Ellipsometry Study of CdSe Thin Films Deposited by PLD on ITO Coated Glass Substrates

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

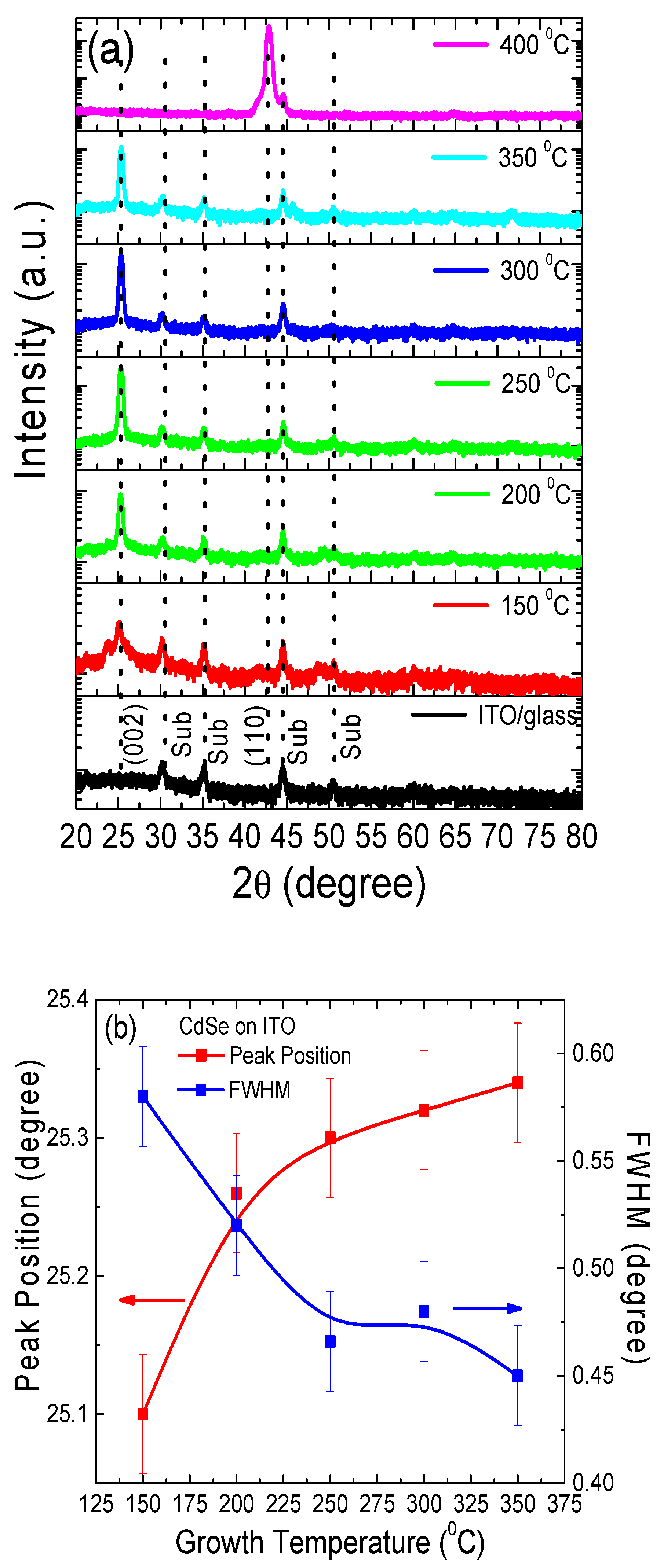

3.1. Crystallinity

3.2. Morphology Analysis

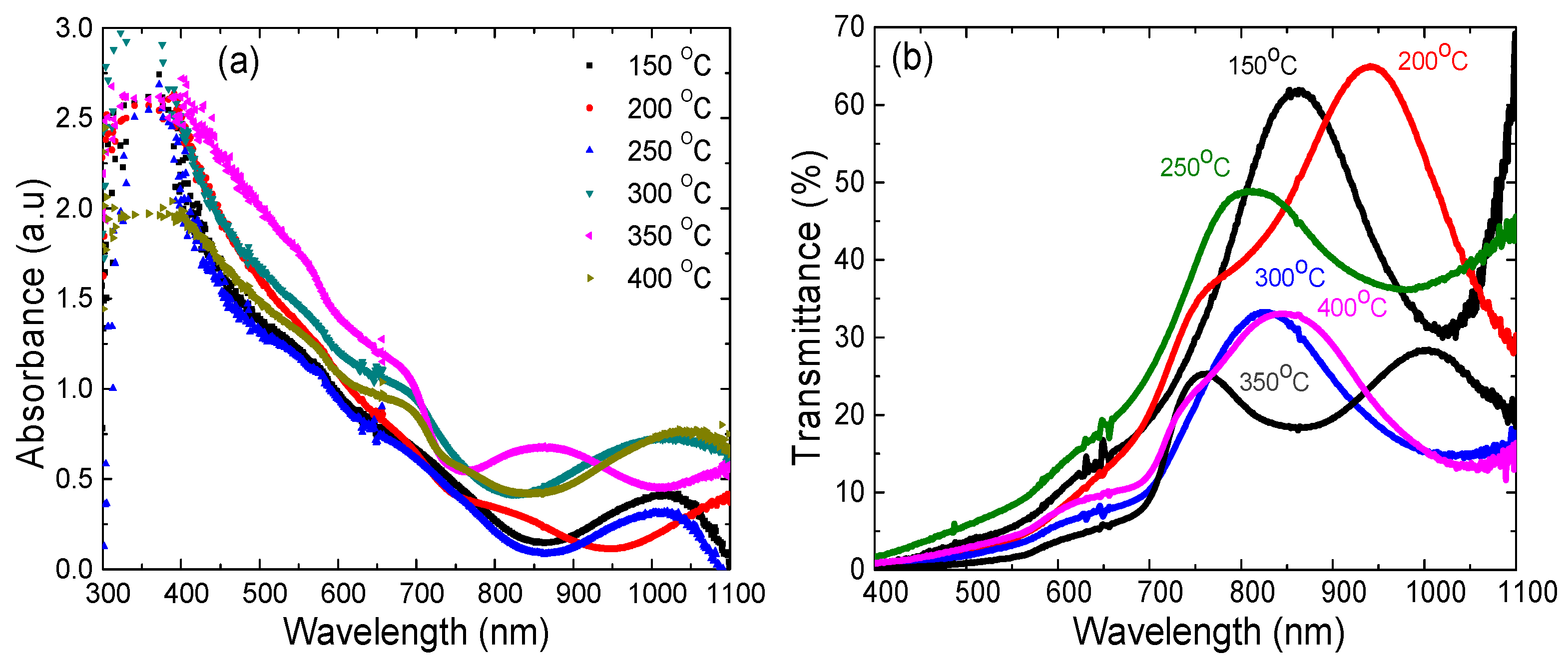

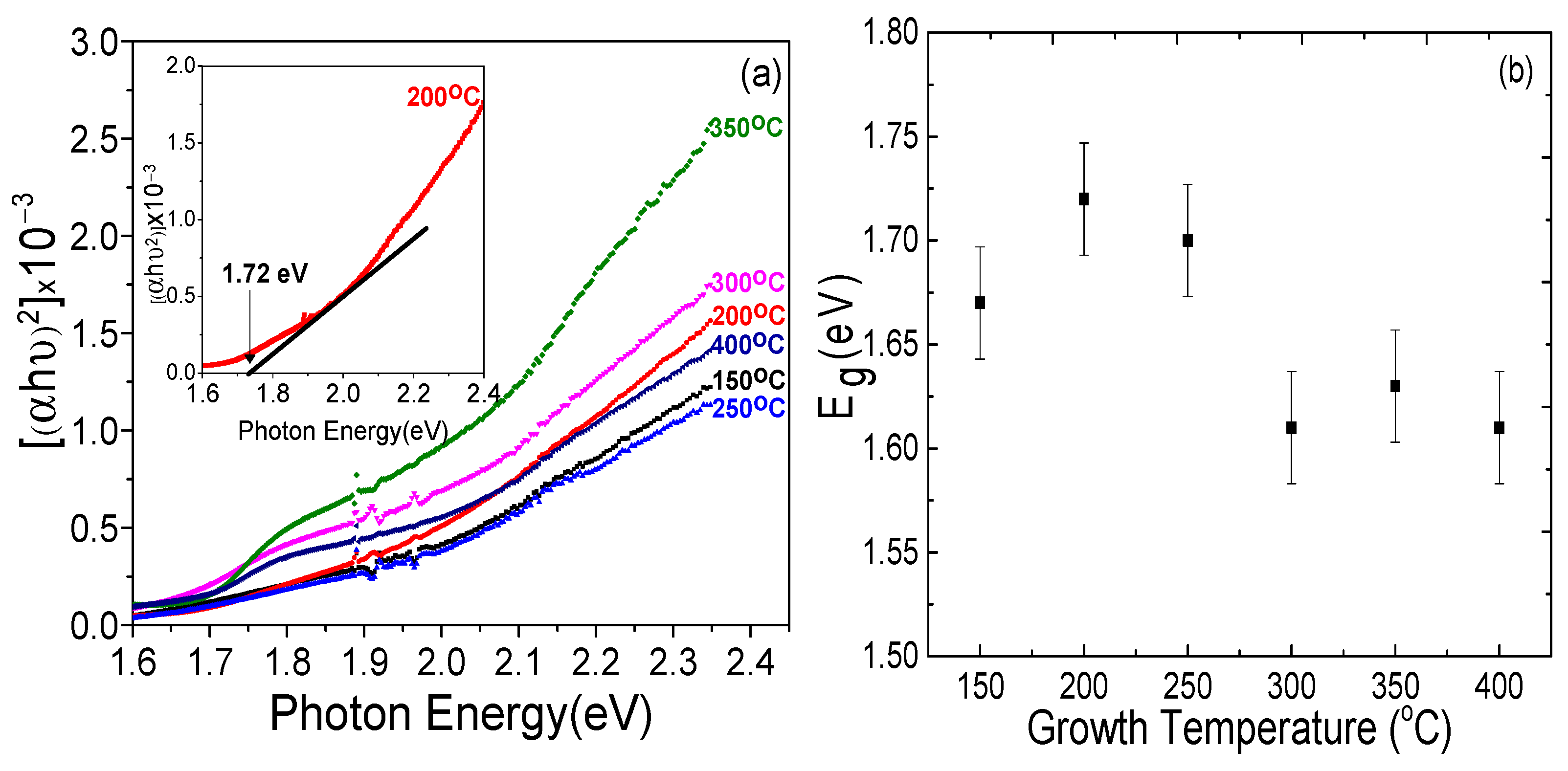

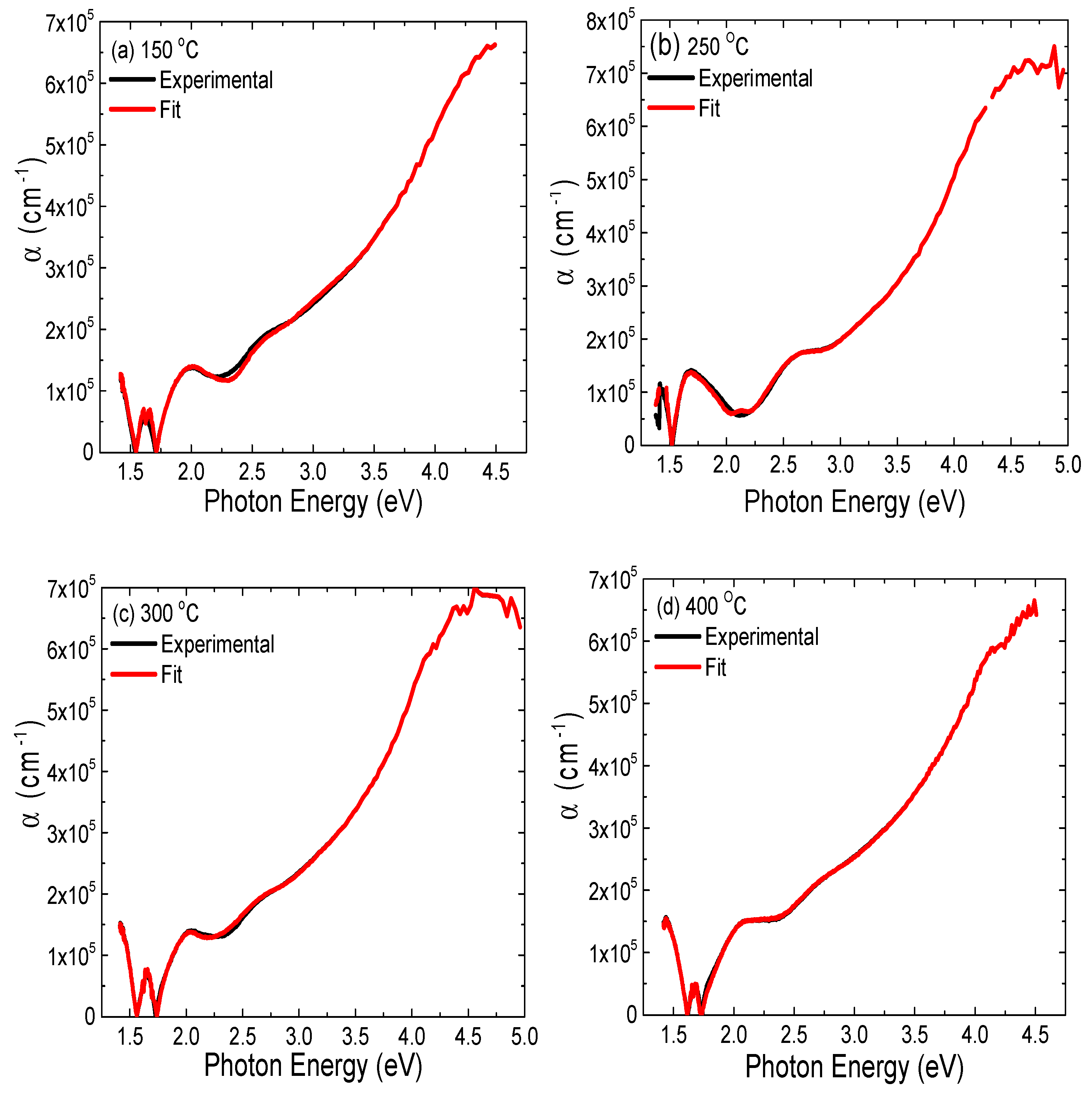

3.3. Optical Analysis

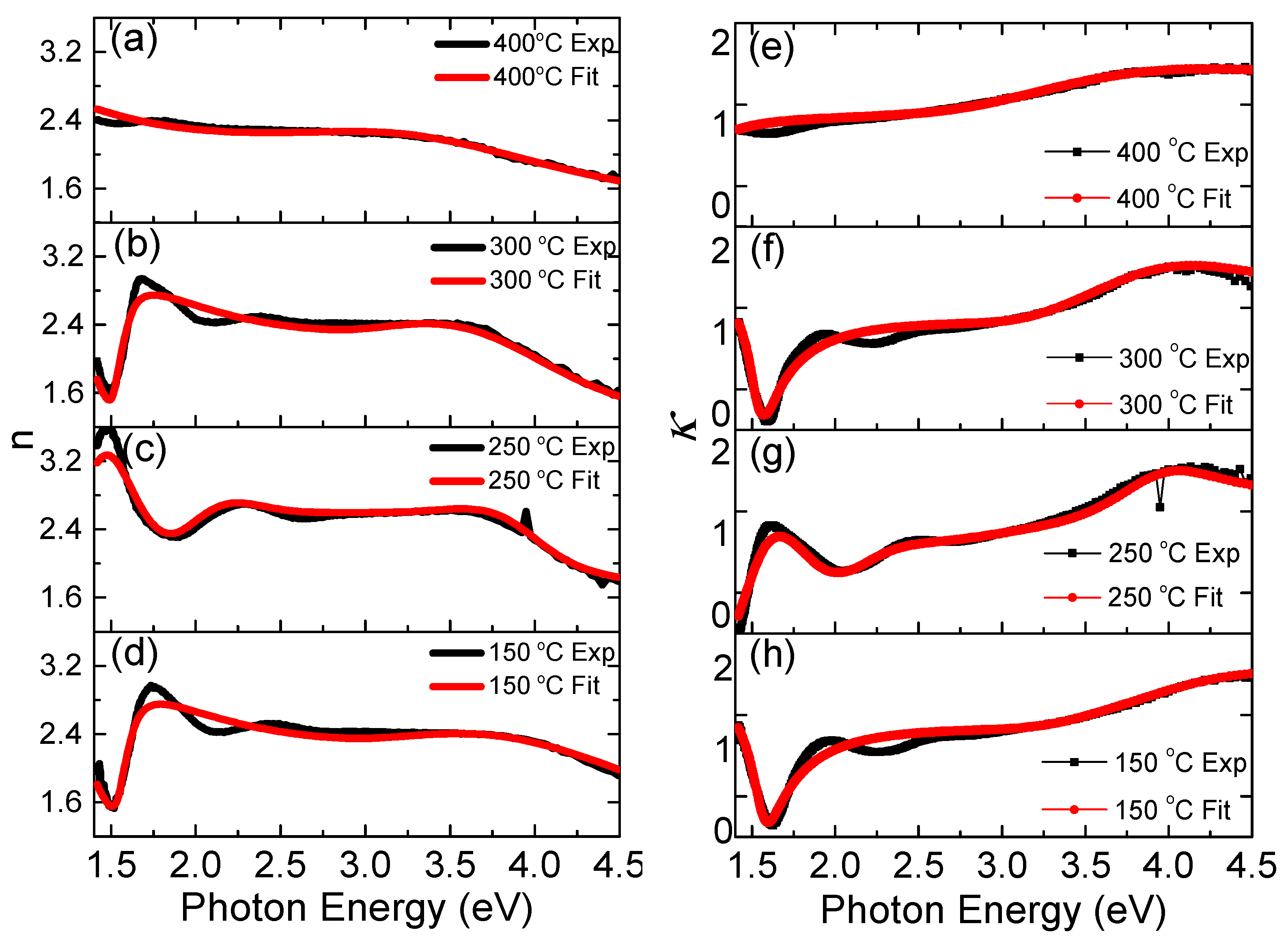

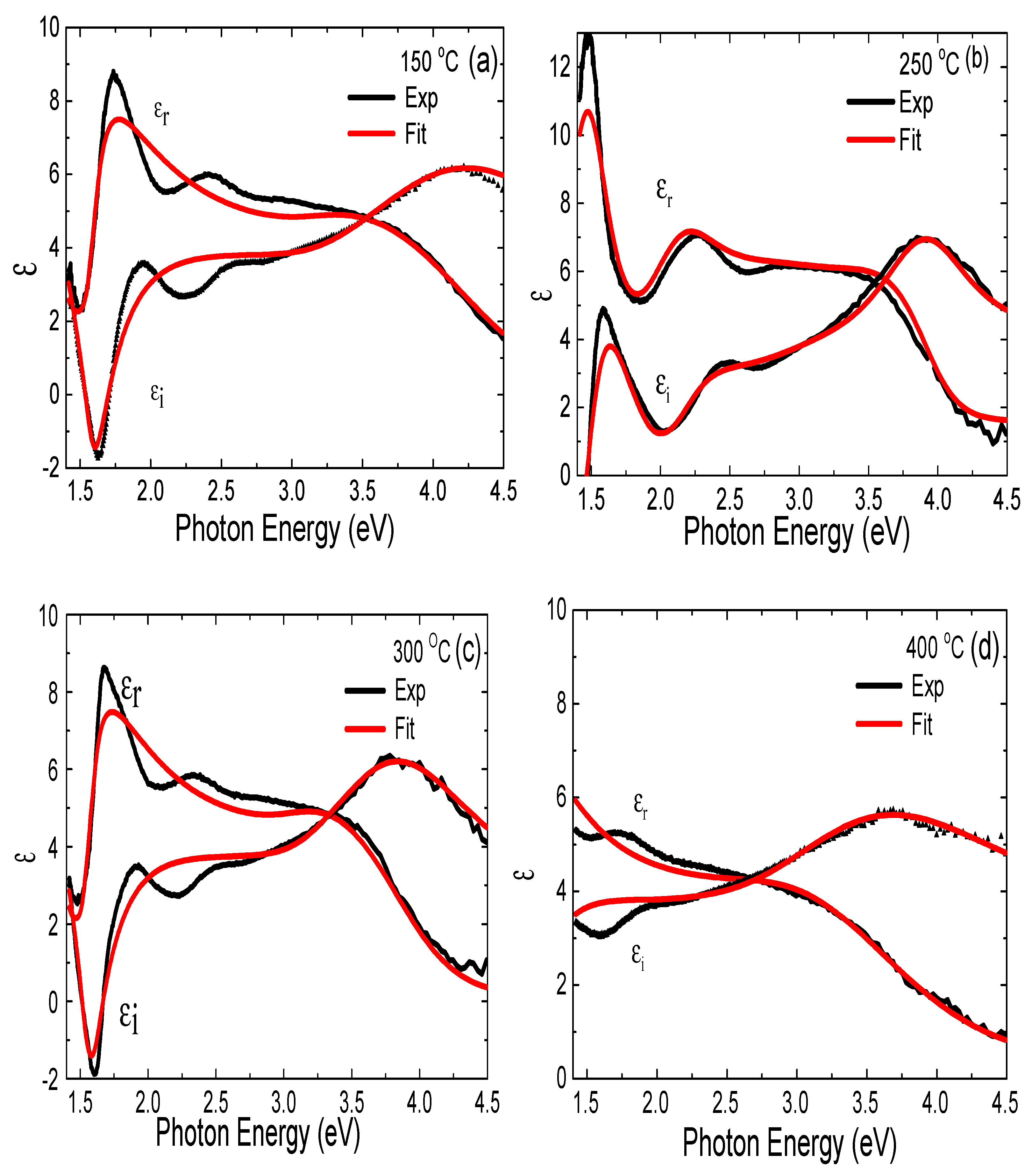

