Seismic Performance of Steel Fiber Reinforced High–Strength Concrete Beam–Column Joints

Abstract

:1. Introduction

2. Experimental Program

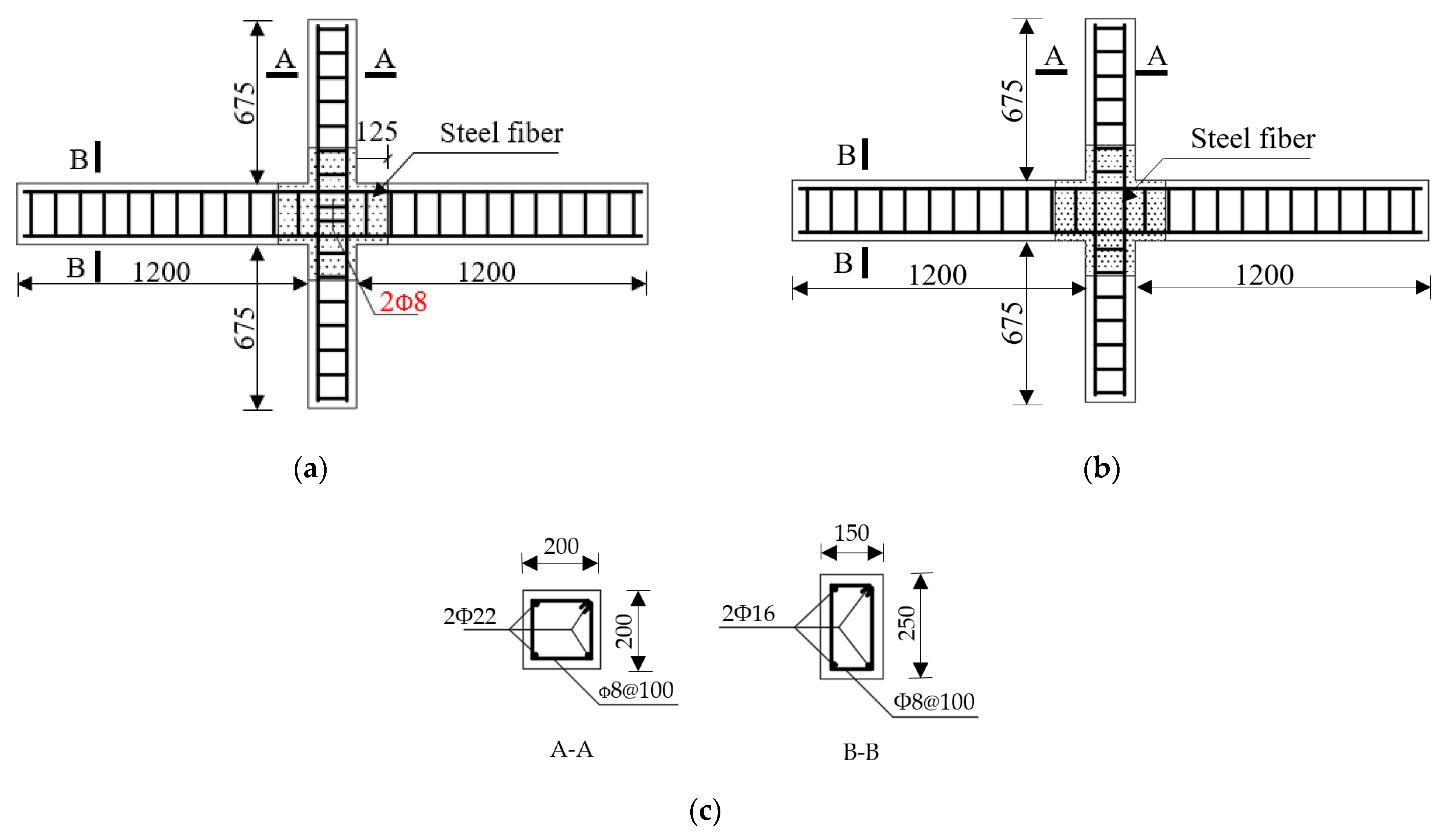

2.1. Test Specimens and Materials

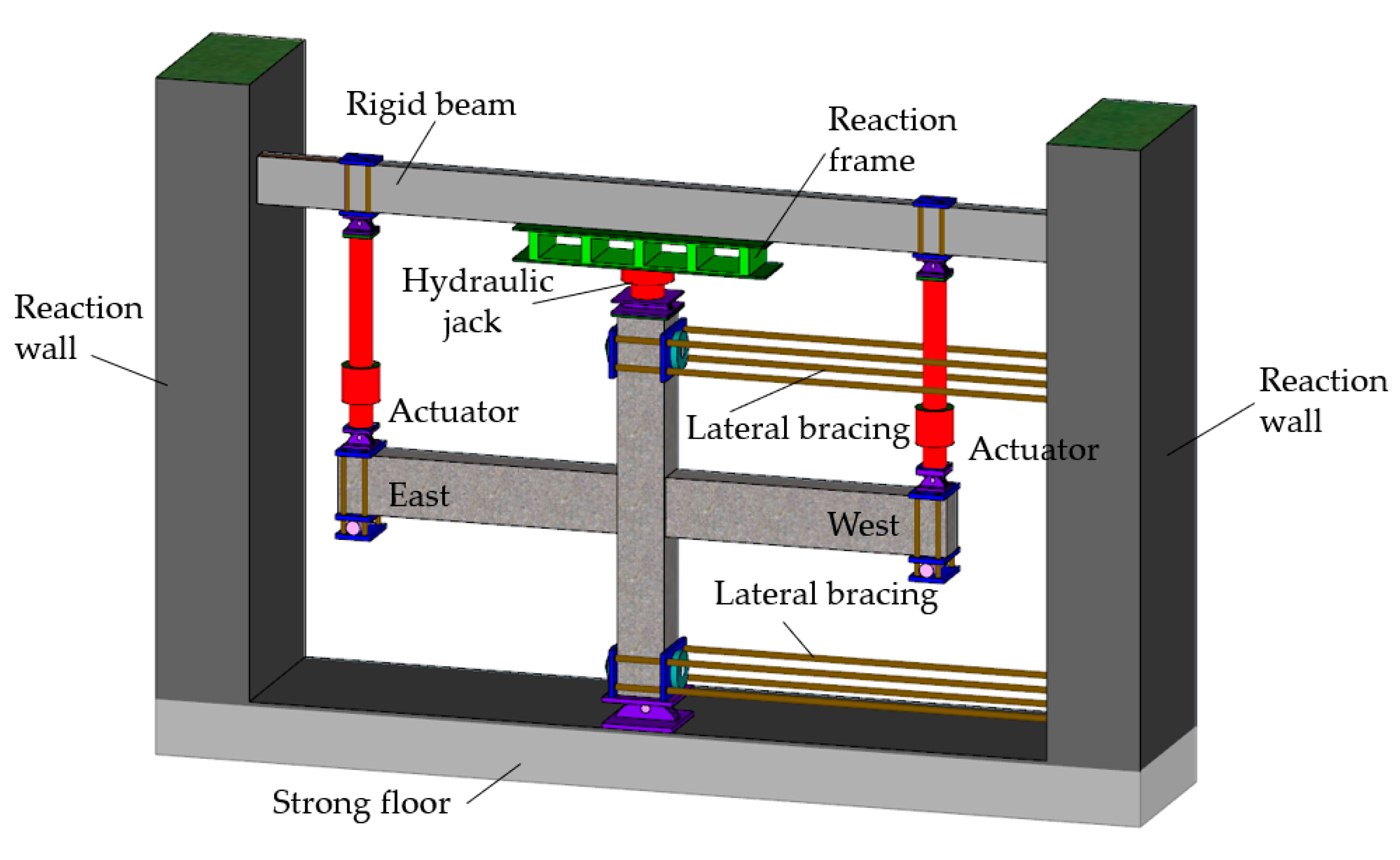

