Evaluation of Energy Absorption Capabilities of Polyethylene Foam under Impact Deformation

Abstract

:1. Introduction

2. Theory Analysis

2.1. Deformation Modes and Transitional Compression Velocity

2.2. Energy Absorption

3. Experimental Testing

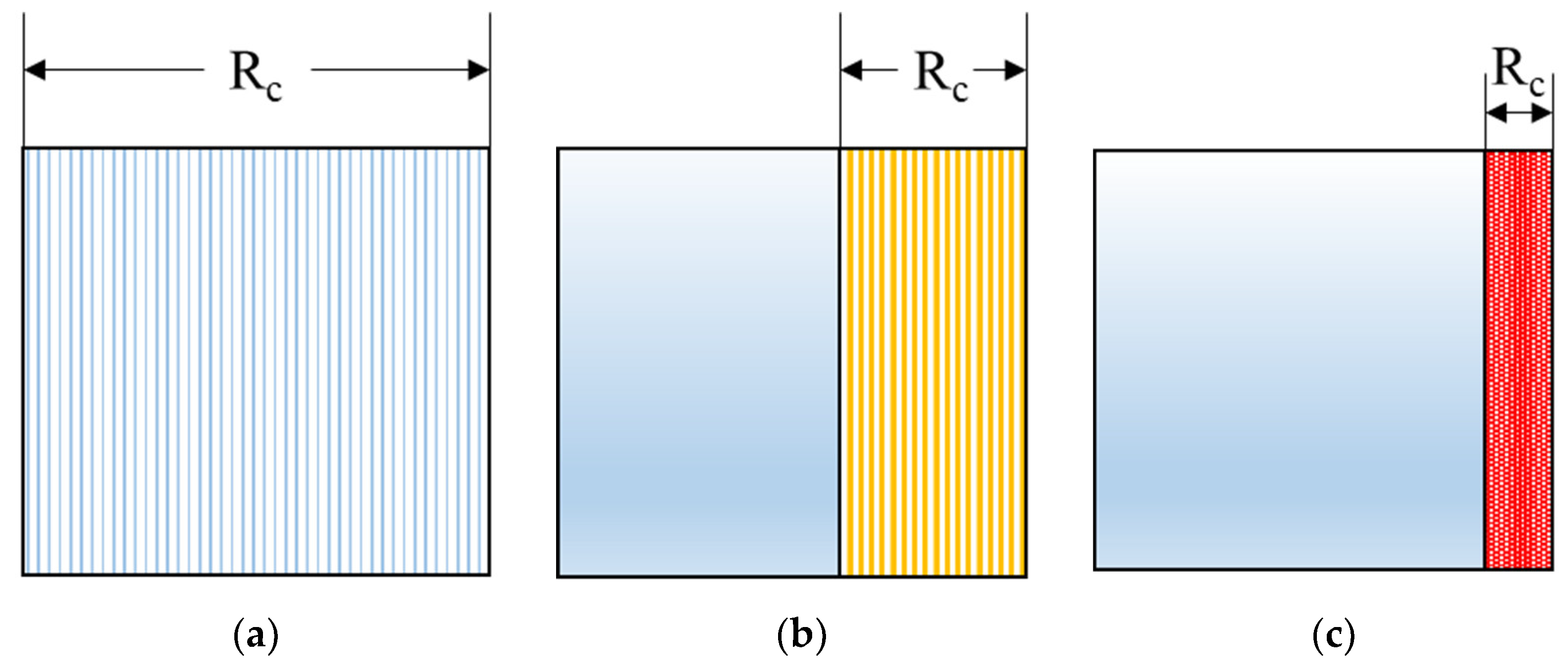

3.1. Specimen Details

3.2. Experimental Methods

4. Results and Discussion

4.1. Stress–Strain Response

4.2. Failure Mechanism

4.3. Energy Absorption

4.4. Discussion

5. Conclusions

- In this study, the first and second transitional velocities of PE foam compression mode are calculated. The results of the theoretical model agree with the experimental results, which verifies the theory.

- The difference in PE foam material behavior in homogeneous mode and shock mode was observed through experiments. The specimen deformation varies as the strain rate changes. In the shock mode, the stress in the specimen is not uniform. Shock tests resulted in strain rates of 6.1 × 103 s−1, which were sufficiently high to cause selective densification in the proximal end of the specimen, as observed with a high-speed camera.

