Wear-Resistant TiC Strengthening CoCrNi-Based High-Entropy Alloy Composite

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

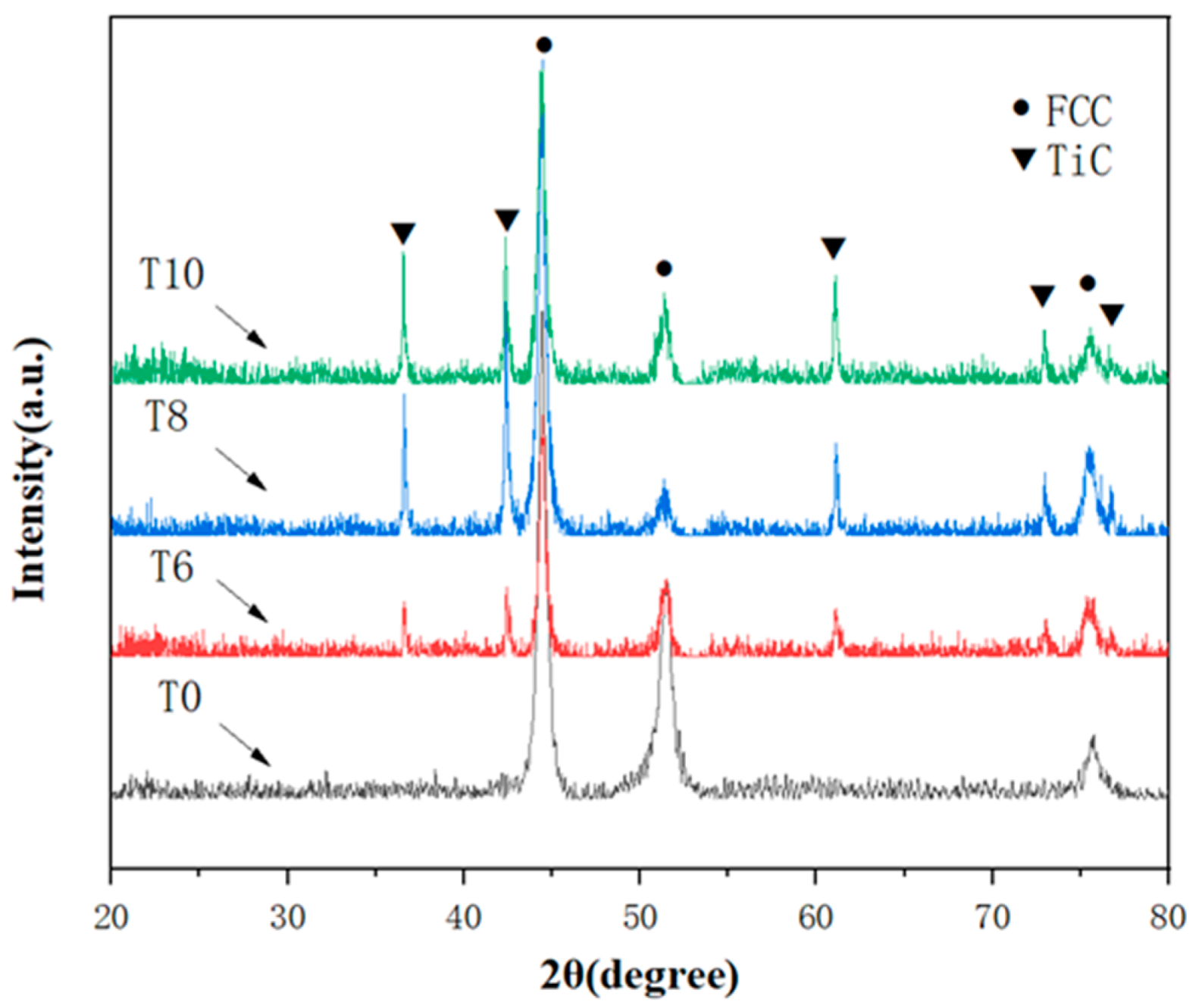

3.1. XRD Analysis

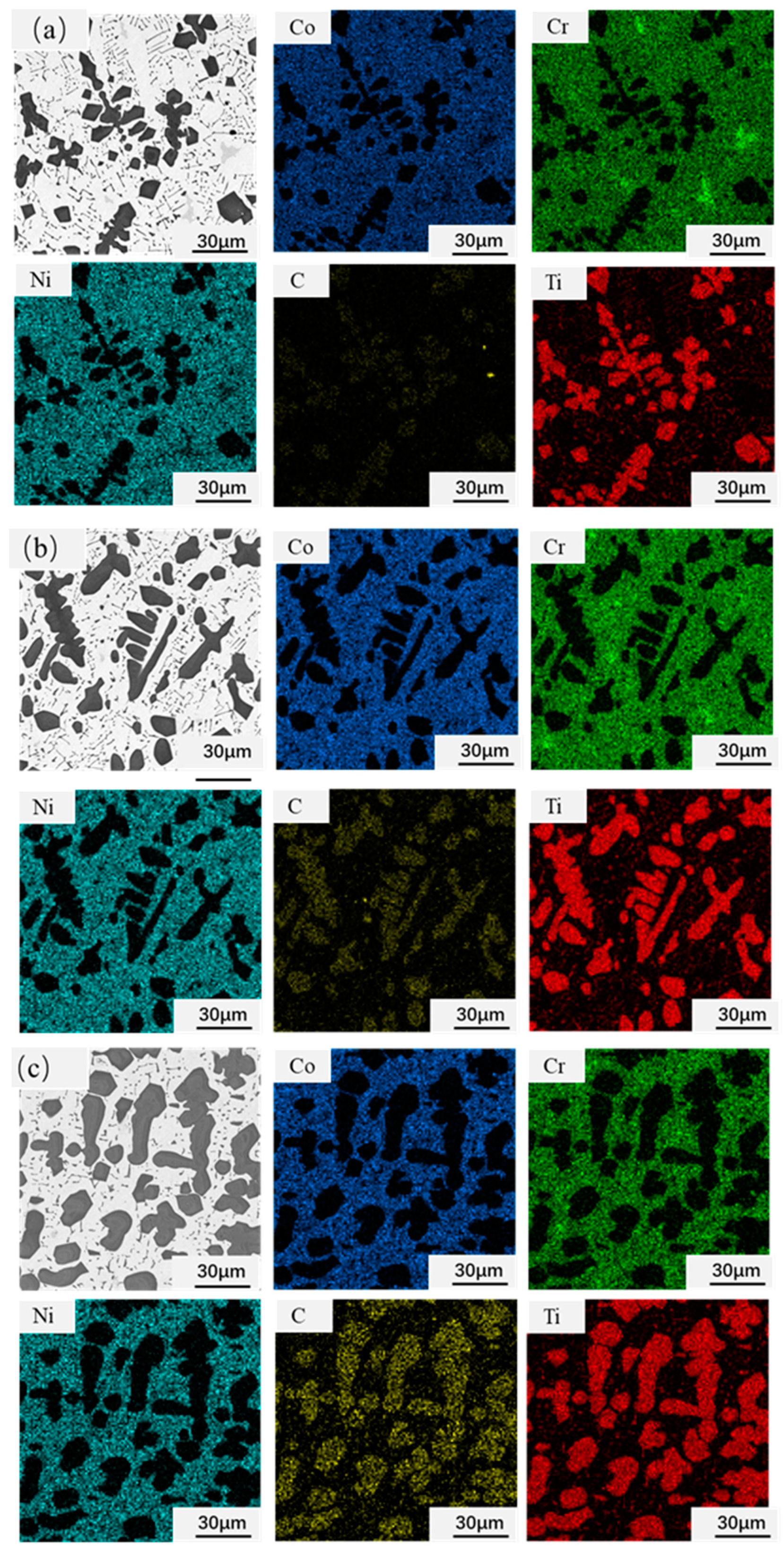

3.2. Microstructure

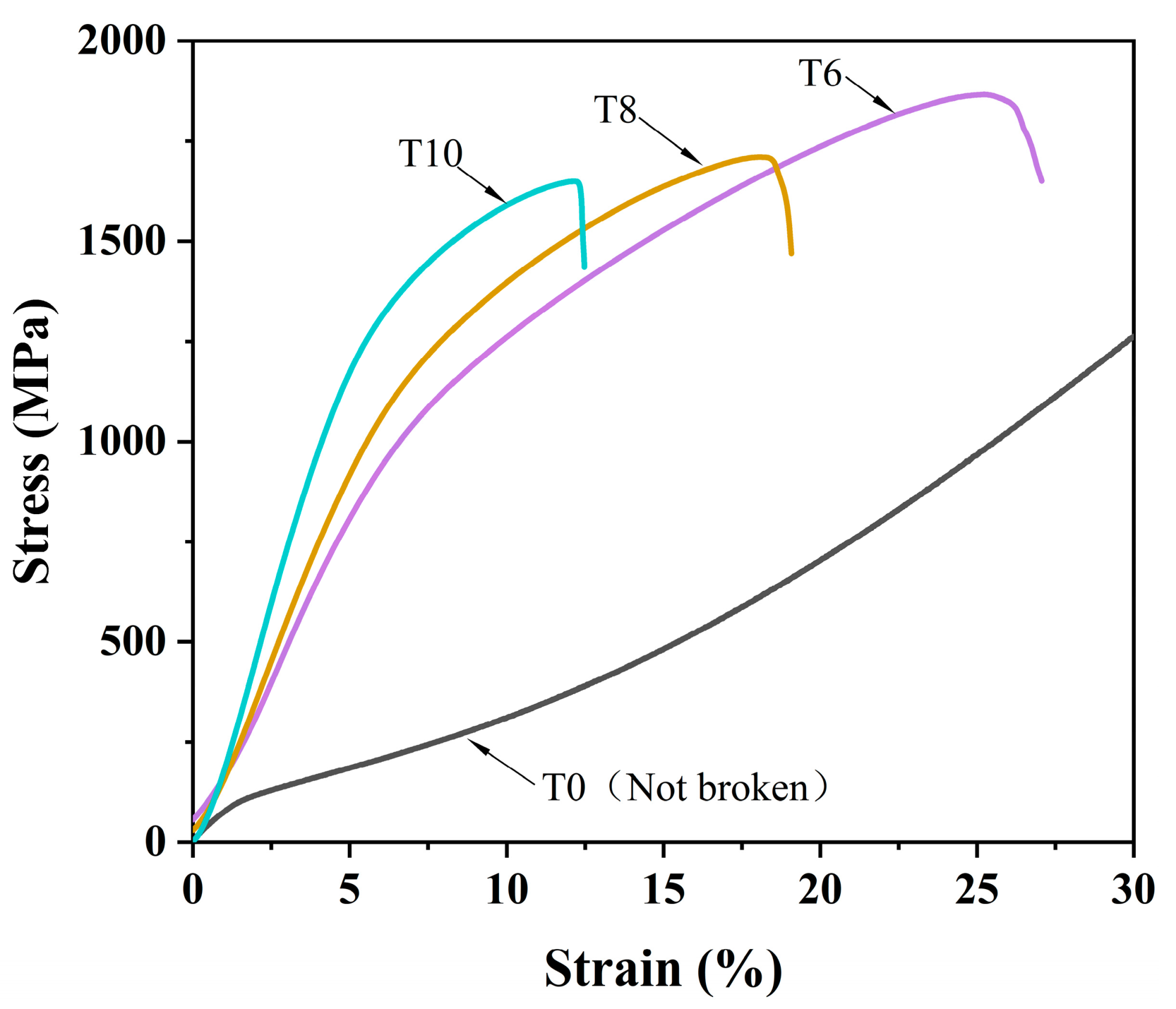

3.3. Mechanical Properties

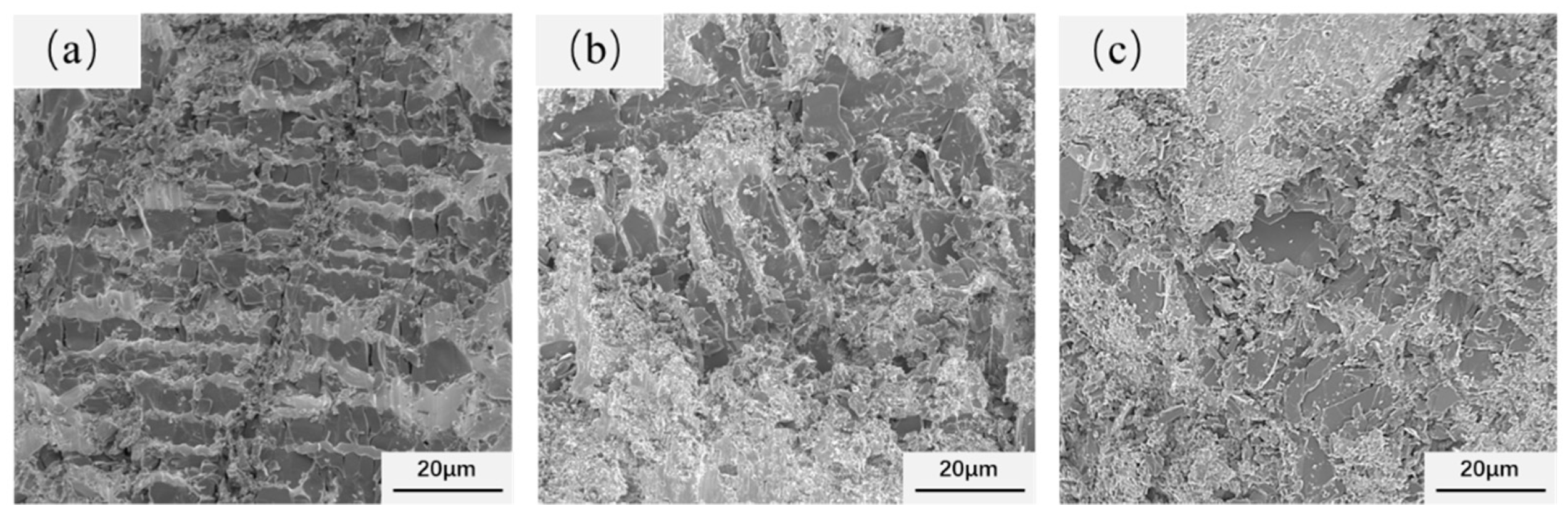

