The Assessment of Strength of Cementitious Materials Impregnated Using Hydrophobic Agents Based on Near-Surface Hardness Measurements

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Concrete Samples

2.2. Impregnation of the Concrete Samples Using Hydrophobic Agents

2.3. Testing of Near-Surface Hardness Using the Sclerometric Method

3. Results and Analysis

4. Conclusions

- the impregnation of concrete using hydrophobic agents affects its near-surface hardness, and consequently the results obtained in the correlation of the rebound number and its relation to the compressive strength of concrete;

- all of the samples impregnated using hydrophobic agents have a higher rebound number than the samples without impregnation;

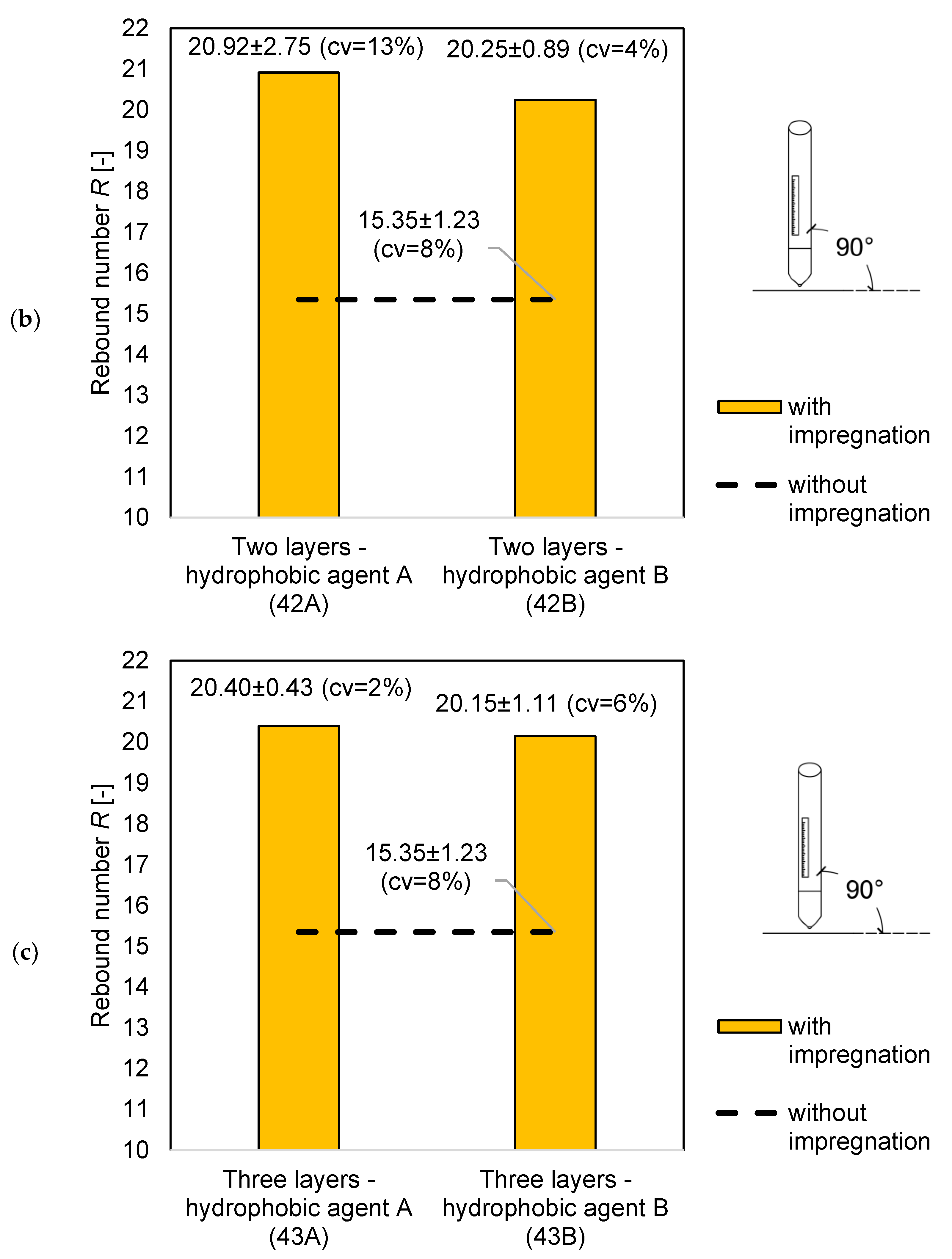

- the rebound number increases with the number of impregnation layers. The highest increase in the rebound number can be seen between the samples without impregnation and the first impregnation layer. When the use for samples with ratio w/c = 0.4 of hydrophobic agent A, the rebound number increased by 5.57 units, while the use of hydrophobic agent B by 4.9. When the use for samples with ratio w/c = 0.5 of hydrophobic agent A, the rebound number increased by 4.89 units, while the use of hydrophobic agent B by 3.15. In both cases, the difference is over 20%;

- based on conducted research it is not possible to clearly state which hydrophobic agent allowed a higher rebound number to be obtained;

- samples with ratio w/c = 0.4 have higher variability than samples with ratio w/c = 0.5. Only after applying three layers does it drop to a similar level. Hydrophobic agent A works better on porous surfaces, therefore for ratio w/c = 0.5 the variability is quite low;

- for hydrophobic agent A the use of more than two layers does not increase the number of rebound. Hydrophobic agent B is more effective for samples with a higher w/c ratio. You can see that the more impregnation layers, the higher the hardness, differences between the impregnated and non-impregnated samples when estimating the compressive strength of concrete are up to 7%;

