Concrete Modular Pavement Structures with Optimized Thickness Based on Characteristics of High Performance Concrete Mixtures with Fibers and Silica Fume

Abstract

:1. Introduction

2. Effect of Concrete Characteristics on Pavement Performance

3. Analytical Calculations of PCP Thickness

3.1. Methods and Input Data for Calculations

3.2. Calculations with Different Methods

4. Analysis and Discussion

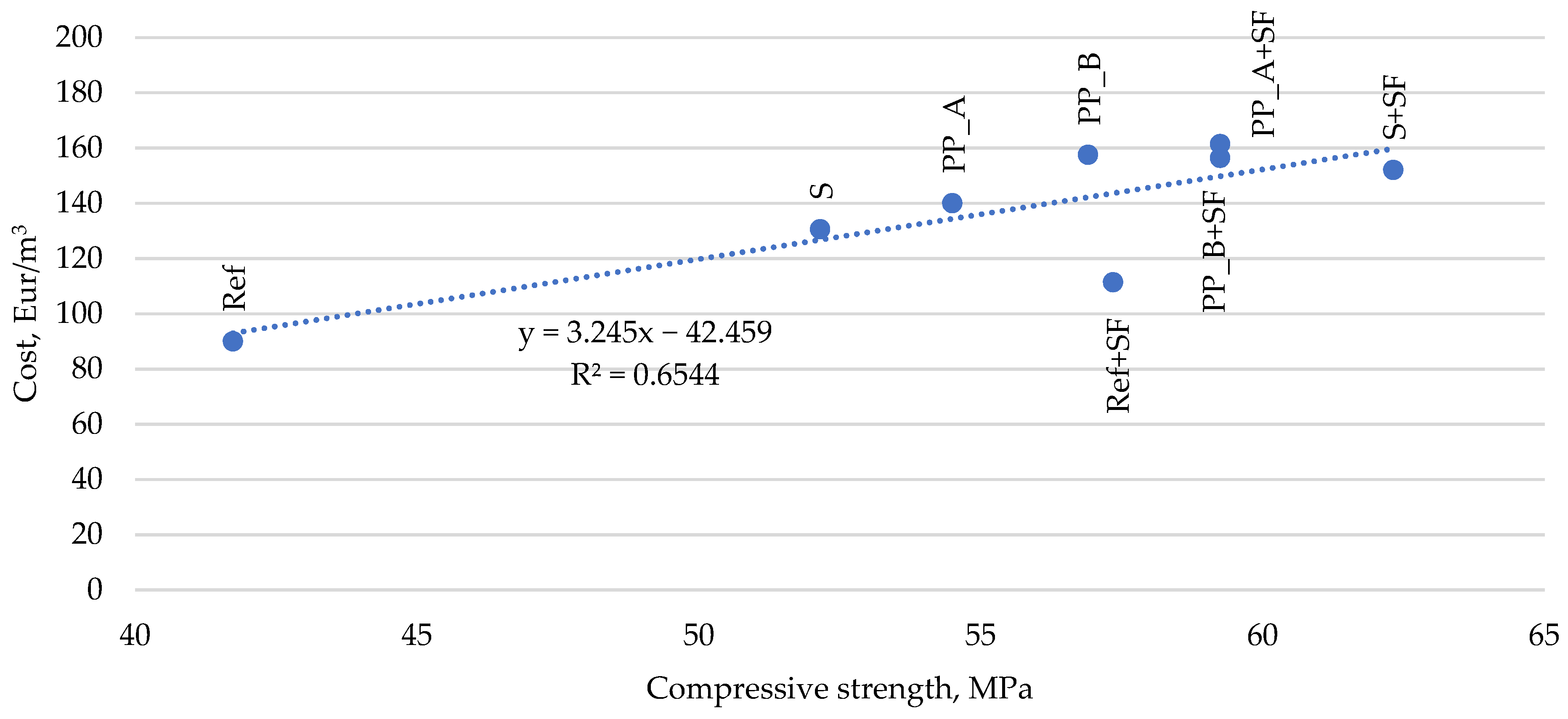

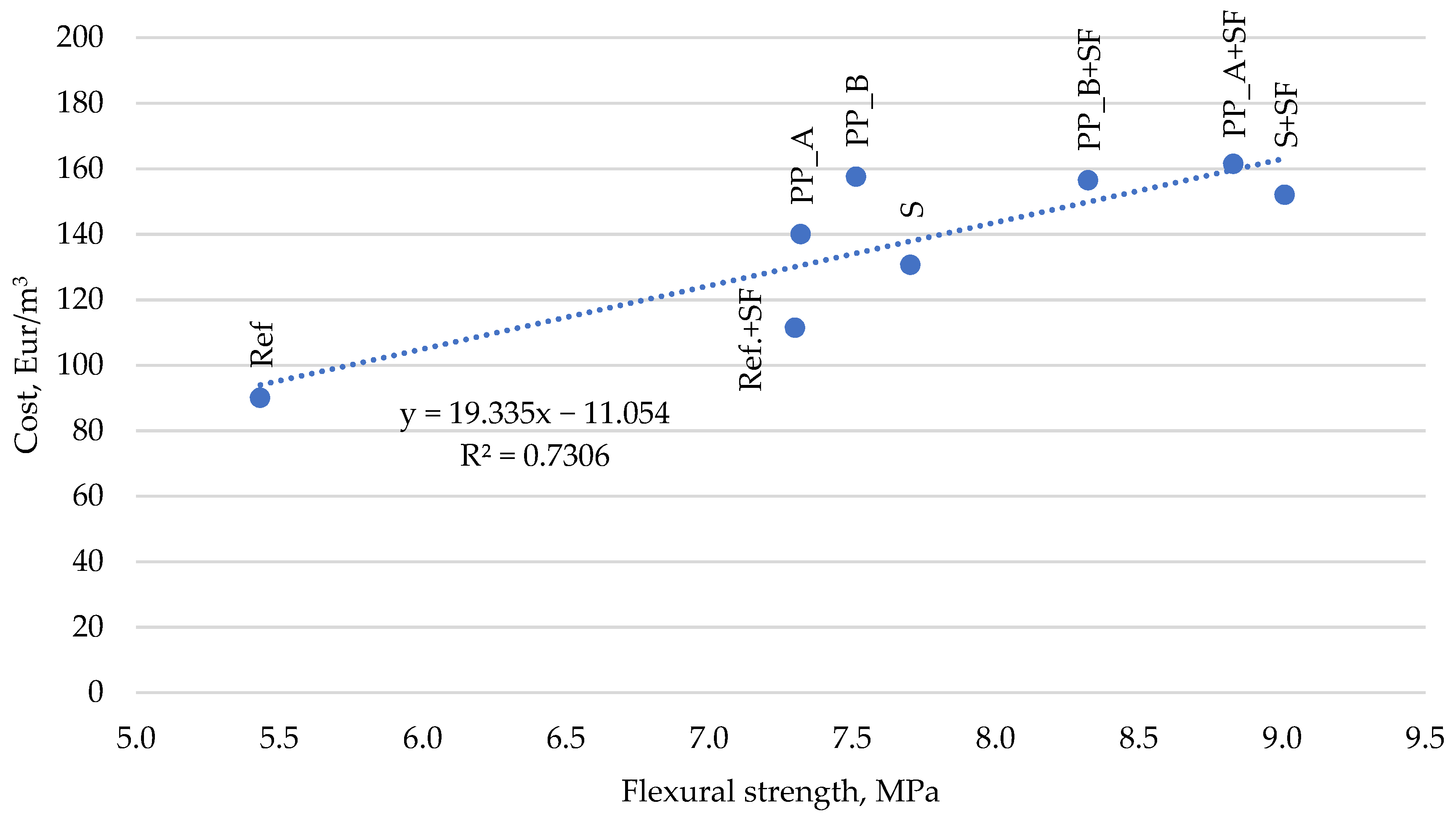