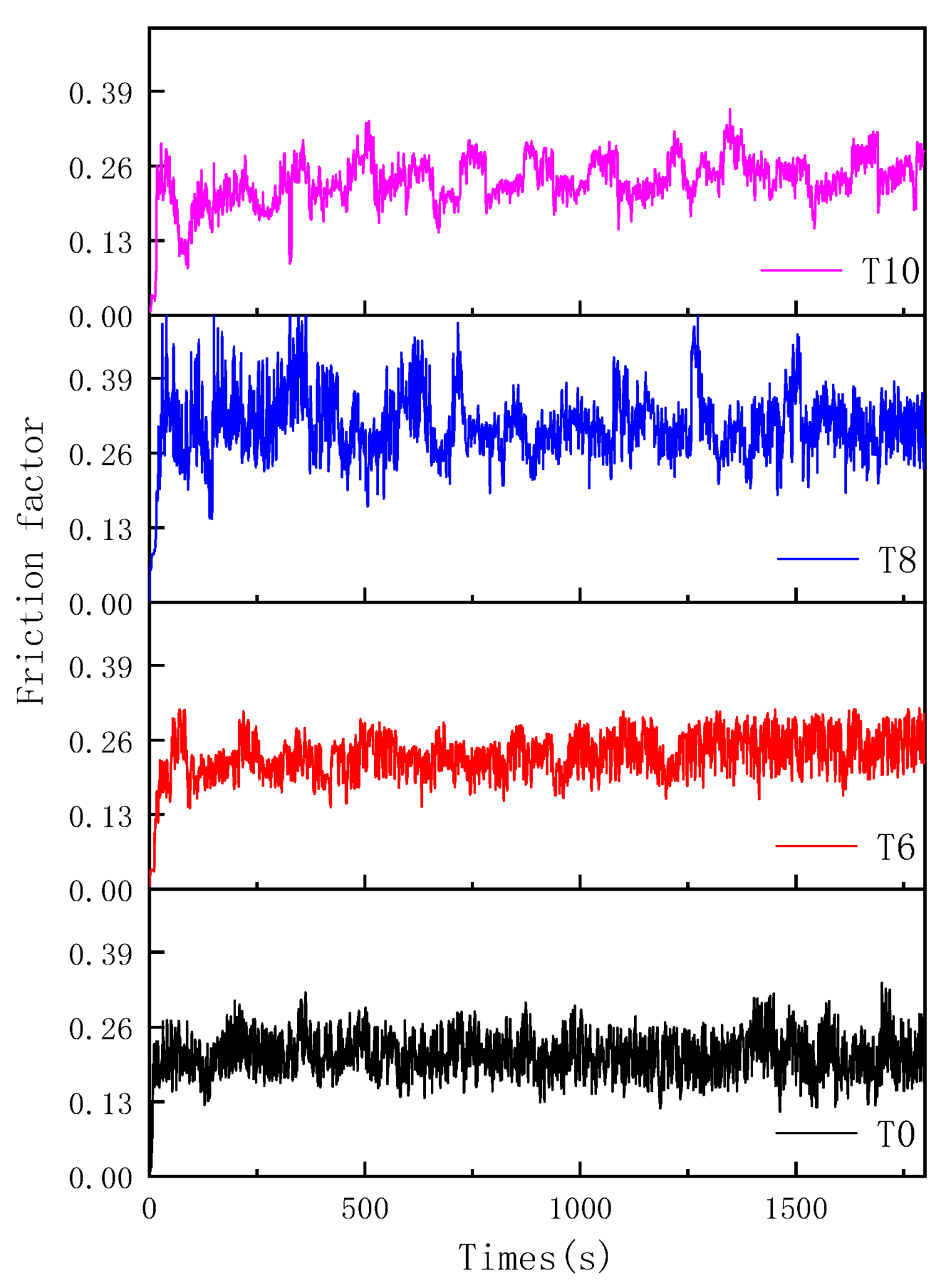

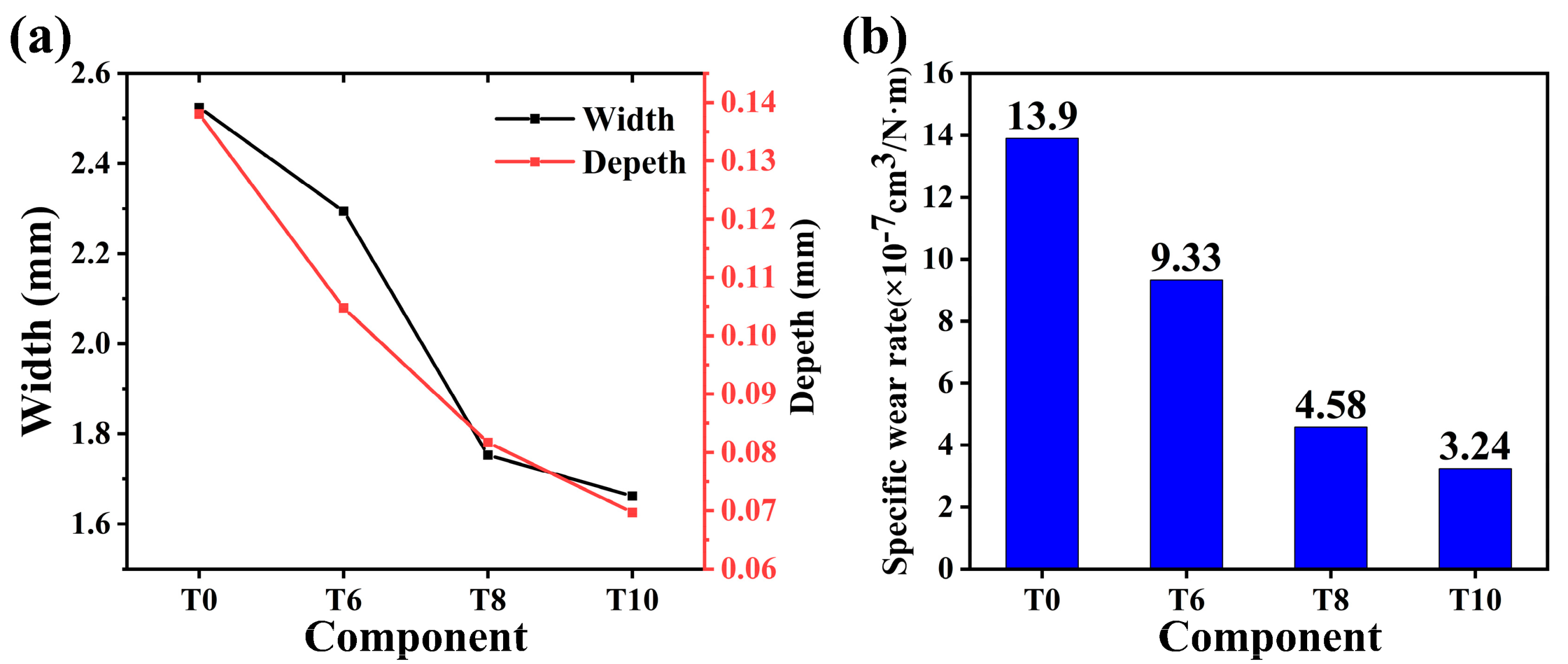

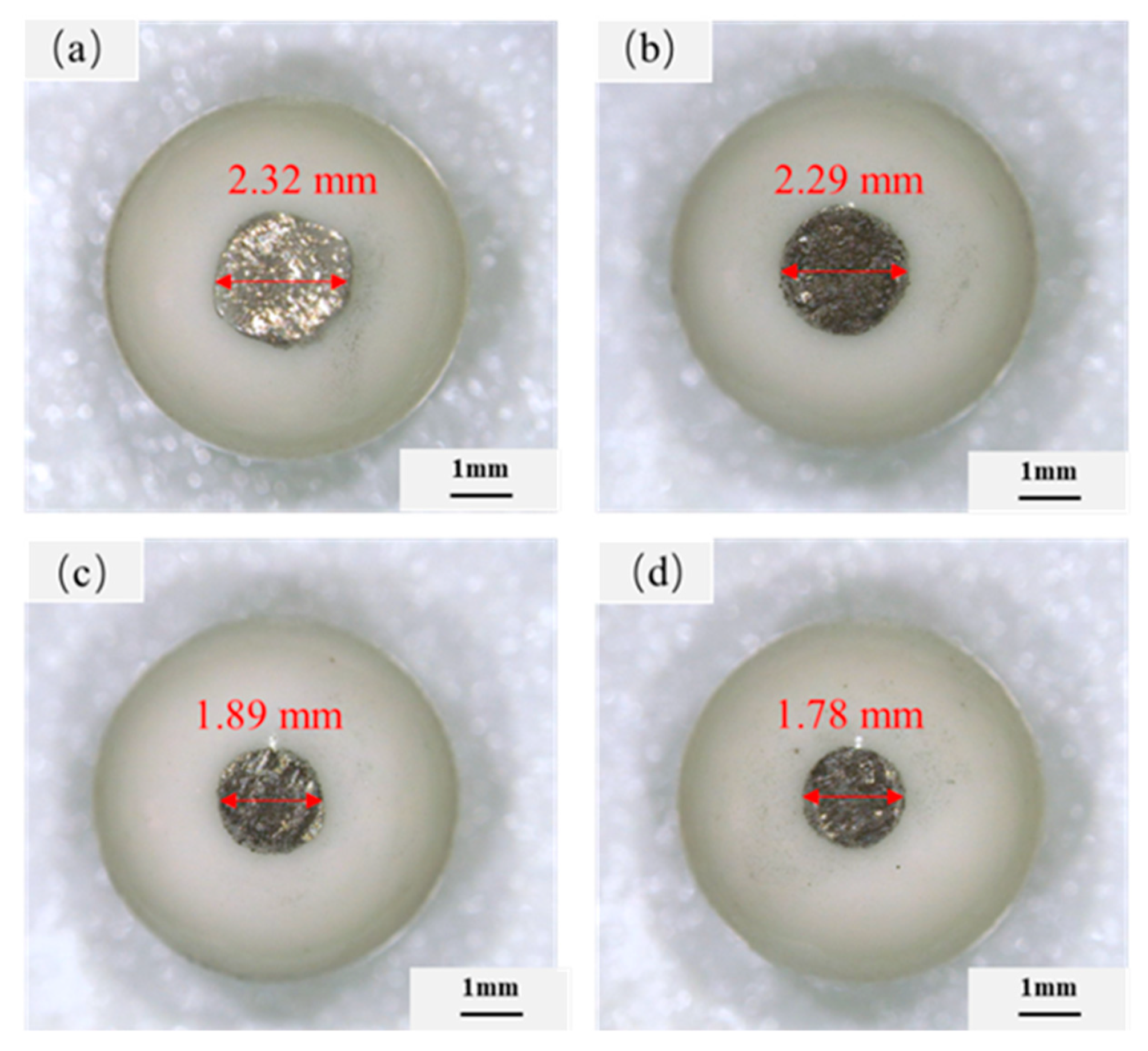

3.4. Wear Properties

4. Conclusions

- (1)

- TiC produced a dissolution and precipitation process in CoCrNi alloy, and the alloy’s structure transformed from single-phase FCC to FCC + TiC dual phases.

- (2)

- The compressive yield strength of the CoCrNi/(TiC)x composites was