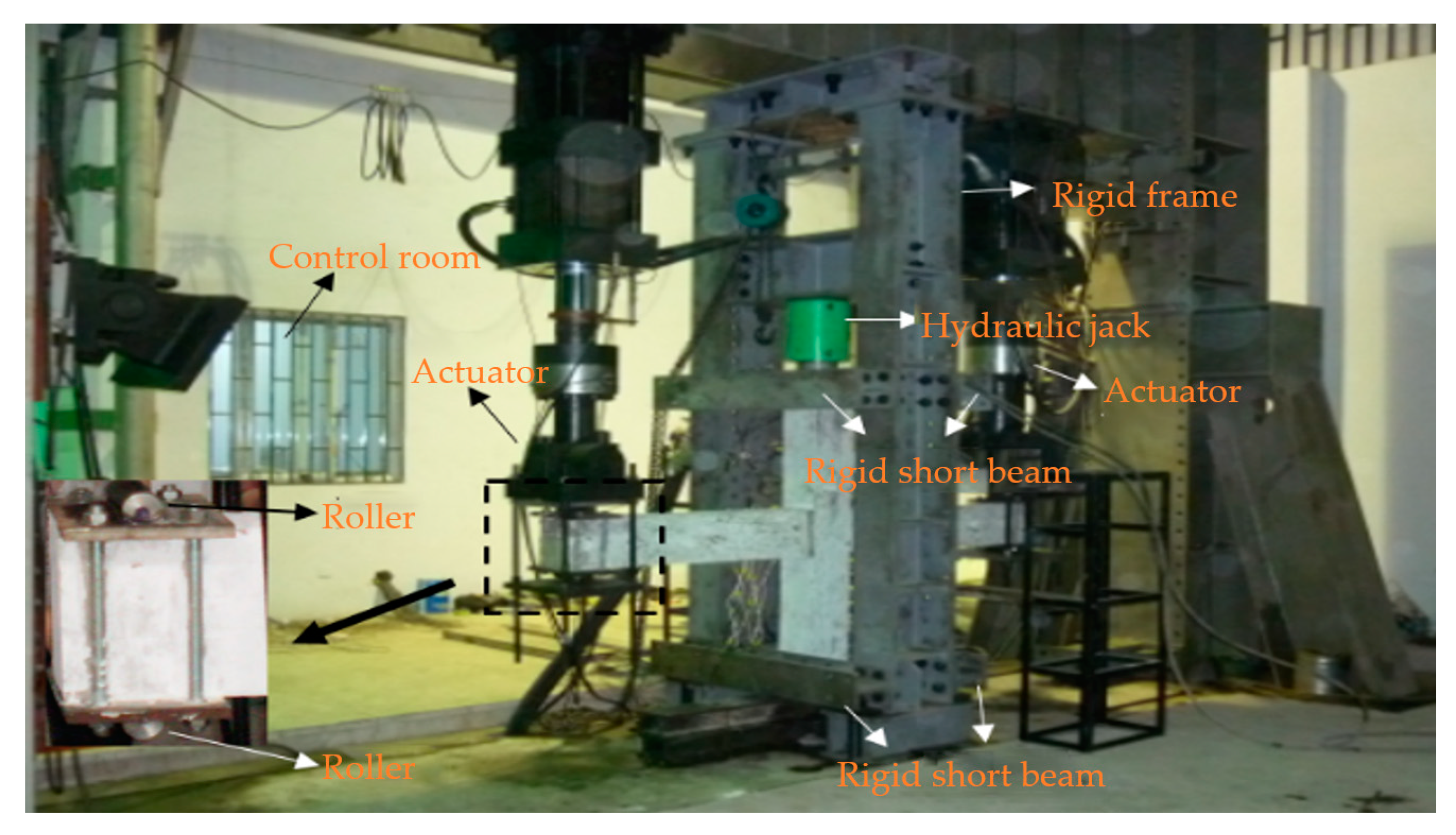

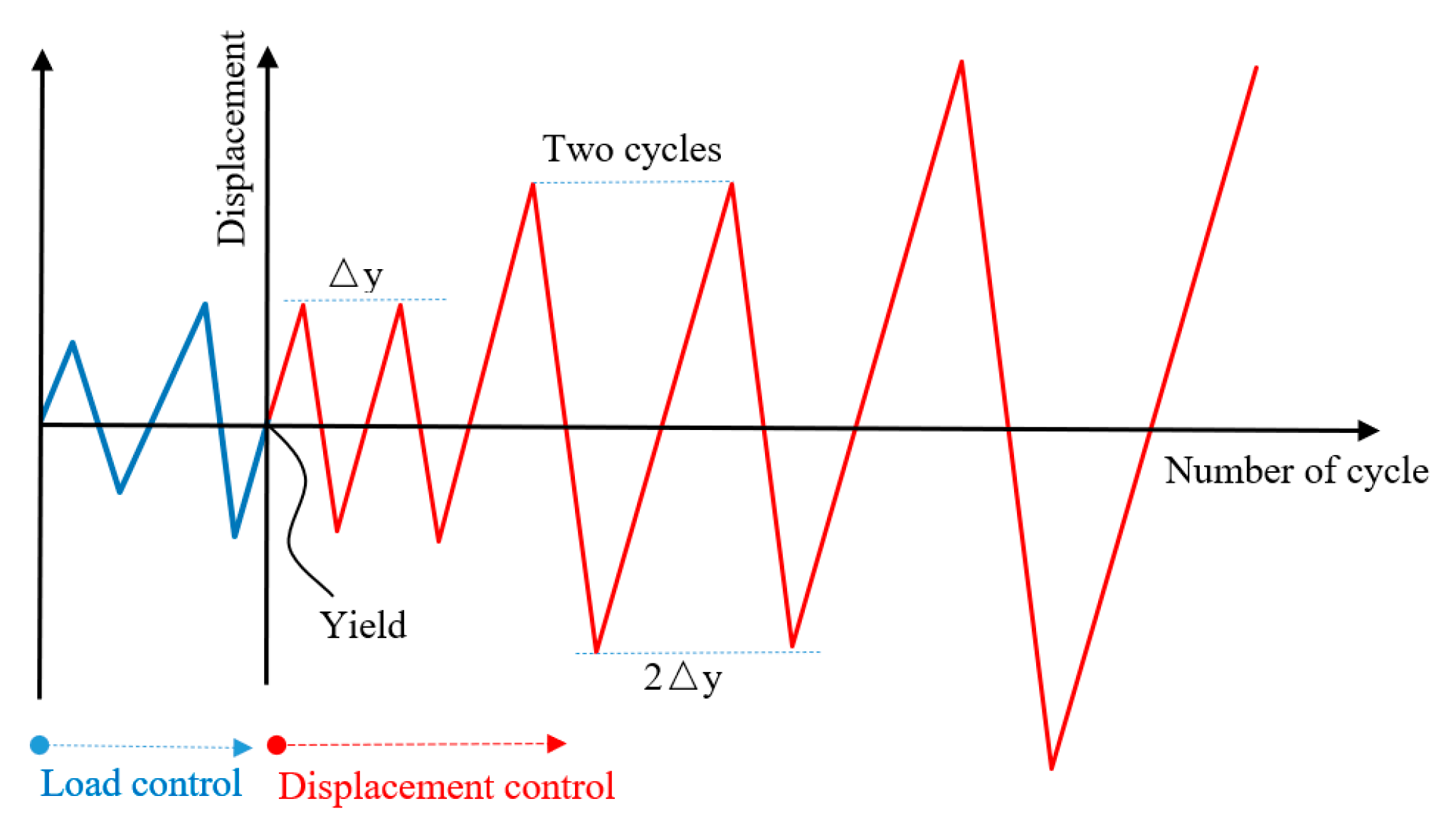

2.2. Experimental Device and Loading System

3. Test Results and Discussion

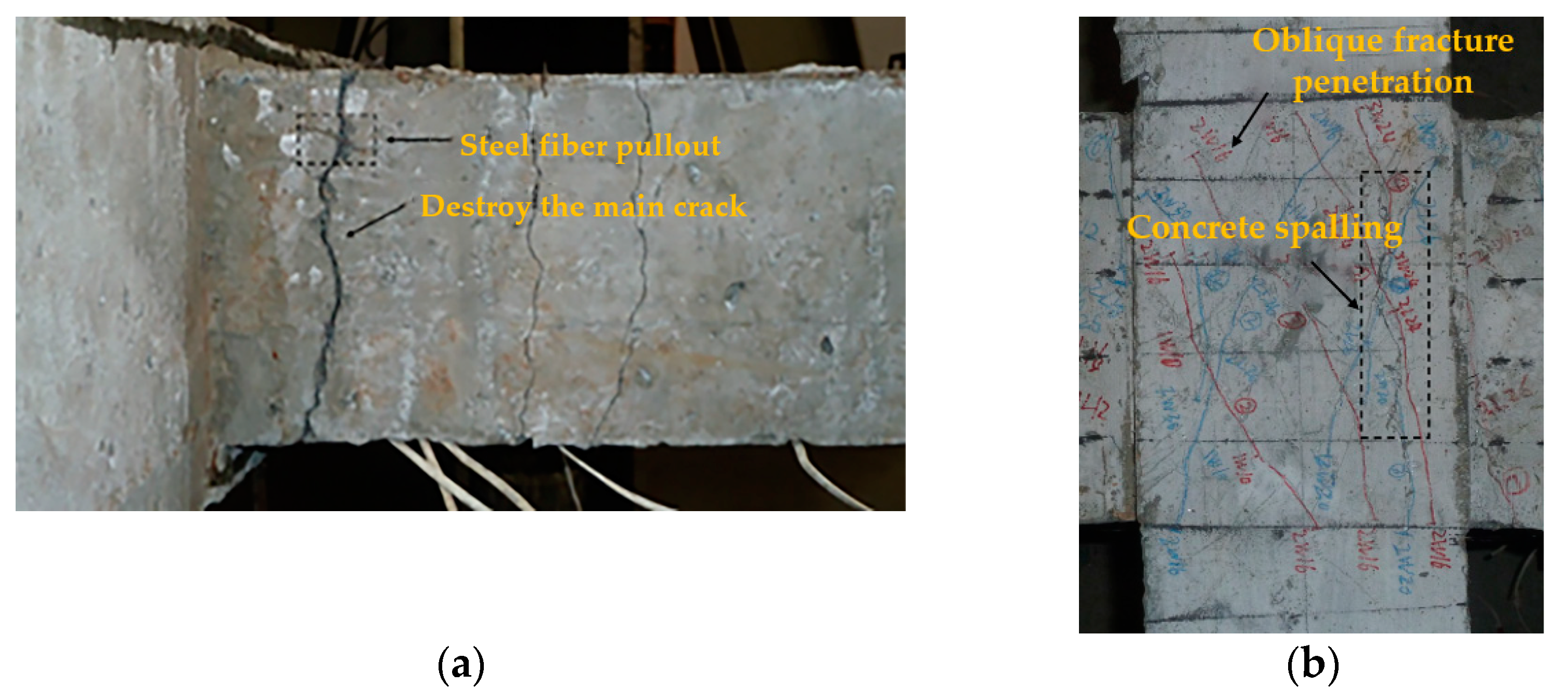

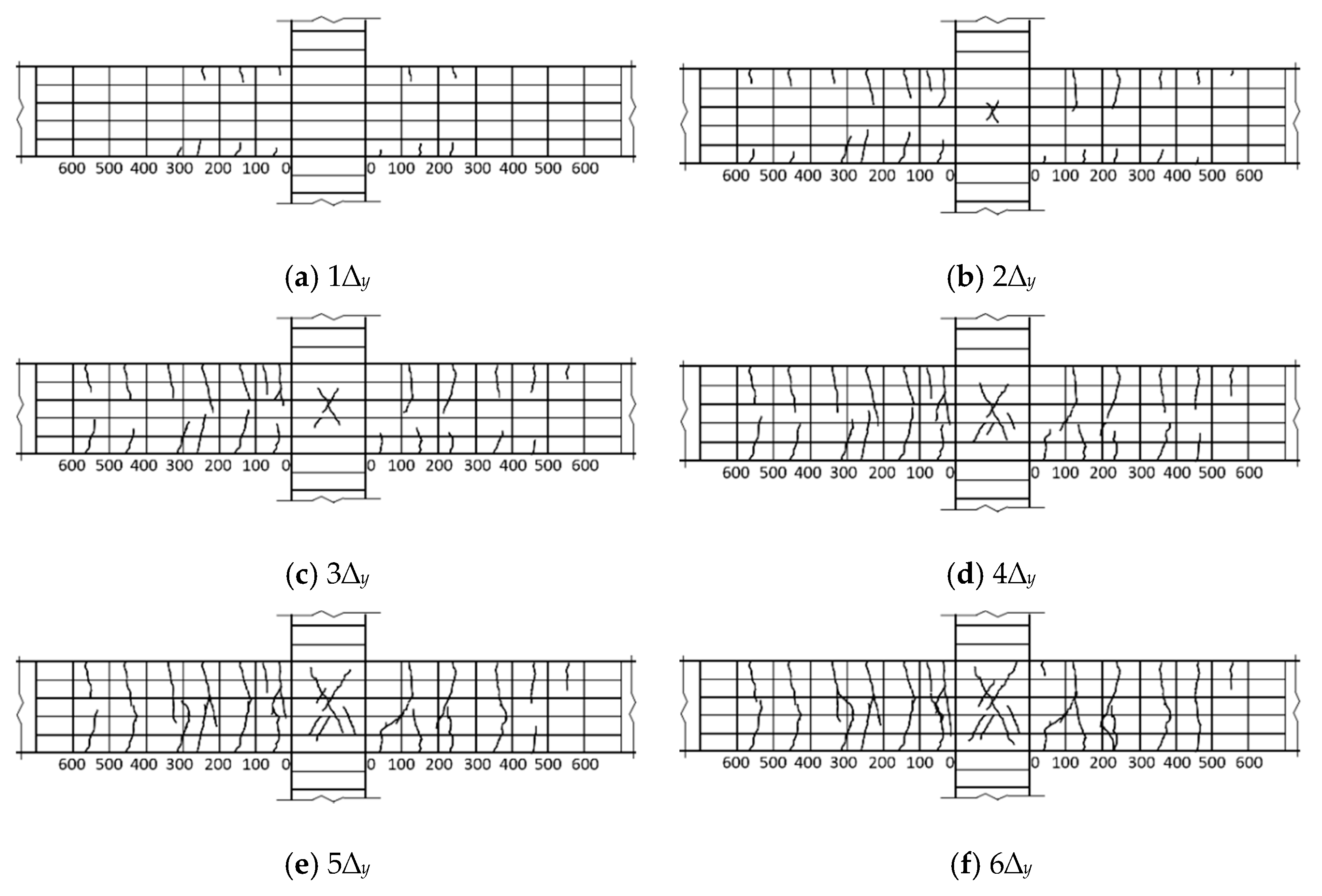

