Moisture Distribution during Water Absorption of Ordinary Portland Cement Mortars Obtained with Low-Field Unilateral Magnetic Resonance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation and Conditioning

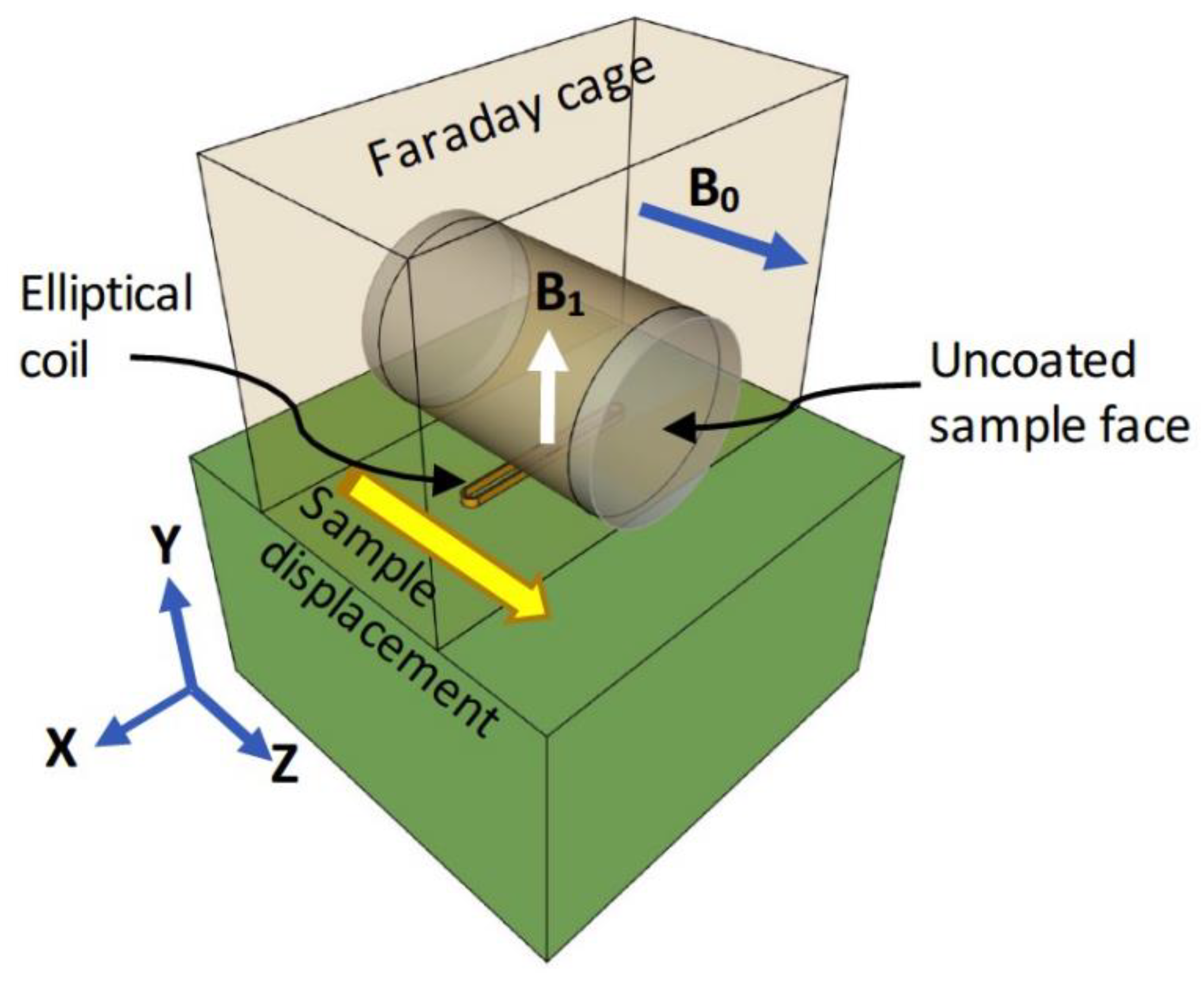

2.3. Water Absorption Experiments and NMR/MRI Measurements

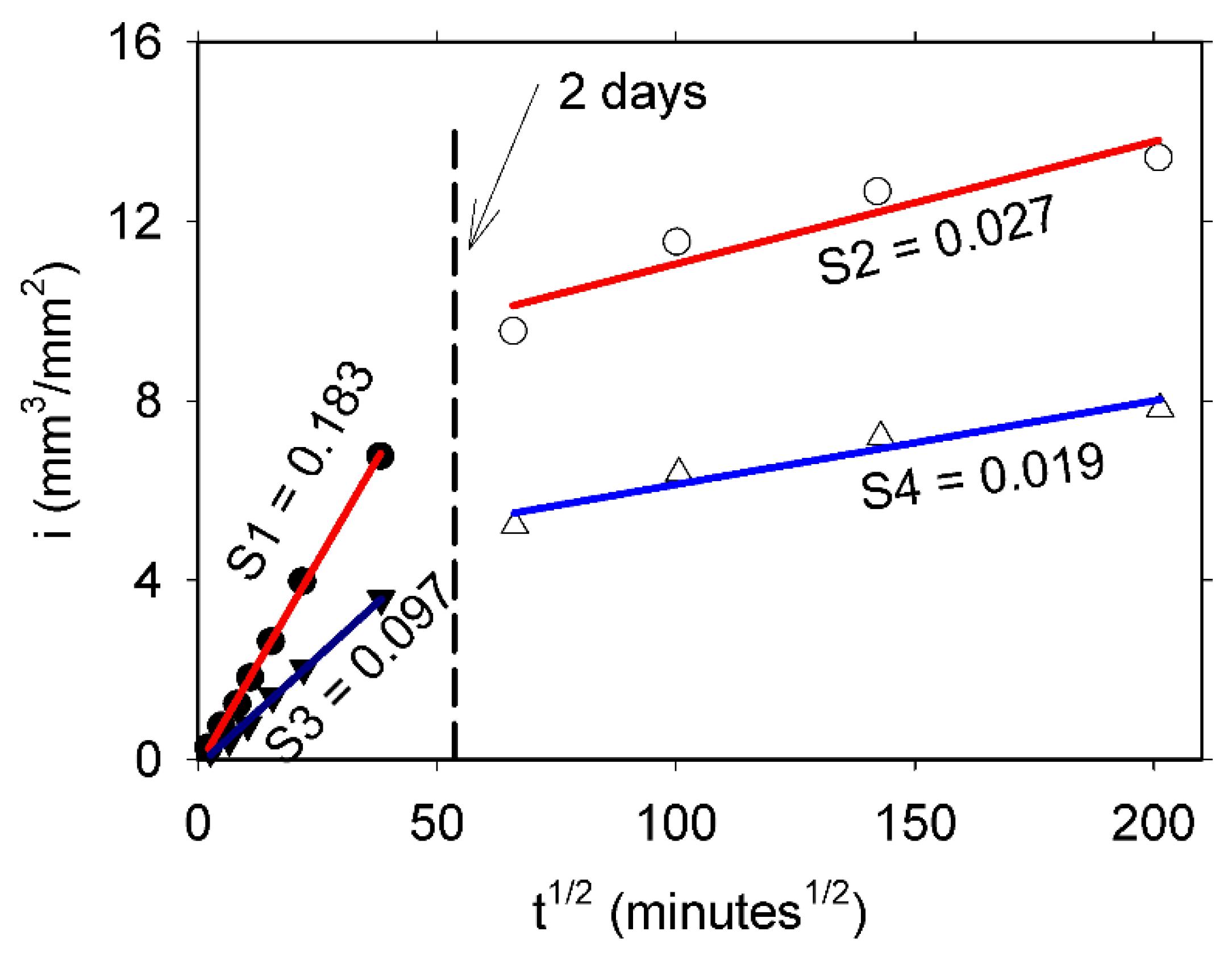

