Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement

Abstract

:1. Introduction

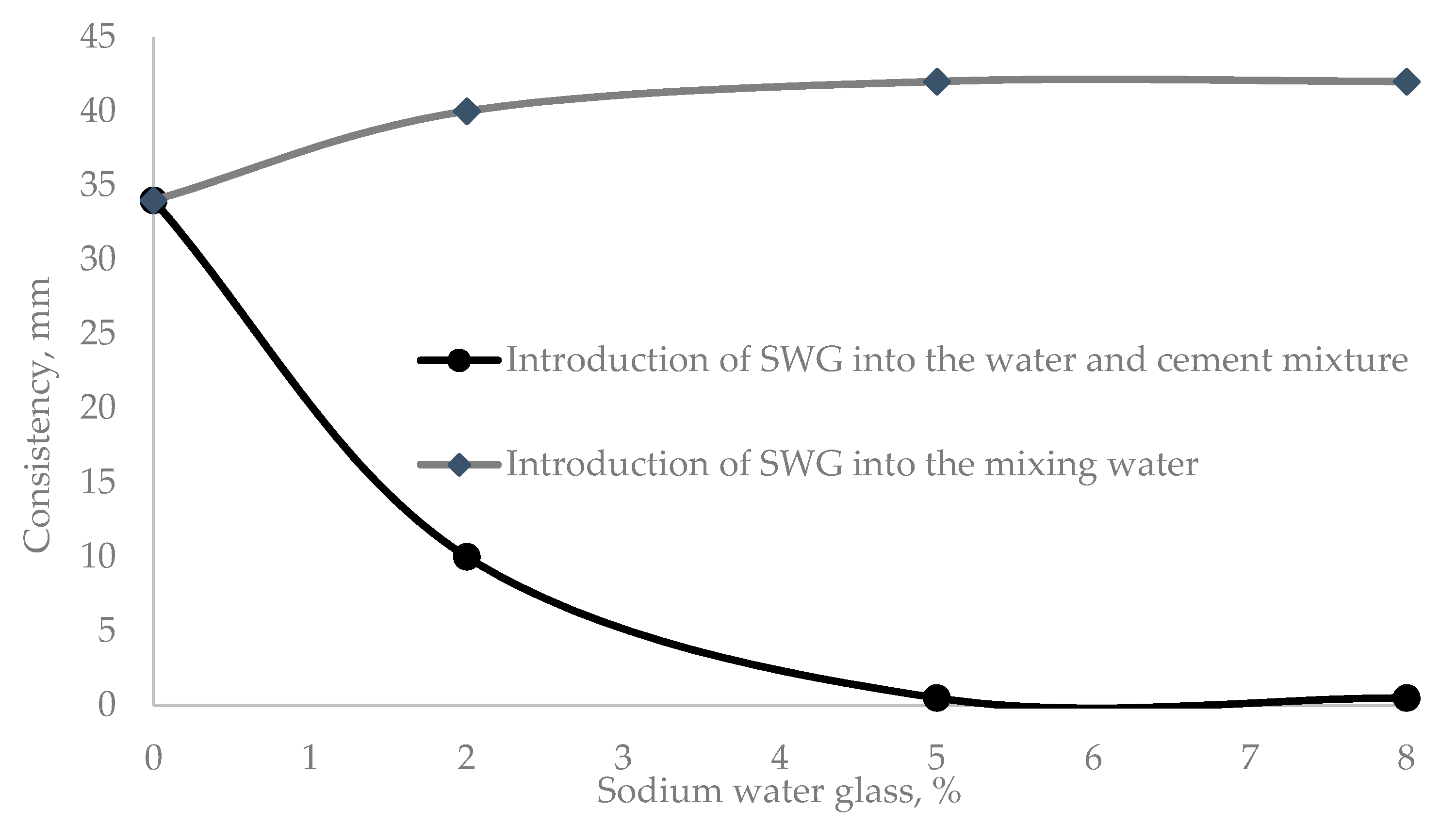

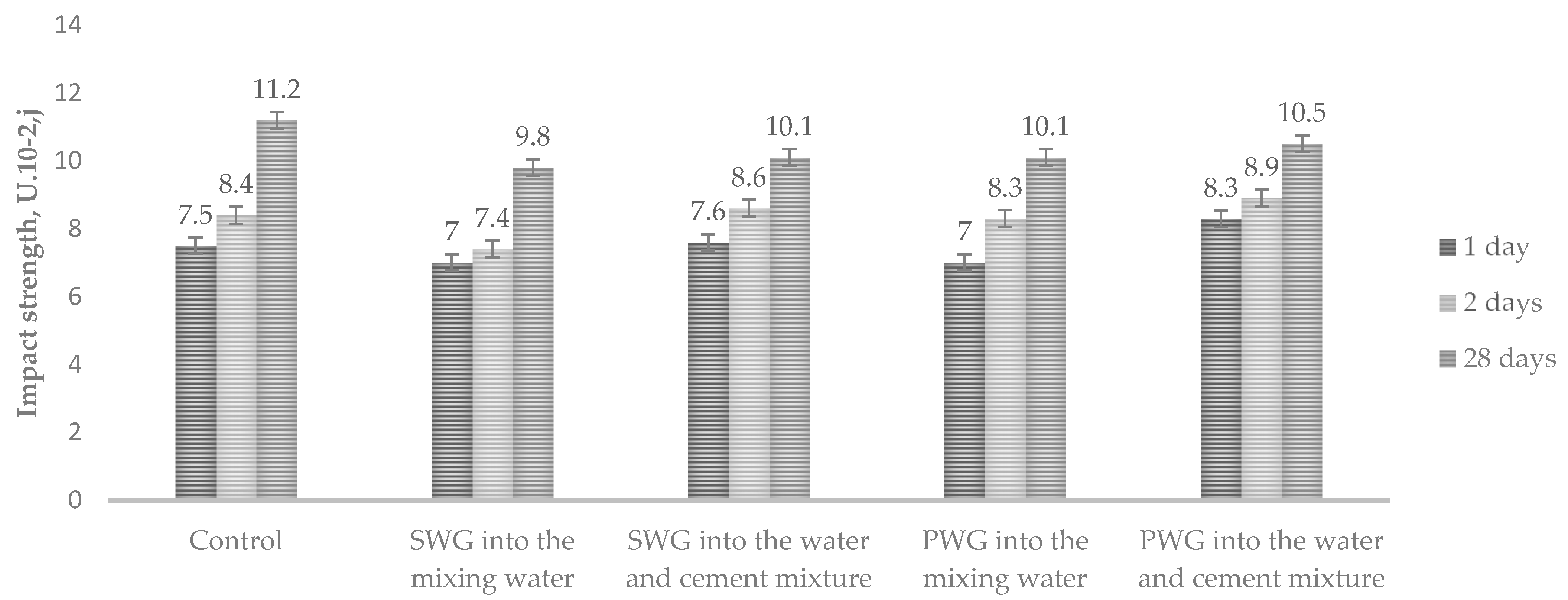

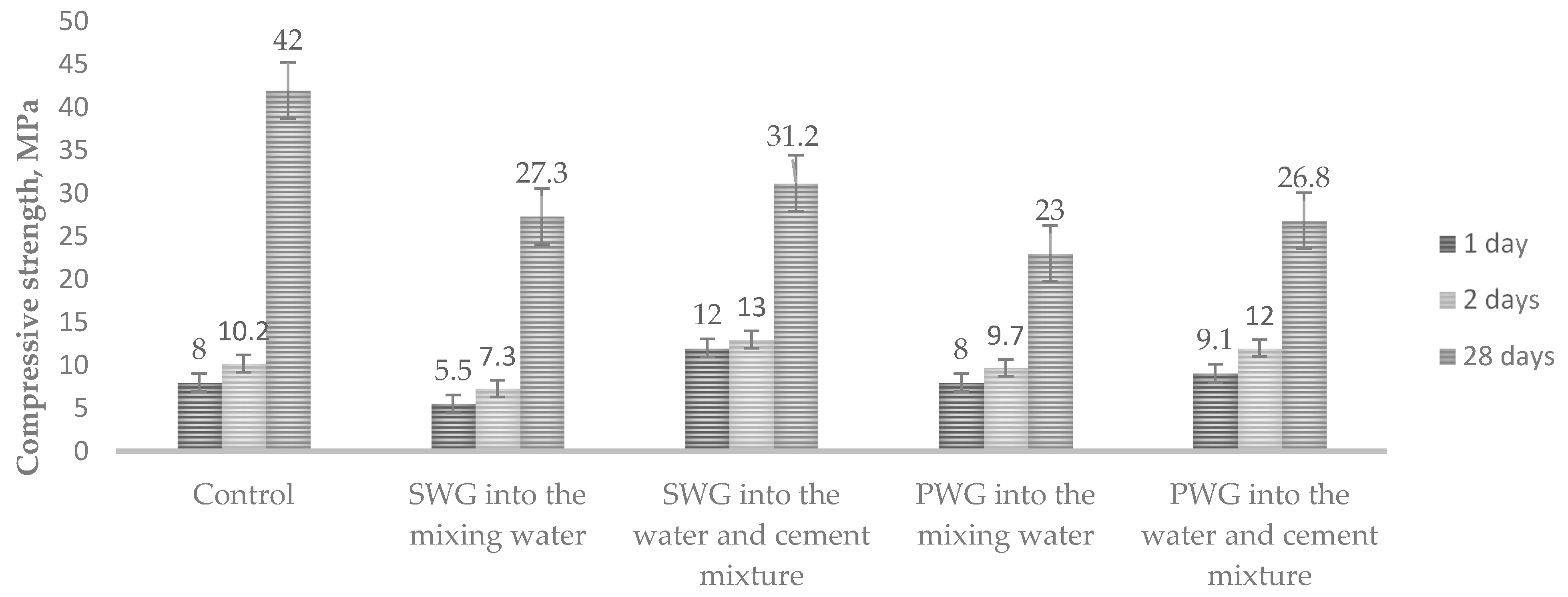

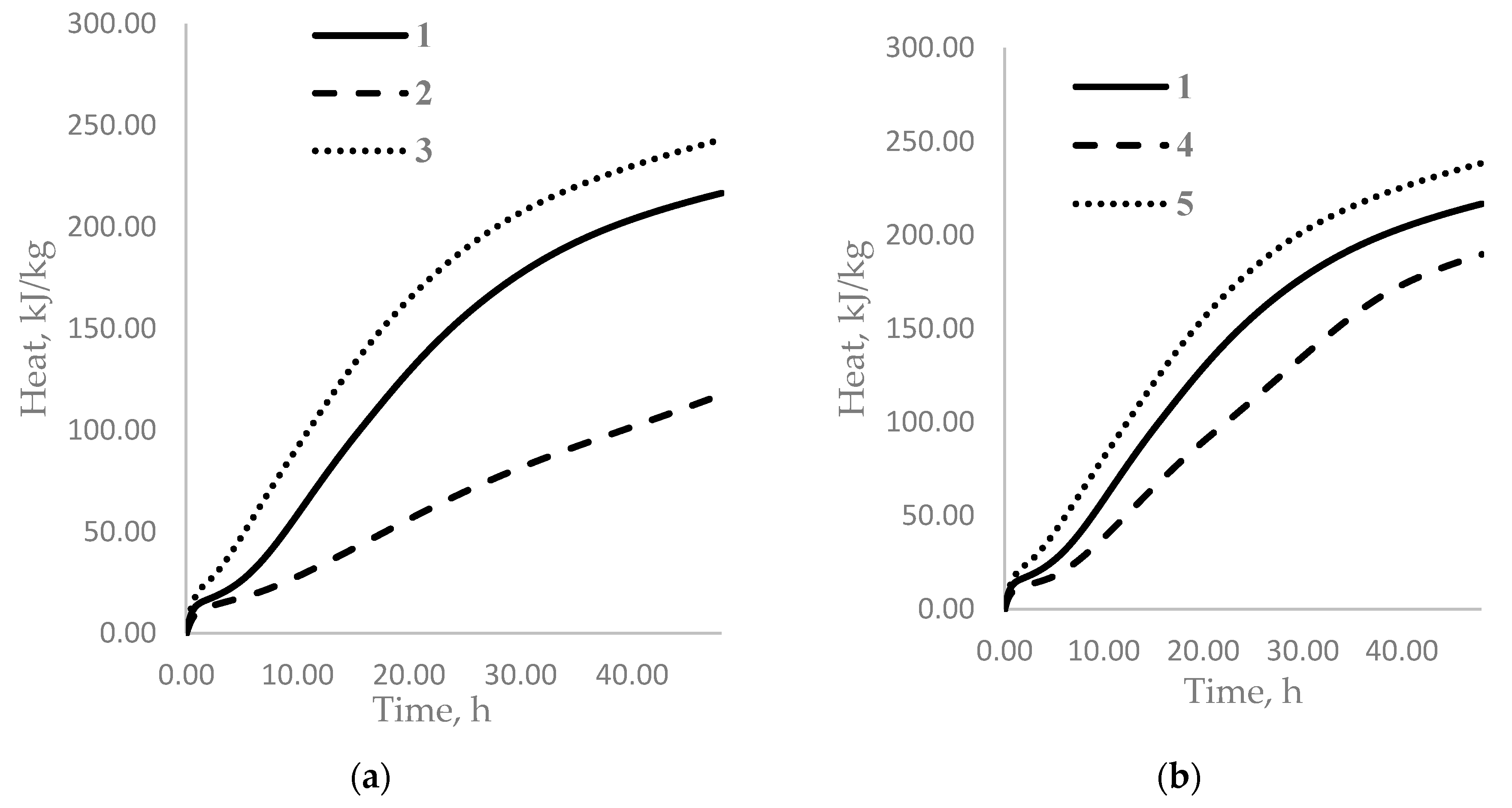

2. Materials and Methods

3. Experimental Section

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramachandran, V.S. Concrete Admixtures Handbook: Properties, Science, and Technology; Noyes Publications: Park Ridge, NJ, USA, 1995. [Google Scholar]

- Neville, A.M. Właściwości Betonu; Polski Cement: Kraków, Poland, 2012. [Google Scholar]

