The Influence of Different Plasma Cell Discharges on the Performance Quality of Surgical Gown Samples

Abstract

:1. Introduction

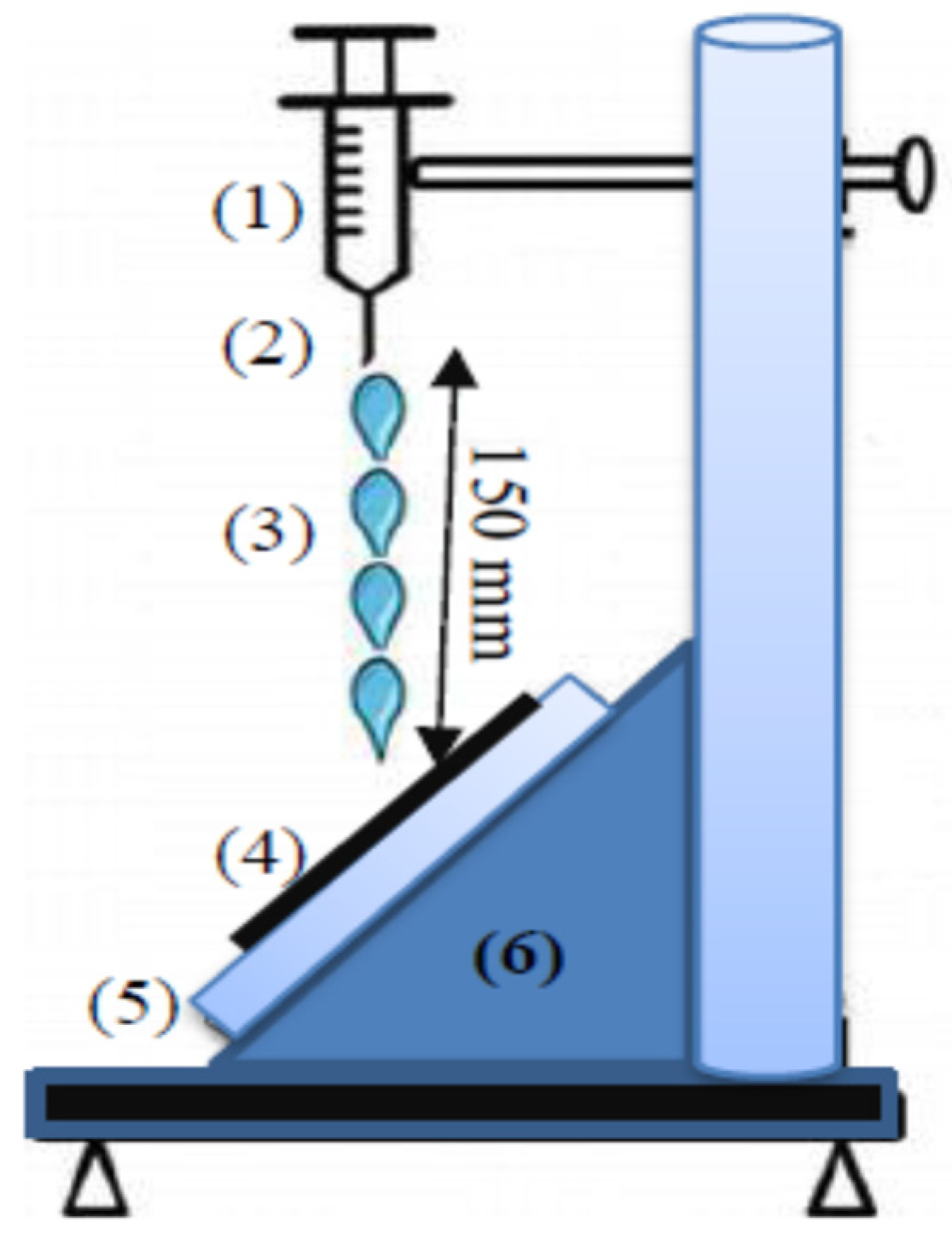

2. Experimental Set-Up

2.1. System Preparations

2.2. Textile Preparations

3. Results and Discussion

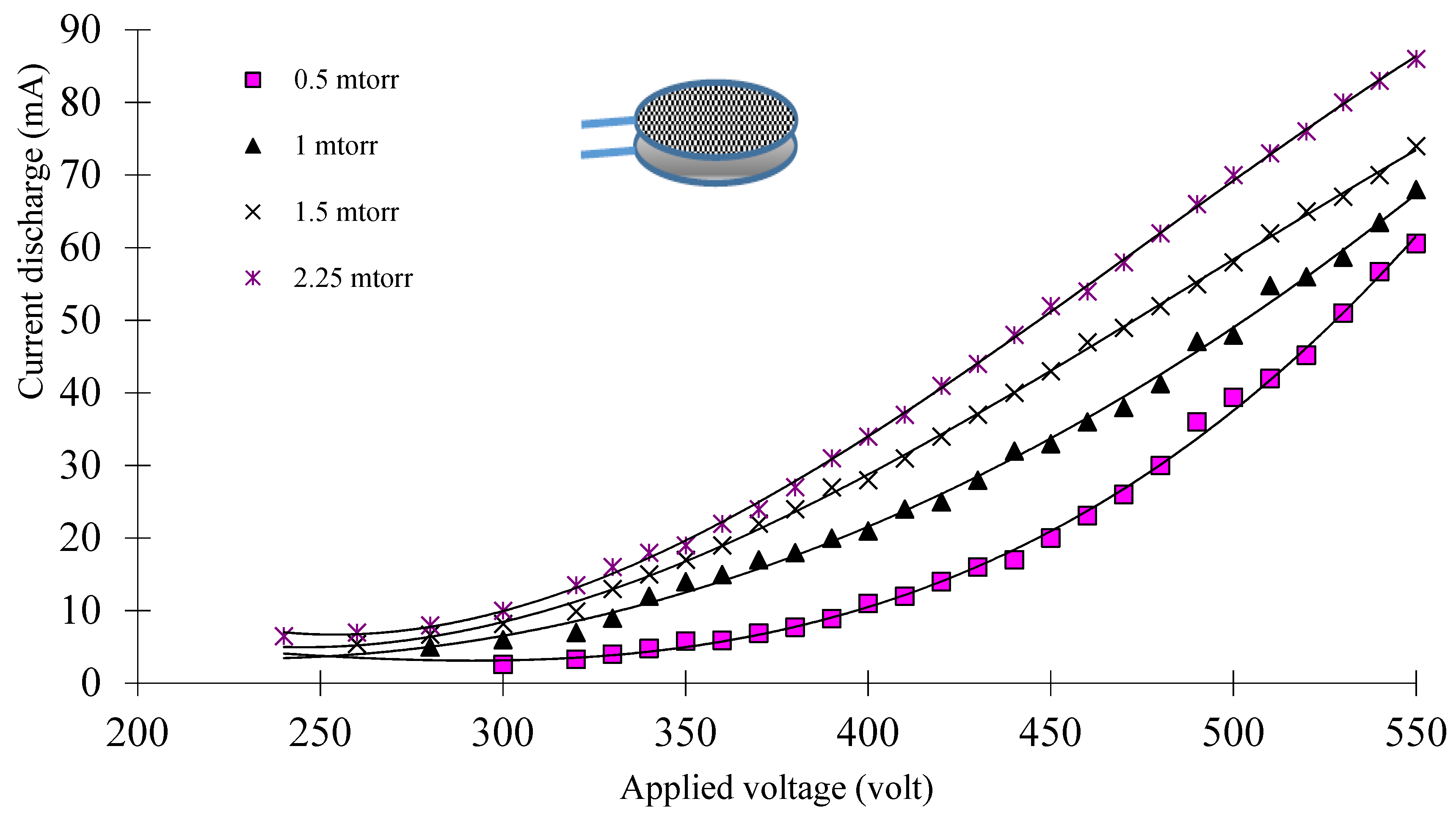

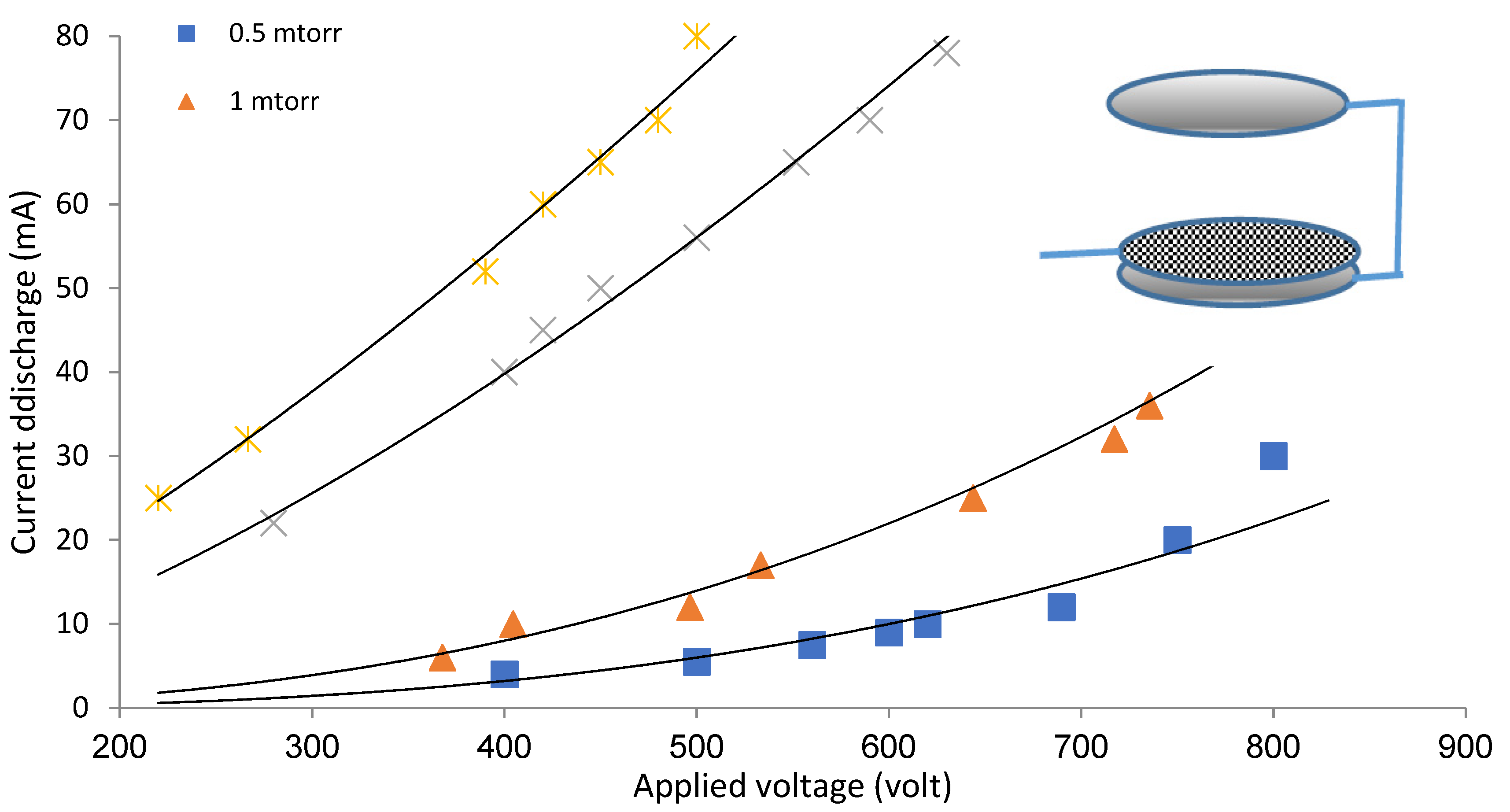

3.1. The Characteristics of Different Cathode Configurationtables

3.1.1. I–V Characteristics

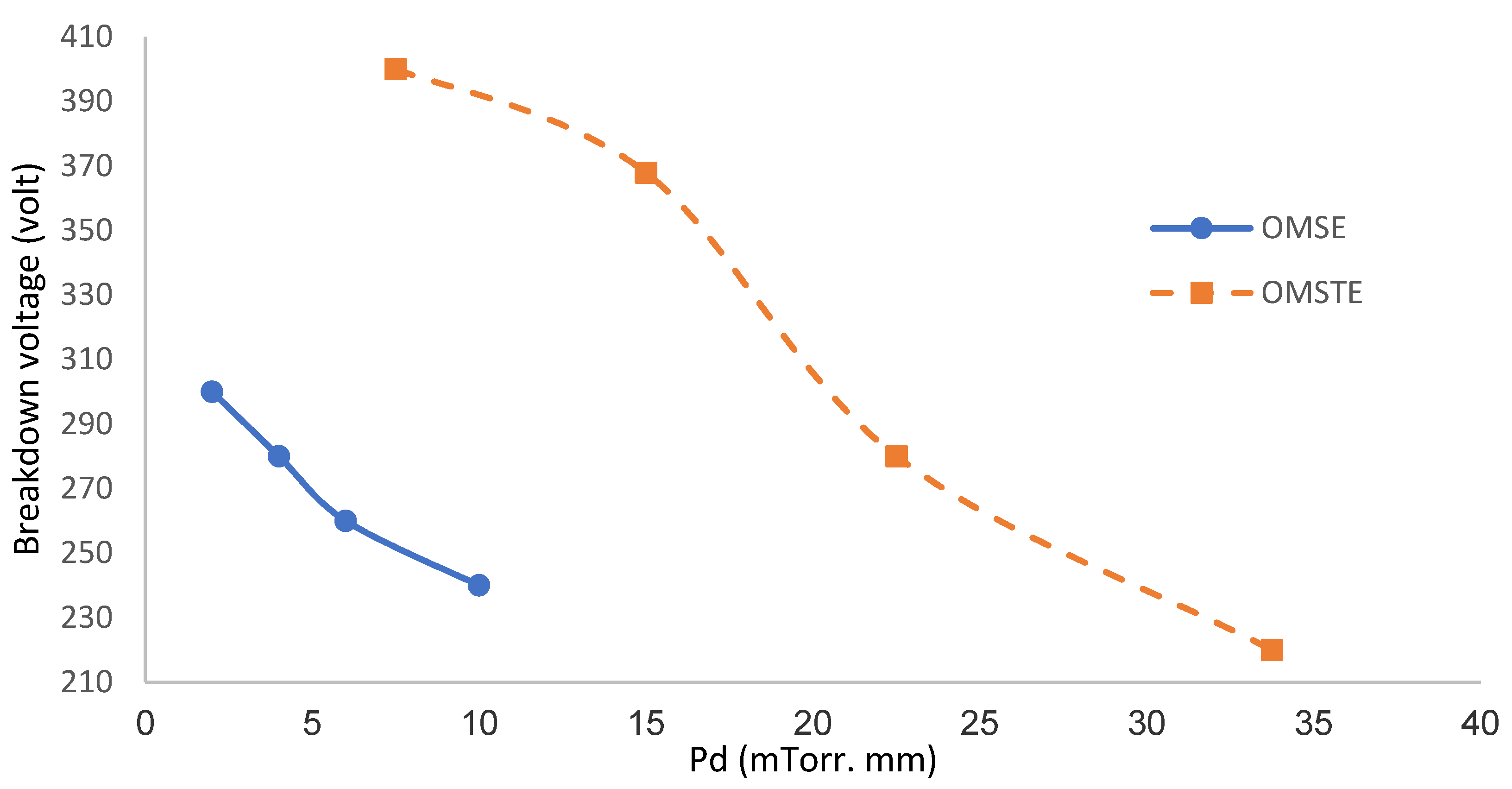

3.1.2. Paschen Curves

- (i)

- The small gap discharge for OMSE, where plasma was confined above the cathode mesh, leading to a decrease of the ionization coefficient and to a higher recombination coefficient of Ar2+ (0.7 × 10−6 cm3/s), whereby argon molecules suffered inelastic collisions with energetic electrons, excitation, and ionization when entering the discharge [29].

- (ii)

- The collision frequency between electrons and neutral atoms or molecules in the gap discharge, which increased more for OMSE than for OMTSE [30].

- (iii)

- The large gap discharge in the OMTSE reactor between the cathode mesh with respect to the secondary anode electrode, where the ionization cross-section decreased, and electrons needed more energy to reach the secondary anode [31].

