Damage Mechanism of PTFE/Al Reactive Charge Liner Structural Parameters on a Steel Target

Abstract

:1. Introduction

- (1)

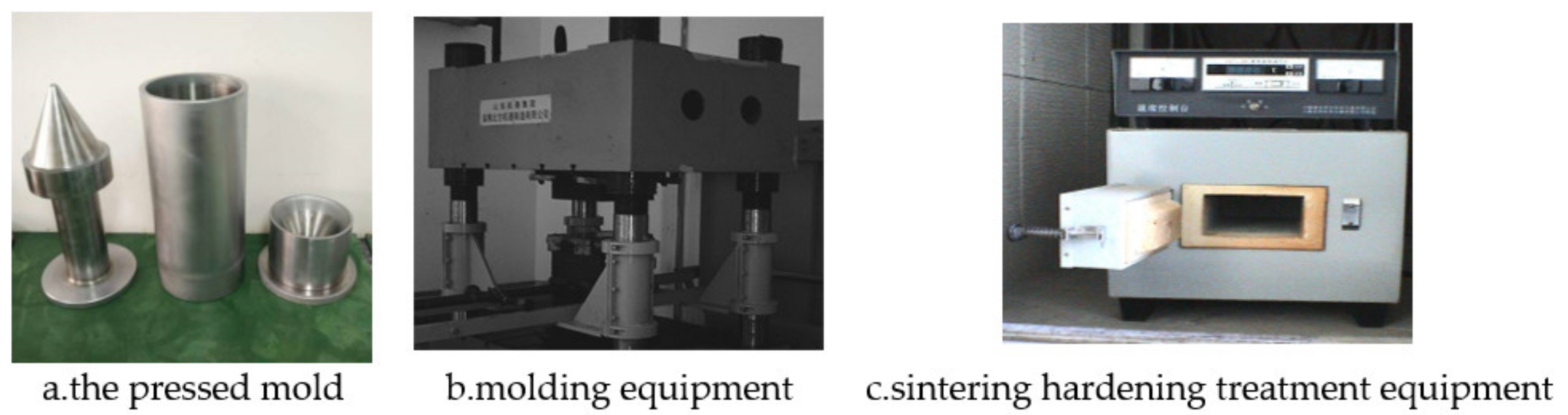

- The reactive material generally consists of metal powders and fluorine polymer powder, prepared through mixing, molding and sinter hardening. Traditional reactive materials are highly explosive and propellant (e.g., gunpowder), and can be characterized by high strength and density, and low sensitivity. They are triggered through a traditional initiation method, such as a flame, detonator, shock wave, etc., contacting the explosive reactive material to cause a self-sustaining stable transmission [8,9,10,11,12,13,14].

- (2)

- When a reactive material hits a high-speed collision target it goes through a process of shock loading and high plastic deformation; following this, the shear strain rate causes a fracture and the fluorine polymer decomposes, releasing fluorine with strong oxidation ability, activating the metal powder rapidly and causing an explosion/deflagration, and releasing a large amount of chemical energy, which has a significant heating effect [15,16,17,18,19,20,21,22].

- (3)

- Compared with a traditional inert metal damage element, a reactive material can greatly enhance the structural disintegration of a target, especially due to its ability to ignite and detonate the target through the combined damage mechanism of kinetic energy penetration and an internal explosion [2,23,24,25].

- (1)

- The fragment killing warhead replaces the existing metal fragments, rods and shell of the warhead. By using the combined effect of penetration and internal explosion of reactive material fragments, the power of warheads can be greatly improved, especially for aerial targets such as missiles and combat aircraft, and the killing radius or K level (destruction level) can be greatly increased, and the effective strike efficiency of “one strike to destroy” can be achieved.

- (2)

- Fluoropolymer-based reactive fragment materials can be used in penetrating warheads to replace part of the inert metal projectile body or as a projectile core. Using the combined effect of the transverse expansion and explosion of the reactive material to deal with aerial targets, such as missiles and aircraft, the K-level damage ability can be greatly improved. Attacking light armored targets, such as infantry fighting vehicles and armored personnel carriers, can significantly improve the comprehensive damage caused. Attacking oil depot/tank targets can greatly improve the ability of ignition and detonation. In addition, the use is safer and cost is lower due to the need for a fuse and explosive charge.

- (3)

- Fluoropolymer-based reactive fragment materials can be applied to energy gathering warheads to replace the metal charge cover. The combined effect of reactive jet penetration and explosion can be used to attack light- and medium-armored targets, which can greatly improve the aftereffect of destroying armor. When attacking concrete targets, such as airport runways and bridges, reactive materials can greatly improve the damage of the internal explosion structure and is comparable to the damage efficiency of the cumulative charge-blasting two-stage series warhead.

