Sustainable Green Lightweight Concrete Containing Plastic-Based Green Lightweight Aggregate

Abstract

:1. Introduction

2. Materials and Methods

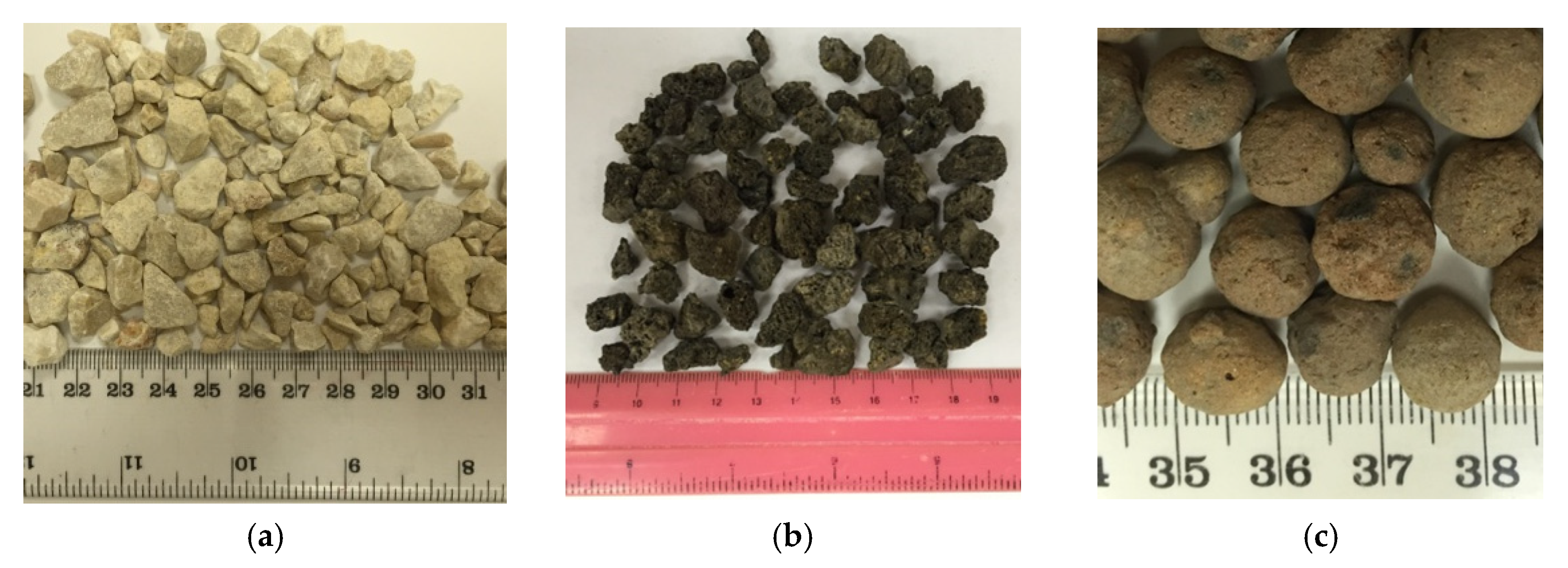

2.1. Material Used

2.2. Mix Design Procedure and Test Conducted

3. Plastic-Based Green Lightweight Aggregate Production

4. Plastic-Based Green Lightweight Aggregate Investigation

- Category 1—contains aggregates that diverged from the maximum limits of [42] for the lower sieve size (#4), as seen in PGLA2 and PGLA3. These aggregates deviated by 19% and 8%, respectively.

- Category 2—which diverged from the minimum limits of [42] for the upper sieve (#3/8). For instance, PGLA1 slightly deviated by 3.5%, while VLA significantly deviated by 39%.

5. Green Lightweight Aggregate Concrete Investigation

5.1. Fresh Properties

5.2. Dry Density

5.3. Compressive Strength

5.4. Splitting Tensile Strength

5.5. Microscopic Investigations and Mechanism of Failure

5.6. Durability Related Properties

6. Conclusions

- PGLAs were successfully developed using PET plastic waste and different types of by product additives. The produced PGLAs presented potential applications for the use in green concrete as a total replacement of conventional VLA and NCA, as they satisfied ASTM C330-04 standard limits. PGLAs exhibit lower water absorption and unit weight together with better grading and high strength.

- Green lightweight aggregate concrete mixes demonstrate high slump due to the shape and texture of the produced aggregates (i.e., PGLAs).

