The Effect of Vibration Mixing on the Mechanical Properties of Steel Fiber Concrete with Different Mix Ratios

Abstract

:1. Introduction

2. Experiment

2.1. Raw Materials

2.2. Experimental Method and Mixture Proportion

- (1)

- Determine the water-binder ratio W/B

- (2)

- Determine unit water consumption

- (3)

- Determine the unit amount of cement and fly ash

- (4)

- Determine the sand rate

2.3. Experiment Instruments

- (1)

- Vibration mixer

- (2)

- Press machines

- (3)

- Scanning electron microscope

3. Experimental Results and Discussion

3.1. Research on the Compressive Strength Performance of Concrete Cubes

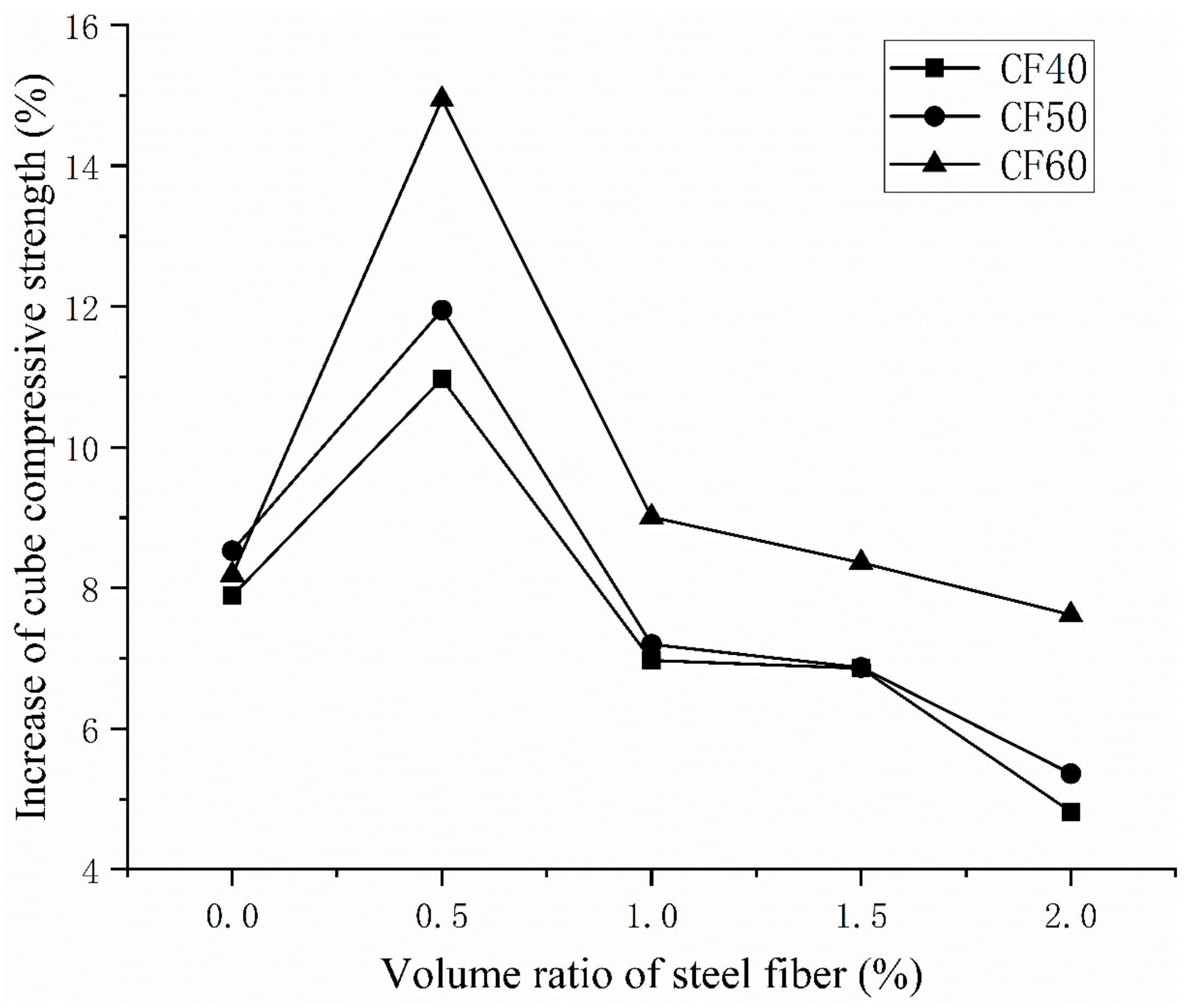

3.1.1. Variation in Cube Compressive Strength

3.1.2. Calculation of Cube Compressive Strength for Vibration-Stirred Concrete

3.2. Research on Performance of Concrete Elastic Modulus

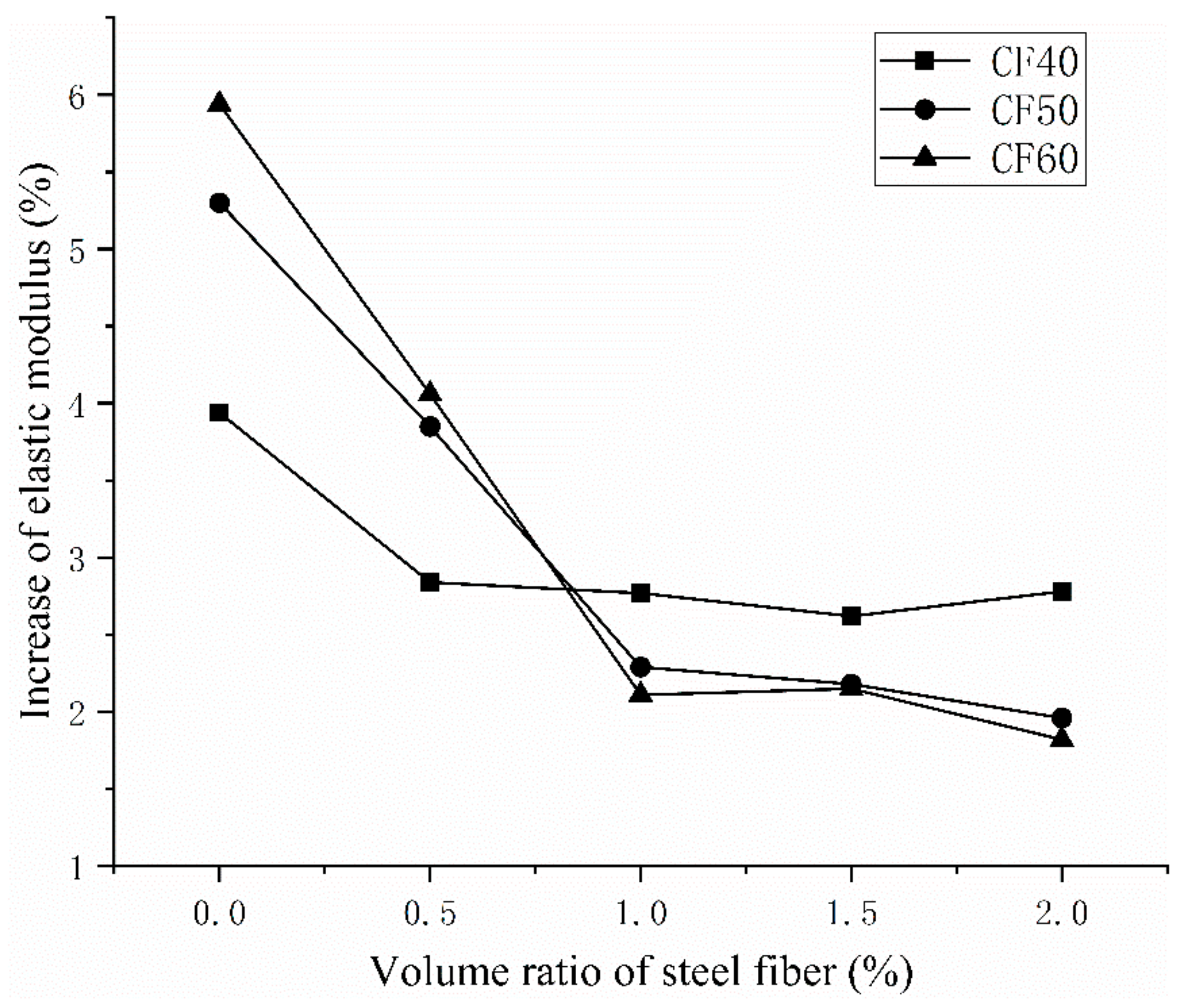

3.2.1. Variation in Elastic Modulus

3.2.2. Calculation of Elastic Modulus of Vibration-Stirred Concrete

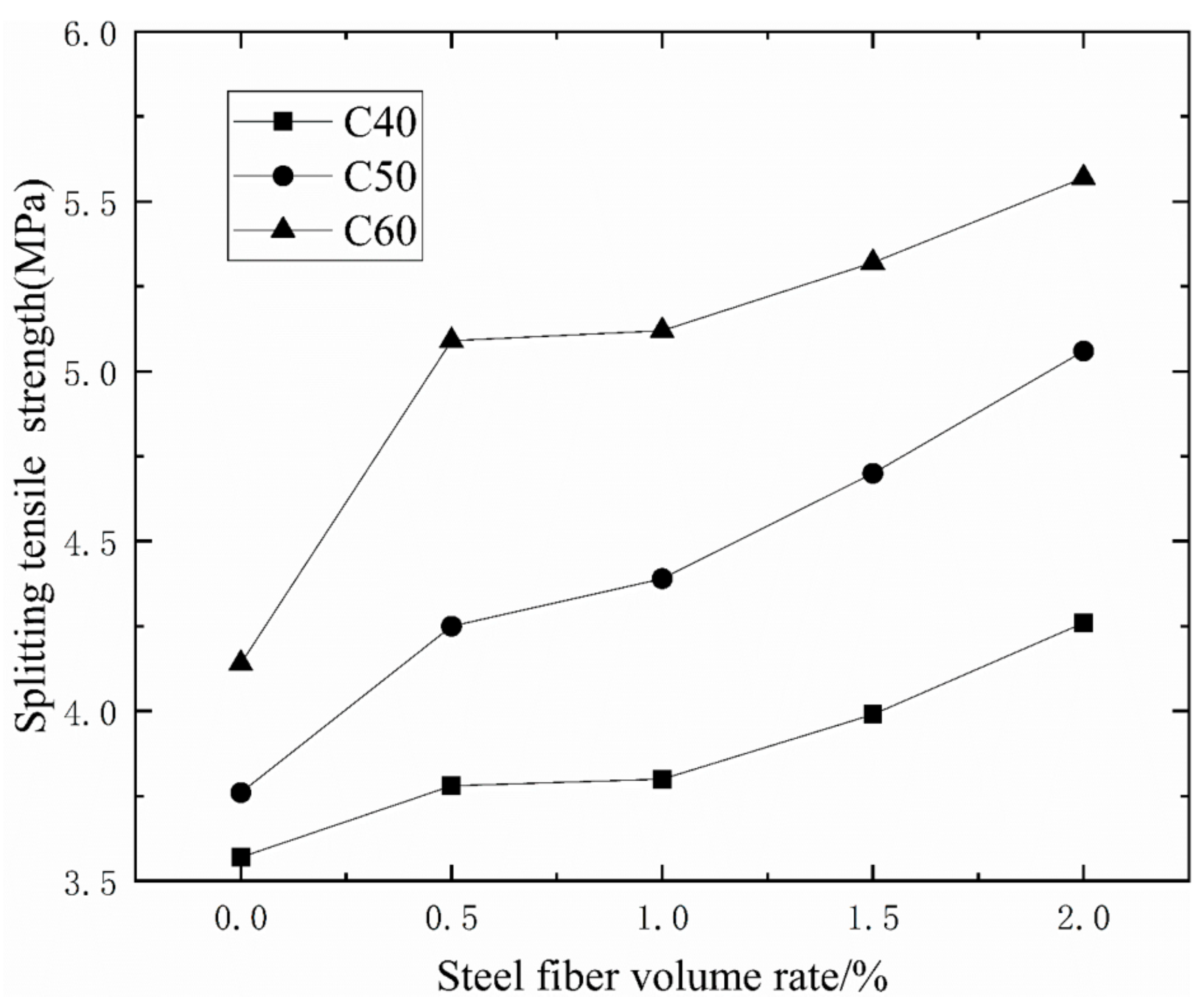

3.3. Research on Splitting Tensile Strength of Concrete

3.3.1. Variation in Splitting Tensile Strength