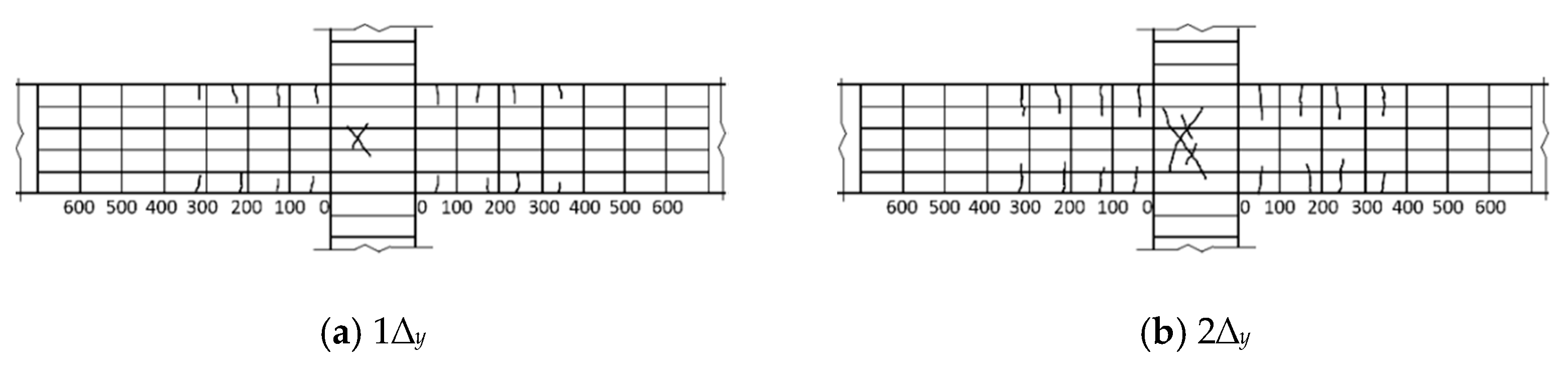

3.1. Failure Modes

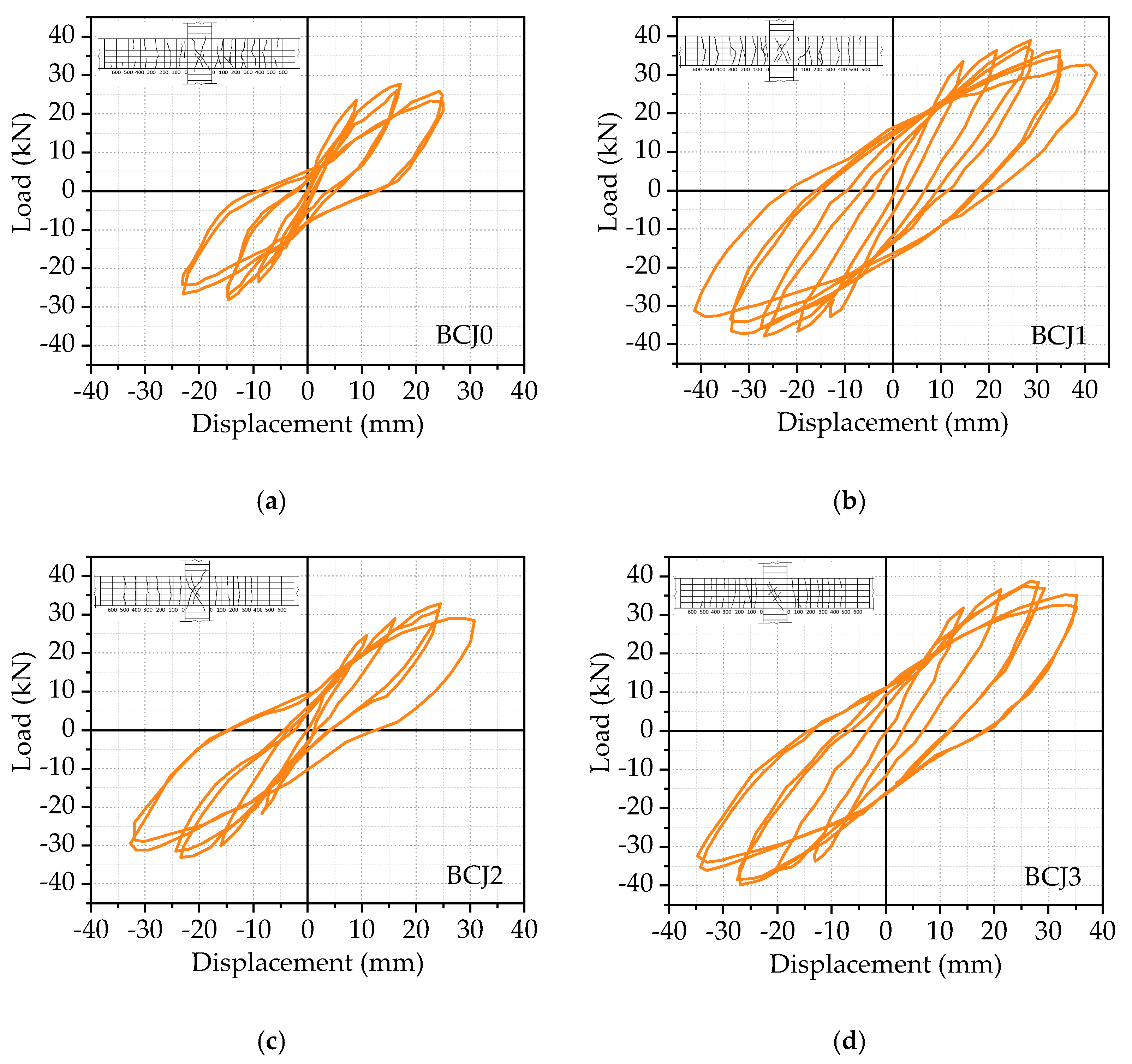

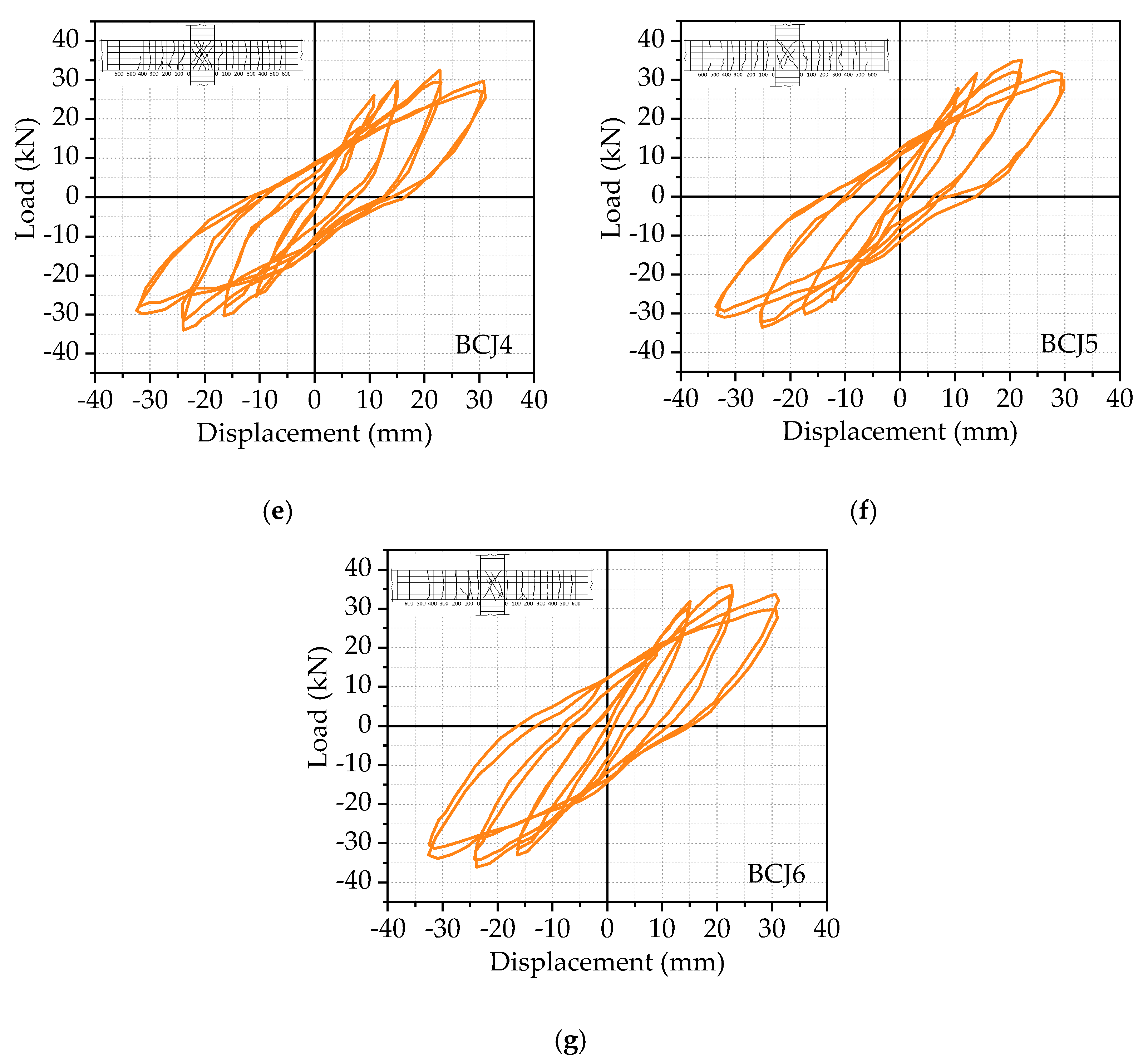

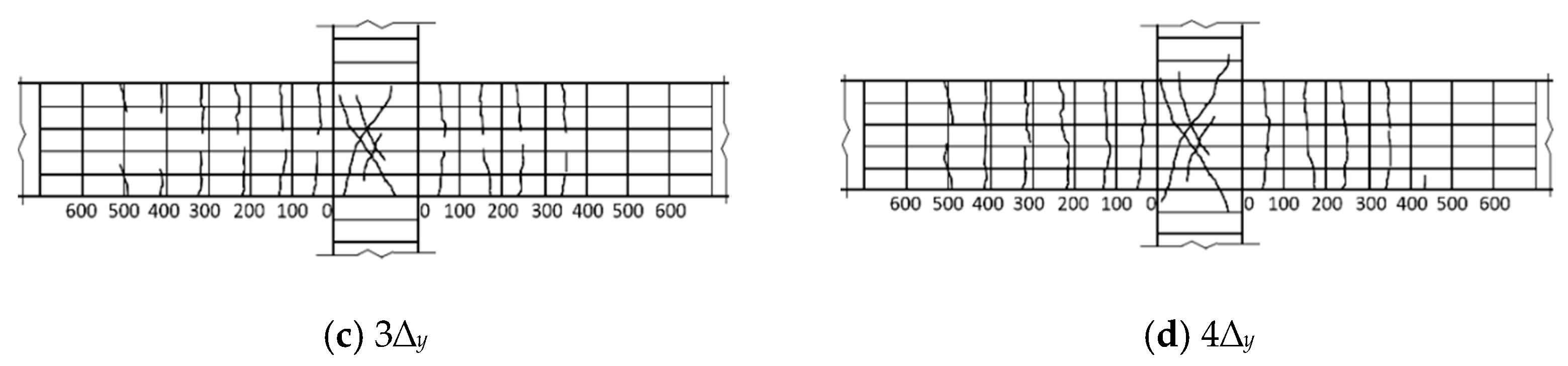

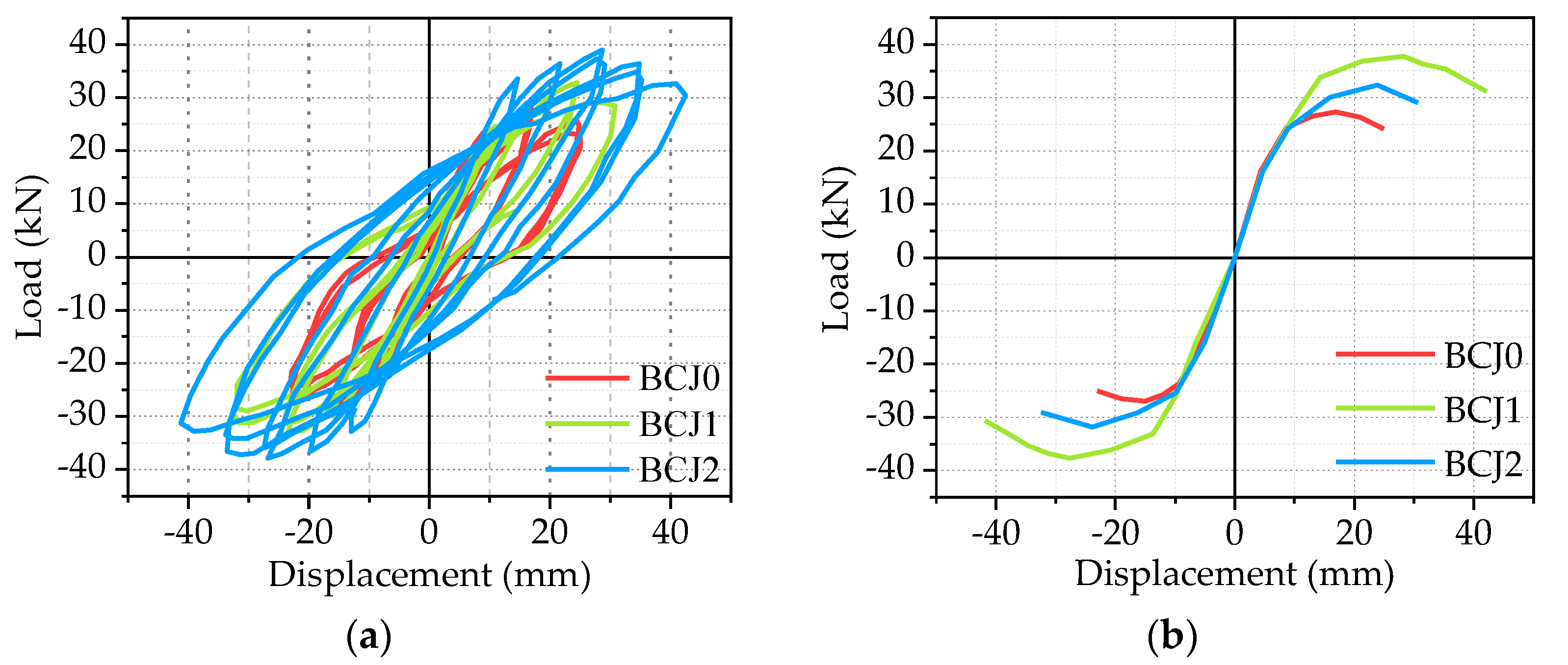

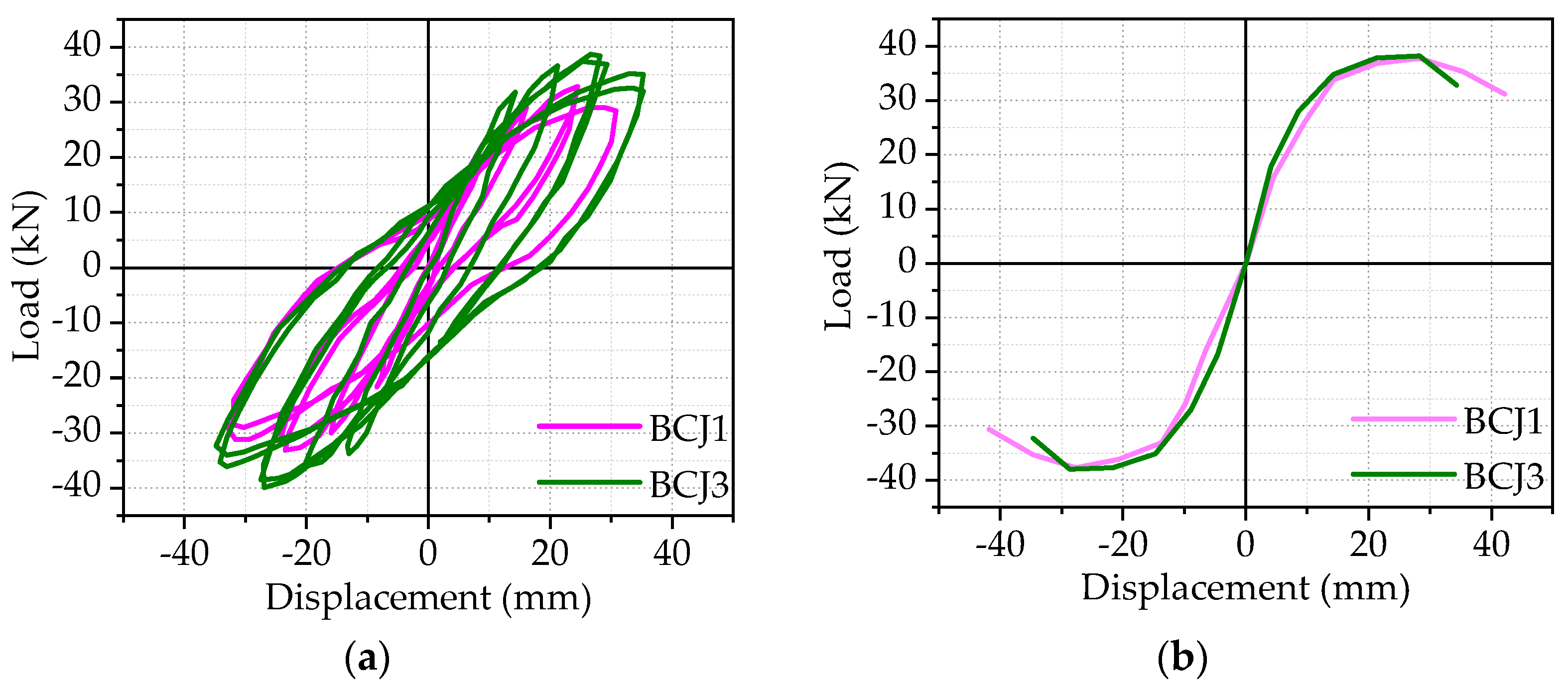