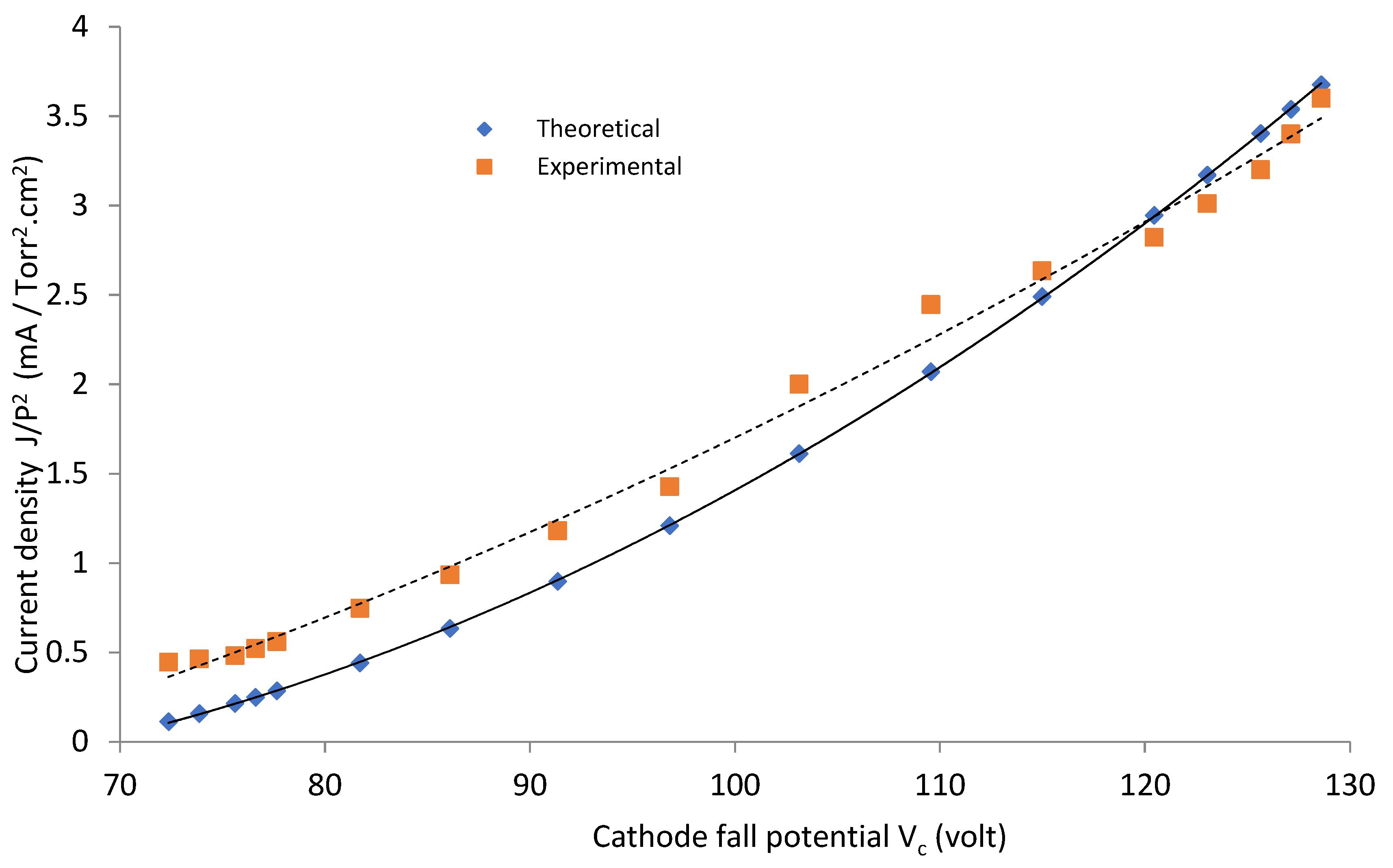

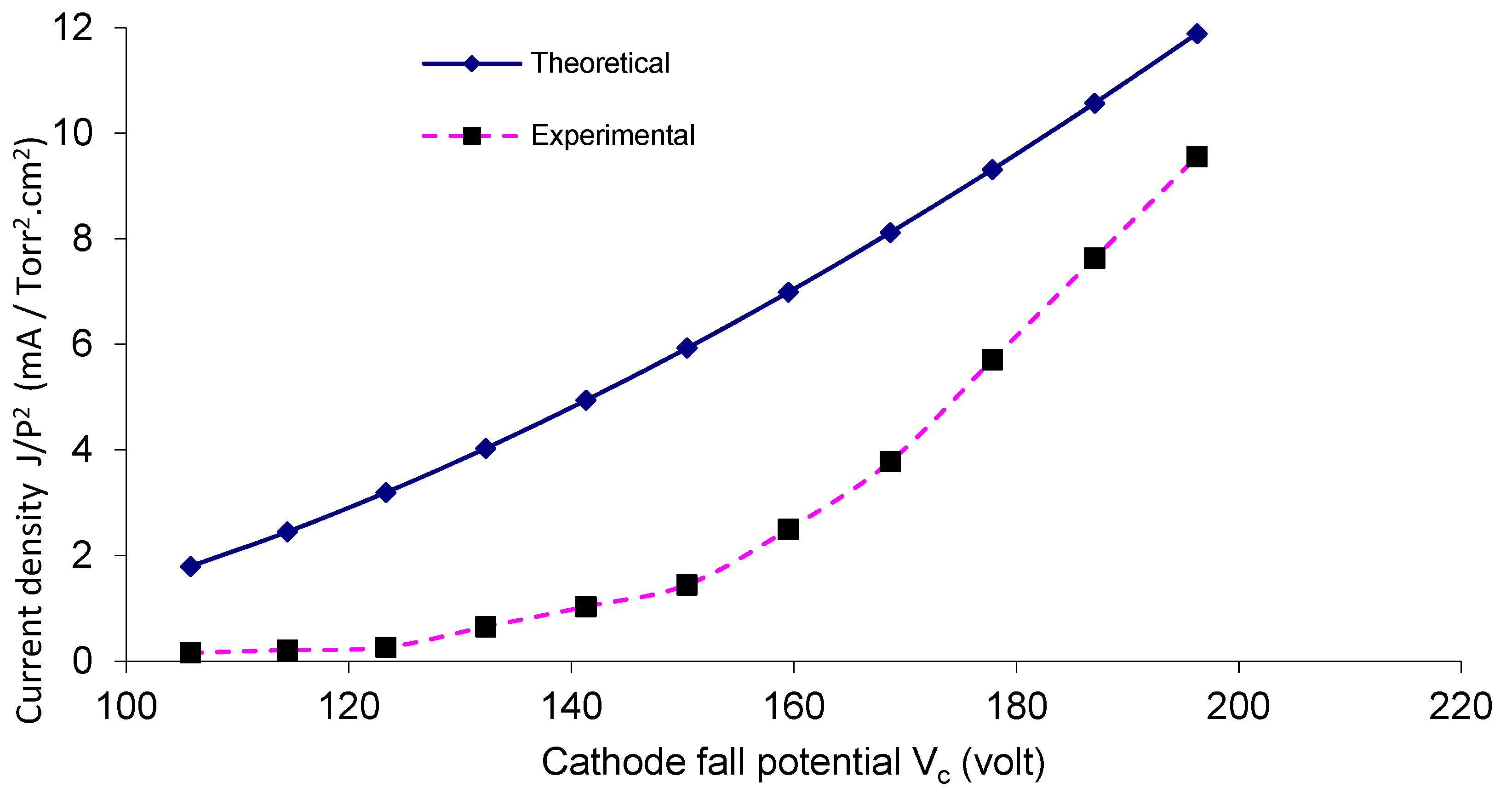

3.1.3. Current Density

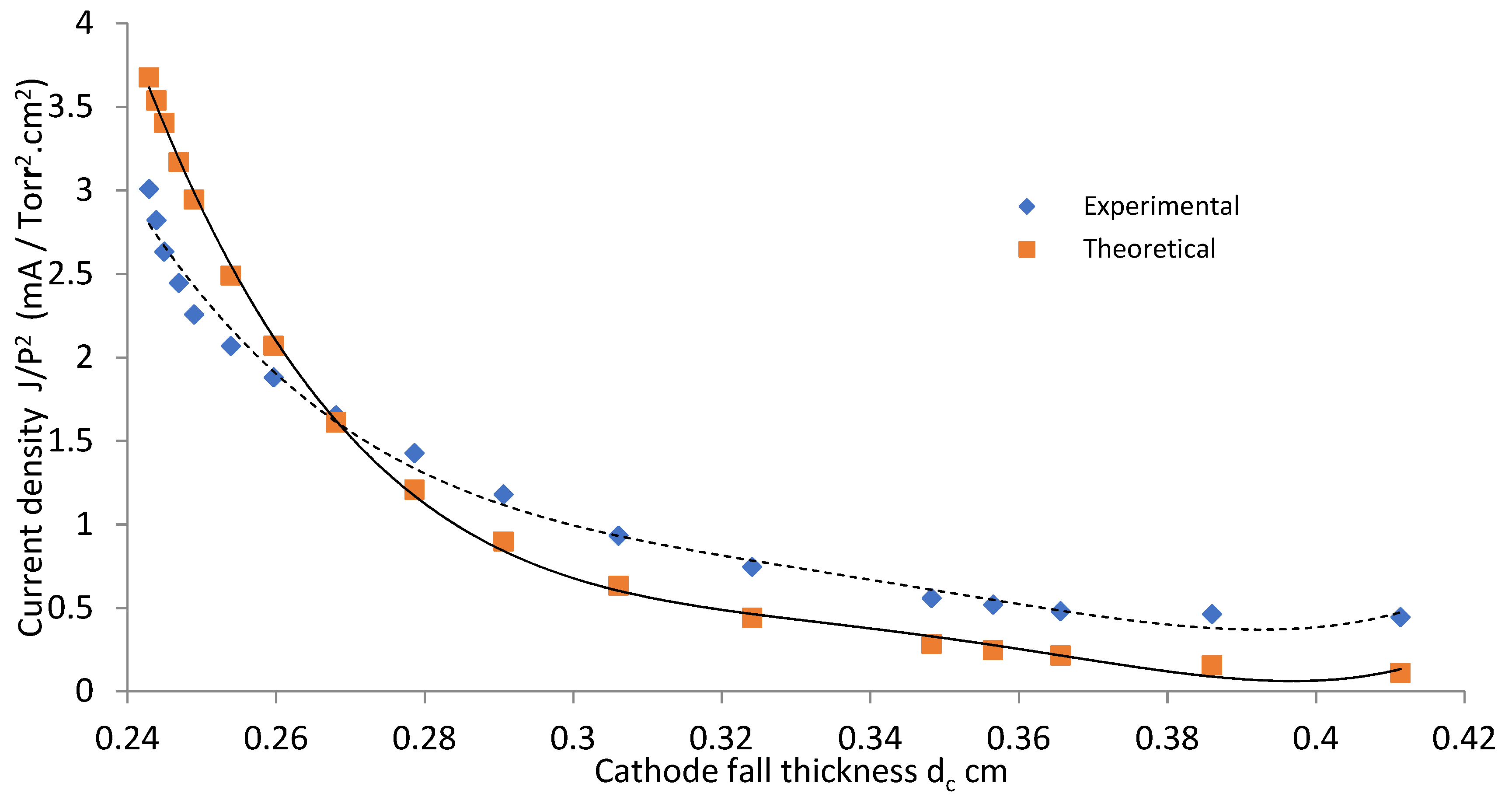

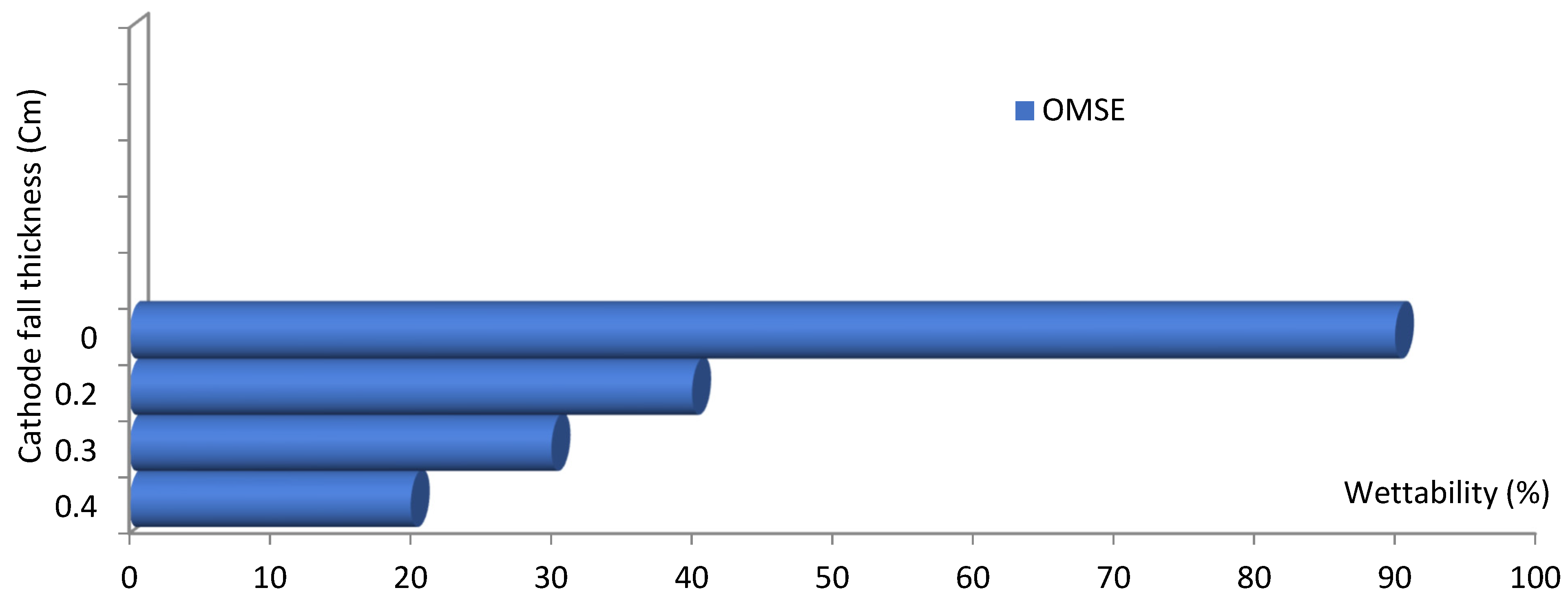

3.1.4. Cathode Fall Thickness

3.2. The Influence of Different Cathode Configurations on the Surgical Gown

- (I)

- As seen in Section 3.1, the OMTSE current density ranged from 0.15 to 9.5 mA/cm2 for dc ranging from 0.22 to 0.27 cm, and the OMSE current density ranged from 0.44 to 3.01 mA/cm2 for dc ranging from 0.24 to 0.41 cm. The treatment efficiency was measured for the surgical gown surface in plasma over the mesh cathode at a distance equivalent to the cathode fall distance dc, and for a very short exposure time.

