Eco-Friendly Lead-Free Solder Paste Printing via Laser-Induced Forward Transfer for the Assembly of Ultra-Fine Pitch Electronic Components

Abstract

:1. Introduction

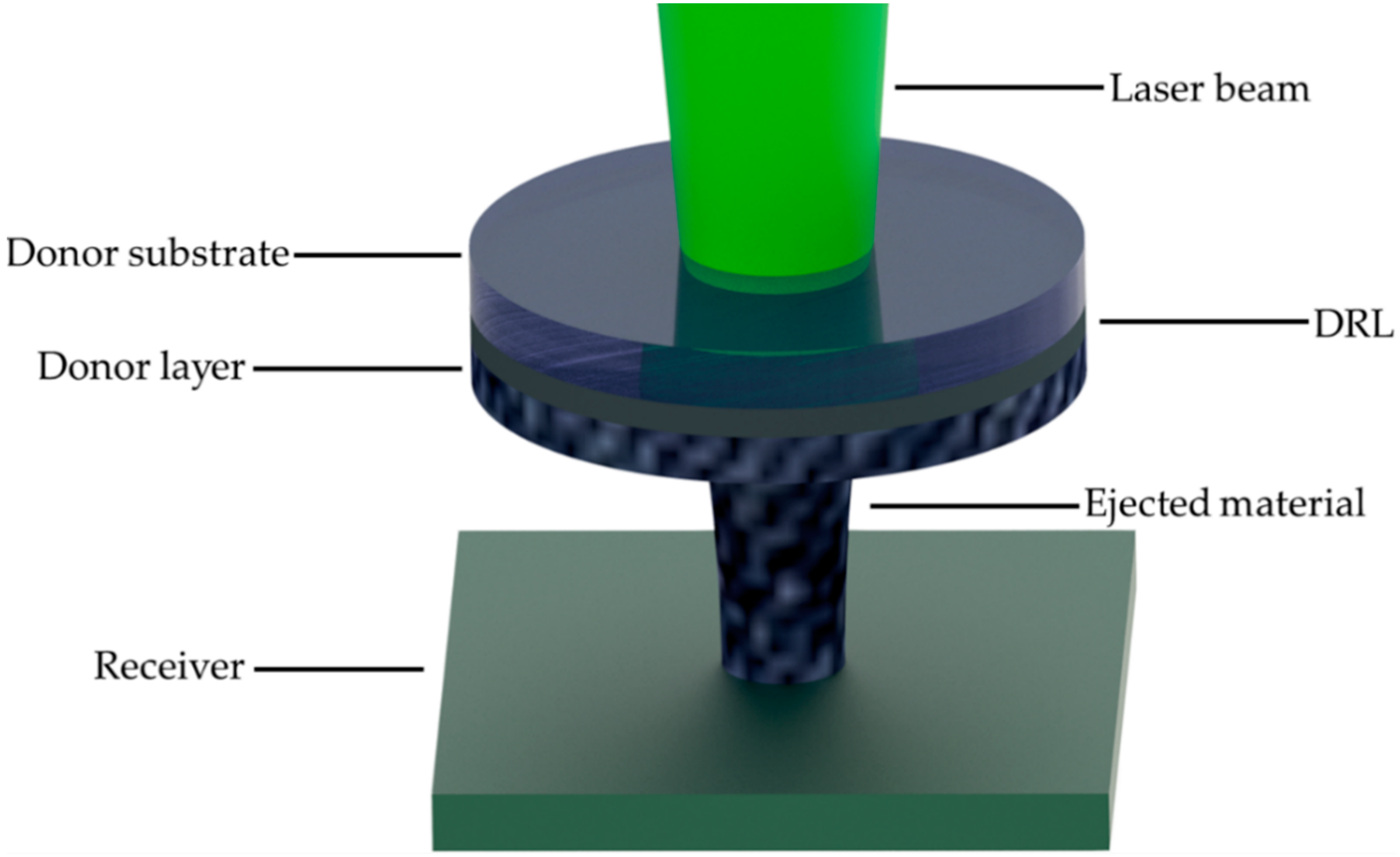

2. Materials and Methods

3. Results and Discussion

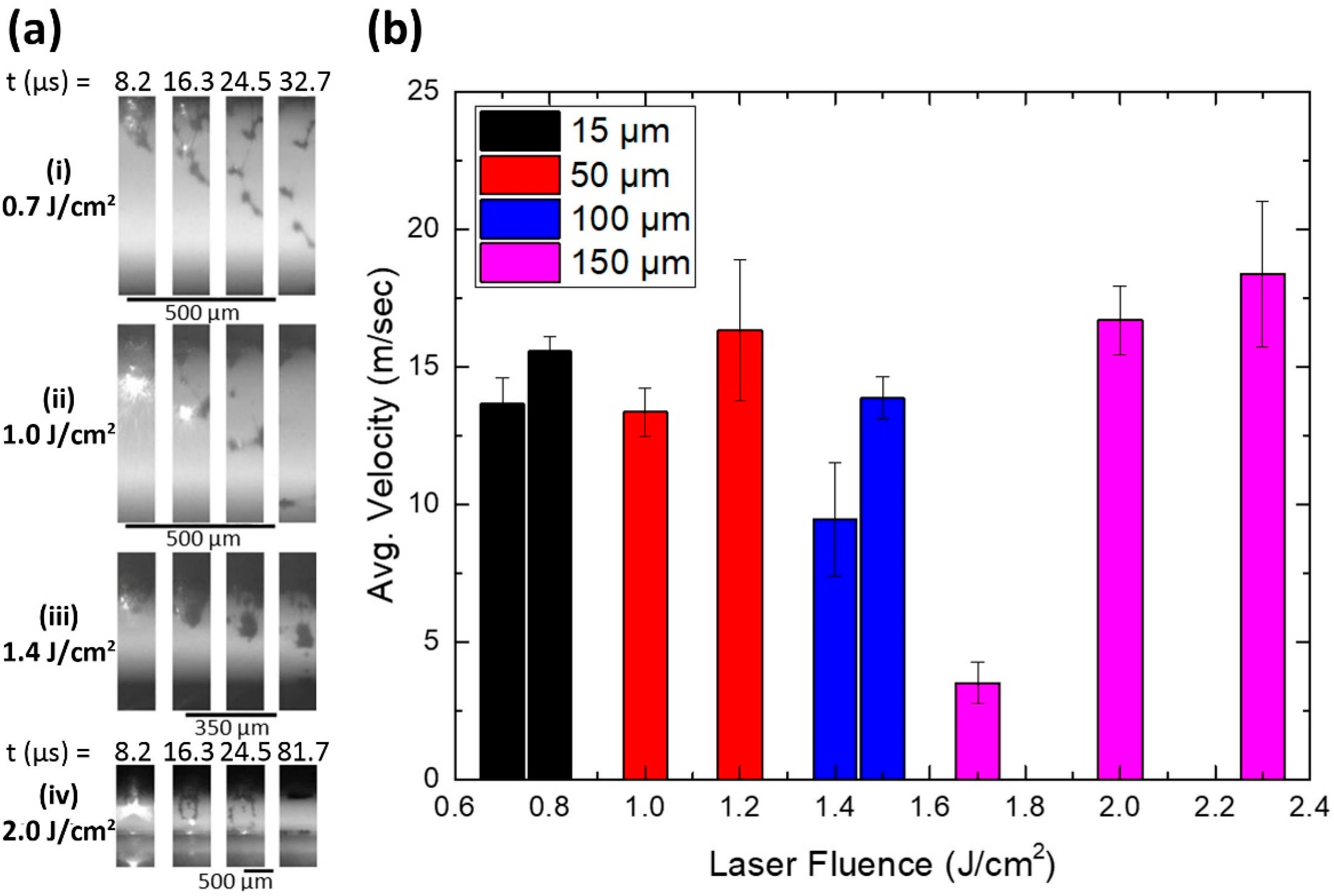

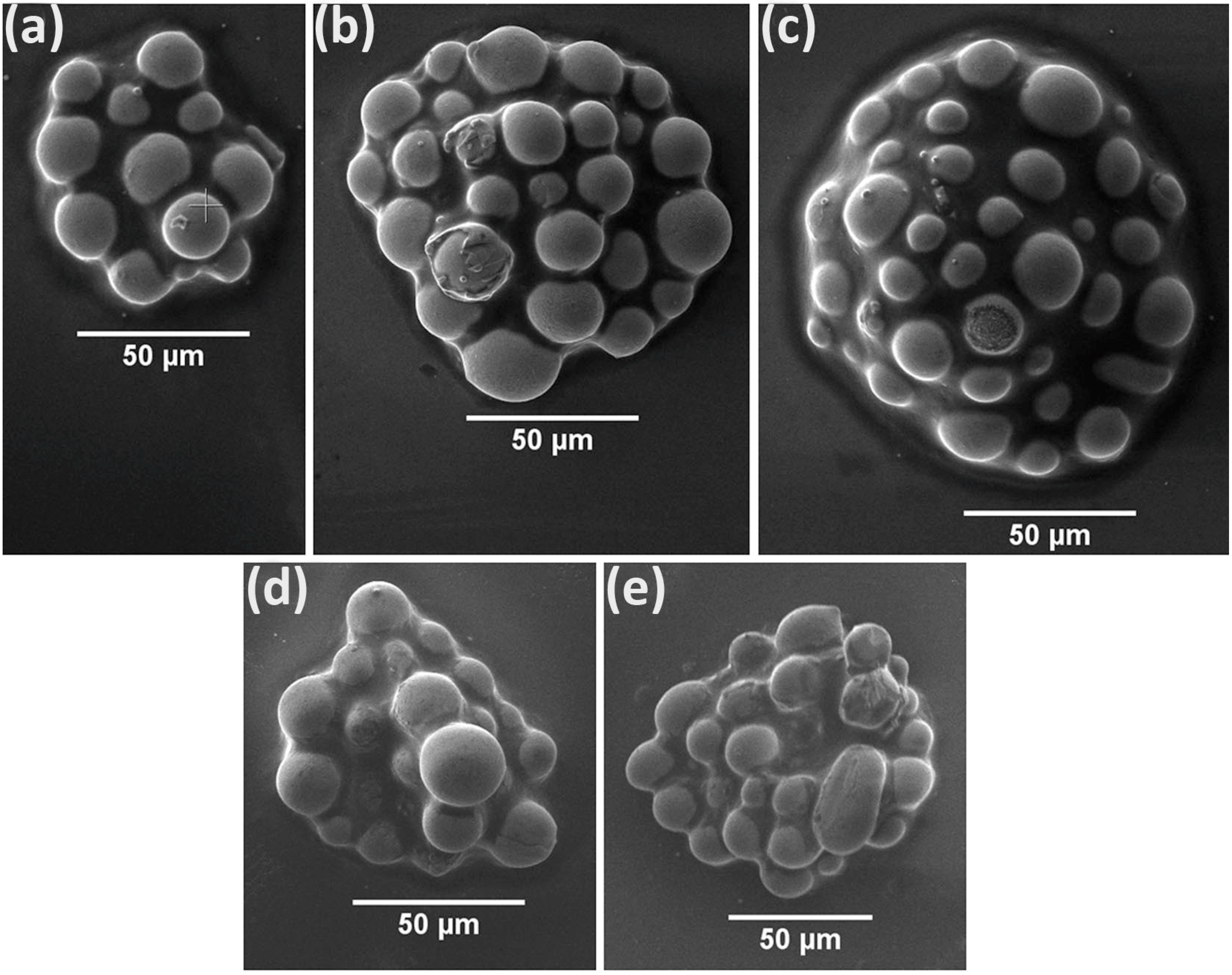

3.1. Influence of Donor Thickness on Jet Dynamics

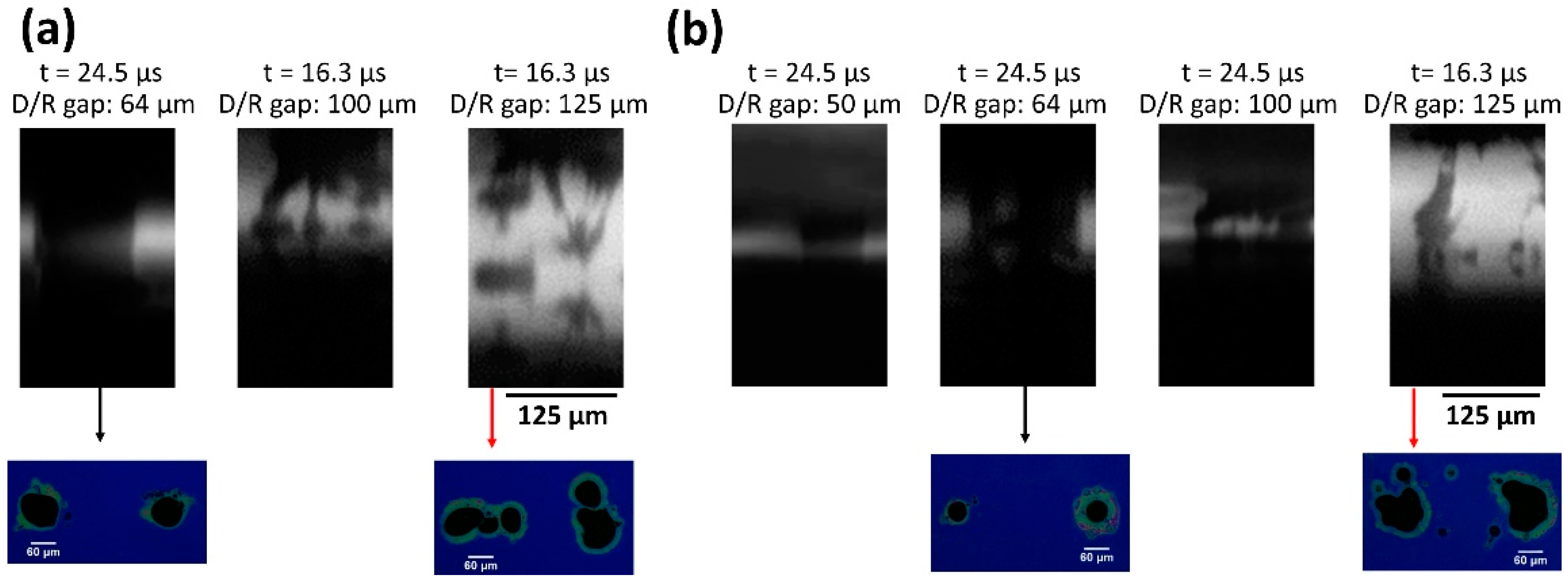

3.2. Influence of the Donor-Receiver Gap

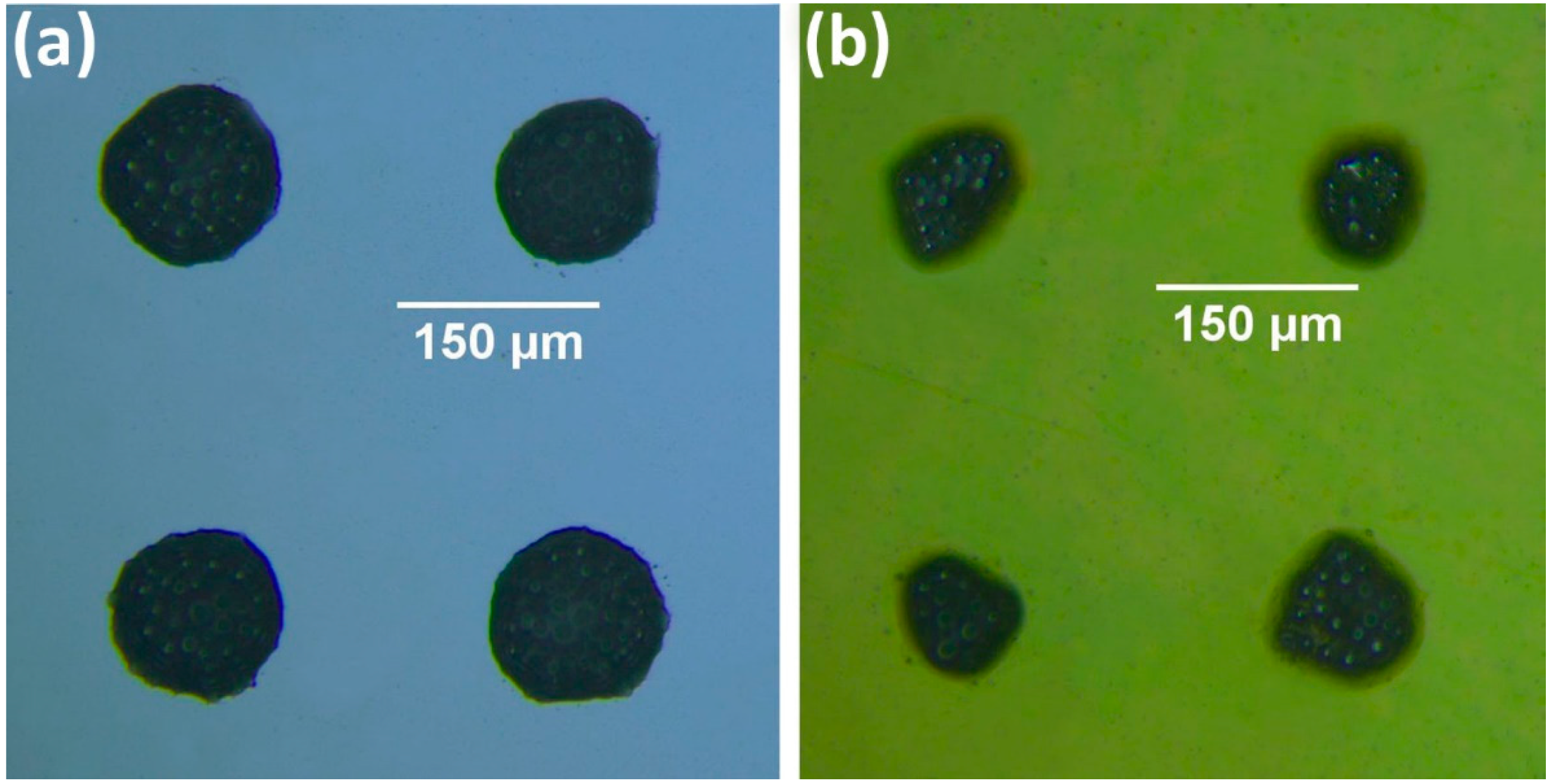

3.3. Printing on Si and Flexible Substrates