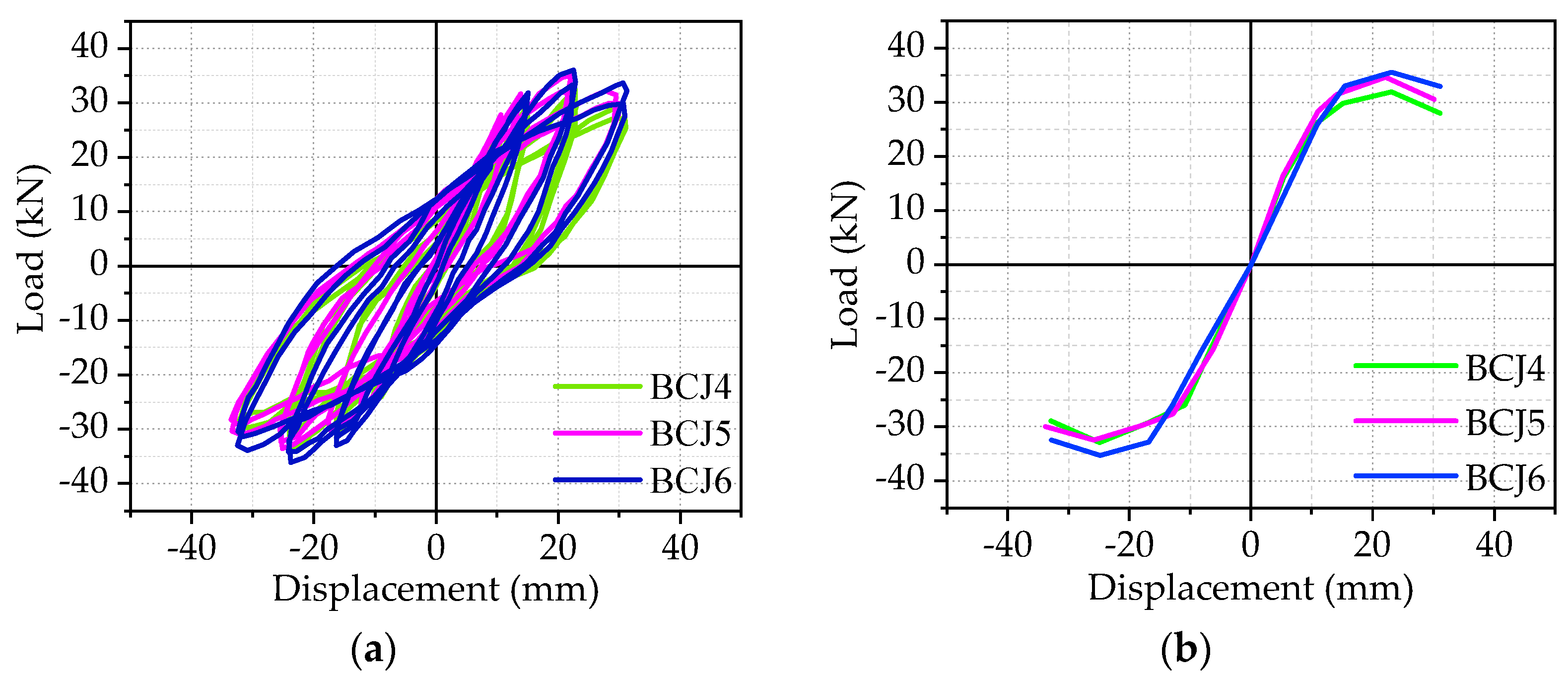

3.2. Hysteretic Curve and Skeleton Curve

- The effect of volume ratios of steel fiber

- The effect of concrete strengths:

- The effect of stirrup ratios in the core area:

- The effect of axial compression ratios:

