Characterization of Archaeological Artefacts Using Methods Specific to Materials Science: The Case Study of Dacian Ceramics from 2nd c. BC to 1st c. AD

Abstract

:1. Introduction

2. Materials and Methods

2.1. Archaeological Context and Potsherd Descriptions

2.2. Petrographic Analysis on Thin Sections

2.3. Cathodoluminescence (CL) on Thick Sections

2.4. X-ray Diffraction (XRD) on Powder

2.5. SEM–EDX on Pellets and Thick Sections

3. Results

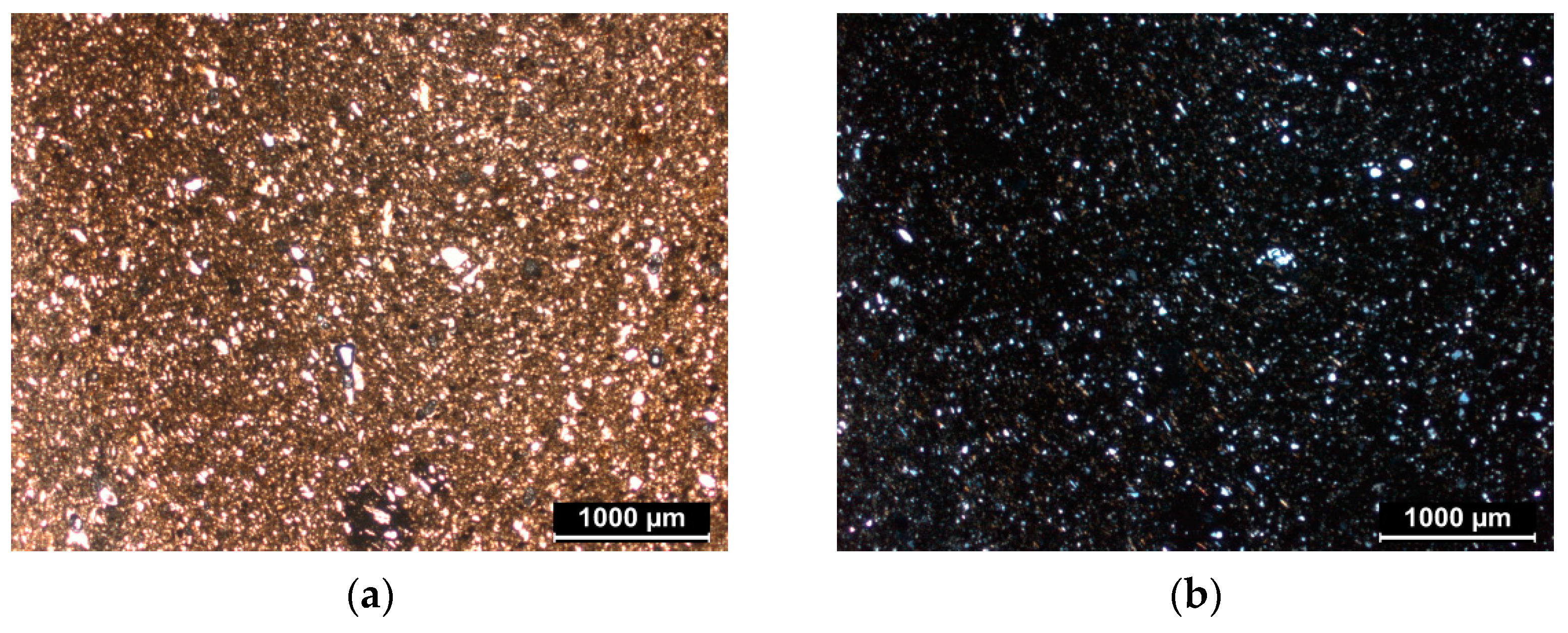

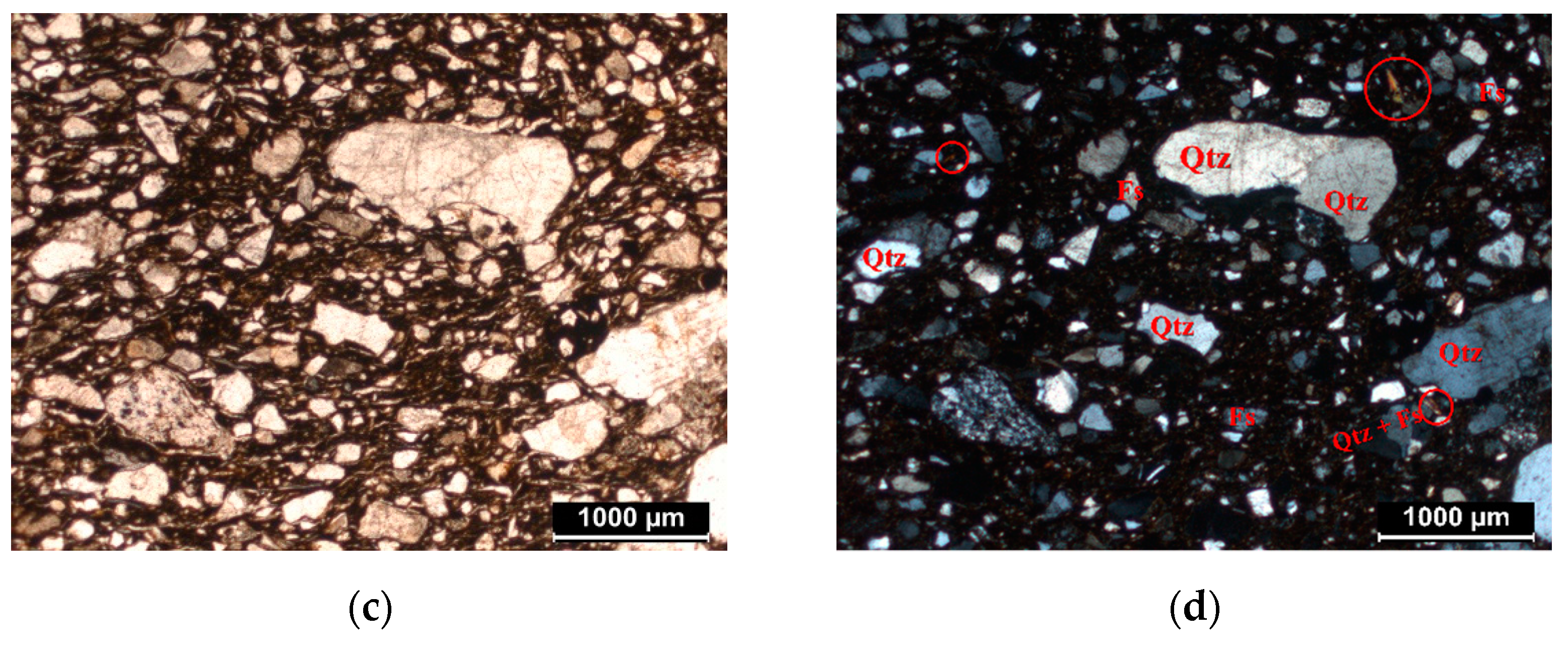

3.1. Petrographic Analysis

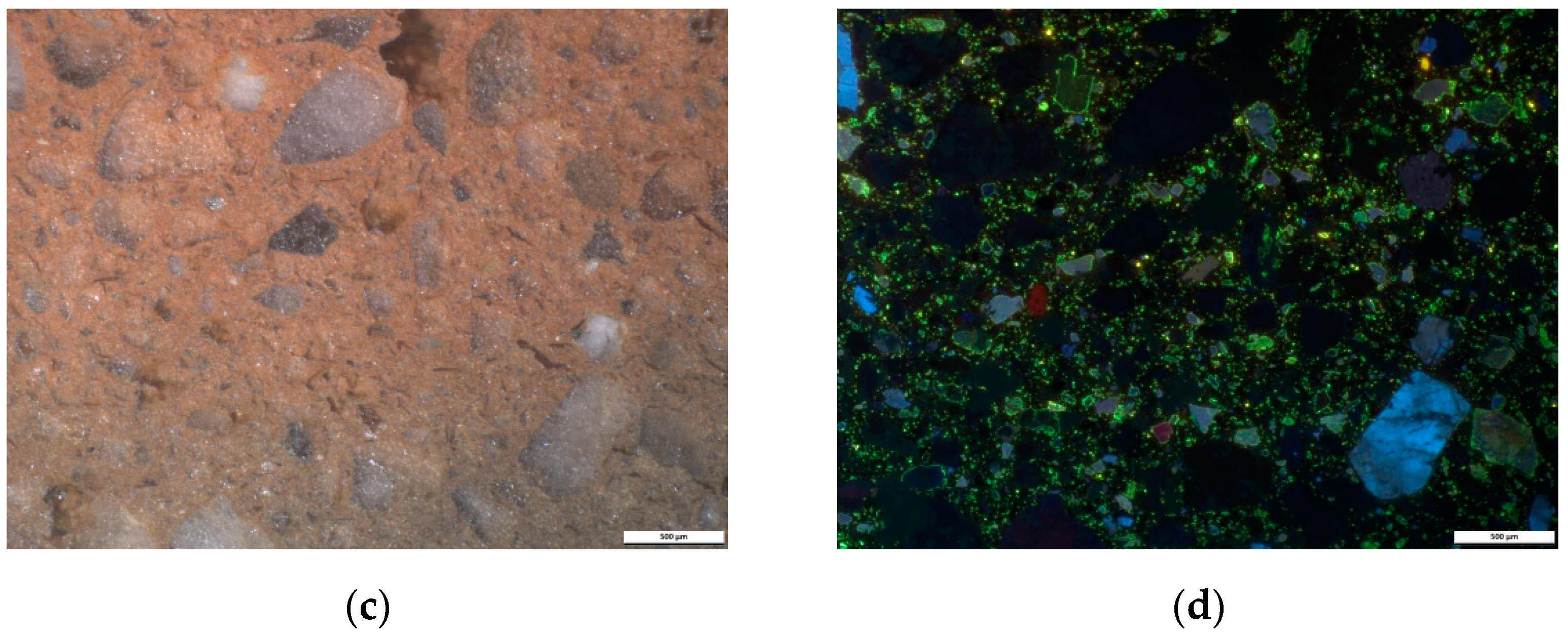

3.2. Cathodoluminescence Imaging

3.3. XRD Analysis

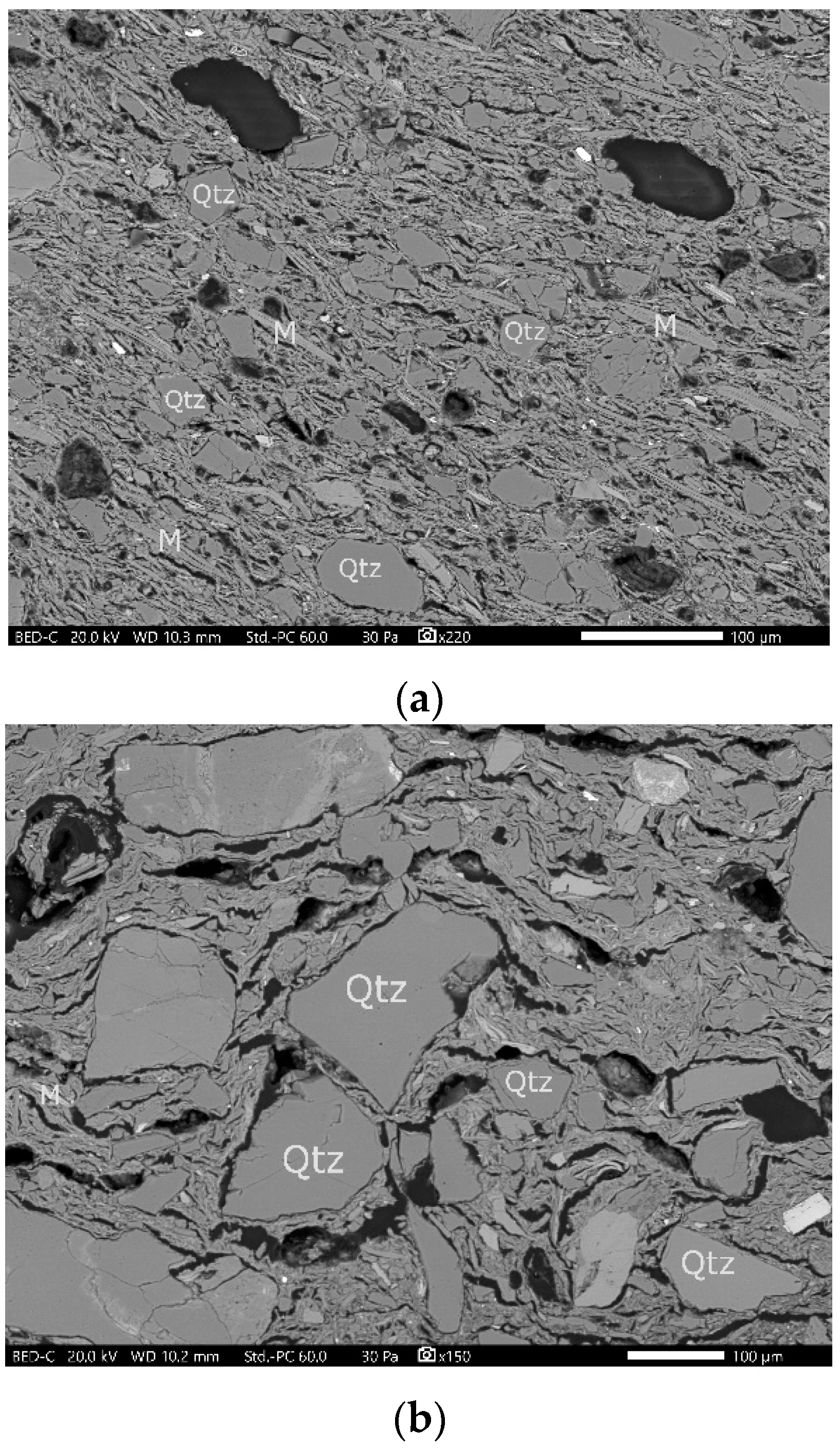

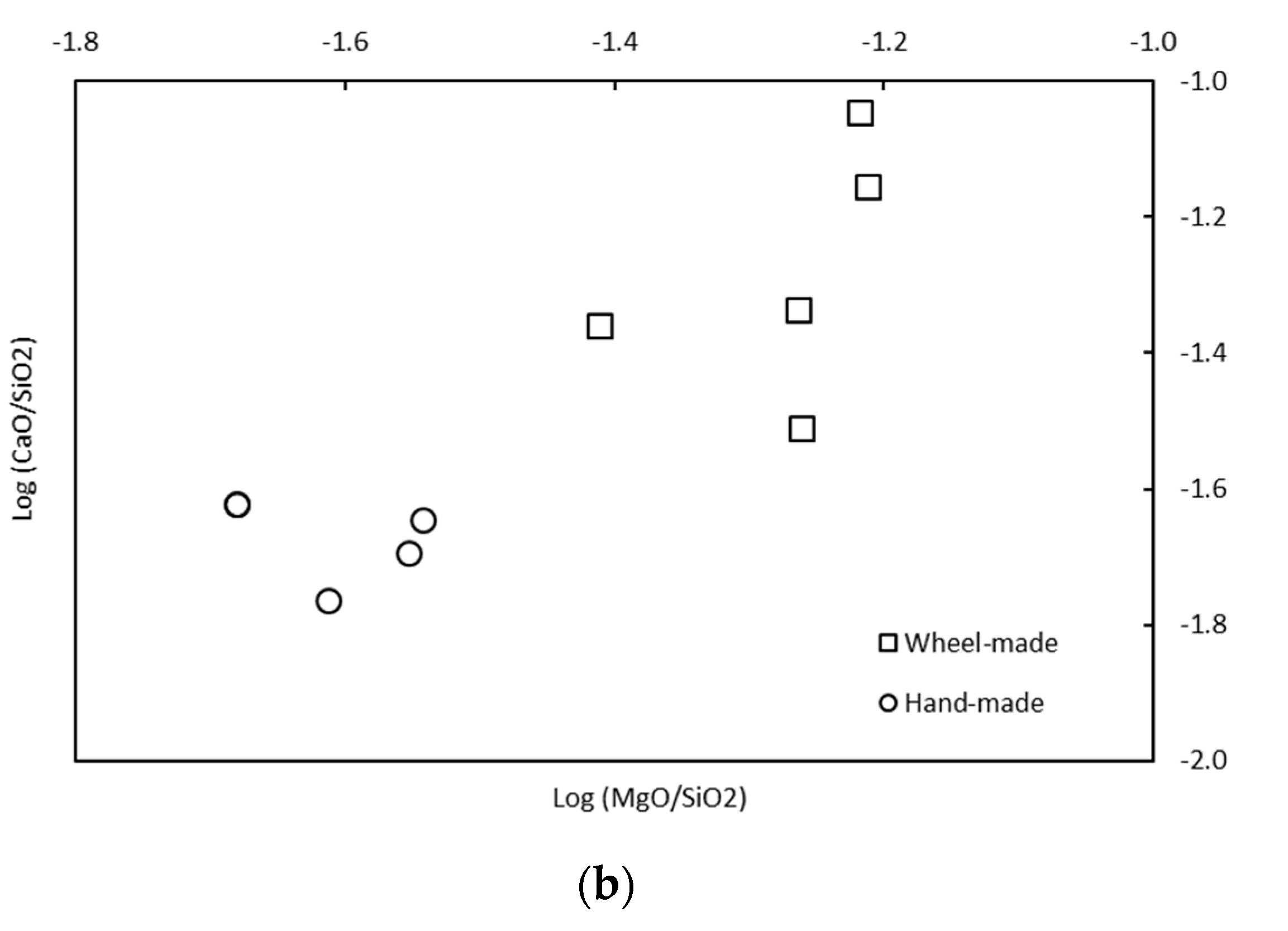