2. Experiments

2.1. Preparation of Reactive Material Liner Sample

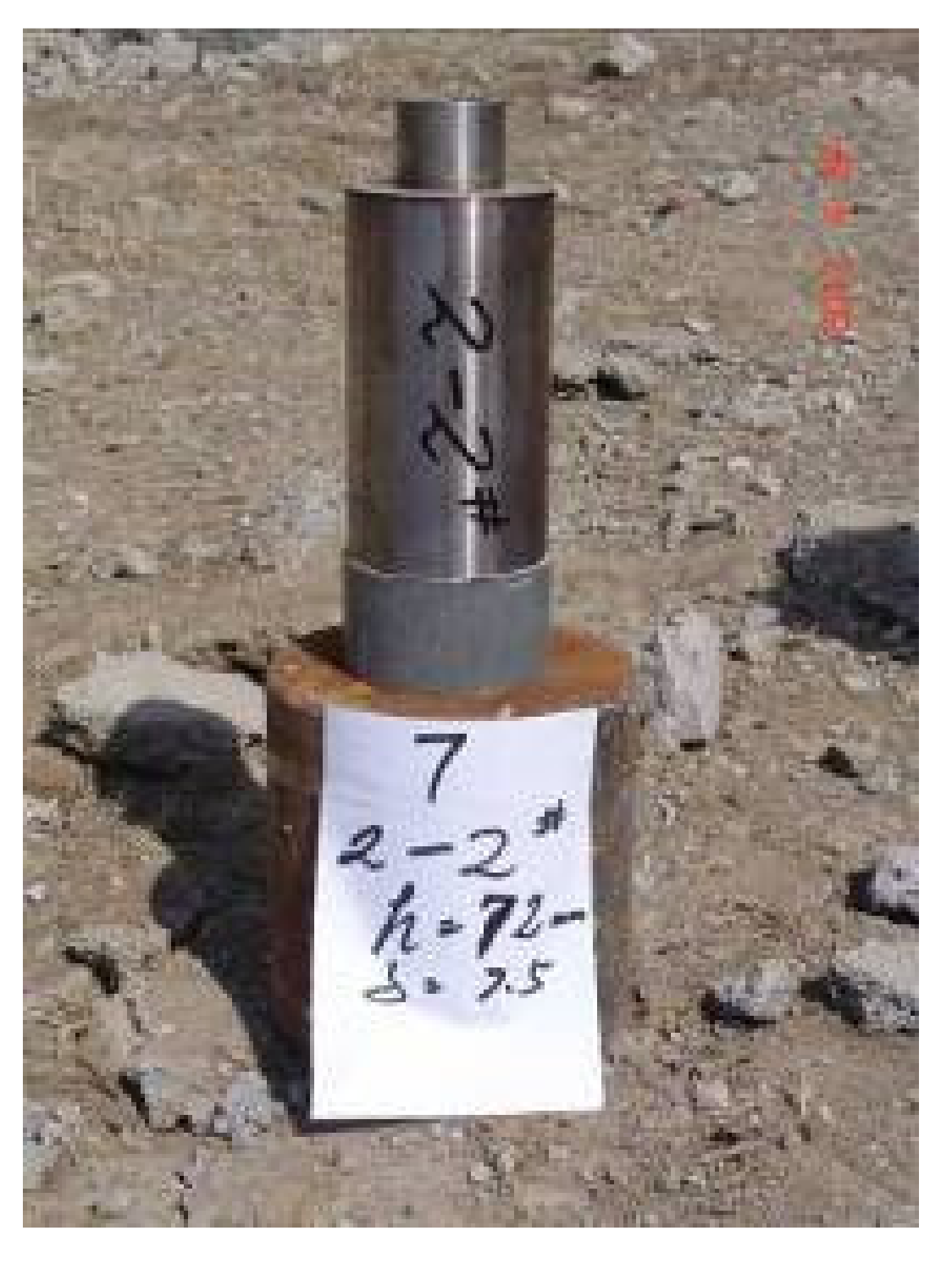

2.2. X-ray Pulse Test

2.3. Penetration Test

3. Results and Discussion

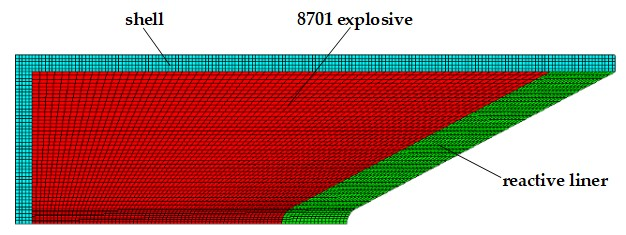

3.1. Finite Element Calculation Model

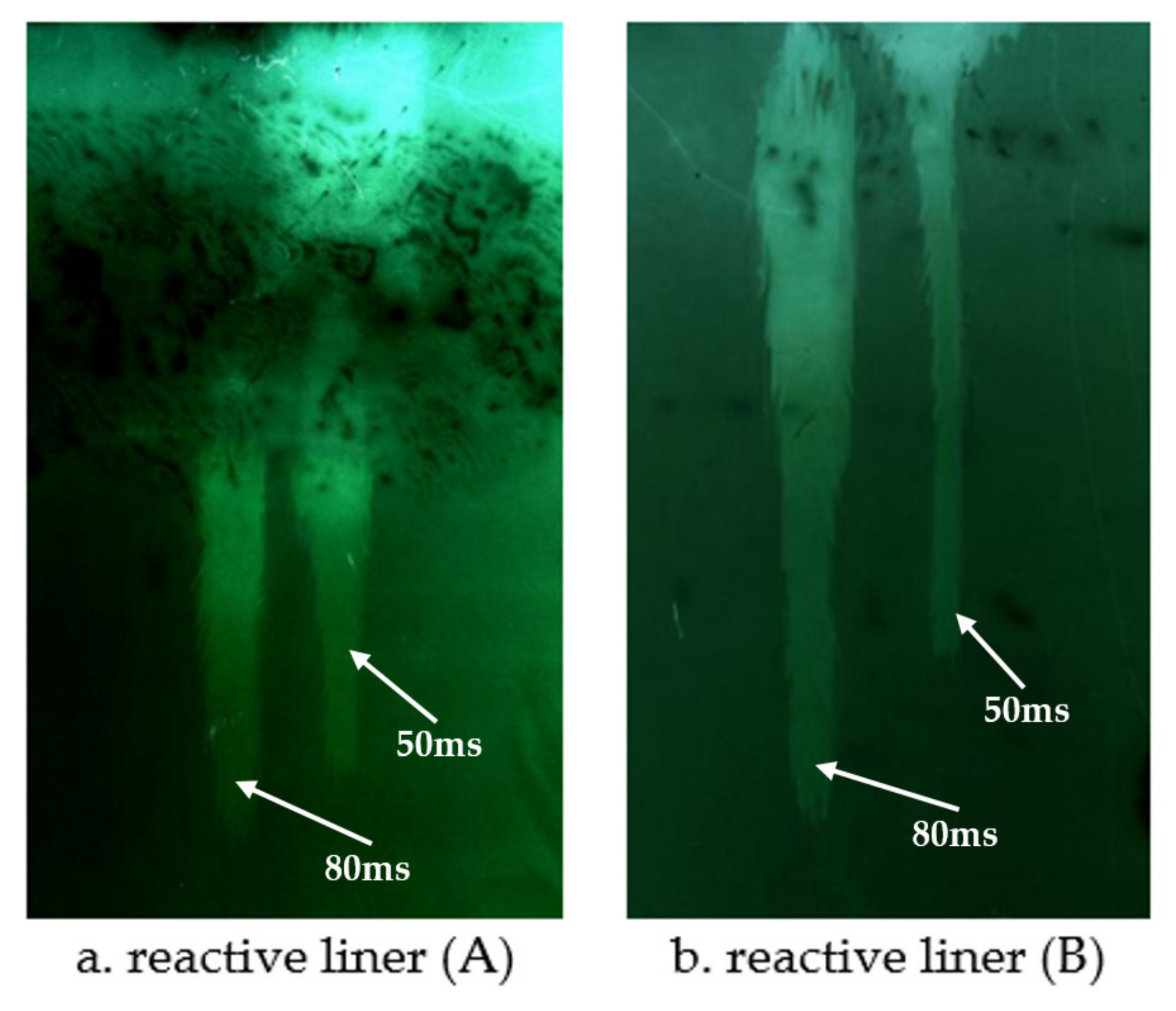

3.2. Analysis of X-ray Pulse Experimental Results

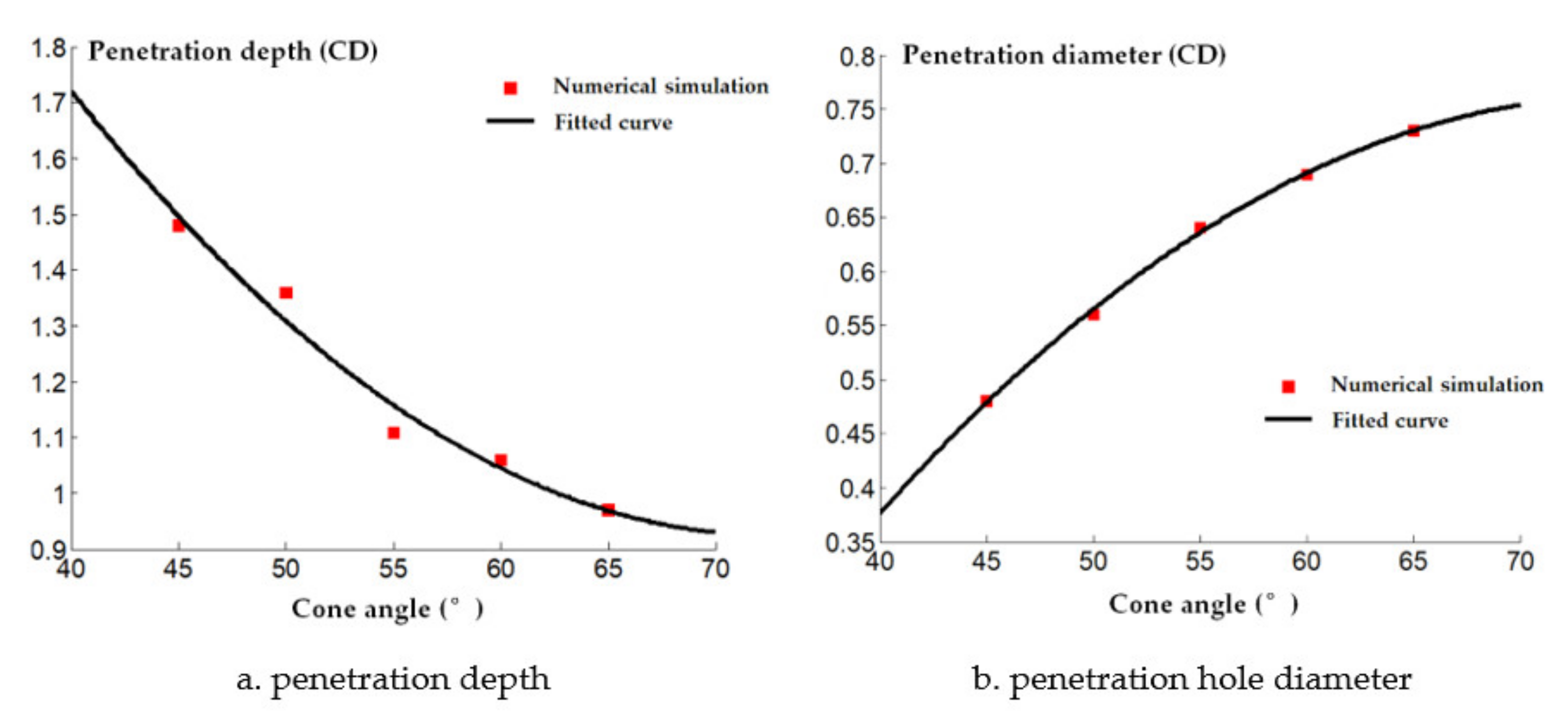

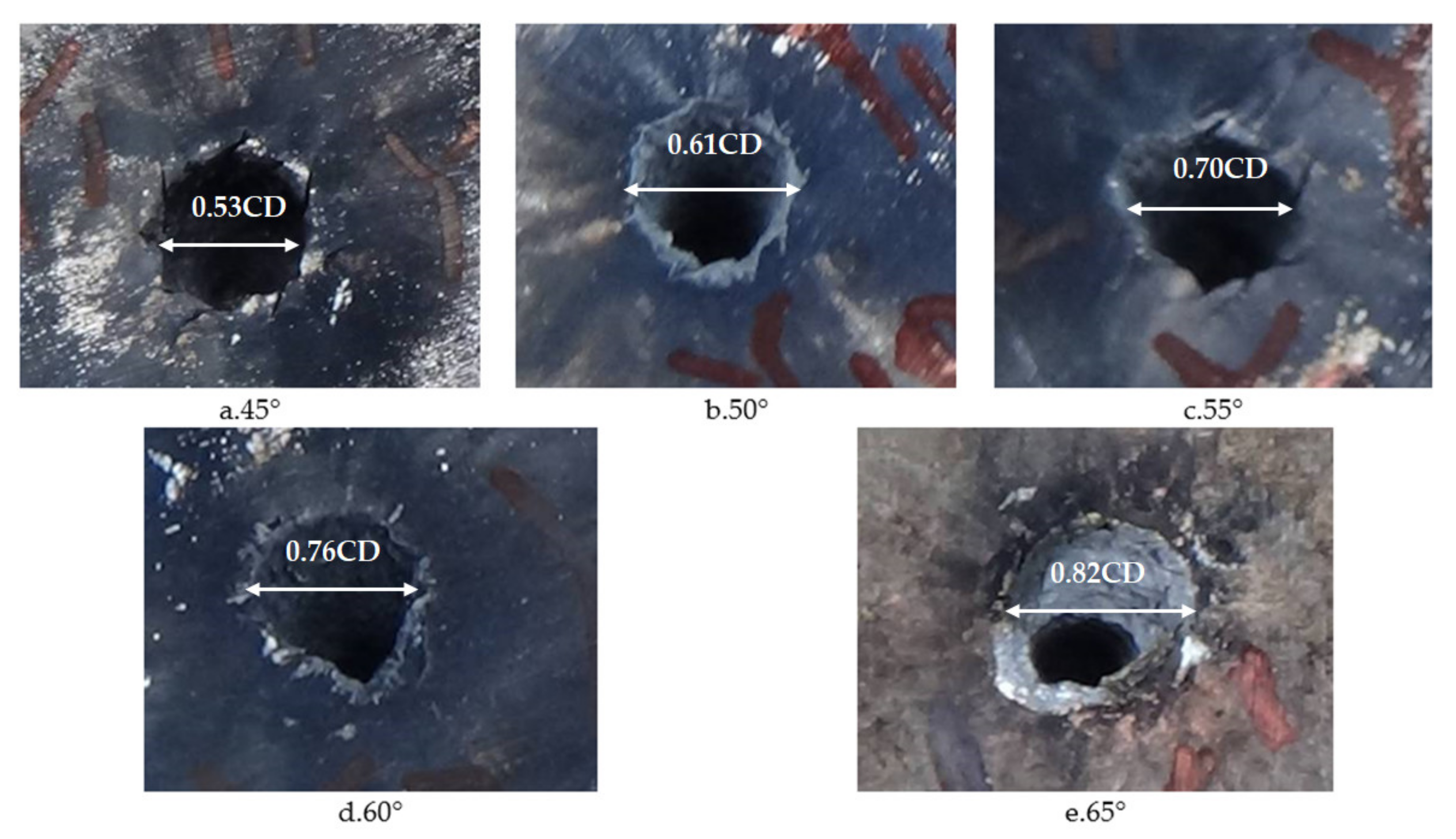

3.3. Effect of Reactive Materials Type Cone Angle on Damage Effect

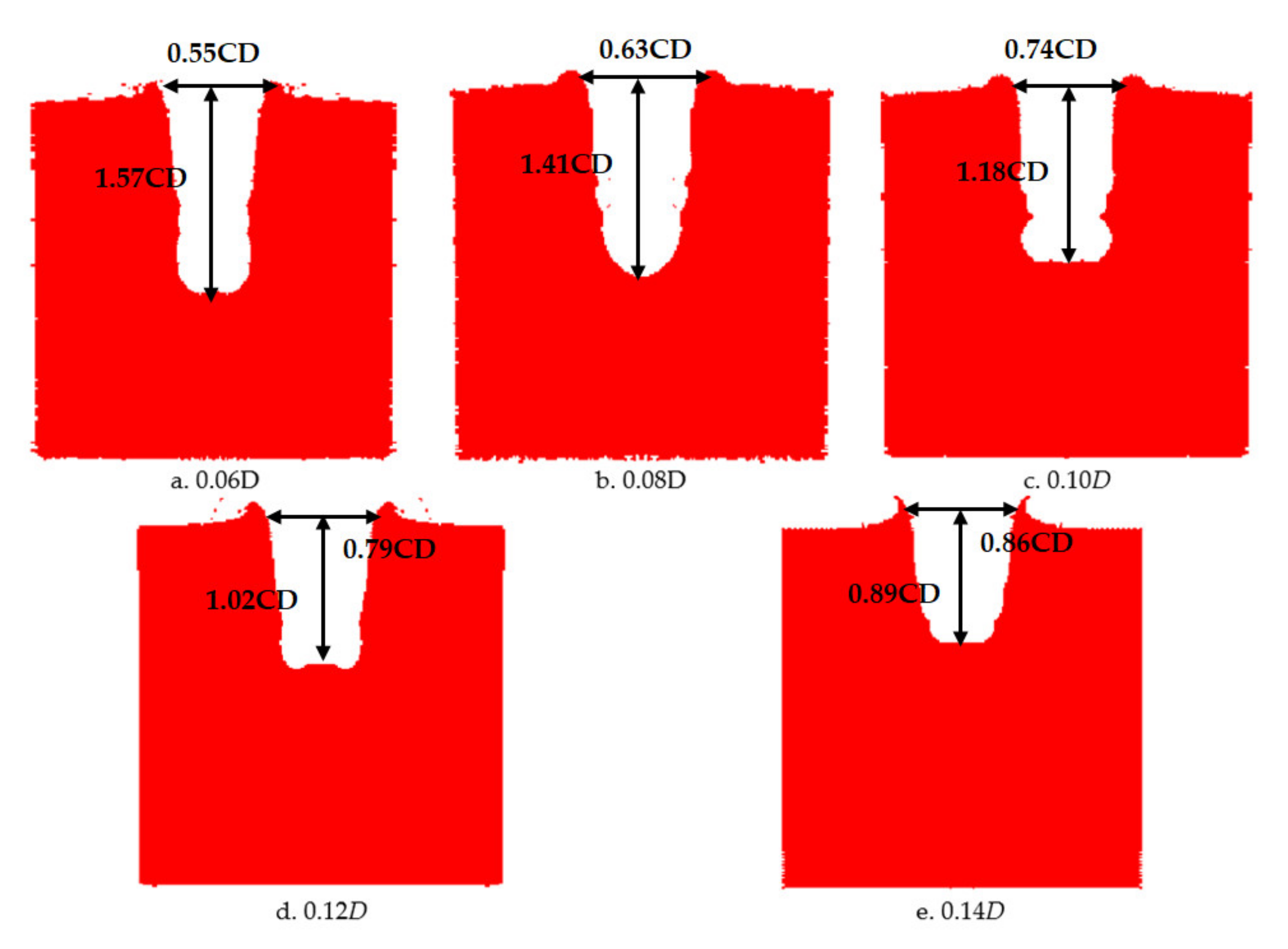

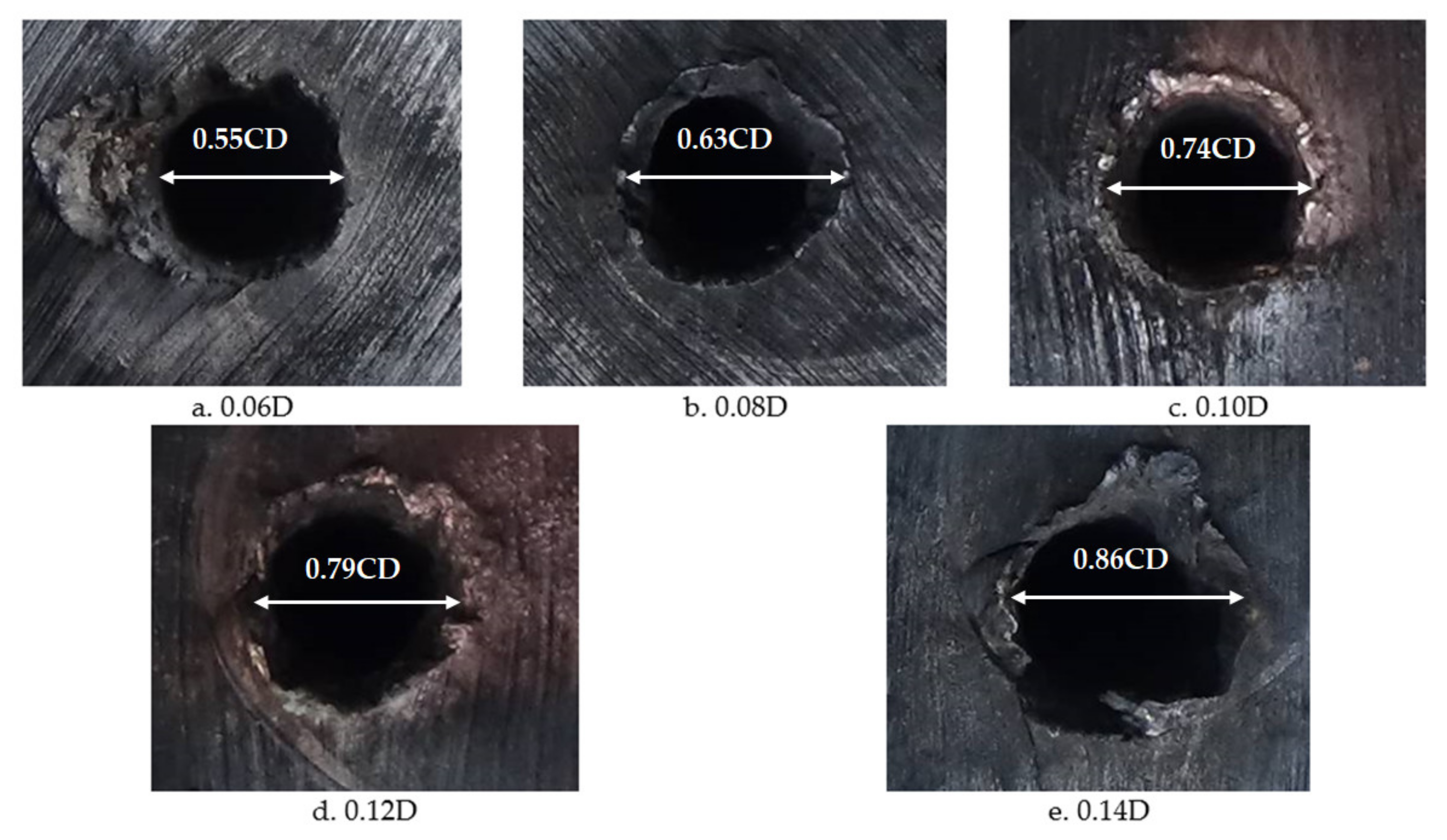

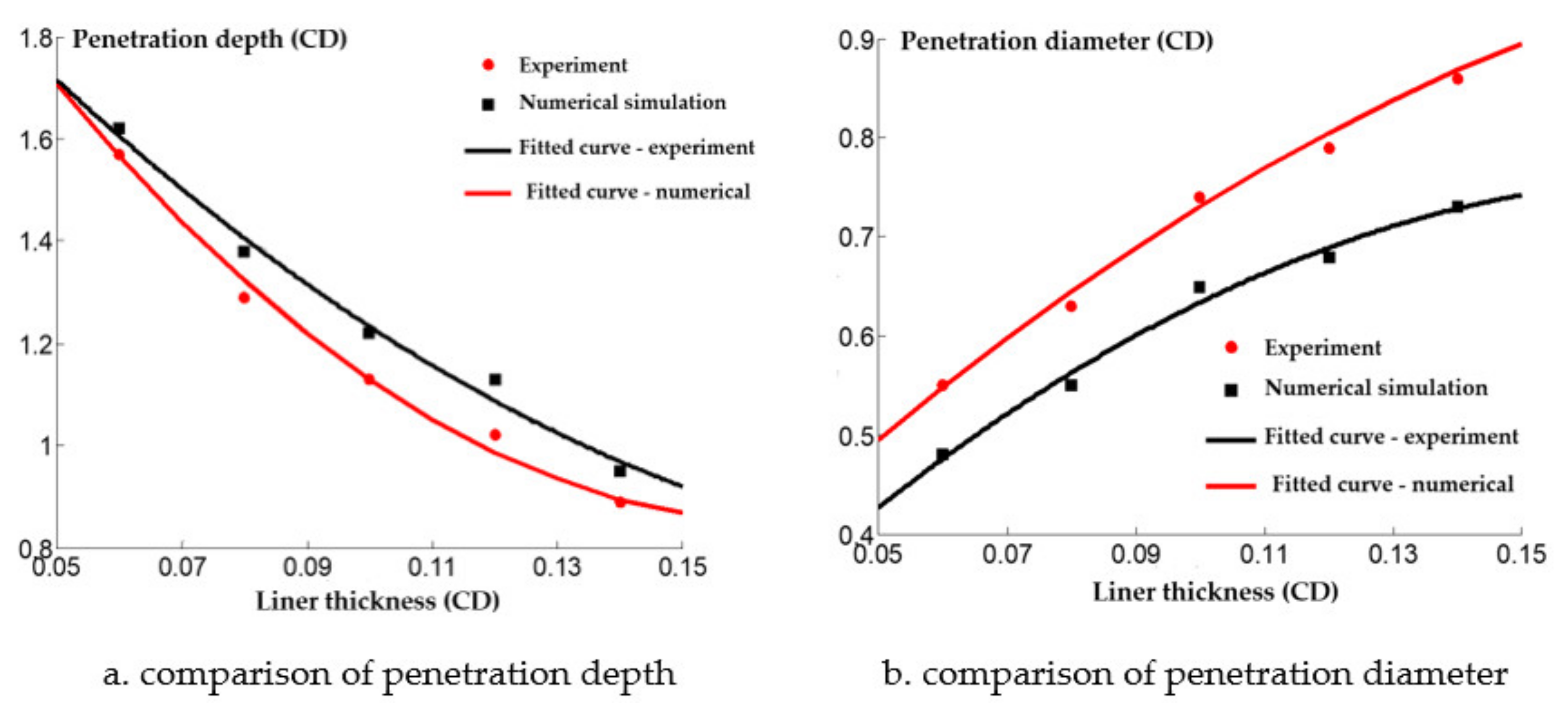

3.4. Influence of the Reactive Charge Liner’s Wall Thickness on Damage Effect

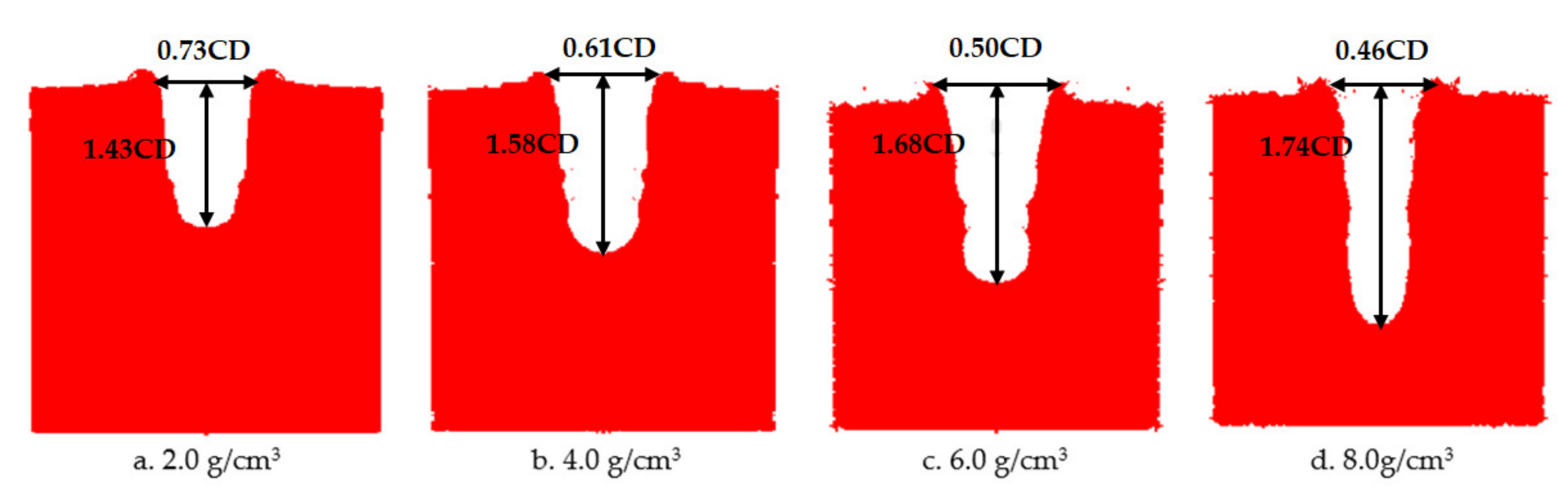

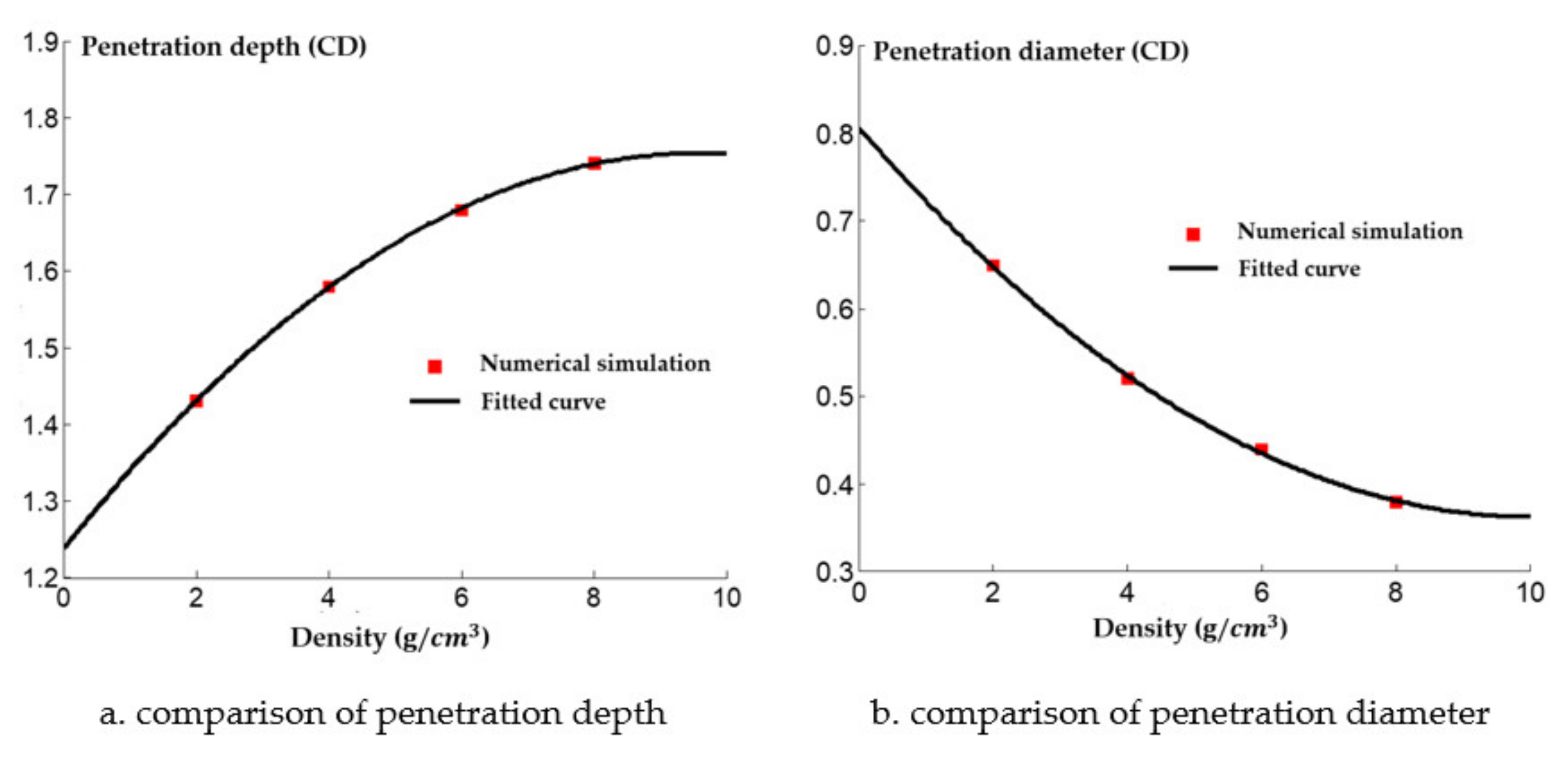

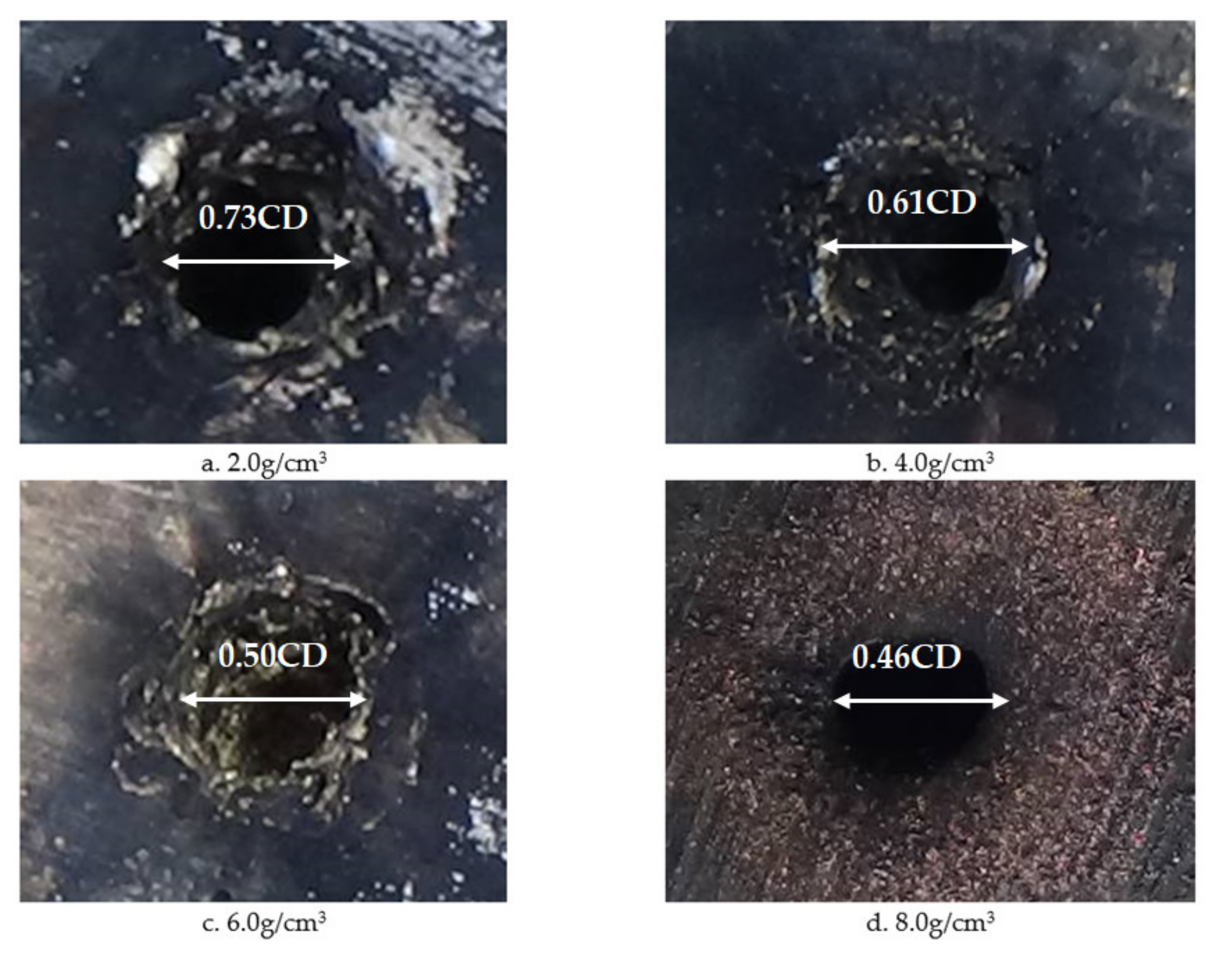