- John, M.; Scanlon, R.J.R. Accelerating Admixtures for Cold Weather Concreting. Available online: https://www.concreteconstruction.net/how-to/materials/accelerating-admixtures-for-cold-weather-concreting_o (accessed on 10 June 2021).

- Pizoń, J.; Miera, P.; Łaźniewska-Piekarczyk, B. Influence of Hardening Accelerating Admixtures on Properties of Cement with Ground Granulated Blast Furnace Slag. Procedia Eng. 2016, 161, 1070–1075. [Google Scholar] [CrossRef] [Green Version]

- Łukowski, P. Modyfikacja Materiałowa Betonu; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2016. [Google Scholar]

- Cheung, J.; Jeknavorian, A.; Roberts, L.; Silva, D. Impact of admixtures on the hydration kinetics of Portland cement. Cem. Concr. Res. 2011, 41, 1289–1309. [Google Scholar] [CrossRef]

- Chen, C.; Sun, Z. Influence of Aluminum Sulfate on Hydration and Properties of Cement Pastes. J. Adv. Concr. Technol. 2018, 16, 522–530. [Google Scholar] [CrossRef] [Green Version]

- Salvador, R.P.; Cavalaro, S.H.P.; Segura, I.; Figueiredo, A.D.; Pérez, J. Early age hydration of cement pastes with alkaline and alkali-free accelerators for sprayed concrete. Constr. Build. Mater. 2016, 111, 386–398. [Google Scholar] [CrossRef]

- Wang, Y.; He, F.; Wang, J.; Hu, Q. Comparison of Effects of Sodium Bicarbonate and Sodium Carbonate on the Hydration and Properties of Portland Cement Paste. Materials 2019, 12, 1033. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pashchenko, A. Teoria Cementa; Budivelnick: Kiev, Ukraine, 1991. [Google Scholar]

- Kurdowski, W. Chemia Cementu i Betonu; Stowarzyszenie Producentów Cementu: Kraków, Poland, 2010. [Google Scholar]

- Massazza, F. Admixtures in concrete. In Advances in Cement Technology; Pergamon Press: New York, NY, USA, 1983; pp. 569–648. [Google Scholar]

- Coppola, L. Role of Admixtures in Advanced Concrete Technology. In Proceedings of the Seventh Canmet/ACI International Conference on “Superplasticizers and Other Chemical Admixtures in Concrete”, Berlin, Germany, 20–23 October 2003; pp. 473–495. [Google Scholar]