3.4. SEM–EDX Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Tite, M. Ceramic production, provenance and use—A review. Archaeometry 2008, 50, 216–231. [Google Scholar] [CrossRef]

- Sciau, P.; Goudeau, P. Ceramics in art and archaeology: A review of the materials science aspects. Eur. Phys. J. B 2015, 88, 132. [Google Scholar] [CrossRef]

- Montana, G.; Cau Ontiveros, M.Á.; Polito, A.M.; Azzaro, E. Characterisation of clayey raw materials for ceramic manufacture in ancient Sicily. Appl. Clay Sci. 2011, 53, 476–488. [Google Scholar] [CrossRef]

- Vandenabeele, P.; Edwards, H. Analytical Archaeometry: Selected Topics, 1st ed.; Royal Society of Chemistry: Cambridge, UK, 2012. [Google Scholar]

- Thér, R. Ceramic technology. How to reconstruct and describe pottery-forming practices. Archaeol. Anthropol. Sci. 2020, 12, 172. [Google Scholar] [CrossRef]

- Iosifaru, M. Situri Arheologice din Oraşul Ocnele Mari, Judeţul Vâlcea Buridava IX, 13. 2011. Available online: http://www.muzee-valcea.ro/buridava/B9_07.iosifaru.pdf (accessed on 5 February 2021).