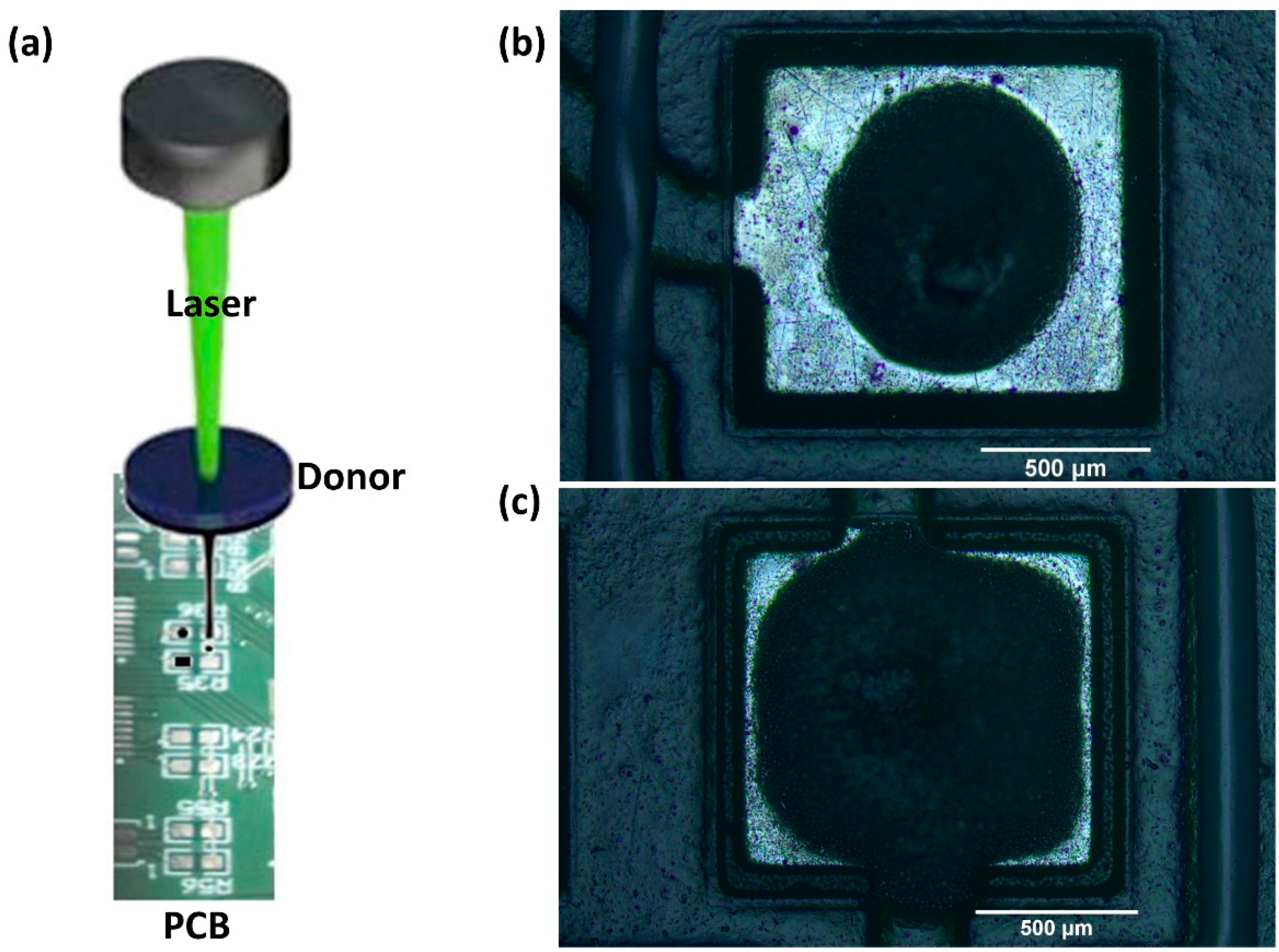

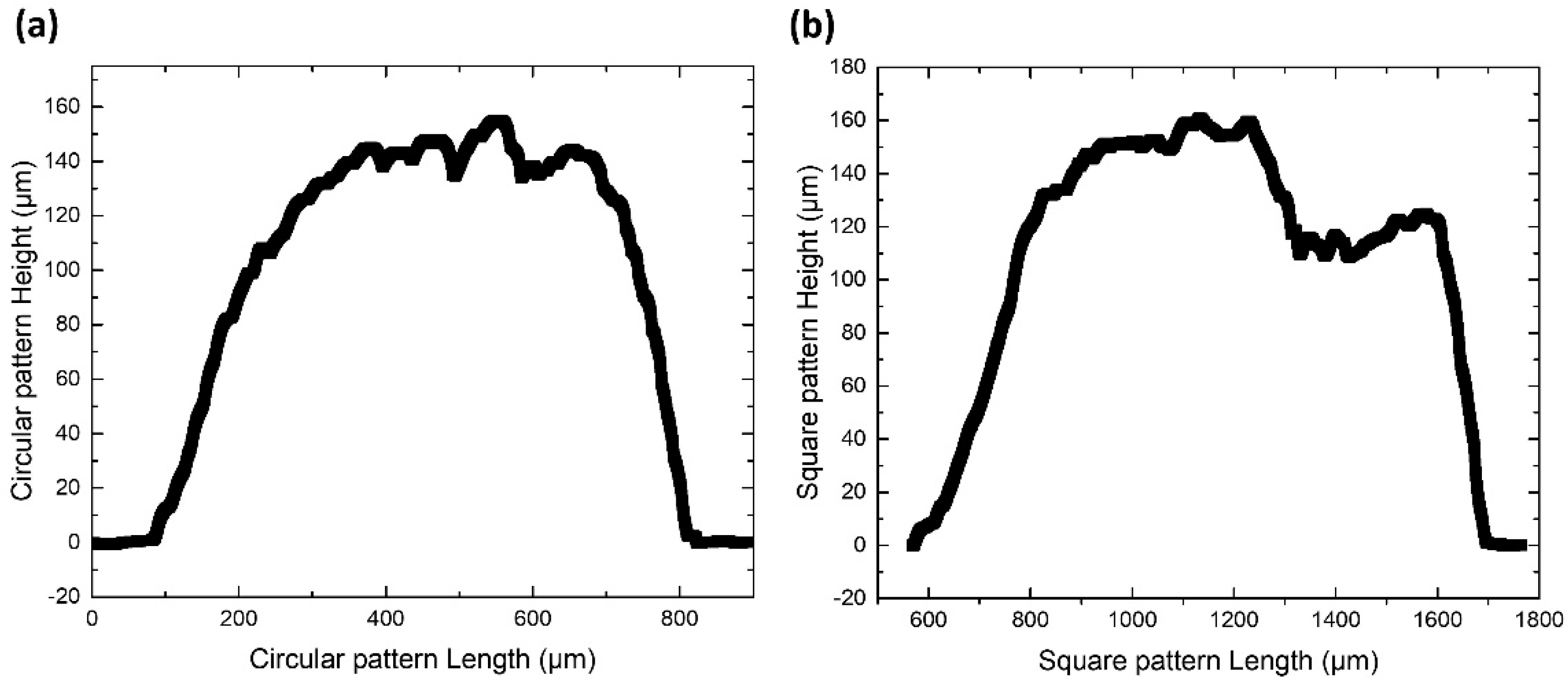

3.4. Printing on PCB Pads

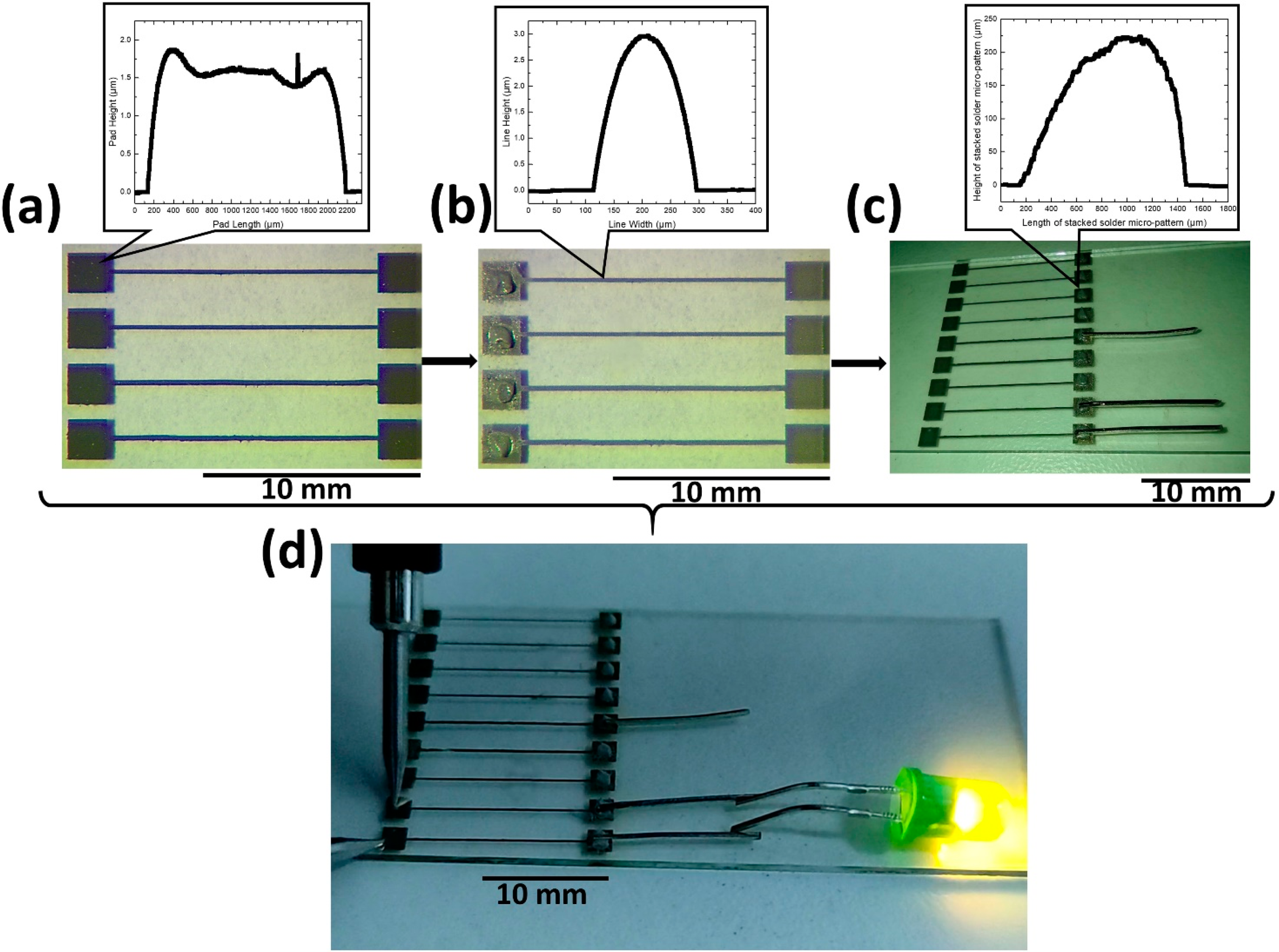

3.5. Proof of Concept: Demonstration of LED Operation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zhong, Z.W.; Tee, T.Y.; Luan, J.E. Recent advances in wire bonding, flip chip and lead-free solder for advanced microelectronics packaging. Microelectron. Int. 2007, 24, 18–26. [Google Scholar] [CrossRef]

- Looe, S.; Wang, S. Challenges & solutions in the die attach process for micro thin die. In Proceedings of the 