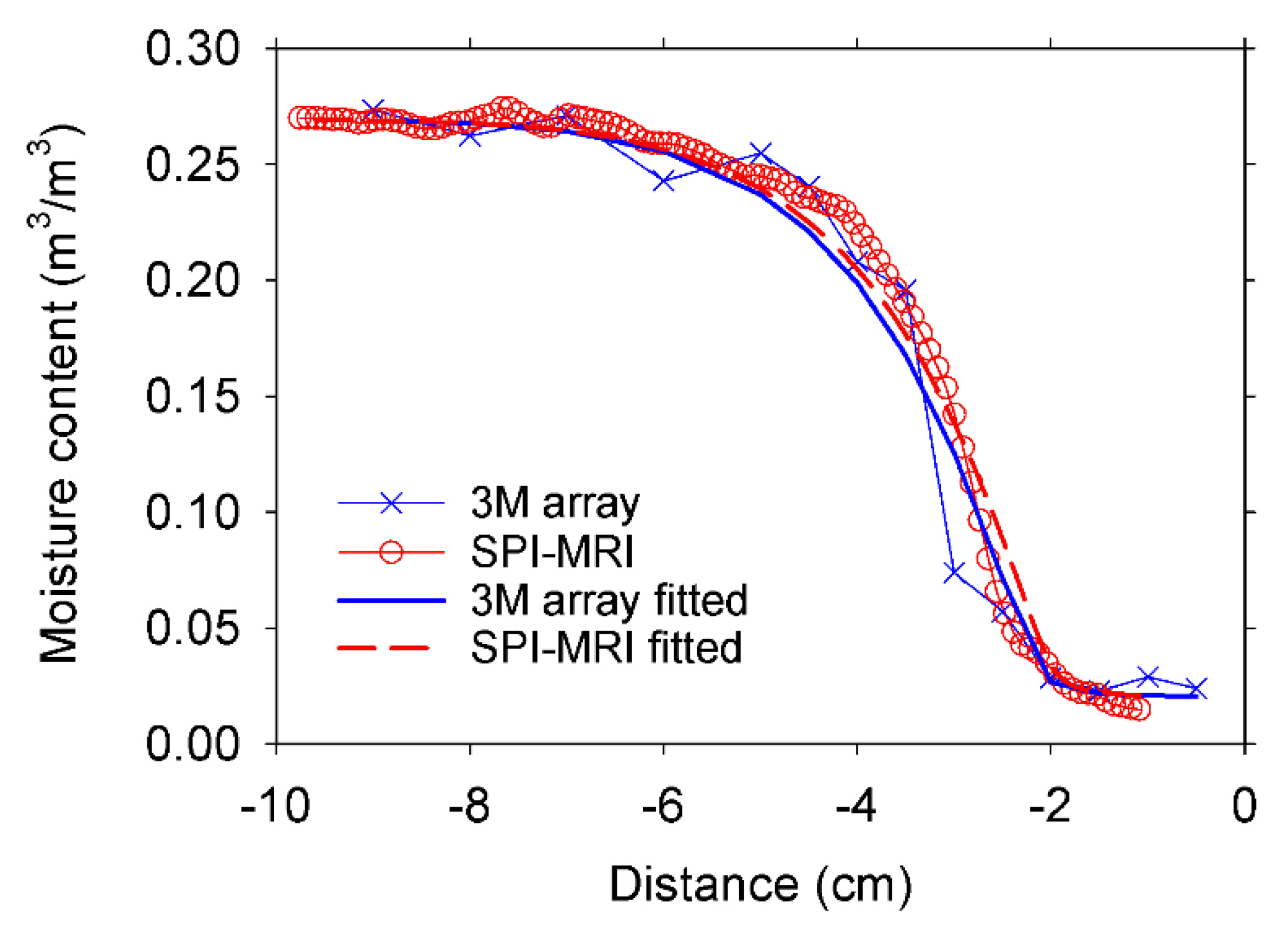

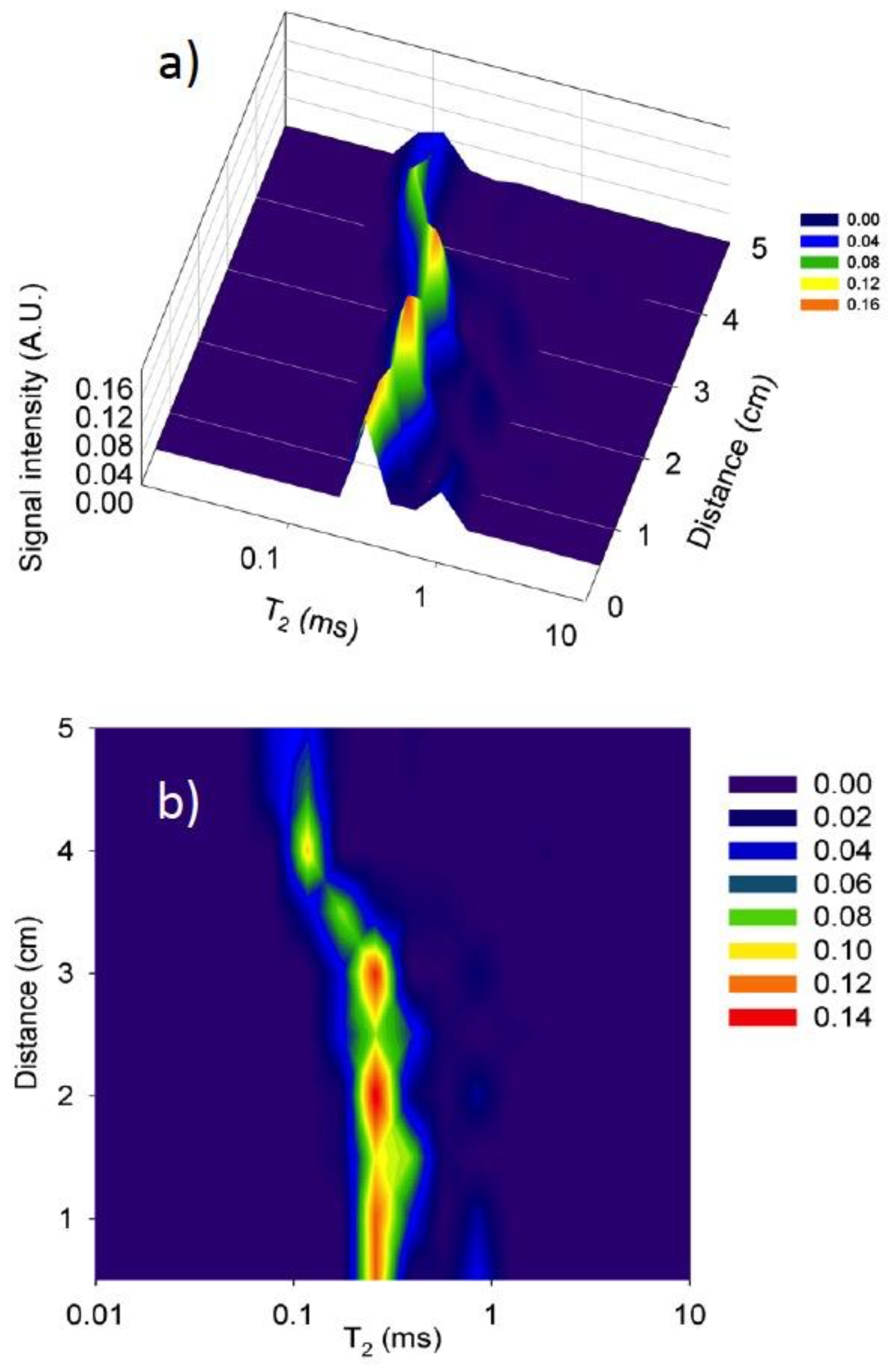

3. Results and Discussion

4. Conclusions

- A three-magnet array with an elliptical surface RF coil operating at a frequency of 4.64 MHz, allows the determination of the NMR signal along mortar and concrete samples containing ordinary materials and with no limitation on the sample size.