3.3.2. Calculation of Splitting Tensile Strength of Vibration-Stirred Concrete

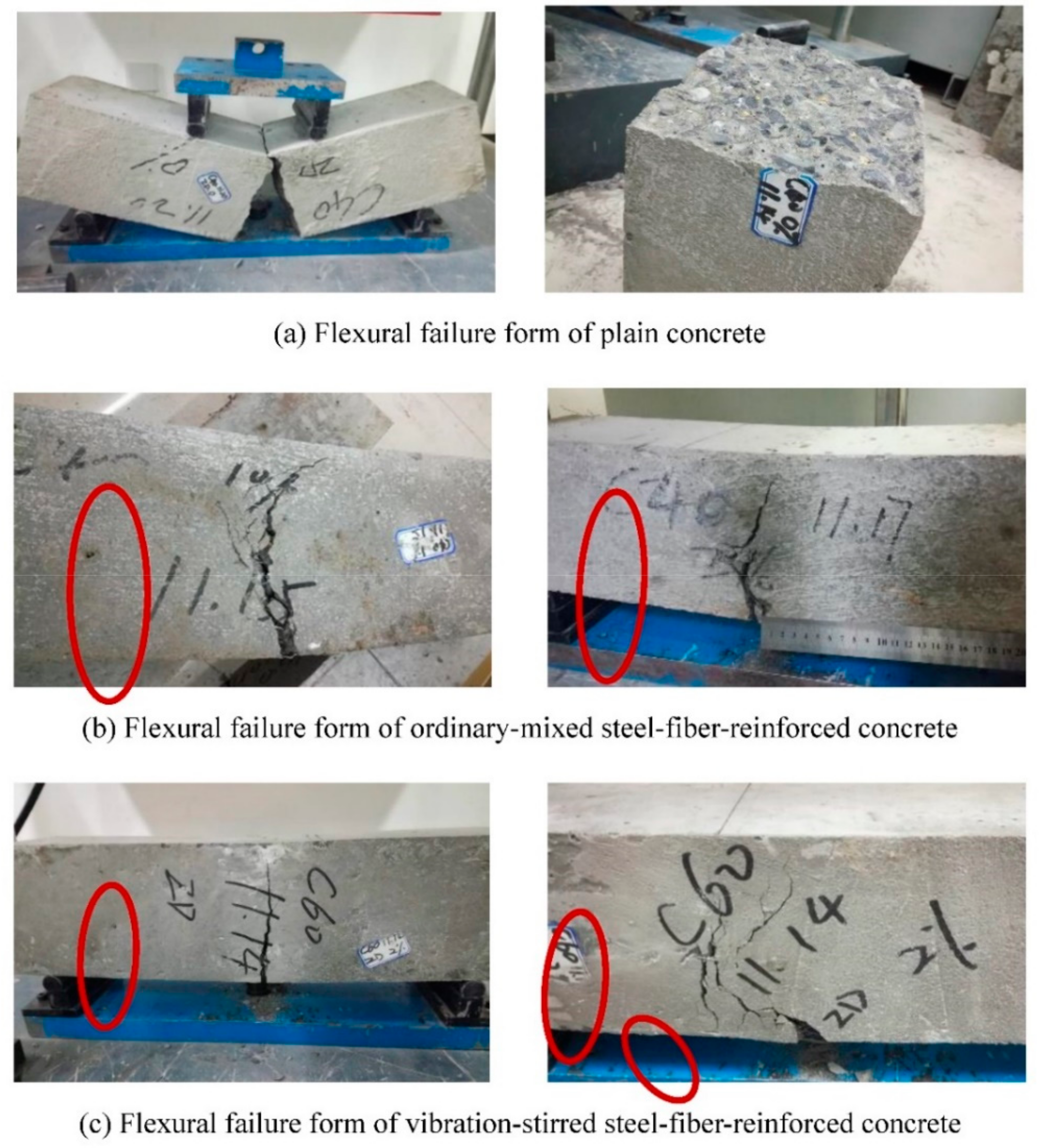

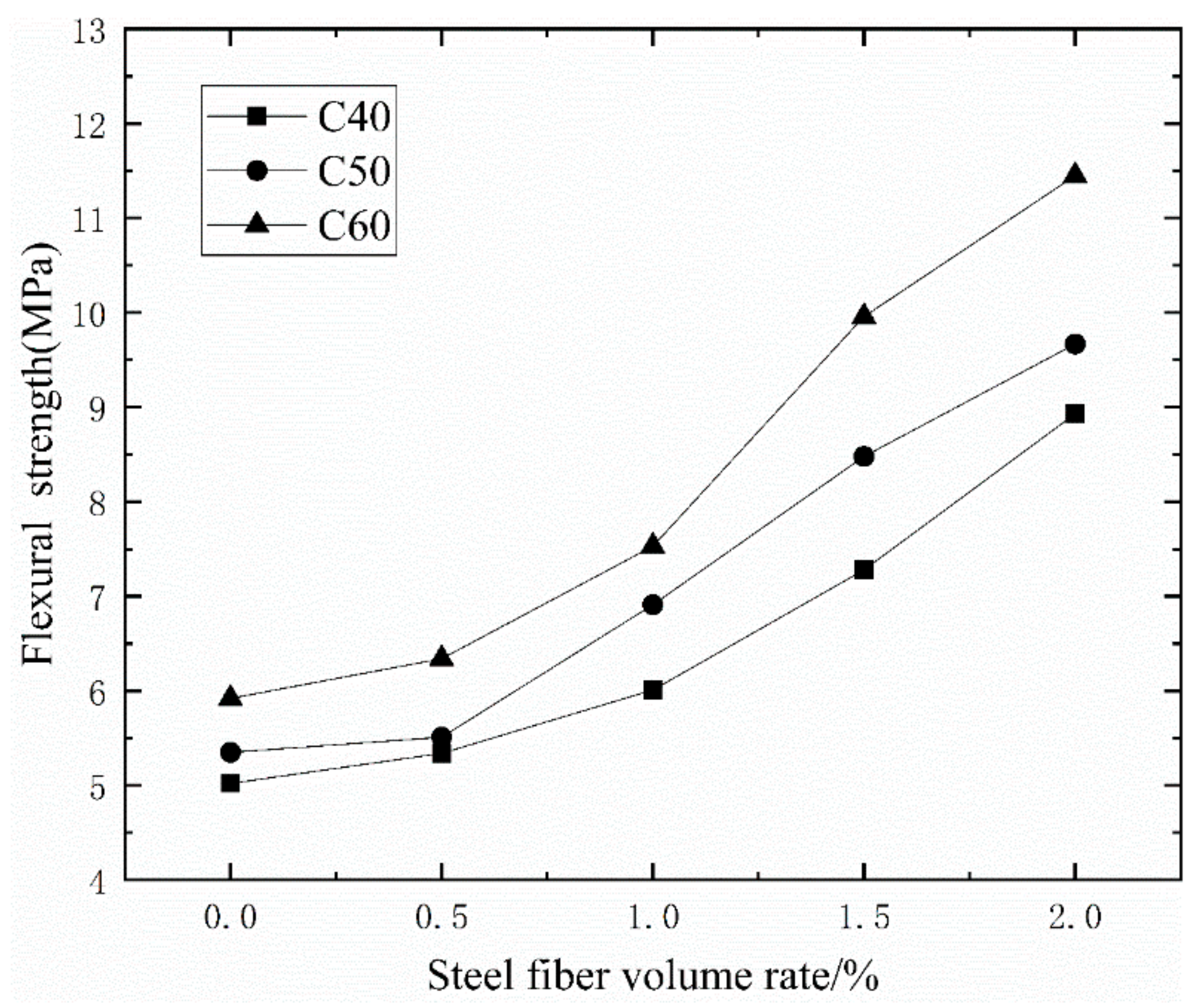

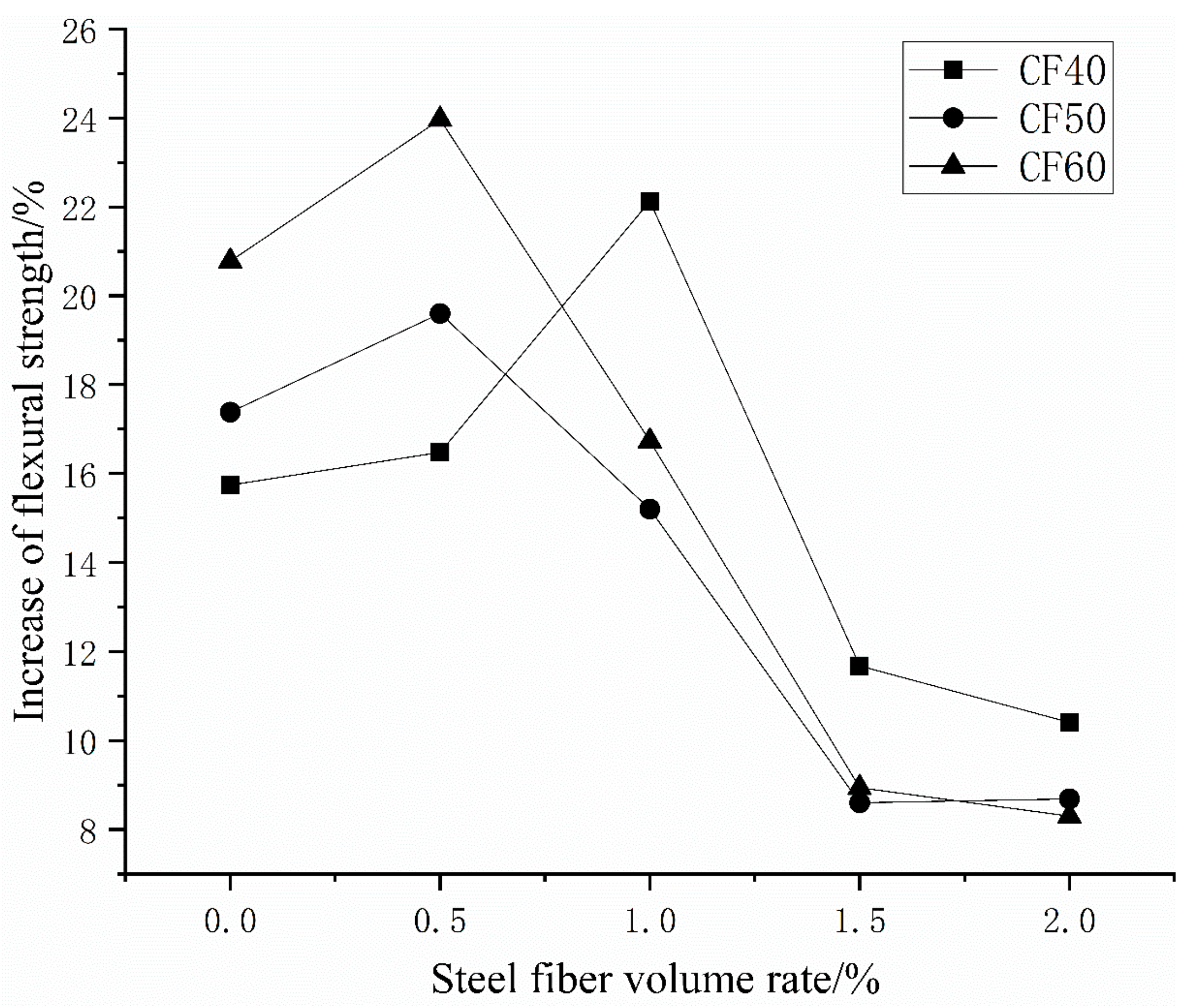

3.4. Research on the Flexural Strength of Concrete

3.4.1. Variation in Flexural Strength

3.4.2. Calculation of Flexural Strength of Vibration-Stirred Concrete

3.5. Relationship between Tension and Compression Ratio

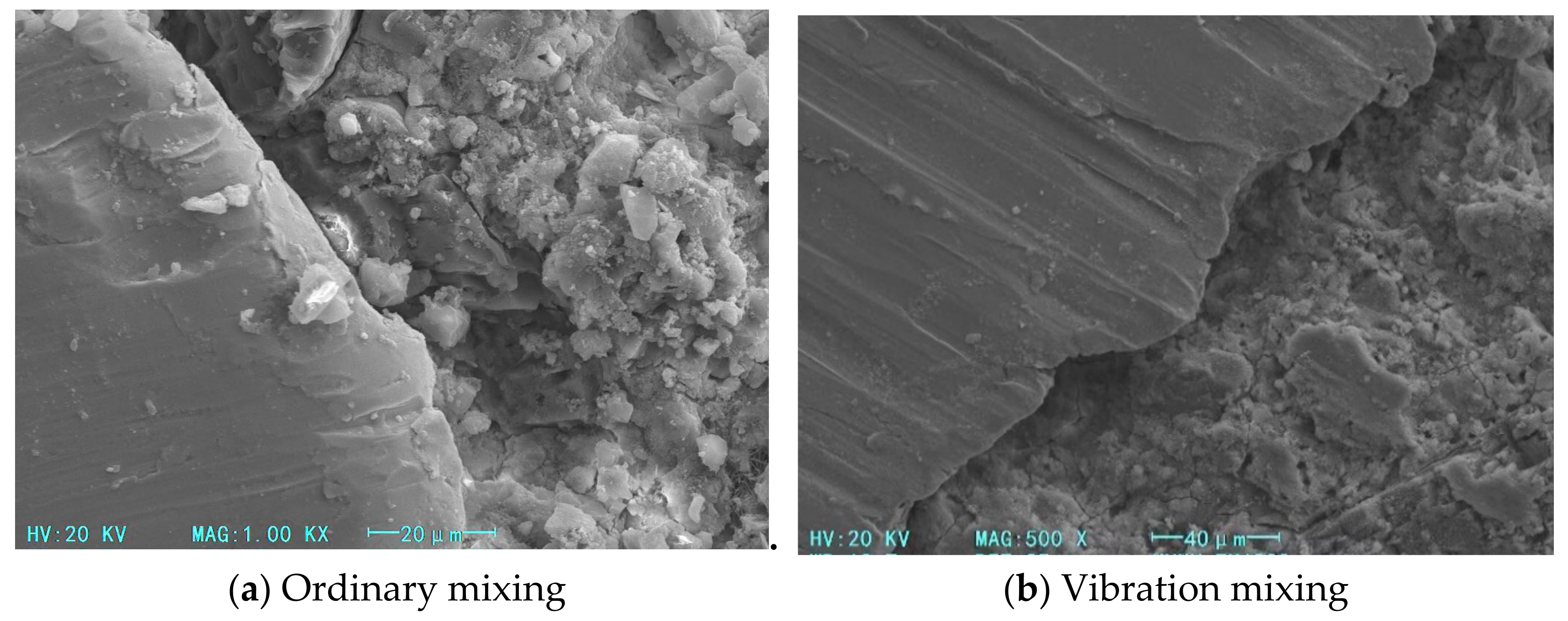

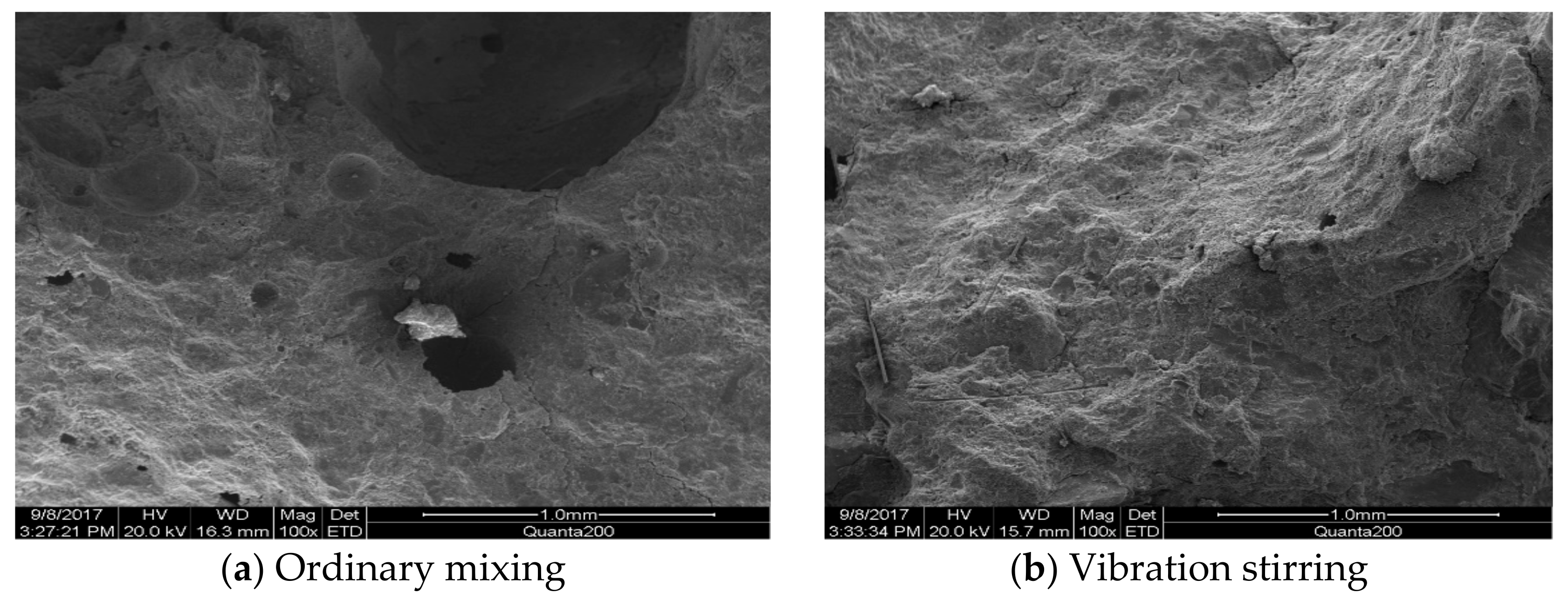

3.6. Microscopic Morphology of Steel-Fiber-Reinforced Concrete

4. Conclusions

- 1.

- When the concrete grade is the same, the concrete performance after vibration mixing is higher than that of ordinary mixing. Among them, the improvement efficiency of compressive strength and elastic modulus is more obvious when the amount of steel fiber is low, and the efficiency of splitting tensile strength and flexural strength is more obvious when the amount of steel fiber is high. From the improvement effect of concrete performance and the influence coefficient fitted by the data, it can be seen that the influence of vibration mixing on concrete performance from high to low is: flexural strength > splitting tensile strength > compressive strength > elastic modulus.

- 2.

- With different matrix strengths, when the volume ratio of steel fiber is higher than 1%, the higher the matrix strength, the lower the increase in elastic modulus and flexural strength of vibration stirring. The main reason is that when the strength of the matrix increases, the water-binder ratio of the concrete decreases and the amount of cementitious material is large, and the fine cementitious particles cannot be dispersed by vibrating stirring.

- 3.