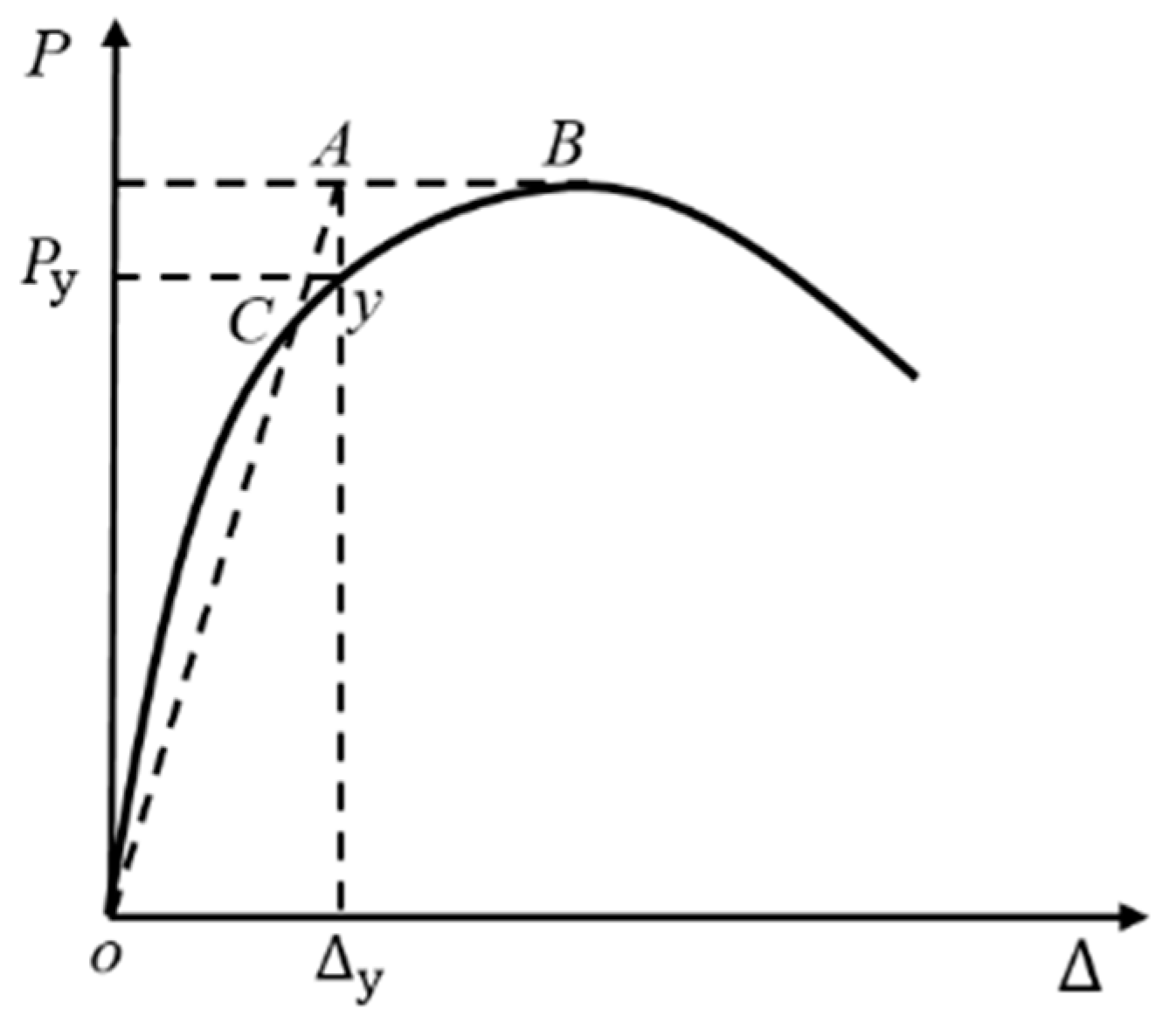

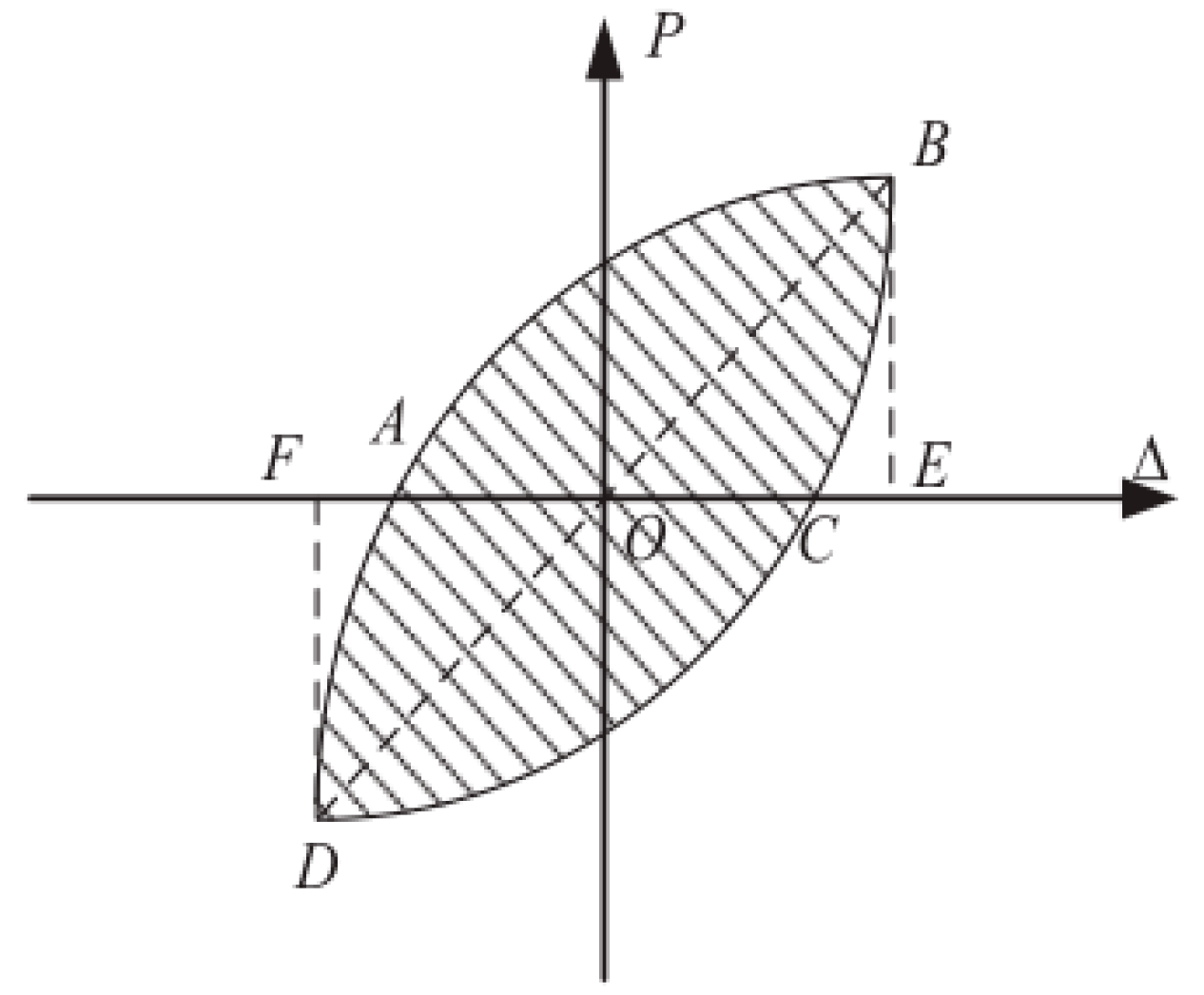

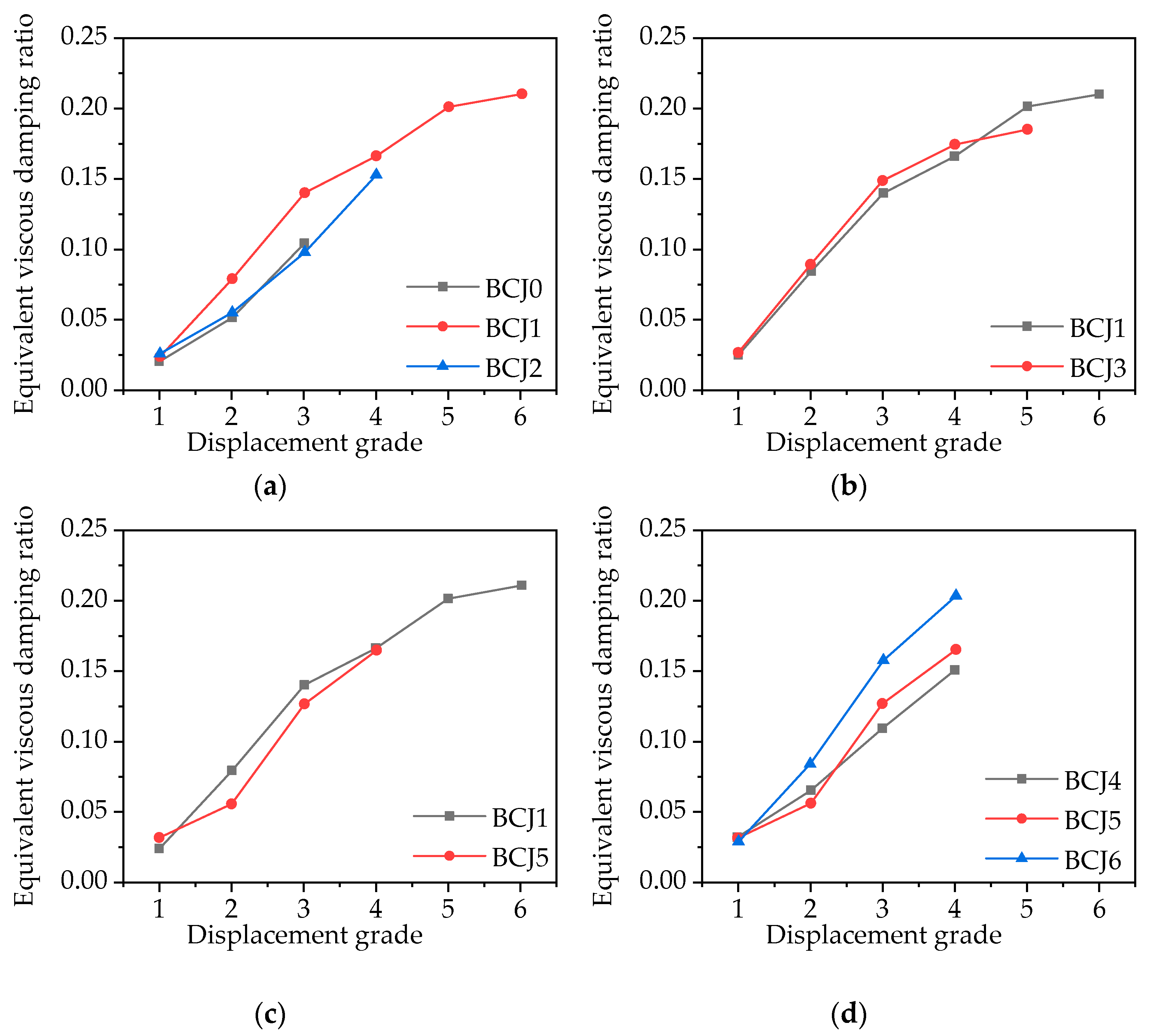

3.3. Ductility and Equivalent Viscous Damping Ratio

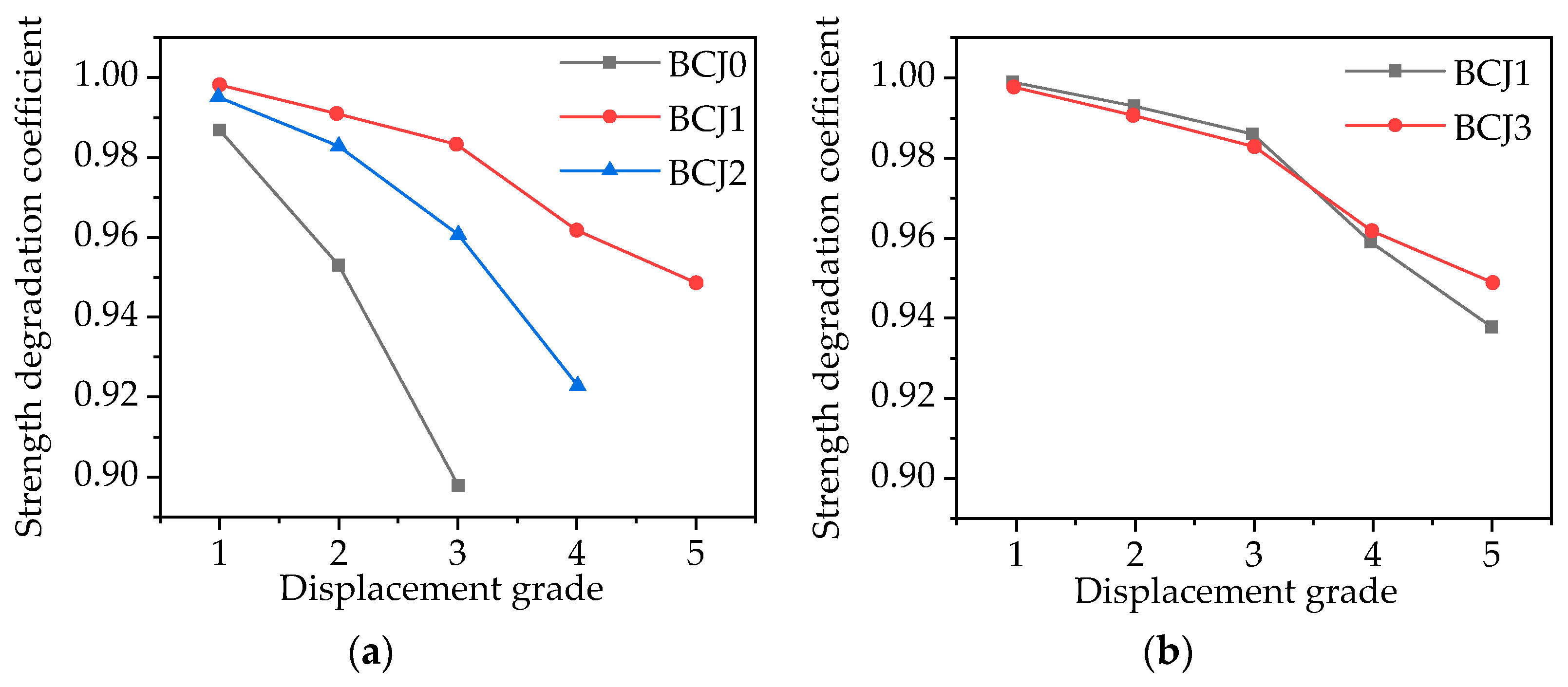

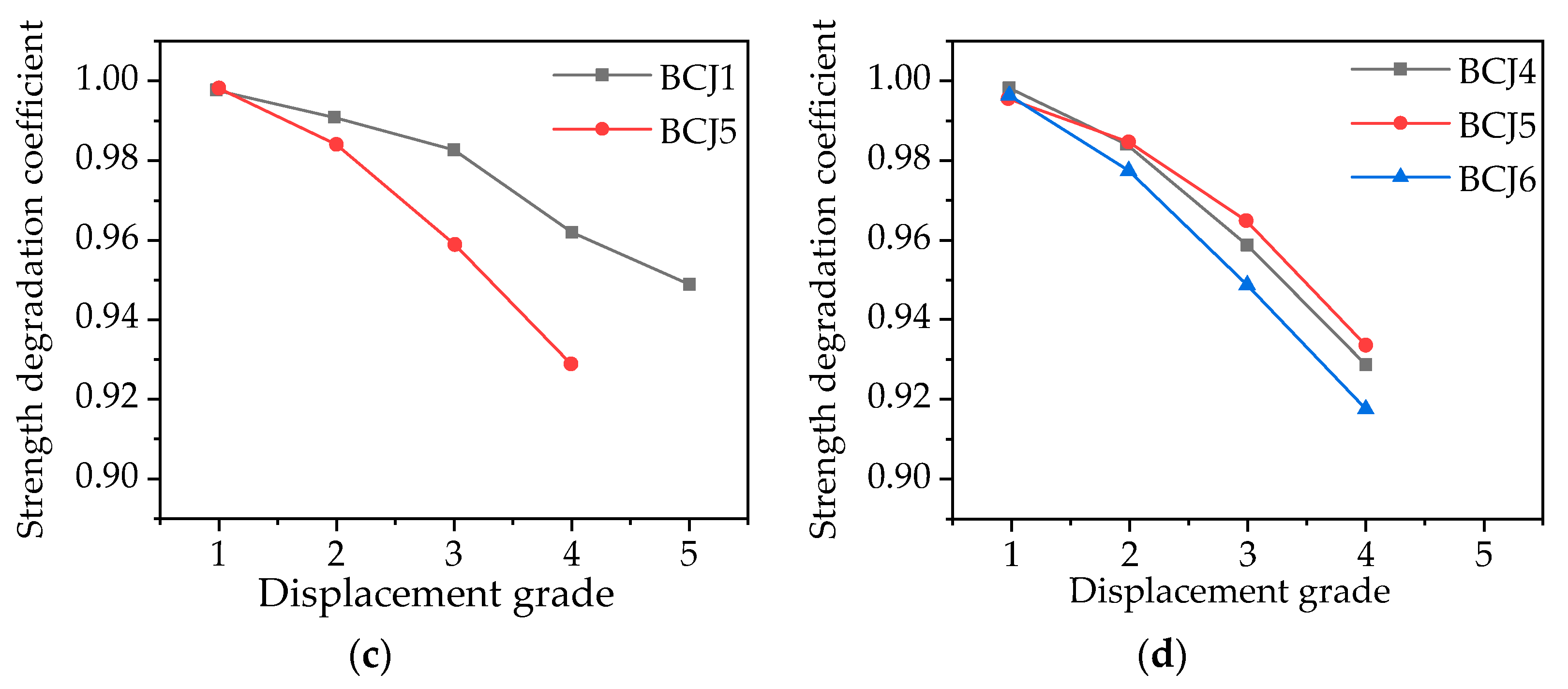

3.4. Strength Degradation

3.5. Stiffness Degradation

4. Conclusions

- With the change in axial compression ratio of column end, concrete strength, the stirrup ratio in the core area, and volume ratio of steel fiber, two modes of the joint–shear–failure area exist in the core area and beam–end–bending failure;

- Because of the bridging effect of steel fiber, the initial crack strength and the through crack strength of BCJs can be improved by adding steel fiber into concrete. Moreover, with the increase in volume ratio of steel fiber from 0 to 1%, the ductility and energy consumption of BCJs increase by 45.2% and 120%, respectively, while the degradation of strength and stiffness slows down;

- With the increase in concrete strength from 80.1 to 89.5 Mpa, the ultimate bearing capacity and energy consumption of beam–column joints increase by 4% and 8%, respectively, while the ductility decreases by 9%.

- With the increase in stirrup ratio in the core area from 0 to 0.6%, the ductility and energy consumption of beam–column joints increases by 25% and 20%, respectively;

- The axial compression load has a limited effect on the strength and deformation capacity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| BCJs | beam–column joints |

| SFRHC | steel fiber reinforced high–strength concrete |

| HC | high–strength concrete |

| SFRC | steel fiber reinforced concrete |

| MTS | material testing system |

References

- GB 50011-2010, Code for Seismic Design of Buildings; China Architecture & Building Press: Beijing, China, 2010.

- American Society of Civil Engineers. Minimum Design Loads and Associated Criteria for Buildings and Other Structures; American Society of Civil Engineers: Reston, VA, USA, 2017.

- NZS 3101:2006, Design of Concrete Structures; Concrete Structures Standards: Wellington, New Zealand, 2016.

- Amato, G.; Campione, G.; Cavaleri, L.; Minafo, G. Flexural behaviour of external R/C steel fibre reinforced beam–column joints. Eur. J. Environ. Civ. Eng. 2011, 15, 1253–1276. [Google Scholar] [CrossRef]

- Kabir, M.R.; Alam, M.S.; Said, A.M.; Ayad, A. Performance of hybrid reinforced concrete beam column joint: A critical review. Fibers 2016, 4, 13. [Google Scholar] [CrossRef] [Green Version]

- Abbas, A.A.; Mohsin, S.M.S.; Cotsovos, D.M. Seismic response of steel fiber reinforced concrete beam–column joints. Eng. Struct. 2014, 59, 261–283. [Google Scholar] [CrossRef] [Green Version]

- Pohoryles, D.A.; Melo, J.; Rossetto, T.; Varum, H.; Bisby, L. Seismic retrofit schemes with FRP for deficient RC beam–column joints: State–of–the–art review. J. Compos. Constr. 2019, 23, 3119001. [Google Scholar] [CrossRef] [Green Version]