- after exceeding the specified impregnation thickness, there is no significant difference between the number of impregnation layers used; and

- during the tests, higher values of the rebound number were obtained for the samples with a lower w/c ratio.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Malhotra, V.M.; Carino, N.J. Handbook on Nondestructive Testing of Concrete, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2004. [Google Scholar]

- Breysse, D.; Romao, X.; Alwash, M.; Sbartaï, Z.M.; Luprano, V.A. Risk evaluation on concrete strength assessment with NDT technique and conditional coring approach. J. Build. Eng. 2020, 32, 101541. [Google Scholar] [CrossRef]

- Dey, A.; Miyani, G.; Debroy, S.; Sil, A. In-situ NDT investigation to estimate degraded quality of concrete on existing structure considering time-variant uncertainties. J. Build. Eng. 2020, 27, 101001. [Google Scholar] [CrossRef]

- Rashid, K.; Waqas, R. Compressive strength evaluation by non-destructive techniques: An automated approach in construction industry. J. Build. Eng. 2017, 12, 147–154. [Google Scholar] [CrossRef]

- Saleem, M.A.; Saleem, M.M.; Ahmad, Z.; Hayat, S. Predicting compressive strength of concrete using impact modulus of toughness. Case Stud. Constr. Mater. 2021, 14, e00518. [Google Scholar]

- Hüsken, G.; Pirskawetz, S.; Hofmann, D.; Basedau, F.; Gründer, K.; Kadoke, D. The load-bearing behaviour of a reinforced concrete beam investigated by optical measuring techniques. Mater. Struct. 2021, 54, 102. [Google Scholar] [CrossRef]

- Long, A.E.; Henderson, G.D.; Montgomery, F.R. Why assess the properties of near-surface concrete? Constr. Build. Mater. 2001, 15, 65–79. [Google Scholar] [CrossRef]

- PN-EN 12504-2:2002: Badania Betonu w Konstrukcjach. Część 2: Badania Nieniszczące-Oznaczanie Liczby Odbicia. Available online: https://portal.piib.org.pl/ (accessed on 14 August 2021).