- Institutul Național al Patrimoniului. Cronica Cercetărilor Arheologice Campania 2016; Institutul Național al Patrimoniului: Bucharest, Romania, 2016. [Google Scholar]

- Tuţulescu, I.; Schuster, C.; Dumitrescu, I. Zum Salz im Nordosten Olteniens (Rumänien) in der Vorgeschichte bis ins Mittelalter. Eine Einführung. In Salt and Gold: The Role of Salt in Prehistoric Europe; Proceedings of the International Symposium, Provadia, Bulgaria, 30 September–4 October 2010; Verlag Faber: Veliko Tarnovo, Bulgaria, 2012; pp. 201–212. [Google Scholar]

- Crisan, I.H. Civilizatia Geto-Dacilor; Editura Meridiane: Bucarest, Romania, 1993. [Google Scholar]

- Berciu, D. Buridava Dacica; Editura Academiei Republicii Socialiste: Bucuresti, Romania, 1981. [Google Scholar]

- Berciu, D. Ancient Peoples and Places Series, 1st ed.; F.A. Praeger: London, UK, 1967. [Google Scholar]

- Berciu, D.; Iosifaru, M. Săpăturile arheologice de la Ocniţa, jud. Vîlcea. Materiale şi Cercetări Arheologice 1980, 14, 183–185. [Google Scholar] [CrossRef]

- Foucault, A.; Raoult, J.-F. Dictionnaire de Géologie, 7th ed.; Dunod: Bucharest, France, 2010. [Google Scholar]

- Regert, M.; Guerra, M.-F.; Reiche, I. Physico-chimie des matériaux du patrimoine culturel—Partie 2. In Techniques de l’Ingenieur; Éditions des archives contemporaines: Paris, France, 2006; pp. 1–21. [Google Scholar]

- Pettijohn, F.J.; Potter, P.E.; Siever, R. Sand and Sandstone; Springer Science & Business Media: New York, NY, USA, 2012. [Google Scholar]

- Chapoulie, R.; Robert, B.; Casenave, S. The cathodoluminescence phenomenon used for the study of ancient ceramics and stones. Cities Mem. Int. J. Cult. Herit. Risk 2016, 1, 53–72. [Google Scholar]

- Chapoulie, R.; Daniel, F. Cathodoluminescence: Recherches sur une Méthode d’analyse en Archéométrie; British Archaeological Reports, BAR S1700; British Archaeological Reports: Oxford, UK, 2007; pp. 1–16. [Google Scholar]

- Chapoulie, R.; Delery, C.; Daniel, F.; Vendrell-Saz, M. Cuerda Seca Ceramics from Al-Andalus, Islamic Spain and Portugal (10th–12th Centuries Ad): Investigation with Sem–Edx and Cathodoluminescence. Archaeometry 2005, 47, 519–534. [Google Scholar] [CrossRef]

- Dudley, R.J. The Use of Cathodoluminescence in the Identification of Soil Minerals. J. Soil Sci. 1976, 27, 487–494. [Google Scholar] [CrossRef]

- Emery, L. Approches Archéométriques des Productions Faïencières Françaises du XVIIIe Siècle. Le cas de la Manufacture Babut à Bergerac (env. 1740–1789). Ph.D. Thesis, Université Michel de Montaigne Bordeaux 3, Bordeaux, France, 2012. [Google Scholar]

- Aitchison, J. The Statistical Analysis of Compositional Data. Monographs on Statistics and Applied Probability; Chapman and Hall: London, UK; New York, NY, USA, 1986. [Google Scholar]

- Frerebeau, N.; Ben Amara, A.; Cantin, N. Analyse de données de composition et identification des altérations géochimiques des matériaux céramiques: Le cas des productions d’un atelier ibérique (Teruel, Espagne; iie-ier siècles avant J.-C.). ArchéoSciences 2020, 44-1, 33–50. [Google Scholar] [CrossRef]

- Anghel, D. Experimente de ardere a ceramicii in cuptoare de tip arhaic. Terra Sebus 2011, 3, 339–350. [Google Scholar]

- Anghel, D. Influenta conditiilor de ardere asupra ceramicii. Revista Terra Sebus 2002, 6, 171–173. [Google Scholar]

