Self-Healing Performance Evaluation of Concrete Incorporating Inorganic Materials Based on a Water Permeability Test

Abstract

:1. Introduction

2. Self-Healing Performance Evaluation

2.1. Self-Healing Performance Evaluation Based on a Water Permeability Test

2.2. Correlation between Crack Width and Water Flow Rate of Cracked Mortar Specimens

2.3. Evaluation of Self-Healing Performance Using the Water Permeability Test

3. Experimental Works

3.1. Test Plan

3.2. Materials and Mixture Proportions

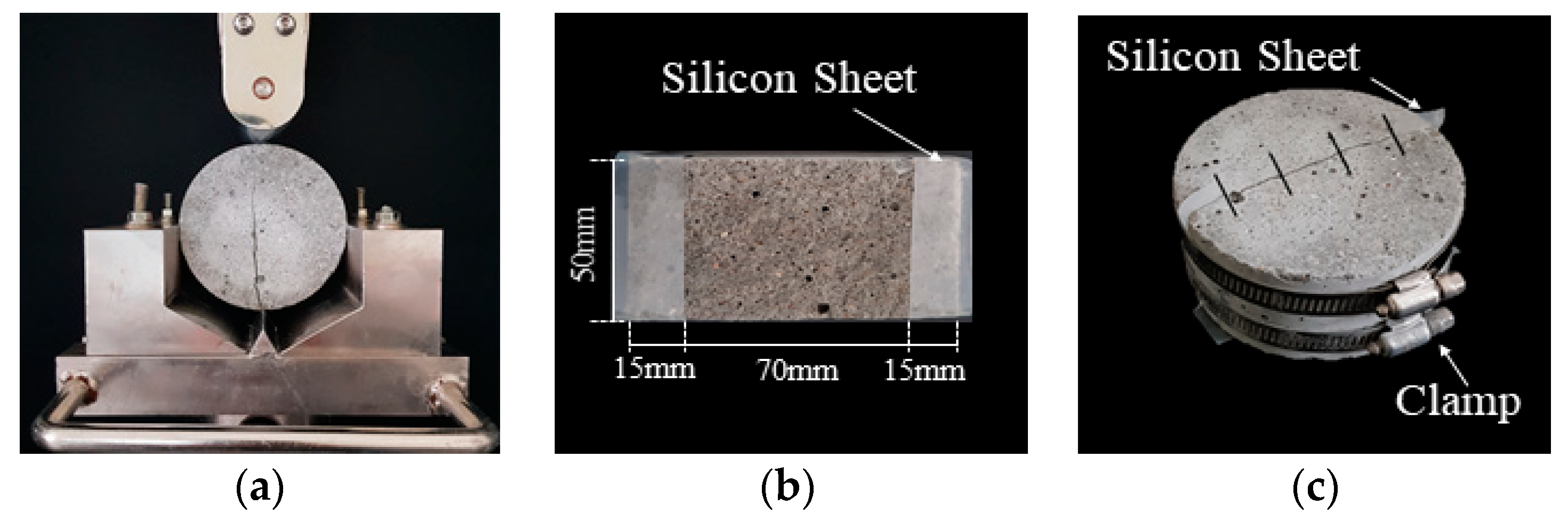

3.3. Preparation of Test Specimens

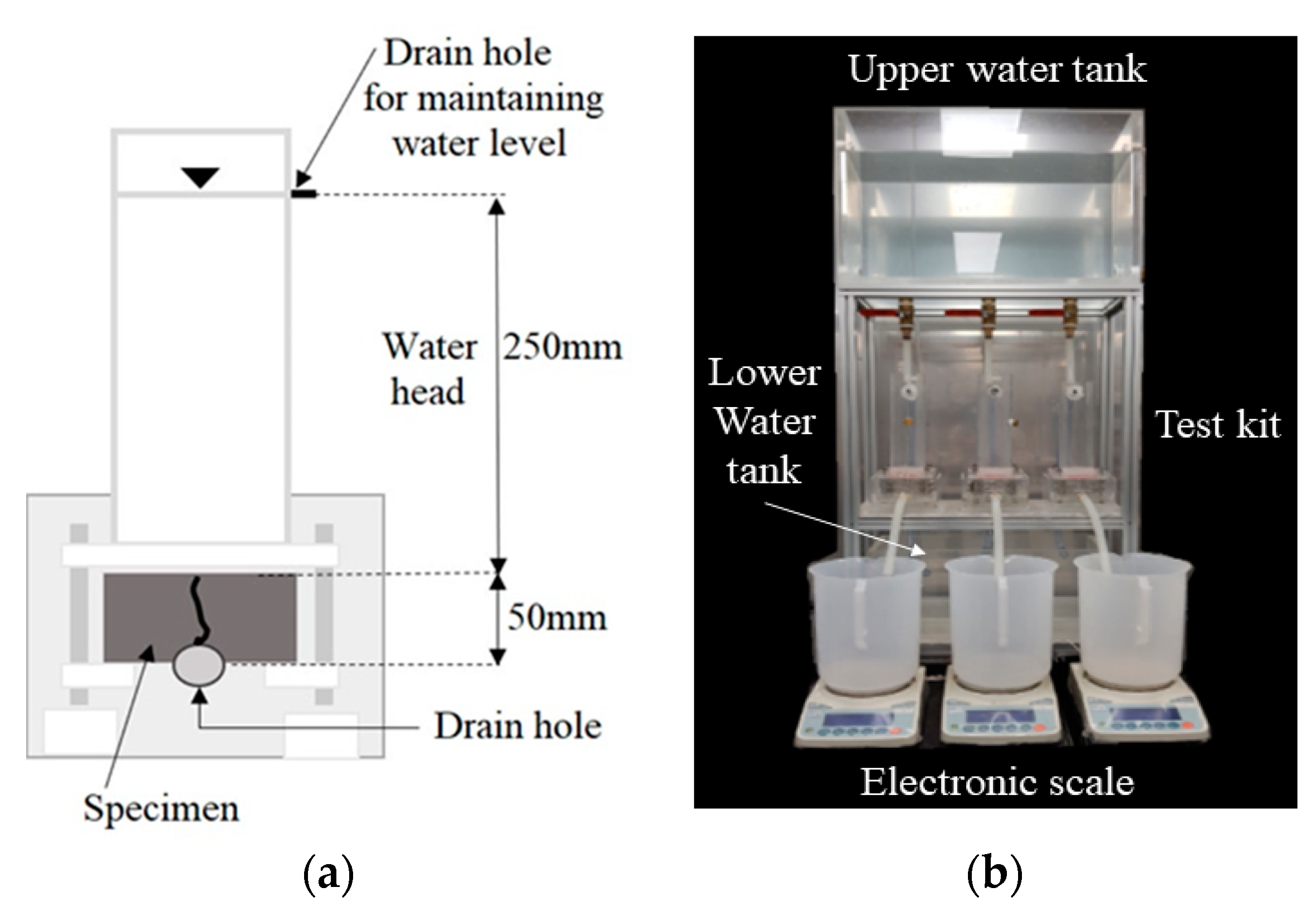

3.4. Water Permeability Test Method

4. Experimental Results and Discussion

4.1. Fundamental Properties

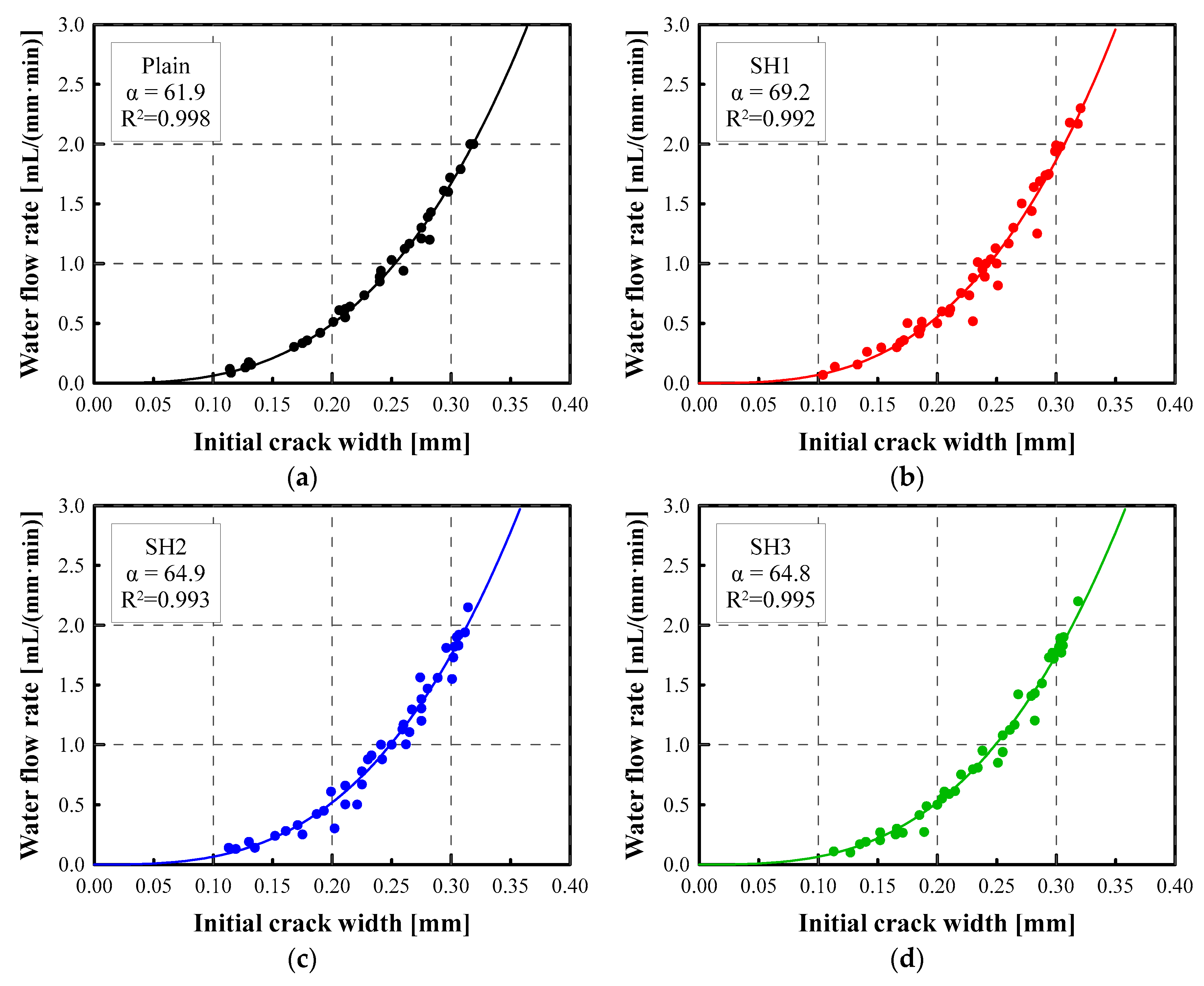

4.2. Correlation between Crack Width and Water Flow Rate

4.3. Evaluation of Self-Healing Performance

