Effects of Modified Al2O3-Decorated Ionic Liquid on the Mechanical Properties and Impact Resistance of a Polyurethane Elastomer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of KH570 Modified Al2O3

2.3. Synthesis of IL

2.4. Preparation of IL@Al2O3

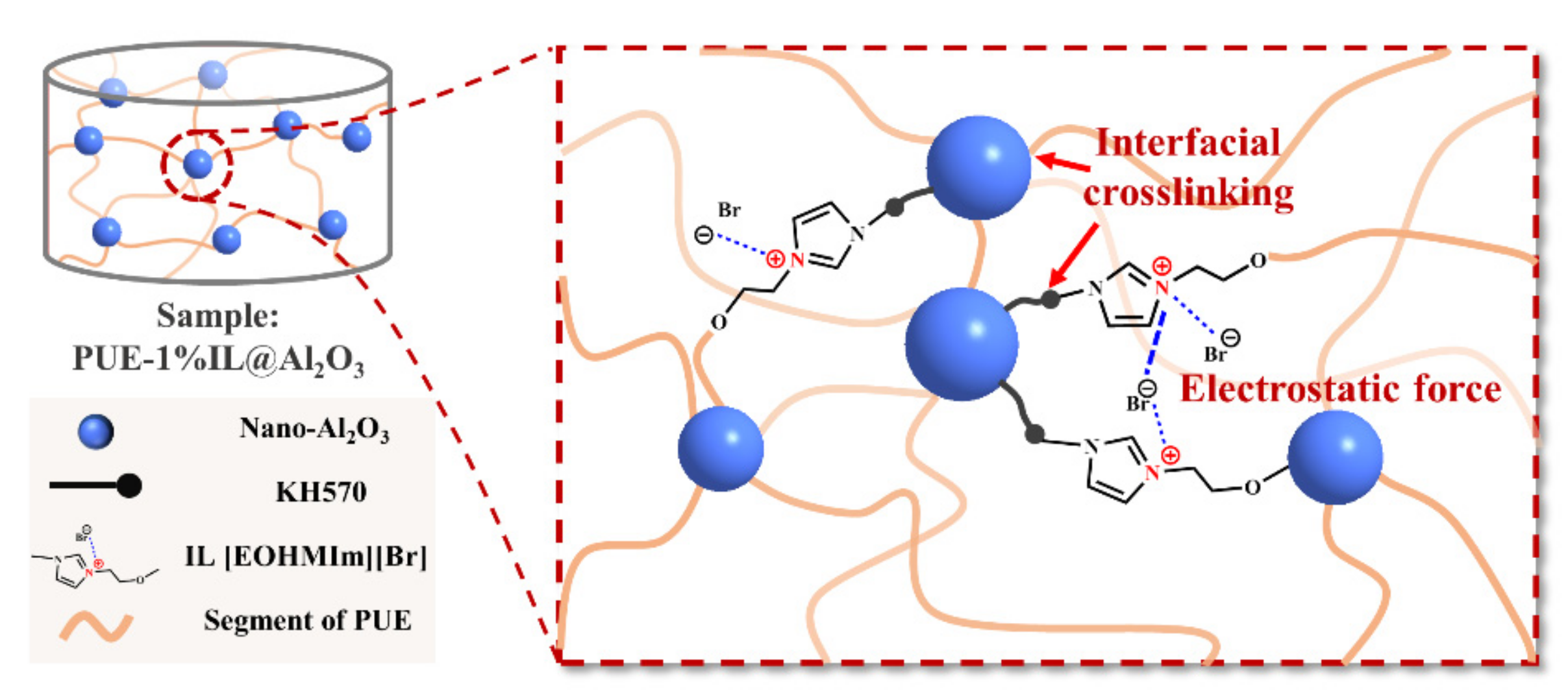

2.5. Preparation of PUE-IL@Al2O3

2.6. Structural Characterization

2.7. Compression Mechanical Tests

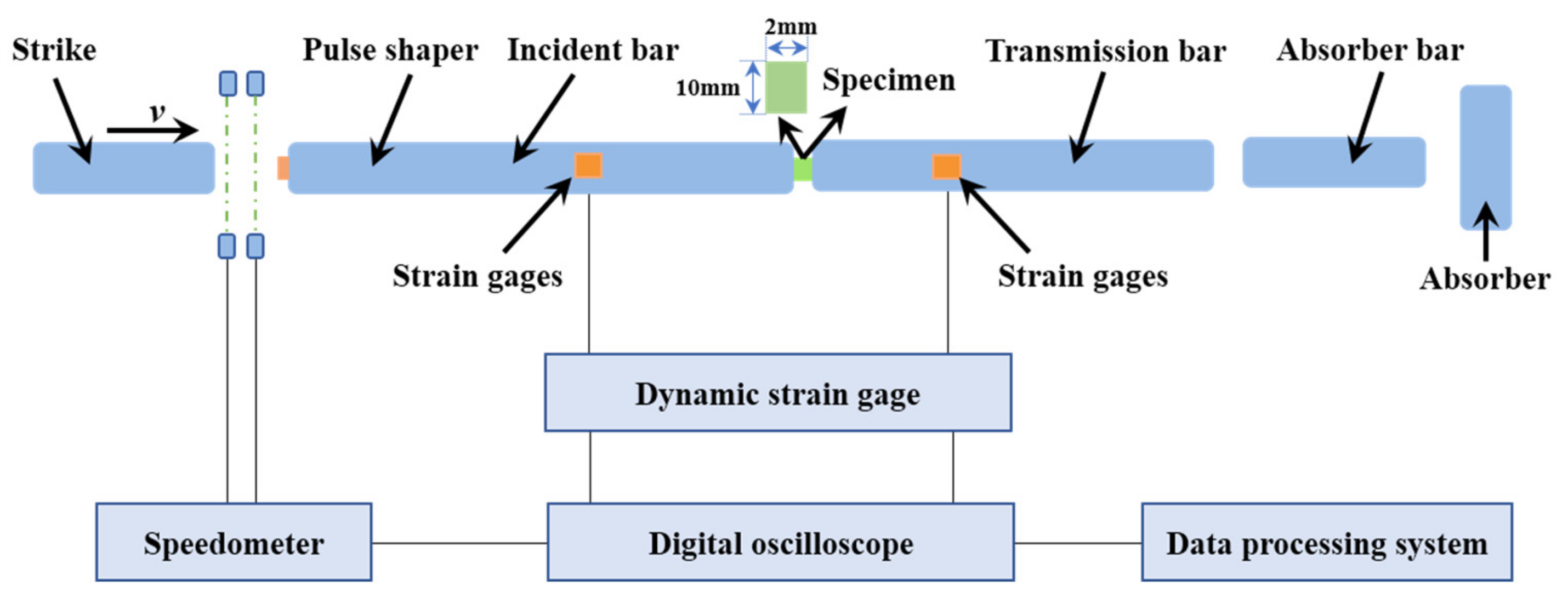

2.8. Dynamic Impact Tests

3. Results

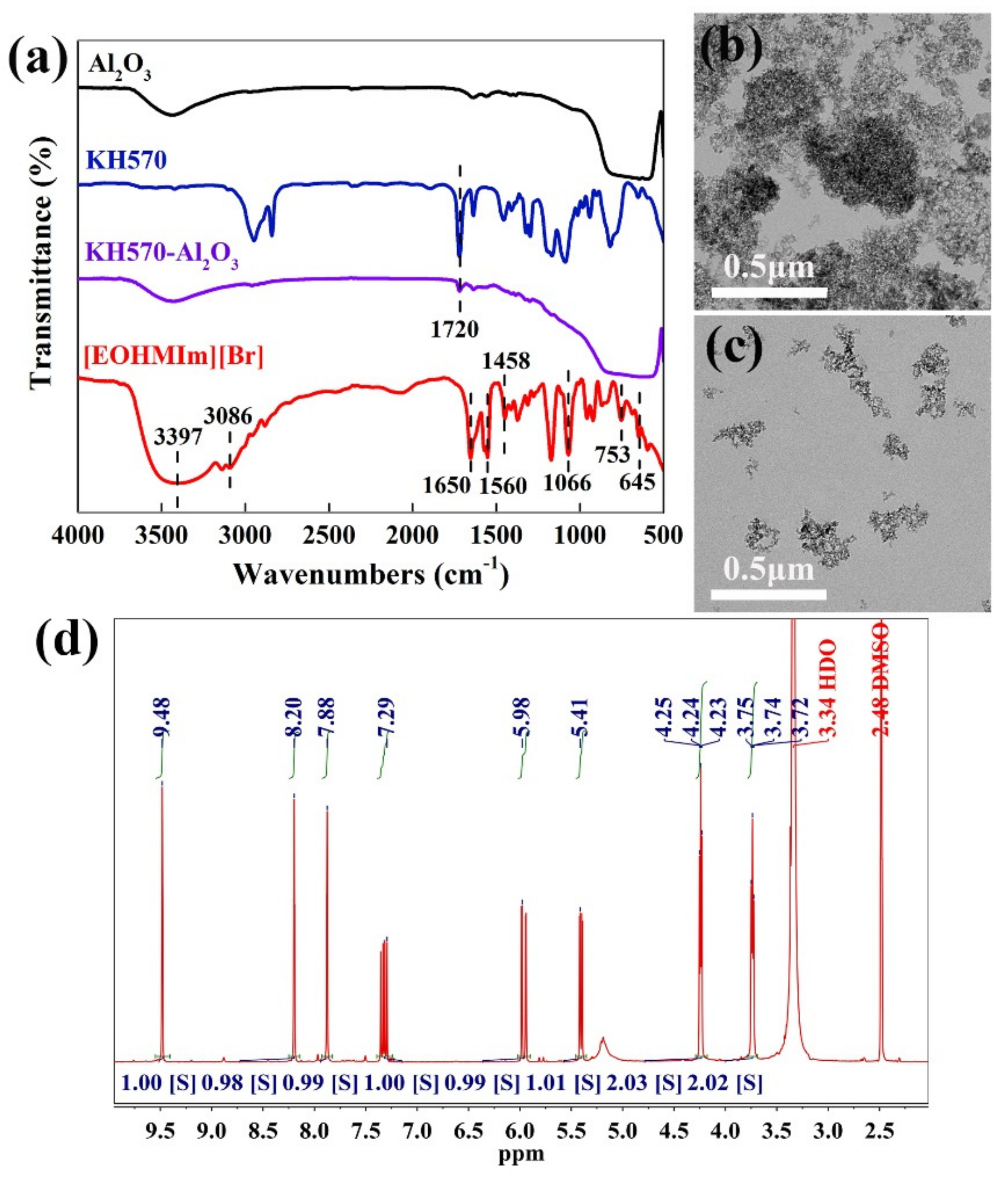

3.1. Structural Characterizations of KH570-Al2O3 and [EOHVIm][Br]

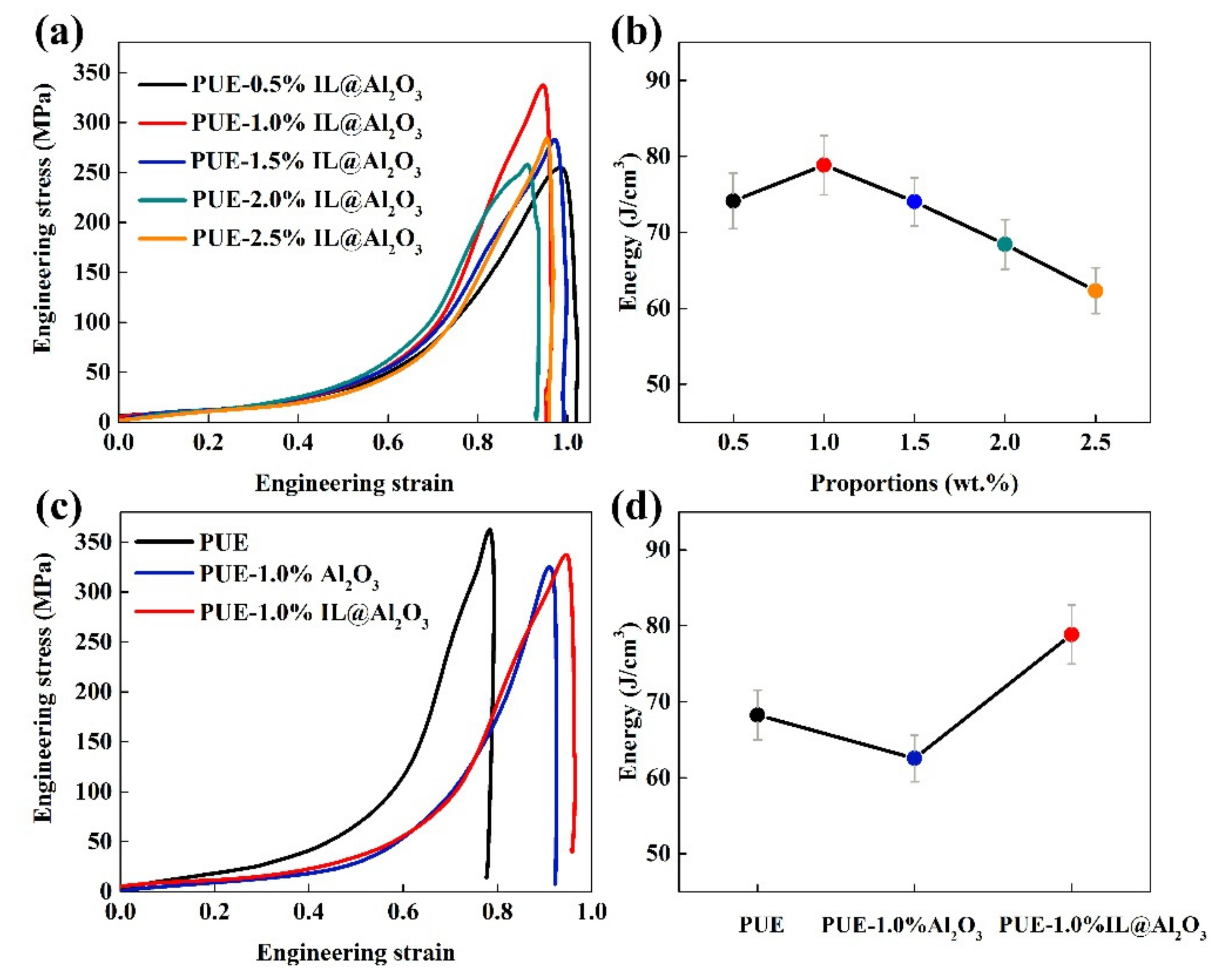

3.2. Quasi-Static Properties of PUE-IL@Al2O3

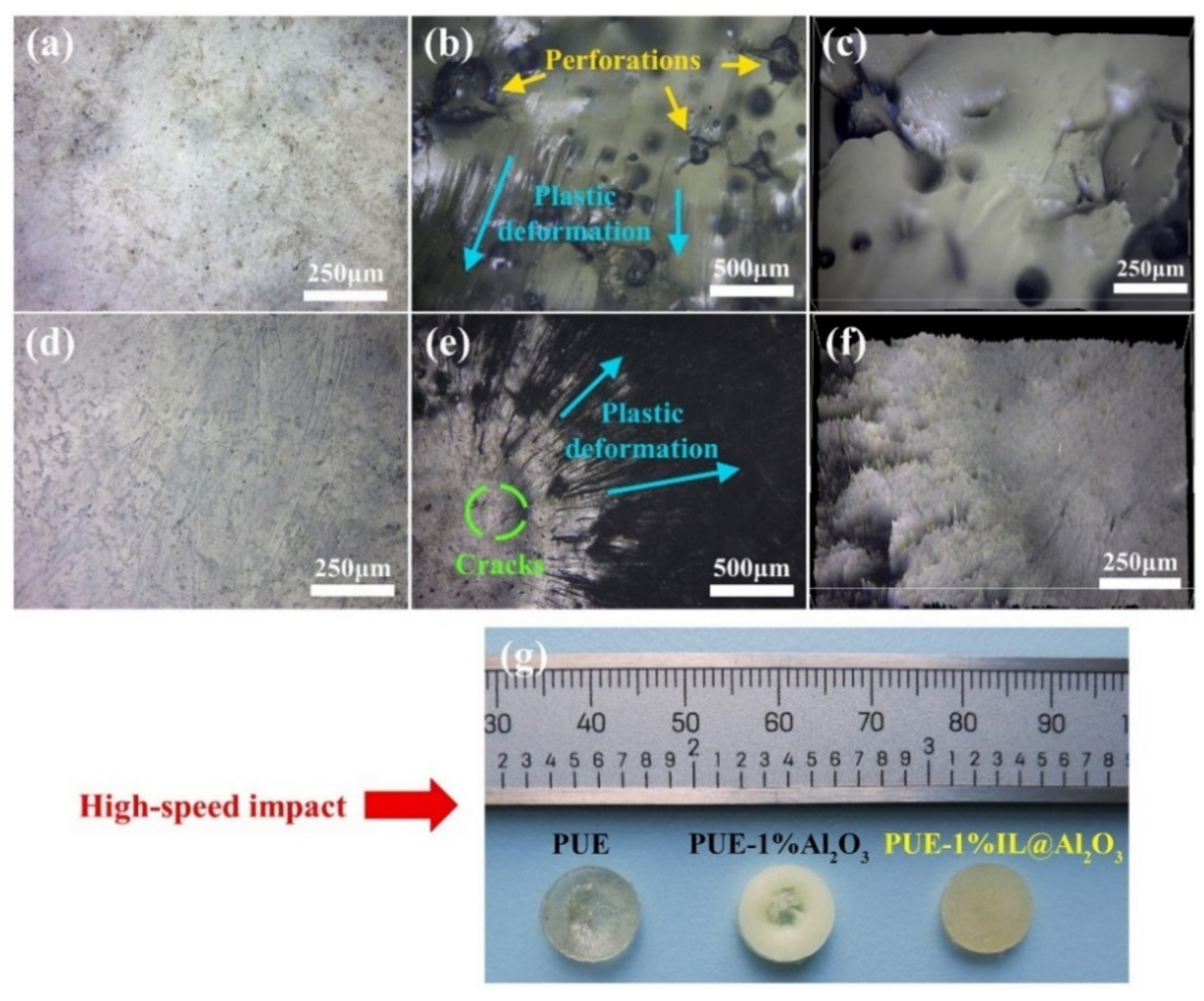