5. Cost-Benefit Analysis of High-Performance Concrete

6. Conclusions

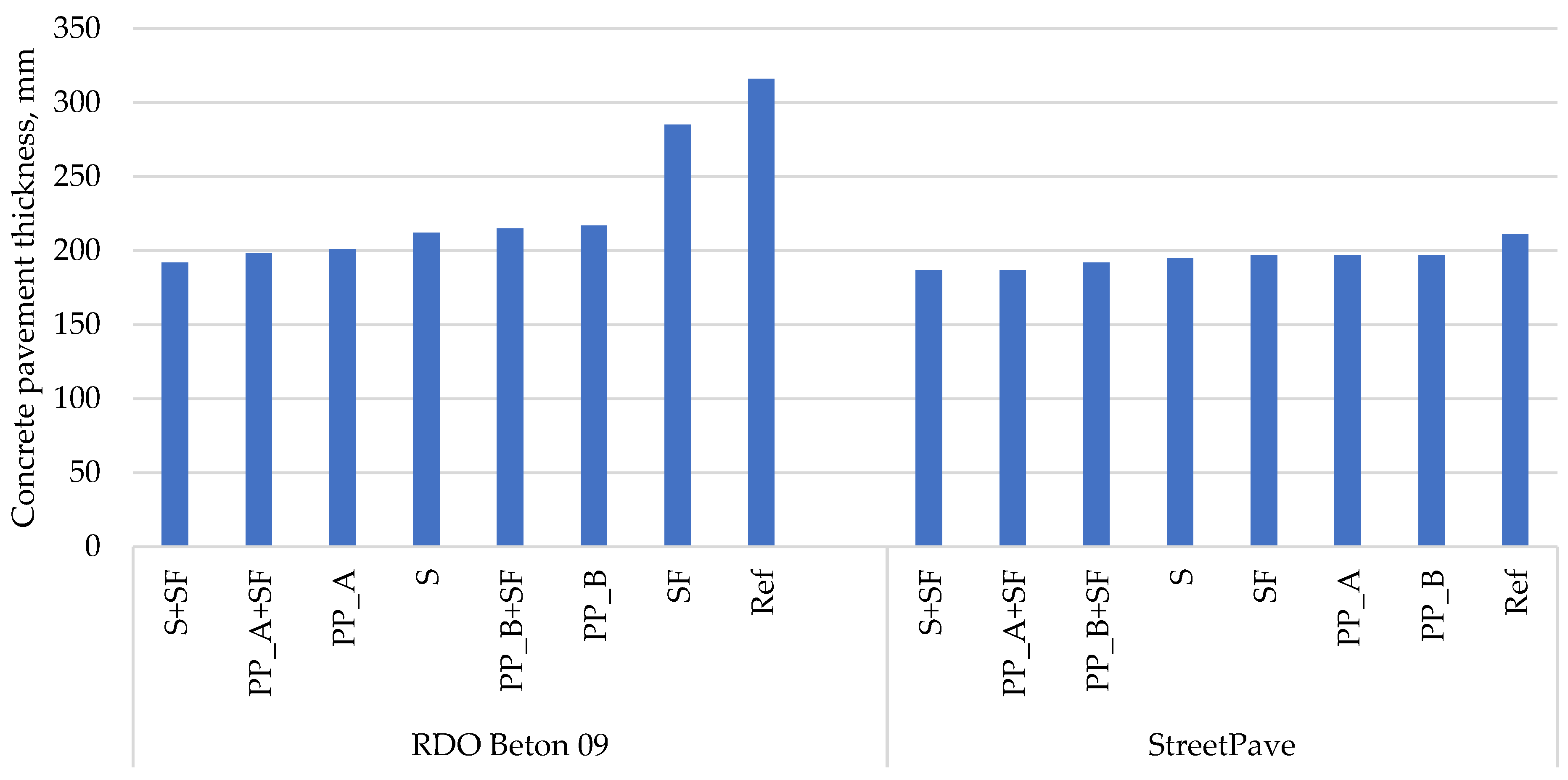

- A minimum thickness of PCP slab depends not only on the pavement structure, joint type and materials characteristics but also on the applied design method. At the same conditions, the semi-probabilistic empirical pavement design method (RDO Beton 09 method) led to a 2–50% thicker PCP slab than the software StreetPave (mechanistic–empirical pavement design method). The lowest difference was determined when a concrete mixture with polypropylene_A fiber and silica fume was used, while a reference mixture gave the highest difference irrespective of the presence or absence of silica fume. The main reason for that is the use of different concrete characteristics for PCP thickness calculation (tensile elastic modulus and tensile splitting strength is required for RDO Beton 09, while StreetPave uses flexural strength) and the different sensitivity to the change in those characteristics.