- During the shock mode compression process, the energy absorption in the specimen varies linearly. When the speed is less than 1.3 m/s, this stable energy absorption state disappears. The energy density is greatly affected by velocity under the shock mode.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Youssef, G.; Reed, N.; Huynh, N.U.; Rosenow, B.; Manlulu, K. Experimentally-validated predictions of impact response of polyurea foams using viscoelasticity based on bulk properties. Mech. Mater. 2020, 148, 8. [Google Scholar] [CrossRef]

- Hohe, J.; Beckmann, C.; Bohme, W.; Weise, J.; Reinfried, M.; Luthardt, F.; Rapp, F.; Diemert, J. An experimental and numerical survey into the potential of hybrid foams. Mech. Mater. 2019, 136, 15. [Google Scholar] [CrossRef]

- Le Barbenchon, L.; Kopp, J.B.; Girardot, J.; Viot, P. Reinforcement of cellular materials with short fibres: Application to a bio-based cork multi-scale foam. Mech. Mater. 2020, 142, 13. [Google Scholar] [CrossRef]

- Duan, Y.; Zhao, X.H.; Du, B.; Shi, X.P.; Zhao, H.; Hou, B.; Li, Y.L. Quasi-static compressive behavior and constitutive model of graded foams. Int. J. Mech. Sci. 2020, 177, 14. [Google Scholar] [CrossRef]

- Drozdov, A.D.; Christiansen, J.D. Modeling the elastic response of polymer foams at finite deformations. Int. J. Mech. Sci. 2020, 171, 11. [Google Scholar] [CrossRef]

- Cao, S.Z.; Liu, T.; Jones, A.; Tizani, W. Particle reinforced thermoplastic foams under quasi-static compression. Mech. Mater. 2019, 136, 17. [Google Scholar] [CrossRef]

- Zhang, Y.; Jin, T.; Li, S.; Ruan, D.; Wang, Z.; Lu, G. Sample size effect on the mechanical behavior of aluminum foam. Int. J. Mech. Sci. 2019, 151, 622–638. [Google Scholar] [CrossRef]

- Khosroshahi, S.F.; Olsson, R.; Wysocki, M.; Zaccariotto, M.; Galvanetto, U. Response of a helmet liner under biaxial loading. Polym. Test. 2018, 72, 110–114. [Google Scholar] [CrossRef]

- Zhang, J.X.; Qin, Q.H.; Chen, S.J.; Yang, Y.; Ye, Y.; Xiang, C.P.; Wang, T.J. Low-velocity impact of multilayer sandwich beams with metal foam cores: Analytical, experimental, and numerical investigations. J. Sandw. Struct. Mater. 2020, 22, 626–657. [Google Scholar] [CrossRef]

- Cetin, E.; Baykasoglu, C. Energy absorption of thin-walled tubes enhanced by lattice structures. Int. J. Mech. Sci. 2019, 157, 471–484. [Google Scholar] [CrossRef]

- Munoz-Pascual, S.; Saiz-Arroyo, C.; Vuluga, Z.; Corobea, M.C.; Rodriguez-Perez, M.A. Foams with Enhanced Ductility and Impact Behavior Based on Polypropylene Composites. Polymers 2020, 12, 943. [Google Scholar] [CrossRef] [Green Version]

- Kesavan, A.; Madhavan, V.R.B.; Chinnadurai, E. Mechanical and thermal properties of PVC and polyurethane foam hybrid composites. Mater. Test. 2020, 62, 544–552. [Google Scholar] [CrossRef]

- Zhao, Z.; Jing, L. The response of clamped sandwich panels with layered-gradient aluminum foam cores to foam projectile impact. Mech. Adv. Mater. Struct. 2020, 27, 744–753. [Google Scholar] [CrossRef]

- Ramirez, B.J.; Misra, U.; Gupta, V. Viscoelastic foam-filled lattice for high energy absorption. Mech. Mater. 2018, 127, 39–47. [Google Scholar] [CrossRef]

- Zhu, Y.F.; Sun, Y.G. Dynamic response of foam core sandwich panel with composite facesheets during low-velocity impact and penetration. Int. J. Impact Eng. 2020, 139, 10. [Google Scholar] [CrossRef]

- Pandey, A.; Muchhala, D.; Kumar, R.; Sriram, S.; Venkat, A.N.C.; Mondal, D.P. Flexural deformation behavior of carbon fiber reinforced aluminium hybrid foam sandwich structure. Compos. Pt. B-Eng. 2020, 183, 11. [Google Scholar] [CrossRef]

- Borovinsek, M.; Vesenjak, M.; Hokamoto, K.; Ren, Z.R. An Experimental and Computational Study of the High-Velocity Impact of Low-Density Aluminum Foam. Materials 2020, 13, 1949. [Google Scholar] [CrossRef]

- Guo, Y.; Yang, H.; Liu, X.; Zheng, Z.; Wang, J. Compressive mechanical behavior of closed cell Aluminum foam under dynamic loading. J. Vib. Eng. 2020, 33, 338–346. [Google Scholar]

- Yang, B.; Cao, Z.; Chang, Z.; Zheng, G. The effect of the reflected shock wave on the foam material. Int. J. Impact Eng. 2021, 149, 103773. [Google Scholar] [CrossRef]