3.3. Dynamic Impact Resistance of PUE-IL@Al2O3

4. Discussion

5. Conclusions

- (1)

- From the static compression curves, the PUE-IL@Al2O3 with 1% IL@Al2O3 could withstand the maximum ultimate peak stress, which is an increase of about 61.13% compared with the pure PUE. Moreover, the compressed specimen had good morphological after unloading.

- (2)

- According to the dynamic impact curve after the high impact force (0.2 MPa), the impact resistance (evaluated by energy absorption) was increased by about 15.36%. Moreover, the deformation recovery of the sample is excellent (approximately 95%). The improvements of the strength and energy absorption of composite material mainly depend on the synergistic enhancement of nano-Al2O3 and IL and the synergistic effects of multiple interface permeations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.X.; Zhang, X.; Shi, Y.; Wu, C.; Li, J. Finite element modeling of FRP retrofitted RC column against blast loading. Compos. Struct. 2021, 263, 113727. [Google Scholar] [CrossRef]

- Choi, J.H.; Choi, S.J.; Kim, J.H.J.; Hong, K.N. Evaluation of blast resistance and failure behavior of prestressed concrete under blast loading. Constr. Build. Mater. 2018, 173, 550–572. [Google Scholar] [CrossRef]

- Wang, S.; Gao, R.; Zhou, K. The influence of cerium dioxide functionalized reduced graphene oxide on reducing fire hazards of thermoplastic polyurethane nanocomposites. J. Colloid. Interf. Sci. 2019, 536, 127–134. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Zhang, D.; Zhang, Y.; Cai, W.; Yao, C.; Hu, Y.; Hu, W. Construction of multifunctional boron nitride nanosheet towards reducing toxic volatiles (CO and HCN) generation and fire hazard of thermoplastic polyurethane. J. Hazard. Mater. 2019, 362, 482–494. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; Lin, L.; Wang, H.; Huang, X.; Xue, H.; Gao, J. Highly stretchable, anti-corrosive and wearable strain sensors based on the PDMS/CNTs decorated elastomer nanofiber composite. Chem. Eng. J. 2019, 362, 89–98. [Google Scholar] [CrossRef]

- Javaid, M.A.; Zia, K.M.; Iqbal, A.; Ahmad, S.; Akram, N.; Liu, X.; Nawaz, H.; Khosa, M.K.; Awais, M. Utilization of waxy corn starch as an efficient chain extender for the preparation of polyurethane elastomers. Int. J. Biol. Macromol. 2020, 148, 415–423. [Google Scholar] [CrossRef]

- Mao, L.; Shen, H.; Han, W.; Chen, L.; Li, J.; Tang, Y. Hybrid polyurethane and silane sized carbon fibre/epoxy composites with enhanced impact resistance. Compos. Part A Appl. Sci. Manuf. 2019, 118, 49–56. [Google Scholar] [CrossRef]

- Alizadeh, N.; Triggs, E.; Farag, R.; Auad, M.L. Flexible acrylic-polyurethane based graft-interpenetrating polymer networks for high impact structural applications. Eur. Polym. J. 2021, 148, 110338. [Google Scholar] [CrossRef]

