2.66 g/cm3 |

| Chemical Composition | Mass Percent (%) |

|---|---|

| SiO2 | 53.97 |

| Al2O3 | 31.15 |

| Fe2O3 | 4.16 |

| CaO | 4.01 |

| MgO | 1.01 |

| Na2O | 0.89 |

| Diameter (μm) | Length (mm) | Tensile Strength (MPa) | Modulus of Elasticity (GPa) | Elongation at Break (%) | Density (g/cm3) |

|---|---|---|---|---|---|

| 40 | 12 | 1560 | 41 | 6.5 | 1.3 |

| W/B | M/P | S/B | Fly Ash Content | Borax Dosage | Fiber Volume Fraction |

|---|---|---|---|---|---|

| 0.14 | 4 | 0.2 | 20% | 6% | 1.6% |

| 0.16 | |||||

| 0.18 | |||||

| 0.20 | |||||

| 0.16 | 3 | 0.2 | 20% | 6% | 1.6% |

| 4 | |||||

| 5 | |||||

| 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, H.; Wang, Y.; Guo, A.; Zhao, X. Mechanical Properties and Water Stability of High Ductility Magnesium Phosphate Cement-Based Composites (HDMC). Materials 2021, 14, 3169. https://doi.org/10.3390/ma14123169

Feng H, Wang Y, Guo A, Zhao X. Mechanical Properties and Water Stability of High Ductility Magnesium Phosphate Cement-Based Composites (HDMC). Materials. 2021; 14(12):3169. https://doi.org/10.3390/ma14123169

Chicago/Turabian StyleFeng, Hu, Yang Wang, Aofei Guo, and Xiangyu Zhao. 2021. "Mechanical Properties and Water Stability of High Ductility Magnesium Phosphate Cement-Based Composites (HDMC)" Materials 14, no. 12: 3169. https://doi.org/10.3390/ma14123169

APA StyleFeng, H., Wang, Y., Guo, A., & Zhao, X. (2021). Mechanical Properties and Water Stability of High Ductility Magnesium Phosphate Cement-Based Composites (HDMC). Materials, 14(12), 3169. https://doi.org/10.3390/ma14123169