Substrate Impact on MR Characteristics of Carbon Nano Films Explored via AFM and Raman Analysis

Abstract

:1. Introduction

2. Experimental Method

3. Results and Discussion

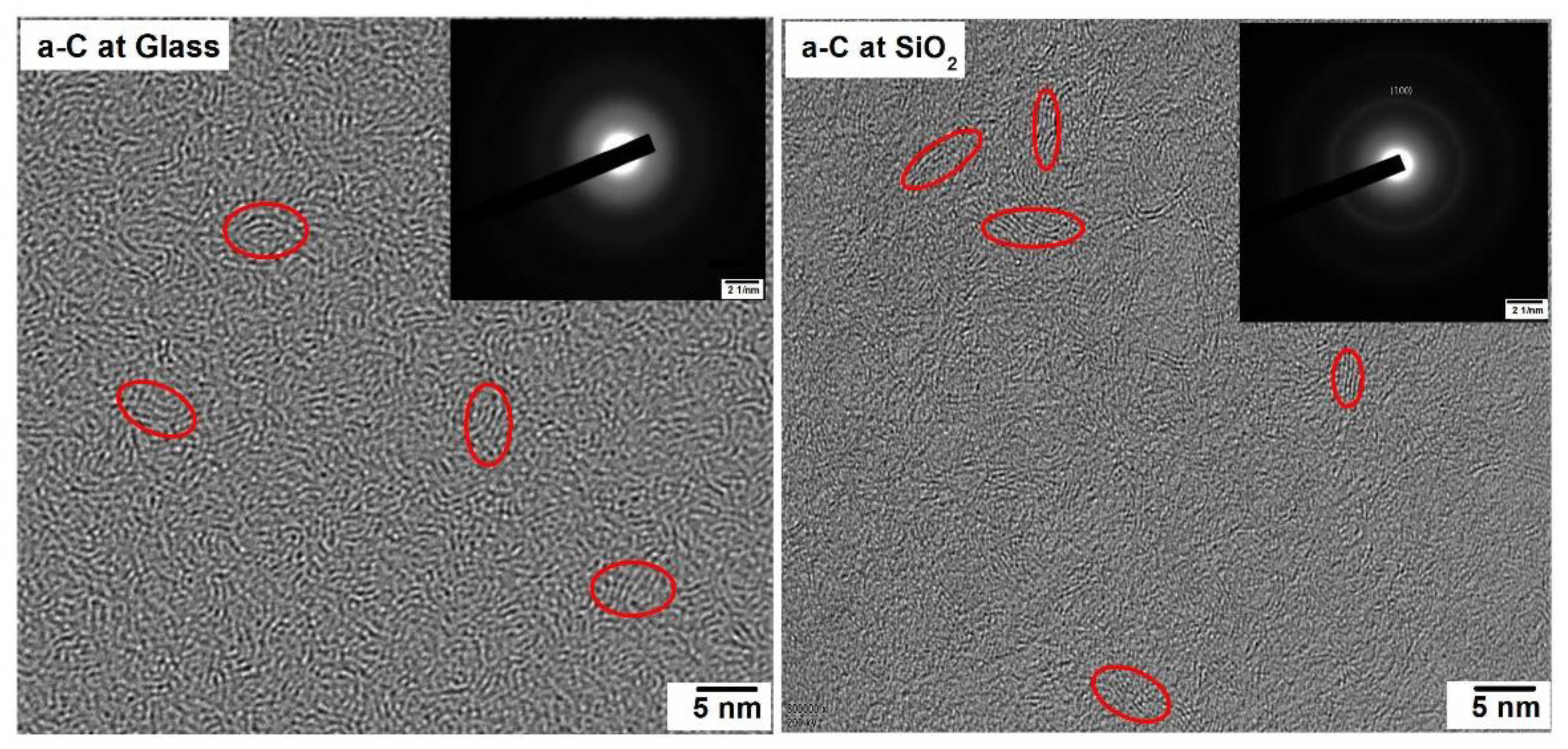

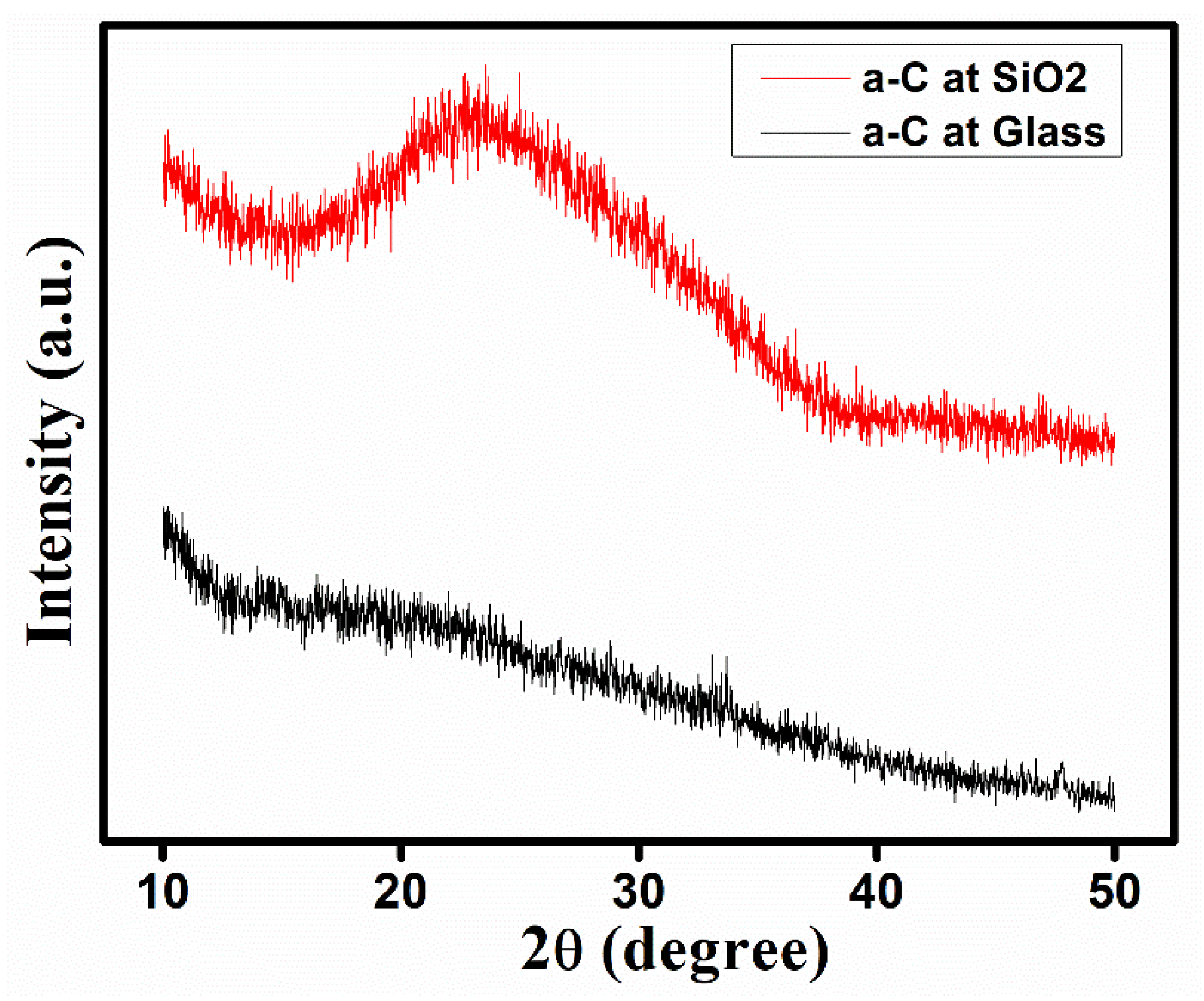