- Fonseca, R.; Couto, H. Application of Cathodoluminescence to the Study of Feldspars: Imaging and Spectrometry. IOP Conf. Ser. Earth Environ. Sci. 2017, 95, 032029. [Google Scholar] [CrossRef]

- Piponnier, D.; Bechtel, F.; Florin, D.; Molera, J.; Schvoerer, M.; Vendrell, M. Apport de la Cathodoluminescence à l’Etude des Transformations de Phases Cristallines dans des Céramiques Kaolinitiques Carbonatées. Key Eng. Mater. 1997, 132–136, 1470–1473. [Google Scholar] [CrossRef]

- Rodriguez-Navarro, C.; Cultrone, G.; Sanchez-Navas, A.; Sebastian, E. TEM study of mullite growth after muscovite breakdown. Am. Mineral. 2003, 88, 713–724. [Google Scholar] [CrossRef]

- Bohor, B.F. High-Temperature Phase Development in Illitic Clays. Clays Clay Miner. 1963, 12, 233–246. [Google Scholar] [CrossRef]

- Holakooei, P.; Tessari, U.; Verde, M.; Vaccaro, C. A new look at XRD patterns of archaeological ceramic bodies: An assessment for the firing temperature of 17th century haft rang tiles from Iran. J. Therm. Anal. Calorim. 2014, 118, 165–176. [Google Scholar] [CrossRef]

| Technology Group | Sample ID | Archaeological Context | Category | Object Type |

|---|---|---|---|---|

| Wheel-made | BDX 24414 | YD. 1975, Tr. XXVE | Fine | Pitcher |

| BDX 24415 | YD. 1976, Tr. XXIX | Fruit bowl | ||

| BDX 24416 | YD. 1975, Tr. XXVF | Fruit bowl | ||

| BDX 24417 | YD. 1968, Tr. Xa | Bowl | ||

| BDX 24418 | YD. 1974, Tr. XXVD | Bowl | ||

| Hand-made | BDX 24419 | YD. 1975, Tr. XXVF | Coarse | Bowl |

| BDX 24420 | YD. 1974, Tr. XXVD | Bowl | ||

| BDX 24421 | YD. 1968, Tr. Xa | Bowl | ||

| BDX 24422 | YD. 1974, Tr. XXVD | Bowl | ||

| BDX 24423 | YD. 1975, Tr. XXVF | Bowl |

| Technology Group | Sample ID | Illite-Muscovite | Biotite | Quartz | Microcline | Orthoclase | Albite | Anorthite | Hornblende |

|---|---|---|---|---|---|---|---|---|---|

| Wheel-made | BDX 24414 | 22 | 3 | 36 | 6 | 5 | 18 | 9 | 1 |

| BDX 24415 | 11 | 4 | 35 | 20 | 1 | 35 | 14 | 3 | |

| BDX 24416 | 11 | 3 | 32 | 16 | 5 | 32 | 14 | 5 | |

| BDX 24417 | 31 | 8 | 23 | 9 | 5 | 23 | 12 | 5 | |

| BDX 24418 | 21 | 7 | 29 | 17 | 1 | 29 | 11 | 4 | |

| Hand-made | BDX 24419 | 19 | 6 | 43 | 3 | 5 | 13 | 7 | 4 |

| BDX 24420 | 14 | 4 | 55 | 7 | 1 | 9 | 7 | 2 | |

| BDX 24421 | 16 | 5 | 43 | 2 | 6 | 20 | 6 | 3 | |

| BDX 24422 | 25 | 5 | 37 | 14 | 1 | 6 | 7 | 4 | |

| BDX 24423 | 20 | 8 | 35 | 8 | 3 | 13 | 10 | 4 |

| Technology Group | Sample ID | Na2O | MgO | Al2O3 | SiO2 | P2O5 | K2O | CaO | TiO2 | MnO | Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheel-made | BDX 24414 | 1.1 | 2.4 | 19.4 | 61.8 | 1.0 | 3.3 | 2.7 | 0.9 | 0.1 | 7.2 |

