Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy

Abstract

:1. Introduction

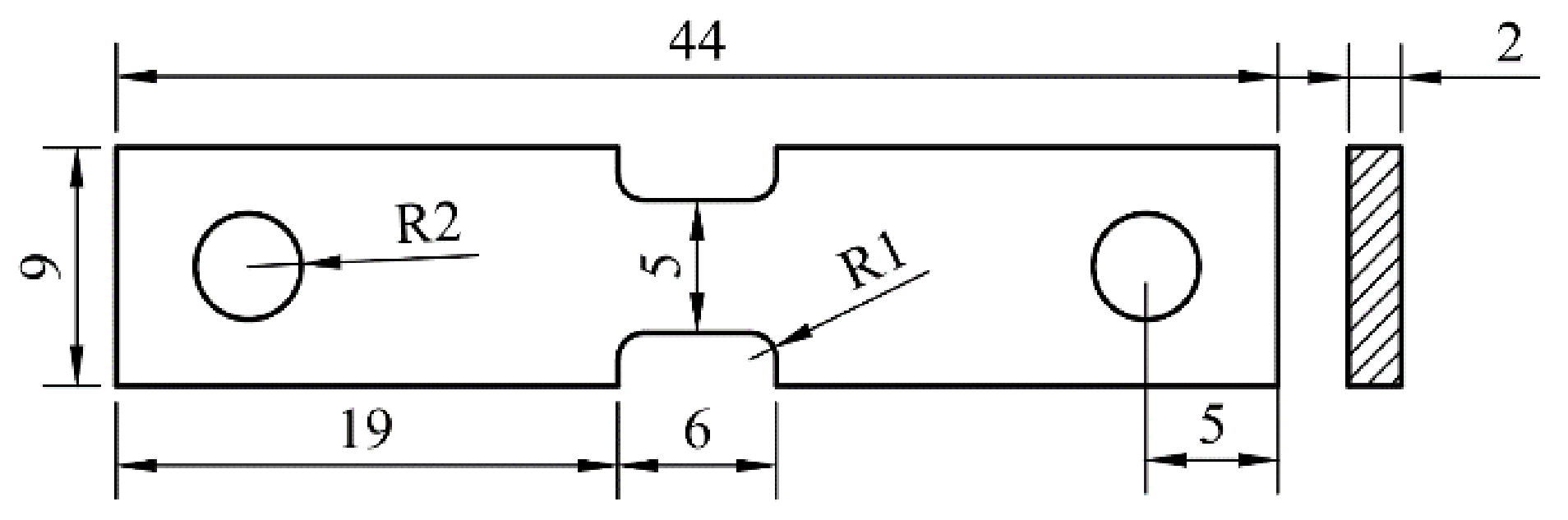

2. Experimental Procedures

3. Results and Discussion

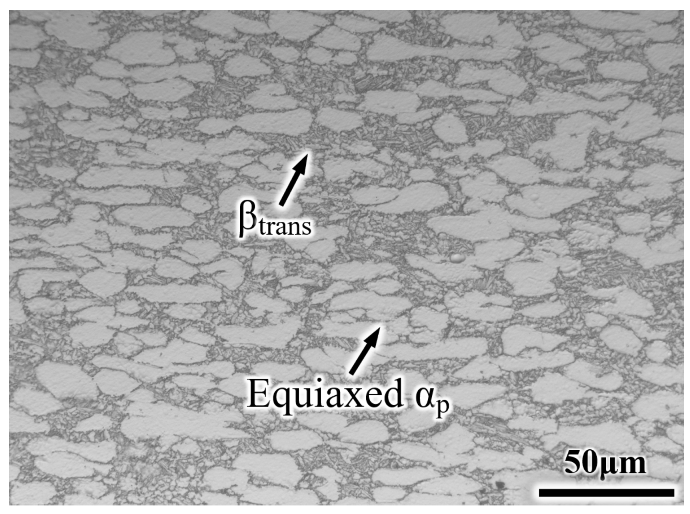

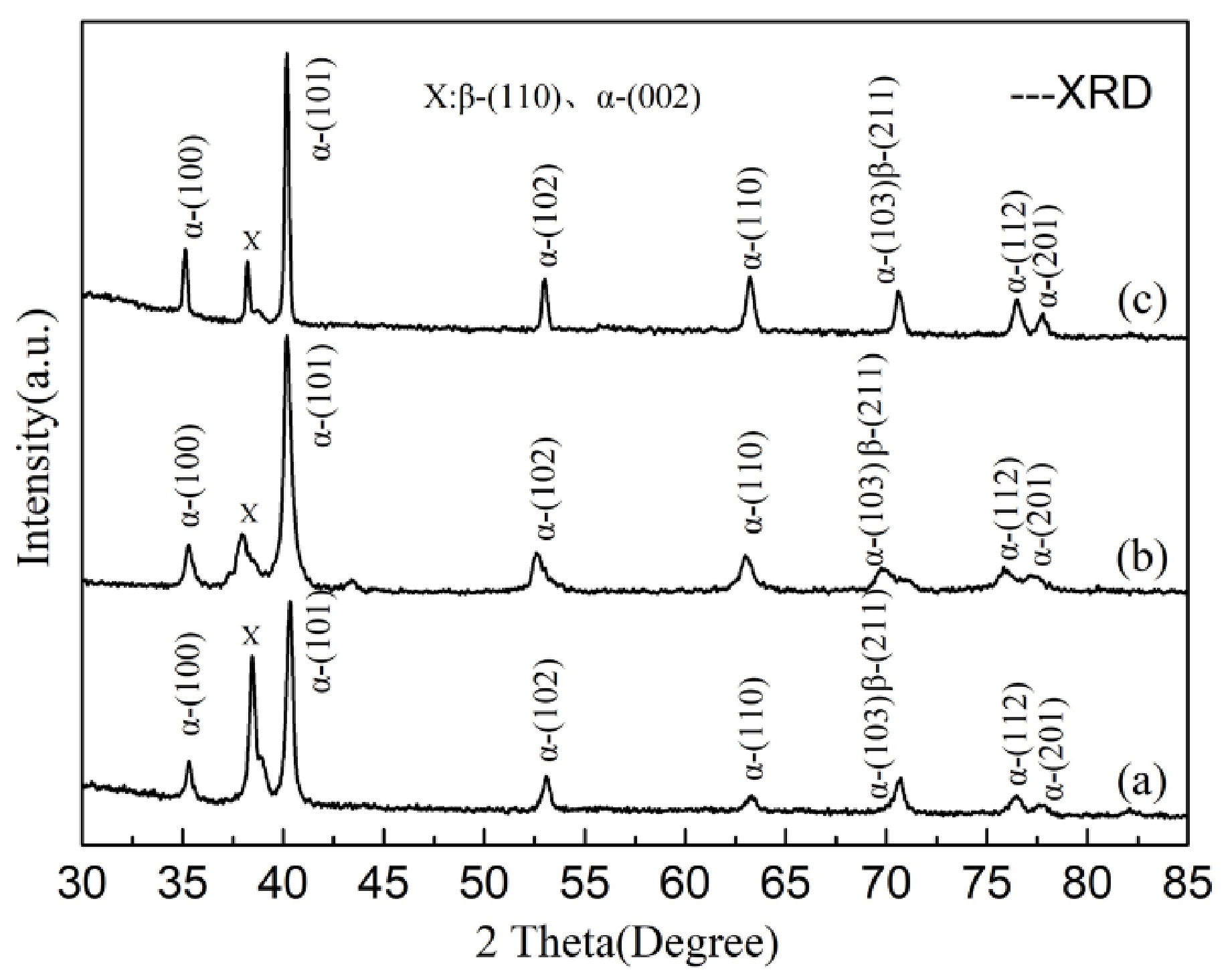

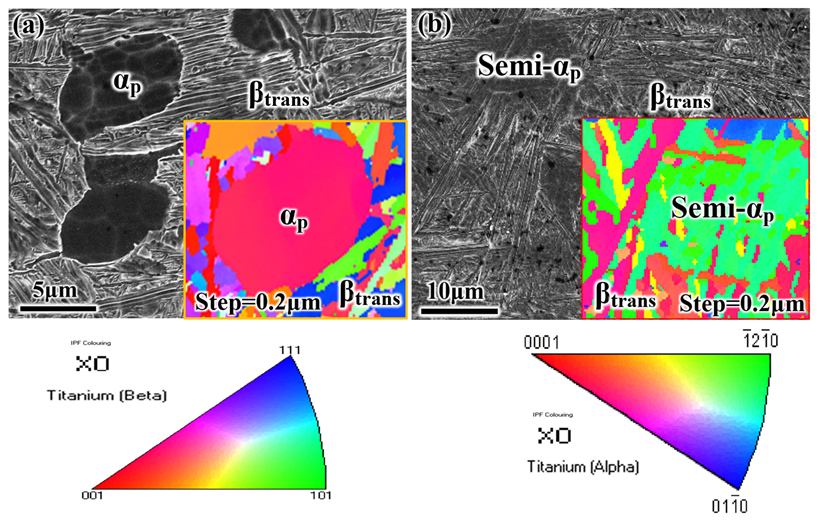