proportional to the TiC content, and the yield strength of the composites was increased to 1371 MPa. The increase of strength was mainly attributed to the second phase strengthening.

- (3)

- The wear resistance of CoCrNi/(TiC)x composites increased with the increasing TiC content. Among them, the specific wear rate of CoCrNi/(TiC)1.0 alloy was the lowest, which was nearly 77% lower than the CoCrNi matrix.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, H.; Li, E.; Wang, Y.; Shi, P.; Xu, B.; Yang, S. Environmental life cycle assessment of remanufactured engines with advanced restoring technologies. Robot. Comput. Integr. Manuf. 2019, 59, 213–221. [Google Scholar] [CrossRef]

- Xiao, L.; Liu, W.; Guo, Q.; Gao, L.; Zhang, G.; Chen, X. Comparative life cycle assessment of manufactured and remanufactured loading machines in China. Resour. Conserv. Recycl. 2018, 131, 225–234. [Google Scholar] [CrossRef]

- Guo, F.; Li, K.; Huang, X.; Xie, Z.; Gong, F. Understanding the wear failure mechanism of TiAlSiCN nanocomposite coating at evaluated temperatures. Tribol. Int. 2021, 154, 106716. [Google Scholar] [CrossRef]

- Suh, N.P. An overview of the delamination theory of wear. Wear 1997, 44, 1–16. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Otto, F.; Yang, Y.; Bei, H.; George, E.P. Relative effects of enthalpy and entropy on the phase stability of equiatomic high-entropy alloys. Acta Mater. 2013, 61, 2628–2638. [Google Scholar] [CrossRef] [Green Version]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef] [Green Version]