3.4. Ellipsometry Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.; Thung, Y.T.; Chen, X.; Wang, L.; Fan, W.; Ding, W.L.; Sun, H. Study of Complex Optical Constants of Neat Cadmium Selenide Nanoplatelets Thin Films by Spectroscopic Ellipsometry. J. Phys. Chem. Lett. 2021, 12, 191–198. [Google Scholar] [CrossRef]

- Lade, S.J.; Uplane, M.D.; Lokhande, C.D. Photoelectrochemical properties of CdX (X = S, Se, Te) films electrodeposited from aqueous and non-aqueous baths. Mater. Chem. Phys. 2001, 68, 36–41. [Google Scholar] [CrossRef]

- Olusola, O.I.; Echendu, O.K.; Dharmadasa, I.M. Development of CdSe thin films for application in electronic devices. J. Mater. Sci. Mater. Electron. 2014, 26, 1066–1076. [Google Scholar] [CrossRef] [Green Version]

- Zhao, L.; Hu, L.; Fang, X. Growth and Device Application of CdSe Nanostructures. Adv. Funct. Mater. 2012, 22, 1551–1566. [Google Scholar] [CrossRef]

- Patel, K.D.; Jani, M.S.; Pathak, V.M.; Srivastava, R. Deposition of CdSe thin films by thermal evaporation and their structural and optical properties. Chalcogenide Lett. 2009, 6, 279–286. [Google Scholar]