3.1. Microstructural Characteristics

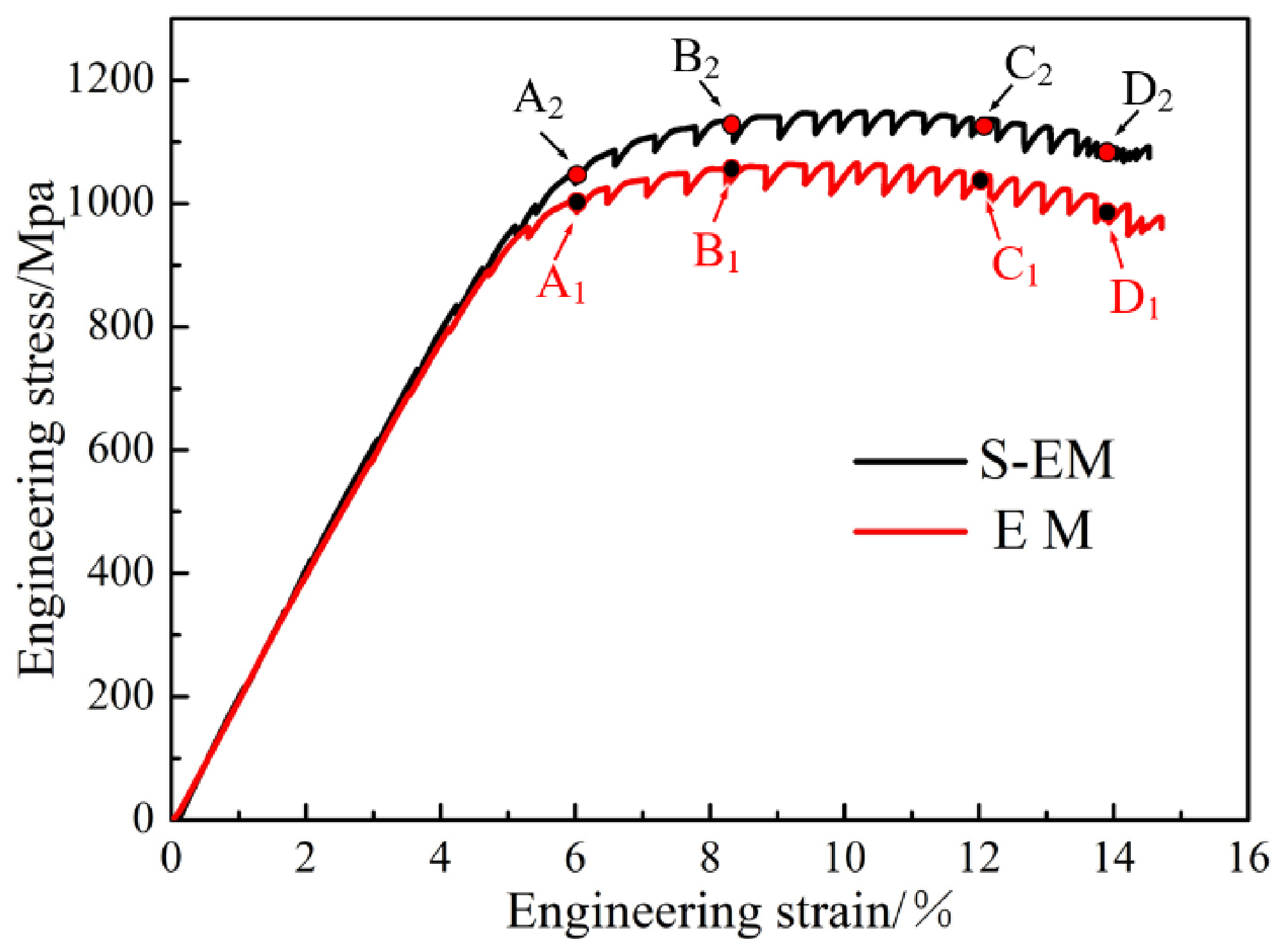

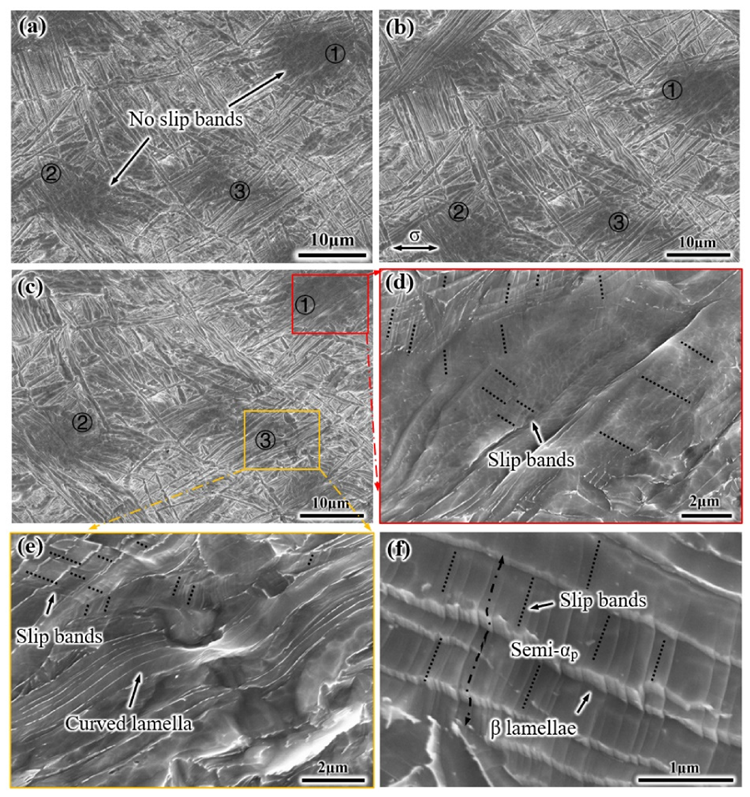

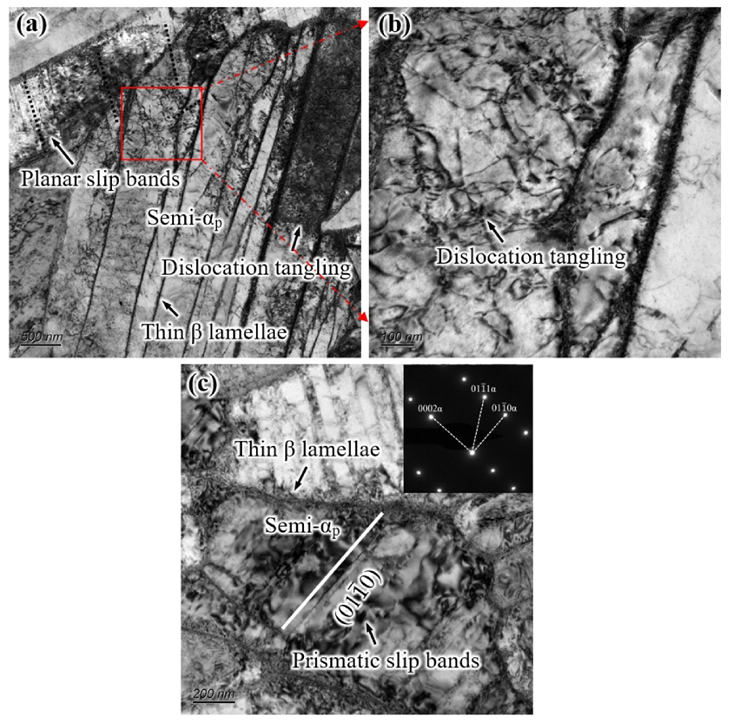

3.2. Research on the Deformation Behavior

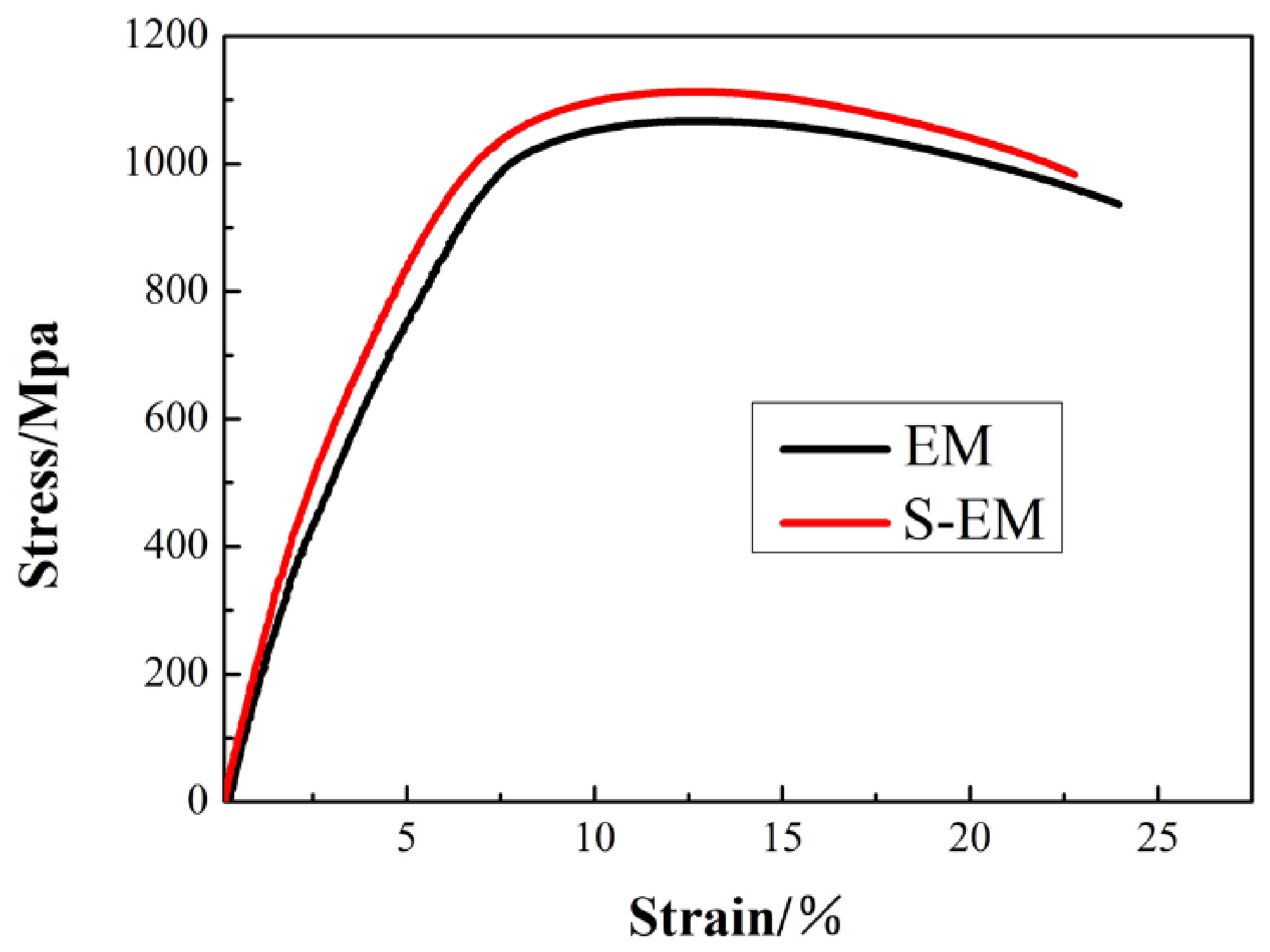

