Improved Mechanical, Anti-UV Irradiation, and Imparted Luminescence Properties of Cyanate Ester Resin/Unzipped Multiwalled Carbon Nanotubes/Europium Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

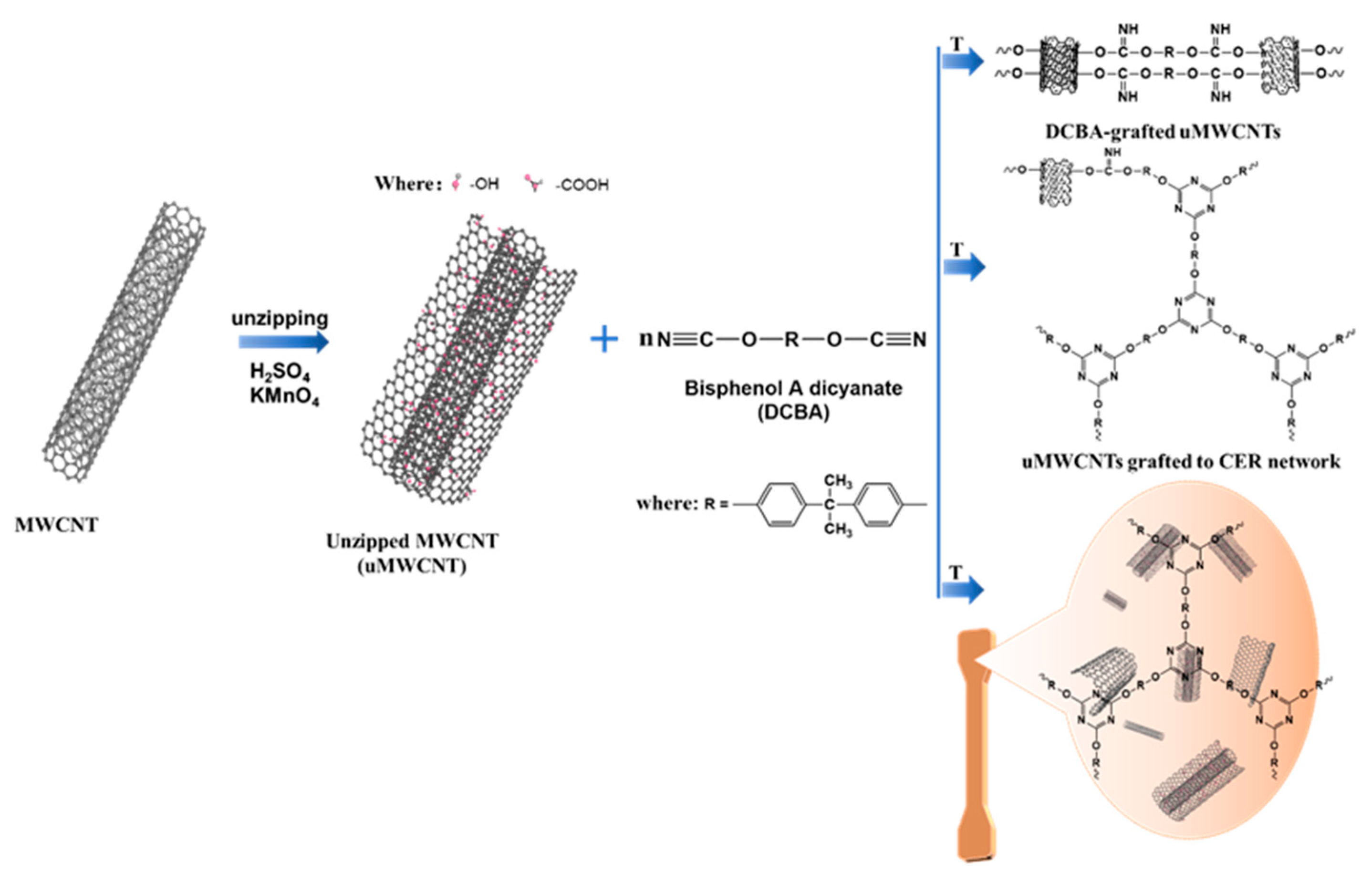

2.2.1. Preparation of Unzipped Multiwalled Carbon Nanotubes (uMWCNTs) and MWCNTs/Eu and uMWCNTs/Eu Composites