- Brencich, A.; Cassini, G.; Pera, D.; Riotto, G. Calibration and Reliability of the Rebound (Schmidt) Hammer Test. Civil Eng. Archit. 2013, 1, 66–78. [Google Scholar] [CrossRef]

- Wróblewski, R.; Stawiski, B. Ultrasonic Assessment of the Concrete Residual Strength after a Real Fire Exposure. Buildings 2020, 10, 154. [Google Scholar] [CrossRef]

- Panedpojaman, P.; Tonnayopas, D. Rebound hammer test to estimate compressive strength of heat exposed concrete. Constr. Build. Mater. 2018, 172, 387–395. [Google Scholar] [CrossRef]

- Kowalski, R.; Wróblewska, J. Application of a sclerometer to the preliminary assessment of concrete quality in structures after fire. Arch. Civil Eng. 2018, I.XIV, 171–186. [Google Scholar] [CrossRef] [Green Version]

- Filipowicz, R. Próba zastosowania młotka Schmidta do badań architektonicznych ceglanych murów. Ochr. Zabyt. 2009, 1, 38–42. [Google Scholar]

- Łątka, D. Możliwości wykorzystania sklerometru elektronicznego do wstępnej oceny konstrukcji murowej. Joanny Bzówki 2014, 519, 327–334. [Google Scholar]

- Matysek, P. Nośność Ścian i Filarów Murowych w Budynkach Istniejących–Wykorzystanie Badan Nieniszczących i Małoniszczących w Analizie Zagadnienia. Available online: http://www.awarie.zut.edu.pl/files/ab2017/referaty/02/02-07%20-%20Matysek%20P%20-%20Nosnosc%20scian%20i%20filarow%20murowych%20w%20budynkach%20istniejacych%20%E2%80%93%20wykorzystanie%20badan.pdf (accessed on 14 August 2021).

- Orłowicz, R.; Tkasz, P. Określenie wytrzymałości zaprawy w istniejących budynkach murowych. Przegląd Bud. 2012, 83, 52–55. [Google Scholar]

- Runkiewicz, L. Wpływ wybranych czynników na wyniki badań sklerometrycznych betonu. Prace Naukowe Instytutu Techniki Budowlanej. Warszawa 1991. Available online: https://bg.pcz.pl/apiszb/book/16476/Wplyw-wybranych-czynnikow-na-wyniki-badan-sklerometrycznych-betonu-Leonard-Runkiewicz (accessed on 14 August 2021).

- Runkiewicz, L. Wpływ naprężenia w betonie na ocenę jego wytrzymałości i jednorodności młotkiem Schmidta. In Proceedings of the I Krajowe Sympozjum Badania Nieniszczące, ITB, Warszawa, Poland, 13–17 June 2016. [Google Scholar]

- Runkiewicz, L. Ocena wytrzymałości betonu w konstrukcji za pomocą sklerometrów Schmidta. ITB Warszawa 1983. Available online: file:///C:/Users/MDPI/AppData/Local/Temp/Brunarski.pdf (accessed on 14 August 2021).

- Dziewiecki, A. Technologie badań elementów betonowych ze szczególnym uwzględnieniem nieniszczących metod szacowania wytrzymałości na ściskanie z użyciem młotka Schmidta typu N. Inżynieria Bezpieczeństwa Obiektów Antropog. 2016, 3, 15–17. [Google Scholar]

- Kog, Y.C. Factors Influencing in Situ Strength of Existing Concrete Structure Estimated by Core Test and NDTs. Pract. Period. Struct. Des. Constr. 2020, 25, 04019033. [Google Scholar] [CrossRef]

- Jasiński, R. Określenie wytrzymałości betonu w konstrukcji. In Proceedings of the XXIX Ogólnopolskie Warsztaty Pracy Projektanta Konstrukcji, Szczyrk, Poland, 26–29 March 2014. [Google Scholar]

- Mitchell, L.J.; Hoagland, G.G. Investigation of the Impact Tube Concrete Test Hammer. Highw. Res. Board Bull. 1961, 305, 14. [Google Scholar]

- PN-74/B-06262 Nieniszczące Badania Konstrukcji z Betonu–Metoda Sklerometryczna–Badania Wytrzymałości Betonu na ściskanie za Pomocą Młotka Schmidta Typu N. Available online: https://portal.piib.org.pl/ (accessed on 14 August 2021).