3.3. Tensile Properties and Fracture Characteristics

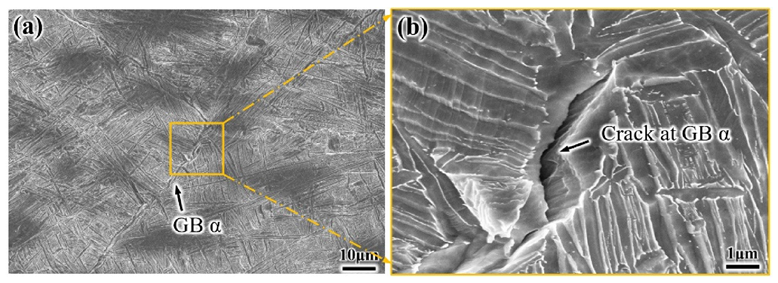

4. Conclusions

- (1)

- In the S-EM, the distinct αp/βtrans interface in the bimodal microstructure primarily disappears, and the thin β lamellae grow through the equiaxed αp phase, leading to partial division of the equiaxed αp phase by the thin β lamellae.

- (2)

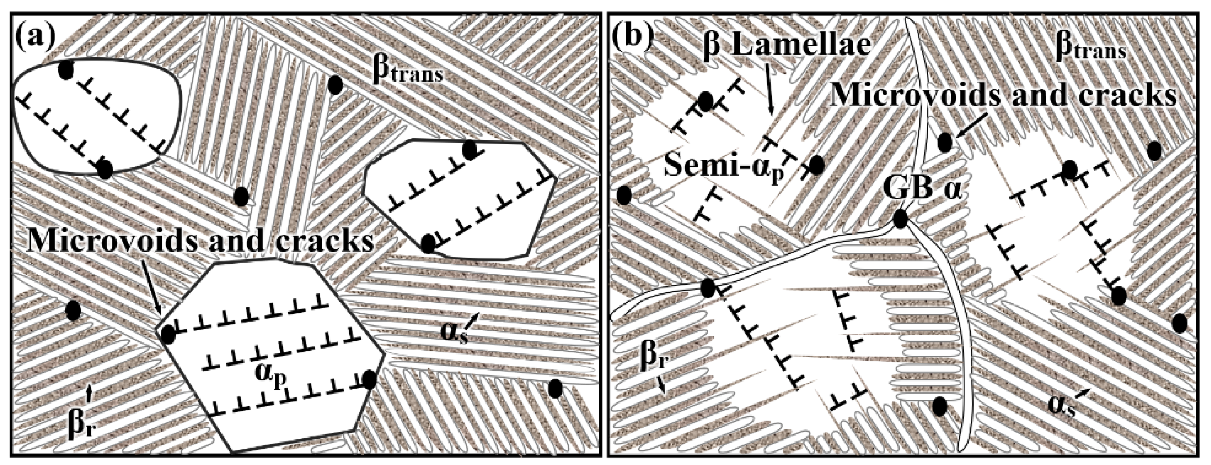

- The S-EM effectively suppress the formation of dense slip bands in the semi-equiaxed αp phase, so the stress concentration at the blurry semi-αp/βtrans interface in the S-EM has been reduced, and the semi-equiaxed αp phase and βtrans microstructure have better deformation compatibility. In addition, the tensile strength of the S-EM is higher than that of the EM due to the thin β lamellae hindering the movement of dislocations within the semi-equiaxed αp phase in the S-EM.