33rd IEEE/CPMT International Electronics Manufacturing Technology Conference (IEMT), Penang, Malaysia, 4–6 November 2008; pp. 1–5. [Google Scholar] [CrossRef]

- Tsai, W.S.; Huang, C.Y.; Chung, C.K.; Yu, K.H.; Lin, C.F. Generational changes of flip chip interconnection technology. In Proceedings of the 12th International Microsystems, Packaging, Taipei, Taiwan, 25–27 October 2017; pp. 306–310, Assembly and Circuits Technology Conference (IMPACT). [Google Scholar] [CrossRef]

- Delmdahl, R.; Pätzel, R.; Brune, J.; Müller, D. Superior microstructures for advanced package integration. Proceedings of SPIE 11268, Laser-Based Micro-and Nanoprocessing XIV, San Francisco, CA, USA, 2 March 2020; p. 1126813. [Google Scholar] [CrossRef]

- Wood, E.P.; Nimmo, K.L. In search of new lead-free electronic solders. J. Electron. Mater. 1994, 23, 709–713. [Google Scholar] [CrossRef]

- Pan, J.; Wang, J.; Shaddock, D.M. Lead-free Solder Joint Reliability—State of the Art and Perspectives. J. Microelectron. Electron. Packag. 2005, 2, 72–83. [Google Scholar] [CrossRef]