2.2.2. Preparation of CER/uMWCNTs and CER/uMWCNTs/Eu Nanocomposites

2.2.3. UV Irradiation Exposure

2.3. Characterization

3. Results and Discussion

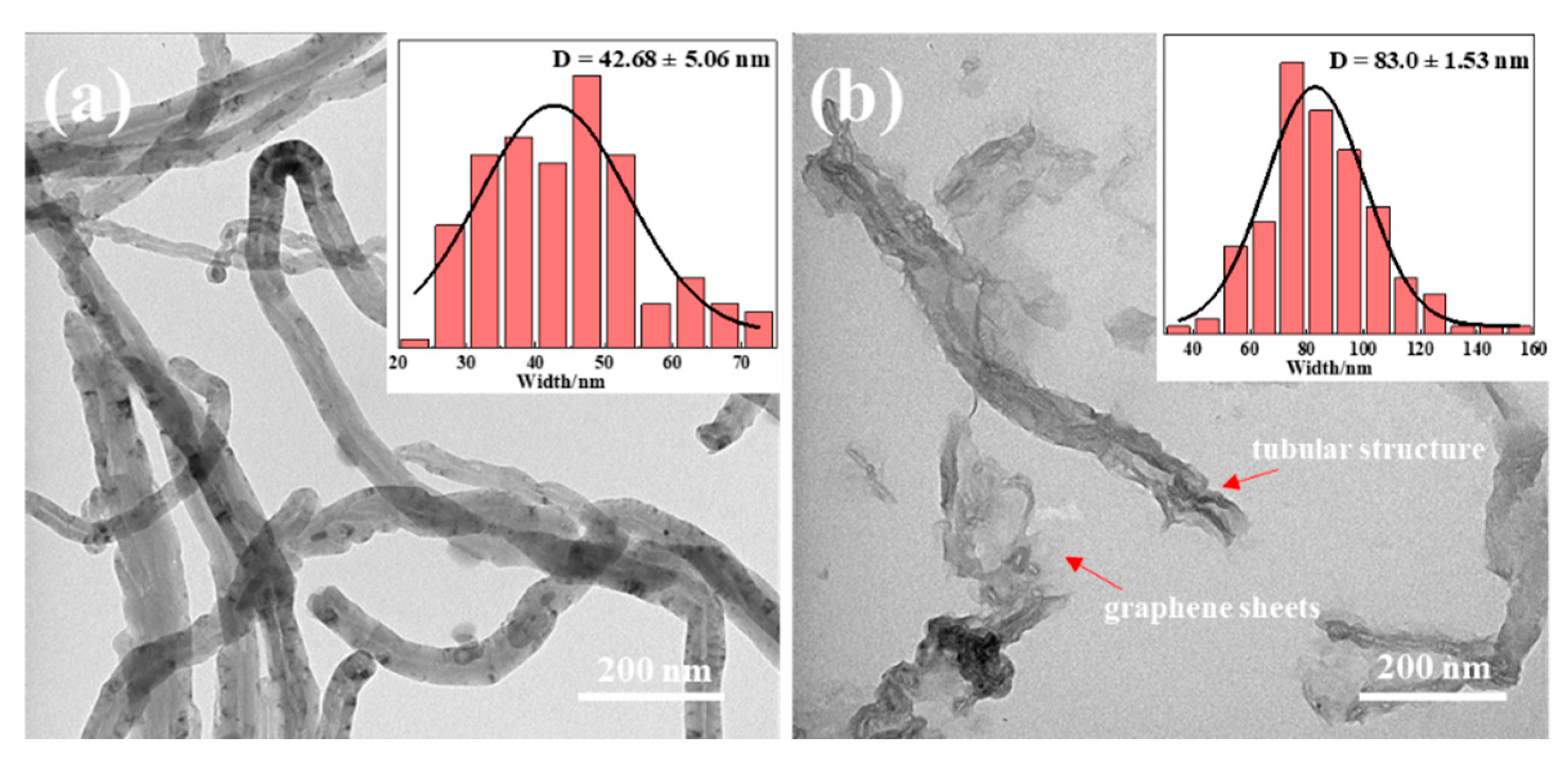

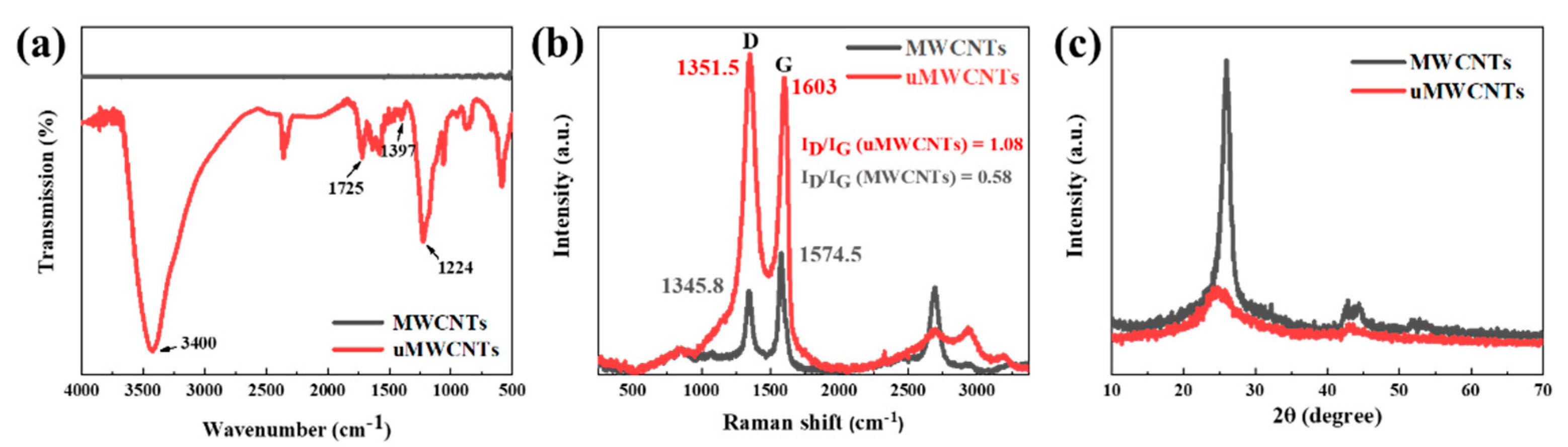

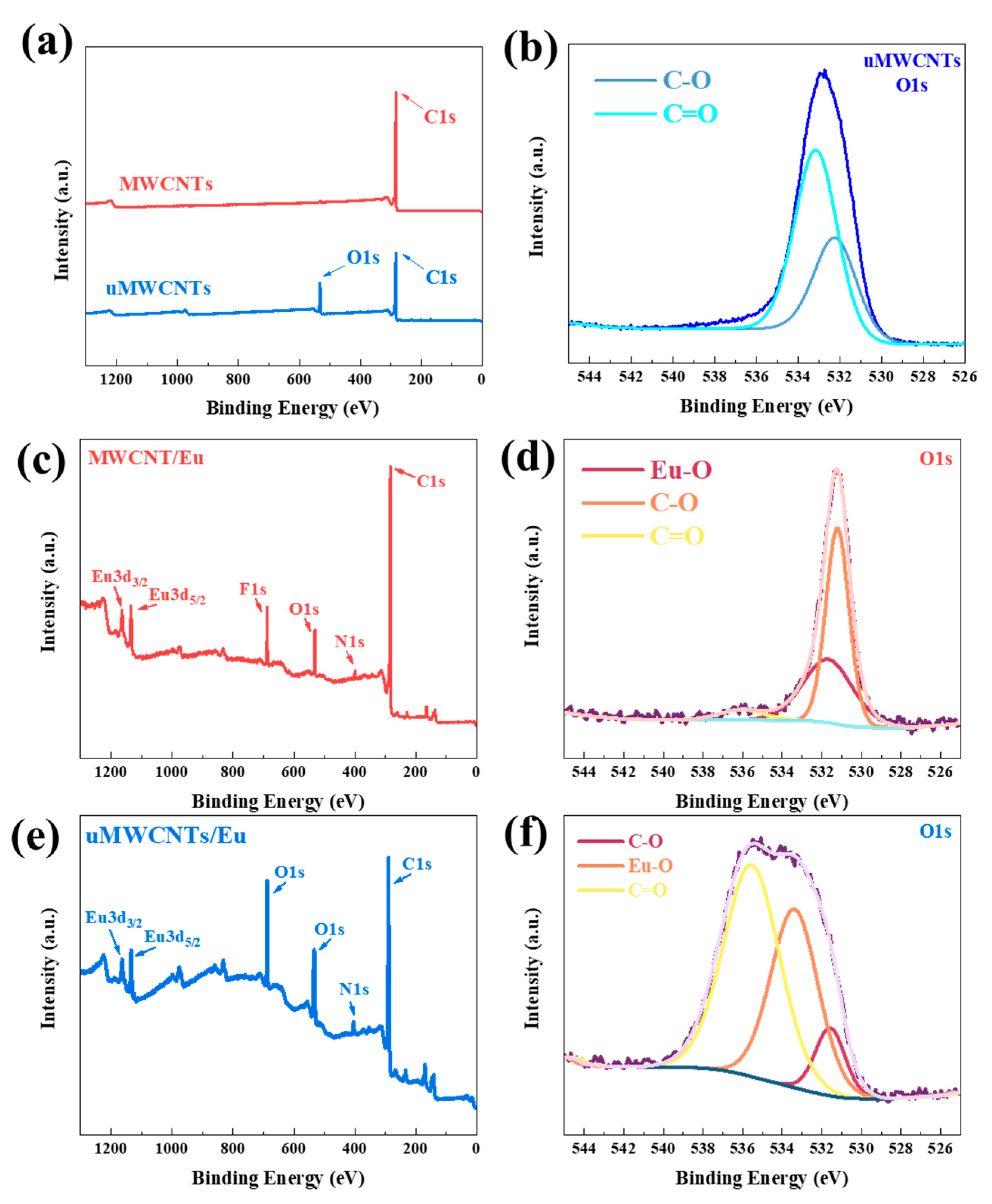

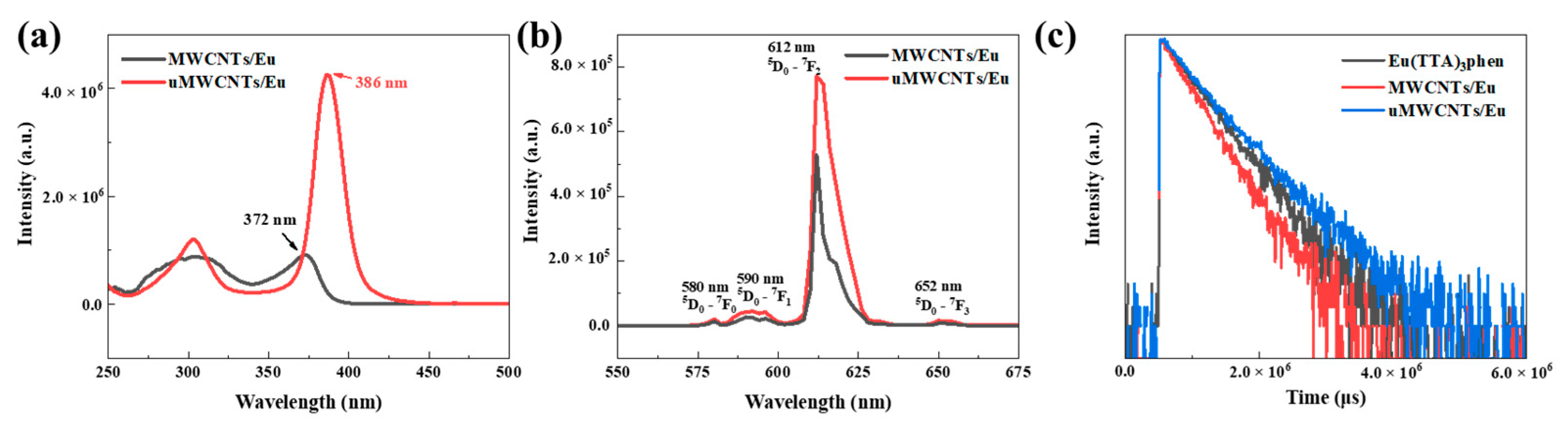