- (3)

- In the S-EM, the prismatic slip and dislocation tangling between the thin β lamellae are the main deformation modes of the semi-equiaxed αp phase. The deformation of the βtrans microstructure in the S-EM is mainly affected by planar slip and dislocation tangling in the αs lamellae.

- (4)

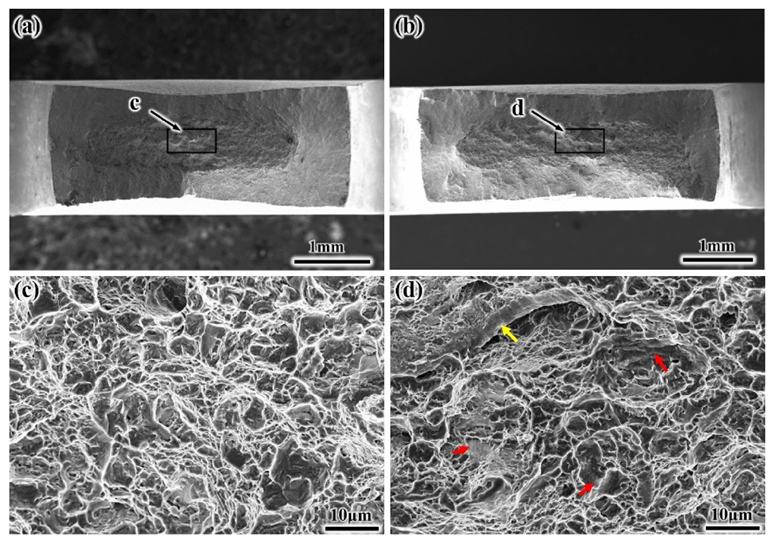

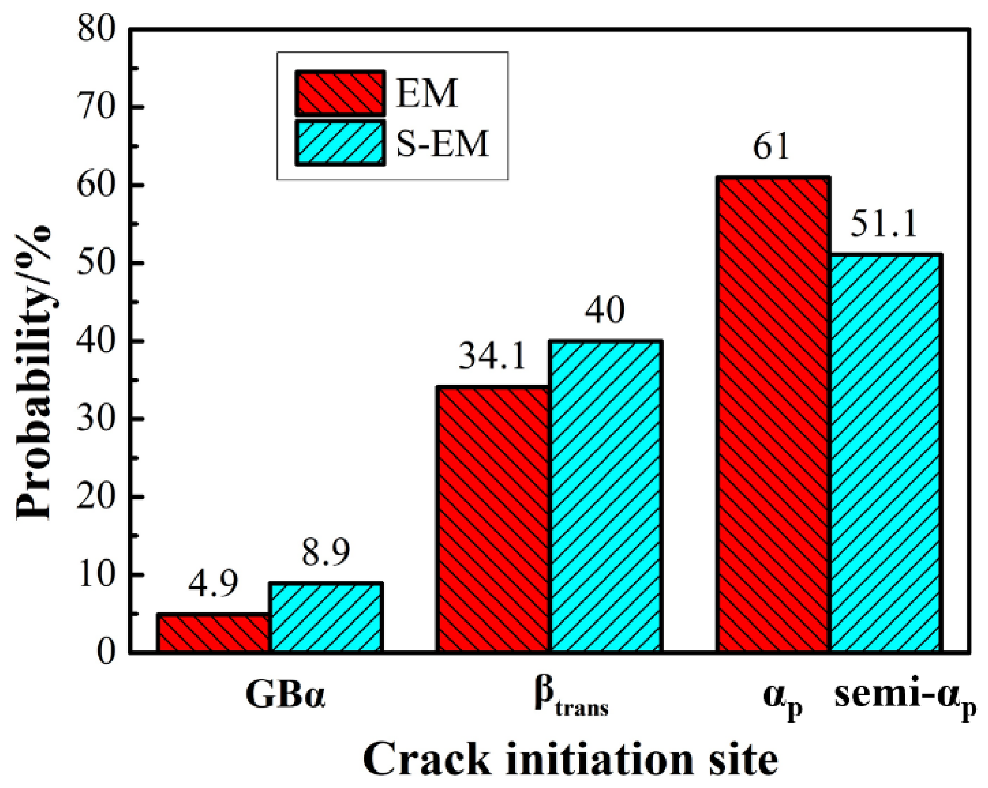

- The tensile fracture failures of both EM and S-EM in TA19 alloy show a mixture fracture mode. Compared to the EM, S-EM samples have shallower dimples and more cleavage facets, which leads to the proportion of brittle fracture mechanism of S-EM is slightly larger than EM.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rezaee, M.; Zarei-Hanzaki, A.; Mohamadizadeh, A.; Ghasemi, E. High-temperature flow characterization and microstructural evolution of Ti6242 alloy: Yield drop phenomenon. Mater. Sci. Eng. A 2016, 673, 346–354. [Google Scholar] [CrossRef]