- Yao, M.J.; Pradeep, K.G.; Tasan, C.C.; Raabe, D. A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility. Scr. Mater. 2014, 72–73, 5–8. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, H.; Huang, H.; Yang, L.; Hu, Y.; Liang, X.; Hua, M.; Zhang, J. Strengthening mechanism of CoCrNiMox high entropy alloys by high-throughput nanoindentation mapping technique. Intermetallics 2021, 135, 107209. [Google Scholar] [CrossRef]

- Slone, C.E.; Miao, J.; George, E.P.; Mills, M.J. Achieving ultra-high strength and ductility in equiatomic CrCoNi with partially recrystallized microstructures. Acta Mater. 2019, 165, 496–507. [Google Scholar] [CrossRef]

- Ma, Y.; Yuan, F.; Yang, M.; Jiang, P.; Ma, E.; Wu, X. Dynamic shear deformation of a CrCoNi medium-entropy alloy with heterogeneous grain structures. Acta Mater. 2018, 148, 407–418. [Google Scholar] [CrossRef] [Green Version]

- Deng, H.W.; Wang, M.M.; Xie, Z.M.; Zhang, T.; Wang, X.P.; Fang, Q.F.; Xiong, Y. Enhancement of strength and ductility in non-equiatomic CoCrNi medium-entropy alloy at room temperature via transformation-induced plasticity. Mater. Sci. Eng. A 2021, 804, 140516. [Google Scholar] [CrossRef]

- Cui, G.; Qian, Y.; Bian, C.; Gao, G.; Hassani, M.; Liu, Y.; Kou, Z. CoCrNi matrix high-temperature wear resistant composites with micro- and nano-Al2O3 reinforcement. Compos. Commun. 2020, 22, 100461. [Google Scholar] [CrossRef]

- Oliveira, M.M.; Bolton, J.D. High-speed steels: Increasing wear resistance by adding ceramic particles. J. Mater. Process. Technol. 1999, 92–93, 15–20. [Google Scholar] [CrossRef]

- Deuis, R.L.; Subramanian, C.; Yellup, J.M. Abrasive wear of aluminium composites—A review. Wear 1996, 201, 132–144. [Google Scholar] [CrossRef]

- Bindumadhavan, P.N.; Wah, H.K.; Prabhakar, O. Dual particle size (DPS) composites: Effect on wear and mechanical properties of particulate metal matrix composites. Wear 2001, 248, 112–120. [Google Scholar] [CrossRef]

- Das, S.; Mondal, D.P.; Dixit, G. Correlation of abrasive wear with microstructure and mechanical properties of pressure die-cast aluminum hard-particle composite. Metall. Mater. Trans. A 2001, 32, 633–642. [Google Scholar] [CrossRef]

- Venkataraman, B.; Sundararajan, G. The sliding wear behaviour of Al□SiC particulate Composites—I. Macrobehaviour. Acta Mater. 1996, 44, 451–460. [Google Scholar] [CrossRef]

- Song, W.Q.; Krauklis, P.; Mouritz, A.P.; Bandyopadhyay, S. The effect of thermal ageing on the abrasive wear behaviour of age-hardening 2014 Al/SiC and 6061 Al/SiC composites. Wear 1995, 185, 125–130. [Google Scholar] [CrossRef]

- Yadav, S.; Aggrawal, A.; Kumar, A.; Biswas, K. Effect of TiB2 addition on wear behavior of (AlCrFeMnV)90Bi10 high-entropy alloy composite. Tribol. Int. 2019, 132, 62–74. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, D.; Liang, X.; Chen, Y. Evolution of microstructure and mechanical properties of in situ synthesized TiC–TiB2/CoCrCuFeNi high-entropy alloy coatings. Surf. Coat. Technol. 2015, 281, 109–116. [Google Scholar] [CrossRef]

- Sun, X.; Zhu, H.; Li, J.; Huang, J.; Xie, Z. High-entropy alloy FeCoNiCu matrix composites reinforced with in-situ TiC particles and graphite whiskers. Mater. Chem. Phys. 2018, 220, 449–459. [Google Scholar] [CrossRef]

- Wang, H.W.; Qi, J.Q.; Zou, C.M.; Zhu, D.D.; Wei, Z.J. High-temperature tensile strengths of in situ synthesized TiC/Ti-alloy composites. Mater. Sci. Eng. A 2012, 545, 209–213. [Google Scholar] [CrossRef]

- Fan, Q.C.; Li, B.S.; Zhang, Y. The microstructure and properties of (FeCrNiCo)Al Cu high-entropy alloys and their TiC-reinforced composites. Mater. Sci. Eng. A 2014, 598, 244–250. [Google Scholar] [CrossRef]