- Attari, N.; Youcef, Y.S.; Amziane, S. Seismic Performance of Reinforced Concrete Beam–Column Joint Strengthening by FRP Sheets, Structures; Elsevier: Amsterdam, The Netherlands, 2019; pp. 353–364. [Google Scholar]

- Engindeniz, M.; Kahn, L.F.; Abdul-Hamid, Z. Repair and strengthening of reinforced concrete beam–column joints: State of the art. ACI Struct. J. 2005, 102, 1. [Google Scholar]

- Kaya, O.; Yalçın, C.; Parvin, A.; Altay, S. Retrofitting of Reinforced Concrete Beam–Column Joints by Composites–Part I: Experimental Study. ACI Struct. J. 2019, 116, 17. [Google Scholar] [CrossRef]

- Karayannis, C.G.; Chalioris, C.E.; Sirkelis, G.M. Local retrofit of exterior RC beam–column joints using thin RC jackets—An experimental study. Earthq. Eng. Struct. D 2008, 37, 727–746. [Google Scholar] [CrossRef]

- Ghobarah, A.; Said, A. Shear strengthening of beam–column joints. Eng. Struct. 2002, 24, 881–888. [Google Scholar] [CrossRef]

- Sumathi, A.; Mohan, K.S.R. Effect of Steel Fiber on Structural Characteristics of High–Strength Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 117–130. [Google Scholar] [CrossRef]

- Ramadoss, P.; Nagamani, K. Stress-strain behavior and toughness of high–performance steel fiber reinforced concrete in compression. Comput. Concr. 2013, 11, 149–167. [Google Scholar] [CrossRef]

- Choi, W.; Jung, K.; Jang, S.; Yun, H. The influence of steel fiber tensile strengths and aspect ratios on the fracture properties of high-strength concrete. Materials 2019, 12, 2105. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, H.R.; Han, S.J.; Yun, H.D. Compressive Properties of High Strength Steel Fiber Reinforced Concrete with Different Fiber Volume Fractions. Appl. Mech. Mater. 2013, 372, 215–218. [Google Scholar] [CrossRef]

- Conforti, A.; Zerbino, R.; Plizzari, G.A. Influence of steel, glass and polymer fibers on the cracking behavior of reinforced concrete beams under flexure. Struct. Concr. 2019, 20, 133–143. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P. Effect of curing period on properties of steel and polypropylene fibre reinforced ultra–high performance concrete. Mater. Sci. Eng. 2017, 245, 032059. [Google Scholar] [CrossRef]

- Cuenca, E.; Ferrara, L. Self–healing capacity of fiber reinforced cementitious composites. State of the art and perspectives. KSCE J. Civ. Eng. 2017, 21, 2777–2789. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X. Relationship between flowability, entrapped air content and strength of UHPC mixtures containing different dosage of steel fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef] [Green Version]