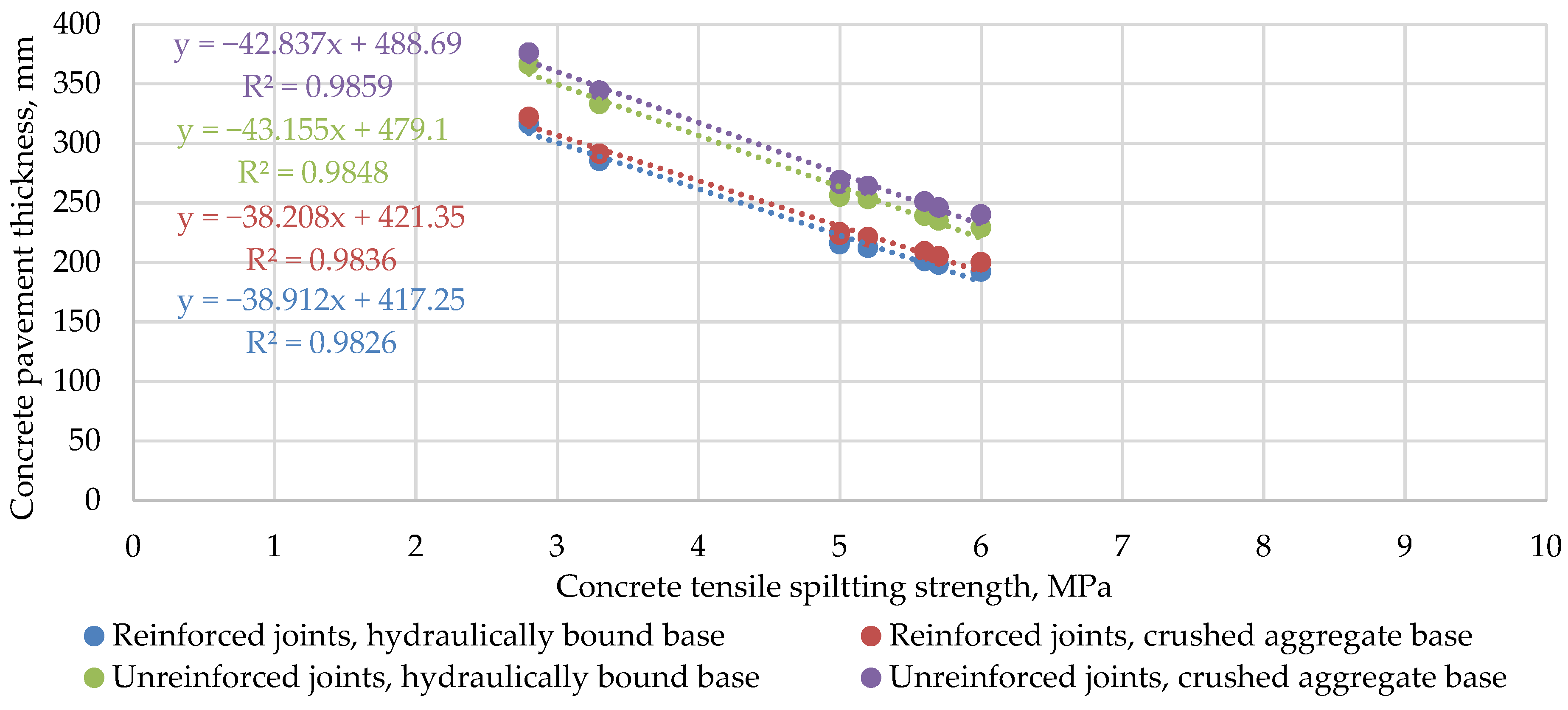

- The comparison of PCP slab thickness with concrete mechanical characteristics used to calculate the thickness showed that the RDO Beton 09 method is significantly more sensitive to the change in the characteristic values of the concrete than StreetPave software. In the case of the RDO Beton 09 method, the 54% increase in the tensile splitting strength of concrete reduced the thickness of the PCP slab by 36%, while the same percentage increase in flexural strength (StreetPave) reduced the thickness of PCP only by 9%.

- The replacement of standard (C30/37) concrete mixture with a high-performance one (C40/50, C45/55 and C50/60) reduces the thickness of PCP slab from 6% to 39% depending on the design method. With both design methods, the highest decrease in thickness of PCP slab (124 mm with RDO Beton 09 method and 24 mm with StreetPave) was determined when a concrete mixture with tensile splitting strength of 6 MPa, tensile elastic modulus of 91 GPa and flexural strength of 9 MPa was used. Those characteristics were achieved by adding 25.2 kg/m3 of silica fume and 49.5 kg/m3 of steel fibers in the concrete mixture.

- Joint type has a much larger effect on the PCP slab thickness than base type, irrespective of design method and the mechanical characteristics of the concrete mixture. The thickness of PCP slab with dowel reinforced joints was 14–17% lower than that with unreinforced joints, while hydraulically bound base course resulted in only 2–5% lower thickness than unbound base course (crushed aggregate).