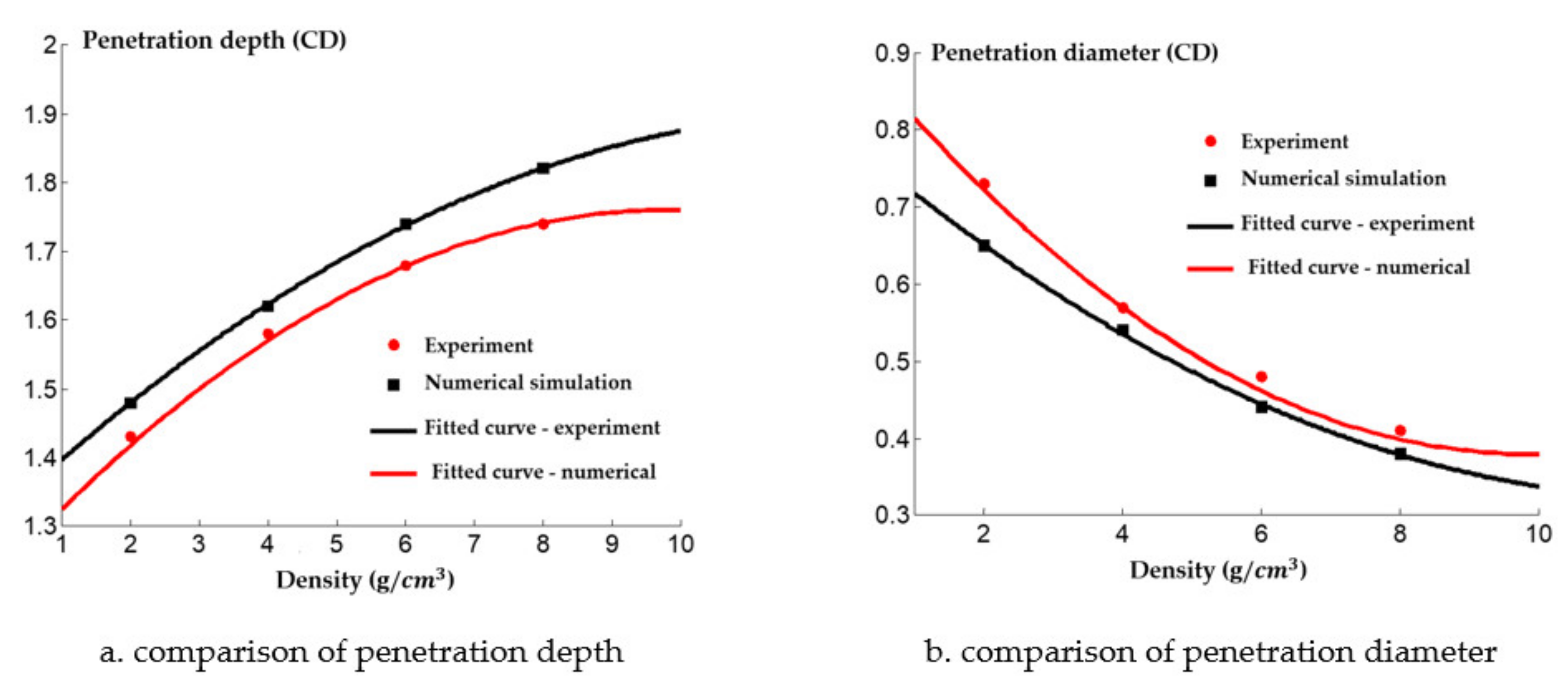

3.5. Influence of the Reactive Charge Liner Density on the Damage Effect

4. Conclusions

- (1)

- Based on the finite software autodyn-2d, structural parameters of the reactive charge liner were numerically simulated and our results show that the optimal cone angle of the reactive charge liner is 55°, and the optimal wall thickness of the reactive charge liner is 0.1 times the charge diameter. In addition, the influence of the performance of the reactive material and the blasting height on the penetration ability of the reactive jet was also studied, and the density of the reactive material was 2.3 g/cm3. The optimal explosive height was about 1.5 times the charge diameter.

- (2)