- Polish Committee for Standardization. PN-EN, 934–2+A1:2012 Admixtures for Concrete, Mortar and Grout—Part 2: Concrete Admixtures—Definitions, Requirements, Conformity, Marking and Labelling; Polish Committee for Standardization: Warsaw, Poland, 2012; p. 24. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry; Thomas Telford Publishing: London, UK, 1997. [Google Scholar]

- Jolicoeur, C.; Simard, M.-A. Chemical admixture-cement interactions: Phenomenology and physico-chemical concepts. Cem. Concr. Compos. 1998, 20, 87–101. [Google Scholar] [CrossRef]

- Chen, G.; Lee, H.; Young, K.L.; Yue, P.L.; Wong, A.; Tao, T.; Choi, K.K. Glass recycling in cement production—An innovative approach. Waste Manag. 2002, 22, 747–753. [Google Scholar] [CrossRef]

- Shi, C.; Wu, Y.; Riefler, C.; Wang, H. Characteristics and pozzolanic reactivity of glass powders. Cem. Concr. Res. 2005, 35, 987–993. [Google Scholar] [CrossRef]

- Schwarz, N.; Neithalath, N. Influence of a fine glass powder on cement hydration: Comparison to fly ash and modeling the degree of hydration. Cem. Concr. Res. 2008, 38, 429–436. [Google Scholar] [CrossRef]

- Jani, Y.; Hogland, W. Waste glass in the production of cement and concrete—A review. J. Environ. Chem. Eng. 2014, 2, 1767–1775. [Google Scholar] [CrossRef]

- Bouchikhi, A.; Benzerzour, M.; Abriak, N.-E.; Maherzi, W.; Mamindy-Pajany, Y. Study of the impact of waste glasses types on pozzolanic activity of cementitious matrix. Constr. Build. Mater. 2019, 197, 626–640. [Google Scholar] [CrossRef]

- Liu, G.; Florea, M.V.A.; Brouwers, H.J.H. Performance evaluation of sustainable high strength mortars incorporating high volume waste glass as binder. Constr. Build. Mater. 2019, 202, 574–588. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Szewczenko, W.; Kotsay, G. Alkaline Activity of Portland Cement with Additives of Waste Glass. Materials 2021, 14, 1346. [Google Scholar] [CrossRef] [PubMed]

- Shevchenko, V.V. ASR effect in glasses used as additives to Portland cement. Glas. Phys. Chem. 2012, 38, 466–471. [Google Scholar] [CrossRef]

- Shevchenko, V.V.; Kotsai, G.N. Alkaline activity of glass powders used as additives to portland cement. Part I. Glas. Phys. Chem. 2015, 41, 500–502. [Google Scholar] [CrossRef]

- Shevchenko, V.V.; Kotsai, G.N. Nucleator Function of Glass Powders Used as Additives for Portland Cement. Glas. Phys. Chem. 2017, 43, 618–621. [Google Scholar] [CrossRef]

- Shevchenko, V.; Kotsay, G. Effect of Water Glass on Early Hardening of Portland Cement. Procedia Eng. 2017, 172, 977–981. [Google Scholar] [CrossRef]

- Czarnecki, L.; Broniewski, T.; Henning, O. Chemia w Budownictwie; Wydawnictwo Arkady: Warszawa, Poland, 2010. [Google Scholar]

- Kątna, Z. Wpływ szkła wodnego potasowego na parametry zaczynów cementowo-lateksowych. NAFTA-GAZ 2010, 6, 471–476. [Google Scholar]

- Baran, T. Influence of the potassium water glass on Portland cement hydration. Cem. Wapno Bet. 2004, 6, 298–306. [Google Scholar]

- Korneev, V.I.; Danilov, V.V. Zhidkoe i Rastvorimoe Steklo (Liquid Glass); Stroiizdat: St. Petersburg, Russia, 1996. [Google Scholar]

- Kessler, V.G. Sol-Gel Precursors. In The Sol-Gel Handbook; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2015; pp. 195–224. [Google Scholar]

- “RUDNIKI” S.A. Available online: http://www.zchrudniki.com.pl (accessed on 10 June 2021).

