Effect of Graphene on Modified Asphalt Microstructures Based on Atomic Force Microscopy

Abstract

:1. Introduction

2. Experimental

2.1. Preparation of AFM Specimens

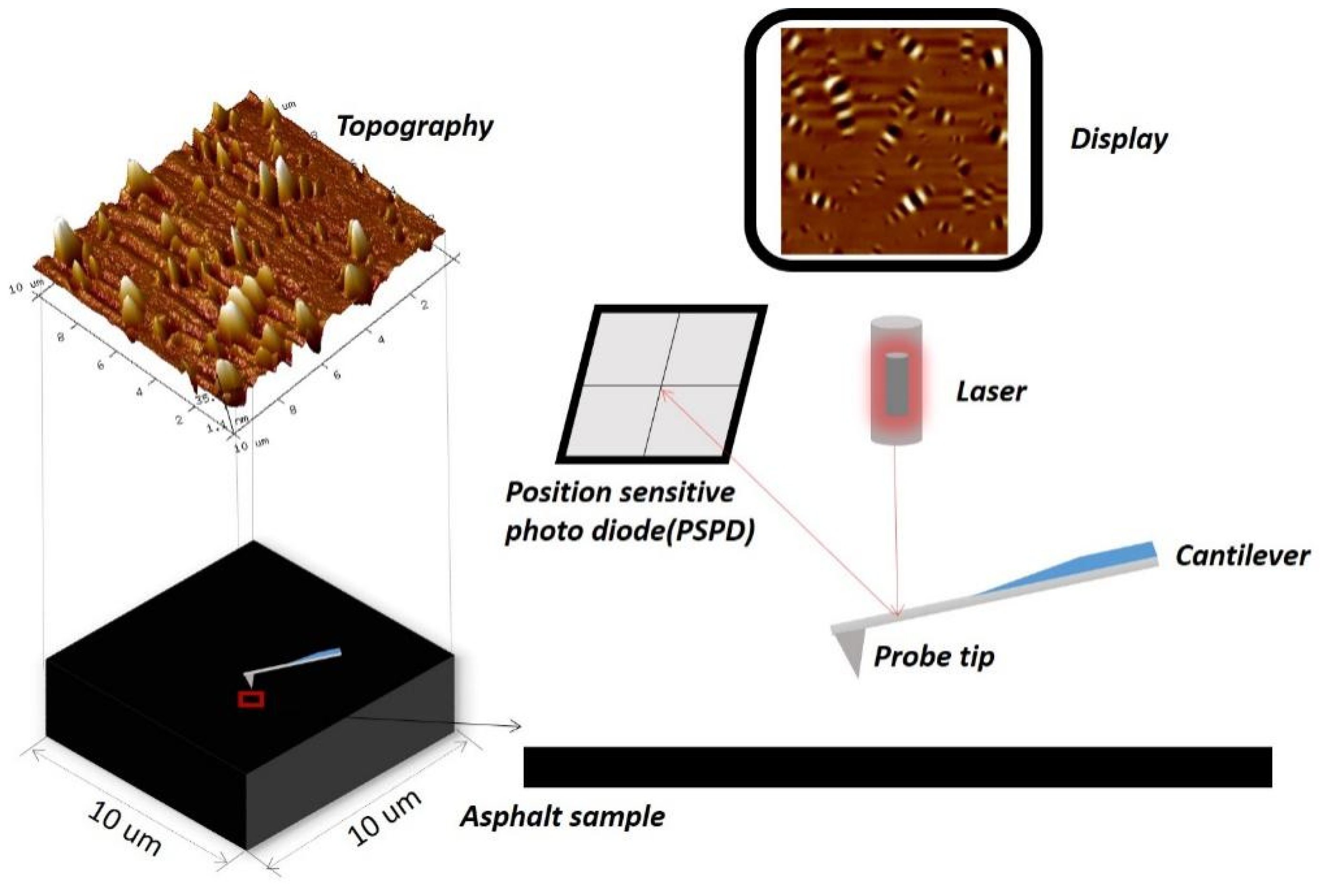

2.2. Atomic Force Microscope Test

3. Results and Discussion

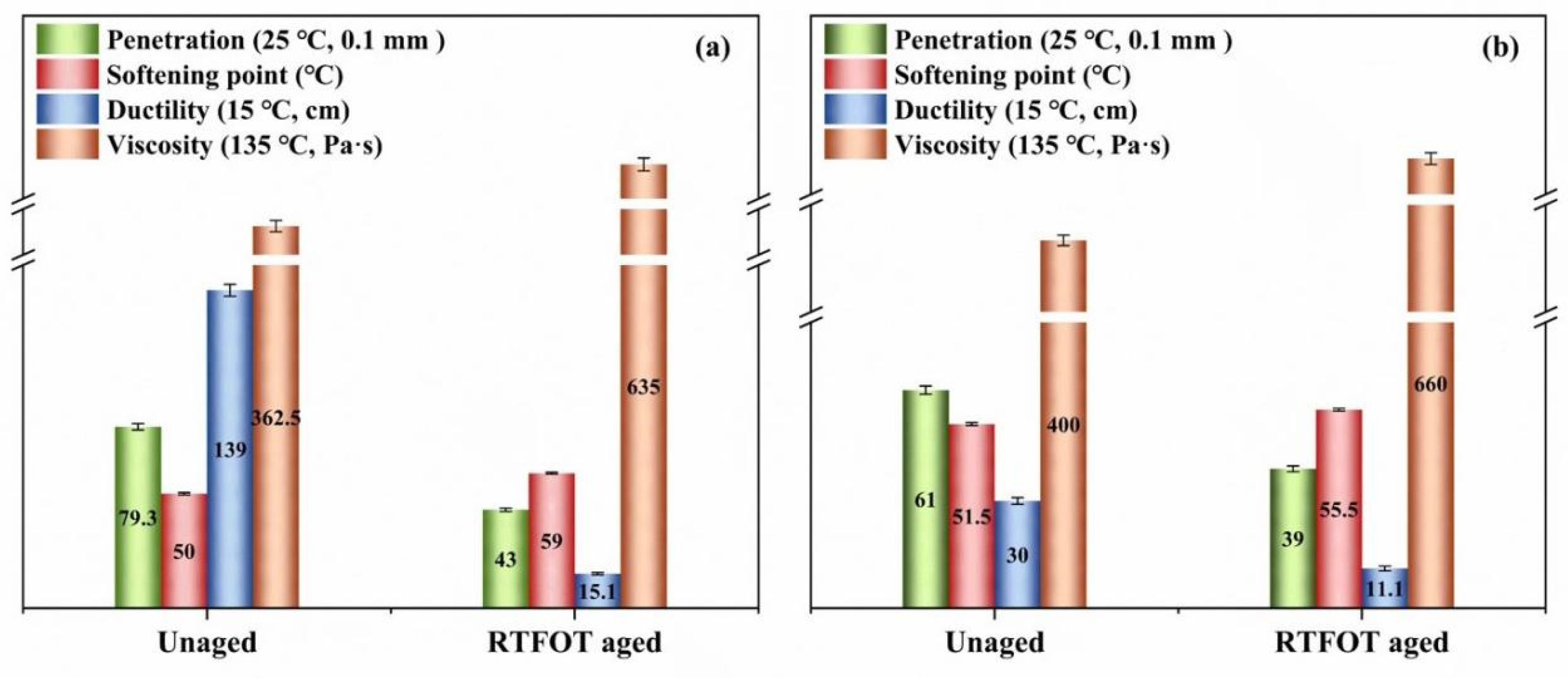

3.1. Effect of Graphene on Fundamental Properties of Asphalt

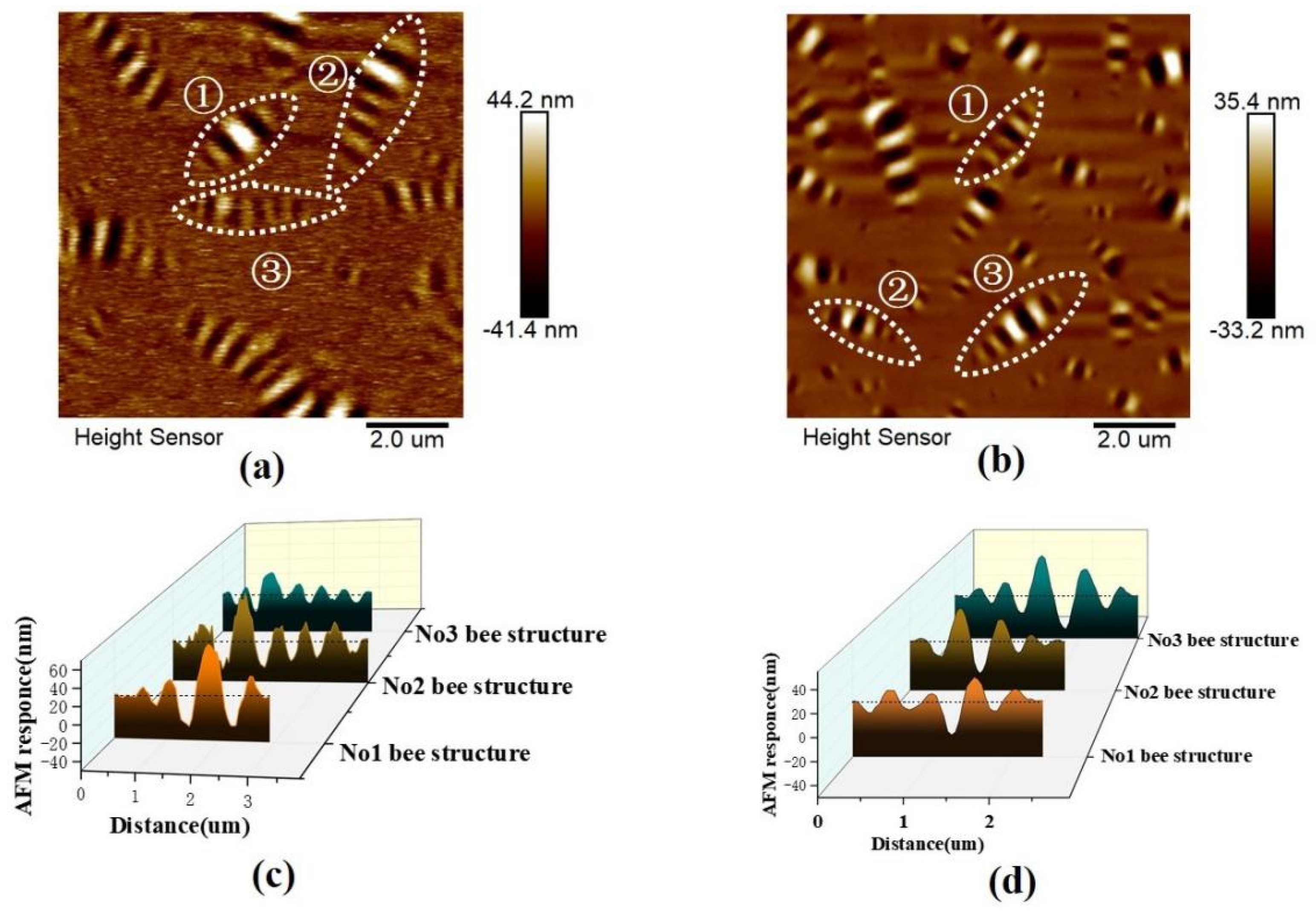

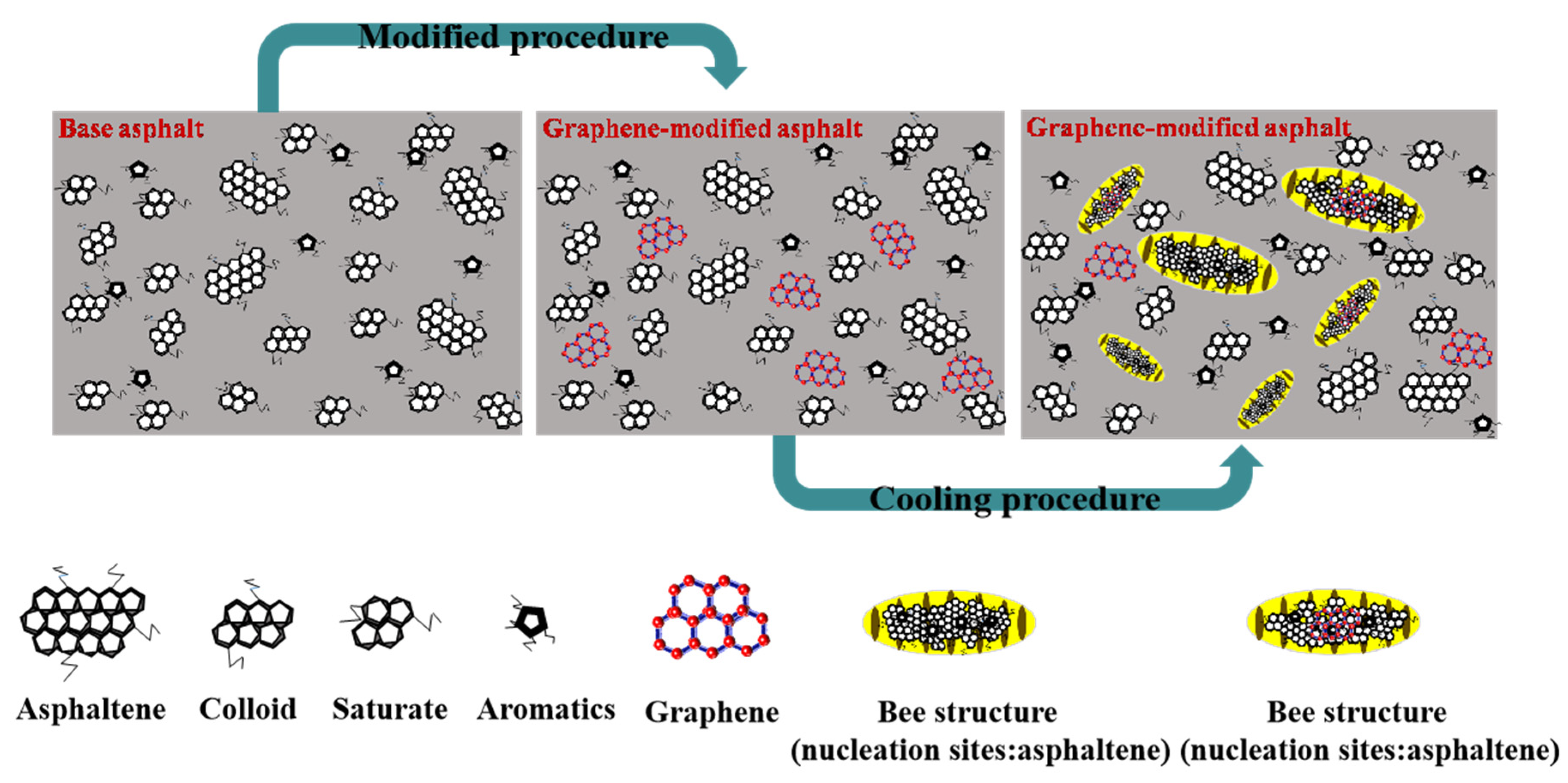

3.2. Effect of Graphene on “Bee Structure”

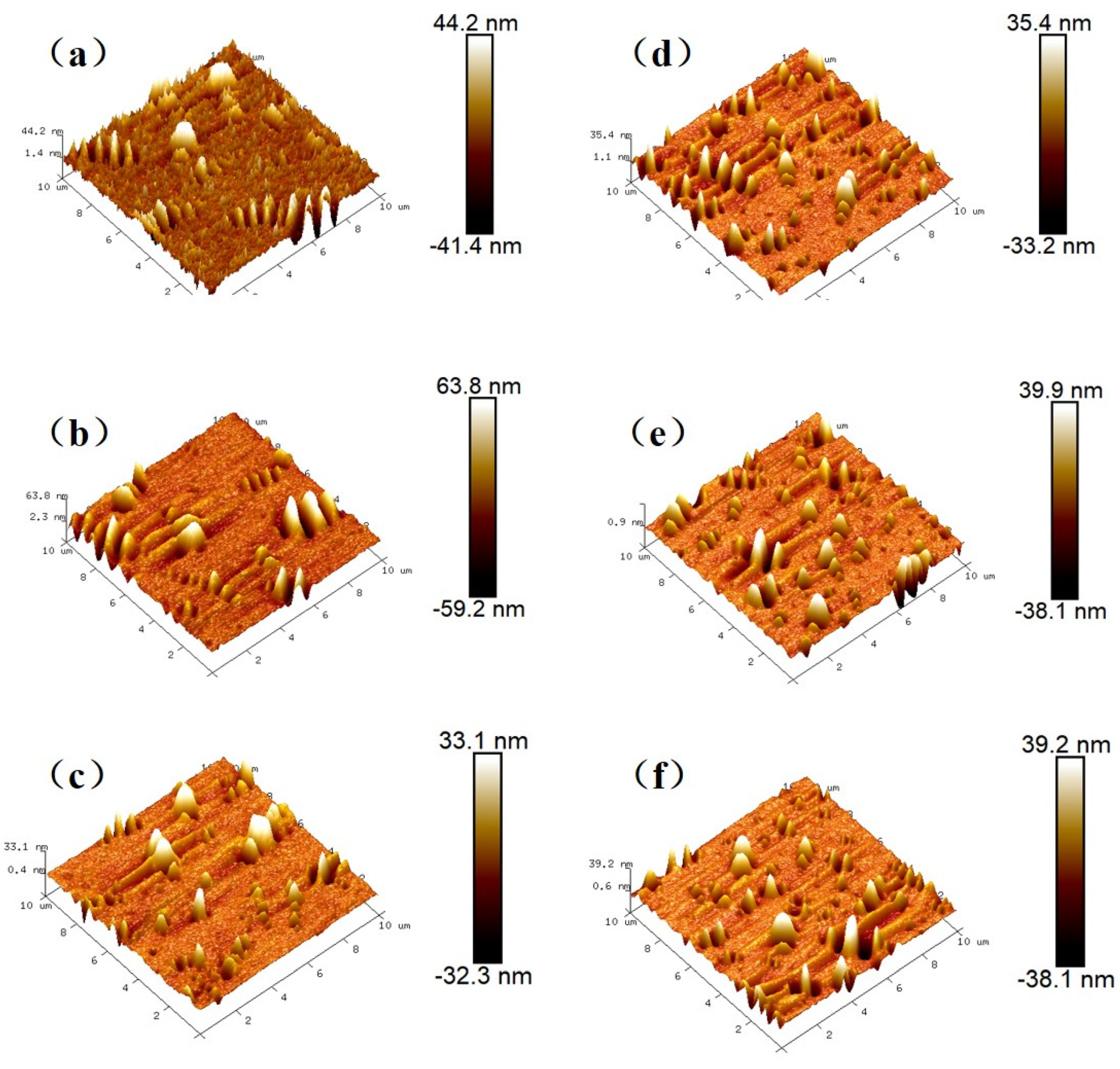

3.3. Effect of Graphene on Microstructure during Asphalt Aging