- The numerical simulation results were verified by the static explosion experiment, and the numerical simulation results were consistent with the experimental results, which verifies the effectiveness of the numerical simulation. However, there were some differences between the numerical simulation and experimental values. The reason for the difference was that the reactive material was treated as an inert material in the numerical simulation. In fact, the reactive jet will be activated and explode during the penetration process, which has a certain impact on the penetration ability of the reactive jet.

- (3)

- Compared with a metal jet, the penetration depth of the steel target with the reactive jet was significantly reduced, but the diameter of the steel target with the reactive jet was larger, and had a stronger burst damage effect. This shows that the reactive jet has more power to damage than a metal jet when it is used to tackle light- and medium-armored targets.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Raftenberg, M.N.; Mock, W.; Kirby, G.C. Modeling the Impact Deformation of Rods of a Pressed PTFE/Al Composite Mixture. Int. J. Impact Eng. 2008, 35, 1735–1744. [Google Scholar] [CrossRef]

- Chang, B.H.; Yin, J.P.; Cui, Z.Q.; Liu, T.X. Numerical simulation of modified low-density jet penetrating shell charge. Int. J. Simul. Model 2015, 14, 426–437. [Google Scholar] [CrossRef]

- Baker, E.L.; Daniels, A.S.; Ng, K.W.; Martin, V.O.; Orosz, J.P. Barnie: A unitary demolition warhead. In Proceedings of the 19th International Symposium on Ballistics, Interlaken, Switzerland, 7–11 May 2001. [Google Scholar]

- Nicolich, S. Rereactive materials enhanced lethality EFP. In Proceedings of the 42nd Annual Armament Systems: Gun and Missile Systems Conference and