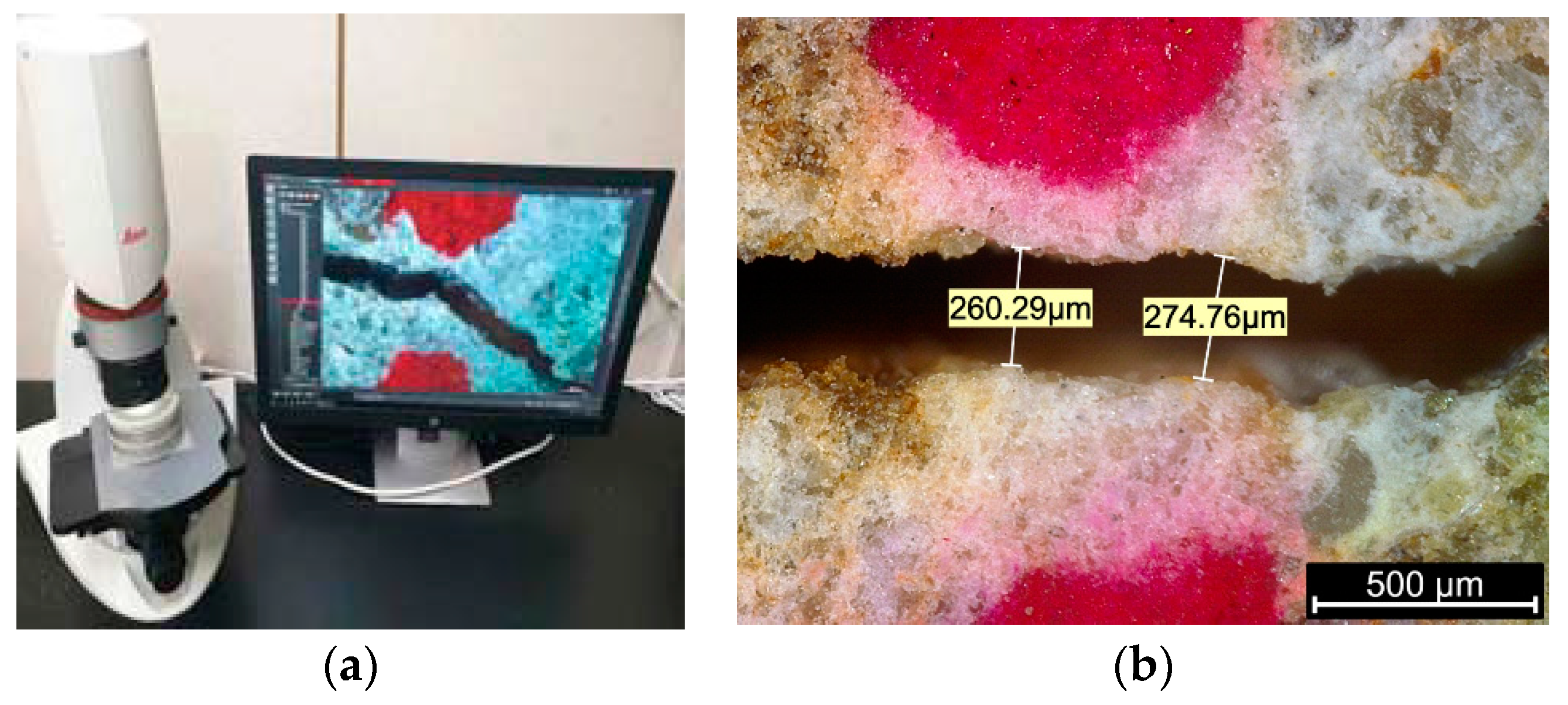

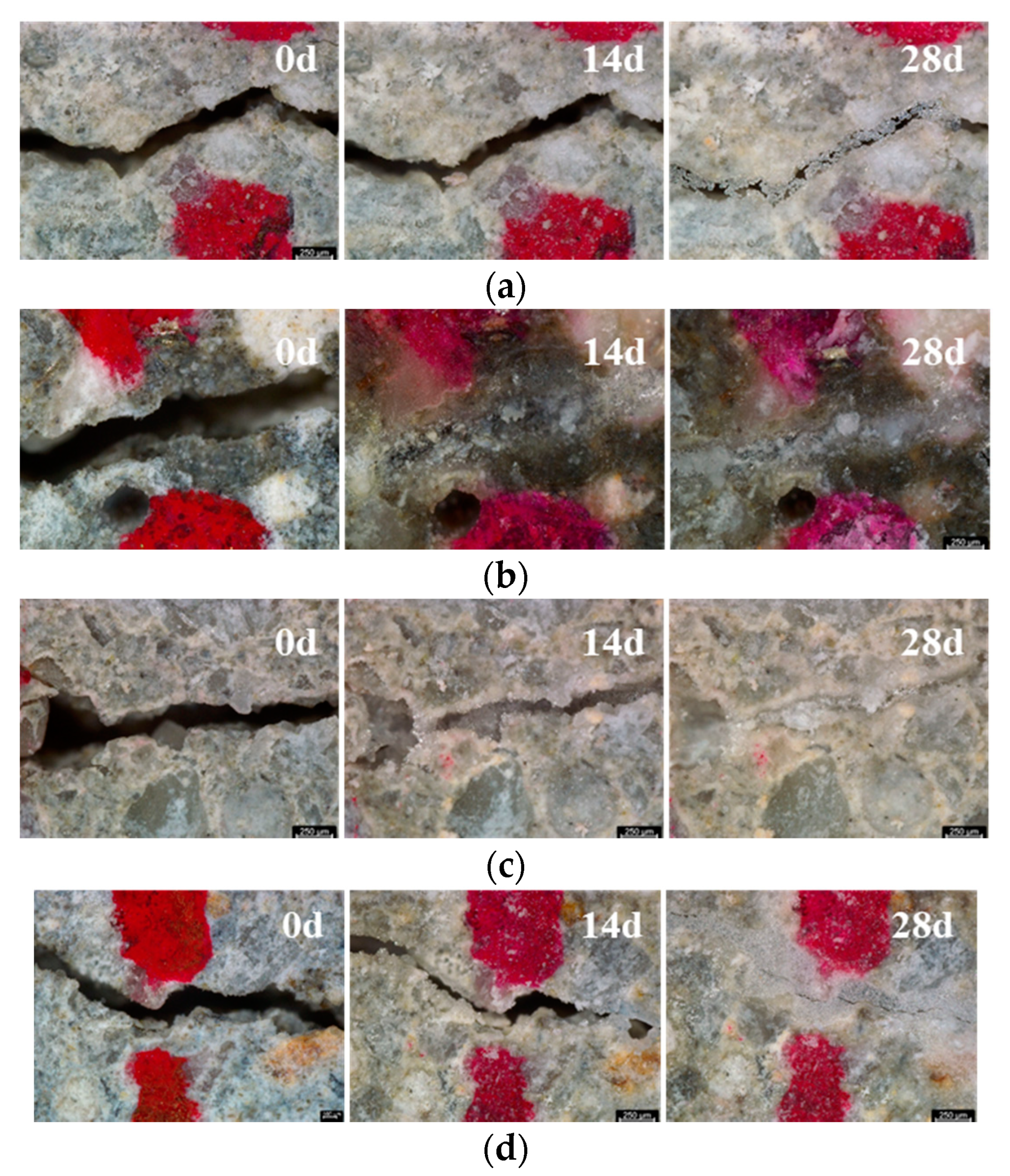

4.3.1. Optical Observation of the Healing Phenomena

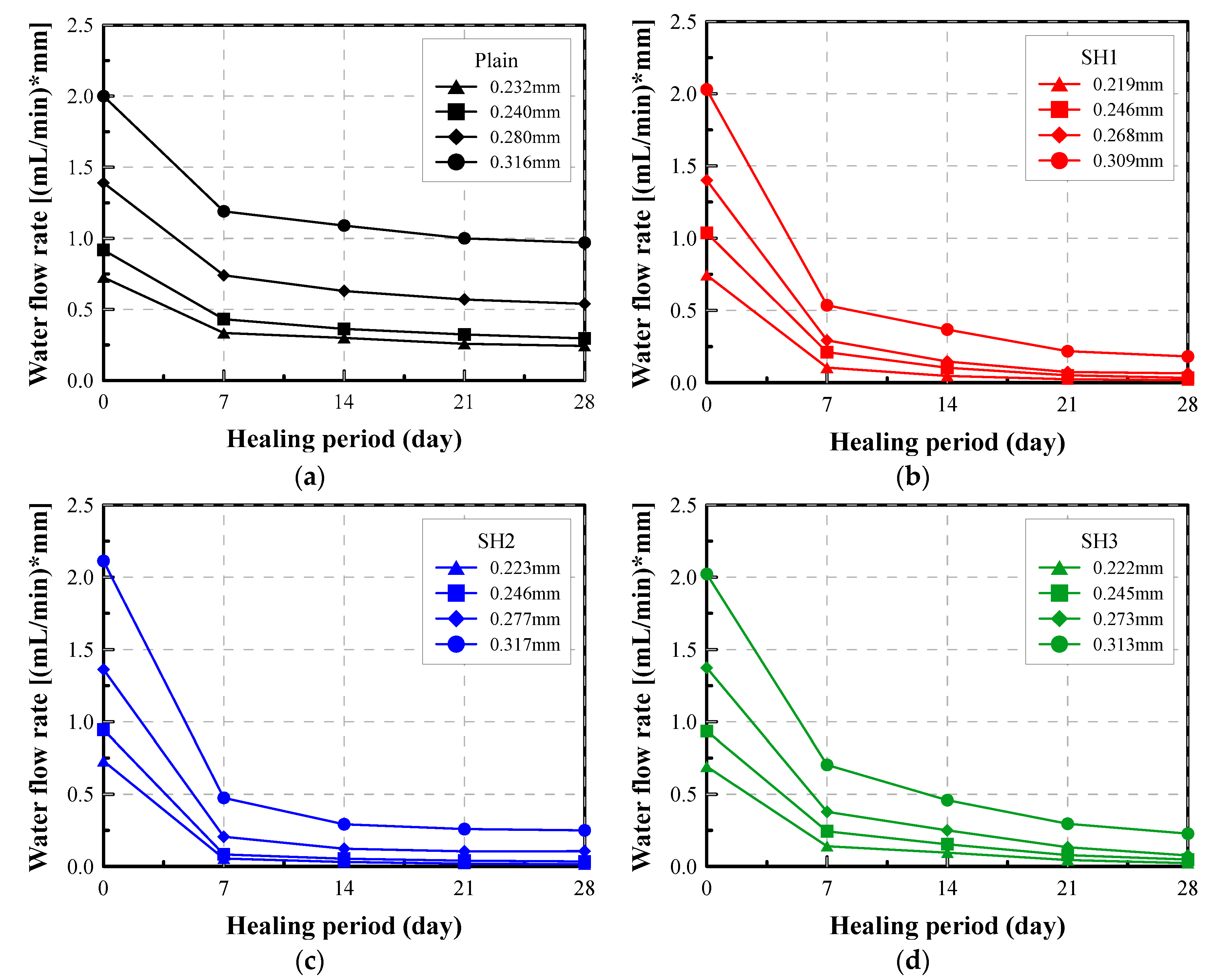

4.3.2. Measurement of Water Permeability

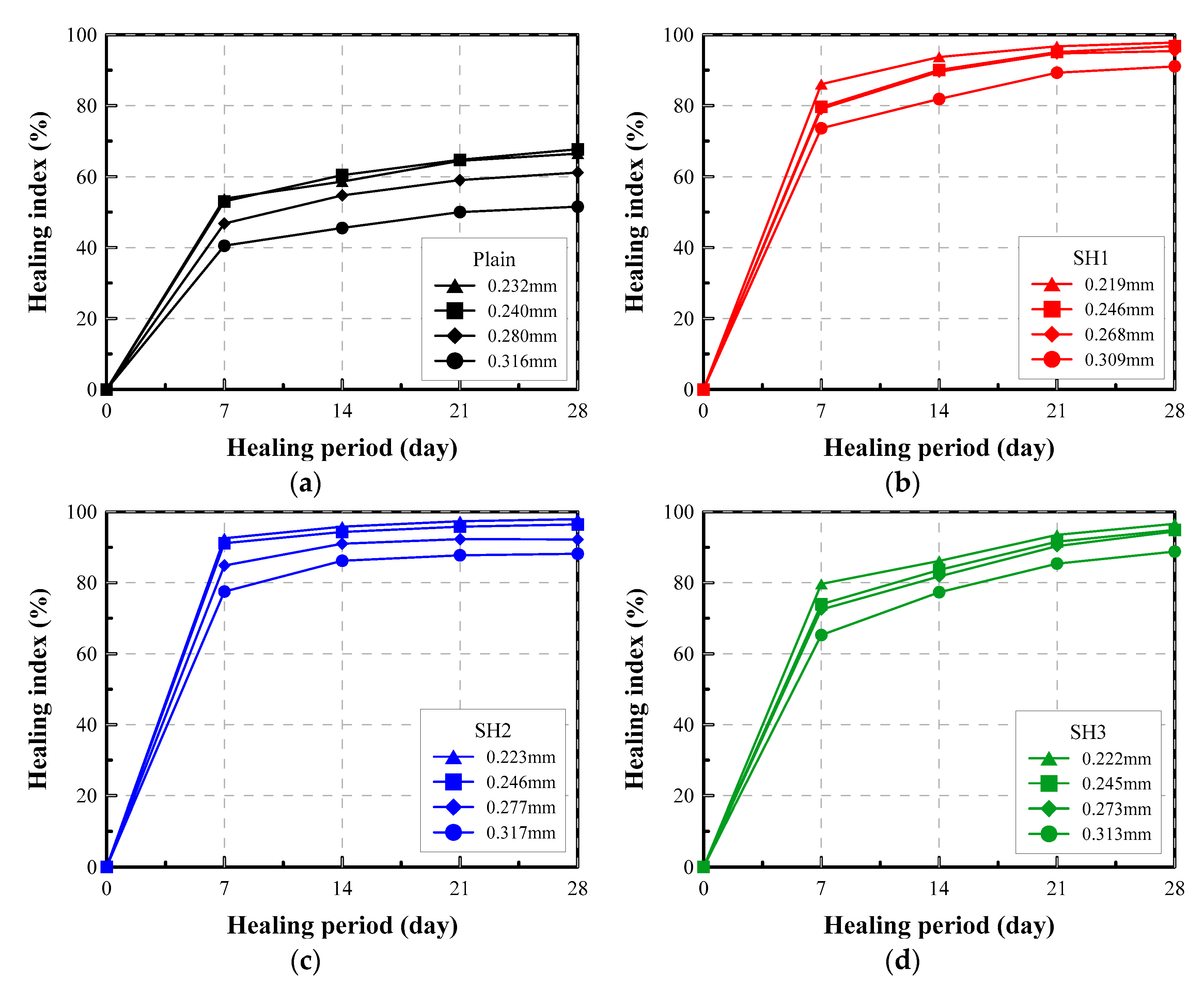

4.3.3. Relative Change in Permeability: Healing Index

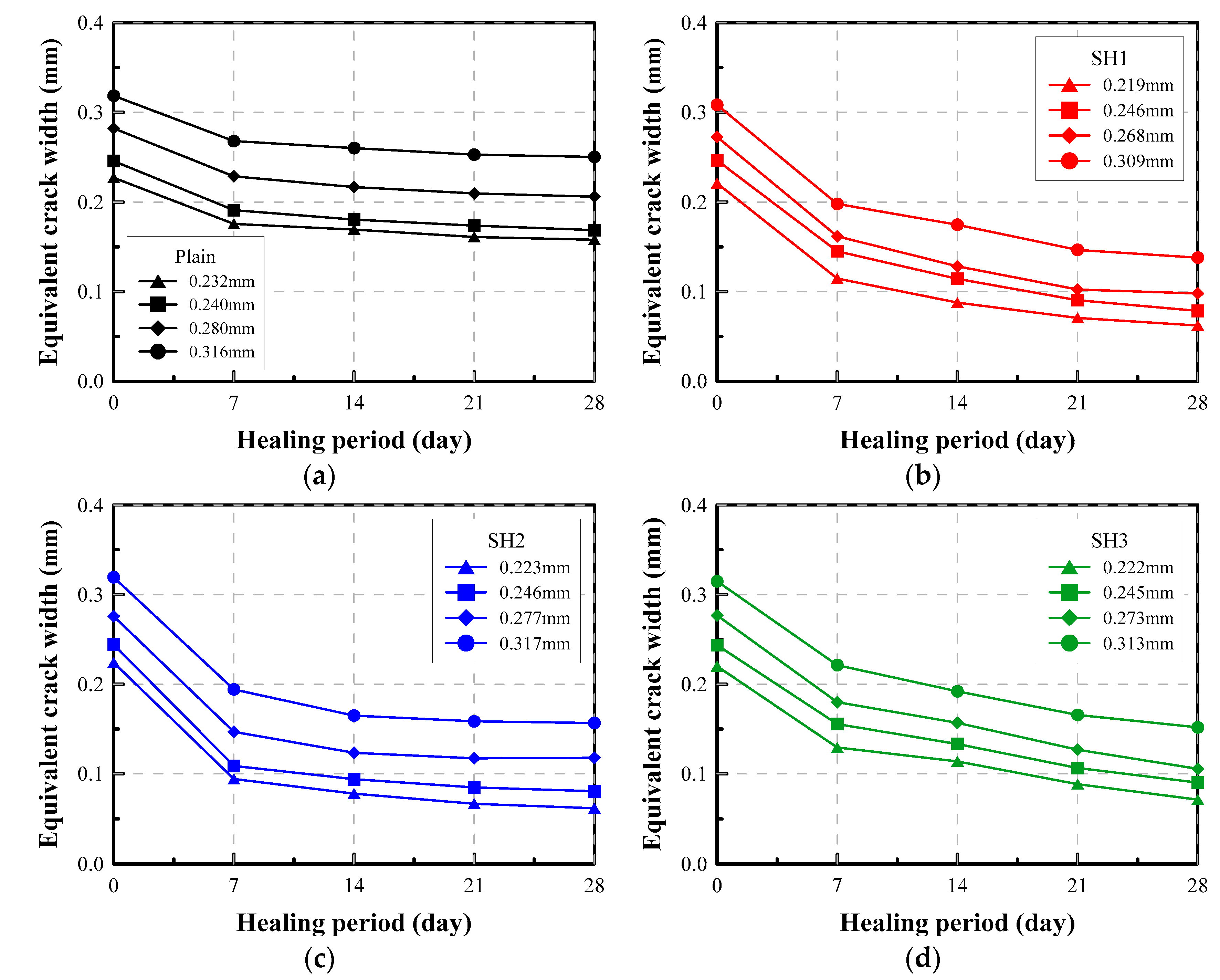

4.3.4. Equivalent Crack Width

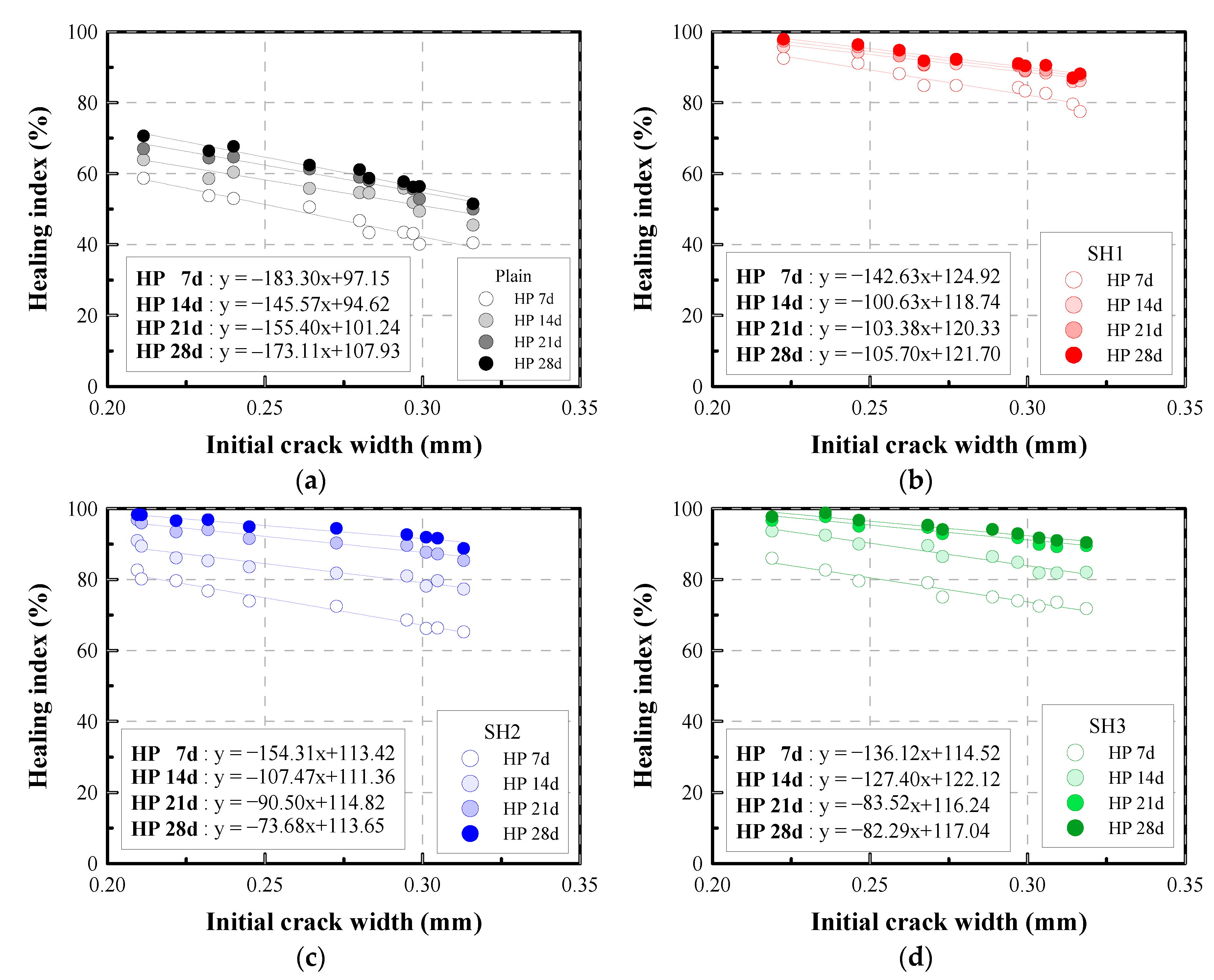

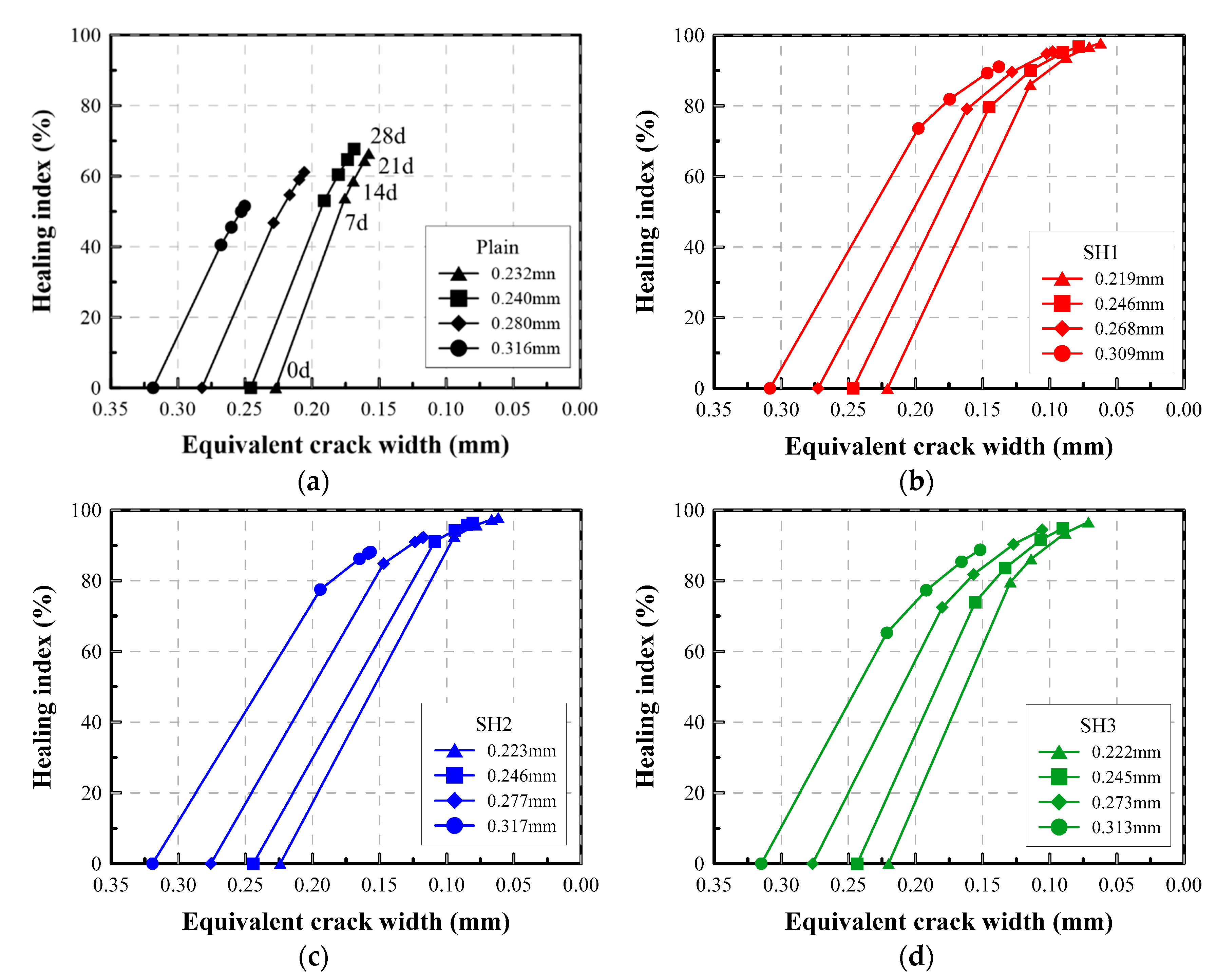

4.3.5. Self-Healing Performance Chart for a Cementitious Material

5. Conclusions

- (1)

- Three self-healing mixtures incorporating inorganic materials and one Plain mixture were selected for the study. The water/binder ratio and the sand/cement ratio were kept constant for every mixture. Each self-healing mixture had its own characteristics, such as a combination of several constituents, use of