3.1. Structure of uMWCNTs, MWCNTs/Eu and uMWCNTs/Eu

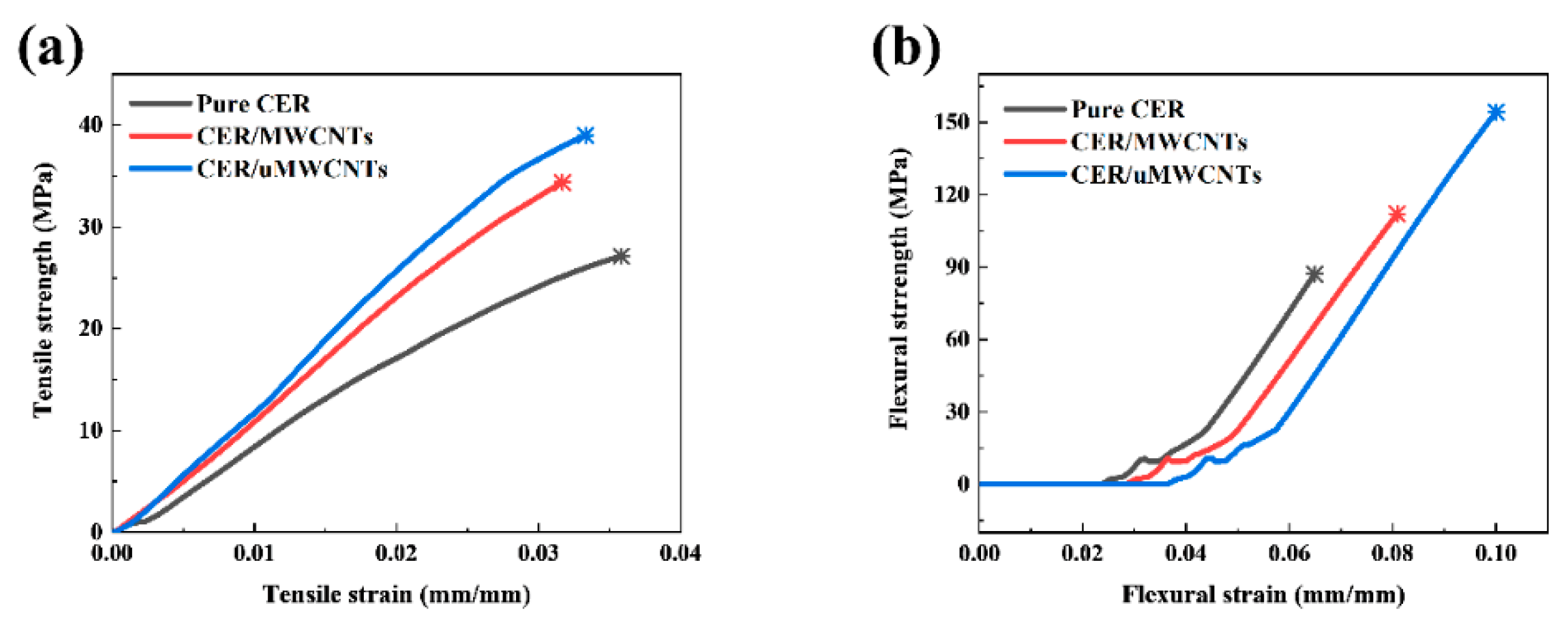

3.2. The Strong Enhancement of CER Mechanical Properties by MWCNTs and uMWCNTs

3.3. Thermal Property of CER/MWCNTs and CER/uMWCNTs Nanocomposites

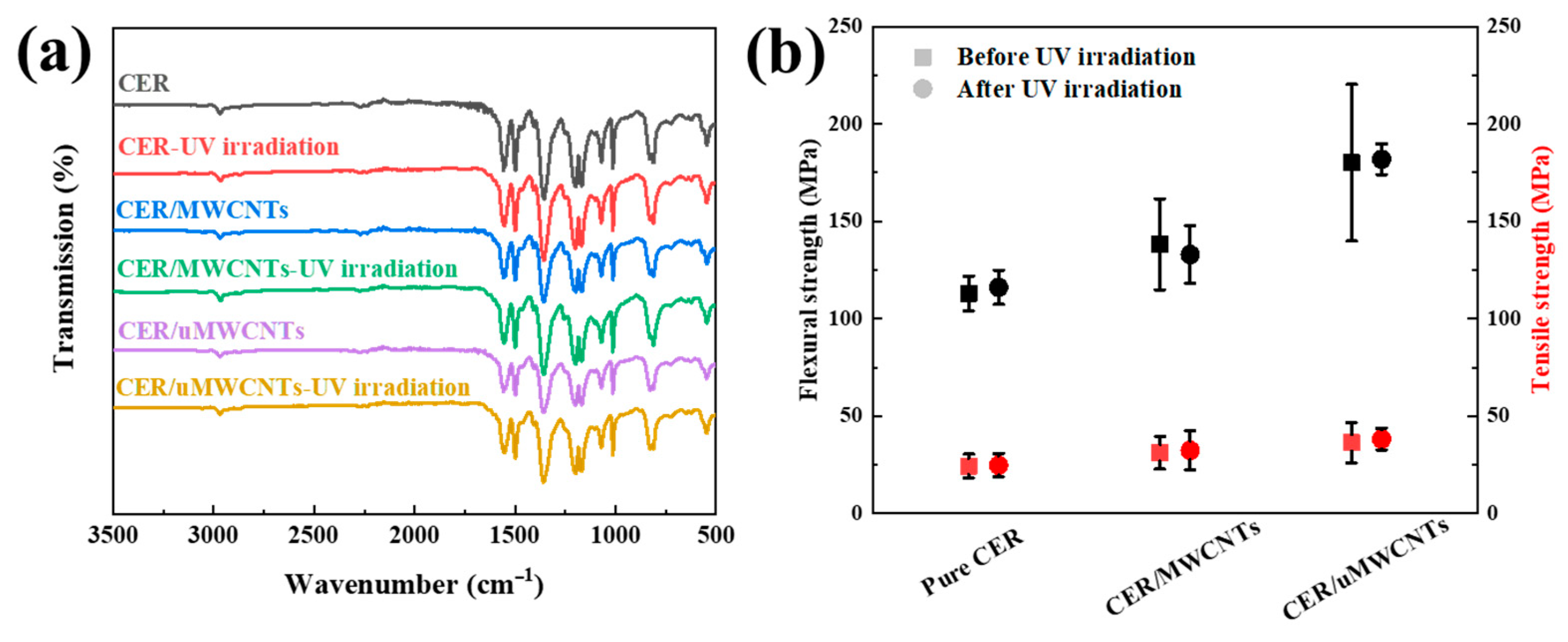

3.4. Aging Property of CER/MWCNTs and CER/uMWCNTs Nanocomposites under UV Irradiation