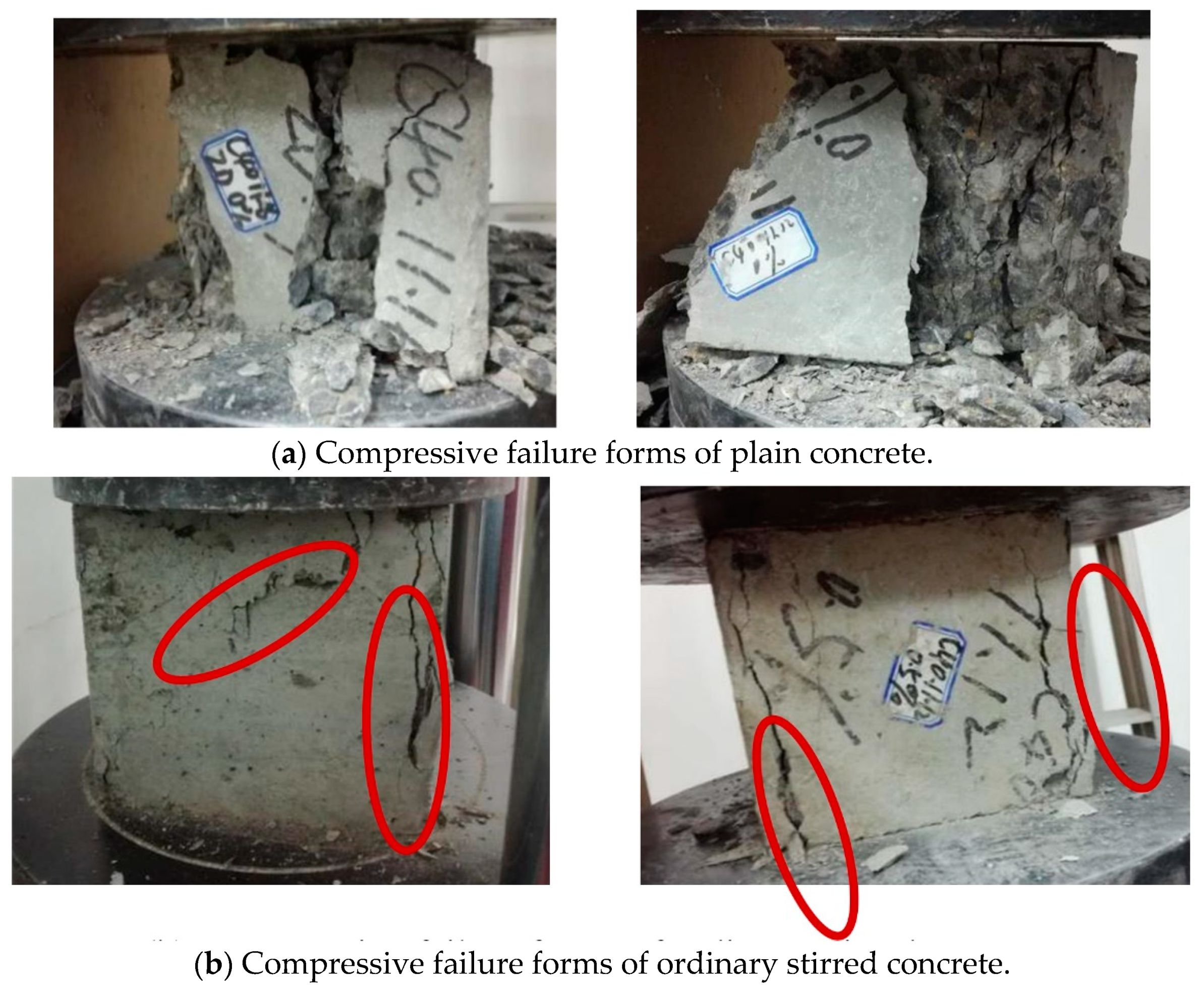

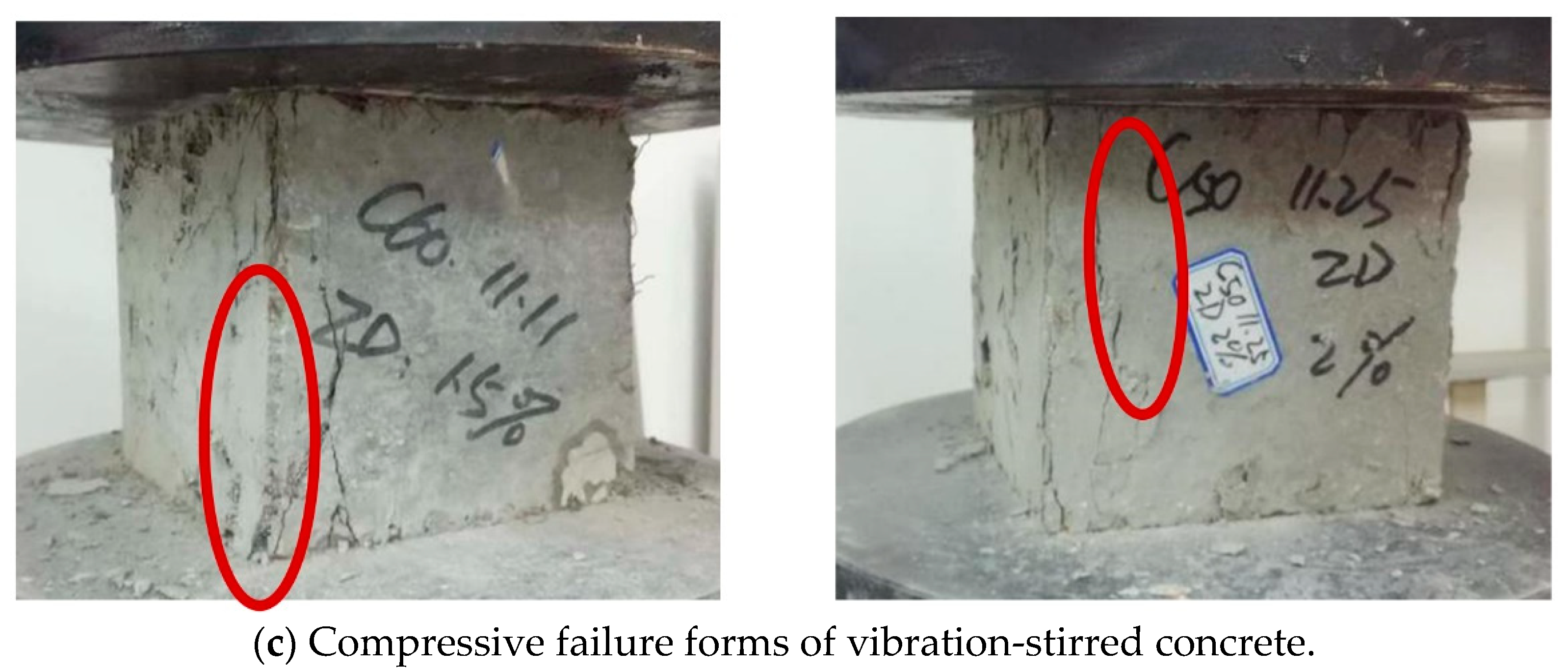

- The addition of steel fiber and vibration mixing can improve the failure morphology of concrete specimens. The larger the volume ratio of steel fiber, the higher the strength of the matrix, the fewer cracks and the less the amount of spalling, and the better the integrity of the specimen.

- 4.

- From the study of the microscopic morphology of the vibration mixing steel fiber concrete, it can be seen that the vibration mixing improves the performance of the transition zone of the concrete interface and the slurry, and increases the structural bonding force. Vibration mixing makes the mixtures have a better compactness and a better performance. At the same time, the steel fibers are evenly distributed among the mixtures to avoid agglomeration, which is beneficial to improve the performance of steel fiber concrete.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghalehnovi, M.; Karimipour, A.; Brito, J.D. Influence of steel fibres on the flexural performance of reinforced concrete beams with lap-spliced bars. Constr. Build. Mater. 2019, 229, 116853. [Google Scholar] [CrossRef]

- Monti, G.; Liotta, M. FRP-strengthening in shear: Tests and design equations. In Proceedings of the 7th International Symposium on Fiber-Reinforced Polymer (FRP) Reinforcement for Concrete Structures, Kansas City, MO, USA, 6–9 November 2005. [Google Scholar]

- Mohammed, T.J.; Bakar, B.A.; Bunnori, N.M. Torsional improvement of reinforced concrete beams using ultra highperformance fifiber reinforced concrete (UHPFC) jackets-experimental study. Constr. Build. Mater. 2016, 106, 533–542. [Google Scholar] [CrossRef]

- GAO Danying. Design and Application of Steel Fiber Reinforced Concrete; China Architecture & Building Press: Beijing, China, 2002; p. 173. [Google Scholar]

- Lim, M.; Lee, C. Flexural Performance of Reinforced Concrete Members with Steel Bars. Appl. Sci. 2021, 11, 4512. [Google Scholar] [CrossRef]

- Choi, S.W.; Choi, J.; Lee, S.C. Probabilistic Analysis for Strain-Hardening Behavior of High-Performance Fiber-Reinforced Concrete. Materials 2019, 12, 2399. [Google Scholar] [CrossRef] [Green Version]

- Kytinou, V.K.; Chalioris, C.E.; Karayannis, C.G. Analysis of Residual Flexural Stiffness of Steel Fiber-Reinforced Concrete Beams with Steel Reinforcement. Materials 2020, 13, 2698. [Google Scholar] [CrossRef]

- Pająk, M.; Ponikiewski, T. Flexural behavior of self-compacting concrete reinforced with different types of steel fibers. Constr. Build. Mater. 2013, 47, 397–408. [Google Scholar] [CrossRef]

- Lantsoght, E.O.L. Database of Shear Experiments on Steel Fiber Reinforced Concrete Beams without Stirrups. Materials 2019, 12, 917. [Google Scholar] [CrossRef] [Green Version]

- Torres, J.A.; Lantsoght, E.O. Influence of Fiber Content on Shear Capacity of Steel Fiber-Reinforced Concrete Beams. Fibers 2019, 7, 102. [Google Scholar] [CrossRef] [Green Version]