- Bogoslovov, R.; Roland, C.; Gamache, R. Impact-induced glass transition in elastomeric coatings. Appl. Phys. Lett. 2007, 90, 221910. [Google Scholar] [CrossRef] [Green Version]

- Heng, C.W.; Leng, T.P.; Supri, A.G.; Keat, Y.C.; Suppiah, K. Effect of graphene loading on mechanical properties of polyurethane elastomer. Mater. Today Proc. 2019, 16, 1617–1621. [Google Scholar] [CrossRef]

- Zhao, S.; Wang, Z.; Pang, H.; Zhang, W.; Zhang, S.; Li, J.; Li, L. Organic-inorganic nanohybrid polyurethane elastomer based on dopamine-mediated biomimetic co-deposition thought toward multiple improved properties. Appl. Surf. Sci. 2019, 493, 1340–1349. [Google Scholar] [CrossRef]

- Tounici, A.; Martín-Martínez, J.M. Influence of the surface chemistry of graphene oxide on the structure–property relationship of waterborne poly(urethane urea) adhesive. Materials 2021, 14, 4377. [Google Scholar] [CrossRef]

- Dagani, R.O.N. Putting the ’nano’ into composites. Chem. Eng. News 1999, 77, 25–37. [Google Scholar] [CrossRef]

- Evora, V.M.F.; Shukla, A. Fabrication, characterization, and dynamic behavior of polyester/TiO2 nanocomposites. Mat. Sci. Eng. A 2003, 361, 358–366. [Google Scholar] [CrossRef]

- Andersons, J.; Kirpluks, M.; Cabulis, U. Reinforcement efficiency of cellulose microfibers for the tensile stiffness and strength of rigid low-density polyurethane foams. Materials 2020, 13, 2725. [Google Scholar] [CrossRef] [PubMed]

- Zheng, C.; Cheng, Y.; Wei, Q.; Li, X.; Zhang, Z. Suspension of surface-modified nano-SiO2 in partially hydrolyzed aqueous solution of polyacrylamide for enhanced oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2017, 524, 169–177. [Google Scholar] [CrossRef]

- Zaiemyekeh, Z.; Liaghat, G.H.; Ahmadi, H.; Khan, M.K.; Razmkhah, O. Effect of strain rate on deformation behavior of aluminum matrix composites with Al2O3 nanoparticles. Mat. Sci. Eng. A 2019, 753, 276–284. [Google Scholar] [CrossRef] [Green Version]

- Lai, S.M.; Wang, C.K.; Shen, H.F. Properties and preparation of thermoplastic polyurethane/silica hybrid using sol-gel process. J. Appl. Polym. Sci. 2005, 97, 1316–1325. [Google Scholar] [CrossRef]

- Chen, G.; Zhou, S.; Gu, G.; Wu, L. Modification of colloidal silica on the mechanical properties of acrylic based polyurethane/silica composites. Colloids Surf. A Physicochem. Eng. Asp. 2007, 296, 29–36. [Google Scholar] [CrossRef]

- Chen, S.; Sui, J.; Chen, L. Positional assembly of hybrid polyurethane nanocomposites via incorporation of inorganic building blocks into organic polymer. Colloid Polym. Sci. 2004, 283, 66–73. [Google Scholar] [CrossRef]

- Park, M.J.; Lee, J.K.; Lee, B.S.; Lee, Y.W.; Lee, S.G. Covalent modification of multiwalled carbon nanotubes with imidazolium-based ionic liquids: Effect of anions on solubility. Chem. Mater. 2006, 18, 1546–1551. [Google Scholar] [CrossRef]

- Hayes, R.; Warr, G.G.; Atkin, R. Structure and Nanostructure in Ionic Liquids. Chem. Rev. 2015, 115, 6357–6426. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yang, Y.K.; He, C.E.; Peng, R.G.; Baji, A.; Du, X.S.; Huang, Y.L.; Xie, X.L.; Mai, Y.W. Non-covalently modified graphene sheets by imidazolium ionic liquids for multifunctional polymer nanocomposites. J. Mater. Chem. 2012, 22, 5666–5675. [Google Scholar] [CrossRef]

- Xu, H.; Tong, F.; Yu, J.; Wen, L.; Zhang, J.; He, J. A one-pot method to prepare transparent poly(methyl methacrylate)/montmorillonite nanocomposites using imidazolium-based ionic liquids. Polym. Int. 2012, 61, 1382–1388. [Google Scholar] [CrossRef]