3.4. Discussion of Asphalt Microstructure Based on Liquid-Solid Phase Transformation Theory

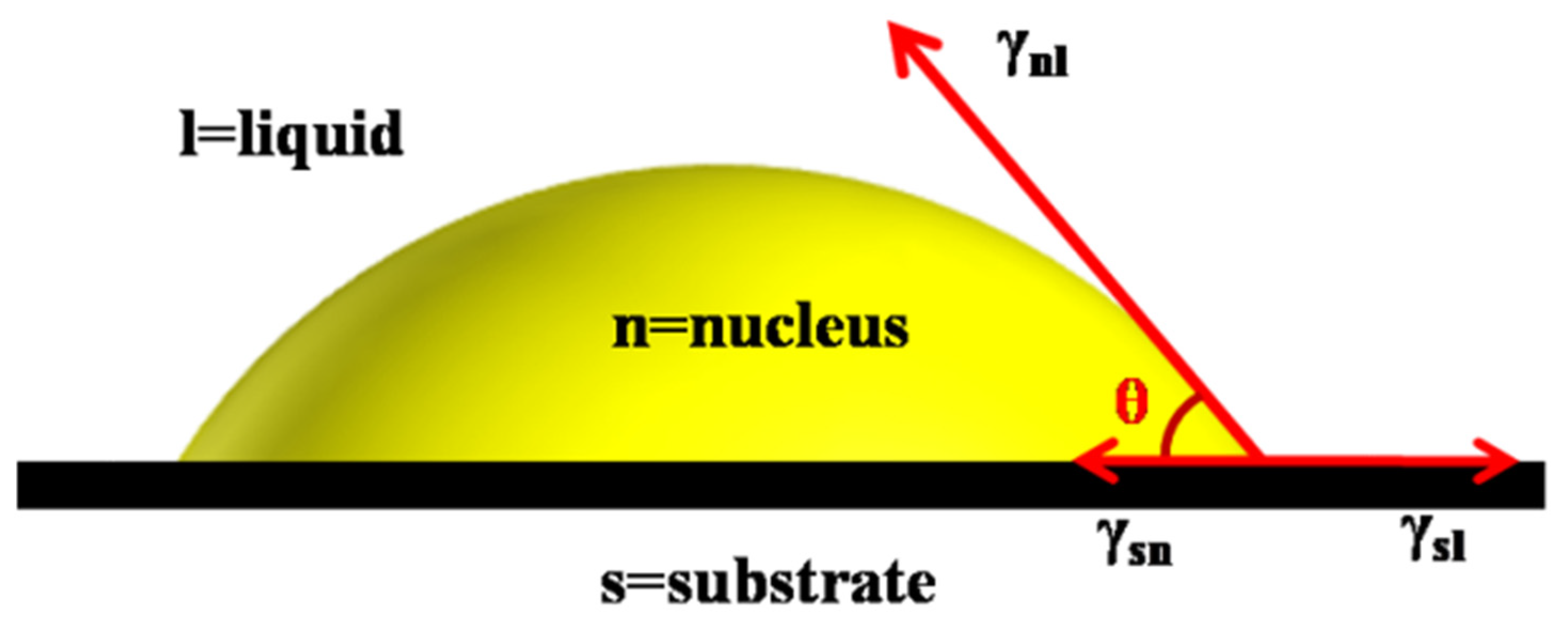

3.4.1. Analysis of “Bee Structure” Formation

3.4.2. Effect of Graphene on the Bee Structures of Asphalt

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, D.; Yu, F.; Li, L.; Lin, T.; Zhu, X.Y. Effect of chemical composition and structure of asphalt binders on self-healing. Constr. Build. Mater. 2017, 133, 495–501. [Google Scholar] [CrossRef]

- Lyne, Å.L.; Wallqvist, V.; Rutland, M.W.; Claesson, P.; Birgisson, B. Surface wrinkling: The phenomenon causing bees in bitumen. J. Mater. Sci. 2013, 48, 6970–6976. [Google Scholar] [CrossRef]