- Cement Ożarów. Available online: http://ozarow.com.pl (accessed on 10 June 2021).

- Polish Committee for Standardization. PN-EN, 196–3:2016-12 Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Polish Committee for Standardization. PN-EN, 196–1:2016 Methods of Testing Cement. Determination of Strength; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Polish Committee for Standardization. PN-EN ISO, 148–1:2016 Charpy Pendulum Impact Test—Part 1: Test Method; Polish Committee for Standardization: Warsaw, Poland, 2016. [Google Scholar]

- Shevchenko, V.V.; Kotsay, G.N. Influence of Glass Powder Additives on the Hydration Process of Portland Cement. Glas. Phys. Chem. 2020, 46, 653–656. [Google Scholar] [CrossRef]

- Baliński, A. O strukturze Uwodnionego Krzemianu Sodu Jako Spoiwa mas Formierskich; Instytut Odlewnictwa: Kraków, Poland, 2009. [Google Scholar]

- Yu, I. Orlov on the Glass Formation in the Na2O–SiO2–H2O System. Glas. Phys. Chem. 2002, 28, 281–287. [Google Scholar]

- Shevchenko, V.V.; Kotsay, G.N. The Effect of Additives of Water-Soluble Glass on the Extraction of Alkali from Portland Cement. Glas. Phys. Chem. 2019, 45, 596–598. [Google Scholar] [CrossRef]

| WG | Chemical Composition of Water Glass, wt % | Siliceous Module | ||

|---|---|---|---|---|

| SiO2 | Na2O | K2O | ||

| Sodium | 26.14 | 7.86 | - | 3.32 |

| Potassium | 23.56 | - | 6.58 | 3.58 |

| Chemical Composition, wt % | Phase Composition 1, wt % | Blaine Surface (cm2/g) | ||

|---|---|---|---|---|

| CaO | 64.23 | Alite (s) | 60.40 | 3380 |

| SiO2 | 21.75 | Belite (b) | 17.42 | |

| Al2O3 | 3.54 | Tricalcium aluminate | 3.47 | |

| Fe2O3 | 3.50 | Tetracalcium aluminoferrite | 10.60 | |

| Na2Oeq | 0.71 | Gypsum | 5.25 | |

| MgO | 0.80 | |||

| SO3 | 2.44 | |||

| Los of ignition | 3.03 | |||

| N Position | Composition | Introduction of WG |

|---|---|---|

| 1 | 100% CEM | - |

| 2 | 100% CEM + 5% sodium water glass (SWG) | Into the mixing water |

| 3 | Into the water and cement mixture | |

| 4 | 100% CEM + 5% potassium water glass (PWG) | Into the mixing water |

| 5 | Into the water and cement mixture |

| N Position | Setting Time, min | |

|---|---|---|

| Initial | Final | |

| 1 | 370 | 410 |

| 2 | 500 | 680 |

| 3 | 280 | 320 |

| 4 | 410 | 490 |

| 5 | 330 | 380 |

| N | Maximum Rate of Heat Evolution, W/kg | ||

|---|---|---|---|

| Pre-Induction Stage of Hydration | Induction Stage of Hydration | Post-Induction Stage of Hydration | |

| 1 | 8.18 | 0.62 | 2.16 |

| 2 | 4.54 | 0.41 | 0.81 |

| 3 | 10.45 | 1.36 | 2.51 |

| 4 | 5.35 | 0.43 | 1.25 |

| 5 | 9.24 | 1.14 | 2.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szewczenko, W.; Kotsay, G. Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement. Materials 2021, 14, 3257. https://doi.org/10.3390/ma14123257

Szewczenko W, Kotsay G. Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement. Materials. 2021; 14(12):3257. https://doi.org/10.3390/ma14123257

Chicago/Turabian StyleSzewczenko, Wiktor, and Galyna Kotsay. 2021. "Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement" Materials 14, no. 12: 3257. https://doi.org/10.3390/ma14123257

APA StyleSzewczenko, W., & Kotsay, G. (2021). Influence of Water Glass Introduction Methods on Selected Properties of Portland Cement. Materials, 14(12), 3257. https://doi.org/10.3390/ma14123257