- Xu, P.B.; Yu, Y.; Li, K.; Wu, X.T. SHPB experiment research on dynamic property of expanded polystyrene foam. Polym. Test. 2018, 69, 431–436. [Google Scholar] [CrossRef]

- Johnsen, J.; Grytten, F.; Hopperstad, O.S.; Clausen, A.H. Influence of strain rate and temperature on the mechanical behaviour of rubber-modified polypropylene and cross-linked polyethylene. Mech. Mater. 2017, 114, 40–56. [Google Scholar] [CrossRef]

- El-Qoubaa, Z.; Othman, R. Strain rate sensitivity of polyetheretherketone’s compressive yield stress at low and high temperatures. Mech. Mater. 2016, 95, 15–27. [Google Scholar] [CrossRef]

- Tang, N.H.; Lei, D.; Huang, D.W.; Xiao, R. Mechanical performance of polystyrene foam (EPS): Experimental and numerical analysis. Polym. Test. 2019, 73, 359–365. [Google Scholar] [CrossRef]

- Henriques, I.R.; Rouleau, L.; Castello, D.A.; Borges, L.A.; Deu, J.F. Viscoelastic behavior of polymeric foams: Experiments and modeling. Mech. Mater. 2020, 148, 11. [Google Scholar] [CrossRef]

- Bosi, F.; Pellegrino, S. Nonlinear thermomechanical response and constitutive modeling of viscoelastic polyethylene membranes. Mech. Mater. 2018, 117, 9–21. [Google Scholar] [CrossRef]

- Li, Z.J.; Chen, W.S.; Hao, H. Mechanical properties of carbon foams under quasi-static and dynamic loading. Int. J. Mech. Sci. 2019, 161, 12. [Google Scholar] [CrossRef]

- Ha, N.S.; Lu, G.X.; Xiang, X.M. High energy absorption efficiency of thin-walled conical corrugation tubes mimicking coconut tree configuration. Int. J. Mech. Sci. 2018, 148, 409–421. [Google Scholar] [CrossRef]

- Ling, C.; Ivens, J.; Cardiff, P.; Gilchrist, M.D. Deformation response of EPS foam under combined compression-shear loading. Part II: High strain rate dynamic tests. Int. J. Mech. Sci. 2018, 145, 9–23. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, Y.; Zhang, F.; Gong, W.; He, L. Studies on Foaming Properties and Mechanical Properties of Polypropylene /beta-Cyclodextrin Foamed Composite. Mater. Rev. 2020, 34, 04148. [Google Scholar]

- Guo, Y.; Yang, H.; Liu, X.; He, S.; Wang, J. Dynamic mechanical properties of closed cell aluminum foam under medium and low strain rates. J. Vib. Shock 2020, 39, 282–288. [Google Scholar]

- Das, S.; Rajak, D.K.; Khanna, S.; Mondal, D.P. Energy Absorption Behavior of Al-SiC-Graphene Composite Foam under a High Strain Rate. Materials 2020, 13, 783. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hwang, B.K.; Kim, S.K.; Kim, J.H.; Kim, J.D.; Lee, J.M. Dynamic compressive behavior of rigid polyurethane foam with various densities under different temperatures. Int. J. Mech. Sci. 2020, 180, 12. [Google Scholar] [CrossRef]

- Guo, A.F.; Li, H.; Xu, J.; Li, J.F.; Li, F.Y. Effect of microstructure on the properties of polystyrene microporous foaming material. e-Polymers 2020, 20, 103–110. [Google Scholar] [CrossRef]

- Krundaeva, A.; De Bruyne, G.; Gagliardi, F.; Van Paepegem, W. Dynamic compressive strength and crushing properties of expanded polystyrene foam for different strain rates and different temperatures. Polym. Test. 2016, 55, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Ouellet, S.; Frost, D.; Bouamoul, A. Using a shock tube to predict the response of polymeric foam to a blast loading. J. Phys. IV Fr. 2006, 134, 783–787. [Google Scholar] [CrossRef]

- Levy, A. Chapter 15.2—Shock Wave Propagation in Multi-Phase Media: 15.2 Weak Shock Wave Interaction with Inert Granular Media; Elsevier Inc.: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Skews, B.W.; Levy, A.; Levi-Hevroni, D. Chapter 15.1—Shock Wave Propagation in Porous Media. In Handbook on Shock Waves; Elsevier Inc.: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Henshall, B.D. The Use of Multiple Diaphragms in Shock Tubes; Aeronautical Research Council: London, UK, 1955. [Google Scholar]

- Alpher, R.A.; White, D.R. Flow in shock tubes with area change at the diaphragm section. J. Fluid Mech. 1958, 3, 457–470. [Google Scholar] [CrossRef]

