The Influence of Sheet Tilting on Forming Quality in Single Point Incremental Forming

Abstract

:1. Introduction

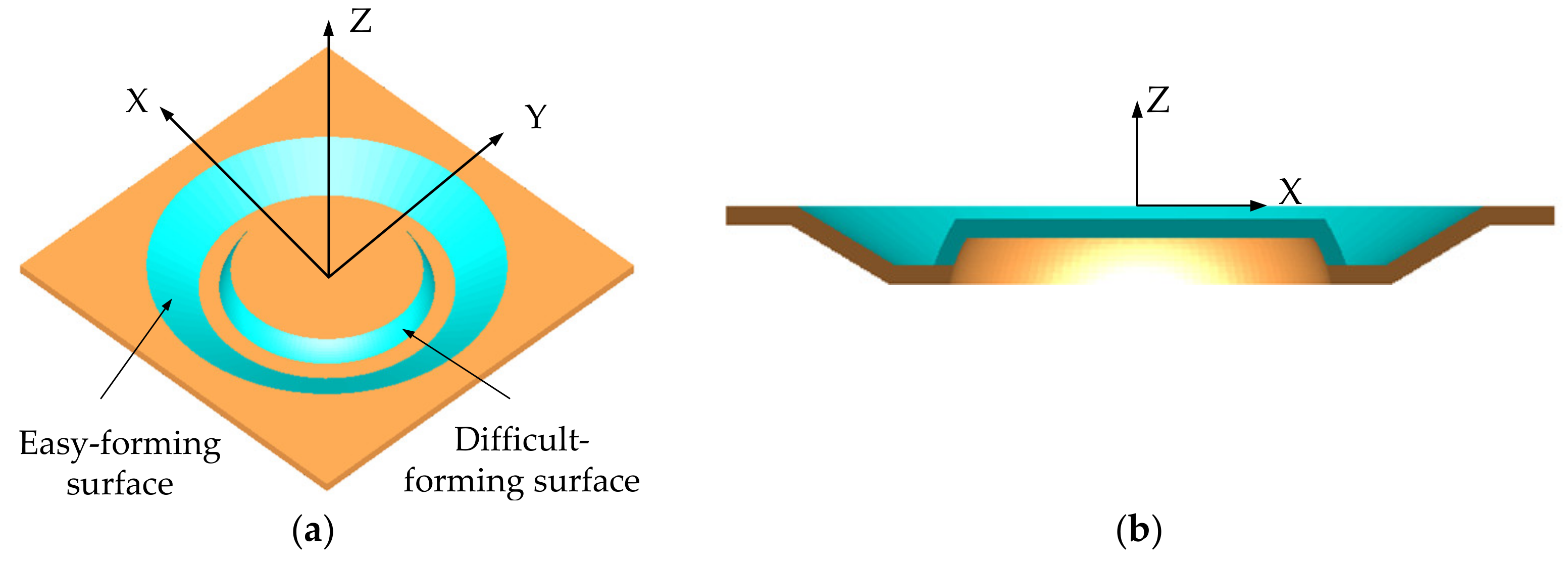

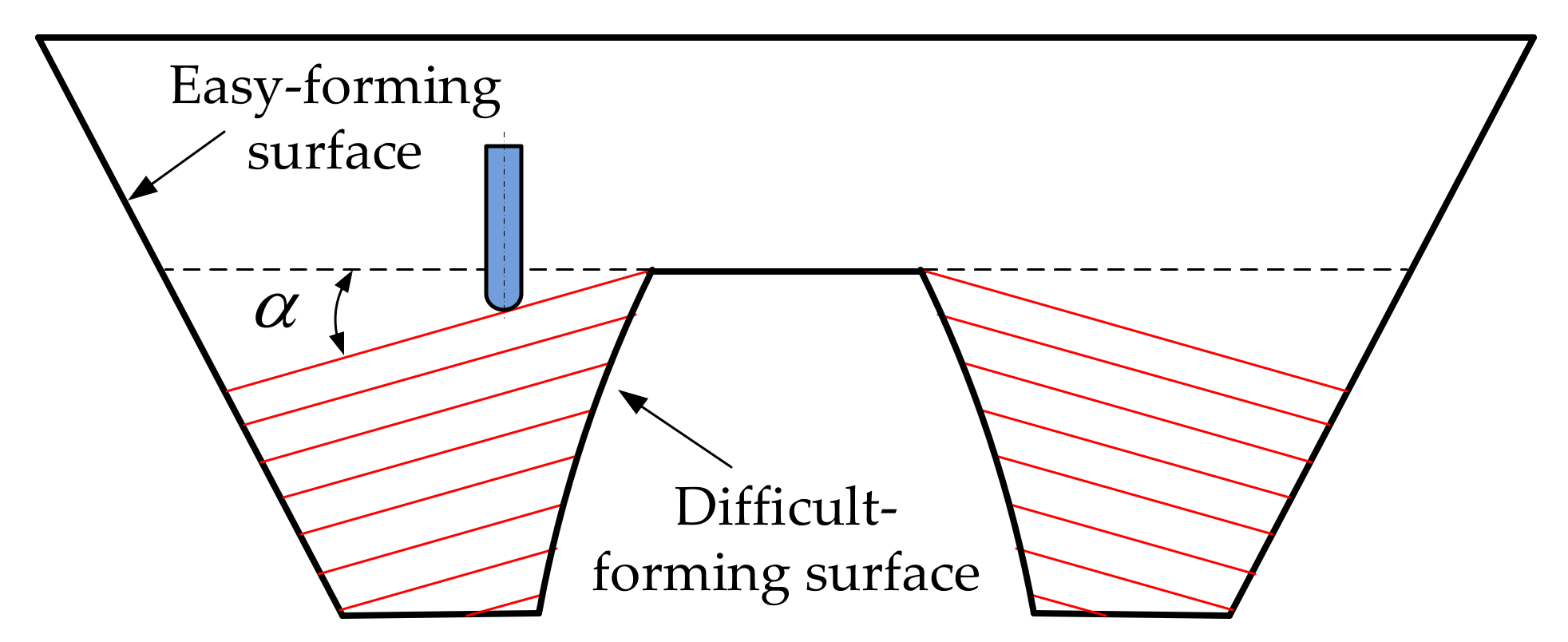

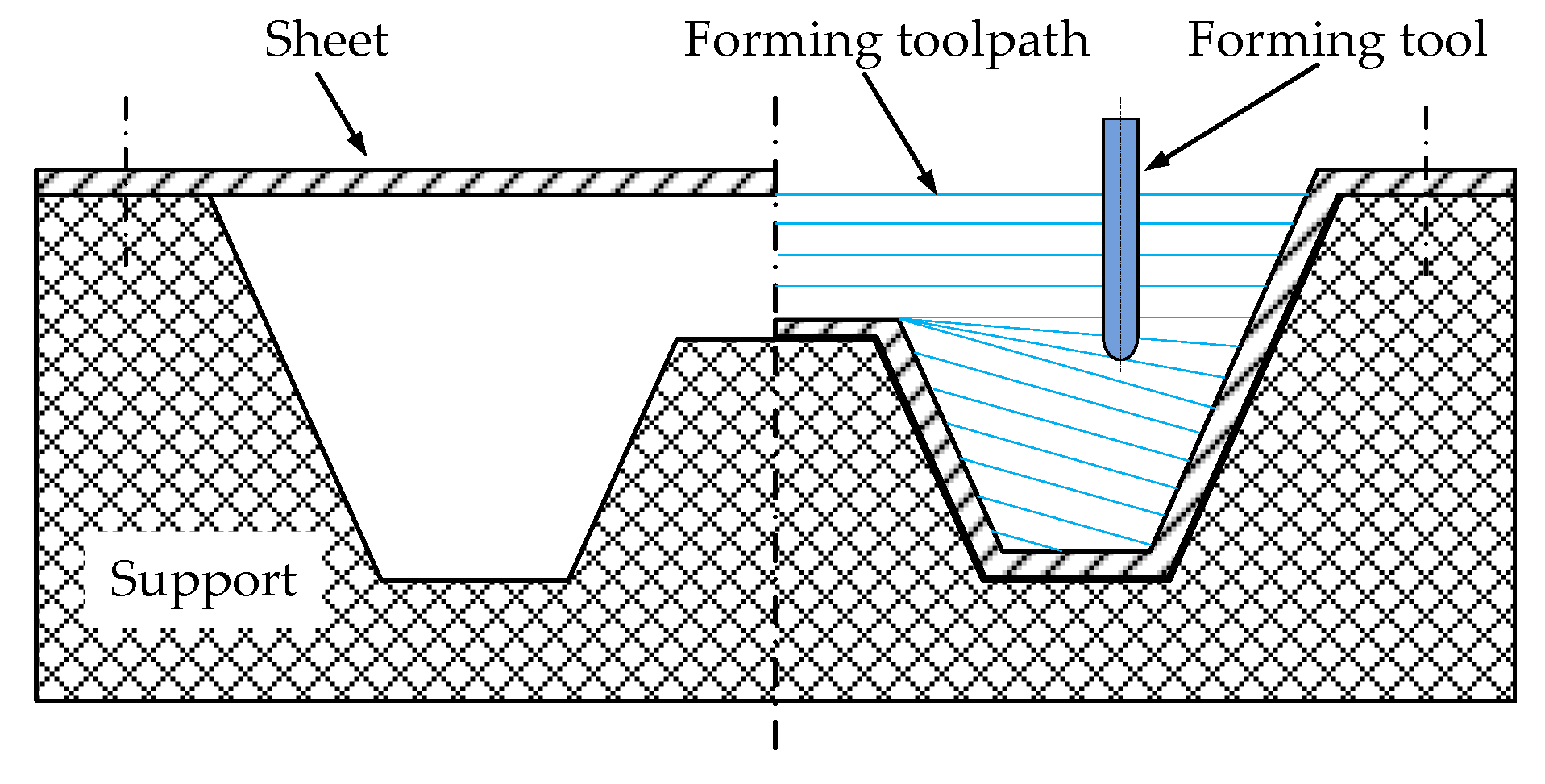

2. The General Method

3. Numerical Simulation

3.1. Parameter Setting of the Finite Element Numerical Simulation

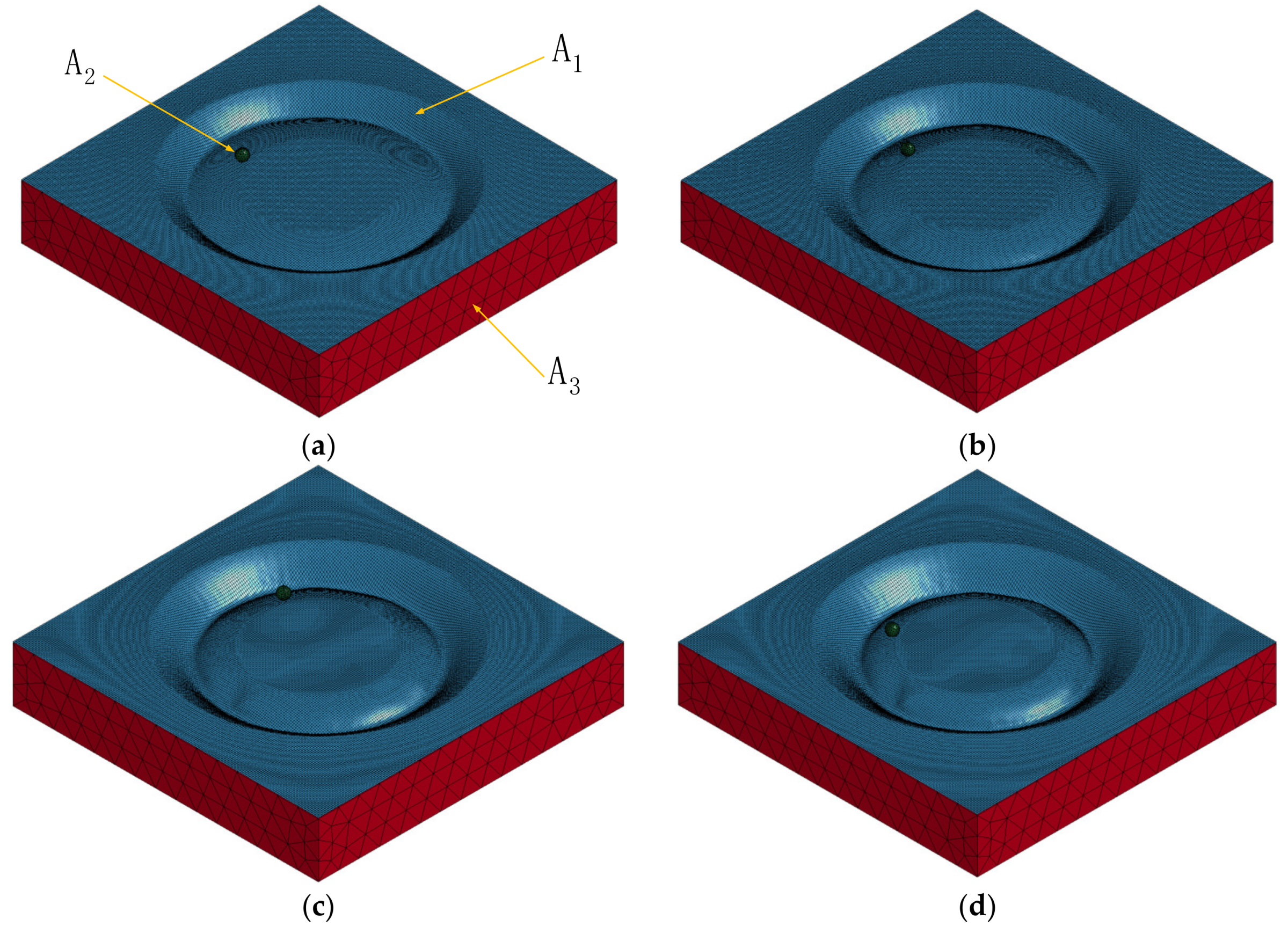