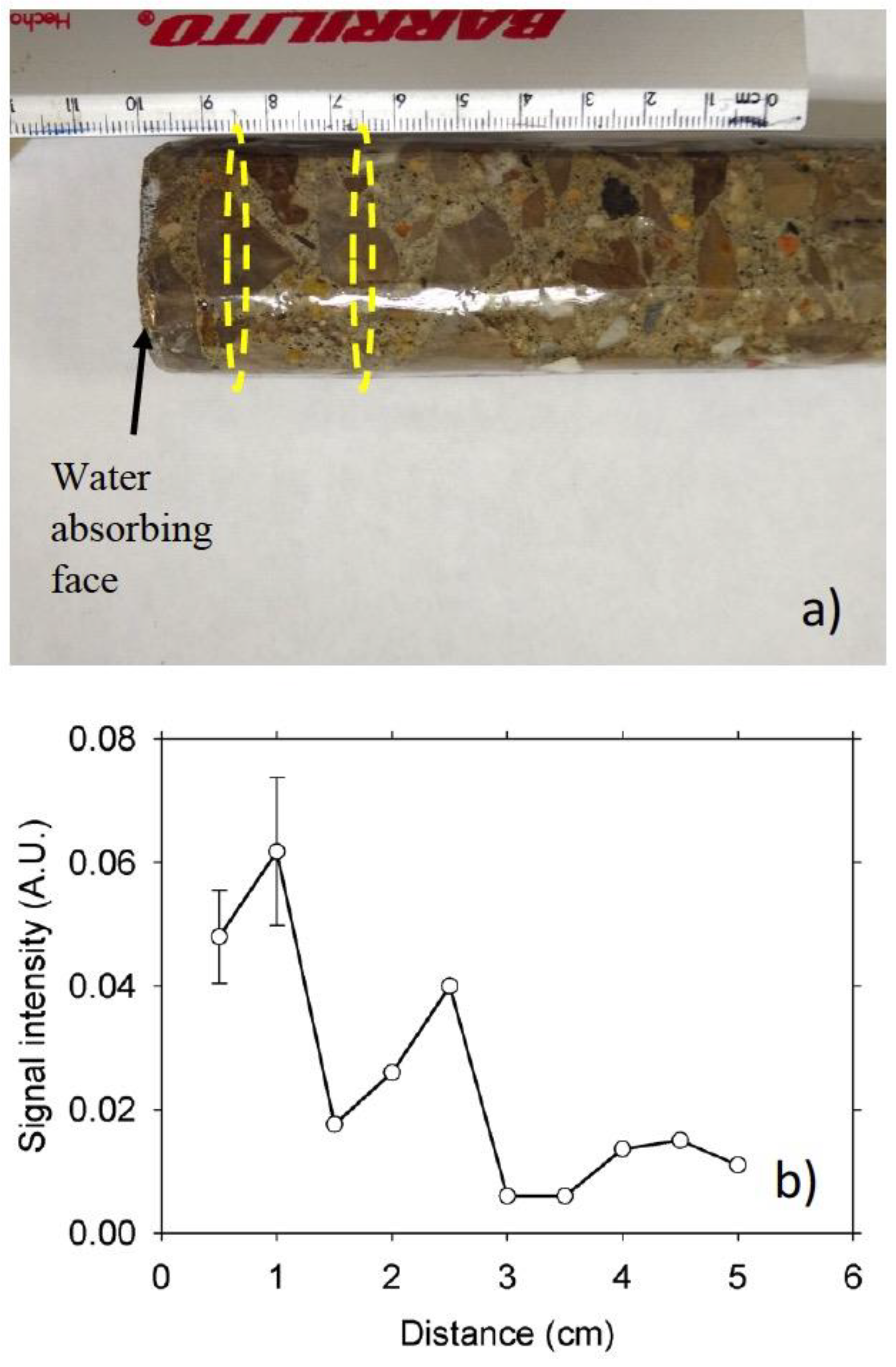

- In the concrete sample, the very short NMR signal lifetime (T2* ≈ 20 μs) caused by paramagnetic impurities in the material precluded the acquisition of an MRI profile.