- Koohbor, B.; Ravindran, S.; Kidane, A. Effects of cell-wall instability and local failure on the response of closed-cell polymeric foams subjected to dynamic loading. Mech. Mater. 2018, 116, 67–76. [Google Scholar] [CrossRef]

- Liu, Y.D.; Yu, J.L.; Zheng, Z.J.; Li, J.R. A numerical study on the rate sensitivity of cellular metals. Int. J. Solids Struct. 2009, 46, 3988–3998. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Z.; Liu, Y.; Yu, J.; Reid, S.R. Dynamic crushing of cellular materials: Continuum-based wave models for the transitional and shock modes. Int. J. Impact Eng. 2012, 42, 66–79. [Google Scholar] [CrossRef]

- Zou, Z.; Reid, S.R.; Tan, P.J.; Li, S.; Harrigan, J.J. Dynamic crushing of honeycombs and features of shock fronts. Int. J. Impact Eng. 2009, 36, 165–176. [Google Scholar] [CrossRef]

- Zheng, Z.J.; Yu, J.L.; Li, J.R. Dynamic crushing of 2D cellular structures: A finite element study. Int. J. Impact Eng. 2005, 32, 650–664. [Google Scholar] [CrossRef]

- Avalle, M.; Belingardi, G.; Montanini, R. Characterization of polymeric structural foams under compressive impact loading by means of energy-absorption diagram. Int. J. Impact Eng. 2001, 25, 455–472. [Google Scholar] [CrossRef]

- Rusch, K.C. Energy-absorbing characteristics of foamed polymers. J. Appl. Polym. Sci. 1970, 14, 1433–1447. [Google Scholar] [CrossRef]

- Miltz, J.; Ramon, O. Energy absorption characteristics of polymeric foams used as cushioning materials. Polym. Eng. Sci. 1990, 30, 129–133. [Google Scholar] [CrossRef]

- Tan, P.J.; Harrigan, J.J.; Reid, S.R. Inertia effects in uniaxial dynamic compression of a closed cell aluminium alloy foam. Mater. Sci. Technol. 2002, 18, 480–488. [Google Scholar] [CrossRef]

- Tan, P.J.; Reid, S.R.; Harrigan, J.J.; Zou, Z.; Li, S. Dynamic compressive strength properties of aluminium foams. Part II—‘shock’ theory and comparison with experimental data and numerical models. J. Mech. Phys. Solids 2005, 53, 2206–2230. [Google Scholar] [CrossRef]

- Reid, S.R.; Peng, C. Dynamic uniaxial crushing of wood. Int. J. Impact Eng. 1997, 19, 531–570. [Google Scholar] [CrossRef]

- Jahnke, D.; Azadeh-Ranjbar, V.; Yildiz, S.; Andreopoulos, Y. Energy exchange in coupled interactions between a shock wave and metallic plates. Int. J. Impact Eng. 2017, 106, 86–102. [Google Scholar] [CrossRef] [Green Version]

- Andena, L.; Caimmi, F.; Leonardi, L.; Nacucchi, M.; De Pascalis, F. Compression of polystyrene and polypropylene foams for energy absorption applications: A combined mechanical and microstructural study. J. Cell. Plast. 2019, 55, 49–72. [Google Scholar] [CrossRef]

- Pei, L.; Guo, Y.B.; Zhou, M.W.; Shim, V.P.W. Response of anisotropic polyurethane foam to compression at different loading angles and strain rates. Int. J. Impact Eng. 2019, 127, 154–168. [Google Scholar]

- Miralbes, R.; Ranz, D.; Ivens, J.; Gomez, J.A. Characterization of cork and cork agglomerates under compressive loads by means of energy absorption diagrams. Eur. J. Wood Wood Prod. 2020, 79, 719–731. [Google Scholar] [CrossRef]

- Fan, Z.; Zhang, B.; Liu, Y.; Suo, T.; Xu, P.; Zhang, J. Interpenetrating phase composite foam based on porous aluminum skeleton for high energy absorption. Polym. Test. 2021, 93, 106917. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Zuo, Y.; Chang, Z. Evaluation of Energy Absorption Capabilities of Polyethylene Foam under Impact Deformation. Materials 2021, 14, 3613. https://doi.org/10.3390/ma14133613

Yang B, Zuo Y, Chang Z. Evaluation of Energy Absorption Capabilities of Polyethylene Foam under Impact Deformation. Materials. 2021; 14(13):3613. https://doi.org/10.3390/ma14133613

Chicago/Turabian StyleYang, Baohui, Yangjie Zuo, and Zhengping Chang. 2021. "Evaluation of Energy Absorption Capabilities of Polyethylene Foam under Impact Deformation" Materials 14, no. 13: 3613. https://doi.org/10.3390/ma14133613