3.2. Analysis of the Finite Element Numerical Simulation Results

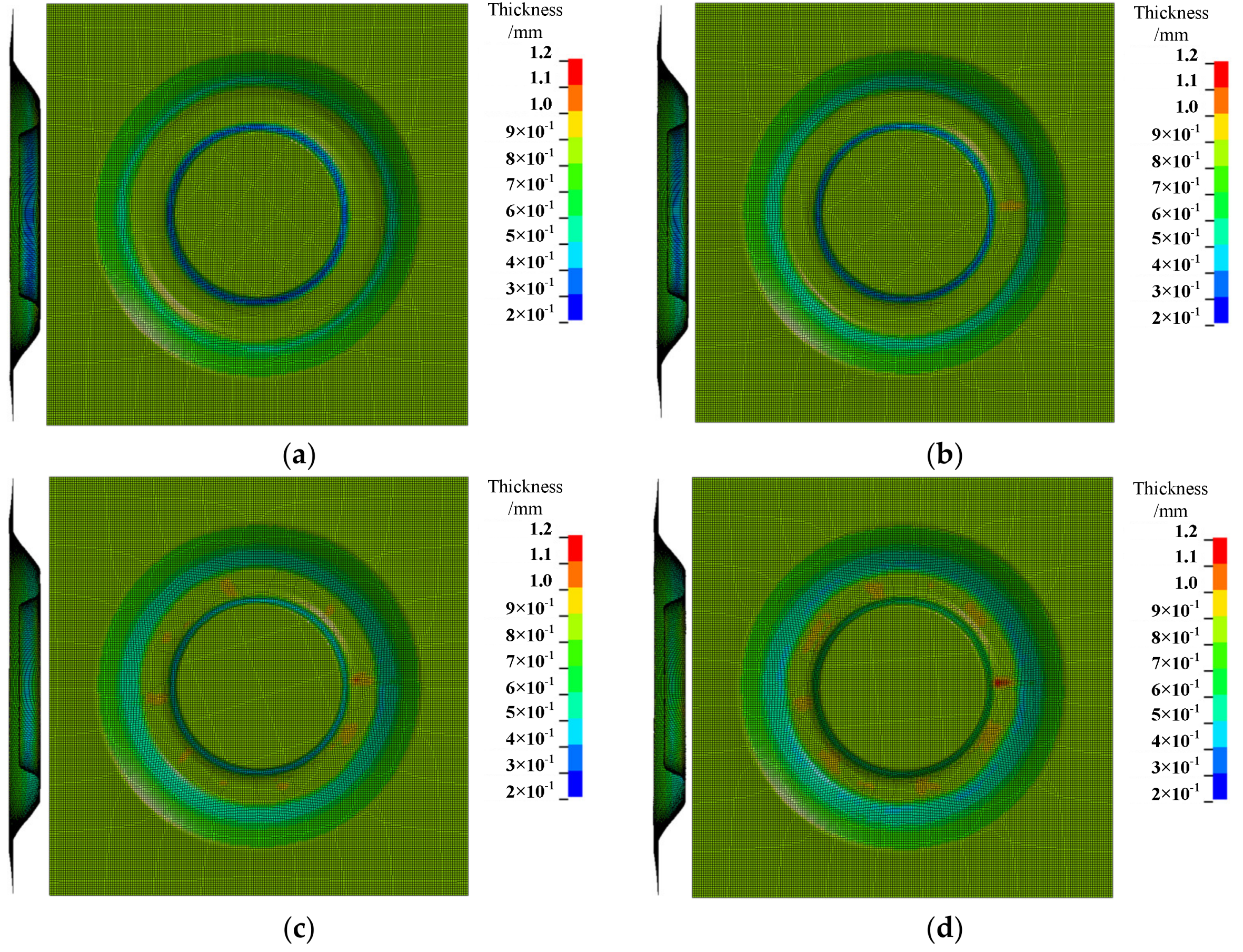

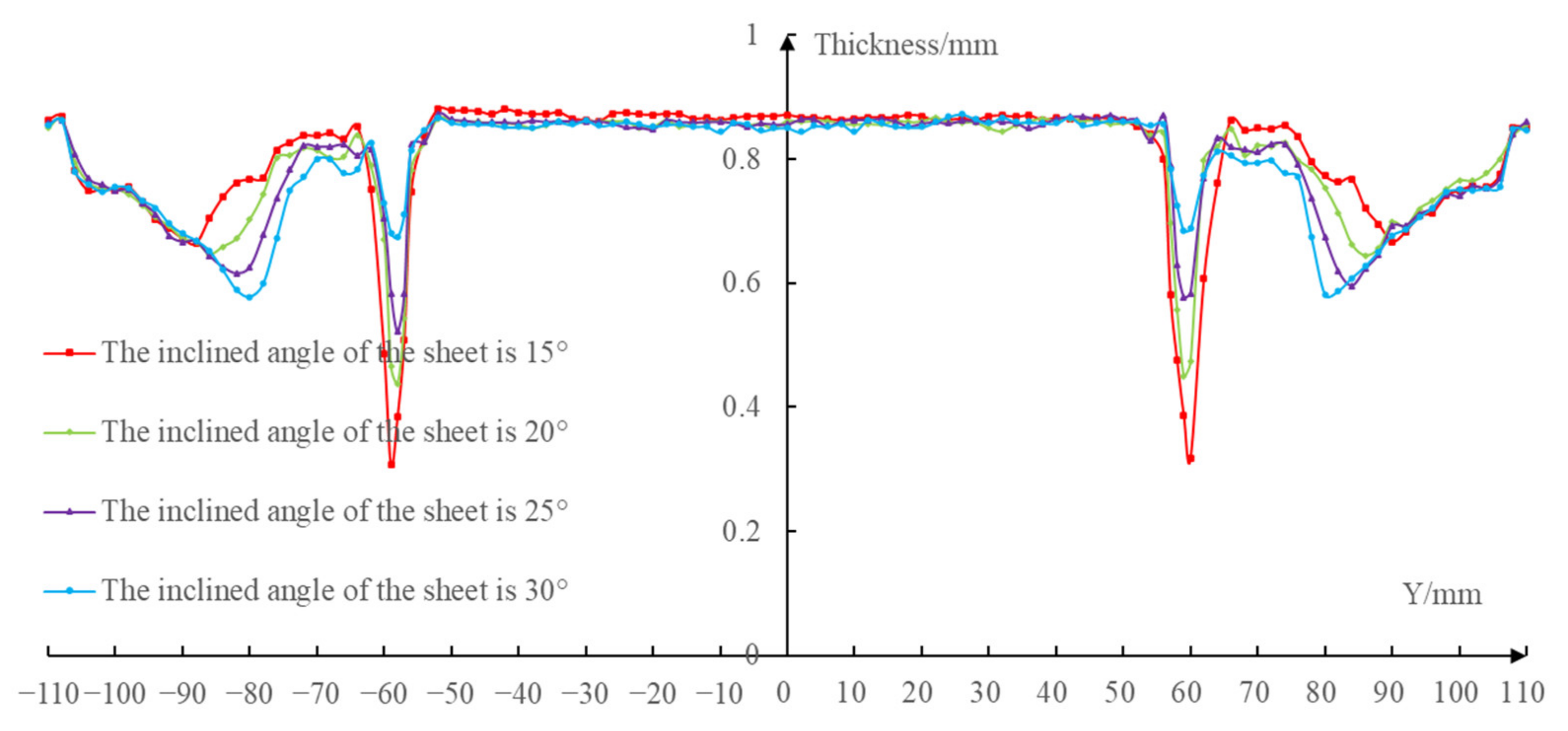

3.2.1. Thickness Distribution

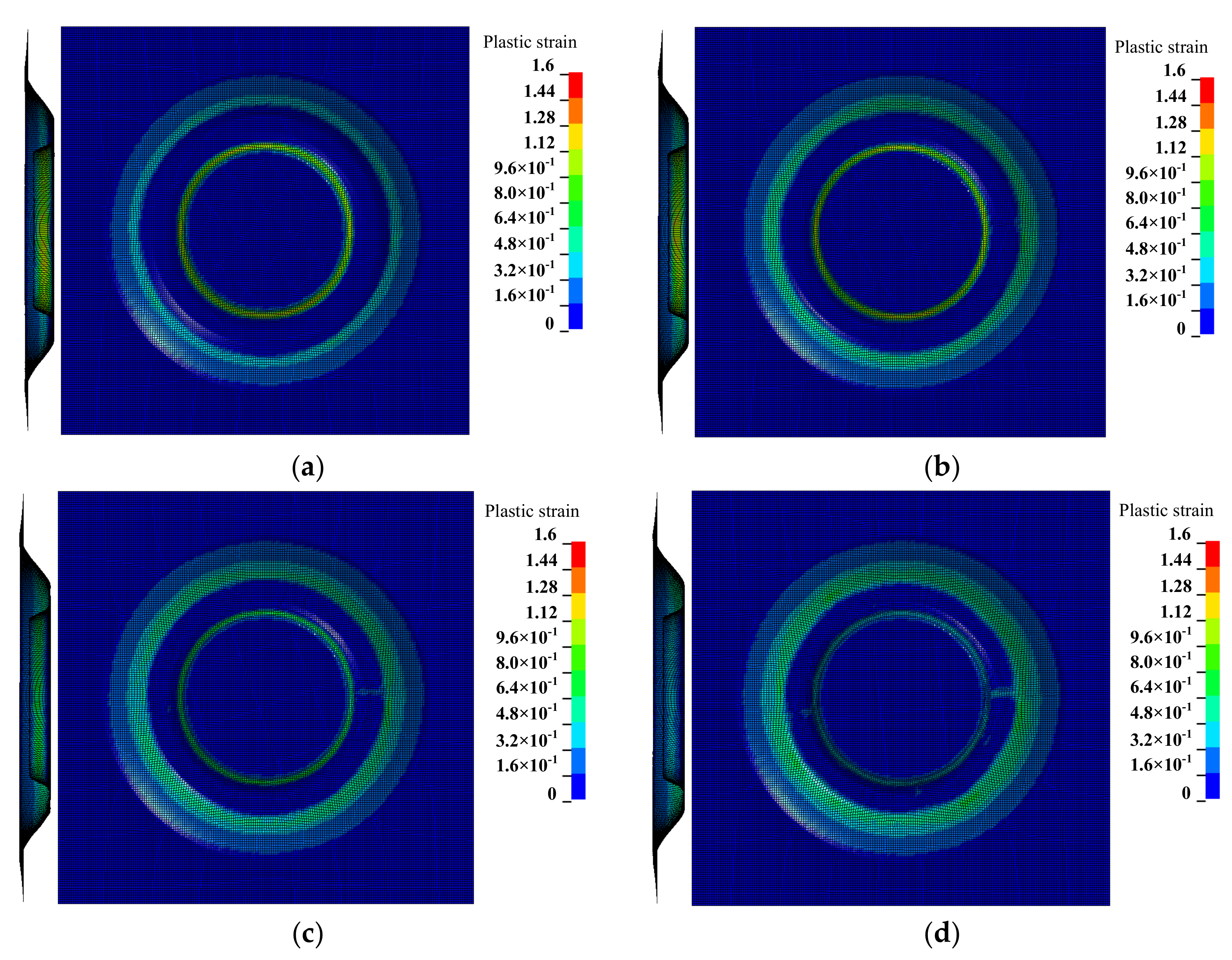

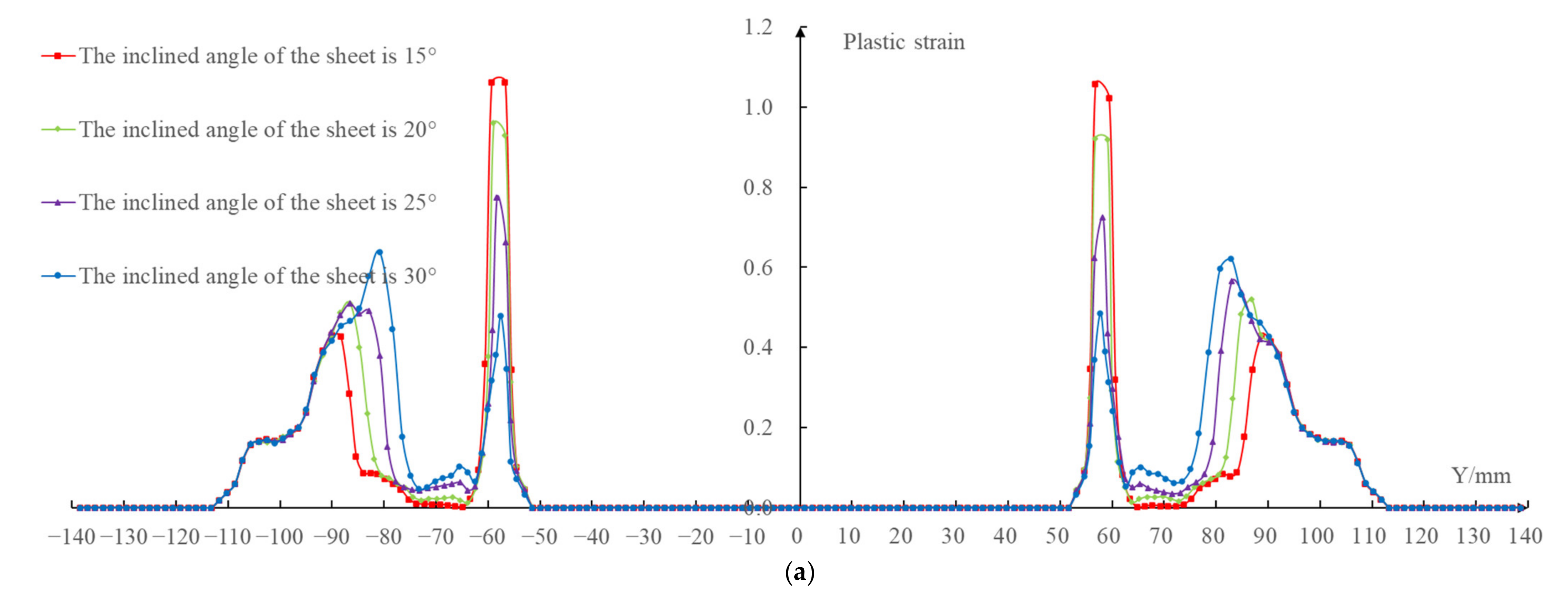

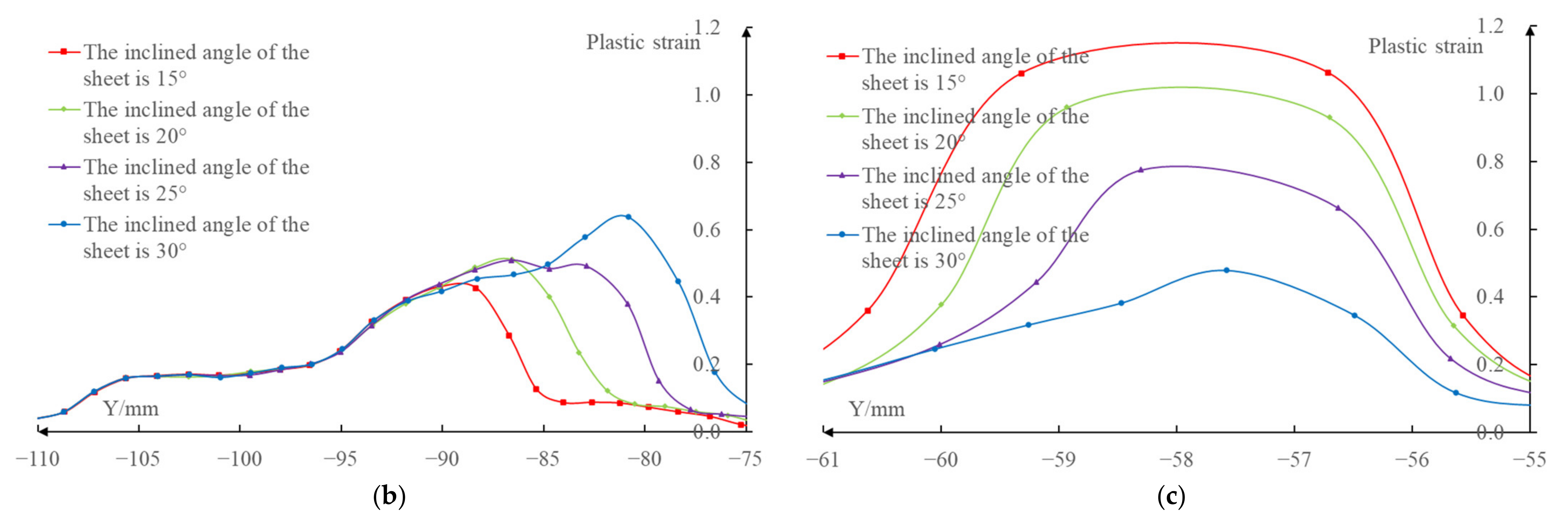

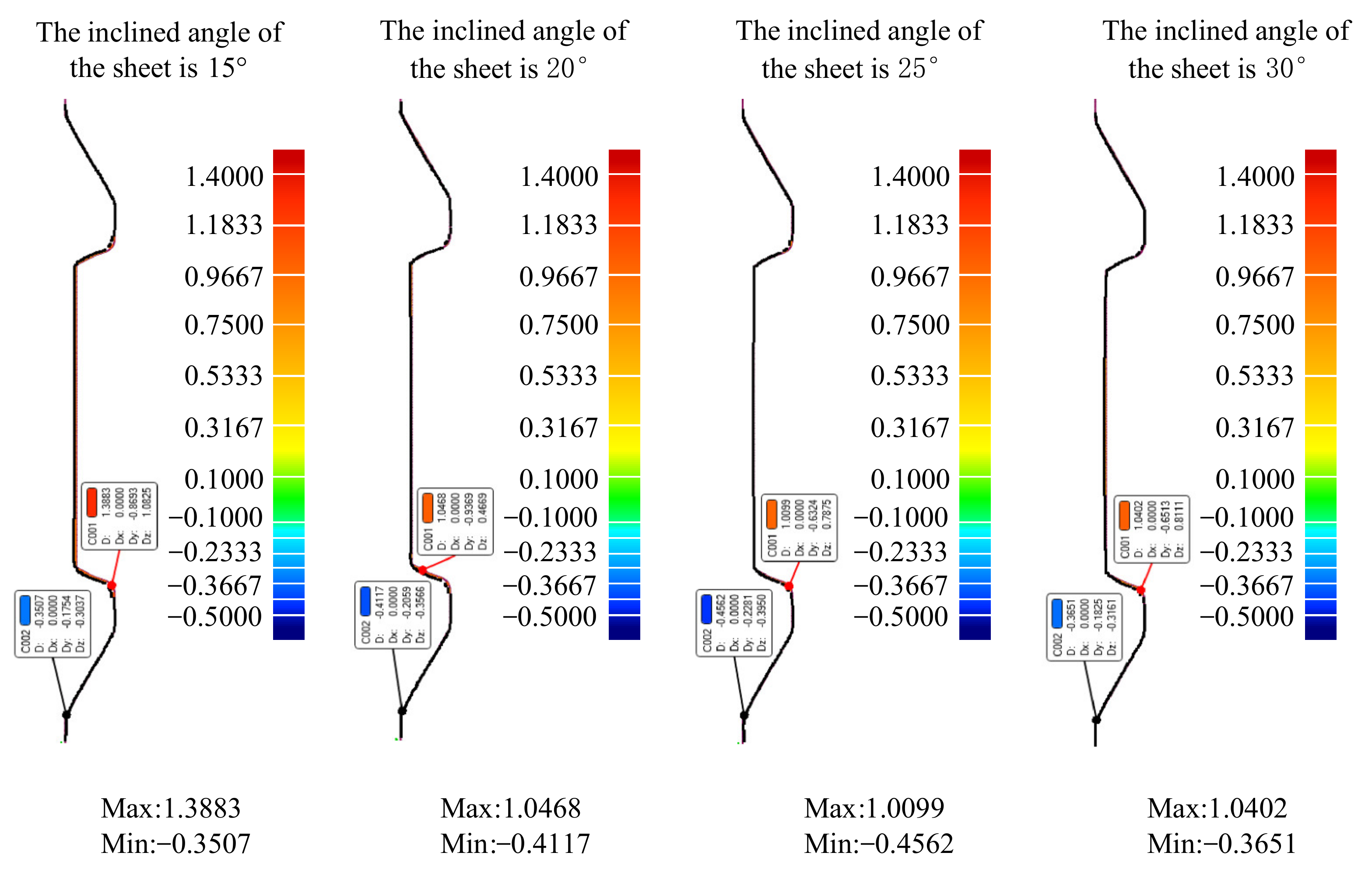

3.2.2. Plastic Strain