- Loeber, L.; Sutton, O.; Morel, J.V.J.M.; Valleton, J.M.; Muller, G. New direct observations of asphalts and asphalt binders by scanning electron microscopy and atomic force microscopy. J. Microsc. 1996, 182, 32–39. [Google Scholar] [CrossRef]

- Pauli, A.T.; Grimes, R.W.; Beemer, A.G.; Turner, T.F.; Branthaver, J.F. Morphology of asphalts, asphalt fractions and model wax-doped asphalts studied by atomic force microscopy. Int. J. Pavement Eng. 2011, 12, 291–309. [Google Scholar] [CrossRef]

- Jäger, A.; Lackner, R.; Eisenmenger-Sittner, C.; Blab, R. Identification of four material phases in bitumen by atomic force microscopy. Road Mater. Pavement Des. 2004, 5, 9–24. [Google Scholar] [CrossRef]

- De Moraes, M.B.; Pereira, R.B.; Simão, R.A.; Leite, L.F.M. High temperature AFM study of CAP 30/45 pen grade bitumen. J. Microsc. 2010, 239, 46–53. [Google Scholar] [CrossRef]

- Masson, J.F.; Leblond, V.; Margeson, J. Bitumen morphologies by phase-detection atomic force microscopy. J. Microsc. 2006, 221, 17–29. [Google Scholar] [CrossRef] [Green Version]

- Li, R.; Wang, P.; Xue, B.; Pei, J. Experimental study on ageing properties and modification mechanism of Trinidad lake asphalt modified bitumen. Constr. Build. Mater. 2015, 101, 878–883. [Google Scholar] [CrossRef]