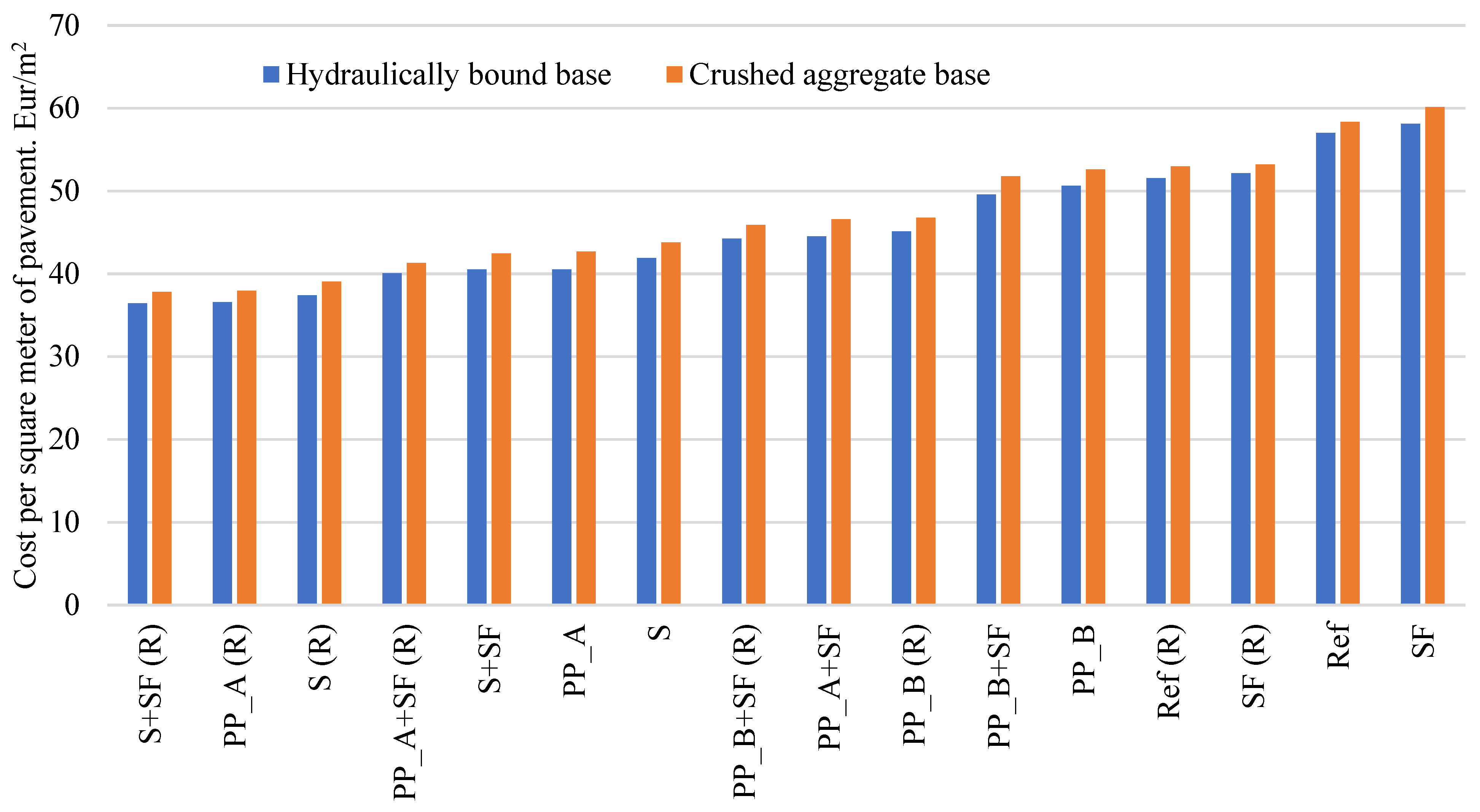

- The cost-benefit analysis showed that the use of a concrete mixture with either steel or polypropylene fibers, irrespective of the presence of silica fume, has a significant economic effect on the total cost per square meter of PCP. Comparing to reference concrete, the total cost per square meter of PCP with fibers decreased from 8.8% to 27.2% when the pavement is on a crushed aggregate base and from 11.2% to 29.0% when the pavement is on a hydraulically bound base. If dowel reinforced joints are used, the economic effect is even higher—the total cost per square meter of PCP decreases from 19.8% to 35.2% when the pavement is on a crushed aggregate base, and from 20.9% to 36.2% when the pavement is on a hydraulically bound base. Based on the theoretical calculations, the use of concrete with both steel fiber and silica fume and reinforced joints is the most economic (37.80 EUR/m2) when comparing to the reference mixture (58.33 EUR/m2).

- From all analyzed pavement structures with different concrete mixtures, four concrete mixtures, which are listed below, can be assumed as the most rational ones in terms of PCP thickness reduction and total pavement cost:

- −

- Concrete mixture with 49.5 kg/m3 of steel fibers and 25.2 kg/m3 of silica fume (reduces the thickness of PCP slab from 316 to 192 mm on hydraulically bound base course and from 322 to 200 mm on the unbound base course);

- −

- Concrete mixture with 10.0 kg/m3 of polypropylene fibers (type A) (reduces the thickness of PCP slab from 316 to 201 mm on hydraulically bound base course and from 322 to 209 mm on the unbound base course);

- −

- Concrete mixture with 49.5 kg/m3 of steel fibers (reduces the thickness of PCP slab from 316 to 212 mm on hydraulically bound base course and from 322 to 221 mm on the unbound base course);

- −

- Concrete mixture with 10.0 kg/m3 of polypropylene fibers (type A) and 25.2 kg/m3 of silica fume 49.5 kg/m3 (reduces the thickness of PCP slab from 316 to 198 mm on hydraulically bound base course and from 322 to 205 mm on the unbound base course).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DG MOVE, European Commision. Transport in the European Union: Current Trends and Issues; DG MOVE: Brussels, Belgium, 2019. [Google Scholar]

- Mu, F.; Mack, J.W.; Rodden, R.A. Review of National and State-Level Calibrations of AASHTOWare Pavement ME Design for New Jointed Plain Concrete Pavement. Int. J. Pavement Eng. 2018, 19, 825–831. [Google Scholar] [CrossRef]

- Nasief, G.H.; Whited, G.C.; Loh, W.-Y. Wisconsin Method for Probing Portland Cement Concrete Pavement for Thickness. Transp. Res. Rec. J. Transp. Res. Board 2011, 2228, 99–107. [Google Scholar] [CrossRef]

- Tayabji, S.; Ye, D.; Buch, N. Precast Concrete Pavement Technology. Report S2-R05-RR-1; Transportation Research Board: Washington, DC, USA, 2013. [Google Scholar]

- Vandenbossche, J.M.; Mu, F.; Burnham, T.R. Comparison of Measured vs. Predicted Performance of Jointed Plain Concrete Pavements Using the Mechanistic–Empirical Pavement Design Guideline. Int. J. Pavement Eng. 2011, 12, 239–251. [Google Scholar] [CrossRef]

- Vaitkus, A.; Gražulytė, J.; Kleizienė, R.; Vorobjovas, V.; Šernas, O. Concrete Modular Pavements—Types, Issues and Challenges. Balt. J. Road Bridg. Eng. 2019, 14, 80–103. [Google Scholar] [CrossRef]