- (II)

- From our previous work with the same construction mentioned in [23], the ion velocity ranged from 1 to 3.5 km/s for OMSE, and from 4 to 22 km/s for OMTSE, while the ion density Ni per unit area for OMSE was in the range of 109 cm−3 and lower than that for OMTSE (in the range of 1010 cm−3).

3.2.1. Performance Quality of the Surgical Gown

- (i)

- The treatment processes of the surgical gown exposed to plasma are described as follows [39,40]: Electrons and ions formed because of the plasma discharge. The sample was initially negatively charged, relative to the plasma bulk, because of the higher mobility of the lighter electrons. Then, more electrons were repelled from the sample and the positive ions were accelerated toward it.

- (ii)

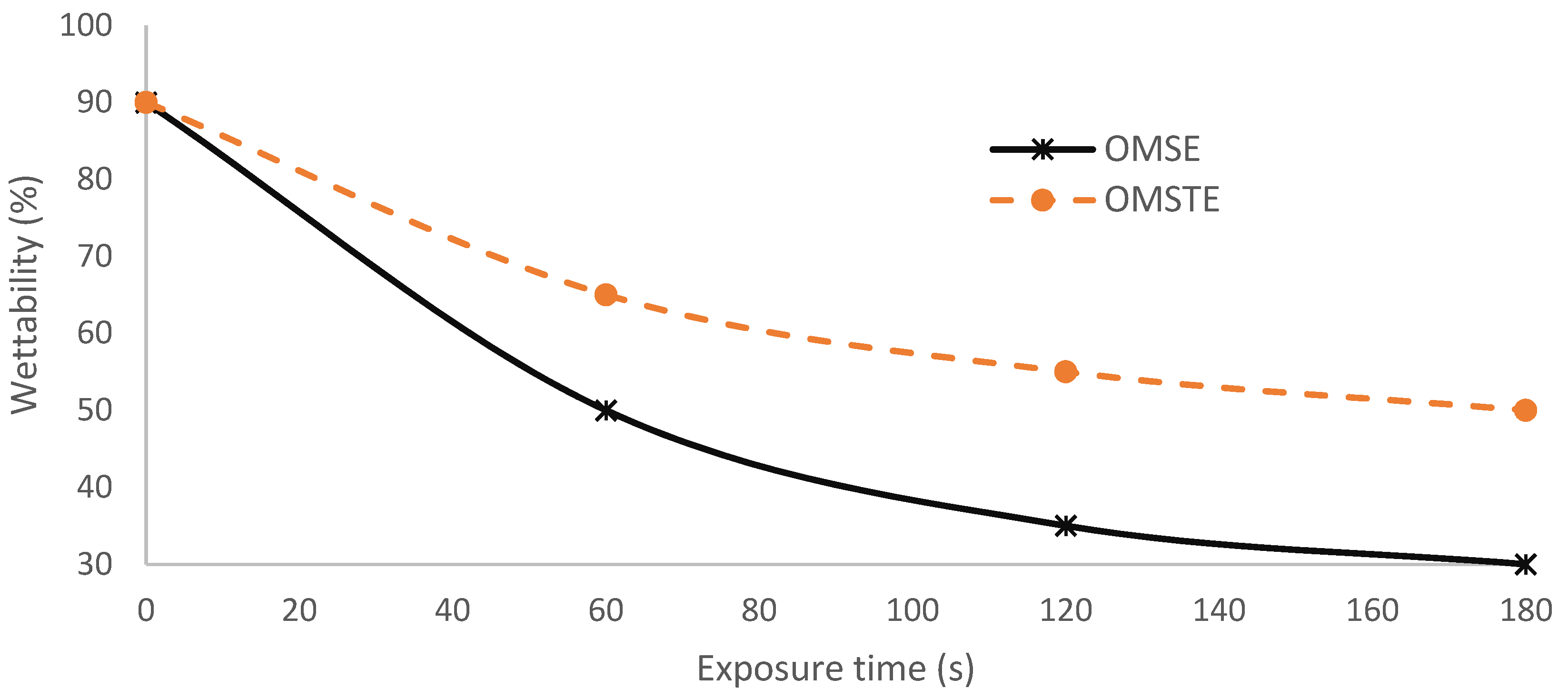

- The wettability of the modified surface decreased when decreasing the gas pressure, increasing the axial exposure distance (dc), and increasing the velocity of the penetrating species (ions, free electrons, neutral atoms, and molecules) on the textile surface [41]. This can be understood from Figure 8 and Figure 9 and Equation (2), where the cathode fall thickness increased with decreasing of the current density at low pressure, 1 mTorr.