- Xing, C.; Liu, L.; Li, M. Chemical Composition and ageing Characteristics of Linear SBS Modified Asphalt Binders. Energy Fuels 2020, 34, 4194–4200. [Google Scholar] [CrossRef]

- Hung, A.M.; Fini, E.H. AFM study of asphalt binder “bee” structures: Origin, mechanical fracture, topological evolution, and experimental artifacts. RSC Adv. 2015, 5, 96972–96982. [Google Scholar] [CrossRef]

- Ji, X.; Hou, Y.; Zou, H.; Chen, B.; Jiang, Y. Study of surface microscopic properties of asphalt based on atomic force microscopy. Constr. Build. Mater. 2020, 242, 118025. [Google Scholar] [CrossRef]

- Hung, A.M.; Goodwin, A.; Fini, E.H. Effects of water exposure on bitumen surface microstructure. Constr. Build. Mater. 2017, 135, 682–688. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Li, L.; Wang, H.; Wang, W.; Zheng, K. Laboratory Study on Performance Evaluation and Automobile Exhaust Degradation of Nano-TiO2 Particles-Modified Asphalt Materials. Adv. Mater. Sci. Eng. 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Su, M.; Si, C.; Zhang, Z.; Zhang, H. Molecular dynamics study on influence of Nano-ZnO/SBS on physical properties and molecular structure of asphalt binder. Fuel 2020, 263, 116777. [Google Scholar] [CrossRef]