- Gražulytė, J.; Vaitkus, A.; Laurinavičius, A.; Čygas, D. Concrete Modular Pavement Type Selection Based on Application Area. In Proceedings of the 13th International Conference “Modern Building Materials, Structures and Techniques”, Vilnius, Lithuania, 16–17 May 2019. [Google Scholar]

- Kou, S.-C.; Poon, C.-S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Valipour, M.; Pargar, F.; Shekarchi, M.; Khani, S. Comparing a Natural Pozzolan, Zeolite, to Metakaolin and Silica Fume in Terms of Their Effect on the Durability Characteristics of Concrete: A Laboratory Study. Constr. Build. Mater. 2013, 41, 879–888. [Google Scholar] [CrossRef]

- Eren, Ö.; Çelik, T. Effect of silica fume and steel fibers on some properties of high-strength concrete. Constr. Build. Mater. 1997, 11, 373–382. [Google Scholar] [CrossRef]

- Köksal, F.; Altun, F.; Yiğit, I.; Şahin, Y. Combined effect of silica fume and steel fiber on the mechanical properties of high strength concretes. Constr. Build. Mater. 2008, 22, 1874–1880. [Google Scholar] [CrossRef]

- Nežerka, V.; Bílý, P.; Hrbek, V.; Fládr, J. Impact of Silica Fume, Fly Ash, and Metakaolin on the Thickness and Strength of the ITZ in Concrete. Cem. Concr. Compos. 2019, 103, 252–262. [Google Scholar] [CrossRef]

- Sarıdemir, M. Effect of Silica Fume and Ground Pumice on Compressive Strength and Modulus of Elasticity of High Strength Concrete. Constr. Build. Mater. 2013, 49, 484–489. [Google Scholar] [CrossRef]

- Yan, H.; Sun, W.; Chen, H. Effect of Silica Fume and Steel Fiber on the Dynamic Mechanical Performance of High-Strength Concrete. Cem. Concr. Res. 1999, 29, 423–426. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of Silica Fume on Mechanical Properties of High-Strength Concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Soroushian, P.; Ziad, B. Fiber-Type Effects on the Performance of Steel Fiber Reinforced Concrete. ACI Mater. J. 1991, 88, 129–134. [Google Scholar]

- Lee, M.; Barr, B. An overview of the fatigue behaviour of plain and fibre reinforced concrete. Cem. Concr. Compos. 2004, 26, 299–305. [Google Scholar] [CrossRef]

- Mínguez, J.; Gutiérrez, L.; González, D.C.; Vicente, M.A. Plain and Fiber-Reinforced Concrete Subjected to Cyclic Compressive Loading: Study of the Mechanical Response and Correlations with Microstructure Using CT Scanning. Appl. Sci. 2019, 9, 3030. [Google Scholar] [CrossRef] [Green Version]

- Vicente, M.A.; Ruiz, G.; González, D.C.; Mínguez, J.; Tarifa, M.; Zhang, X. Effects of fiber orientation and content on the static and fatigue behavior of SFRC by using CT-Scan technology. Int. J. Fatigue 2019, 128, 105178. [Google Scholar] [CrossRef]

- Yurtseven, A.E.; Yaman, I.O.; Tokyay, M. Mechanical Properties of Hybrid Fiber Reinforced Concrete. In Measuring, Monitoring and Modeling Concrete Properties; Konsta-Gdoutos, M.S., Ed.; Springer: Dordrecht, The Netherlands, 2006; pp. 207–214. [Google Scholar]

- Ahmed, T.W.; Ali, A.A.M.; Zidan, R.S. Properties of high strength polypropylene fiber concrete containing recycled aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Balendran, R.; Zhou, F.; Nadeem, A.; Leung, A. Influence of steel fibres on strength and ductility of normal and lightweight high strength concrete. Build. Environ. 2002, 37, 1361–1367. [Google Scholar] [CrossRef]

- Gao, D.-Y.; Gu, Z.-Q.; Wu, C. Bending Behavior and Deflection Prediction of High-Strength SFRC Beams under Fatigue Loading. J. Mater. Res. Technol. 2020, 9, 6143–6159. [Google Scholar] [CrossRef]

- Setti, F.; Ezziane, K.; Setti, B. Investigation of Mechanical Characteristics and Specimen Size Effect of Steel Fibers Reinforced Concrete. J. Adhes. Sci. Technol. 2020, 34, 1426–1441. [Google Scholar] [CrossRef]

- Guo, H.; Tao, J.; Chen, Y.; Li, D.; Jia, B.; Zhai, Y. Effect of steel and polypropylene fibers on the quasi-static and dynamic splitting tensile properties of high-strength concrete. Constr. Build. Mater. 2019, 224, 504–514. [Google Scholar] [CrossRef]

- Roesler, J.R.; Cervantes, V.G.; Amirkhanian, A.N. Accelerated Performance Testing of Concrete Pavement with Short Slabs. Int. J. Pavement Eng. 2012, 13, 494–507. [Google Scholar] [CrossRef]