- Gao, P.F.; Lei, Z.N.; Li, Y.K.; Zhan, M. Low-cycle fatigue behavior and property of TA15 titanium alloy with tri-modal microstructure. Mater. Sci. Eng. A 2018, 736, 1–11. [Google Scholar] [CrossRef]

- Tarzimoghadam, Z.; Sandlöbes, S.; Pradeep, K.G.; Raabe, D. Microstructure design and mechanical properties in a near-α Ti–4Mo alloy. Acta Mater. 2015, 97, 291–304. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V. Flow and fracture characteristics of near alpha titanium alloy. J. Alloys Compd. 2016, 684, 162–170. [Google Scholar] [CrossRef]

- Jia, W.; Zeng, W.; Yu, H. Effect of aging on the tensile properties and microstructures of a near-alpha titanium alloy. Mater. Des. 2014, 58, 108–115. [Google Scholar] [CrossRef]

- Gao, P.F.; Qin, G.; Wang, X.X.; Li, Y.X.; Zhan, M.; Li, G.J.; Li, J.S. Dependence of mechanical properties on the microstructural parameters of TA15 titanium alloy with tri-modal microstructure. Mater. Sci. Eng. A 2019, 739, 203–213. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Zhang, C.J.; Guo, C.X.; Zhang, S.Z.; Feng, H.; Chen, C.Y.; Zhang, H.Z.; Cao, P. Microstructural manipulation and improved mechanical properties of a near α titanium alloy. Mater. Sci. Eng. A 2020, 771, 138569. [Google Scholar] [CrossRef]

- Huang, C.W.; Zhao, Y.Q.; Xin, S.W.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on torsion properties of Ti–5Al–5Mo–5V–3Cr–1Zr alloy. J. Alloys Compd. 2017, 693, 582–591. [Google Scholar] [CrossRef]

- Tan, C.; Sun, Q.; Xiao, L.; Zhao, Y.; Sun, J. Characterization of deformation in primary α phase and crack initiation and propagation of TC21 alloy using in-situ SEM experiments. Mater. Sci. Eng. A 2018, 725, 33–42. [Google Scholar] [CrossRef]

- Shao, H.; Zhao, Y.; Ge, P.; Zeng, W. Crack initiation and mechanical properties of TC21 titanium alloy with equiaxed microstructure. Mater. Sci. Eng. A 2013, 586, 215–222. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Zhou, W.; Li, Q.; Zeng, W.; Tan, C. High cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy with bimodal microstructure. J. Alloys Compd. 2017, 695, 1966–1975. [Google Scholar] [CrossRef]

- Yang, Y.; Jiang, Z.; Wang, C.; Hu, H.B.; Tang, T.G.; Zhang, H.S.; Fu, Y.N. Effects of the phase interface on initial spallation damage nucleation and evolution in dual phase titanium alloy. Mater. Sci. Eng. A 2018, 731, 385–393. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.; Zhao, Y.; Xin, S.; Tan, C.; Zhou, W.; Li, Q.; Zeng, W. Effect of microstructure on high cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy. Int. J. Fatigue 2017, 94, 30–40. [Google Scholar] [CrossRef]

- Sadeghpour, S.; Abbasi, S.M.; Morakabati, M.; Bruschi, S. Correlation between alpha phase morphology and tensile properties of a new beta titanium alloy. Mater. Des. 2017, 121, 24–35. [Google Scholar] [CrossRef]

- Attallah, M.M.; Preuss, M.; Boonchareon, C.; Steuwer, A.; Daniels, J.E.; Hughes, D.J.; Dungey, C.; Baxter, G.J. Microstructural and Residual Stress Development due to Inertia Friction Welding in Ti-6246. Metall. Mater. Trans. A 2012, 43, 3149–3161. [Google Scholar] [CrossRef]

- Wang, G.; Chen, Z.; Li, J.; Liu, J.; Wang, Q.; Yang, R. Microstructure and Mechanical Properties of Electron Beam Welded Titanium Alloy Ti-6246. J. Mater. Sci. Technol. 2018, 34, 570–576. [Google Scholar] [CrossRef]

- Xu, P.; Zhou, L.; Han, M.; Wei, Z.; Liang, Y. Flash-butt welded Ti6242 joints preserved base-material strength and ductility. Mater. Sci. Eng. A 2020, 774, 138915. [Google Scholar] [CrossRef]

- Han, M.; Xu, P.; Wan, M.; Liang, Y.; Du, J. Semi-equiaxed Structure and Tensile Properties of TA19 Titanium Alloy. Rare Met. Mater. Eng. 2018, 47, 3768–3775. [Google Scholar]

- ASTM International. Standard Guide for Preparation of Metallographic Specimens; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Steel, S.; Axial, C.; Application, F. E8/E8M Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2011. [Google Scholar]