- Bock, K.; Feil, M. Thin chips for flexible and 3D-integrated electronic systems. In Foldable Flex and Thinned Silicon Multichip Packaging Technology; Kluwer Academic Publishers: Boston, MA, USA, 2003; pp. 101–148. [Google Scholar]

- Cruz, S.M.F.; Rocha, L.A.; Viana, J.C. Printing Technologies on Flexible Substrates for Printed Electronics. In Flexible Electronics; InTech: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Khorramdel, B.; Kraft, T.M.; Mäntysalo, M. Inkjet printed metallic micropillars for bare die flip-chip bonding. Flex. Print. Electron. 2017, 2, 045005. [Google Scholar] [CrossRef]

- Lu, S.; Chen, X.; Zheng, H.; Zhao, Y.; Long, Y. Simulation and Experiment on Droplet Volume for the Needle-Type Piezoelectric Jetting Dispenser. Micromachines 2019, 10, 623. [Google Scholar] [CrossRef] [Green Version]

- Stoukatch, S.; Laurent, P.; Dricot, S.; Axisa, F.; Seronveaux, L.; Vandormael, D.; Beeckman, E.; Heusdens, B.; Destiné, J. Evaluation of Aerosol Jet Printing (AJP) technology for electronic packaging and interconnect technique. In Proceedings of the 4th Electronic System-Integration Technology Conference, Amsterdam, The Netherlands, 17–20 September 2012; pp. 1–5. [CrossRef] [Green Version]