- Caggiano, A.; Gambarelli, S.; Martinelli, E.; Nisticò, N.; Pepe, M. Experimental characterization of the post–cracking response in hybrid steel/polypropylene fiber–reinforced concrete. Constr. Build. Mater. 2016, 125, 1035–1043. [Google Scholar] [CrossRef]

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of hybrid fiber reinforced concrete with recycled and industrial steel fibers. Constr. Build. Mater. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Simoes, T.; Octavio, C.; Valença, J.; Costa, H.; Dias–da–Costa, D.; Júlio, E. Influence of concrete strength and steel fiber geometry on the fiber/matrix interface. Compos. Part B Eng. 2017, 122, 156–164. [Google Scholar] [CrossRef] [Green Version]

- Shon, C.-S.; Mukashev, T.; Lee, D.; Zhang, D.; Kim, J.R. Can common reed fiber become an effective construction material? Physical, mechanical, and thermal properties of mortar mixture containing common reed fiber. Sustainability 2019, 11, 903. [Google Scholar] [CrossRef] [Green Version]

- Rizzuti, L.; Bencardino, F. Effects of fiber volume fraction on the compressive and flexural experimental behavior of SFRC. Contemp. Eng. Sci. 2014, 7, 379–390. [Google Scholar] [CrossRef]

- Lee, S.-C.; Oh, J.-H.; Cho, J.-Y. Compressive behavior of fiber–reinforced concrete with end–hooked steel fibers. Materials 2015, 8, 1442–1458. [Google Scholar] [CrossRef] [Green Version]

- Perceka, W.; Liao, W.-C.; Wang, Y.-D. High strength concrete columns under axial compression load: Hybrid confinement efficiency of high strength transverse reinforcement and steel fibers. Materials 2016, 9, 264. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Song, W.; Yin, J. Hybrid effect evaluation of steel fiber and carbon fiber on the performance of the fiber reinforced concrete. Materials 2016, 9, 704. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.; Yang, J. Effects of stirrup, steel fiber, and beam size on shear behavior of high–strength concrete beams. Cem. Concr. Compos. 2018, 87, 137–148. [Google Scholar] [CrossRef]

- Halimi, M.; Kioumarsi, M.; Bakhshi, H.; Sarkardeh, H. Numerical investigation on effects of steel fibers content on flexural behavior of UHPCC. In Proceedings of the 7th International Conference on Structural Engineering, Mechanics and Computation (SEMC 2019), Cape Town, South Africa, 2–4 September 2019. [Google Scholar]

- Kazemi, H.; Kioumarsi, M.; Zarghani, M.; Sarkardeh, H. Numerical simulation of reinforced concrete cut–off wall with steel fibers under dam. In Proceedings of the SynerCrete’18: Interdisciplinary Approaches for Cement–based Materials and Structural Concrete, Madeira, Portugal, 24–26 October 2018. [Google Scholar]

- Almusallam, T.; Ibrahim, S.; Al-Salloum, Y.; Abadel, A.; Abbas, H. Analytical and experimental investigations on the fracture behavior of hybrid fiber reinforced concrete. Cem. Concr. Compos. 2016, 74, 201–217. [Google Scholar] [CrossRef]