- The unit weight of green lightweight aggregate concretes in fresh and dry state was reduced as compared to normal weight concrete.

- The 28-day compressive strength of green lightweight aggregate concretes was reduced from 24% to 39%, with respect to normal weight concrete; whereas insignificant differences varied between −8% and 13%, as compared to conventional lightweight concrete.

- The 28-day splitting tensile strength of green lightweight aggregate concretes was significantly reduced from 13% to 30% and from 35% to 48%, as compared to lightweight and normal weight concrete, respectively.

- Under flexural loading, the green lightweight aggregate concretes exhibited the same mode of failure for those mixes made with conventional lightweight and normal weight aggregates, as expected. However, under compression loading, the mode of failure in green lightweight aggregate concretes behaved similarly to normal weight concrete, with crack propagation through the cement matrix; in contrast with crack propagation through the aggregate itself, which was observed for conventional lightweight concrete.

- The resistance of concrete to chloride ion penetrability increases with the incorporation of plastic-based green lightweight aggregates. Thus, green lightweight aggregate concrete has potential application in structural and non-structural lightweight applications that are exposed to the risk of chloride attack, as it satisfied the requirements of ASTM C1202-12.

- Green lightweight concrete has the potential to be used in structural and non-structural lightweight applications since it satisfied dry density, compressive and splitting tensile strength requirements specified in ASTM C330. However, these results must be checked in terms of different W/C ratio, chemical admixtures, lone term test and durability test before it can be recommended in a large-scale application.

Funding

Acknowledgments

Conflicts of Interest

References

- Monteiro, P.J.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutiérrez, A. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Juki, M.I.; Awang, M.; Annas, M.M.K.; Boon, K.H.; Othman, N.; Roslan, M.A.; Khalid, F.S. Relationship between Compressive, Splitting Tensile and Flexural Strength of Concrete Containing Granulated Waste Polyethylene Terephthalate (PET) Bottles as Fine Aggregate. Adv. Mater. Res. 2013, 795, 356–359. [Google Scholar] [CrossRef] [Green Version]

- Rahmani, E.; Dehestani, M.; Beygi, M.H.A.; Allahyari, H.; Nikbin, I.M. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Remadnia, A.; Dheilly, R.; Laidoudi, B.; Quéneudec, M. Use of animal proteins as foaming agent in cementitious concrete composites manufactured with recycled PET aggregates. Constr. Build. Mater. 2009, 23, 3118–3123. [Google Scholar] [CrossRef]

- Ferreira, L.; de Brito, J.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Saikia, N.; Brito, J.D. Waste polyethylene terephthalate as an aggregate in concrete. Mater. Res. 2013, 16, 341–350. [Google Scholar] [CrossRef] [Green Version]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Silva, R.; de Brito, J.; Saikia, N. Influence of curing conditions on the durability-related performance of concrete made with selected plastic waste aggregates. Cem. Concr. Compos. 2013, 35, 23–31. [Google Scholar] [CrossRef]

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Rai, B.; Rushad, S.T.; Kr, B.; Duggal, S. Study of waste plastic mix concrete with plasticizer. ISRN Civ. Eng. 2012, 2012, 469272. [Google Scholar] [CrossRef] [Green Version]

- Choi, Y.W.; Moon, D.J.; Kim, Y.J.; Lachemi, M. Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles. Constr. Build. Mater. 2009, 23, 2829–2835. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Properties of lightweight expanded polystyrene concrete reinforced with steel fiber. Cem. Concr. Res. 2004, 34, 1259–1263. [Google Scholar] [CrossRef]

- Tang, W.; Lo, Y.; Nadeem, A. Mechanical and drying shrinkage properties of structural-graded polystyrene aggregate concrete. Cem. Concr. Compos. 2008, 30, 403–409. [Google Scholar] [CrossRef]

- Ben Fraj, A.; Kismi, M.; Mounanga, P. Valorization of coarse rigid polyurethane foam waste in lightweight aggregate concrete. Constr. Build. Mater. 2010, 24, 1069–1077. [Google Scholar] [CrossRef] [Green Version]

- Al-Manaseer, A.; Dalal, T. Concrete containing plastic aggregates. Concr. Int. 1997, 19, 47–52. [Google Scholar]

- Haghi, A.; Arabani, M.; Ahmadi, H. Applications of expanded polystyrene (EPS) beads and polyamide-66 in civil engineering, Part One: Lightweight polymeric concrete. Compos. Interfaces 2006, 13, 441–450. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Zafar, I. Plastic-based sustainable synthetic aggregate in Green Lightweight concrete—A review. Constr. Build. Mater. 2021, 292, 123321. [Google Scholar] [CrossRef]