- Palmer, J.A.; Summers, J.L.; Davis, D.W.; Gallegos, P.L.; Chavez, B.D.; Yang, P.; Medina, F.; Wicker, R.B. Realizing 3-D Interconnected Direct Write Electronics Within Smart Stereolithography Structures. In Proceedings of the ASME 2005 International Mechanical Engineering Congress and Exposition, Orlando, FL, USA, 5–11 November 2005; pp. 287–293. [Google Scholar] [CrossRef]

- Shan, Y.; Zhang, X.; Chen, G.; Li, H. Laser direct printing of solder paste. AIP Adv. 2019, 9, 125306. [Google Scholar] [CrossRef] [Green Version]

- Mathews, S.A.; Charipar, N.A.; Auyeung, R.C.; Kim, H.; Piqué, A. Laser forward transfer of solder paste for microelectronics fabrication. In Proceedings of the Laser-Based Micro-Nanoprocessing IX, San Francisco, CA, USA, 7–12 February 2015; p. 93510Y. [Google Scholar] [CrossRef]

- Pqué, A.; Kim, H.; Auyeung, R.C.Y.; Beniam, I.; Breckenfeld, E. Laser-induced forward transfer (LIFT) of congruent voxels. Appl. Surf. Sci. 2016, 374, 42–48. [Google Scholar] [CrossRef] [Green Version]

- Pique, A.; Beniam, I.; Mathews, S.; Charipar, N. Laser Printed Interconnects for Flexible Electronics. APS 2016, 2016, A51. Available online: https://ui.adsabs.harvard.edu/abs/2016APS..MARA51001P/abstract (accessed on 15 March 2021).

- Wang, J.; Auyeung, R.C.Y.; Kim, H.; Charipar, N.A.; Piqué, A. Three-Dimensional Printing of Interconnects by Laser Direct-Write of Silver Nanopastes. Adv. Mater. 2010, 22, 4462–4466. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.; Duocastella, M.; Charipar, K.M.; Auyeung, R.C.Y.; Piqué, A. Laser printing of conformal and multi-level 3D interconnects. Appl. Phys. A 2013, 113, 5–8. [Google Scholar] [CrossRef]

- Tan, H.W.; An, J.; Chua, C.K.; Tran, T. Metallic Nanoparticle Inks for 3D Printing of Electronics. Adv. Electron. Mater. 2019, 5, 1800831. [Google Scholar] [CrossRef]

- Braudy, R.S. Laser Writing. Proc. IEEE 1969, 57, 1771–1772. [Google Scholar] [CrossRef]

- Levene, M.L.; Scott, R.D.; Siryj, B.W. Material Transfer Recording. Appl. Opt. 1970, 9, 2260. [Google Scholar] [CrossRef]

- Willis, D.A.; Grosu, V. Microdroplet deposition by laser-induced forward transfer. Appl. Phys. Lett. 2005, 86, 1–3. [Google Scholar] [CrossRef]

- Banks, D.P.; Grivas, C.; Mills, J.D.; Eason, R.W.; Zergioti, I. Nanodroplets deposited in microarrays by femtosecond Ti:sapphire laser-induced forward transfer. Appl. Phys. Lett. 2006, 89, 193107. [Google Scholar] [CrossRef] [Green Version]

- Logothetidis, S. Handbook of Flexible Organic Electronics: Materials, Manufacturing and Applications; Elsevier Inc.: Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- Munoz-Martin, D.; Brasz, C.F.; Chen, Y.; Morales, M.; Arnold, C.B.; Molpeceres, M. Laser-induced forward transfer of high-viscosity silver pastes. Appl. Surf. Sci. 2016, 366, 389–396. [Google Scholar] [CrossRef]

- Makrygianni, M.; Milionis, A.; Kryou, C.; Trantakis, I.; Poulikakos, D.; Zergioti, I. On-Demand Laser Printing of Picoliter-Sized, Highly Viscous, Adhesive Fluids: Beyond Inkjet Limitations. Adv. Mater. Interfaces 2018, 5, 1800440. [Google Scholar] [CrossRef]

- Zacharatos, F.; Theodorakos, I.; Karvounis, P.; Tuohy, S.; Braz, N.; Melamed, S.; Kabla, A.; De la Vega, F.; Andritsos, K.; Hatziapostolou, A.; et al. Selective Laser Sintering of Laser Printed Ag Nanoparticle Micropatterns at High Repetition Rates. Materials 2018, 11, 2142. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koritsoglou, O.; Theodorakos, I.; Zacharatos, F.; Makrygianni, M.; Kariyapperuma, D.; Price, R.; Cobb, B.; Melamed, S.; Kabla, A.; de la Vega, F.; et al. Copper micro-electrode fabrication using laser printing and laser sintering processes for on-chip antennas on flexible integrated circuits. Opt. Mater. Express. 2019, 9, 3046. [Google Scholar] [CrossRef]

- Papazoglou, S.; Makrygianni, M.; Zergioti, I.; Filippidou, M.; Chatzandroulis, S. All laser printed resistive chemical sensor: Fabrication and evaluation. In Proceedings of the 2016 IEEE SENSORS, Orlando, FL, USA, 30 October–3 November 2016. [Google Scholar] [CrossRef]

- Andritsos, K.; Theodorakos, I.; Zacharatos, F.; Zergioti, I. The effect of electromigration on the lifetime and performance of flexible interconnections fabricated by laser printing and sintering. Appl. Surf. Sci. 2020, 506, 144968. [Google Scholar] [CrossRef]