- (iii)

- The treatment efficiency reaches a maximum in plasma in a very short exposure time [42]; the poor wettability and maximum water repellency properties for OMSE, more so than OMTSE may be due to the apparent increase in the pressure and the change of the laminar mode for OMSE to turbulent mode for OMTSE because of the long distance between the mesh and the secondary electrode.

- (i)

- (ii)

- The physical changes from the exposure to the plasma. These changes produce more reactive surfaces and affect wettability, as will be discussed in Section 3.3 [46].

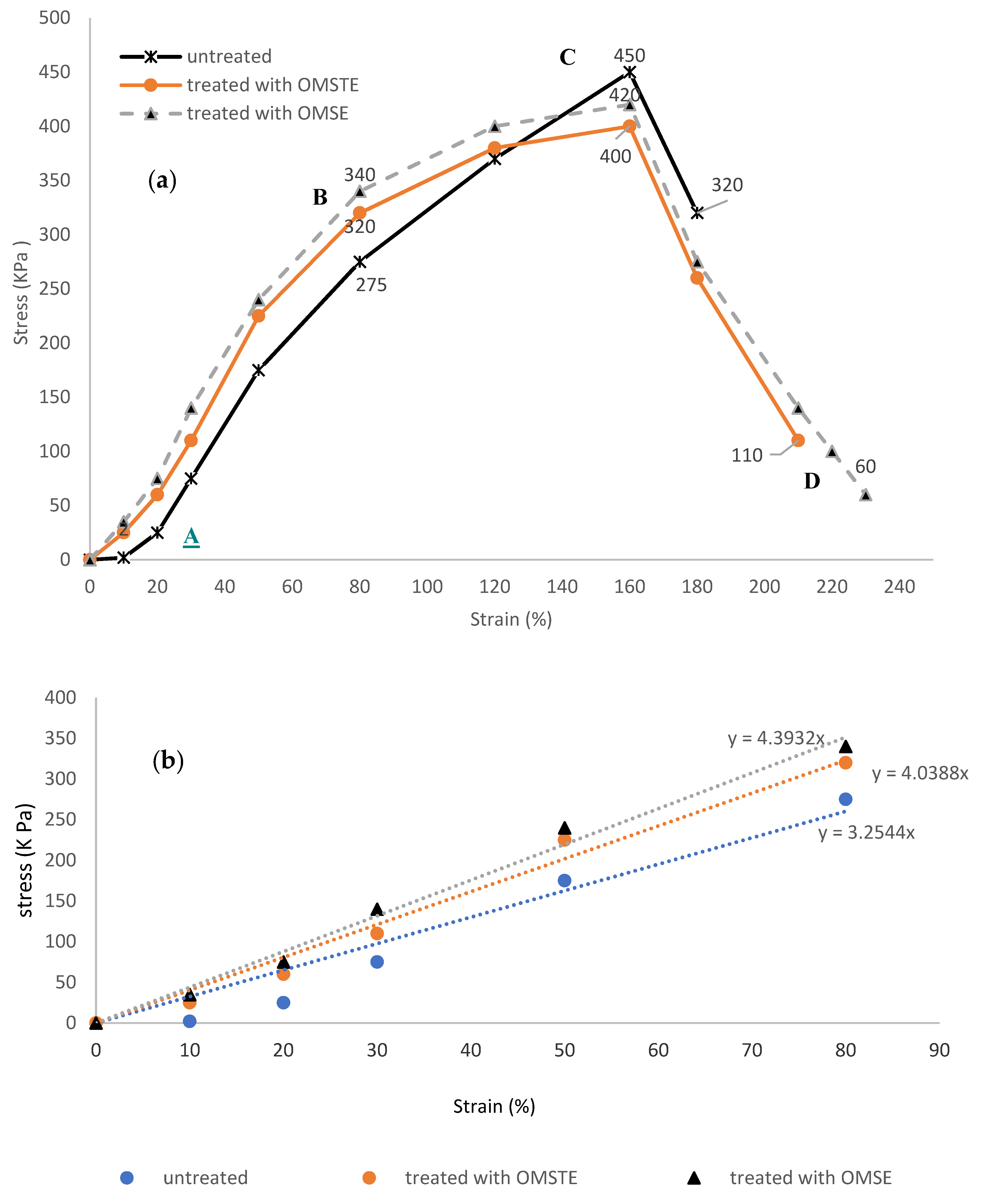

3.2.2. Mechanical Properties

- (i)

- The mechanical properties of the surgical gown samples treated with plasma were more positively influenced in the OMSE reactor than in the OMTSE reactor.

- (ii)

- The use of plasma to treat the surgical gown samples increased the elasticity area, the stretch, and the strain percentages.

- (iii)

- The density and the energy of the positive ions emerging from the mesh and colliding with the surgical gown sample for OMSE were much greater than those for OMTSE. This can be attributed to the fact that there was a loss of energy for OMTSE due to (a) creation of a sheath around the mesh for OMTSE and (b) creation of dusty plasma due to more scattering in the longer distance between the mesh and the secondary electrode for OMTSE [52,53].