- Yang, L.; Zhou, D.; Kang, Y. Rheological Properties of Graphene Modified Asphalt Binders. Nanomaterials 2020, 10, 2197. [Google Scholar] [CrossRef]

- Qian, G.; Yang, C.; Huang, H.; Gong, X.; Yu, H. Resistance to ultraviolet aging of nano-SiO2 and rubber powder compound modified asphalt. Materials 2020, 13, 5067. [Google Scholar] [CrossRef]

- Ren, Z.; Zhu, Y.; Wu, Q.; Zhu, M.; Guo, F.; Yu, H.; Yu, J. Enhanced storage stability of different polymer modified asphalt binders through nano-montmorillonite modification. Nanomaterials 2020, 10, 641. [Google Scholar] [CrossRef] [Green Version]

- Cheraghian, G.; Wistuba, M.P. Effect of Fumed silica nanoparticles on ultraviolet aging resistance of bitumen. Nanomaterials 2021, 11, 454. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, Y.; Guo, G.; Zhao, B.; Yu, J. Effects of ZnO particle size on properties of asphalt and asphalt mixture. Constr. Build. Mater. 2018, 159, 578–586. [Google Scholar] [CrossRef]

- Wu, S.; Zhao, Z.; Li, Y.; Pang, L.; Amirkhanian, S.; Riara, M. Evaluation of ageing resistance of graphene oxide modified asphalt. Appl. Sci. 2017, 7, 702. [Google Scholar] [CrossRef]

- Zeng, W.; Wu, S.; Pang, L.; Sun, Y.; Chen, Z. The utilization of graphene oxide in traditional construction materials: Asphalt. Materials 2017, 10, 48. [Google Scholar] [CrossRef]

- Li, Y.; Wu, S.; Amirkhanian, S. Investigation of the graphene oxide and asphalt interaction and its effect on asphalt pavement performance. Constr. Build. Mater. 2018, 165, 572–584. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, K.; Shi, X. Performance evaluation and modification mechanism analysis of asphalt binders modified by graphene oxide. Constr. Build. Mater. 2018, 163, 880–889. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, K.; Wu, J.; Muhunthan, B.; Shi, X. Evaluation of mechanical performance and modification mechanism of asphalt modified with graphene oxide and warm mix additives. J. Clean. Prod. 2018, 193, 87–96. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Adhesion characteristics of graphene oxide modified asphalt unveiled by surface free energy and AFM-scanned micro-morphology. Constr. Build. Mater. 2020, 244, 118404. [Google Scholar] [CrossRef]

- Moreno-Navarro, F.; Sol-Sánchez, M.; Gámiz, F.; Rubio-Gámez, M.C. Mechanical and thermal properties of graphene modified asphalt binders. Constr. Build. Mater. 2018, 180, 265–274. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.M.; Wu, Y.L.; Wang, H.R.; Chen, M.; Sun, H.D.; Fan, L. Properties and modification mechanism of asphalt with graphene as modifier. Constr. Build. Mater. 2021, 272, 121919. [Google Scholar] [CrossRef]

- Yu, X.; Burnham, N.A.; Tao, M. Surface microstructure of bitumen characterized by atomic force microscopy. Adv. Colloid Interface Sci. 2015, 218, 17–33. [Google Scholar] [CrossRef]

- Giessibl, F.J. The qPlus sensor, a powerful core for the atomic force microscope. Rev. Sci. Instrum. 2019, 90, 011101. [Google Scholar] [CrossRef]

- Hong, H.; Zhang, H.; Zhang, S. Effect of multi-dimensional nanomaterials on the ageing behavior of asphalt by atomic force microscope. Constr. Build. Mater. 2020, 260, 120389. [Google Scholar] [CrossRef]

- Redelius, P.; Soenen, H. Relation between bitumen chemistry and performance. Fuel 2015, 140, 34–43. [Google Scholar] [CrossRef]

- Chen, A.; Liu, G.; Zhao, Y.; Li, J.; Pan, Y.; Zhou, J. Research on the aging and rejuvenation mechanisms of asphalt using atomic force microscopy. Constr. Build. Mater. 2018, 167, 177–184. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L. Investigation of microscale ageing behavior of asphalt binders using atomic force microscopy. Constr. Build. Mater. 2017, 135, 411–419. [Google Scholar] [CrossRef]