- Hamilakis, S.; Balgis, D.; Milonakou-Koufoudaki, K.; Mitzithra, C.; Kollia, C.; Loizos, Z. Electrodeposition of CdSe photoabsorber thin films in the presence of selected organic additives. Mater. Lett. 2015, 15, 11–14. [Google Scholar] [CrossRef]

- Mahato, S.; Kar, A.K. The effect of annealing on structural, optical and photosensitive properties of electrodeposited cadmium selenide thin films. J. Scien. Adv. Mater. Dev. 2017, 2, 165–171. [Google Scholar] [CrossRef]

- Kwon, D. Studies of Sputtered CdTe and CdSe Solar Cells. Ph.D. Thesis, The University of Telodo, Toledo, OH, USA, December 2012. [Google Scholar]

- Chandra, S.; Pandey, R.K.; Agrawal, R.C. Solar energy conversion using CdSe photoelectrochemical cells with low cost substrates. Solar Cells 1980, 1, 367–370. [Google Scholar] [CrossRef]

- Smyntyna, V.; Gerasutenko, V.; Golovanov, V.; Kaciulis, S.; Mattogno, G.; Viticoli, S. Surface spectroscopy study of CdSe and CdS thin film oxygen sensors. Sens. Actuator 1994, 22, 189–194. [Google Scholar] [CrossRef]

- Navale, S.T.; Mane, A.T.; Chougule, M.A.; Shinde, N.M.; Kim, J.; Patil, V.B. Highly selective and sensitive CdS thin film sensors for detection of NO2 gas. RSC Adv. 2014, 4, 44547–44554. [Google Scholar] [CrossRef]

- Alaani, M.A.R.; Koirala, P.; Pradhan, P.; Phillips, A.B.; Podraza, N.J.; Heben, M.J.; Collins, R.W. Tailoring the CdS/CdSe/CdTe multilayer structure for optimization of photovoltaic device performance guided by mapping spectroscopic ellipsometry. Solar Energy Mater. Solar Cells 2021, 221, 110907. [Google Scholar] [CrossRef]