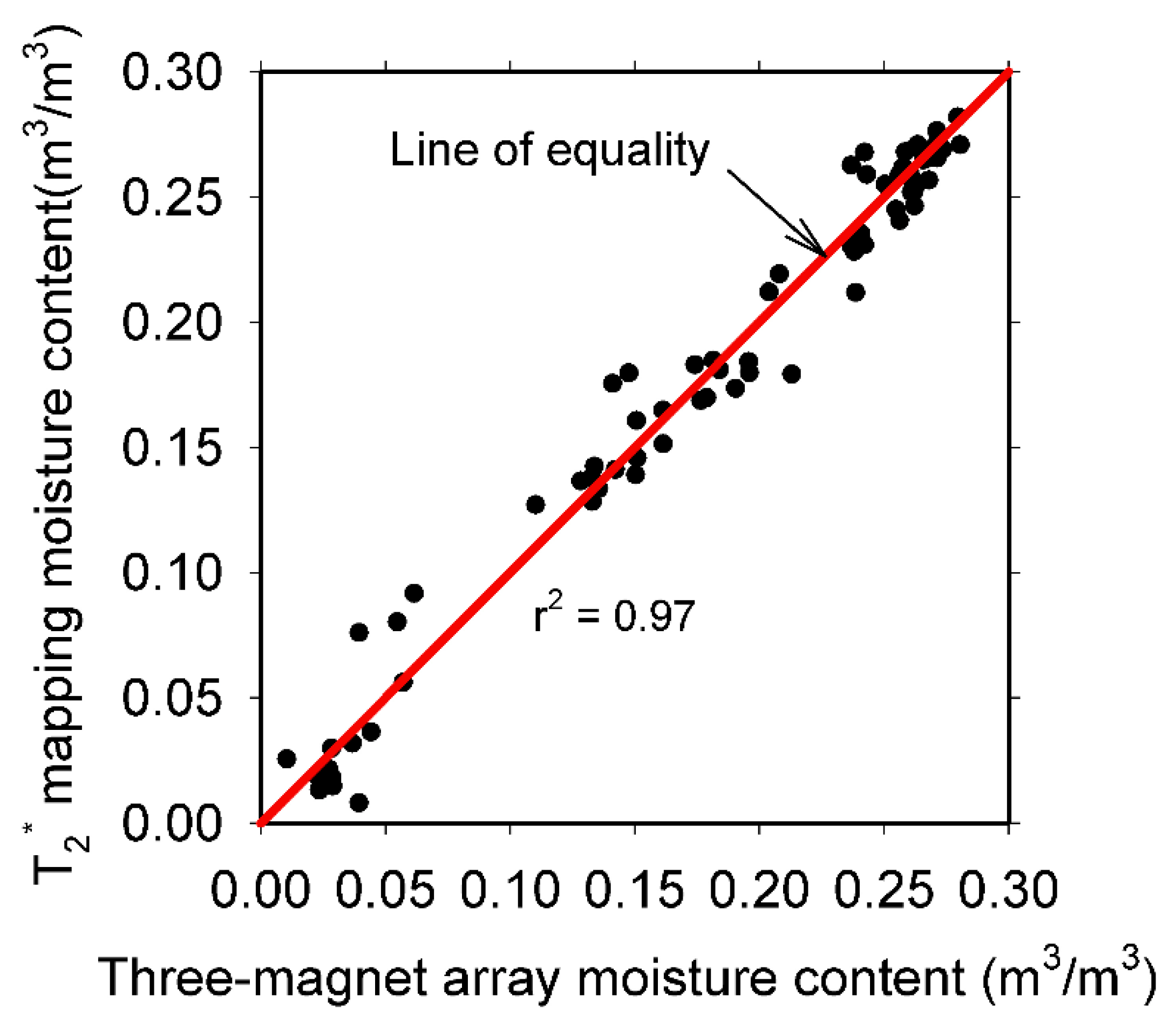

- There is a linear relationship between the signal intensities (moisture content) obtained with the three-magnet array and the corresponding signal intensities from MRI profiles taken as a reference (r2 = 0.97).

- Similar values of saturated permeability (Ks) of mortar samples with identical w/c ratios were obtained from profiles acquired by the two techniques outlined in this paper, demonstrating the feasibility of the three-magnet array with an elliptical surface RF coil to acquire valuable data for transport properties determination of cement-based materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kropp, J.; Hilsdorf, H.K. (Eds.) Performance Criteria for Concrete Durability; Rilem Report 12; Taylor & Francis: London, UK, 2004; p. 226. ISBN 9780203626672. [Google Scholar]

- Fischer, N.; Haerdtl, R.; McDonald, P.J. Is colour change a good measure of a water penetration front? Mag. Concr. Res. 2015, 67, 1048–1053. [Google Scholar] [CrossRef] [Green Version]

- Castro, J.; Bentz, D.; Weiss, J. Effect of sample conditioning on the water absorption of concrete. Cem. Concr. Compos. 2011, 33, 805–813. [Google Scholar] [CrossRef]