clinker, or encapsulation, but they were designed to heal 0.3 mm cracks to a 90% level. The results showed that, as expected, the self-healing performance of these self-healing mixtures were much improved compared to the Plain mixture.

- (2)

- Because many factors related to the permeability test apparatus and method might affect the test results, a detailed setup and method for the water permeability test were proposed as a part of the standardized performance evaluation of the self-healing materials. Based on the proposed method, it was verified that the water flow rate was linearly proportional to the cube of the crack width by using a total of 160 specimens with crack widths ranging from 70 to 320 µm. The crack width can be accurately estimated from the flow rate using a theoretical equation, although the relationship between the crack width and the water flow rate varied with respect to the mixture type.

- (3)

- To evaluate the self-healing performance, several parameters were analyzed and discussed. The water flow rate can be a primary index for the evaluation of self-healing performance. However, the value itself does not produce an intuitive understanding of the condition of the specimens. This study shows that the relative self-healing index is a more rational way to represent the change of permeability than the flow rate itself. In addition, the use of an equivalent crack width could be a reasonable method to directly understand the test results and relate them to crack widths.

- (4)

- It was proven that the initial crack width is linearly related to the healed equivalent crack width or the self-healing index. The equations for these relationships were estimated for each mixture based on the test results. Thus, it was proven that the condition of a crack after healing can be estimated from the initial crack width, or the maximum allowable crack width can be suggested based on the expected healing performance. In addition, a self-healing performance chart was proposed, which shows the variations of the crack width and the healing index during the self-healing process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aldea, C.M.; Song, W.J.; Popovics, J.S.; Shah, S.P. Extent of Healing of Cracked Normal Strength Concrete. J. Mater. Civ. Eng. 2000, 12, 92–96. [Google Scholar] [CrossRef]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- De Rooij, M.R.; Schlangen, E. Self-Healing Phenomena in Cement-Based Materials; State-of-the-Art Report of RILEM Technical Committee 221-SHC; Springer: Cham, Switzerland, 2011. [Google Scholar]

- Alghamri, R.; Kanellopoulos, A.; Al-Tabbaa, A. Impregnation and encapsulation of lightweight aggregates for self-healing concrete. Constr. Build. Mater. 2016, 124, 910–921. [Google Scholar] [CrossRef]

- Araújo, M.; Van Vlierberghe, S.; Feiteira, J.; Graulus, G.-J.; Van Tittelboom, K.; Martins, J.C.; Dubruel, P.; De Belie, N. Cross-linkable polyethers as healing/sealing agents for self-healing of cementitious materials. Mater. Des. 2016, 98, 215–222. [Google Scholar] [CrossRef]

- Silva, F.B.; De Belie, N.; Boon, N.; Verstraete, W. Production of non-axenic ureolytic spores for self-healing concrete applications. Constr. Build. Mater. 2015, 93, 1034–1041. [Google Scholar] [CrossRef]

- Bundur, Z.B.; Amiri, A.; Erşan, Y.C.; Boon, N.; De Belie, N. Impact of air entraining admixtures on biogenic calcium carbonate precipitation and bacterial viability. Cem. Concr. Res. 2017, 98, 44–49. [Google Scholar] [CrossRef]