- Qin, D.; Lu, Y.; Guo, D.; Zheng, L.; Liu, Q.; Zhou, L. Tensile deformation and fracture of Ti–5Al–5V–5Mo–3Cr–1.5Zr–0.5Fe alloy at room temperature. Mater. Sci. Eng. A 2013, 587, 100–109. [Google Scholar] [CrossRef]

- Mayeur, J.R.; McDowell, D.L. A three-dimensional crystal plasticity model for duplex Ti–6Al–4V. Int. J. Plast. 2007, 23, 1457–1485. [Google Scholar] [CrossRef]

- Tan, C.; Li, X.; Sun, Q.; Xiao, L.; Zhao, Y.; Sun, J. Effect of α-phase morphology on low-cycle fatigue behavior of TC21 alloy. Int. J. Fatigue 2015, 75, 1–9. [Google Scholar] [CrossRef]

- Gao, P.; Cai, Y.; Zhan, M.; Fan, X.; Lei, Z. Crystallographic orientation evolution during the development of tri-modal microstructure in the hot working of TA15 titanium alloy. J. Alloys Compd. 2018, 741, 734–745. [Google Scholar] [CrossRef]

- Seshacharyulu, T.; Medeiros, S.C.; Morgan, J.T.; Malas, J.C.; Frazier, W.G.; Prasad, Y.V.R.K. Hot deformation and microstructural damage mechanisms in extra-low interstitial (ELI) grade Ti–6Al–4V. Mater. Sci. Eng. A 2000, 279, 289–299. [Google Scholar] [CrossRef]

- Chong, Y.; Deng, G.; Gao, S.; Yi, J.; Shibata, A.; Tsuji, N. Yielding nature and Hall-Petch relationships in Ti-6Al-4V alloy with fully equiaxed and bimodal microstructures. Scr. Mater. 2019, 172, 77–82. [Google Scholar] [CrossRef]

- Yu, H.; Xin, Y.; Wang, M.; Liu, Q. Hall-Petch relationship in Mg alloys: A review. J. Mater. Sci. Technol. 2018, 34, 248–256. [Google Scholar] [CrossRef]

- Liu, C.; Lu, Y.; Tian, X.; Liu, D. Influence of continuous grain boundary α on ductility of laser melting deposited titanium alloys. Mater. Sci. Eng. A 2016, 661, 145–151. [Google Scholar] [CrossRef]

- Yan, Z.; Wang, K.; Zhou, Y.; Zhu, X.; Xin, R.; Liu, Q. Crystallographic orientation dependent crack nucleation during the compression of a widmannstätten-structure α/β titanium alloy. Scr. Mater. 2018, 156, 110–114. [Google Scholar] [CrossRef]

- Liu, R.; Hui, S.; Ye, W.; Yu, Y.; Fu, Y.; Song, X.; Deng, X. Tensile and fracture properties of Ti-62A alloy plate with different microstructures. Rare Met. 2012, 31, 420–423. [Google Scholar] [CrossRef]

| Al | Sn | Zr | Mo | W | Si | Ti |

|---|---|---|---|---|---|---|

| 6.61 | 1.75 | 4.12 | 1.91 | 0.32 | 0.10 | Bal. |

| Microstructure | αp (vol %) | αp Diameter (μm) | αs Length (μm) | αs Width (nm) | GB α (vol %) | GB α Width (nm) |

|---|---|---|---|---|---|---|

| EM | 42 ± 2 | 12 ± 1 | 10 ± 1 | 400 ± 20 | 0.3 | 420 ± 30 |

| S-EM | 41 ± 2 | 13 ± 1 | 11 ± 1 | 410 ± 20 | 1.2 | 850 ± 30 |

| Microstructure | YS/Mpa | UTS/Mpa | El/% | RA/% |

|---|---|---|---|---|

| EM | 984 | 1067 | 23.9 | 32.9 |

| S-EM | 1022 | 1113 | 22.8 | 30.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, M.; Lin, T.; Zhou, L.; Li, W.; Liang, Y.; Han, M.; Liang, Y. Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy. Materials 2021, 14, 3380. https://doi.org/10.3390/ma14123380

Luo M, Lin T, Zhou L, Li W, Liang Y, Han M, Liang Y. Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy. Materials. 2021; 14(12):3380. https://doi.org/10.3390/ma14123380

Chicago/Turabian StyleLuo, Minglang, Tingyi Lin, Lei Zhou, Wei Li, Yilong Liang, Moliu Han, and Yu Liang. 2021. "Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy" Materials 14, no. 12: 3380. https://doi.org/10.3390/ma14123380

APA StyleLuo, M., Lin, T., Zhou, L., Li, W., Liang, Y., Han, M., & Liang, Y. (2021). Deformation Behavior and Tensile Properties of the Semi-Equiaxed Microstructure in Near Alpha Titanium Alloy. Materials, 14(12), 3380. https://doi.org/10.3390/ma14123380