- Šelih, J.; Bremner, T.W. Drying of saturated lightweight concrete: An experimental investigation. Mater. Struct. 2006, 29, 401–405. [Google Scholar] [CrossRef]

- Villmann, B.; Slowik, V.; Wittmann, F.H.; Vontobel, P.; Hovind, J. Time-dependent moisture distribution in drying cement mortars: Results of neutron radiography and inverse analysis of drying tests. Restor. Build. Monum. 2014, 20, 49–62. [Google Scholar] [CrossRef]

- Balcom, B.J.; Barrita, J.C.; Choi, C.; Beyea, S.D.; Goodyear, D.J.; Bremner, T.W. Single-point magnetic resonance imaging (MRI) of cement based materials. Mater. Struct. 2003, 36, 166–182. [Google Scholar] [CrossRef]

- Garcia-Naranjo, J.C. Three-Magnet Arrays for Unilateral Magnetic Resonance. Ph.D. Thesis, University of New Brunswick, Fredericton, NB, Canada, 2012. [Google Scholar]

- García-Naranjo, J.C.; Guo, P.; Marica, F.; Liao, G.; Balcom, B.J. Magnetic resonance core-plug analysis with the three-magnet array unilateral magnet. Petrophysics 2014, 55, 229–239. [Google Scholar]

- Lamason, C.; Macmillan, B.; Balcom, B.; Leblon, B.; Pirouz, Z. Water content measurement in black spruce and aspen sapwood with benchtop and portable magnetic resonance devices. Wood Mater. Sci. Eng. 2015, 10, 86–93. [Google Scholar] [CrossRef]

- Cano-Barrita, P.F.J.; Balcom, B.J.; Castellanos, F. Carbonation front in cement paste detected by T2 NMR measurements using a low field unilateral magnet. Mater. Struct. 2017, 50, 150. [Google Scholar] [CrossRef] [Green Version]

- Díaz-Díaz, F.; Cano-Barrita, P.F.D.J.; León-Martínez, F.M.; Castellanos, F. Unilateral low-field magnetic resonance measurements of carbonation depth in unsaturated and saturated Portland cement mortars. Cem. Concr. Res. 2020, 138, 106237. [Google Scholar] [CrossRef]

- Beyea, S.D.; Balcom, B.J.; Prado, P.J.; Cross, A.R.; Kennedy, C.B.; Armstrong, R.L.; Bremner, T.W. Relaxation time mapping of short T2* nuclei with single-point imaging (SPI) methods. J. Magn. Reson. 1998, 135, 156–164. [Google Scholar] [CrossRef]

- Radcliffe, D.E.; Simunek, J. Soil Physics with Hydrus—Modeling and Applications; CRC Press, Taylor & Francis Group: New York, NY, USA, 2010; ISBN 9781420073805. [Google Scholar]

- Schulte Holthausen, R.; Raupach, M. A phenomenological approach on the influence of paramagnetic iron in cement stone on 2D T1-T2 relaxation in single-sided 1H nuclear magnetic resonance. Cem. Concr. Res. 2019, 120, 279–293. [Google Scholar] [CrossRef]

- ASTM C305. Standard Practice for Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic Consistency; ASTM Int.: West Conshohocken, PA, USA, 2014; pp. 1–3. [Google Scholar]

- Hall, C. Water sorptivity of mortars and concretes: A review. Mag. Concr. Res. 1989, 41, 51–61. [Google Scholar] [CrossRef]

- ASTM C1585-13. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic Cement Concretes; ASTM: West Conshohocken, PA, USA, 2013; Volume 41. [Google Scholar]

- Meiboom, S.; Gill, D. Modified spin-echo method for measuring nuclear relaxation times. Rev. Sci. Instrum. 1958, 29, 688–691. [Google Scholar] [CrossRef] [Green Version]

- Coates, G.R.; Xiao, L.; Prammer, M.G. NMR Logging Principles & Applications; Sigal, R.F., Bollich, S.J., Eds.; Halliburton Energy Services: Houston, TX, USA, 1999. [Google Scholar]