- Rapp, L.; Constantinescu, C.; Delaporte, P.; Alloncle, A.P. Laser-induced forward transfer of polythiophene-based derivatives for fully polymeric thin film transistors. Org. Electron. 2014, 15, 1868–1875. [Google Scholar] [CrossRef]

- Makrygianni, M.; Ainsebaa, A.; Nagel, M.; Sanaur, S.; Raptis, Y.S.; Zergioti, I.; Tsamakis, D. Laser printed organic semiconductor PQT-12 for bottom-gate organic thin-film transistors: Fabrication and characterization. App. Surf. Sci. 2016, 390, 823–830. [Google Scholar] [CrossRef]

- Shaw-Stewart, J.; Lippert, T.; Nagel, M.; Nüesch, F.; Wokaun, A. Red-green-blue polymer light-emitting diode pixels printed by optimized laser-induced forward transfer. Appl. Phys. Lett. 2012, 100, 203303. [Google Scholar] [CrossRef] [Green Version]

- Heath, D.J.; Feinäugle, M.; Grant-Jacob, J.; Mills, B.; Eason, R.W. Dynamic spatial pulse shaping via a digital micromirror device for patterned laser-induced forward transfer of solid polymer films. Opt. Mater. Expr. 2015, 5, 1129–1136. [Google Scholar] [CrossRef] [Green Version]

- Pohl, R.; Jansink, M.; Römer, G.R.B.E.; Huis in ‘t Veld, A.J. Solid-phase laser-induced forward transfer of variable shapes using a liquid-crystal spatial light modulator. Appl. Phys. 2015, 120, 427–434. [Google Scholar] [CrossRef] [Green Version]

- Piqué, A.; Mathews, S.A.; Pratap, B.; Auyeung, R.C.Y.; Karns, B.J.; Lakeou, S. Embedding electronic circuits by laser direct-write. Microelectron. Eng. 2006, 83, 2527–2533. [Google Scholar] [CrossRef]

- Makrygianni, M.; Margariti, E.; Andritsos, K.; Reppas, D.; Zacharatos, F.; Oikonomidis, N.; Spandonidis, C.; Zergioti, I. High Speed Soldering Using Laser Printing for the Assembly of Electronic Components. JLMN 2020, 15, 204–208. [Google Scholar] [CrossRef]

- Theodorakos, I.; Kalaitzis, A.; Makrygianni, M.; Hatziapostolou, A.; Kabla, A.; Melamed, S.; de la Vega, F.; Zergioti, I. Laser-Induced Forward Transfer of High Viscous, Non-Newtonian Silver Nanoparticle Inks: Jet Dynamics and Temporal Evolution of the Printed Droplet Study. Adv. Eng. Mater. 2019, 21, 1900605. [Google Scholar] [CrossRef] [Green Version]

- Mittal, K.L. Adhesion Aspects of Thin Films; CRC Press: Boca Raton, FL, USA, 2005; Volume 2. [Google Scholar] [CrossRef]

- Jothi Prakash, C.G.; Prasanth, R. Approaches to design a surface with tunable wettability: A review on surface properties. J. Mater. Sci. 2021, 56, 108–135. [Google Scholar] [CrossRef]

- Kalaitzis, A.; Makrygianni, M.; Theodorakos, I.; Hatziapostolou, A.; Melamed, S.; Kabla, A.; de la Vega, F.; Zergioti, I. Jetting dynamics of Newtonian and non-Newtonian fluids via Laser-induced forward transfer: Experimental and simulation studies. Appl. Surf. Sci. 2019, 465, 136–142. [Google Scholar] [CrossRef]

| Solder Paste | Type | Particle Size | Category | Flux | |

|---|---|---|---|---|---|

| ALPHA JP-500 | Lead-free, no-clean solder paste for Jet Printing | Type 5 | 15–25 μm | SAC305 96.5% tin 3% silver 0.5% copper | Zero halogen flux formulation, colorless flux residue |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makrygianni, M.; Zacharatos, F.; Andritsos, K.; Theodorakos, I.; Reppas, D.; Oikonomidis, N.; Spandonidis, C.; Zergioti, I. Eco-Friendly Lead-Free Solder Paste Printing via Laser-Induced Forward Transfer for the Assembly of Ultra-Fine Pitch Electronic Components. Materials 2021, 14, 3353. https://doi.org/10.3390/ma14123353

Makrygianni M, Zacharatos F, Andritsos K, Theodorakos I, Reppas D, Oikonomidis N, Spandonidis C, Zergioti I. Eco-Friendly Lead-Free Solder Paste Printing via Laser-Induced Forward Transfer for the Assembly of Ultra-Fine Pitch Electronic Components. Materials. 2021; 14(12):3353. https://doi.org/10.3390/ma14123353

Chicago/Turabian StyleMakrygianni, Marina, Filimon Zacharatos, Kostas Andritsos, Ioannis Theodorakos, Dimitris Reppas, Nikolaos Oikonomidis, Christos Spandonidis, and Ioanna Zergioti. 2021. "Eco-Friendly Lead-Free Solder Paste Printing via Laser-Induced Forward Transfer for the Assembly of Ultra-Fine Pitch Electronic Components" Materials 14, no. 12: 3353. https://doi.org/10.3390/ma14123353

APA StyleMakrygianni, M., Zacharatos, F., Andritsos, K., Theodorakos, I., Reppas, D., Oikonomidis, N., Spandonidis, C., & Zergioti, I. (2021). Eco-Friendly Lead-Free Solder Paste Printing via Laser-Induced Forward Transfer for the Assembly of Ultra-Fine Pitch Electronic Components. Materials, 14(12), 3353. https://doi.org/10.3390/ma14123353