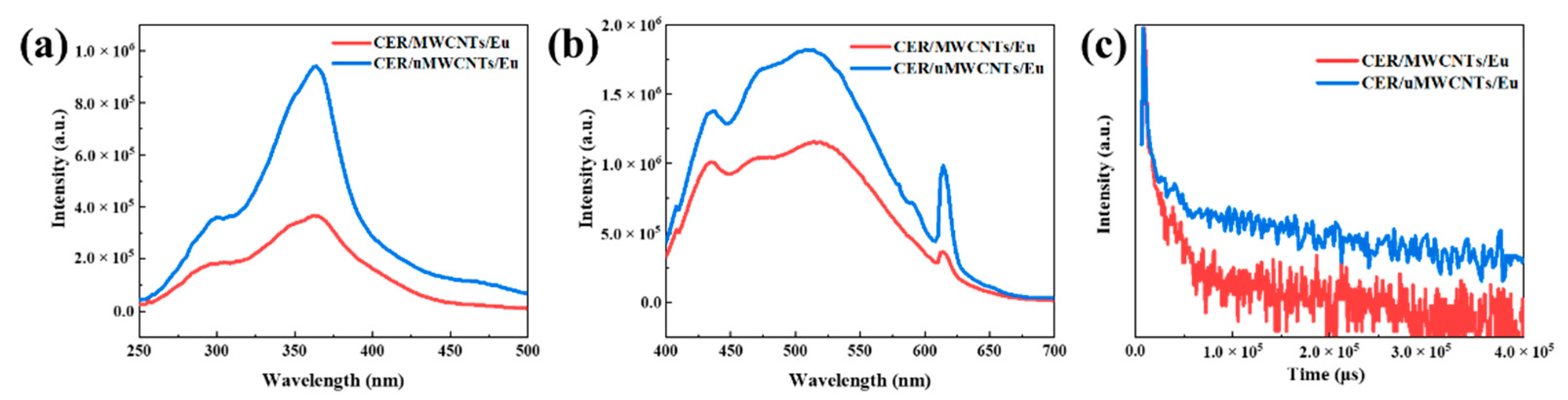

3.5. Luminescence Property of CER/MWCNTs/Eu, CER/uMWCNTs/Eu Nanocomposites

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, T.; Shimp, D.A. Polycyanate esters: Science and applications. Prog. Polym. Sci. 1995, 20, 61–118. [Google Scholar] [CrossRef]

- Hamerton, I. Chemistry and Technology of Cyanate Ester Resins; Chapman & Hall: Tunbridge Wells, UK, 1994; pp. 2–3. [Google Scholar]

- Tang, Y.; Dong, W.; Tang, L.; Zhang, Y.K.; Kong, J.; Gu, J. Fabrication and investigations on the polydopamine/KH-560 functionalized PBO fibers/cyanate ester wave-transparent composites. Compos. Commun. 2018, 8, 36–41. [Google Scholar] [CrossRef]