3.3. The Mechanisms of Plasma Interaction with Textile Surface

3.3.1. Interaction Type

3.3.2. Gas Type

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Phelps, A. Abnormal glow discharges in Ar: Experiments and models. Plasma Sources Sci. Technol. 2001, 10, 329. [Google Scholar] [CrossRef]

- Nasser, E. Fundamentals of Gaseous Ionization and Plasma Electronics; John Wiley and Sons Inc.: New York, NY, USA, 1971. [Google Scholar]

- Rida Galaly, A. Distributions of Electron Density and Electron Temperature in Magnetized DC Discharge. Phys. Sci. Int. J. 2014, 4, 930. [Google Scholar] [CrossRef]

- Fancey, S.; Matthews, A. Some fundamental aspects of glow discharges in plasma-assisted processes. Surf. Coat. Technol. 1987, 33, 17. [Google Scholar] [CrossRef]

- Chapman, B. Glow Discharges Processes; John Wiley and Sons Inc.: New York, NY, USA, 1980. [Google Scholar]

- Richards, J. Energies of particles at the cathode of a glow discharge. Vacuum 1984, 34, 559. [Google Scholar] [CrossRef]

- Rida Galaly, A.; Zahran, H. Inactivation of bacteria using combined effects of magnetic field, low pressure and ultra low frequency plasma discharges (ULFP). J. Phys. Conf. Ser. (IOP) 2013, 431, 012014. [Google Scholar] [CrossRef] [Green Version]

- Spasojević, D.; Steflekova, V.; Šišović, N.M.; Konjević, N. Electric field distribution in the cathode-fall region of an abnormal glow discharge in hydrogen: Experiment and theory. Plasma Sources Sci Technol 2012, 21, 025006. [Google Scholar] [CrossRef]

- Simonchikpp, L.; Pitchfordpp, L.; Safronau, Y. Effect of the Cathode Surface Temperature on the Cathode Fall Layer Parameters ESCAMPIG xxi Conference. In Proceedings of the Escampig XXI Conference, Viana do Castelo, Portugal, 10–14 July 2012; p. 169. [Google Scholar]

- Rida Galaly, A.; Elakshar, F.; Khedr, M. Study of the Etching Processes of Si [1 0 0] Wafer Using Ultra Low Frequency Plasma. Mater. Sci. Forum 2013, 756, 143. [Google Scholar] [CrossRef]

- Garamoon, A.; Samir, A.; Elakshar, F.; Kotp, E. Electrical characteristics of a DC glow discharge. Plasma Sources Sci. Technol. 2003, 12, 417. [Google Scholar] [CrossRef]

- Grill, A. Cold Plasma in Material Fabrication from Fundamental to Applications; IEEE Press: Piscataway, NJ, USA, 1993. [Google Scholar]

- Morris, H.; Murray, R. Modeling the effect of weave structure and fabric thread density on the barrier effectiveness of woven surgical gowns Medical textiles. Text. Prog. 2020, 52, 1–127. [Google Scholar] [CrossRef]

- Tabares, F.; Junkar, I. Cold Plasma Systems and Their Application in Surface Treatments for Medicine. Molecules 2021, 26, 1903. [Google Scholar] [CrossRef]

- Wolf, R.; Sparavigna, A. Role of Plasma Surface Treatments on Wetting and Adhesion. Engineering 2010, 2, 397–402. [Google Scholar] [CrossRef] [Green Version]

- Rani, K.V.; Sarma, B.; Sarma, A. Plasma sputtering process of copper on polyester/silk blended fabrics for preparation of multifunctional properties. Vacuum 2017, 146, 206–215. [Google Scholar] [CrossRef]

- Hari Prakash, N.; Mariammal, M.; Solomon, I.; Sarma, B.; Sarma, A. Structural and Characteristics Change of Water Hyacinth Fiber due to Combine Effect of Plasma and Nano-technology. Am. J. Mater. Sci. Eng. 2017, 5, 17–27. [Google Scholar]

- Roth, J.R. Industrial Plasma Engineering. Applications to Nonthermal Plasma Processing; IOP: Bristol, UK, 2001; Volume 2. [Google Scholar]

- Beauchamp, J.; Buttrill, S. Proton Affinities of H2S and H2O. J. Chem. Phys. 1968, 48, 1783. [Google Scholar] [CrossRef] [Green Version]

- Grill, A. Institute of electrical and electronics engineers. In Cold Plasma in Material Fabrications; IEEE Press: Piscataway, NJ, USA, 1993. [Google Scholar]

- Kaplan, S.; Lopata, E.; Smith, J. Plasma processes and adhesive bonding of polytetrafluoroethylene. Surf. Interface Anal. 1993, 29, 331. [Google Scholar] [CrossRef]

- Rida Galaly, A.; Van Oost, G. Comparison between Theoretical and Experimental Radial Electron Temperature Profiles in a Low Density Weakly Ionized Plasma. J. Mod. Phys. 2019, 10, 699. [Google Scholar] [CrossRef] [Green Version]

- Galaly, A.R. The Effect of Different Cathode Configurations of the Plasma Cell on the Ion Velocity Distribution Function. IEEE Trans. Plasma Sci. 2020, 49, 535–545. [Google Scholar] [CrossRef]

- Available online: https://textiletuts.com/spray-test-for-water-repellency (accessed on 12 April 2021).

- Maqsood, M.; Nawab, Y.; Hamdani, S.T.A.; Shaker, K.; Umair, M.; Ashraf, W. Modeling the effect of weave structure and fabric thread density on the barrier effectiveness of woven surgical gowns. J. Text. Inst. 2016, 107, 873–878. [Google Scholar] [CrossRef]

- Brown, S. Introduction to Electrical Discharges in Gases; John Wiley and Sons Inc.: New York, NY, USA, 1966. [Google Scholar]

- Petraconi, G.; Maciel, H.S.; Pessoa, R.S.; Murakami, G.; Massi, M.; Otani, C.; Uruchi, W.M.I.; Sismanoglu, B.N. Longitudinal Magnetic Field Effect on the Electrical Breakdown in Low Pressure Gases. Braz. J. Phys. 2004, 34, 1662. [Google Scholar] [CrossRef]

- Chen, F. 2003 Mini-Course on Plasma Diagnostics. In Proceedings of the IEEE-ICOPS Meeting, Jeju, Korea, 5 June 2003. [Google Scholar]

- Yasuda, H. Plasma Polymerization and Plasma Interactions with Polymeric Materials; John Wiley and Sons Inc.: New York, NY, USA, 1990. [Google Scholar]

- Radmilovi’c, M. The breakdown mechanisms in electrical discharges: The role of the field emission effect in direct current discharges in microgaps. Acta Phys. Slovaca. 2013, 63, 105. [Google Scholar]

- Ledernez, L.; Olcaytug, F.; Urban, G. Inter-Electrode Distance and Breakdown Voltage in Low Pressure Argon Discharges Contrib. Plasma. Phys. 2012, 52, 276. [Google Scholar]

- Rida Galaly, A.; El Akshar, F. Determination of the cathode fall thickness in the magnetized DC plasma for Argon gas discharge. Phys. Scr. 2013, 88, 065503-7. [Google Scholar] [CrossRef]

- McDaniel, E. Collision Phenomena in Ionized Gases; John Wiley and Sons Inc.: New York, NY, USA, 1964. [Google Scholar]

- Parker, P. The Fundamentals of Gas Discharge Tubes; Chapter 15; Edward Arnold (Pub.) Ltd.: London, UK; p. 163.