- Marcalikova, Z.; Cajka, R.; Bilek, V.; Bujdos, D.; Sucharda, O. Determination of Mechanical Characteristics for Fiber-Reinforced Concrete with Straight and Hooked Fibers. Crystals 2020, 10, 545. [Google Scholar] [CrossRef]

- Jeong, G.Y.; Jang, S.J.; Kim, Y.C.; Yun, H.D. Effects of Steel Fiber Strength and Aspect Ratio on Mechanical Properties of High-Strength Concrete. J. Korea Concr. Inst. 2018, 30, 197–205. [Google Scholar] [CrossRef]

- Choi, W.-C.; Jung, K.-Y.; Jang, S.-J.; Yun, H.-D. The Influence of Steel Fiber Tensile Strengths and Aspect Ratios on the Fracture Properties of High-Strength Concrete. Materials 2019, 12, 2105. [Google Scholar] [CrossRef] [Green Version]

- Yang, S.; Han, M. Research progress in the influence of environmental factors on the compression and bending performance of reinforced concrete columns. Low Temp. Build. Technol. 2021, 43, 36–40. [Google Scholar]

- Lee, J.-H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Guerini, V.; Conforti, A.; Plizzari, G.; Kawashima, S. Influence of Steel and Macro-Synthetic Fibers on Concrete Properties. Fibers 2018, 6, 47. [Google Scholar] [CrossRef] [Green Version]

- Almusallam, T.; Ibrahim, S.; Al-Salloum, Y.; Abadel, A.; Abbas, H. Analytical and experimental investigations on the fracture behavior of hybrid fiber reinforced concrete. Cem. Concr. Compos. 2016, 74, 201–217. [Google Scholar] [CrossRef]

- Xie, T.; Ozbakkaloglu, T. Behavior of steel fiber-reinforced high-strength concrete-filled FRP tube columns under axial compression. Eng. Struct. 2015, 90, 158–171. [Google Scholar] [CrossRef]

- Li, B.; Xu, L.; Shi, Y.; Chi, Y.; Liu, Q.; Li, C. Effects of fiber type, volume fraction and aspect ratio on the flexural and acoustic emission behaviors of steel fiber reinforced concrete. Constr. Build. Mater. 2018, 181, 474–486. [Google Scholar] [CrossRef]

- Safawi, M.I.; Iwaki, I.; Miura, T. A study on the applicability of vibration in fresh high fluidity concrete. Cem. Concr. Res. 2005, 35, 1834–1845. [Google Scholar] [CrossRef]

- Navarrete, I.; Lopez, M. Estimating the segregation of concrete based on mixture design and vibratory energy. Constr. Build. Mater. 2016, 122, 384–390. [Google Scholar] [CrossRef]

- Dong, W.; Feng, Z.; Zhao, L. Effect of vibratory mixing on performance of recycled concrete. Bull. Chin. Ceram. Soc. 2018, 37, 1714–1721. [Google Scholar]

- Zhang, L.; Kong, X.; Feng, Z. The development and industrial tests of vibratory cement stable macadam mixer. J. Guangxi Univ. Nat. Sci. Ed. 2015, 40, 1155–1161. [Google Scholar]

- Zhao, W.; Yue, C.; Shen, W. Finite element analysis and structural optimization of the mixing mechanism of a double vertical shaft vibrating mixer. Mech. Strength 2020, 42, 1496–1502. [Google Scholar]

- Feng, Z.; Jiang, J.; Yu, L. The experiment study of vibratory mixing theory and mixer. China J. Highw. Transp. 1999, 3, 122–126. [Google Scholar]

- Huang, T.; Chen, X.; Li, S.; Chen, F. The influence of vibration mixing on the performance of concrete and its application prospect analysis. Concrete 2020, 1, 123–126. [Google Scholar]

- Zhao, L.J.; Jiang, W.Z.; Hou, J.R.; Feng, Z.; Xue, S. Influence of mixing methods on performance of compressive strength for cement stabilized macadam mixture. China J. Highw. Transp. 2018, 31, 151–158. [Google Scholar]

- Yang, C.; Zhao, W.; Wang, S.; Song, R.; Liu, K. Application test of vibration mixing technology in concrete optimization mix ratio. Mech. Res. Appl. 2020, 33, 31–34. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. JGJ 55-2011. Design Specification for Mix Proportion of Ordinary Concrete; China Construction Industry Press: Beijing, China, 2011. [Google Scholar]

- Zhang, L. Steel Fiber Recycled Concrete Mix Design and Performance Calculation Method. Ph.D. Thesis, Zhengzhou University, Zhengzhou, Henan, 2017. [Google Scholar]

- Zhou, M.; Ke, G.; Xie, Y.; Li, R. Experiment on the influence of sand ratio on the workability and strength of waste glass powder concrete. Sichuan Build. Sci. Res. 2016, 42, 102–105. [Google Scholar]

- Chen, W.; Feng, Z. Parametric design and finite element analysis of a twin-shaft vibration mixer. Mech. Eng. 2019, 5, 16–18, 26. [Google Scholar]

- National Bureau of Technical Supervision. GB/T 2611-1992. General Technical Requirements for Testing Machines; China Standards Press: Beijing, China, 1992. [Google Scholar]

| Water Absorption | Void Ratio | Crush Index | Apparent Density (kg/m3) | Loose Bulk Density (kg/m3) | Close Packing Density (kg/m3) |

|---|---|---|---|---|---|

| 0.38% | 44.8% | 7.6% | 2749 | 1536 | 1576 |

| Screen Hole Diameter (mm) | Cumulative Sieve Residue |

|---|---|

| 0.15 | 96.70% |

| 0.3 | 87.70% |

| 0.6 | 49.80% |

| 1.18 | 20.80% |

| 2.36 | 7.90% |

| 4.75 | 1.40% |

| Matrix Strength | Sand Ratio | Mix Proportion (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Steel Fiber | Water | Cement | Coarse Aggregate | Fine Aggregate | Fly Ash | Water Reducing Agent | |||