- Guan, Q.; Yuan, L.; Zhang, Y.; Gu, A.; Liang, G. Improving the mechanical, thermal, dielectric and flame retardancy properties of cyanate ester with the encapsulated epoxy resin-penetrated aligned carbon nanotube bundle. Compos. Part B Eng. 2017, 123, 81–91. [Google Scholar] [CrossRef]

- Fainleib, A. Thermostable Polycyanurates: Synthesis, Modification, Structure and Properties; Nova Science Publishers: New York, NY, USA, 2011; pp. 1–364. [Google Scholar]

- Motoc, D.L.; Bou, S.F.; Balart, R. Thermal properties comparison of hybrid CF/FF and BF/FF cyanate ester-based composites. J. Therm. Anal. Calorim. 2018, 133, 1–10. [Google Scholar]

- Gu, J.; Dong, W.; Tang, Y.; Guo, Y.; Guo, Z. Ultralow dielectric, fluoride-containing cyanate ester resins with improved mechanical properties and high thermal and dimensional stabilities. J. Mater. Chem. C 2017, 5, 6929–6936. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube–polymer composites chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Hu, J.; Xiong, X.; Guan, W.; Long, H. Recent advances in carbon nanomaterial-optimized perovskite solar cells. Mater. Today Energy 2021, 21, 100769. [Google Scholar] [CrossRef]

- Zhang, S.; Kang, L.; Wang, Z.; Tong, L.; Yang, L.; Wang, Z.; Qi, K.; Deng, S.; Li, Q.; Bai, X.; et al. Arrays of horizontal carbon nanotubes of controlled chirality grown using designed catalysts. Nature 2017, 543, 234–238. [Google Scholar] [CrossRef] [PubMed]

- Yoong-Ahm, K.; Hiroyuki, M.; Masahito, K.; Takuya, H.; Yutaka, K.; Morinobu, E. Stacking nature of the catalytic chemical vapor deposition-derived double-walled carbon nanotubes. J. Nanosci. Nanotechnol. 2019, 6, 3321–3324. [Google Scholar]

- Wu, H.; Gu, A.; Liang, G.; Yuan, L. Novel permittivity gradient carbon nanotubes/cyanate ester composites with high permittivity and extremely low dielectric loss. J. Mater. Chem. 2011, 21, 14838–14848. [Google Scholar] [CrossRef]

- Han, C.; Gu, A.; Liang, G.; Yuan, L. Carbon nanotubes/cyanate ester composites with low percolation threshold, high dielectric constant and outstanding thermal property. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1321–1328. [Google Scholar] [CrossRef]

- Fainleib, A.; Bardash, L.; Boiteux, G.; Grigoryeva, O. Thermosetting cyanate ester resins filled with CNTs. In Advances in progressive thermoplastic and thermosetting polymers, perspectives and applications; Mamunya, Y., Iurzhenko, M., Eds.; Tehnopress editura: Iasi, Romania, 2012; Volume 10, pp. 379–424. [Google Scholar]

- Fainleib, A.; Bardash, L.; Boiteux, G. Catalytic effect of carbon nanotubes on polymerization of cyanate ester resins. Exp. Polym. Lett. 2009, 3, 477–482. [Google Scholar] [CrossRef]

- Bardash, L.; Boiteux, G.; Grykien, R.; Glowacki, I.; Pastorczak, M.; Ulanski, J.; Fainleib, A. Electrical conductivity of polymer/carbon nanotubes nanocomposites at low temperatures. Polym. J. 2018, 40, 230–239. [Google Scholar] [CrossRef]

- Li, P.; Li, T.; Yan, H. Mechanical, Tribological and heat resistant properties of fluorinated multi-walled carbon nanotube/bismaleimide/cyanate resin nanocomposites. J. Mater. Sci. Technol. 2017, 33, 118–122. [Google Scholar] [CrossRef]

- Lu, C.; Yuan, L.; Guan, Q.; Liang, G.; Gu, A. Optimizing Ply Pattern and Composition of Layered Composites Based on Cyanate Ester, Carbon Nanotube and Boron Nitride: Toward Ultralow Dielectric Loss and High Energy Storage. J. Phys. Chem. C 2018, 122, 5238–5247. [Google Scholar] [CrossRef]

- Mei, H.; Xia, J.; Zhang, D.; Li, H.; Bai, Q.; Cheng, L. Mechanical properties of carbon fiber reinforced bisphenol A dicyanate ester composites modified with multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2017, 134, 45100. [Google Scholar] [CrossRef]

- Pisani, W.A.; Radue, M.S.; Patil, S.U.; Odegard, G.M. Interfacial modeling of flattened CNT composites with cyanate ester and PEEK polymers. Compos. Part B Eng. 2021, 211, 108672. [Google Scholar] [CrossRef]

- Yu, M.F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2016, 287, 637–640. [Google Scholar] [CrossRef] [Green Version]

- Kosynkin, D.V.; Higginbotham, A.L.; Sinitskii, A.; Lomeda, J.R.; Dimiev, A.; Price, B.K.; Tour, J.M. Longitudinal unzipping of carbon nanotubes to form graphene nanoribbons. Nature 2009, 458, 872–876. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Y.; Shi, Z.X.; Yin, J. Unzipped multiwalled carbon nanotubes for mechanical reinforcement of polymer composites. J. Phys. Chem. C 2010, 114, 19621–19628. [Google Scholar] [CrossRef]