Exhibition, Charlotte, NC, USA, 23–26 April 2007; National Defence Industrial Association: Arlington, VA, USA, 2007. [Google Scholar]

- Daniels, A.S.; Baker, E.L.; De Fisher, S.E.; Ng, K.W.; Pham, J. Bam bam: Large scale unitary demolition warheads. In Proceedings of the 23rd International Symposium on Ballistics, Tarragona, Spain, 16–20 April 2007. [Google Scholar]

- Cai, X.; Zhang, W.; Xie, W.; Ni, Y.; Li, D.; Sun, Y. Initiation and energy release characteristics studies on polymer bonded explosive materials under high speed impact. Mater. Des. 2015, 68, 18–23. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhang, J.; Qiao, L. Experimental study of the compression properties of Al/W/PTFE granular composites under elevated strain rates. Mater. Sci. Eng. A 2013, 581, 48–55. [Google Scholar] [CrossRef]

- Xiao, J.G.; Zhang, X.P.; Wang, Y.Z.; Xu, F.Y.; Wang, H.F. Demolition mechanism and behavior of shaped charge with rereactive liner. Propellants Explos. Pyrotech. 2016, 41, 612–617. [Google Scholar] [CrossRef]

- Xiao, J.G.; Zhang, X.P.; Guo, Z.X.; Wang, H.F. Enhanced damage effects of multi-layered concrete target produced by rereactive materials liner. Propellants Explos. Pyrotech. 2018, 43, 955–961. [Google Scholar] [CrossRef]

- Zhang, X.P.; Xiao, J.G.; Yu, Q.B.; Zheng, Y.F.; Wang, H.F. Armor penetration aftereffect overpressure produced by rereactive material liner shaped charge. Acta Armamentarii 2016, 37, 1388–1394. [Google Scholar]

- Guo, H.G.; Zheng, Y.F.; Tang, L.; Yu, Q.B.; Ge, C.; Wang, H.F. Effect of wave shaper on rereactive materials jet formation and its penetration performance. Def. Technol. 2019, 15, 495–505. [Google Scholar] [CrossRef]