- Lee, J.-H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Yoon, Y.-S.; Banthia, N. Flexural response of steel–fiber–reinforced concrete beams: Effects of strength, fiber content, and strain–rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Canbolat, B.A.; Parra-Montesinos, G.J.; Wight, J.K. Experimental study on the seismic behavior of high–performance fiber–reinforced cement composite coupling beams. ACI Struct. J. 2005, 102, 159–166. [Google Scholar]

- Ma, K.; Qi, T.; Liu, H.; Wang, H. Shear behavior of hybrid fiber reinforced concrete deep beams. Materials 2018, 11, 2023. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torres, J.A.; Lantsoght, E.O.L. Influence of fiber content on shear capacity of steel fiber–reinforced concrete beams. Fibers 2019, 7, 102. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P. Hybrid fibers as shear reinforcement in high–performance concrete beams with and without openings. Appl. Sci. 2018, 8, 2070. [Google Scholar] [CrossRef] [Green Version]

- Smarzewski, P. Analysis of failure mechanics in hybrid fiber–reinforced high–performance concrete deep beams with and without openings. Materials 2019, 12, 101. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, J.; Liang, J.; Chu, L.; Shen, F. Experimental study on shear behavior of steel fiber reinforced concrete beams with high–strength reinforcement. Materials 2018, 11, 1682. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Colajanni, P.; Recupero, A.; Spinella, N. Generalization of shear truss model to the case of SFRC beams with stirrups. Comput. Concr. 2012, 9, 227–244. [Google Scholar] [CrossRef]

- Hwang, J.-H.; Lee, D.H.; Ju, H.; Kim, K.S.; Seo, S.-Y.; Kang, J.-W. Shear behavior models of steel fiberreinforced concrete beams modifying softened truss model approaches. Materials 2013, 6, 4847–4867. [Google Scholar] [CrossRef] [Green Version]

- Barros, J.A.; Figueiras, J.A. Flexural behavior of SFRC: Testing and modeling. ASCE J. Mater. Civ. Eng. 1999, 11, 331–339. [Google Scholar] [CrossRef] [Green Version]

- Campione, G.; Mangiavillano, M.L. Fibrous reinforced concrete beams in flexure: Experimental investigation, analytical modelling and design considerations. Eng. Struct. 2008, 30, 2970–2980. [Google Scholar] [CrossRef]

- Chalioris, C.E.; Kosmidou, P.M.; Karayannis, C.G. Cyclic Response of Steel Fiber Reinforced Concrete Slender Beams: An Experimental Study. Materials 2019, 12, 1398. [Google Scholar] [CrossRef] [Green Version]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G.; Elenas, A. Effect of Steel Fibers on the Hysteretic Performance of Concrete Beams with Steel Reinforcement—Tests and Analysis. Materials 2020, 13, 2923. [Google Scholar] [CrossRef]

- Hammad, N.; El-Nemr, A.; Hasan, E.D. The performance of fiber GGBS based alkali-activated concrete. J. Build. Eng. 2021, 42, 102464. [Google Scholar] [CrossRef]

- Lehner, P.; Konen, P.; Ponikiewski, T. Comparison of Material Properties of SCC Concrete with Steel Fibres Related to Ingress of Chlorides. Crystals 2020, 10, 220. [Google Scholar] [CrossRef] [Green Version]

- Issa, M.S.; Metwally, I.M.; Elzeiny, S.M. Influence of fibers on flexural behavior and ductility of concrete beams reinforced with GFRP rebars. Eng. Struct. 2011, 33, 1754–1763. [Google Scholar] [CrossRef]

- Zhu, H.; Li, Z.; Wen, C.; Cheng, S.; Wei, Y. Prediction model for the flexural strength of steel fiber reinforced concrete beams with fiber-reinforced polymer bars under repeated loading. Compos. Struct. 2020, 250, 112609. [Google Scholar] [CrossRef]

- Henager, C.H. Steel fibrous–ductile concrete joint for seismic–resistant structures. Spec. Publ. 1977, 53, 371–386. [Google Scholar]

- Filiatrault, A.; Pineau, S.; Houde, J. Seismic behavior of steel–fiber reinforced concrete interior beam–column joints. Struct. J. 1995, 92, 543–552. [Google Scholar]

- Gebman, M. Application of Steel Fiber Reinforced Concrete in Seismic Beam–Column Joints. Master’s Thesis, San Diego State University, San Diego, CA, USA, 2001. [Google Scholar]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites: Modern Concrete Technology Series, 2nd ed.; Taylor & Francis: New York, NY, USA, 2007; p. 624. [Google Scholar]

- Karayannis, C.G. Nonlinear analysis and tests of steel–fiber concrete beams in torsion. Struct. Eng. Mech. 2000, 9, 323–338. [Google Scholar] [CrossRef]

- Naaman, A.E. Engineered steel fibers with optimal properties for reinforcement of cement composites. J. Adv. Concr. Technol. 2003, 1, 241–252. [Google Scholar] [CrossRef] [Green Version]

- Chalioris, C.E.; Panagiotopoulos, T.A. Flexural analysis of steel fiber–reinforced concrete members. Comput. Concr. 2018, 22, 11–25. [Google Scholar]

- Li, Y.; Aoude, H. Influence of steel fibers on the static and blast response of beams built with high–strength concrete and high–strength reinforcement. Eng. Struct. 2020, 221, 111031. [Google Scholar] [CrossRef]

- Shannag, M.J.; Abu-Dyya, N.; Abu-Farsakh, G. Lateral load response of high performance fiber reinforced concrete beam–column joints. Constr. Build. Mater. 2005, 19, 500–508. [Google Scholar] [CrossRef]

- Ganesan, N.; Indira, P.V.; Abraham, R. Steel fibre reinforced high performance concrete beam–column joints subjected to cyclic loading. ISET J. Earthq. Technol. 2007, 44, 445–456. [Google Scholar]

- Rodrigues, H.; Arêde, A.; Varum, H.; Costa, A.G. Experimental evaluation of rectangular reinforced concrete column behaviour under biaxial cyclic loading. Earthq. Eng. Struct. D 2013, 42, 239–259. [Google Scholar] [CrossRef]

- Jiuru, T.; Chaobin, H.; Kaijian, Y.; Yongcheng, Y. Seismic behavior and shear strength of framed joint using steel–fiber reinforced concrete. J. Struct. Eng. 1992, 118, 341–358. [Google Scholar] [CrossRef]

- Hwang, S.J.; Lee, H.J. Analytical Model for Predicting Shear Strengths of Interior Reinforced Concrete Beam–Column Joints for Seismic Resistance. ACI Struct. J. 2000, 96, 846–857. [Google Scholar]

- Guo, Z.; Shi, X. Principle and Analysis of Reinforced Concrete; Tsinghua University Publication: Beijing, China, 2003. [Google Scholar]

- Chopra, A.K. Dynamics of Structures: Theory and Applications to Earthquake Engineering; Prentice Hall: Hoboken, NJ, USA, 2017. [Google Scholar]

- Zhao, G. Advanced Theory for Reinforced Concrete Structures; Machine Industry Press: Beijing, China, 2005. [Google Scholar]

| Joint Number | Concrete Strength (Mpa) | Axial Compression Ratio | Volume Ratio of Steel Fiber (%) | Stirrup Ratio (%) | Cubic Compressive Strength (Mpa) | Modulus of Elasticity (Mpa) |

|---|---|---|---|---|---|---|

| BCJ0 | C60 | 0.3 | 0 | 0.6 | 87.4 | 44,100 |

| BCJ1 | CF60 | 0.3 | 1.0 | 0.6 | 80.1 | 43,800 |

| BCJ2 | CF60 | 0.3 | 0.5 | 0.6 | 82.1 | 46,600 |

| BCJ3 | CF80 | 0.3 | 1.0 | 0.6 | 89.5 | 44,500 |

| BCJ4 | CF60 | 0.2 | 1.0 | 0 | 79.1 | 43,700 |

| BCJ5 | CF60 | 0.3 | 1.0 | 0 | 81.7 | 45,300 |

| BCJ6 | CF60 | 0.4 | 1.0 | 0 | 78.1 | 44,400 |

| Category | Diameter (mm) | Yield Strength fy (MPa) | Ultimate Strength fu (Mpa) | Elastic Modulus (Mpa) | Elongation |

|---|---|---|---|---|---|

| HPB235 | 8 | 306.9 | 472.7 | 209,000 | 30% |

| HRB335 | 16 | 360.5 | 594.9 | 201,000 | 23% |

| HRB335 | 22 | 418.2 | 652.1 | 195,000 | 27% |

| Joint Number | Yield Load Py (kN) | Yield Displacement ∆y (mm) | Ultimate Load Pu (kN) | The Ultimate Displacement ∆u (mm) | μ = ∆u/∆y | Equivalent Viscous Damping (he) |

|---|---|---|---|---|---|---|

| BCJ0 | 23.34 | 9.65 | 22.02 | 23.91 | 2.478 | 0.085 |

| BCJ1 | 28.36 | 11.42 | 31.22 | 41.09 | 3.598 | 0.187 |

| BCJ2 | 26.73 | 10.98 | 27.43 | 32.05 | 2.919 | 0.136 |

| BCJ3 | 29.81 | 11.03 | 32.39 | 35.92 | 3.257 | 0.201 |

| BCJ4 | 26.49 | 10.96 | 27.68 | 31 | 2.828 | 0.151 |

| BCJ5 | 26.87 | 11.05 | 29.53 | 31.88 | 2.885 | 0.156 |

| BCJ6 | 27.92 | 11.14 | 29.8 | 32.56 | 2.923 | 0.159 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, K.; Zhang, M.; Zhang, T.; Li, P.; Zhu, J.; Li, L. Seismic Performance of Steel Fiber Reinforced High–Strength Concrete Beam–Column Joints. Materials 2021, 14, 3235. https://doi.org/10.3390/ma14123235

Shi K, Zhang M, Zhang T, Li P, Zhu J, Li L. Seismic Performance of Steel Fiber Reinforced High–Strength Concrete Beam–Column Joints. Materials. 2021; 14(12):3235. https://doi.org/10.3390/ma14123235

Chicago/Turabian StyleShi, Ke, Mengyue Zhang, Tao Zhang, Pengfei Li, Junpeng Zhu, and Li Li. 2021. "Seismic Performance of Steel Fiber Reinforced High–Strength Concrete Beam–Column Joints" Materials 14, no. 12: 3235. https://doi.org/10.3390/ma14123235