- Ferrara, L.; Van Mullem, T.; Alonso, M.C.; Antonaci, P.; Borg, R.P.; Cuenca, E.; Jefferson, A.; Ng, P.-L.; Peled, A.; Roig-Flores, M.; et al. Experimental characterization of the self-healing capacity of cement based materials and its effects on the material performance: A state of the art report by COST Action SARCOS WG2. Constr. Build. Mater. 2018, 167, 115–142. [Google Scholar] [CrossRef] [Green Version]

- Ahn, E.; Kim, H.; Sim, S.-H.; Shin, S.W.; Shin, M. Principles and Applications of Ultrasonic-Based Nondestructive Methods for Self-Healing in Cementitious Materials. Materials 2017, 10, 278. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akhavan, A.; Rajabipour, F. Evaluating ion diffusivity of cracked cement paste using electrical impedance spectroscopy. Mater. Struct. 2013, 46, 697–708. [Google Scholar] [CrossRef]

- Aldea, C.-M.; Shah, S.P.; Karr, A. Permeability of cracked concrete. Mater. Struct. 1999, 32, 370–376. [Google Scholar] [CrossRef]

- Borg, R.P.; Cuenca, E.; Gastaldo Brac, E.M.; Ferrara, L. Crack sealing capacity in chloride rich environments of mortars containing different cement substitutes and crystalline admixtures. J. Sustain. Cement Based Mater. 2017, 7, 141–159. [Google Scholar] [CrossRef]

- Gruyaert, E.; Debbaut, B.; Snoeck, D.; Díaz, P.; Arizo, A.; Tziviloglou, E.; Schlangen, E.; De Belie, N. Self-healing mortar with pH-sensitive superabsorbent polymers: Testing of the sealing efficiency by water flow tests. Smart Mater. Struct. 2016, 25, 084007. [Google Scholar] [CrossRef]

- Tang, W.; Kardani, O.; Cui, H. Robust evaluation of self-healing efficiency in cementitious materials—A review. Constr. Build. Mater. 2015, 81, 233–247. [Google Scholar] [CrossRef]

- Litina, C.; Bumanis, G.; Anglani, G.; Dudek, M.; Maddalena, R.; Amenta, M.; Papaioannou, S.; Pérez, G.; García Calvo, J.L.; Asensio, E.; et al. Evaluation of Methodologies for Assessing Self-Healing Performance of Concrete with Mineral Expansive Agents: An Interlaboratory Study. Materials 2021, 14, 2024. [Google Scholar] [CrossRef]

- Edvardsen, C. Water Permeability and Autogenous Healing of Cracks in Concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar]

- Lepech, M.; Li, V.C. Water permeability of engineered cementitious composites. Cem. Concr. Compos. 2009, 31, 744–753. [Google Scholar] [CrossRef]

- Shin, K.J.; Bae, W.; Choi, S.W.; Son, M.W.; Lee, K.M. Parameters influencing water permeability coefficient of cracked concrete specimens. Constr. Build. Mater. 2017, 151, 907–915. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; De Belie, N.; De Muynck, W.; Verstraete, W. Use of bacteria to repair cracks in concrete. Cem. Concr. Res. 2010, 40, 157–166. [Google Scholar] [CrossRef]

- Tziviloglou, E.; Wiktor, V.; Wang, J.; Paine, K.; Alazhari, M.; Richardson, A.; Gueguen, M.; De Belie, N.; Schlangen, E.; Jonkers, H. Evaluation of experimental methodology to assess the sealing efficiency of bacteria-based selfhealing concrete: Round Robin test. In Proceedings of the International RILEM Conference on Microorganisms-Cementitious Materials Interactions, RILEM Pro 102, Delft, The Netherlands, 23 June 2016; Wiktor, V., Jonkers, H., Bertron, A., Eds.; Rilem: Paris, France; pp. 156–170. [Google Scholar]

- Choi, Y.C.; Park, B. Enhanced autogenous healing of ground granulated blast furnace slag blended cements and mortars. J. Mater. Res. Technol. 2019, 8, 3443–3452. [Google Scholar] [CrossRef]

- Takagi, E.M.; Lima, M.G.; Helene, P.; Meideros-Junior, R.A. Self-healing of self-compacting concretes made with blast furnace slag cements activated by crystalline admixture. Int. J. Mater. Prod. Technol. 2018, 56, 169–186. [Google Scholar] [CrossRef]

- Yuan, L.; Chen, S.; Wang, S.; Huang, Y.; Yang, Q.; Liu, S.; Wang, J.; Du, P.; Cheng, X.; Zhou, Z. Research on the improvement of concrete autogenous self-healing based on the regulation of cement particle size distribution (PSD). Materials 2019, 12, 2818. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- White, F.M. Fluid Mechanics, 9th ed.; McGraw–Hill: New York, NY, USA, 2003. [Google Scholar]

- Roig-Flores, M.; Moscato, S.; Serna, P.; Ferrara, L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr. Build. Mater. 2015, 86, 1–11. [Google Scholar] [CrossRef]

- Yi, S.T.; Hyun, T.Y.; Kim, J.K. The effects of hydraulic pressure and crack width on water permeability of penetration crack-induced concrete. Constr. Build. Mater. 2011, 25, 2576–2583. [Google Scholar] [CrossRef]

- Snoeck, D.; Van Tittelboom, K.; Steuperaert, S.; Dubruel, P.; De Belie, N. Self-healing cementitious materials by the combination of microfibres and superabsorbent polymers. J. Int. Mater. Syst. Struct. 2014, 25, 13–24. [Google Scholar] [CrossRef] [Green Version]

- Van Mier, J. Fracture Process of Concrete; CRC Press: Boca Raton, FL, USA, 1996. [Google Scholar]

- Oesch, T.; Weise, F.; Bruno, G. Detection and Quantification of Cracking in Concrete Aggregate through Virtual Data Fusion of X-ray Computed Tomography Images. Materials 2020, 13, 3921. [Google Scholar] [CrossRef] [PubMed]

| Mix Type | Water | Cement | GGBFS | Fine Aggregate | Healing Agent |

|---|---|---|---|---|---|

| Plain | 0.40 | 1.00 | 0 | 2.00 | - |

| SH1 | 0.40 | 1.00 | 0 | 1.95 | 0.05 |

| SH2 | 0.40 | 1.00 | 0 | 1.92 | 0.08 |

| SH3 | 0.40 | 0.65 | 0.20 | 1.80 | 0.35 |

| Types | Slump Flow (mm) | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|

| 0 min | 30 min | 60 min | 7 d | 28 d | |

| Plain | 180 | 160 | 150 | 38.43 | 49.96 |

| SH1 | 180 | 160 | 145 | 40.74 | 53.24 |

| SH2 | 195 | 170 | 140 | 35.01 | 46.12 |

| SH3 | 175 | 145 | 125 | 47.41 | 54.02 |

| Classification | Crack Width [mm] | Water Flow Rate [mL/(mm∙min)] | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