- He, X.; Shi, J.; Wu, L.; Jiang, P.; Liu, B. Study on synergistic toughening of polypropylene with high-density polyethylene and elastomer-olefin block copolymers under ultrasonic application. Compos. Sci. Technol. 2018, 161, 115–123. [Google Scholar] [CrossRef]

- Misasi, J.M.; Jin, Q.; Knauer, K.M.; Morgan, S.E.; Wiggins, J.S. Hybrid POSS-Hyperbranched polymer additives for simultaneous reinforcement and toughness improvements in epoxy networks. Polymer 2017, 117, 54–63. [Google Scholar] [CrossRef]

- Chopra, S.; Deshmukh, K.A.; Deshmukh, A.D.; Gogte, C.L.; Peshwe, D. Prediction, evaluation and mechanism governing interphase strength in tensile fractured PA-6/MWCNT nanocomposites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 255–262. [Google Scholar] [CrossRef]

- Li, W.; Li, Y.; Xiang, D.; Zhao, C.; Wang, B.; Li, H.; Han, H. Simultaneous enhancement of electrical conductivity and interlaminar shear strength of CF/EP composites through MWCNTs doped thermoplastic polyurethane film interleaves. J. Appl. Polym. Sci. 2019, 136, 47988. [Google Scholar] [CrossRef]

- Li, P.; Liu, D.; Zhu, B.; Li, B.; Jia, X.; Wang, L.; Li, G.; Yang, X. Synchronous effects of multiscale reinforced and toughened CFRP composites by MWNTs-EP/PSF hybrid nanofibers with preferred orientation. Compos. Part A Appl. Sci. Manuf. 2015, 68, 72–80. [Google Scholar] [CrossRef]

- Mamusa, M.; Siriex-Plénet, J.; Cousin, F.; Dubois, E.; Peyre, V. Tuning the colloidal stability in ionic liquids by controlling the nanoparticles/liquid interface. Soft Matter 2014, 10, 1097–1101. [Google Scholar] [CrossRef] [Green Version]

- International Organization for Standardization. International Standard: Plastics-Determination of Compressive Properties; ISO 604:2002; International Organization for Standardization: Geneva, Switzerland, 2002. [Google Scholar]

- Xu, J.; Wang, P.; Pang, H.; Wang, Y.; Wu, J.; Xuan, S.; Gong, X. The dynamic mechanical properties of magnetorheological plastomers under high strain rate. Compos. Sci. Technol. 2018, 159, 50–58. [Google Scholar] [CrossRef]

- Pandya, K.S.; Naik, N.K. Energy absorption capability of carbon nanotubes dispersed in resins under compressive high strain rate loading. Compos. Part B Eng. 2015, 72, 40–44. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, H.; Zhao, J.; Li, T.; Bie, B.-X.; Luo, S.-N.; Zhang, Z. High strain rate compression of epoxy based nanocomposites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 62–70. [Google Scholar] [CrossRef]

- Fan, J.T.; Weerheijm, J.; Sluys, L.J. Compressive response of multiple-particles-polymer systems at various strain rates. Polymer 2016, 91, 62–73. [Google Scholar] [CrossRef]

- Ghosh, S.; Otorgust, G.; Idelevich, A.; Regev, O.; Lapsker, I.; Lewitus, D.Y.; Zak, A. Reinforcement of poly (methyl methacrylate) by WS2 nanotubes towards antiballistic applications. Compos. Sci. Technol. 2021, 207, 108736. [Google Scholar] [CrossRef]

- Sanaty-Zadeh, A. Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall–Petch effect. Mat. Sci. Eng. A 2012, 531, 112–118. [Google Scholar] [CrossRef]

- Christman, T.; Needleman, A.; Nutt, S.; Suresh, S. On microstructural evolution and micromechanical modelling of deformation of a whisker-reinforced metal-matrix composite. Mat. Sci. Eng. A 1989, 107, 49–61. [Google Scholar] [CrossRef]

- Miao, Y.G.; Liu, H.Y.; Suo, T.; Mai, Y.W.; Xie, F.Q.; Li, Y.L. Effects of strain rate on mechanical properties of nanosilica/epoxy. Compos. Part B Eng. 2016, 96, 119–124. [Google Scholar] [CrossRef]