- Rida Galaly, A.; El Akshar, F.F. Dust Plasma Effect on the Etching Process of Si[100] by Ultra Low Frequency RF Plasma. J. Mod. Phys. 2013, 4, 215. [Google Scholar] [CrossRef] [Green Version]

- Al-Hakary, S.K. Effect of Pressure and Hot Filament Cathode on Some Plasma Parameters of Hollow Anode Argon Glow Discharge Plasma. Am. J. Mod. Phys. 2016, 5, 30–38. [Google Scholar] [CrossRef]

- Yasuda, H.; Tao, W.; Prelas, M. Spatial distributions of electron density and electron temperature in direct current glow discharge. J. Vac. Sci. Technol. 1996, 14, 2113–2121. [Google Scholar]

- Clement, F.; Held, B.; Soulem, N.; Martinez, H. A study on the aging process of polystyrene thin films treated under DC pulsed discharges conditions in oxygen and argon-oxygen mixtures. Eur. Phys. J. 2003, 21, 59–66. [Google Scholar] [CrossRef]

- Abd Jelil, R. A review of low-temperature plasma treatment of textile materials. J. Mater. Sci. 2015, 50, 5913. [Google Scholar] [CrossRef]

- Rashidi, A. The effect of low temperature plasma treatment on surface modification of cotton and polyester fabrics. Indian J. Fiber Text. Res. 2004, 29, 74. [Google Scholar]

- Clement, F.; Held, B.; Soulem, N.; Spyrou, N. Polystyrene thin films treatment under DC pulsed discharges conditions in nitrogen. Eur. Phys. J. 2021, 13, 67. [Google Scholar] [CrossRef]

- Clement, F.; Held, B.; Soulem, N.; Guimon, C. XPS analyses of polystyrene thin films treated under DC pulsed discharges conditions in nitrogen, oxygen and oxygen-argon mixtures. Eur. Phys. J. 2002, 18, 135. [Google Scholar] [CrossRef]

- Bilek, M.; Newton-McGee, K.; McKenzie, D.R.; McCulloch, D.G. The role of energetic ions from plasma in the creation of nanostructured materials and stable polymer surface treatments. Nucl. Instr. Methods Phys. Res. 2006, 242, 221. [Google Scholar] [CrossRef]

- Clement, F.; Held, B.; Soulem, N. Polystyrene thin films treatment under DC pulsed discharges conditions in nitrogen-argon and oxygen-argon mixtures. Eur. Phys. J. 2002, 17, 119. [Google Scholar] [CrossRef]

- Isaiah, N.; Giovanni, M.; Ronan, Q. Ar/O2 Atmospheric Pressure Plasma Jet Treatment of Pure Surgical gown for Antibacterial Application. Plasma Fusion Res. 2018, 13, 3406116. [Google Scholar]

- Kan, C.-W.; Lam, Y.-L. Low Stress Mechanical Properties of Plasma-Treated Surgical gown Subjected to Zinc Oxide-Anti-Microbial Treatment. Materials 2013, 6, 314–333. [Google Scholar] [CrossRef] [Green Version]

- Kan, C.-W.; Man, W.-S. Parametric Study of Effects of Atmospheric Pressure Plasma Treatment on the Wettability of Surgical gown. Polymers 2018, 10, 233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tadesse, M.G.; Nagy, L.; Nierstrasz, V.; Loghin, C.; Chen, Y.; Wang, L. Low-Stress Mechanical Property Study of Various Functional Fabrics for Tactile Property Evaluation. Materials 2018, 11, 2466. [Google Scholar] [CrossRef] [Green Version]

- Kan, C.-w.; Lam, C.-f. Atmospheric Pressure Plasma Treatment for Grey Cotton Knitted Fabric. Polymers 2018, 10, 53. [Google Scholar] [CrossRef] [Green Version]

- Kan, C.-W.; Man, W.-S. Surface Characterisation of Atmospheric Pressure Plasma Treated Surgical gown—Effect of Operation Parameters. Polymers 2018, 10, 250. [Google Scholar] [CrossRef] [Green Version]

- Mendhe, P.; Arolkar, G.; Shukla, S.; Deshmukh, R. Low-temperature plasma processing for the enhancement of surface properties and dyeability of wool fabric. J. Appl. Polym. Sci. 2016, 133, 43097. [Google Scholar] [CrossRef]

- Teli, M.D.; Kartick, K.; Pintu, S.; Pandit, S.; Basak, S.K. Chattopadhyay. Low-temperature dyeing of surgical gown using atmospheric pressure helium/nitrogen plasma. Fibers Polym. 2015, 16, 2375–2383. [Google Scholar] [CrossRef]

- Zille, A.; Oliveira, F.R.; Souto, A.P. Plasma Treatment in Textile Industry. Plasma Process. Polym. 2015, 12, 98–131. [Google Scholar] [CrossRef] [Green Version]

- Samanta, K.K.; Jassal, M.; Agrawal, A.K. Improvement in water and oil absorbency of textile substrate by atmospheric pressure cold plasma treatment. Surf. Coat. Technol. 2009, 203, 1336–1342. [Google Scholar] [CrossRef]

- Maamoun, D.; Ghalab, S. Plasma utilization for treating wool/ polyester blended fabric to improve its printability. Indian J. Fibre Text. Res. 2013, 38, 180–185. [Google Scholar]

- Kale, K.; Palaskar, S. Atmospheric pressure glow discharge of helium-oxygen plasma treatment on polyester/cotton blended fabric. Indian J. Fibre Text. Res. 2011, 36, 137–144. [Google Scholar]

- Kale, K.H.; Desaia, A.N. Atmospheric Pressure Plasma Treatment of Textiles Using Non-Polymerising Gases. Indian J. Fibre Text. Res. 2011, 36, 289–299. [Google Scholar]

- Hsieh, Y. Surface Characteristics of Polyester Fibers. In Surf. Charact FIBERS Text, 1st ed.; Christopher, M.P., Paul, K., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 34–55. [Google Scholar]

| Units | Treated with OMTSE | Treated with OMSE | Untreated | Parameters | Position |

|---|---|---|---|---|---|

| KPa | 4.04 | 4.39 | 3.25 | stiffness | From A to B |

| KPa | 320 | 340 | 225 | Yield strength | B |

| KPa | 420 | 450 | 400 | ultimate tensile strength | C |

| KPa | 100 | 110 | 175 | strain hardening | B–C |

| % | 210 | 230 | 180 | elongation percent at breaking point | D |

| J/m3 | 12,800 | 13,600 | 9000 | resilience | Area under the curve of the elastic region |

| J/m3 | 54,675 | 58,675 | 51,695 | toughness | Area under the stress–strain curve up to fracture |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asghar, A.H.; Galaly, A.R. The Influence of Different Plasma Cell Discharges on the Performance Quality of Surgical Gown Samples. Materials 2021, 14, 4329. https://doi.org/10.3390/ma14154329

Asghar AH, Galaly AR. The Influence of Different Plasma Cell Discharges on the Performance Quality of Surgical Gown Samples. Materials. 2021; 14(15):4329. https://doi.org/10.3390/ma14154329

Chicago/Turabian StyleAsghar, Atif H., and Ahmed Rida Galaly. 2021. "The Influence of Different Plasma Cell Discharges on the Performance Quality of Surgical Gown Samples" Materials 14, no. 15: 4329. https://doi.org/10.3390/ma14154329

APA StyleAsghar, A. H., & Galaly, A. R. (2021). The Influence of Different Plasma Cell Discharges on the Performance Quality of Surgical Gown Samples. Materials, 14(15), 4329. https://doi.org/10.3390/ma14154329