- Lima, P.R.L.; Leite, M.B.; Santiago, E.Q.R. Recycled lightweight concrete made from footwear industry waste and CDW. Waste Manag. 2010, 30, 1107–1113. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Islam, M.A.; Ahmed, M. Recycling of waste polymeric materials as a partial replacement for aggregate in concrete. In Proceedings of the International Conference on Chemical, Environmental and Biological Sciences (ICCEBS’12), Penang, Malaysia, 11–12 February 2012. [Google Scholar]

- Sabaa, B.; Ravindrarajah, R.S. Engineering properties of lightweight concrete containing crushed expanded polystyrene waste. In Proceedings of the Symposium MM: Advances in Materials for Cementitious Composites, Boston, MA, USA, 1–3 December 1997; pp. 1–3. [Google Scholar]

- Jansen, D.C.; Kiggins, M.L.; Swan, C.W.; Malloy, R.A.; Kashi, M.G.; Chan, R.A.; Javdekar, C.; Siegal, C.; Weingram, J. Lightweight Fly Ash-Plastic Aggregates in Concrete. Transp. Res. Rec. J. Transp. Res. Board 2001, 1775, 44–52. [Google Scholar] [CrossRef]

- Kashi, M.; Swan, C.; Holmstrom, O.; Malloy, R. Innovative lightweight synthetic aggregates developed from coal Flyash. In Proceedings of the 13th International Symposium on Use and Management of Coal Combustion Products (CCPs), Orlando, FL, USA, 10–14 January 1999; Volume 1, pp. 1–5. [Google Scholar]

- Slabaugh, S.; Swan, C.; Malloy, R. Development and properties of Foamed synthetic Lightweight Aggregates. In Proceedings of the World of Coal Ash (WOCA) Conference, Covington, KY, USA, 7–10 May 2007. [Google Scholar]

- Malloy, R.; Desai, N.; Wilson, C.; Swan, C.; Jansen, D.; Kashi, M. High Carbon Fly Ash/Mixed Thermoplastic Aggregate for Use in Lightweight Concrete (859). In Proceedings of the Technical Papers of the Annual Technical Conference-Society of Plastics Engineers Incorporated, Dallas, TX, USA, 6–10 May 2001; Volume 3, pp. 2743–2752. [Google Scholar]

- Kou, S.; Lee, G.; Poon, C.; Lai, W. Properties of lightweight aggregate concrete prepared with PVC granules derived from scraped PVC pipes. Waste Manag. 2009, 29, 621–628. [Google Scholar] [CrossRef] [PubMed]

- Sakr, K.; El-Hakim, E. Effect of high temperature or fire on heavy weight concrete properties. Cem. Concr. Res. 2005, 35, 590–596. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.-M.; Queneudec, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef] [PubMed]

- Alqahtani, F.K.; Ghataora, G.; Dirar, S.; Khan, M.I.; Zafar, I. Experimental study to investigate the engineering and durability performance of concrete using synthetic aggregates. Constr. Build. Mater. 2018, 173, 350–358. [Google Scholar] [CrossRef] [Green Version]

- Alqahtani, F.K.; Ghataora, G.; Khan, M.I.; Dirar, S. Novel lightweight concrete containing manufactured plastic aggregate. Constr. Build. Mater. 2017, 148, 386–397. [Google Scholar] [CrossRef]

- Alqahtani, F.K.; Khan, M.I.; Ghataora, G.; Dirar, S. Production of Recycled Plastic Aggregates and Its Utilization in Concrete. J. Mater. Civ. Eng. 2017, 29, 04016248. [Google Scholar] [CrossRef] [Green Version]

- Alqahtani, F.K.; Zafar, I. Characterization of processed lightweight aggregate and its effect on physical properties of concrete. Constr. Build. Mater. 2020, 230, 116992. [Google Scholar] [CrossRef]

- Koide, H.; Tomon, M.; Sasaki, T. Investigation of the use of waste plastic as an aggregate for lightweight concrete. In Challenges of Concrete Construction: Volume 5, Sustainable Concrete Construction, Proceedings of the International Conference Held at the University of Dundee, Scotland, UK, 9–11 September 2002; Thomas Telford Publishing: London, UK, 2002; Volume 5, pp. 177–185. [Google Scholar]