- Vachon, A.; Pépin, K.; Balampanis, E.; Veilleux, J.; Vuillaume, P.Y. Compatibilization of PLA/PEBA blends via reactive extrusion: A comparison of different coupling agents. J. Polym. Environ. 2017, 25, 812–827. [Google Scholar] [CrossRef]

- Lim, J.W.; Hassan, A.; Rahmat, A.R.; Wahit, M.U. Morphology, thermal and mechanical behavior of polypropylene nanocomposites toughened with poly(ethylene-co-octene). Polym. Int. 2006, 55, 204–215. [Google Scholar] [CrossRef]

- Baouz, T.; Rezgui, F.; Yilmazer, U. Ethylene-methyl acrylate-glycidyl methacrylate toughened poly(lactic acid) nanocomposites. J. Appl. Polym. Sci. 2013, 128, 3193–3204. [Google Scholar] [CrossRef]

- Dyke, C.A.; Tour, J.M. Overcoming the Insolubility of Carbon Nanotubes Through High Degrees of Sidewall Functionalization. Chem. Eur. J. 2004, 10, 812–817. [Google Scholar] [CrossRef] [PubMed]

- Cai, W.; Hu, Y.; Pan, Y.; Zhou, X.; Chu, F.; Han, L.; Mu, X.; Zhuang, Z.; Wang, X.; Xing, W. Self-assembly followed by radical polymerization of ionic liquid for interfacial engineering of black phosphorus nanosheets: Enhancing flame retardancy, toxic gas suppression and mechanical performance of polyurethane. J. Colloid Interf. Sci. 2020, 561, 32–45. [Google Scholar] [CrossRef]

- Sun, N.; Di, M.; Liu, Y. Lignin-containing polyurethane elastomers with enhanced mechanical properties via hydrogen bond interactions. Int. J. Biol. Macromol. 2021, 184, 1–8. [Google Scholar] [CrossRef]

| Sample | Relative Mole Ratio A(–NCO):B(–OH):IL@Al2O3 | IL@Al2O3 Content (wt.%) |

|---|---|---|

| PUE-0.5%IL@Al2O3 | 1:0.99:0.02 | 0.5 |

| PUE-1.0%IL@Al2O3 | 1:0.97:0.04 | 1.0 |

| PUE-1.5%IL@Al2O3 | 1:0.95:0.06 | 1.5 |

| PUE-2.0%IL@Al2O3 | 1:0.93:0.08 | 2.0 |

| PUE-2.5%IL@Al2O3 | 1:0.91:0.10 | 2.5 |

| Sample | Maximum Force (kN) | Elastic Modulus (MPa) | Maximum Strength (MPa) | Compression Rate (%) |

|---|---|---|---|---|

| PUE | 28.34 | 95.8 | 90.2 | 48.76 |

| PUE-1.0%Al2O3 | 21.24 | 57.0 | 67.6 | 58.16 |

| PUE-0.5%IL@Al2O3 | 32.90 | 97.4 | 104.7 | 54.52 |

| PUE-1.0%IL@Al2O3 | 60.32 | 210.2 | 192.0 | 51.14 |

| PUE-1.5%IL@Al2O3 | 44.11 | 161.8 | 140.37 | 48.93 |

| PUE-2.0%IL@Al2O3 | 41.61 | 140.2 | 132.5 | 49.99 |

| PUE-2.5%IL@Al2O3 | 34.72 | 119.8 | 110.5 | 50.22 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, F.; Gao, J.; Zhang, B.; Qi, F.; Zhao, N.; Ouyang, X. Effects of Modified Al2O3-Decorated Ionic Liquid on the Mechanical Properties and Impact Resistance of a Polyurethane Elastomer. Materials 2021, 14, 4712. https://doi.org/10.3390/ma14164712

Hu F, Gao J, Zhang B, Qi F, Zhao N, Ouyang X. Effects of Modified Al2O3-Decorated Ionic Liquid on the Mechanical Properties and Impact Resistance of a Polyurethane Elastomer. Materials. 2021; 14(16):4712. https://doi.org/10.3390/ma14164712

Chicago/Turabian StyleHu, Fan, Jun Gao, Biao Zhang, Fugang Qi, Nie Zhao, and Xiaoping Ouyang. 2021. "Effects of Modified Al2O3-Decorated Ionic Liquid on the Mechanical Properties and Impact Resistance of a Polyurethane Elastomer" Materials 14, no. 16: 4712. https://doi.org/10.3390/ma14164712