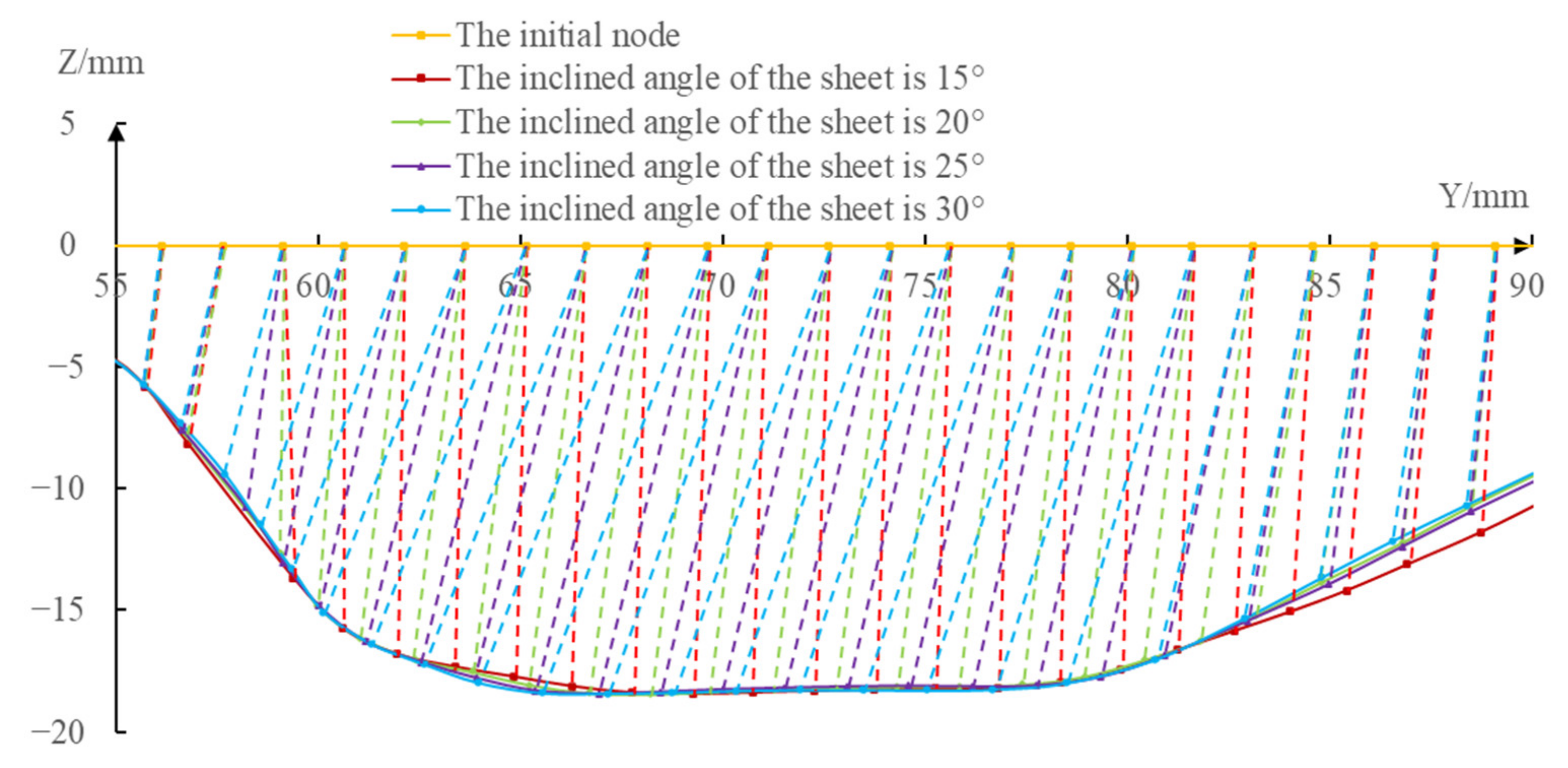

3.2.3. Material Flow

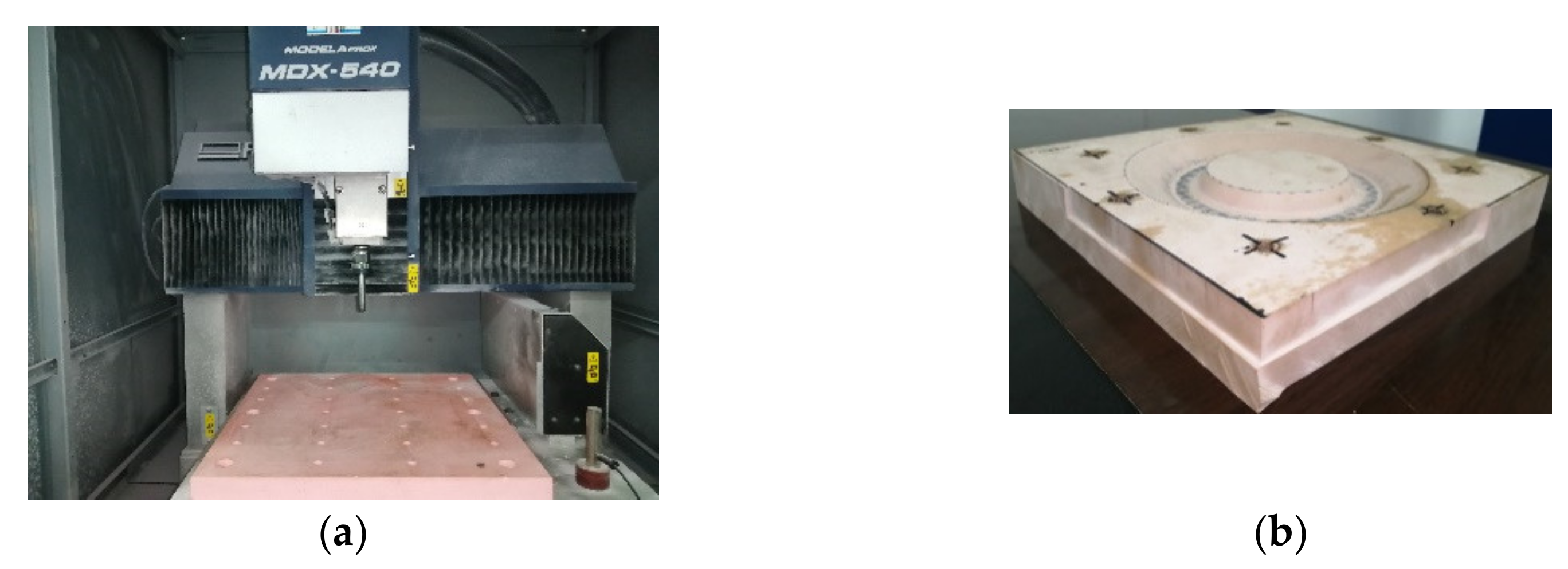

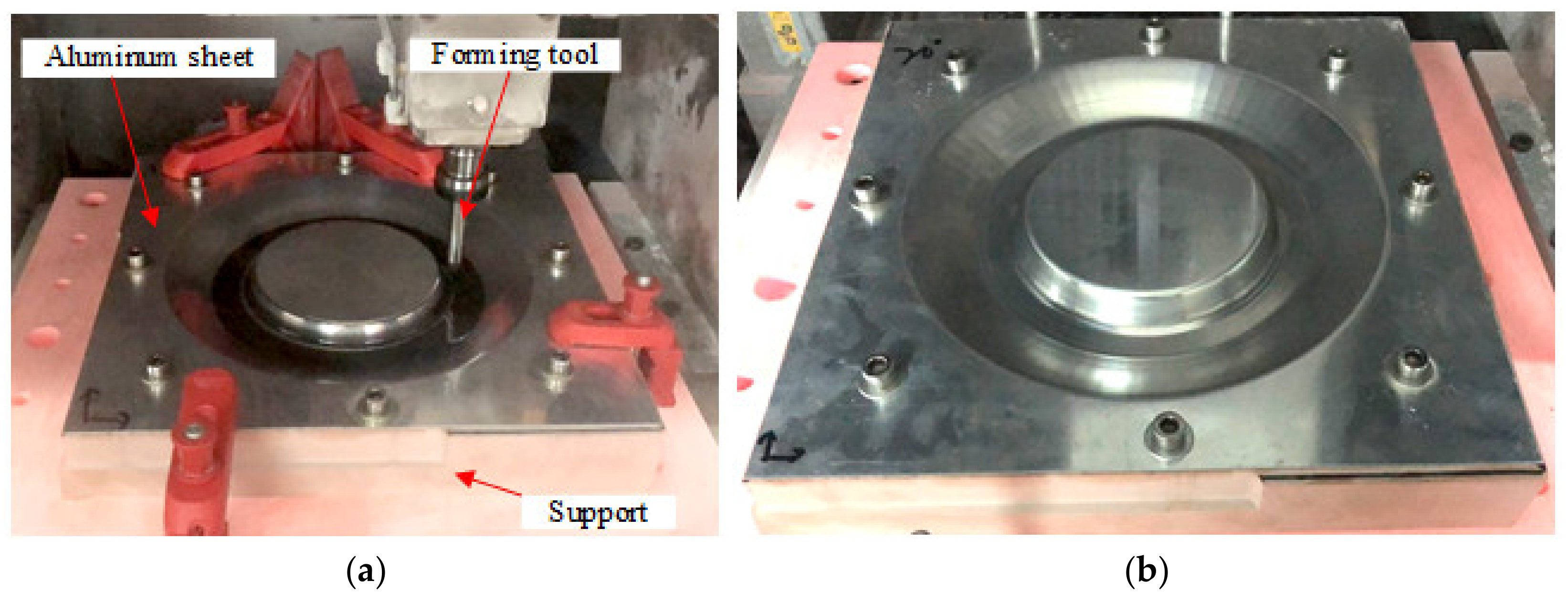

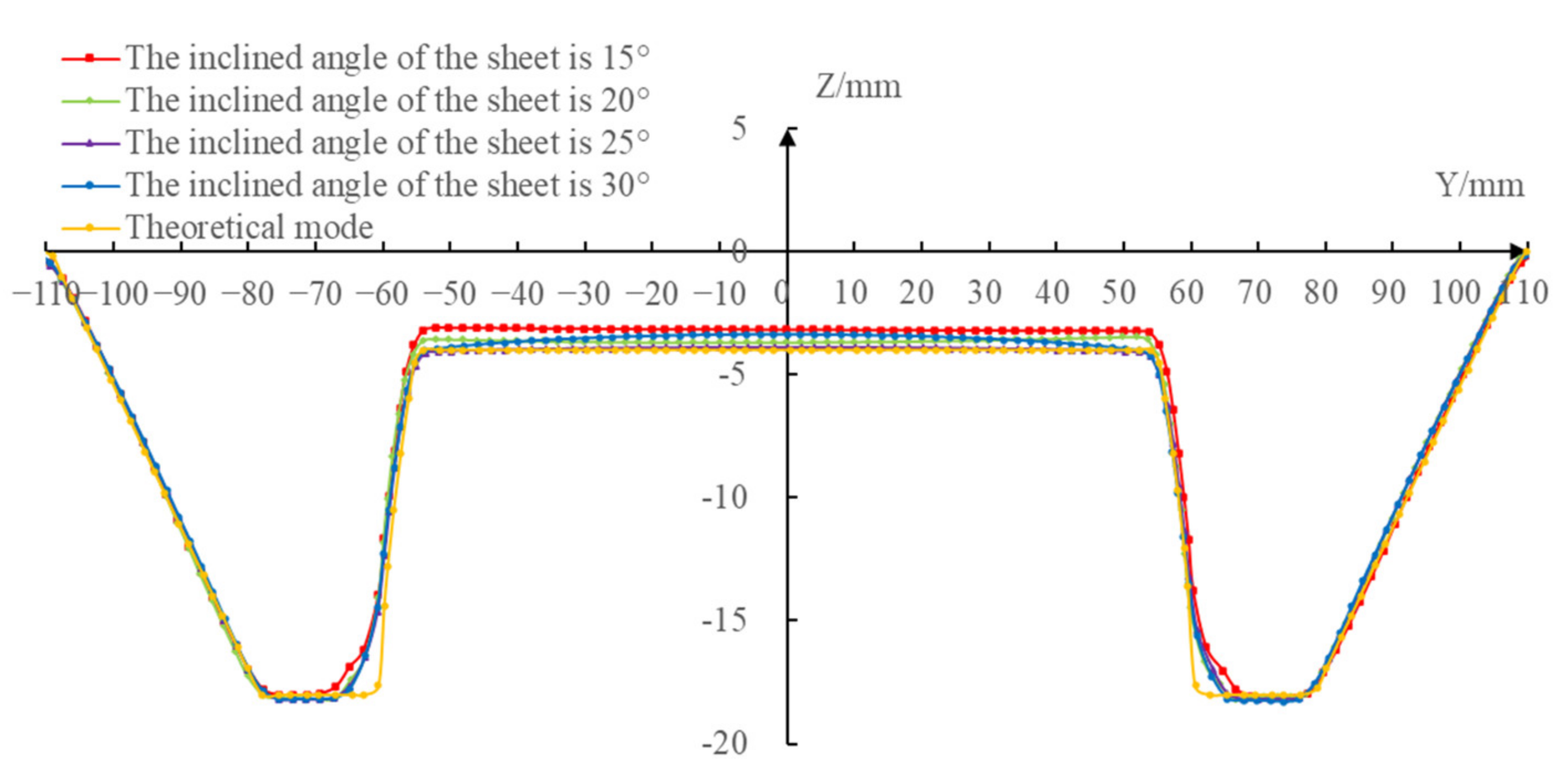

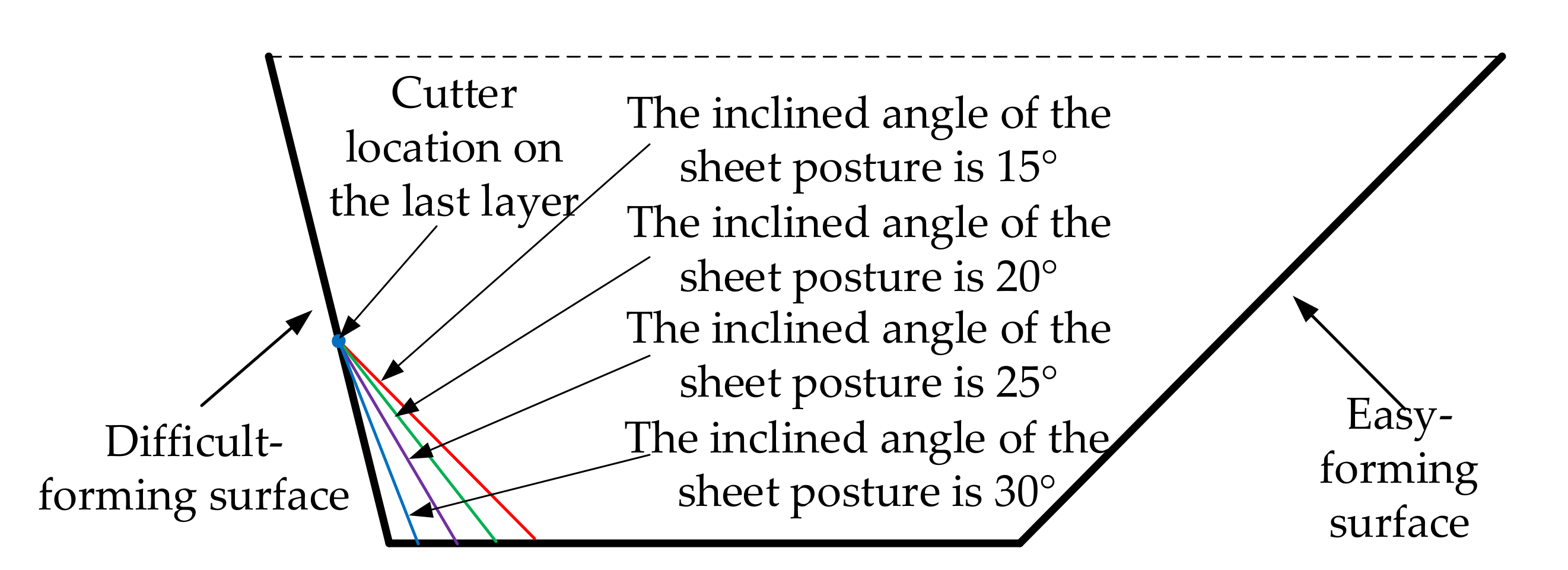

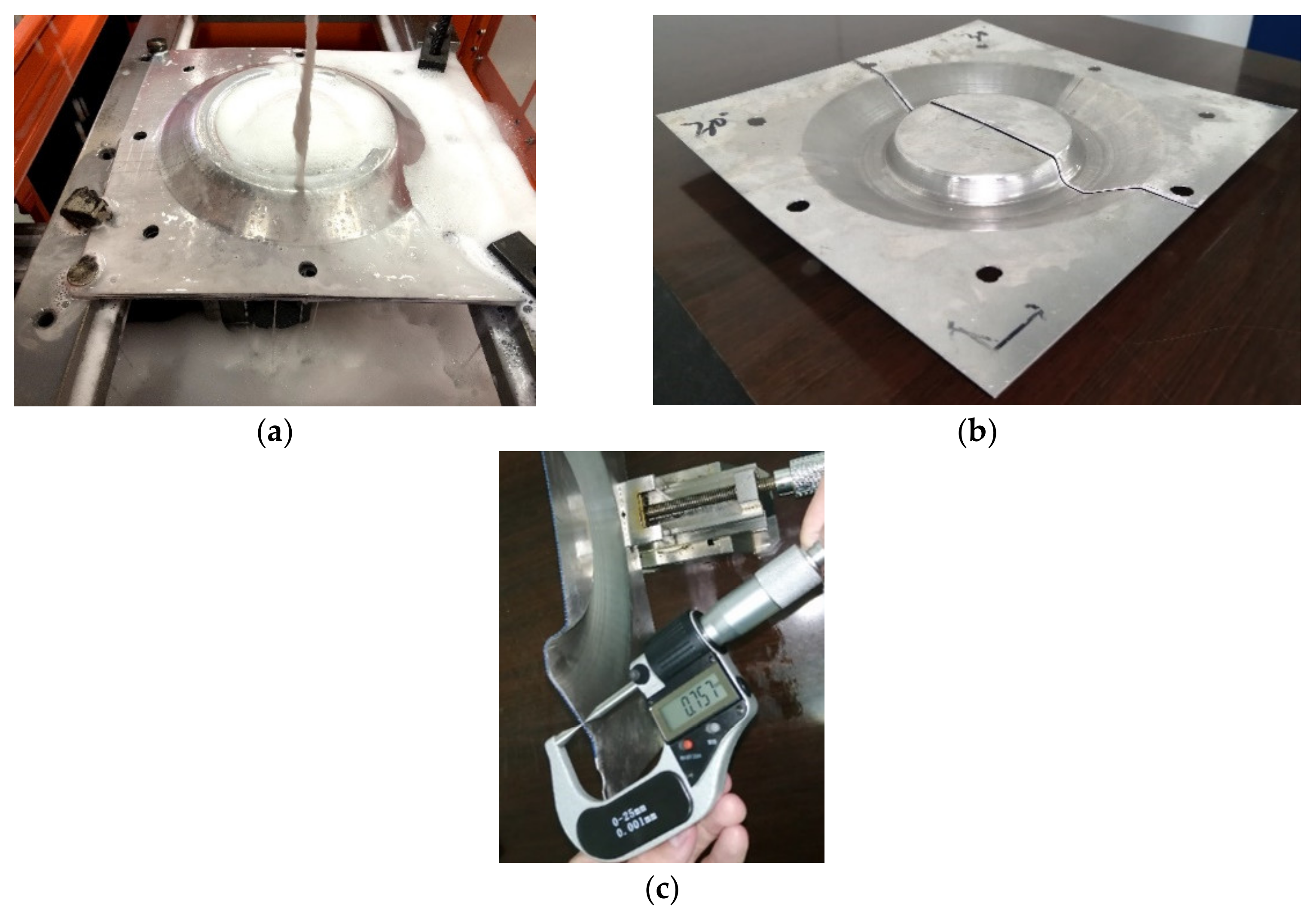

4. Forming Experiment

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jeswiet, J.; Adams, D.; Doolan, M. Single