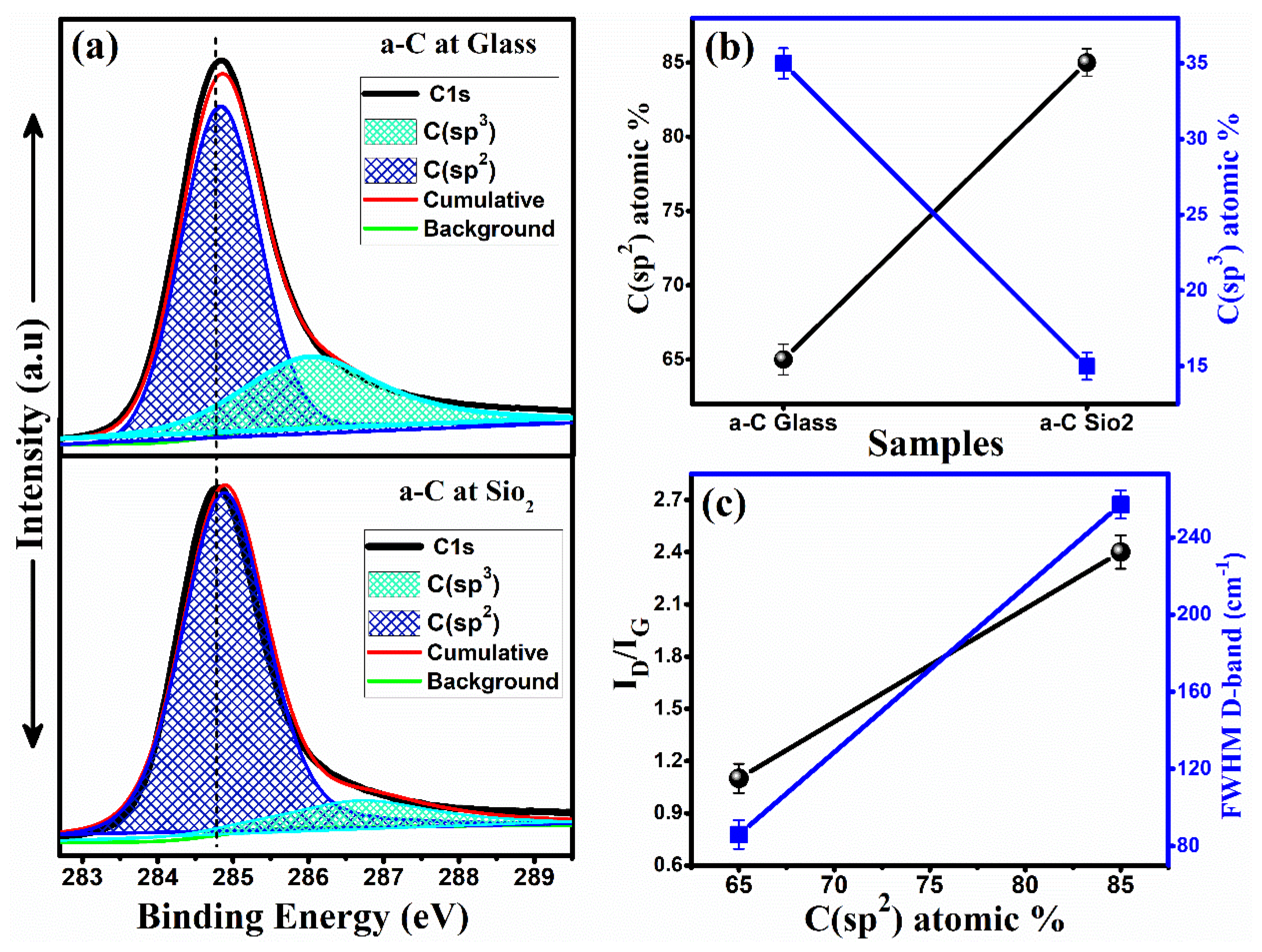

3.1. Structural Analysis

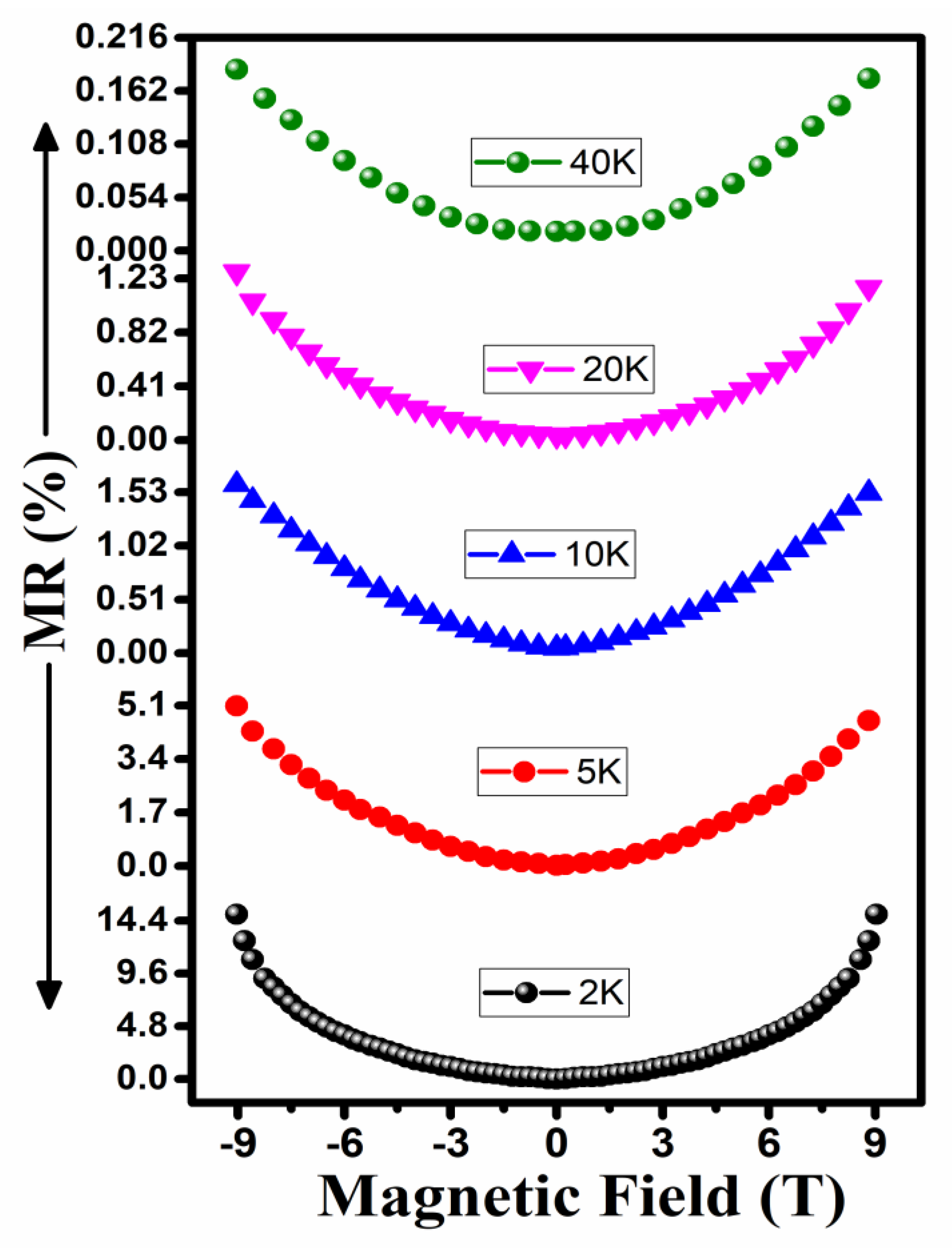

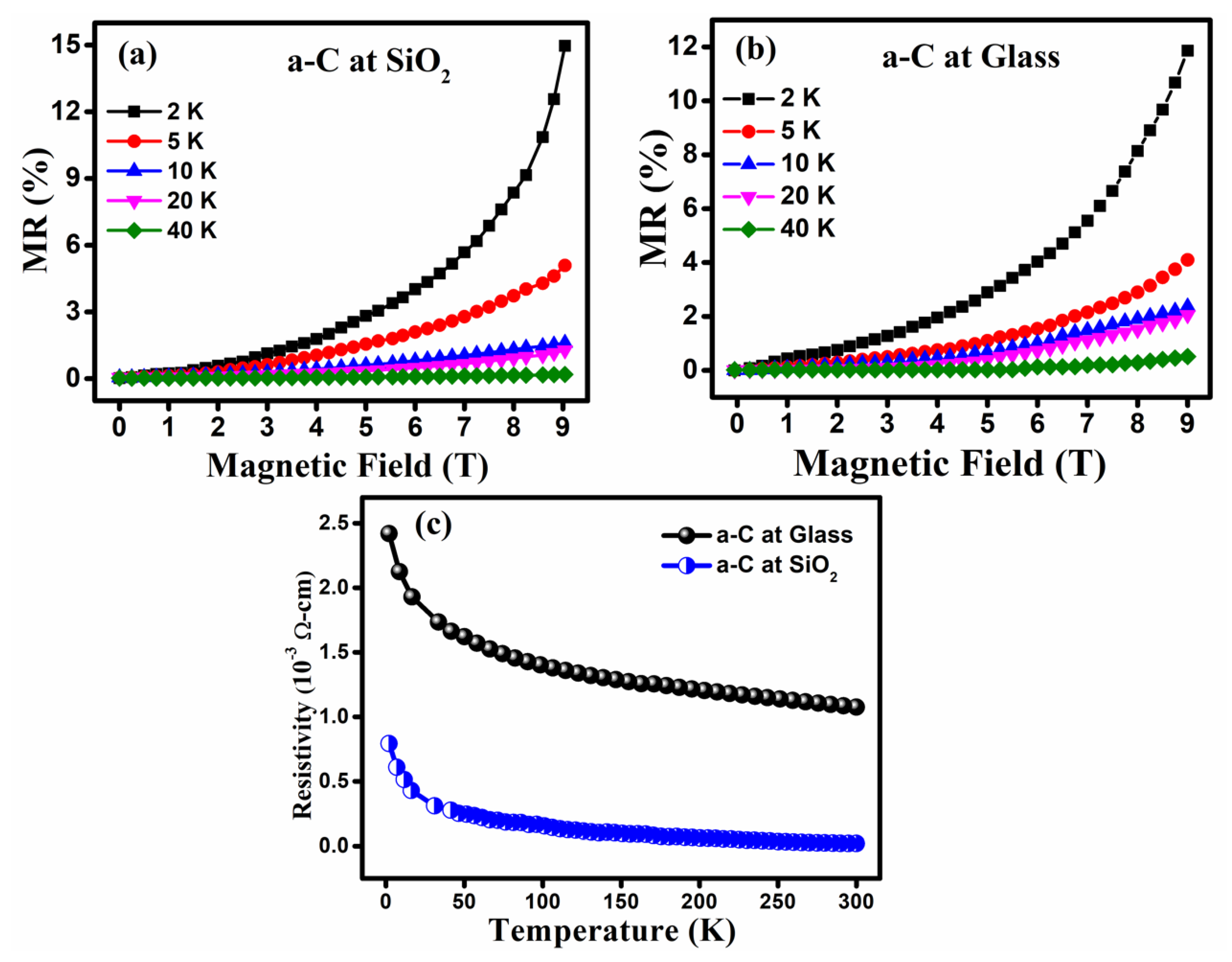

3.2. Magnetoresistance Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fredriksson, H. Nanostructures of Graphite and Amorphous Carbon—Fabrication and Properties. In Department of Applied Physics; Chalmers University of Technology: Göteborg, Sweden, 2009. [Google Scholar]

- Harris, P.J.F. New Perspectives on the Structure of Graphitic Carbons. Crit. Rev. Solid State Mater. Sci. 2005, 30, 235–253. [Google Scholar] [CrossRef] [Green Version]

- Robertson, J. Amorphous carbon. Adv. Phys. 1986, 35, 317–374. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 1999, 61, 14095–14107. [Google Scholar] [CrossRef] [Green Version]

- Shabbir, B.; Nadeem, M.; Dai, Z.; Fuhrer, M.S.; Xue, Q.K.; Wang, X.; Bao, Q. Long range intrinsic ferromagnetism in two dimensional materials and dissipationless future technologies. Appl. Phys. Rev. 2018, 5, 041105. [Google Scholar] [CrossRef] [Green Version]