- Baines, T.; Zoppi, G.; Bowen, L.; Shalvey, T.P.; Mariotti, S.; Durose, K.; Major, J.D. Incorporation of CdSe layers into CdTe thin film solar cells. Solar Energy Mater. Solar Cells 2018, 180, 196–204. [Google Scholar] [CrossRef]

- Ogugua, S.N.; Ntwaeaborwa, O.M.; Swart, H.C. Latest Development on Pulsed Laser Deposited Thin Films for Advanced Luminescence Applications. Coatings 2020, 10, 1078. [Google Scholar] [CrossRef]

- Bao, Z.; Yang, X.; Li, B.; Luo, R.; Liu, B.; Tang, P.; Zhang, J.; Wu, L.; Li, W.; Feng, L. The study of CdSe thin film prepared by pulsed laser deposition for CdSe/CdTe solar cell. J. Mater. Sci. Mater. Electron. 2016, 27, 7233–7239. [Google Scholar] [CrossRef]

- Selvakumar, N.; Harish, C.B. Review of physical vapor deposited (PVD) spectrally selective coatings for mid- and high-temperature solar thermal applications. Solar Energy Mater. Solar Cells 2012, 98, 1–23. [Google Scholar] [CrossRef]

- Gopakumar, N.; Anjana, P.S.; Vidyadharan Pillai, P.K. Chemical bath deposition and characterization of CdSe thin films for optoelectronic applications. J. Mater. Sci. 2010, 45, 6653–6656. [Google Scholar] [CrossRef]

- Yadav, A.A.; Barote, M.A.; Masumdar, E.U. Studies on cadmium selenide (CdSe) thin films deposited by spray pyrolysis. Mater. Chem. Phys. 2010, 121, 53–57. [Google Scholar] [CrossRef]

- Choudhary, R.; Chauhan, R.P. Thickness dependent variation in structural, optical and electrical properties of CdSe thin films. J. Mater. Sci. Mater. Electron. 2019, 30, 5753–5759. [Google Scholar] [CrossRef]

- Mahato, S.; Shakti, N.; Kar, A.K. Annealing temperature dependent structural and optical properties of electrodeposited CdSe thin films. Mater. Sci. Semicond. Process. 2015, 39, 742–747. [Google Scholar] [CrossRef]

- Yang, Q.; Zhao, J.; Guan, M.; Liu, C.; Cui, L.; Han, D.; Zeng, Y. Growth and annealing of zinc-blende CdSe thin films on GaAs (0 0 1) by molecular beam epitaxy. Appl. Surf. Sci. 2011, 257, 9038–9043. [Google Scholar] [CrossRef]

- Das, N.K.; Chakrabartty, J.; Farhad, S.F.U.; Sen Gupta, A.K.; Ahamed, E.M.K.I.; Rahman, K.S.; Wafi, A.; Alkahtani, A.A.; Matin, M.A.; Amin, N. Effect of substrate temperature on the properties of RF sputtered CdS thin films for solar cell applications. Results Phys. 2020, 17, 103–132. [Google Scholar] [CrossRef]

- Kumar, M.M.D.; Suganthi, D. Phase transformation and quantum confinement effect in CdSe/Se multilayer thin films prepared by physical vapor deposition. Phase Transit. 2013, 86, 1216–1226. [Google Scholar] [CrossRef]

- Christen, H.M.; Eres, G. Recent advances in pulsed-laser deposition of complex oxides. J. Phys. Condens. Mat. 2008, 20, 264005. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kale, R.B.; Lokhande, C.D. Systematic Study on Structural Phase Behavior of CdSe Thin Films. J. Phys. Chem. B 2005, 109, 20288–20294. [Google Scholar] [CrossRef] [PubMed]

- Forouhi, A.R.; Bloomer, I. Optical dispersion relations for amorphous semiconductors and amorphous dielectrics. Phys. Rev. B 1986, 34, 7018. [Google Scholar] [CrossRef]

- Tauc, J.; Grigorovici, R.; Vancu, A. Optical Properties and Electronic Structure of Amorphous Germanium. Phys. Status Solidi 1966, 15, 627. [Google Scholar] [CrossRef]