point and asymmetric incremental forming. Adv. Manuf. 2015, 3, 253–262. [Google Scholar] [CrossRef]

- Leacock, A.G. The future of sheet metal forming research. Mater. Manuf. Process. 2012, 27, 366–369. [Google Scholar] [CrossRef]

- Duflou, J.R.; Habraken, A.M.; Cao, J. Single point incremental forming: State-of-the-art and prospects. Int. J. Mater. Form. 2018, 11, 743–773. [Google Scholar] [CrossRef]

- Li, Y.; Chen, X.; Liu, Z. A review on the recent development of incremental sheet-forming process. Int. J. Adv. Manuf. Technol. 2017, 92, 2439–2462. [Google Scholar] [CrossRef]

- Behera, A.K.; De Sousa, R.A.; Ingarao, G. Single point incremental forming: An assessment of the progress and technology trends from 2005 to 2015. J. Manuf. Process. 2017, 27, 37–62. [Google Scholar] [CrossRef] [Green Version]

- Ambrogio, G.; Filice, L.; Gaudioso, M.; Manco, G.L. Optimized tool-path design to reduce thinning in ISF process. Int. J. Mater. Form. 2010, 3, 959–962. [Google Scholar] [CrossRef]

- Jeswiet, J.; Micari, F.; Hirt, G. Asymmetric single point incremental forming of sheet metal. CIRP Ann. 2005, 54, 88–114. [Google Scholar] [CrossRef]

- Vignesh, G.; Pandivelan, C.; Narayanan, C.S. Review on multi-stage incremental forming process to form vertical walled cup. Mater. Today Proceed. 2020, 27, 2297–2302. [Google Scholar] [CrossRef]

- Kim, T.J.; Yang, D.Y. Improvement of formability for the incremental sheet metal forming process. Int. J. Mech. Sci. 2000, 42, 1271–1286. [Google Scholar] [CrossRef]