- Ma, W.; Shabbir, B.; Ou, Q.; Chen, Y.D.H.; Li, P.; Zhang, X.; Lu, Y.; Bao, Q. Anisotropic polaritons in van der Waals materials. InfoMat 2020, 2, 777. [Google Scholar] [CrossRef]

- Fan, Z.W.; Li, P.; Zhang, L.T.; Mi, W.B.; Jiang, E.Y.; Bai, H.L. Electrical transport properties and room-temperature positive magnetoresistance of Fe3O4/a-C/n-Si junctions. Thin Solid Films 2012, 520, 3641–3646. [Google Scholar] [CrossRef]

- Robertson, J. Diamond-like amorphous carbon. Mater. Sci. Eng. R Rep. 2002, 37, 129–281. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.W.; Robertson, J. Nature of disorder and localization in amorphous carbon. J. Non-Cryst. Solids 1998, 227–230, 602–606. [Google Scholar] [CrossRef]

- Chen, I.W.P.; Liang, Z.; Wang, B.; Zhang, C. Charge-induced asymmetrical displacement of an aligned carbon nanotube buckypaper actuator. Carbon 2010, 48, 1064–1069. [Google Scholar] [CrossRef]

- Jin, R.; Jiang, Y.; Li, G.; Meng, Y. Amorphous carbon coated multiwalled carbon nanotubes@transition metal sulfides composites as high performance anode materials for lithium ion batteries. Electrochim. Acta 2017, 257, 20–30. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Wan, C.; Vanacken, J.; Luo, Z.; Xiong, C.; Moshchalkov, V.V. Magnetoresistance sign change in iron-doped amorphous carbon films at low temperatures. J. Phys. D Appl. Phys. 2014, 47, 215002. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Wan, C.; Vanacken, J.; Moshchalkov, V.V. Magnetotransport properties of undoped amorphous carbon films. Carbon 2013, 59, 278–282. [Google Scholar] [CrossRef]

- Hishiyama, Y.; Irumano, H.; Kaburagi, Y.; Soneda, Y. Structure, Raman scattering, and transport properties of boron-doped graphite. Phys. Rev. B 2001, 63, 245406. [Google Scholar] [CrossRef]

- Zhang, X.; Wan, C.; Wu, L. A bias voltage dependent positive magnetoresistance in Cox–C1-x/Si heterostructure. Appl. Phys. Lett. 2009, 95, 022503. [Google Scholar] [CrossRef]

- Wan, C.; Zhang, X.; Vanacken, J.; Gao, X.; Zhang, X.; Wu, L.; Tan, X.; Lin, H.; Moshchalkov, V.V.; Yuan, J. Electro- and magneto-transport properties of amorphous carbon films doped with iron. Diam. Relat. Mater. 2011, 20, 5. [Google Scholar] [CrossRef]

- Zeb, M.H.; Shabbir, B.; Sagar, R.U.R.; Mahmood, N.; Chen, K.; Qasim, I.; Malik, M.I.; Yu, W.; Hossain, M.M.; Dai, Z.; et al. Superior Magnetoresistance Performance of Hybrid Graphene Foam/Metal Sulfide Nanocrystal Devices. ACS Appl. Mater. Interfaces 2019, 11, 19397–19403. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; He, M.F.; Liu, Z.W.; Zeng, D.C.; Gu, Z.F.; Cheng, G. Structure and giant magnetoresistance of carbon-based amorphous films prepared by magnetron sputtering. Thin Solid Films 2014, 556, 460–463. [Google Scholar] [CrossRef]

- Kim, T.; Kim, D.; Kim, Y.-S.; Park, S.H.; Lim, S.K.; Park, K.O.; Kim, T.; Kang, S.-W. Strain-controlled boron and nitrogen doping of amorphous carbon layers for hard mask applications. Diam. Relat. Mater. 2016, 69, 102–107. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Raman spectroscopy of amorphous, nanostructured, diamond-like carbon, and nanodiamond. Philos. Trans. A Math. Phys. Eng. Sci. 2004, 362, 2477–2512. [Google Scholar] [CrossRef]