- Zhou, X.; Sun, B.; Wu, S.; Zhang, X.; Liu, Q.; Xiao, Y. Evaluation on self-healing mechanism and hydrophobic performance of asphalt modified by siloxane and polyurethane. J. Wuhan Univ. Technol. Sci. Ed. 2019, 34, 630–637. [Google Scholar] [CrossRef]

- Ma, W.; Huang, T.; Guo, S.; Yang, C.; Ding, Y.; Hu, C. Atomic force microscope study of the ageing/rejuvenating effect on asphalt morphology and adhesion performance. Constr. Build. Mater. 2019, 205, 642–655. [Google Scholar] [CrossRef]

- Xu, M.; Yi, J.; Feng, D.; Huang, Y.; Wang, D. Analysis of adhesive characteristics of asphalt based on atomic force microscopy and molecular dynamics simulation. ACS Appl. Mater. Interfaces 2016, 8, 12393–12403. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Zhu, H.; Li, C.; Yao, B.; Wang, F.; Chen, J.; Sun, G. Investigation on the mechanism of wax deposition inhibition induced by asphaltenes and wax inhibitors. J. Pet. Sci. Eng. 2021, 204, 108723. [Google Scholar] [CrossRef]

- Wang, T. Study on the Wax Crystals’ Microscopic Characteristic of Nan Yang Crude Oil; China University of Petroleum: Beijing, China, 2009. [Google Scholar]

- Singhal, H.K.; Sahai, G.C.; Pundeer, G.S.; Chandra, K. Designing and selecting wax crystal modifier for optimum field performance based on crude oil composition. In Proceedings of the SPE Annual Technical Conference and Exhibition, Dallas, TX, USA, 6–9 October 1991; Society of Petroleum Engineers: Richardson, TX, USA, 1991. [Google Scholar] [CrossRef]

- Yang, F.; Paso, K.; Norrman, J.; Li, C.; Oschmann, H.; Sjöblom, J. Hydrophilic nanoparticles facilitate wax inhibition. Energy Fuels 2015, 29, 1368–1374. [Google Scholar] [CrossRef]

- Yang, F.; Zhao, Y.; Sjöblom, J.; Li, C.; Paso, K.G. Polymeric wax inhibitors and pour point depressants for waxy crude oils: A critical review. J. Dispers. Sci. Technol. 2015, 36, 213–225. [Google Scholar] [CrossRef]

| Indicators | Base Asphalt | Graphene-Modified Asphalt | ||

|---|---|---|---|---|

| Aging states | Unaged | Roughness (nm) | 9.1 | 6.5 |

| Number Peaks Found (number) | 141.0 | 137.0 | ||

| Minimum Peak Depth (nm) | 70.5 | 48.4 | ||

| Maximum peak Depth (nm) | 69.2 | 45.3 | ||

| RTFOT | Roughness (Rq) | 12.0 | 7.5 | |

| Number Peaks Found (number) | 133.0 | 140.0 | ||

| Minimum Peak Depth (nm) | 77.9 | 67.9 | ||

| Maximum Peak Depth (nm) | 83.1 | 63.9 | ||

| PAV | Roughness (Rq) | 11.0 | 7.3 | |

| Number Peaks Found (number) | 130.0 | 137.0 | ||

| Minimum Peak Depth (nm) | 53.3 | 68.3 | ||

| Maximum Peak Depth (nm) | 57.7 | 64.5 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Wang, Y.; Wu, Y.; Wang, H.; Wang, Q.; Zhu, X.; Liu, X.; Sun, H.; Fan, L. Effect of Graphene on Modified Asphalt Microstructures Based on Atomic Force Microscopy. Materials 2021, 14, 3677. https://doi.org/10.3390/ma14133677

Li X, Wang Y, Wu Y, Wang H, Wang Q, Zhu X, Liu X, Sun H, Fan L. Effect of Graphene on Modified Asphalt Microstructures Based on Atomic Force Microscopy. Materials. 2021; 14(13):3677. https://doi.org/10.3390/ma14133677

Chicago/Turabian StyleLi, Xian, Yanmin Wang, Yanling Wu, Huiru Wang, Qingliang Wang, Xingxing Zhu, Xiaocun Liu, Huadong Sun, and Liang Fan. 2021. "Effect of Graphene on Modified Asphalt Microstructures Based on Atomic Force Microscopy" Materials 14, no. 13: 3677. https://doi.org/10.3390/ma14133677