- Hirt, G.; Ames, J.; Bambach, M. Forming strategies and process modelling for CNC incremental sheet forming. CIRP Ann. 2004, 53, 203–206. [Google Scholar] [CrossRef]

- Gupta, P.; Szekeres, A.; Jeswiet, J. Design and development of an aerospace component with single-point incremental forming. Int. J. Adv. Manuf. Technol. 2019, 103, 3683–3702. [Google Scholar] [CrossRef]

- Zhou, L.R.; Zhou, Y.M.; Luo, Z.M. Study on forming method of vertical wall cylinder parts formed by multi-stage incremental forming. Mater. Res. Innov. 2015, 19, 102–104. [Google Scholar]

- Liu, Z.B.; Li, Y.L.; Meehan, P.A. Vertical wall formation and material flow control for incremental sheet forming by revisiting multistage deformation path strategies. Mater. Manuf. Process. 2013, 28, 562–571. [Google Scholar] [CrossRef]

- Skjoedt, M.; Bay, N.; Endelt, B. Multi stage strategies for single point incremental forming of a cup. J. Manuf. Process. 2008, 1, 1199–1202. [Google Scholar] [CrossRef]

- Duflou, J.R.; Verbert, J.; Belkassem, B. Process window enhancement for single point incremental forming through multi-step toolpaths. CIRP Ann. 2008, 57, 253–256. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.B.; Daniel, W.J.T.; Li, Y.L. Multi-pass deformation design for incremental sheet forming: Analytical modeling, finite element analysis and experimental validation. J. Mater. Process. Technol. 2014, 214, 620–634. [Google Scholar] [CrossRef] [Green Version]

- Dai, P.P.; Chang, Z.D.; Li, M. Reduction of geometric deviation by multi-pass incremental forming combined with tool path compensation for non-axisymmetric aluminum alloy component with stepped feature. Int. J. Adv. Manuf. Technol. 2019, 102, 809–817. [Google Scholar] [CrossRef]

- Nirala, H.K.; Agrawal, A. Residual stress inclusion in the incrementally formed geometry using Fractal Geometry Based Incremental Toolpath (FGBIT). J. Mater. Process. Technol. 2020, 279, 116623. [Google Scholar] [CrossRef]

- Li, Z.F.; Lu, S.H.; Chen, P. Improvement of dimensional accuracy based on multistage single point incremental forming of a straight wall cylinder part. Int. J. Precis. Eng. Manuf. 2017, 18, 1281–1286. [Google Scholar] [CrossRef]

- Li, Z.F.; Lu, S.H.; Zhang, T. Analysis of geometrical accuracy based on multistage single point incremental forming of a straight wall box part. Int. J. Adv. Manuf. Technol. 2017, 93, 2783–2789. [Google Scholar] [CrossRef]

- Lingam, R.; Bansal, A.; Reddy, N.V. Analytical prediction of formed geometry in multi-stage single point incremental forming. Int. J. Mater. Form. 2016, 9, 395–404. [Google Scholar] [CrossRef]

- Malhotra, R.; Bhattacharya, A.; Kumar, A. A new methodology for multi-pass single point incremental forming with mixed toolpaths. CIRP Ann. 2011, 60, 323–326. [Google Scholar] [CrossRef]

- Ndip-Agbor, E.; Cheng, P.; Moser, N. Prediction of rigid body motion in multi-pass single point incremental forming. J. Mater. Process. Technol. 2019, 269, 117–127. [Google Scholar] [CrossRef]

- Mostafanezhad, H.; Menghari, H.G.; Esmaeili, S. Optimization of two-point incremental forming process of AA1050 through response surface methodology. Measurement 2018, 127, 21–28. [Google Scholar] [CrossRef]

- Xiao, X.; Kim, J.J.; Hong, M.P. RSM and BPNN Modeling in incremental sheet forming process for AA5052 sheet: Multi-objective optimization using genetic algorithm. Metals 2020, 10, 1003. [Google Scholar] [CrossRef]

- Li, X.Q.; Han, K.; Xu, P.; Wang, H.B.; Li, D.S.; Li, Y.L.; Li, Q. Experimental and theoretical analysis of the thickness distribution in multistage two point incremental sheet forming. Int. J. Adv. Manuf. Technol. 2020, 107, 191–203. [Google Scholar] [CrossRef]

- Cao, T.T.; Lu, B.; Xu, D.K.; Zhang, H.; Chen, J.; Long, H.; Cao, J. An efficient method for thickness prediction in multi-pass incremental sheet forming. Int. J. Adv. Manuf. Technol. 2015, 77, 469–483. [Google Scholar] [CrossRef] [Green Version]

- Li, J.C.; Geng, P.; Shen, J.J. Numerical simulation and experimental investigation of multistage incremental sheet forming. Int. J. Adv. Manuf. Technol. 2013, 68, 2637–2644. [Google Scholar] [CrossRef]

- Vanhove, H.; Gu, J.; Sol, H.; Duflou, J.R. Process window extension for incremental forming through optimal work plane rotation. In Special Edition: 10th International Conference on Technology of Plasticity, ICTP 2011; KU Leuven: Aachen, Germany, 2011; pp. 508–512. [Google Scholar]

- Tanaka, S.; Hayakawa, K.; Nakamura, T. Incremental sheet forming with direction control of path planes. In Special Edition: 10th International Conference on Technology of Plasticity, ICTP 2011; KU Leuven: Aachen, Germany, 2011; pp. 503–507. [Google Scholar]

- Zhu, H.; Li, J.L. Research on the CNC incremental forming based on multidirectional real-time adjustment of the sheet posture. Int. J. Adv. Manuf. Technol. 2020, 110, 1339–1350. [Google Scholar] [CrossRef]

- Zhu, H.; Ju, J.; Bai, J.L. Sheet thickness homogenization in CNC incremental forming based on tilted forming path. Comput. Integr. Manuf. Syst. 2018, 24, 631–638. [Google Scholar]

- Zhu, H.; Wang, Y.; Jaeguan, K. Research on combinatorial optimization method of multidirectional sheet postures for formed part thickness uniformity. J. Mech. Sci. Technol. 2020, 34, 4251–4426. [Google Scholar] [CrossRef]

- Bambach, M. A geometrical model of the kinematics of incremental sheet forming for the prediction of membrane strains and sheet thickness. J. Mater. Process. Technol. 2010, 210, 1562–1573. [Google Scholar] [CrossRef]

| Name | Density /kg•m−3 | Elastic Modulus /GPa | Poisson Ratio | Yield Stress /MPa | Tangent Modulus /GPa | Hardening Coefficient |

|---|---|---|---|---|---|---|

| Al1060 | 2700 | 55.94 | 0.324 | 153.6 | 2.9 | 0.19775 |

| GCr15 | 8160 | 218 | 0.30 | — | — | — |

| W6Mo5Cr4V2 | 7810 | 212 | 0.29 | — | — | — |

| Name | Horizontal Sheet | The Inclined Angle of the Sheet Is | The Inclined Angle of the Sheet Is | The Inclined Angle of the Sheet Is | The Inclined Angle of the Sheet Is |

|---|---|---|---|---|---|

| Forming angle of the easy-forming surface. | |||||

| Maximum forming angle of the difficult-forming surface. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Wang, Y.; Liu, Y.; Jung, D. The Influence of Sheet Tilting on Forming Quality in Single Point Incremental Forming. Materials 2021, 14, 3907. https://doi.org/10.3390/ma14143907

Zhu H, Wang Y, Liu Y, Jung D. The Influence of Sheet Tilting on Forming Quality in Single Point Incremental Forming. Materials. 2021; 14(14):3907. https://doi.org/10.3390/ma14143907

Chicago/Turabian StyleZhu, Hu, Yang Wang, Yibo Liu, and Dongwon Jung. 2021. "The Influence of Sheet Tilting on Forming Quality in Single Point Incremental Forming" Materials 14, no. 14: 3907. https://doi.org/10.3390/ma14143907

APA StyleZhu, H., Wang, Y., Liu, Y., & Jung, D. (2021). The Influence of Sheet Tilting on Forming Quality in Single Point Incremental Forming. Materials, 14(14), 3907. https://doi.org/10.3390/ma14143907