- Kayali, O. Fly ash lightweight aggregates in high performance concrete. Constr. Build. Mater. 2008, 22, 2393–2399. [Google Scholar] [CrossRef]

- ASTM C33/C33M-16. Standard Specification for Concrete Aggregates; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM C136/C136M-14. Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ACI 211.2-98. Standard Practice for Selecting Proportions for Structural Lightweight Concrete (Reapproved 2004); American Concrete-ACI Committee 211; American Concrete Institute: Farmington Hills, MI, USA, 1998. [Google Scholar]

- ASTM C330/C330M-14. Standard Specification for Lightweight Aggregates for Structural Concrete; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM C192/C192M-16. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM C143/C143M-15. Standard Test Method for Slump of Hydraulic-Cement Concrete; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C138/C138M-16. Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- BS EN 12390-7:2009. Testing Hardened Concrete:Density of Hardened Concrete; British Standards Institution: London, UK, 2009. [Google Scholar]

- ASTM C579-02. Standard Test Methods for Compressive Strength of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer Concretes; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- ASTM C496/C496M-11. Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- ASTM C1202-12. Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [Green Version]

- Rebeiz, K.; Craft, A. Plastic waste management in construction: Technological and institutional issues. Resour. Conserv. Recycl. 1995, 15, 245–257. [Google Scholar] [CrossRef]

- Alqahtani, F.K. Recycled Plastic Aggregate for Use in Concrete. U.S. Patent 10,294,155, 21 May 2019. [Google Scholar]

- Gambhir, M.L. Concrete Technology: Theory and Practice; Tata McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Rached, M.M.; de Moya, M.; Fowler, D.W. Utilizing Aggregates Characteristics to Minimize Cement Content in Portland Cement Concrete; The University of Texas at Austin: Austin, TX, USA, 2009. [Google Scholar]

- Phillips, P.; Richards, G. The use of mixed polymer waste products to produce paving grade asphalt. In Proceedings of the 3rd Eurasphalt and Eurobitume Congress, Vienna, Austria, 12–14 May 2004. [Google Scholar]

- Swan, C.; Sacks, A. Properties of synthetic lightweight aggregates for use in pavement systems. Adv. Pavement Eng. 2005, 1–12. [Google Scholar] [CrossRef]

- Rodrigues, F.; Evangelista, L.; de Brito, J. A new method to determine the density and water absorption of fine recycled aggregates. Mater. Res. 2013, 16, 1045–1051. [Google Scholar] [CrossRef] [Green Version]

- Kozul, R.; Darwin, D. Effects of Aggregate Type, Size, and Content on Concrete Strength and Fracture Energy; University of Kansas Center for Research, Inc.: Lawrence, KS, USA, 1997. [Google Scholar]

- BS 812-112:1990. Methods for Determination of Aggregate Impact Value (AIV); British Standards Institution: London, UK, 1990. [Google Scholar]

- ACI 213R-03. Guide for Structural Lightweight-Aggregate Concrete-ACI Committee 213; American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Hamad, A.J. Size and shape effect of specimen on the compressive strength of HPLWFC reinforced with glass fibres. J. King Saud Univ. Eng. Sci. 2017, 29, 373–380. [Google Scholar] [CrossRef] [Green Version]

- Neville, A.M. Properties of Concrete; Pearson Education Limited: Essex, UK, 2011. [Google Scholar]

- Alqahtani, F.K.; Rashid, K.; Zafar, I.; Khan, M.I. Assessment of morphological characteristics and physico-mechanical properties of geopolymer green foam lightweight aggregate formulated by microwave irradiation. J. Build. Eng. 2021, 35, 102081. [Google Scholar] [CrossRef]

- Verbeck, G.J.; Helmuth, R.H. Structures and physical properties of cement paste. In Proceedings of the 5th International Congress on the Chemistry of Cement, Tokyo, Japan, 7–11 October 1968; Volume 3, pp. 1–32. [Google Scholar]

| Test | Coarse Aggregate | Fine Aggregate | |||

|---|---|---|---|---|---|

| Normal Weight Aggregate (NCA) | Volcanic Lightweight Aggregate (VLA) | Lytag aggregate (LYA) | Crushed Sand | Red Sand | |