- Sagar, R.U.R.; Qazi, H.I.A.; Zeb, M.H.; Stadler, F.J.; Shabbir, B.; Wang, X.; Zhang, M. Tunable sign of magnetoresistance in graphene foam Ecoflex® composite for wearable magnetoelectronic devices. Mater. Lett. 2019, 253, 166. [Google Scholar] [CrossRef]

- Sagar, R.U.R.; Zhang, X.; Wang, J.; Xiong, C. Negative magnetoresistance in undoped semiconducting amorphous carbon films. J. Appl. Phys. 2014, 115, 123708. [Google Scholar] [CrossRef]

- Sagar, R.U.R.; Shabbir, B.; Hasnain, S.M.; Nasir, M. Large magnetotransport properties in mixed-dimensional heterostructures of 2D Dirac van der Waals materials. Carbon 2020, 159, 648. [Google Scholar] [CrossRef]

- Sagar, R.U.R.; Zhang, X.; Xiong, C.; Yu, Y. Semiconducting amorphous carbon thin films for transparent conducting electrodes. Carbon 2014, 76, 64–70. [Google Scholar] [CrossRef]

- Saleemi, A.S.; Sagar, R.U.R.; Singh, R.; Luo, Z.; Zhang, X. Angle dependent magnetotransport in transfer-free amorphous carbon thin films. J. Phys. D Appl. Phys. 2016, 49, 415005. [Google Scholar] [CrossRef]

- Saleemi, A.S.; Saeed, M.; Hussan, M.; Rehman, S.U.; Hafeez, M.; Mehmood, S.; Sial, M.A.Z.G.; Lee, S.L. Anomalous Non-linear to Linear shift in Magnetoresistance of Amorphous Carbon Films. Crystals 2019, 9, 618. [Google Scholar] [CrossRef] [Green Version]

- Saleemi, A.S.; Sun, W.; Singh, R.; Luo, Z.; Zhang, X. Structure dependent negative and positive magnetoresistance of amorphous carbon films. J. Appl. Phys. 2017, 121, 233903. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Basko, D.M. Raman spectroscopy as a versatile tool for studying the properties of graphene. Nat. Nano 2013, 8, 235–246. [Google Scholar] [CrossRef] [Green Version]

- Sagar, R.U.R.; Zhang, M.; Wang, X.; Shabbir, B.; Stadler, F.J. Facile magnetoresistance adjustment of graphene foam for magnetic sensor applications through microstructure tailoring. Nano Mater. Sci. 2020, 2, 346. [Google Scholar] [CrossRef]

- Mayadas, A.F.; Shatzkes, M. Electrical-Resistivity Model for Polycrystalline Films: The Case of Arbitrary Re6ection at External Surfaces. Phys. Rev. B 1970, 1, 1382. [Google Scholar] [CrossRef]

- Chung, C.K.; Nautiyal, A.; Chen, T.S.; Chang, Y.L. Grain boundary scattering for temperature coefficient of resistance (TCR) behaviour of Ta–Si–N thin films. J. Phys. D Appl. Phys. 2008, 41, 185404. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleemi, A.S.; Hafeez, M.; Saeed, M.; Abdullah, A.; Rehman, M.A.-u.-; Lee, S.-L. Substrate Impact on MR Characteristics of Carbon Nano Films Explored via AFM and Raman Analysis. Materials 2021, 14, 3649. https://doi.org/10.3390/ma14133649

Saleemi AS, Hafeez M, Saeed M, Abdullah A, Rehman MA-u-, Lee S-L. Substrate Impact on MR Characteristics of Carbon Nano Films Explored via AFM and Raman Analysis. Materials. 2021; 14(13):3649. https://doi.org/10.3390/ma14133649

Chicago/Turabian StyleSaleemi, Awais Siddique, Muhammad Hafeez, Muhammad Saeed, Ali Abdullah, Muhammad Anis-ur- Rehman, and Shern-Long Lee. 2021. "Substrate Impact on MR Characteristics of Carbon Nano Films Explored via AFM and Raman Analysis" Materials 14, no. 13: 3649. https://doi.org/10.3390/ma14133649