- Bai, L.; Ge, C.; Shen, W.; Mao, X.; Zhang, K. Densification, microstructure, and fracture behavior of TiC/Si3N4 composites by spark plasma sintering. Rare Met. 2008, 27, 315–319. [Google Scholar] [CrossRef]

- Akhtar, F.; Guo, S.; Feng, P.; Khadijahali, S.; Syedjavid, A. TiC-maraging stainless steel composite: Microstructure, mechanical and wear properties. Rare Met. 2006, 25, 630–635. [Google Scholar] [CrossRef]

- Zhou, Y.-F.; Tan, X.-Y.; Luo, L.-M.; Xu, Y.; Zan, X.; Xu, Q.; Tokunaga, K.; Zhu, X.-Y.; Wu, Y.-C. Microstructure evolutions of the W–TiC composite conducted by dual-effects from thermal shock and He-ion irradiation. Tungsten 2019, 1, 213–219. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Chen, H.Y.; Luo, L.M.; Miyamoto, M.; Tokitani, M.; Wu, Y.C. Microstructural evolution in W-1%TiC alloy irradiated He ions at high temperatures. Tungsten 2019, 1, 229–235. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.K.; Das, K. Microstructural and mechanical characterization of in situ TiC and (Ti,W)C-reinforced high manganese austenitic steel matrix composites. Mater. Sci. Eng. A 2009, 516, 1–6. [Google Scholar] [CrossRef]

- Hadian, R.; Emamy, M.; Varahram, N.; Nemati, N. The effect of Li on the tensile properties of cast Al–Mg2Si metal matrix composite. Mater. Sci. Eng. A 2008, 490, 250–257. [Google Scholar] [CrossRef]

| Position | Co | Cr | Ni | Ti | C |

|---|---|---|---|---|---|

| Entire area of Figure 3b | 18.14 | 17.10 | 17.96 | 14.69 | 32.11 |

| Figure 3b–1 | – | – | – | 47.51 | 52.49 |

| Figure 3b–2 | 28.85 | 22.04 | 27.97 | 2.16 | 18.98 |

| Figure 3b–3 | 12.52 | 11.79 | 11.53 | 15.51 | 48.65 |

| Entire area of Figure 3c | 15.65 | 14.78 | 15.39 | 18.34 | 35.84 |

| Figure 3c–1 | – | – | – | 47.51 | 52.49 |

| Figure 3c–2 | 28.66 | 22.06 | 27.75 | 2.46 | 19.07 |

| Figure 3c–3 | 15.09 | 17.04 | 15.70 | 19.46 | 32.71 |

| Entire area of Figure 3d | 12.25 | 11.88 | 12.22 | 23.06 | 40.59 |

| Figure 3d–1 | – | – | – | 48.12 | 51.88 |

| Figure 3d–2 | 28.02 | 23.99 | 27.58 | 2.65 | 17.76 |

| Figure 3d–3 | 21.40 | 19.44 | 21.77 | 5.95 | 31.44 |

| Alloying Constituent | Yield Strength (MPa) | Compressive Strength (MPa) | Fracture Strain (%) |

|---|---|---|---|

| T0 | 108 | – | – |

| T6 | 883 | 1865 | 25 |

| T8 | 1102 | 1709 | 18 |

| T10 | 1371 | 1649 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, Y.; Tong, Y.; Hu, Y.; Huang, H.; Zhang, X.; Hua, M.; Xu, S.; Mei, Y.; Ma, C.; Li, Z. Wear-Resistant TiC Strengthening CoCrNi-Based High-Entropy Alloy Composite. Materials 2021, 14, 4665. https://doi.org/10.3390/ma14164665

Cai Y, Tong Y, Hu Y, Huang H, Zhang X, Hua M, Xu S, Mei Y, Ma C, Li Z. Wear-Resistant TiC Strengthening CoCrNi-Based High-Entropy Alloy Composite. Materials. 2021; 14(16):4665. https://doi.org/10.3390/ma14164665

Chicago/Turabian StyleCai, Yanlin, Yonggang Tong, Yongle Hu, Hongfeng Huang, Xiancheng Zhang, Manyu Hua, Shan Xu, Yongbing Mei, Chengbiao Ma, and Zhifeng Li. 2021. "Wear-Resistant TiC Strengthening CoCrNi-Based High-Entropy Alloy Composite" Materials 14, no. 16: 4665. https://doi.org/10.3390/ma14164665

APA StyleCai, Y., Tong, Y., Hu, Y., Huang, H., Zhang, X., Hua, M., Xu, S., Mei, Y., Ma, C., & Li, Z. (2021). Wear-Resistant TiC Strengthening CoCrNi-Based High-Entropy Alloy Composite. Materials, 14(16), 4665. https://doi.org/10.3390/ma14164665