- Verreault, J. Analytical and numerical description of the PELE fragmentation upon impact with thin target plates. Int. J. Impact Eng. 2015, 76, 196–206. [Google Scholar] [CrossRef]

- Jiang, J.-W. Modeling and Simulation of JWL Equation of State for Reactive Al/PTFE Mixture. Beijing Inst. Technol. 2012, 21, 150–156. [Google Scholar]

- Hunt, E.M.; Malcolm, S.; Pantoya, M.L.; Davis, F. Impact Ignition of Nano and Micron Composite Energetic Materials. Int. J. Impact Eng. 2009, 36, 842–846. [Google Scholar] [CrossRef]

- Guo, H.G.; Zheng, Y.F.; Yu, Q.B.; Ge, C.; Wang, H.F. Penetration behavior of rereactive liner shaped charge jet impacting steel plates. Int. J. Impact Eng. 2019, 126, 76–84. [Google Scholar] [CrossRef]

- Held, M. Dynamic plate thickness of era sandwiches against shaped charge jets. Propellants Explos. Pyrotech. 2004, 29, 244–246. [Google Scholar] [CrossRef]

- Held, M. Time distance diagram of the jet initation of covered high explosive charges. Int. J. Impact Eng. 2007, 34, 702–707. [Google Scholar] [CrossRef]

- Hussain, T.; Liu, Y.; Huang, F.L. Preshock desensitization phenomena during initiation of covered heterogeneous explosives by shaped charge jets. J. Energetic Mater. 2016, 34, 152–169. [Google Scholar] [CrossRef]

- Mickovic, D.; Jaramaz, S.; Elek, P.; Miloradovic, N. A model for explosive rereactive armor interaction with shaped charge jet. Propellants Explos. Pyrotech. 2016, 41, 53–61. [Google Scholar] [CrossRef]

- Pyka, D.; Kurzawa, A. Numerical and experimental studies of the Łk type shaped charge. Appl. Sci. 2020, 10, 6742. [Google Scholar] [CrossRef]

- Żochowski, P.; Warchoł, R.; Miszczak, M.; Nita, M.; Pankowski, Z.; Bajkowski, M. Experimental and Numerical Study on the PG-7VM Warhead Performance against High-Hardness Armor Steel. Materials 2021, 14, 3020. [Google Scholar] [CrossRef]

- Feng, B.; Fang, X.; Li, C.; Wang, H.X.; Mao, S.; Wu, Z. An initiation phenomenon of Al-PTFE under quasi-static compression. Chem. Phys. Lett. 2015, 637, 38–41. [Google Scholar] [CrossRef]

- Kobylkin, I.F. Detonation initiation in shielded thin layers of explosives by shaped-charge jets. Combust. Explos. Shock Waves 2015, 51, 358–365. [Google Scholar] [CrossRef]

- Chang, B.H.; Yin, J.P.; Cui, Z.Q.; Liu, T.X. Improved dynamic mechanical properties of modified PTFE jet penetrating charge with shell. Strength Mater. 2016, 48, 82–89. [Google Scholar] [CrossRef]

- Yi, J.Y.; Wang, Z.J.; Yin, J.P.; Chang, B.H. Numerical simulation of steel target penetration by shaped charge distended jet with a high-polymer liner. Strength Mater. 2017, 49, 27–36. [Google Scholar] [CrossRef]

- Yi, J.Y.; Wang, Z.J.; Yin, J.P. Simulation Study on Expansive Jet Formation Characteristics of Polymer Liner. Materials 2019, 12, 744. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yi, J.Y.; Wang, Z.J. Damage characteristics of polymer expansive jet based on the crater growth enhanced effect. Mater. Express 2019, 9, 732–740. [Google Scholar] [CrossRef]

- Smestada, E.; Moxnesb, J.F.; Degardstuena, G. Modelling of Deflagration, establishing Material Data into ANSYS AUTODYN’s Powder Burn Model. In Proceedings of the International Annual Conference–Fraunhofer Institute Chemical Technology, Karlsruhe, Germany, 26–29 June 2012. [Google Scholar]

| Materials | State Equation | Strength Model | Failure Model | Density (g/cm3) |

|---|---|---|---|---|

| Air | Ideal Gas | — | — | 1.225 × 10−3 |

| 45# steel | Shock | Johnson–Cook | None | 7.896 |

| 8701 | JWL | None | None | 1.680 |

| PTFE/Al | Shock | Johnson–Cook | None | 2.340 |

| PTFE/Al | Powder Burn | Johnson–Cook | None | 2.270 |

| Angle (°) | Wall Thickness | Density (g/cm3) | Stand-Off | Target (mm) | Penetration Depth | Perforation Diameter |

|---|---|---|---|---|---|---|

| 45 | 0.1 | 2.3 | 1 | Φ200 × 200 | 1.43 | 0.53 |

| 50 | 1.28 | 0.61 | ||||

| 55 | 1.18 | 0.70 | ||||

| 60 | 0.92 | 0.76 | ||||

| 65 | 0.83 | 0.82 |

| Angle (°) | Wall Thickness | Density (g/cm3) | Stand-Off | Target (mm) | Penetration Depth | Perforation Diameter |

|---|---|---|---|---|---|---|

| 55 | 0.06 | 2.3 | 1 | Φ200 × 200 | 1.57 | 0.55 |

| 0.08 | 1.41 | 0.63 | ||||

| 0.10 | 1.18 | 0.74 | ||||

| 0.12 | 1.02 | 0.79 | ||||

| 0.14 | 0.89 | 0.86 |

| Angle (°) | Wall Thickness | Density (g/cm3) | Stand-Off | Target (mm) | Penetration Depth | Perforation Diameter |

|---|---|---|---|---|---|---|

| 55 | 0.1 | 2.0 | 1 | Φ200 × 200 | 1.43 | 0.73 |

| 4.0 | 1.58 | 0.61 | ||||

| 6.0 | 1.68 | 0.50 | ||||

| 8.0 | 1.74 | 0.46 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Wang, Z.; Yin, J.; Yi, J.; Wang, H. Damage Mechanism of PTFE/Al Reactive Charge Liner Structural Parameters on a Steel Target. Materials 2021, 14, 3701. https://doi.org/10.3390/ma14133701

Zhang X, Wang Z, Yin J, Yi J, Wang H. Damage Mechanism of PTFE/Al Reactive Charge Liner Structural Parameters on a Steel Target. Materials. 2021; 14(13):3701. https://doi.org/10.3390/ma14133701

Chicago/Turabian StyleZhang, Xuepeng, Zhijun Wang, Jianping Yin, Jianya Yi, and Haifu Wang. 2021. "Damage Mechanism of PTFE/Al Reactive Charge Liner Structural Parameters on a Steel Target" Materials 14, no. 13: 3701. https://doi.org/10.3390/ma14133701

APA StyleZhang, X., Wang, Z., Yin, J., Yi, J., & Wang, H. (2021). Damage Mechanism of PTFE/Al Reactive Charge Liner Structural Parameters on a Steel Target. Materials, 14(13), 3701. https://doi.org/10.3390/ma14133701