- Johnston, C.D.; Robert, W.Z. Flexural Fatigue Performance of Steel Fiber Reinforced Concrete—Influence of Fiber Content, Aspect Ratio, and Type. Mater. J. 1991, 88, 374–383. [Google Scholar]

- Vicente, M.A.; Mínguez, J.; González, D.C. Computed tomography scanning of the internal microstructure, crack mechanisms, and structural behavior of fiber-reinforced concrete under static and cyclic bending tests. Int. J. Fatigue 2019, 121, 9–19. [Google Scholar] [CrossRef]

- Cajka, R.; Marcalikova, Z.; Kozielova, M.; Mateckova, P.; Sucharda, O. Experiments on Fiber Concrete Foundation Slabs in Interaction with the Subsoil. Sustainability. 2020, 12, 3939. [Google Scholar] [CrossRef]

- Kim, W.; Oh, R.-O.; Lee, J.-H.; Kim, M.-S.; Jeon, S.-M.; Park, C.-G. Mechanical and Durability Characteristics of Latex-Modified Fiber-Reinforced Segment Concrete as a Function of Microsilica Content. Adv. Civ. Eng. 2019, 2019, 3658125. [Google Scholar] [CrossRef] [Green Version]

- Parker, F. Steel Fibrous Concrete for Airport Pavement Applications; US Army Engineer Waterways Experiment Station: Vicksburg, MS, USA, 1974. [Google Scholar]

- Vaitkus, A.; Kleizienė, R.; Vorobjovas, V.; Čygas, D. Mixture Strength Class and Slab Dimensions’ Effect on The Precast Concrete Pavement Structural Performance. Balt. J. Road Bridg. Eng. 2019, 14, 443–471. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre Reinforced Cement-Based (FRC) Composites after over 40 Years of Development in Building and Civil Engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Rodden, R.; Ferrebee, E.; Sullivan, S.; Covarrubias, J.P.; Nantasai, B. Comparison of Modern Concrete Pavement Performance Predictions, Thickness Requirements, and Sensitivity to Joint Spacing. In Proceedings of the Conference and Exhibition of the Transportation Association of Canada, St. John’s, NL, Canada, 24–27 September 2017. [Google Scholar]

- Die Forschungsgesellschaft für Straßen- und Verkehrswesen. Richtlinien Für die Rechnerische Dimensionierung von Betondecken im Oberbau von Verkehrsf Lächen RDO Beton 09; Die Forschungsgesellschaft für Straßen- und Verkehrswesen: Köln, German, 2009. [Google Scholar]

- FAA. Airport Pavement Design and Evaluation; AC No. 150/5320-6F; Federal Aviation Administration (FAA): Washington, DC, USA, 2016; pp. 1–173.

- PCA. Thickness Design for Concrete Highways and Streets Pavements; Portland Cement Association: Washington, DC, USA, 1984; pp. 1–50. [Google Scholar]

- Minnesota Department of Transportation. Use of Street Pave for Design of Concrete Pavements for Cities and Counties in Minnesota; Minnesota Department of Transportation: St. Paul, MN, USA, 2012; pp. 1–56.

- Titus-Glover, L.; Mallela, J.; Darter, M.I.; Voigt, G.; Waalkes, S. Enhanced Portland Cement Concrete Fatigue Model for StreetPave. J. Transp. Res. Board 2005, 1919, 29–37. [Google Scholar] [CrossRef]

- Vaitkus, A.; Šernas, O.; Gražulytė, J. Modular pavements: Developing high performance concrete. Constr. Build. Mater. 2021, 292, 123362. [Google Scholar] [CrossRef]

- Lietuvos automobilių kelių direkcija prie Susisiekimo Ministerijos (Lithuanian Road Administration under Ministry of Transportation). KPT SDK 19 Automobilių Kelių Standartizuotų Dangų Konstrukcijų Projektavimo Taisyklės (Rules for the Design of Road Standard Pavement Structures); Lietuvos automobilių kelių direkcija prie Susisiekimo Ministerijos (LAKD): Vilnius, Lithuania, 2019. (In Lithuanian)

| Concrete Mixture Type | Concrete Mixture‘s Code | Amount of Fiber, kg/m3 | Amount of Silica Fume, kg/m3 | Compressive Strength, MPa | Tensile Splitting Strength, MPa | Tensile Elastic Modulus, MPa | Flexural Strength, MPa |

|---|---|---|---|---|---|---|---|

| REF w/o silica fume | Ref | 0.0 | 0.0 | 41.7 | 2.8 | 51,084 | 5.4 |

| REF w/silica fume | SF | 0.0 | 25.2 | 57.3 | 3.3 | 60,248 | 7.3 |

| Steel fiber w/o silica fume | S | 49.5 | 0.0 | 52.2 | 5.2 | 83,385 | 7.7 |

| Steel fiber w/silica fume | S + SF | 49.5 | 25.2 | 62.3 | 6.0 | 91,428 | 9.0 |

| Polypropylene_A fiber w/o silica fume | PP_A | 10.0 | 0.0 | 54.5 | 5.6 | 78,346 | 7.3 |