- Runkiewicz, L.; Sieczkowski, J. Ocena wytrzymałości betonu w konstrukcji na podstawie badań sklerometrycznych. Poradnik. Instytut Techniki Budowlanej. Warszawa 2020, 12, 5–9. [Google Scholar]

- Hoła, J.; Sadowski, Ł. Wiarygodność Metod Nieniszczących Stosowanych w Diagnostyce Obiektów Budowlanych. Available online: https://www.rzeczoznawstwo2020.tu.kielce.pl/program-konferencji.pdf (accessed on 14 August 2021).

- PN-EN 13791:2019-12 Ocena Wytrzymałości Betonu na Ściskanie w Konstrukcjach i Prefabrykowanych Wyrobach Budowlanych. Available online: https://portal.piib.org.pl/ (accessed on 14 August 2021).

- Instrukcja ITB 210/1977 Instrukcja stosowania młotków Schmidta do nieniszczącej kontroli jakości betonu. Available online: https://biblioteka.itb.pl/F?func=find-b&request=000076441&find_code=SYS&local_base=ITB01 (accessed on 14 August 2021).

- Plechawski, S. Porównanie metod skalowania krzywych korelacji na przykładzie żelbetowego stropu płytowo-żebrowego. Badania Nieniszcz. Diagn. 2019, 1, 22–26. [Google Scholar] [CrossRef]

- Runkiewicz, L.; Runkiewicz, M.; Sieczkowski, J. Nowe zasady stosowania badań nieniszczących do oceny wytrzymałości i jednorodności betonów. Cz. 2. Builder 2021, 2. [Google Scholar] [CrossRef]

- EN 1504-2-Products and Systems for the the Protection and Repair of Concrete Structures-Definitions, Requirements, Quality Control and Evaluation of Conformity-Part 2: Surface Protection Systems for Concrete; ISO: Geneva, Switzerland, 2005.

- Coffetti, D.; Crotti, E.; Gazzaniga, G.; Gottardo, R.; Pastore, T.; Coppola, L. Protection of Concrete Structures: Performance Analysis of Different Commercial Products and Systems. Materials 2021, 14, 3719. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.C.; Li, N. A review on surface treatment for concrete–Part 2: Performance. Constr. Build. Mater. 2017, 133, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Mundo, R.D.; Labianca, C.; Carbone, G.; Notarnicola, M. Recent Advances in Hydrophobic and Icephobic Surface Treatments of Concrete. Coatings 2020, 10, 449. [Google Scholar] [CrossRef]

- Pan, X.; Shi, Z.; Shi, C.; Ling, T.; Li, N. A review on surface treatment for concrete–Part 1: Types and mechanism. Constr. Build. Mater. 2017, 132, 578–590. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Góra, J.; Widomski, M.K. Durability of Hydrophobic/Icephobic Coatings in Protection of Lightweight Concrete with Waste Aggregate. Materials 2021, 14, 1011. [Google Scholar]

| Name of the Factor | Description |

|---|---|

| Age of concrete | Is associated with the carbonation of concrete, which causes an uneven distribution of strength. The greatest impact of carbonation occurs in the first year. Near-surface hardness measurement should not be used in the early stage of concrete solidification or in places where a strength of 7 MPa has not been achieved. The rebound number is then too low and the concrete may be damaged [23]. |

| Concrete moisture | Concrete moisture reduces the rebound number by worsening the dynamic hardness. |