| CF40 | 0 | 0.37 | 0 | 172 | 300.68 | 1195.26 | 701.98 | 30.07 | 1.65 |

| 0.5% | 0.37 | 39.25 | 172 | 300.68 | 1173.17 | 712.06 | 30.07 | 1.65 | |

| 1.0% | 0.37 | 78.50 | 172 | 300.68 | 1151.09 | 722.14 | 30.07 | 1.65 | |

| 1.5% | 0.37 | 117.75 | 172 | 300.68 | 1129.01 | 732.22 | 30.07 | 1.65 | |

| 2.0% | 0.37 | 157.00 | 172 | 300.68 | 1106.93 | 742.31 | 30.07 | 1.65 | |

| CF50 | 0 | 0.36 | 0 | 172 | 347.47 | 1181.30 | 664.48 | 34.75 | 2.68 |

| 0.5% | 0.36 | 39.25 | 172 | 347.47 | 1159.49 | 674.29 | 34.75 | 2.68 | |

| 0.75% | 0.36 | 58.88 | 172 | 347.47 | 1148.58 | 679.20 | 34.75 | 2.68 | |

| 1.0% | 0.36 | 78.50 | 172 | 347.47 | 1137.68 | 684.10 | 34.75 | 2.68 | |

| 1.5% | 0.36 | 117.75 | 172 | 347.47 | 1116.87 | 693.91 | 34.75 | 2.68 | |

| 2.0% | 0.36 | 157.00 | 172 | 347.47 | 1094.06 | 703.72 | 34.75 | 2.68 | |

| CF60 | 0 | 0.36 | 0 | 164 | 451.79 | 1078.20 | 660.83 | 45.18 | 4.97 |

| 0.5% | 0.36 | 39.25 | 164 | 451.79 | 1056.84 | 671.19 | 45.18 | 4.97 | |

| 1.0% | 0.36 | 78.50 | 164 | 451.79 | 1033.49 | 681.54 | 45.18 | 4.97 | |

| 1.5% | 0.36 | 117.75 | 164 | 451.79 | 1011.13 | 691.90 | 45.18 | 4.97 | |

| 2.0% | 0.36 | 157.00 | 164 | 451.79 | 989.78 | 702.25 | 45.18 | 4.97 | |

| Volume (L) | Size (mm3) | Mixing Power (kW) | Vibration Power (kW) | Vibration Intensity (G) |

|---|---|---|---|---|

| 60 | 1900 × 1195 × 1620 | 2.2 | 4 | 1.75 |

| No. | Cube Compressive Strength (MPa) | Axial Compressive Strength (MPa) | Elastic Modulus (GPa) | Tensile Strength (MPa) | Flexural Strength (MPa) | Tensile to Compression Ratio | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OM | VM | OM | VM | OM | VM | OM | VM | OM | VM | OM | VM | |

| CF40·0 | 45.89 | 49.51 | 33.75 | 36.53 | 32.54 | 33.82 | 3.57 | 3.83 | 5.02 | 5.81 | 0.078 | 0.077 |

| CF40·0.5 | 48.06 | 53.33 | 36.14 | 39.13 | 33.76 | 34.72 | 3.78 | 4.09 | 5.34 | 6.22 | 0.079 | 0.077 |

| CF40·1.0 | 50.77 | 54.31 | 37.06 | 39.42 | 34.01 | 34.95 | 3.80 | 4.21 | 6.01 | 7.34 | 0.075 | 0.078 |

| CF40·1.5 | 51.62 | 55.16 | 37.42 | 39.61 | 33.94 | 34.83 | 3.99 | 4.53 | 7.28 | 8.13 | 0.077 | 0.082 |

| CF40·2.0 | 53.89 | 56.49 | 38.15 | 40.01 | 34.21 | 35.16 | 4.26 | 4.94 | 8.93 | 9.86 | 0.079 | 0.087 |

| CF50·0 | 52.64 | 57.13 | 39.46 | 42.90 | 33.79 | 35.58 | 3.76 | 4.07 | 5.35 | 6.28 | 0.071 | 0.071 |

| CF50·0.5 | 56.67 | 63.44 | 42.76 | 46.89 | 35.06 | 36.41 | 4.25 | 4.65 | 5.51 | 6.59 | 0.075 | 0.073 |

| CF50·1.0 | 60.24 | 64.58 | 44.75 | 47.54 | 35.81 | 36.63 | 4.39 | 4.92 | 6.91 | 7.96 | 0.073 | 0.076 |

| CF50·1.5 | 62.56 | 66.86 | 45.50 | 48.13 | 35.74 | 36.52 | 4.70 | 5.39 | 8.48 | 9.21 | 0.075 | 0.081 |

| CF50·2.0 | 63.98 | 67.41 | 47.01 | 49.12 | 36.23 | 36.94 | 5.06 | 5.94 | 9.67 | 10.51 | 0.079 | 0.088 |

| CF60·0 | 59.84 | 64.74 | 43.25 | 47.36 | 35.46 | 37.57 | 4.14 | 4.47 | 5.92 | 7.15 | 0.069 | 0.069 |

| CF60·0.5 | 64.67 | 74.33 | 47.11 | 52.23 | 36.74 | 38.23 | 5.09 | 5.64 | 6.34 | 7.86 | 0.079 | 0.076 |

| CF60·1.0 | 72.60 | 79.14 | 52.45 | 56.17 | 37.91 | 38.71 | 5.12 | 5.75 | 7.53 | 8.79 | 0.071 | 0.073 |

| CF60·1.5 | 75.32 | 81.62 | 54.32 | 57.86 | 37.76 | 38.57 | 5.32 | 6.19 | 9.96 | 10.85 | 0.071 | 0.076 |

| CF60·2.0 | 76.39 | 82.21 | 55.13 | 58.27 | 38.57 | 39.27 | 5.57 | 6.79 | 11.45 | 12.40 | 0.073 | 0.083 |

| Matrix Strength | Steel-Fiber Volume Ratio (%) | Cube Compressive Strength (MPa) | Ratio | |

|---|---|---|---|---|

| Expt. | Theory | |||

| CF40 | 0 | 49.51 | 51.93 | 0.95 |

| 0.50% | 53.33 | 53.76 | 0.99 | |

| 1.00% | 54.31 | 55.59 | 0.98 | |

| 1.50% | 55.16 | 57.41 | 0.96 | |

| 2.00% | 56.49 | 59.24 | 0.95 | |

| CF50 | 0 | 57.13 | 52.69 | 1.08 |

| 0.50% | 63.44 | 62.56 | 1.01 | |

| 0.75% | 63.77 | 63.63 | 1.00 | |

| 1.00% | 64.58 | 64.69 | 1.00 | |

| 1.50% | 66.86 | 66.82 | 1.00 | |

| 2.00% | 67.41 | 68.95 | 0.98 | |

| CF60 | 0 | 64.74 | 62.34 | 1.04 |

| 0.50% | 74.33 | 73.36 | 1.01 | |

| 1.00% | 79.14 | 75.86 | 1.04 | |

| 1.50% | 81.62 | 78.35 | 1.04 | |

| 2.00% | 82.21 | 80.85 | 1.02 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Sun, Y.; Xu, J.; Wang, B. The Effect of Vibration Mixing on the Mechanical Properties of Steel Fiber Concrete with Different Mix Ratios. Materials 2021, 14, 3669. https://doi.org/10.3390/ma14133669

Zhang C, Sun Y, Xu J, Wang B. The Effect of Vibration Mixing on the Mechanical Properties of Steel Fiber Concrete with Different Mix Ratios. Materials. 2021; 14(13):3669. https://doi.org/10.3390/ma14133669

Chicago/Turabian StyleZhang, Chunyu, Yikai Sun, Jianguo Xu, and Bo Wang. 2021. "The Effect of Vibration Mixing on the Mechanical Properties of Steel Fiber Concrete with Different Mix Ratios" Materials 14, no. 13: 3669. https://doi.org/10.3390/ma14133669

APA StyleZhang, C., Sun, Y., Xu, J., & Wang, B. (2021). The Effect of Vibration Mixing on the Mechanical Properties of Steel Fiber Concrete with Different Mix Ratios. Materials, 14(13), 3669. https://doi.org/10.3390/ma14133669