| Bulk Specific Gravity | 2.59 | 1.41 | 1.44 | 2.59 | 2.62 |

| Dry Unit Weight (kg/m3) | 1554 | 697 | 889 | 1599 | 1589 |

| Absorption (%) | 1.48 | 18.6 | 16.82 | 1.67 | 0.28 |

| Fineness Modulus | 5.83 | 6.5 | - | 3.89 | 1.54 |

| Type | Crushed | Uncrushed | Pelletising | Crushed | Uncrushed |

| Nominal Maximum Size (mm) | 10 | 10 | 10 | 4.75 | 1.18 |

| Concrete Type | Water Cement Ratio (W/C) | Total Water | Free Water | Cement | Fine Aggregates | Coarse Aggregate | ||

|---|---|---|---|---|---|---|---|---|

| NCA | VLA | PGLA | ||||||

| Kg/m3 | ||||||||

| NCAC | 0.5 | 243.9 | 228 | 456 | 770 | 784 | - | - |

| VLAC | 299 | 228 | 456 | 909 | - | 352 | - | |

| GLAC1 | 240.8 | 228 | 456 | 708 | - | - | 637 | |

| GLAC2 | 239.2 | 228 | 456 | 729 | - | - | 570 | |

| GLAC3 | 242.6 | 228 | 456 | 729 | - | - | 618 | |

| Test Type | Testing Age (Day) | Standard Used |

|---|---|---|

| Slump test | - | ASTM C143/C143M-15 [44] |

| Fresh density test | - | ASTM C138/C138M-16 [45] |

| Dry density test | 28 | BS EN 12390-7:2009 [46] |

| Compressive strength test | 7, 14, 28 | ASTM C579-02 [47] |

| Splitting tensile strength test | 7,14,28 | ASTM C496/C496M-11 [48] |

| Chloride ion penetration test | 28 | ASTM C1202-12 [49] |

| Sr. No. | Designation | Type of Plastic Waste | Percentage of Plastic Waste | Type of Additives | Percentage of Additives |

|---|---|---|---|---|---|

| 4 | PGLA1 | PET | 30 | DDA | 70 |

| 5 | PGLA2 | PET | 30 | FAA | 70 |

| 6 | PGLA3 | PET | 30 | QDA | 70 |

| Property | NCA | VLA | LYA | PGLA1 | PGLA2 | PGLA3 |

|---|---|---|---|---|---|---|

| Bulk Specific Gravity (OD basis) | 2.59 | 1.4 | 1.44 | 1.95 | 1.79 | 1.94 |

| Bulk Specific Gravity (SSD basis) | 2.63 | 1.67 | 1.69 | 1.98 | 1.81 | 1.97 |

| Absorption (%) | 1.48 | 18.6 | 16.82 | 1.38 | 1.21 | 1.68 |

| Dry Unit Weight (kg/m3) | 1554 | 697 | 889 | 1260 | 1128 | 1222 |

| Voids (%) | 37.79 | 50 | 39.02 | 24.97 | 32.82 | 27.22 |

| Fineness Modulus | 5.83 | 6.5 | - | 5.87 | 5.65 | 5.74 |

| Impact Value (%) | 9.65 | 39.46 | 21.55 | 21.33 | 22.64 | 19.84 |

| Particles Shape | Angular | Pours | Round | Sub-angular | Sub-angular | Angular |

| Surface Texture | Rough | Rough | Smooth | Partially rough | Partially smooth | Rough |

| Colour | White | Black | Brown | Red | Grey | Yellow |

| Type | Crushed | Uncrushed | Pelletising | Crushed | ||

| Nominal Maximum Size (mm) | 10 | |||||

| Sample | Slump (mm) | Fresh Density (kg/m3) |

|---|---|---|

| NCAC | 100 | 2331 |

| VLAC | 210 | 1968 |

| GLAC1 | 250 | 2030 |

| GLAC2 | 125 | 1961 |

| GLAC3 | 210 | 2013 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alqahtani, F.K. Sustainable Green Lightweight Concrete Containing Plastic-Based Green Lightweight Aggregate. Materials 2021, 14, 3304. https://doi.org/10.3390/ma14123304

Alqahtani FK. Sustainable Green Lightweight Concrete Containing Plastic-Based Green Lightweight Aggregate. Materials. 2021; 14(12):3304. https://doi.org/10.3390/ma14123304

Chicago/Turabian StyleAlqahtani, Fahad K. 2021. "Sustainable Green Lightweight Concrete Containing Plastic-Based Green Lightweight Aggregate" Materials 14, no. 12: 3304. https://doi.org/10.3390/ma14123304

APA StyleAlqahtani, F. K. (2021). Sustainable Green Lightweight Concrete Containing Plastic-Based Green Lightweight Aggregate. Materials, 14(12), 3304. https://doi.org/10.3390/ma14123304