| BDX 24415 | 1.4 | 3.5 | 19.1 | 57.8 | 0.8 | 3.5 | 5.2 | 0.9 | 0.1 | 7.6 | |

| BDX 24416 | 1.3 | 3.6 | 19.2 | 58.7 | 0.5 | 3.6 | 4.1 | 1.0 | 0.1 | 7.9 | |

| BDX 24417 | 1.1 | 3.2 | 21.1 | 58.4 | 2.1 | 3.6 | 1.8 | 1.0 | 0.1 | 7.7 | |

| BDX 24418 | 1.1 | 3.2 | 20.1 | 58.7 | 1.5 | 3.6 | 2.7 | 1.0 | 0.1 | 8.0 | |

| Average | 1.2 | 3.2 | 19.8 | 59.1 | 1.2 | 3.5 | 3.3 | 1.0 | 0.1 | 7.7 | |

| SD | 0.1 | 0.5 | 0.8 | 1.6 | 0.6 | 0.1 | 1.3 | 0.1 | 0.1 | 0.3 | |

| Hand-made | BDX 24419 | 1.7 | 1.4 | 17.4 | 67.1 | 1.5 | 2.5 | 1.6 | 0.7 | 0.2 | 5.9 |

| BDX 24420 | 1.6 | 1.4 | 17.4 | 67.1 | 1.6 | 2.5 | 1.6 | 0.7 | 0.2 | 6.0 | |

| BDX 24421 | 1.5 | 1.7 | 15.7 | 69.7 | 0.7 | 2.6 | 1.2 | 0.8 | 0.1 | 6.1 | |

| BDX 24422 | 0.9 | 1.8 | 18.5 | 64.3 | 1.4 | 3.5 | 1.3 | 0.8 | 0.2 | 7.1 | |

| BDX 24423 | 1.6 | 1.9 | 17.7 | 66.2 | 0.8 | 2.7 | 1.5 | 0.8 | 0.1 | 6.6 | |

| Average | 1.5 | 1.6 | 17.3 | 66.9 | 1.2 | 2.8 | 1.4 | 0.8 | 0.2 | 6.3 | |

| SD | 0.3 | 0.2 | 1.0 | 1.9 | 0.4 | 0.4 | 0.2 | 0.1 | 0.1 | 0.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teodorescu, L.; Ben Amara, A.; Cantin, N.; Chapoulie, R.; Ducu, C.; Ciucă, S.; Tulugea, C.; Terteci, C.; Abrudeanu, M. Characterization of Archaeological Artefacts Using Methods Specific to Materials Science: The Case Study of Dacian Ceramics from 2nd c. BC to 1st c. AD. Materials 2021, 14, 3908. https://doi.org/10.3390/ma14143908

Teodorescu L, Ben Amara A, Cantin N, Chapoulie R, Ducu C, Ciucă S, Tulugea C, Terteci C, Abrudeanu M. Characterization of Archaeological Artefacts Using Methods Specific to Materials Science: The Case Study of Dacian Ceramics from 2nd c. BC to 1st c. AD. Materials. 2021; 14(14):3908. https://doi.org/10.3390/ma14143908

Chicago/Turabian StyleTeodorescu, Laura, Ayed Ben Amara, Nadia Cantin, Rémy Chapoulie, Cătălin Ducu, Sorin Ciucă, Claudiu Tulugea, Carol Terteci, and Mărioara Abrudeanu. 2021. "Characterization of Archaeological Artefacts Using Methods Specific to Materials Science: The Case Study of Dacian Ceramics from 2nd c. BC to 1st c. AD" Materials 14, no. 14: 3908. https://doi.org/10.3390/ma14143908

APA StyleTeodorescu, L., Ben Amara, A., Cantin, N., Chapoulie, R., Ducu, C., Ciucă, S., Tulugea, C., Terteci, C., & Abrudeanu, M. (2021). Characterization of Archaeological Artefacts Using Methods Specific to Materials Science: The Case Study of Dacian Ceramics from 2nd c. BC to 1st c. AD. Materials, 14(14), 3908. https://doi.org/10.3390/ma14143908