| Polypropylene_A fiber w/silica fume | PP_A + SF | 10.0 | 25.2 | 59.2 | 5.7 | 75,945 | 8.8 |

| Polypropylene_B fiber w/o silica fume | PP_B | 15 | 0 | 56.9 | 5.0 | 83,014 | 7.5 |

| Polypropylene_B fiber w/silica fume | PP_B + SF | 10 | 25.2 | 59.2 | 5.0 | 73,635 | 8.3 |

| RDO Beton 09 | StreetPave | |||

|---|---|---|---|---|

| Boundary conditions | Criteria | Boundary Conditions | Criteria | |

| At Longitudinal Joint | At Transverse Joint | |||

| Bearing capacity | MR,BCBC,L ≥ ME,BCBC,L 1 | MR,BCBC,T ≥ ME,BCBC,T | Fatigue | 2 |

| Serviceability | MR,BCBC,L ≥ ME,BCBC,L | MR,BCBC,T ≥ ME,BCBC,T | Erosion | |

| Fatigue resistance | MR,F,L ≥ ME,F,L | MR,F,T ≥ ME,F,T | ||

| Parameter | Value | |

|---|---|---|

| Road category | National roads | |

| Design speed | 90 km/h | |

| Traffic distribution per day | Normal | |

| Reference axle load | 70 kN | |

| Bedding modulus, N/mm3 | On crushed aggregate base | 0.12 |

| On hydraulically bound base | 0.15 | |

| Factor for determining the temperature gradient, – | 0.14 | |

| Thermal expansion coefficient of concrete, 10−6/K | 11.0 | |

| PCP slab dimensions, m | 4.60 × 4.10 | |

| Layer | Thickness, cm | E modulus, MPa |

|---|---|---|

| Hydraulically bound base/crushed aggregate base | 15/20 | 10,350/310 |

| Frost-resistant subbase | 45 | 150 |

| Subgrade | – | 45 |

| Parameter | Value |

|---|---|

| Terminal serviceability | 2 |

| Reliability | 80% |

| CBR | 5% |

| Percent of slab cracked at the end of design life | 15% |

| k | 193.5 MPa/m |

| Flexural strength | According to Table 1 |

| Concrete Mixture Type | Unreinforced Joints | Reinforced Joints | ||||||

|---|---|---|---|---|---|---|---|---|

| On Hydraulically Bound Base | On Crushed Aggregate Base | On Hydraulically Bound Base | On Crushed Aggregate Base | |||||

| RDO Beton 09 | StreetPave | RDO Beton 09 | StreetPave | RDO Beton 09 | StreetPave | RDO Beton 09 | StreetPave | |

| Ref | 366 | 246 | 376 | 251 | 316 | 211 | 322 | 214 |

| SF | 333 | 230 | 344 | 235 | 285 | 197 | 291 | 200 |

| S | 253 | 228 | 264 | 233 | 212 | 195 | 221 | 198 |

| S + SF | 229 | 220 | 240 | 225 | 192 | 187 | 200 | 190 |

| PP_A | 239 | 230 | 251 | 235 | 201 | 197 | 209 | 200 |

| PP_A + SF | 235 | 220 | 246 | 225 | 198 | 187 | 205 | 190 |

| PP_B | 257 | 230 | 269 | 235 | 217 | 197 | 225 | 200 |

| PP_B + SF | 255 | 225 | 266 | 230 | 215 | 192 | 223 | 195 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaitkus, A.; Gražulytė, J.; Šernas, O.; Karbočius, M.; Mickevič, R. Concrete Modular Pavement Structures with Optimized Thickness Based on Characteristics of High Performance Concrete Mixtures with Fibers and Silica Fume. Materials 2021, 14, 3423. https://doi.org/10.3390/ma14123423

Vaitkus A, Gražulytė J, Šernas O, Karbočius M, Mickevič R. Concrete Modular Pavement Structures with Optimized Thickness Based on Characteristics of High Performance Concrete Mixtures with Fibers and Silica Fume. Materials. 2021; 14(12):3423. https://doi.org/10.3390/ma14123423

Chicago/Turabian StyleVaitkus, Audrius, Judita Gražulytė, Ovidijus Šernas, Martynas Karbočius, and Rafal Mickevič. 2021. "Concrete Modular Pavement Structures with Optimized Thickness Based on Characteristics of High Performance Concrete Mixtures with Fibers and Silica Fume" Materials 14, no. 12: 3423. https://doi.org/10.3390/ma14123423

APA StyleVaitkus, A., Gražulytė, J., Šernas, O., Karbočius, M., & Mickevič, R. (2021). Concrete Modular Pavement Structures with Optimized Thickness Based on Characteristics of High Performance Concrete Mixtures with Fibers and Silica Fume. Materials, 14(12), 3423. https://doi.org/10.3390/ma14123423