- Makula, P.; Pacia, M.; Macyk, W. How To Correctly Determine the Band Gap Energy of Modified Semiconductor Photocatalysts Based on UV–Vis Spectra. J. Phys. Chem. Lett. 2018, 9, 6814–6817. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trujillo, O.; Moss, R.; Vuong, K.D.; Lee, D.H.; Noble, R.; Finnigan, D.; Orloff, S.; Tenpas, E.; Park, C.; Fagan, J.; et al. CdS thin film deposition by CW Nd: YAG laser. Thin Solid Films 1996, 290–291, 13–17. [Google Scholar] [CrossRef]

- Salem, A.; Saion, E.; Al-Hadaa, N.M.; Kamari, H.M.; Shaari, A.H.; Abdullah, C.A.; Radiman, S. Synthesis and characterization of CdSe nanoparticles via thermal treatment technique. Results Phys. 2017, 7, 1556–1562. [Google Scholar] [CrossRef]

- Ninomiya, S.; Adachi, S. Optical properties of cubic and hexagonal CdSe. J. Appl. Phys. 1995, 78, 4681. [Google Scholar] [CrossRef]

- Logothetidis, S. Surface-roughness and grain-boundary effects on the optical properties of low-pressure chemical-vapor-deposited silicon thin films by spectroscopic ellipsometry. J. Appl. Phys. 1989, 65, 2416–2426. [Google Scholar] [CrossRef]

- Yu, W.; Qu, L.; Guo, W.; Peng, X. Experimental Determination of the Extinction Coefficient of CdTe, CdSe, and CdS Nanocrystals. Chem. Mater. 2003, 15, 2854–2860. [Google Scholar] [CrossRef]

- Rickus, E. Photovoltaic Behaviour of CdSe Thin Film Solar Cells. In Proceedings of the Fourth E. C. Photovoltaic Solar Energy Conference, Stresa, Italy, 10–14 May 1982; Bloss, W.H., Grassi, G., Eds.; Springer: Dordrecht, The Netherlands, 1982. [Google Scholar] [CrossRef]

- Ming, Z.; Ding, C.; Li, B.; Feng, L.; Wu, J. Study of Ar + O2 deposition pressures on properties of pulsed laser deposited CdTe thin films at high substrate temperature. J. Mater. Sci. Mater. Electron. 2014, 25, 1901. [Google Scholar] [CrossRef]

| Growth Temperature (°C) | 150 | 200 | 250 | 300 | 350 | 400 |

| RMS roughness (nm) | 2.1 | 2.6 | 2.5 | 2.7 | 3.0 | 5.7 |

| Parameter/Temperature | 150 °C | 250 °C | 300 °C | 400 °C |

| Thickness (nm) of CdSe layer | 184 | 253 | 241 | 163 |

| Eg (eV) | 1.63 ± 0.03 | 1.71 ± 0.03 | 1.71 ± 0.03 | 1.67 ± 0.03 |

| Refractive index nmax (at 1.75 eV) | 3.0 ± 0.2 | 3.6 ± 0.4 | 3.0 ± 0.2 | 2.4 ± 0.1 |

| Extinction coefficient κmax (at 4.5 eV) | 1.50 | 1.25 | 1.50 | 1.40 |

| εr (at 1.75 eV) | 8.9 | 13.0 | 8.9 | 5.3 |

| εi (at 4.25 eV) | 6.0 | 7.4 | 6.0 | 5.7 |

| α (cm−1) (at 4.5 eV) | 65 × 104 | 70 × 104 | 70 × 104 | 65 × 104 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Inbanathan, F.P.N.; Kumar, P.; Dasari, K.; Katiyar, R.S.; Chen, J.; Jadwisienczak, W.M. Ellipsometry Study of CdSe Thin Films Deposited by PLD on ITO Coated Glass Substrates. Materials 2021, 14, 3307. https://doi.org/10.3390/ma14123307

Inbanathan FPN, Kumar P, Dasari K, Katiyar RS, Chen J, Jadwisienczak WM. Ellipsometry Study of CdSe Thin Films Deposited by PLD on ITO Coated Glass Substrates. Materials. 2021; 14(12):3307. https://doi.org/10.3390/ma14123307

Chicago/Turabian StyleInbanathan, Flavia P. N., Pawan Kumar, Kiran Dasari, Ram S. Katiyar, Jixin Chen, and Wojciech M. Jadwisienczak. 2021. "Ellipsometry Study of CdSe Thin Films Deposited by PLD on ITO Coated Glass Substrates" Materials 14, no. 12: 3307. https://doi.org/10.3390/ma14123307