(Equation (3)) | (%) | (Equation (4)) | (Equation (2)) | (%) | (%) (Equation (5)) | |||||

| Plain | 1 | 0.211 | 0.215 | −1.59 | 0.143 | 0.61 | 0.58 | 4.61 | 0.18 | 70.65 |

| 2 | 0.232 | 0.227 | 2.20 | 0.158 | 0.72 | 0.77 | −6.89 | 0.24 | 66.44 | |

| 3 | 0.240 | 0.246 | −2.37 | 0.169 | 0.92 | 0.86 | 6.78 | 0.30 | 67.70 | |

| 4 | 0.264 | 0.262 | 0.66 | 0.189 | 1.12 | 1.14 | −2.00 | 0.42 | 62.43 | |

| 5 | 0.280 | 0.282 | −0.76 | 0.206 | 1.39 | 1.36 | 2.24 | 0.54 | 61.15 | |

| 6 | 0.283 | 0.285 | −0.64 | 0.212 | 1.43 | 1.40 | 1.89 | 0.59 | 58.74 | |

| 7 | 0.294 | 0.296 | −0.78 | 0.222 | 1.61 | 1.57 | 2.30 | 0.68 | 57.76 | |

| 8 | 0.297 | 0.296 | 0.45 | 0.224 | 1.60 | 1.62 | −1.35 | 0.70 | 56.25 | |

| 9 | 0.299 | 0.303 | −1.30 | 0.230 | 1.72 | 1.65 | 3.80 | 0.75 | 56.40 | |

| 10 | 0.316 | 0.319 | −0.79 | 0.250 | 2.00 | 1.95 | 2.34 | 0.97 | 51.50 | |

| SH1 | 1 | 0.219 | 0.221 | −0.88 | 0.062 | 0.74 | 0.65 | 12.88 | 0.02 | 97.76 |

| 2 | 0.236 | 0.235 | 0.23 | 0.053 | 0.90 | 0.81 | 9.92 | 0.01 | 98.83 | |

| 3 | 0.246 | 0.246 | −0.02 | 0.078 | 1.04 | 0.93 | 10.60 | 0.03 | 96.78 | |

| 4 | 0.268 | 0.273 | −1.59 | 0.098 | 1.40 | 1.20 | 14.69 | 0.06 | 95.36 | |

| 5 | 0.273 | 0.274 | −0.47 | 0.107 | 1.43 | 1.26 | 11.81 | 0.08 | 94.14 | |

| 6 | 0.289 | 0.292 | −1.03 | 0.113 | 1.72 | 1.49 | 13.24 | 0.10 | 94.13 | |

| 7 | 0.297 | 0.297 | −0.06 | 0.123 | 1.81 | 1.62 | 10.71 | 0.13 | 92.97 | |

| 8 | 0.304 | 0.308 | −1.43 | 0.134 | 2.02 | 1.73 | 14.27 | 0.17 | 91.75 | |

| 9 | 0.309 | 0.308 | 0.29 | 0.138 | 2.03 | 1.83 | 9.78 | 0.18 | 91.06 | |

| 10 | 0.319 | 0.324 | −1.69 | 0.148 | 2.35 | 2.00 | 14.93 | 0.22 | 90.49 | |

| SH2 | 1 | 0.223 | 0.224 | −0.70 | 0.062 | 0.73 | 0.68 | 6.59 | 0.02 | 97.92 |

| 2 | 0.246 | 0.244 | 0.80 | 0.081 | 0.95 | 0.92 | 2.30 | 0.03 | 96.41 | |

| 3 | 0.259 | 0.257 | 1.02 | 0.096 | 1.10 | 1.08 | 1.65 | 0.06 | 94.83 | |

| 4 | 0.267 | 0.271 | −1.38 | 0.117 | 1.29 | 1.18 | 8.46 | 0.11 | 91.85 | |

| 5 | 0.277 | 0.276 | 0.53 | 0.118 | 1.36 | 1.32 | 3.08 | 0.11 | 92.19 | |

| 6 | 0.297 | 0.299 | −0.50 | 0.133 | 1.73 | 1.62 | 6.04 | 0.15 | 91.08 | |

| 7 | 0.299 | 0.298 | 0.56 | 0.136 | 1.71 | 1.66 | 2.99 | 0.16 | 90.41 | |

| 8 | 0.306 | 0.302 | 1.12 | 0.138 | 1.79 | 1.77 | 1.35 | 0.17 | 90.57 | |

| 9 | 0.314 | 0.319 | −1.62 | 0.162 | 2.12 | 1.92 | 9.12 | 0.27 | 87.05 | |

| 10 | 0.317 | 0.319 | −0.85 | 0.157 | 2.11 | 1.96 | 7.02 | 0.25 | 88.17 | |

| SH3 | 1 | 0.209 | 0.210 | −0.11 | 0.054 | 0.60 | 0.57 | 4.80 | 0.01 | 98.31 |

| 2 | 0.211 | 0.213 | −0.95 | 0.055 | 0.62 | 0.58 | 7.15 | 0.01 | 98.25 | |

| 3 | 0.222 | 0.220 | 0.74 | 0.071 | 0.69 | 0.68 | 2.34 | 0.02 | 96.62 | |

| 4 | 0.232 | 0.232 | −0.16 | 0.073 | 0.81 | 0.77 | 4.93 | 0.03 | 96.90 | |

| 5 | 0.245 | 0.244 | 0.61 | 0.090 | 0.94 | 0.91 | 2.72 | 0.05 | 94.91 | |

| 6 | 0.273 | 0.277 | −1.51 | 0.106 | 1.37 | 1.25 | 8.69 | 0.08 | 94.45 | |

| 7 | 0.295 | 0.297 | −0.78 | 0.124 | 1.70 | 1.59 | 6.66 | 0.12 | 92.68 | |

| 8 | 0.301 | 0.306 | −1.65 | 0.132 | 1.86 | 1.69 | 9.05 | 0.15 | 91.94 | |

| 9 | 0.305 | 0.304 | 0.29 | 0.133 | 1.82 | 1.75 | 3.63 | 0.15 | 91.68 | |

| 10 | 0.313 | 0.315 | −0.59 | 0.152 | 2.02 | 1.90 | 6.14 | 0.23 | 88.78 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, K.-M.; Kim, H.-S.; Lee, D.-K.; Shin, K.-J. Self-Healing Performance Evaluation of Concrete Incorporating Inorganic Materials Based on a Water Permeability Test. Materials 2021, 14, 3202. https://doi.org/10.3390/ma14123202

Lee K-M, Kim H-S, Lee D-K, Shin K-J. Self-Healing Performance Evaluation of Concrete Incorporating Inorganic Materials Based on a Water Permeability Test. Materials. 2021; 14(12):3202. https://doi.org/10.3390/ma14123202

Chicago/Turabian StyleLee, Kwang-Myong, Hyung-Suk Kim, Do-Keun Lee, and Kyung-Joon Shin. 2021. "Self-Healing Performance Evaluation of Concrete Incorporating Inorganic Materials Based on a Water Permeability Test" Materials 14, no. 12: 3202. https://doi.org/10.3390/ma14123202