| Measuring place | An appropriate size and number of measuring points are required. According to [24], the minimum size of the measurement site is 50 cm2, while according to [8] the size is 900 cm2. The standard [24] requires 12 measuring location with 5 measuring points in each of these places. In turn, the standard [8] requires 9 measuring points in each measuring location. |

| Thickness of the tested element | Thickness should not be less than 10 cm or greater than 20 cm when accessed from one side, greater than 40 cm when accessed from two sides or greater than 60 cm when accessed from three sides [8,25]. |

| Measurement site | Measuring points should be evenly distributed over the surface and be located no less than 3 cm from the edge. They should not be arranged in places where coarse aggregate and reinforcement is less than 3 cm from the surface [26]. |

| w/c Ratio [-] | Mass of Water [kg] | Cement Mass [kg] |

|---|---|---|

| 0.4 | 5.0 | 12.5 |

| 0.5 | 5.5 | 11.0 |

| Designation of the Sample | w/c Ratio | The Number of Layers of Applied Hydrophobic Agent | Type of the Hydrophobic Agent |

|---|---|---|---|

| 4 | 0.4 | 0 | - |

| 41A | 0.4 | 1 | A |

| 42A | 0.4 | 2 | A |

| 43A | 0.4 | 3 | A |

| 41B | 0.4 | 1 | B |

| 42B | 0.4 | 2 | B |

| 43B | 0.4 | 3 | B |

| 5 | 0.5 | 0 | - |

| 51A | 0.5 | 1 | A |

| 52A | 0.5 | 2 | A |

| 53A | 0.5 | 3 | A |

| 51B | 0.5 | 1 | B |

| 52B | 0.5 | 2 | B |

| 53B | 0.5 | 3 | B |

| Sample | Rebound Number R (-) | Estimated Strength fR (MPa) | The Difference between a Sample with and without Impregnation | |

|---|---|---|---|---|

| (MPa) | (%) | |||

| 4 | 15.4 | 45.15 | - | - |

| 41A | 18.6 | 46.66 | 1.52 | 3.00 |

| 42A | 20.9 | 48.33 | 3.18 | 7.00 |

| 43A | 20.4 | 47.93 | 2.78 | 6.00 |

| 41B | 18.8 | 46.82 | 1.67 | 4.00 |

| 42B | 20.3 | 47.81 | 2.67 | 6.00 |

| 43B | 20.2 | 47.74 | 2.59 | 5.00 |

| 5 | 13.9 | 33.35 | - | - |

| 51A | 17.4 | 34.64 | 1.29 | 4.00 |

| 52A | 18.8 | 35.43 | 2.08 | 6.00 |

| 53A | 16.5 | 34.21 | 0.86 | 3.00 |

| 51B | 14.6 | 33.52 | 0.16 | 0.00 |

| 52B | 15.1 | 33.68 | 0.33 | 1.00 |

| 53B | 17.1 | 34.47 | 1.11 | 0.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nieświec, M.; Sadowski, Ł. The Assessment of Strength of Cementitious Materials Impregnated Using Hydrophobic Agents Based on Near-Surface Hardness Measurements. Materials 2021, 14, 4583. https://doi.org/10.3390/ma14164583

Nieświec M, Sadowski Ł. The Assessment of Strength of Cementitious Materials Impregnated Using Hydrophobic Agents Based on Near-Surface Hardness Measurements. Materials. 2021; 14(16):4583. https://doi.org/10.3390/ma14164583

Chicago/Turabian StyleNieświec, Martyna, and Łukasz Sadowski. 2021. "The Assessment of Strength of Cementitious Materials Impregnated Using Hydrophobic Agents Based on Near-Surface Hardness Measurements" Materials 14, no. 16: 4583. https://doi.org/10.3390/ma14164583

APA StyleNieświec, M., & Sadowski, Ł. (2021). The Assessment of Strength of Cementitious Materials Impregnated Using Hydrophobic Agents Based on Near-Surface Hardness Measurements. Materials, 14(16), 4583. https://doi.org/10.3390/ma14164583