- Emid, S.; Creyghton, J.H.N. High Resolution NMR Imaging in solids. Physica 1985, 128B, 81–83. [Google Scholar] [CrossRef]

- Enjilela, R.; Cano-Barrita, P.F.d.J.; Komar, A.; Boyd, A.J.; Balcom, B.J. Monitoring steady state moisture distribution during wick action in mortar by magnetic resonance imaging (MRI). Mater. Struct. 2017, 50, 1–12. [Google Scholar] [CrossRef]

- Šimůnek, J.; van Genuchten, M.T.; Šejna, M. Recent Developments and Applications of the HYDRUS Computer Software Packages. Vadose Zone J. 2016, 15, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Enjilela, R.; Cano-Barrita, P.F.d.J.; Komar, A.; Boyd, A.J.; Balcom, B.J. Wet front penetration with unsteady state wicking in mortar studied by Magnetic Resonance Imaging (MRI). Mater. Struct. Constr. 2018, 50, 1–16. [Google Scholar] [CrossRef]

- Halperin, W.P.; Jehng, J.Y.; Song, Y.Q. Application of spin-spin relaxation to measurement of surface area and pore size distributions in a hydrating cement paste. Magn. Reson. Imaging 1994, 12, 169–173. [Google Scholar] [CrossRef]

- Fischer, N.; Haerdtl, R.; McDonald, P.J. Observation of the redistribution of nanoscale water filled porosity in cement based materials during wetting. Cem. Concr. Res. 2015, 68, 148–155. [Google Scholar] [CrossRef] [Green Version]

- Neville, A.M. Properties of Concrete, 4th ed.; Longman Group Limited: Harlow Essex, UK, 1995. [Google Scholar]

- Baroghel-Bouny, V.; Thiery, M.; Wang, X. Modelling of isothermal coupled moisture-ion transport in cementitious materials. Cem. Concr. Res. 2011, 41, 828–841. [Google Scholar] [CrossRef]

- Buenfeld, N.R.; Shurafa-Daoudi, M.T.; McLoughlin, I.M. Chloride Transport Due to Wick Action in Concrete. In Proceedings of the 1st RILEM workshop on Chloride Penetration into Concrete, St Remy les Chevreuse, France, 15–18 October 1995; pp. 315–324. [Google Scholar]

- Marchand, J. Modeling the behavior of unsaturated cement systems exposed to aggressive chemical environments. Mater. Struct. 2001, 34, 195–200. [Google Scholar] [CrossRef]

| Oxide | Weight (%) |

|---|---|

| SiO2 | 21.07 |

| Al2O3 | 3.69 |

| Fe2O3 | 4.50 |

| CaO | 61.93 |

| MgO | 1.83 |

| Na2O | 0.09 |

| K2O | 0.30 |

| SO3 | 2.54 |

| LOI | 4.38 |

| Sample | w/c Ratio | Ks (m/s) SPI-MRI | Ks (m/s) Three-Magnet Array |

|---|---|---|---|

| 1 | 0.60 | 7.63 × 10−12 | 7.33 × 10−12 |

| 2 | 0.60 | 7.97 × 10−12 | 7.88 × 10−12 |

| 3 | 0.35 | 1.37 × 10−12 | 1.36 × 10−12 |

| 4 | 0.35 | 1.55 × 10−12 | 1.35 × 10−12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cano-Barrita, P.F.d.J.; Díaz-Díaz, F. Moisture Distribution during Water Absorption of Ordinary Portland Cement Mortars Obtained with Low-Field Unilateral Magnetic Resonance. Materials 2021, 14, 4279. https://doi.org/10.3390/ma14154279

Cano-Barrita PFdJ, Díaz-Díaz F. Moisture Distribution during Water Absorption of Ordinary Portland Cement Mortars Obtained with Low-Field Unilateral Magnetic Resonance. Materials. 2021; 14(15):4279. https://doi.org/10.3390/ma14154279

Chicago/Turabian StyleCano-Barrita, Prisciliano Felipe de Jesús, and Floriberto Díaz-Díaz. 2021. "Moisture Distribution during Water Absorption of Ordinary Portland Cement Mortars Obtained with Low-Field Unilateral Magnetic Resonance" Materials 14, no. 15: 4279. https://doi.org/10.3390/ma14154279