- Chen, S.; Sun, J.; Li, G. Study on the modification of cyanate ester resin used hydroxylated multi-walled carbon nanotubes. New Chem. Mater. 2018, 46, 95–99. [Google Scholar]

- Zhang, Z.; Sun, Z.; Yao, J.; Kosynkin, D.V.; Tour, J.M. Transforming carbon nanotube devices into nanoribbon devices. J. Am. Chem. Soc. 2009, 131, 13460–13463. [Google Scholar] [CrossRef]

- Amanda, L.; Higginbotham, D.V.K.; Sinitskii, A.; Sun, Z.; Tour, J.M. Lower-Defect Graphene Oxide Nanoribbons from Multiwalled Carbon Nanotubes. Am. Chem. Soc. 2010, 4, 13460–13463. [Google Scholar]

- Han, J.-H.; Kim, C.-G. Low earth orbit space environment simulation and its effects on graphite/epoxy composites. Compos. Struct. 2006, 72, 218–226. [Google Scholar] [CrossRef]

- Xie, F.; Liu, L.; Gong, X.; Huang, L.; Leng, J.; Liu, Y. Effects of accelerated aging on thermal, mechanical and shape memory properties of cyanate-based shape memory polymer: Ivacuum ultraviolet radiation. Polym. Degrad. Stab. 2017, 138, 91–97. [Google Scholar] [CrossRef]

- Cui, G.; Chen, S.; Jiang, B.; Zhang, Y.; Qiu, N.; Satoh, T.; Kakuchi, T.; Duan, Q. Synthesis and characterization of novel thermoresponsive fluorescence complexes based on copolymers with rare earth ions. Opt. Mater. 2013, 35, 2250–2256. [Google Scholar] [CrossRef]

- Silva, C.; Bispo, A.G., Jr.; Lima, S.; Pires, A.M. Eu3+ complex/polymer films for light-emitting diode applications. Opt. Mater. 2019, 96, 109323. [Google Scholar] [CrossRef]

- Itankar, S.G.; Dandekar, M.P.; Koinkar, P.M.; Kondawar, S.B. Influence of Polymer in Photoluminescence Properties of Electrospun Eu3+ Doped Polymer Nanofibers; Springer: Singapore, 2020; Volume 242. [Google Scholar]

- Mosse, I.S.; Sodisetti, V.R.; Coleman, C.; Nc Ube, S.; Bhattacharyya, S. Tuning Magnetic Properties of a Carbon Nanotube-Lanthanide Hybrid Molecular Complex through Controlled Functionalization. Molecules 2021, 26, 563. [Google Scholar] [CrossRef]

- Mohanraj, J.; Armaroli, N. Luminophores and Carbon Nanotubes: An Odd Combination? J. Phys. Chem. Lett. 2013, 4, 767–778. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.X.; Cao, W.M.; Wang, J.; Yang, H.; Yang, S.P. Coating multi-walled carbon nanotubes with rare-earth complexes by an in situ synthetic method. Nanotechnology 2008, 19, 345701. [Google Scholar] [CrossRef]

- Yoo, H.J.; Kim, K.H.; Yadav, S.K.; Cho, J.W. Effects of carbon nanotube functionalization and annealing on crystallization and mechanical properties of melt-spun carbon nanotubes/poly(ethylene terephthalate) fibers. Compos. Sci. Technol. 2012, 72, 1834–1840. [Google Scholar] [CrossRef]

- Li, Y.; Jiao, J.; Yan, P.; Liu, L.; Wang, J.; Wang, Y.; Huang, L.; Liu, J.; Belfiore, L.A.; Tang, J. Synthesis and tunable photoresponse for core-shell structured NaGdF4:Yb,Er@SiO2@Eu(TTA)3 Phen nanocomplexes. Scr. Mater. 2018, 152, 1–5. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y.; Huang, L.; Lu, P.; Sun, Q.; Wang, Y.; Tang, J.; Belfiore, L.A.; Kipper, M.J. Polyvinylpyrrolidone Nanofibers Encapsulating an Anhydrous Preparation of Fluorescent SiO(2)(-)Tb(3+) Nanoparticles. Nanomaterials 2019, 9, 510. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, H.; Gu, J.; Liu, C.; Wang, D. Thermal and mechanical properties of cyanate ester resin modified with acid-treated multiwalled carbon nanotubes. High Perform. Polym. 2018, 30, 38–46. [Google Scholar] [CrossRef]

- Li, H.; Wang, D.; Qu, C.; Liu, Z.; Feng, H.; Su, K. Preparation and performances of bisphthalonitrile resin and novolac cyanate ester resin blends. Polym. Bull. 2019, 76, 5649–5660. [Google Scholar] [CrossRef]

- Jana, S.; Zhong, W.H. Effects of Hygrothermal Conditions and UV Radiation on UHMWPE Fibers/Nanofiber—Epoxy Composites. J. Compos. Mater. 2016, 41, 2897–2914. [Google Scholar] [CrossRef]

- Yuen, S.-M.; Ma, C.-C.M.; Lin, Y.-Y.; Kuan, H.-C. Preparation, Morphology and properties of acid and amine modified multiwalled carbon nanotube/polyimide composite. Compos. Sci. Technol. 2007, 67, 2564–2573. [Google Scholar] [CrossRef]

- Zhang, Y.; Song, Y.; Gan, Y.; Feng, M.; Zhan, H. Broadband nonlinear optical and optical limiting effects of partially unzipped carbon nanotubes. J. Mater. Chem. C 2015, 3, 9948–9954. [Google Scholar] [CrossRef]

- Kumar, S.; Raj, S.; Sarkar, K.; Chatterjee, K. Engineering a multi-biofunctional composite using poly(ethylenimine) decorated graphene oxide for bone tissue regeneration. Nanoscale 2016, 8, 6820–6836. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, A.C.; Robertson, J. Interpretation of raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef] [Green Version]

- Ferrari, A.C.; Meyer, J.C.; Scardaci, V.; Casiraghi, C.; Lazzeri, M.; Mauri, F.; Piscanec, S.; Jiang, D.; Novoselov, K.S.; Roth, S. Raman spectrum of graphene and graphene layers. Phys. Rev. Lett. 2006, 97, 187401. [Google Scholar] [CrossRef] [Green Version]

- Pei, S.; Wei, Q.; Huang, K.; Cheng, H.M.; Ren, W. Green synthesis of graphene oxide byseconds timescale water electrolytic oxidation. Nat. Commun. 2018, 9, 145. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bardash, L.; Fainleib, A.; Grigoryeva, O.; Boiteux, G.; Ulanski, J. Effect of Carbon Nanotubes on Formation Process, Structure and Properties of Nanocomposites Based on Thermostable Crosslinked Polycyanurates. Ukr. Chem. J. 2013, 79, 58–68. [Google Scholar]

- Santhosh Kumar, K.S.; Reghunadhan Nair, C.P.; Ninan, K.N. Investigations on the cure chemistry and polymer properties of benzoxazine–cyanate ester blends. Eur. Polym. J. 2009, 45, 494–502. [Google Scholar] [CrossRef]

- Hill, L.W.; Korzeniowski, H.M.; Ojunga-Andrew, M.; Wilson, R.C. Accelerated clearcoat weathering studied by dynamic mechanical analysis. Prog. Org. Coat. 1994, 24, 147–173. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, C.-Y.; Liu, Y. Investigation on fluorescence quenching of dyes by graphite oxide and graphene. Appl. Surf. Sci. 2011, 257, 5513–5518. [Google Scholar] [CrossRef]

| Sample | C (%) | O (%) | O/C | Eu (%) | F (%) | N (%) |

|---|---|---|---|---|---|---|

| MWCNTs | 99.59 | 0.41 | 0.0041 | – | – | – |

| uMWCNTs | 86.32 | 13.75 | 0.1593 | – | – | – |

| MWCNTs/Eu | 82.67 | 7.44 | 0.0899 | 0.84 | 6.30 | 2.29 |

| uMWCNTs/Eu | 70.02 | 15.57 | 0.2223 | 1.30 | 9.33 | 4.24 |

| Sample | Lifetime (μs) |

|---|---|

| Eu(TTA)3phen | 515.2 |

| MWCNTs/Eu | 424.1 |

| uMWCNTs/Eu | 606.1 |

| Sample | Lifetime (μs) | QY (%) |

|---|---|---|

| CER/MWCNTs/Eu | 8.61 | 1.02 |

| CER/uMWCNTs/Eu | 186.39 | 2.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, N.; Qi, X.; Yang, D.; Chen, M.; Wang, Y.; Huang, L.; Grygoryeva, O.; Strizhak, P.; Fainleib, A.; Tang, J. Improved Mechanical, Anti-UV Irradiation, and Imparted Luminescence Properties of Cyanate Ester Resin/Unzipped Multiwalled Carbon Nanotubes/Europium Nanocomposites. Materials 2021, 14, 4244. https://doi.org/10.3390/ma14154244

Yang N, Qi X, Yang D, Chen M, Wang Y, Huang L, Grygoryeva O, Strizhak P, Fainleib A, Tang J. Improved Mechanical, Anti-UV Irradiation, and Imparted Luminescence Properties of Cyanate Ester Resin/Unzipped Multiwalled Carbon Nanotubes/Europium Nanocomposites. Materials. 2021; 14(15):4244. https://doi.org/10.3390/ma14154244

Chicago/Turabian StyleYang, Na, Xiaohua Qi, Di Yang, Mengyao Chen, Yao Wang, Linjun Huang, Olga Grygoryeva, Peter Strizhak, Alexander Fainleib, and Jianguo Tang. 2021. "Improved Mechanical, Anti-UV Irradiation, and Imparted Luminescence Properties of Cyanate Ester Resin/Unzipped Multiwalled Carbon Nanotubes/Europium Nanocomposites" Materials 14, no. 15: 4244. https://doi.org/10.3390/ma14154244

APA StyleYang, N., Qi, X., Yang, D., Chen, M., Wang, Y., Huang, L., Grygoryeva, O., Strizhak, P., Fainleib, A., & Tang, J. (2021). Improved Mechanical, Anti-UV Irradiation, and Imparted Luminescence Properties of Cyanate Ester Resin/Unzipped Multiwalled Carbon Nanotubes/Europium Nanocomposites. Materials, 14(15), 4244. https://doi.org/10.3390/ma14154244