Early Age Sealing Capacity of Structural Mortar with Integral Crystalline Waterproofing Admixture

Abstract

:1. Introduction

2. Materials and Methods

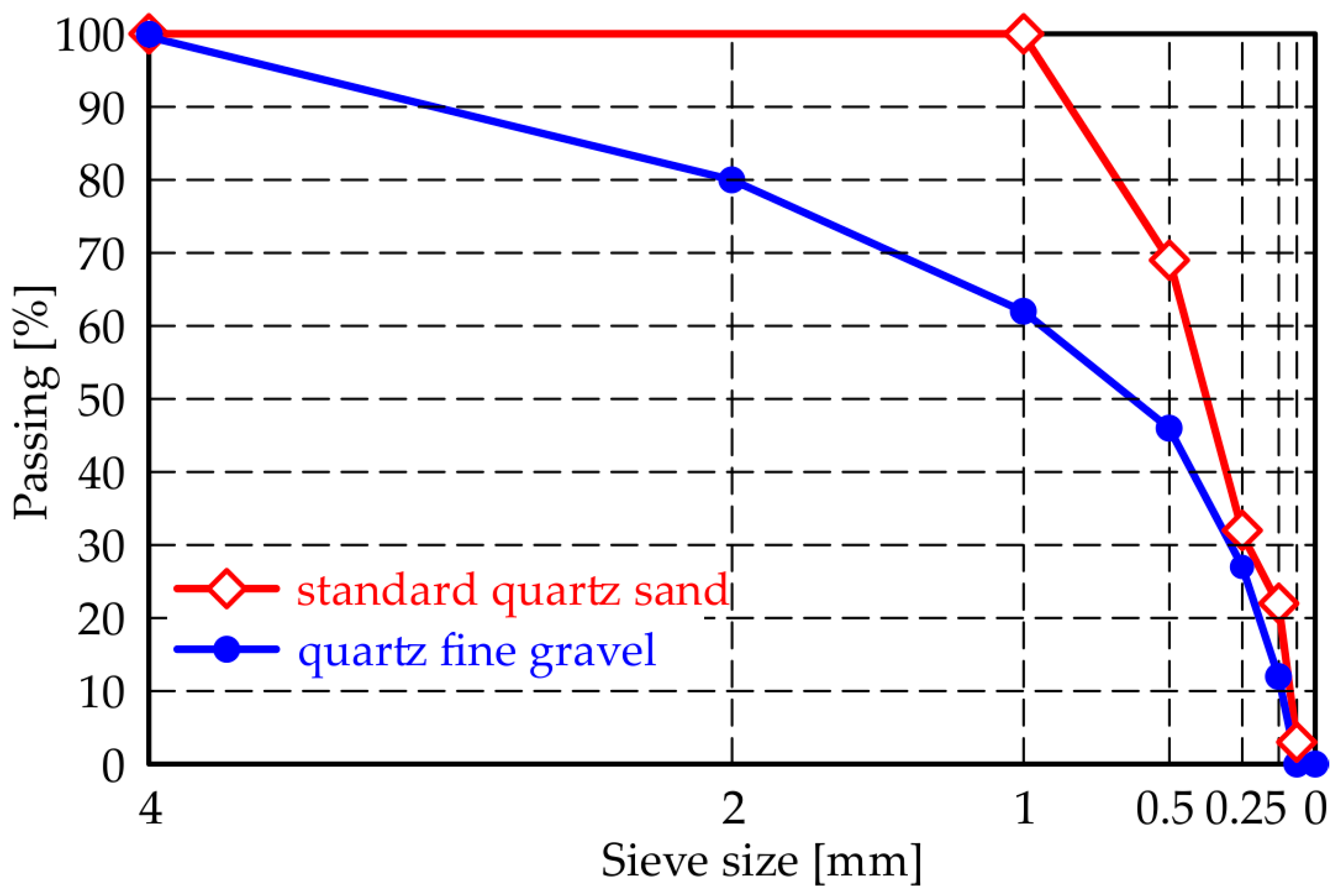

2.1. Ingredients and Mix Proportions

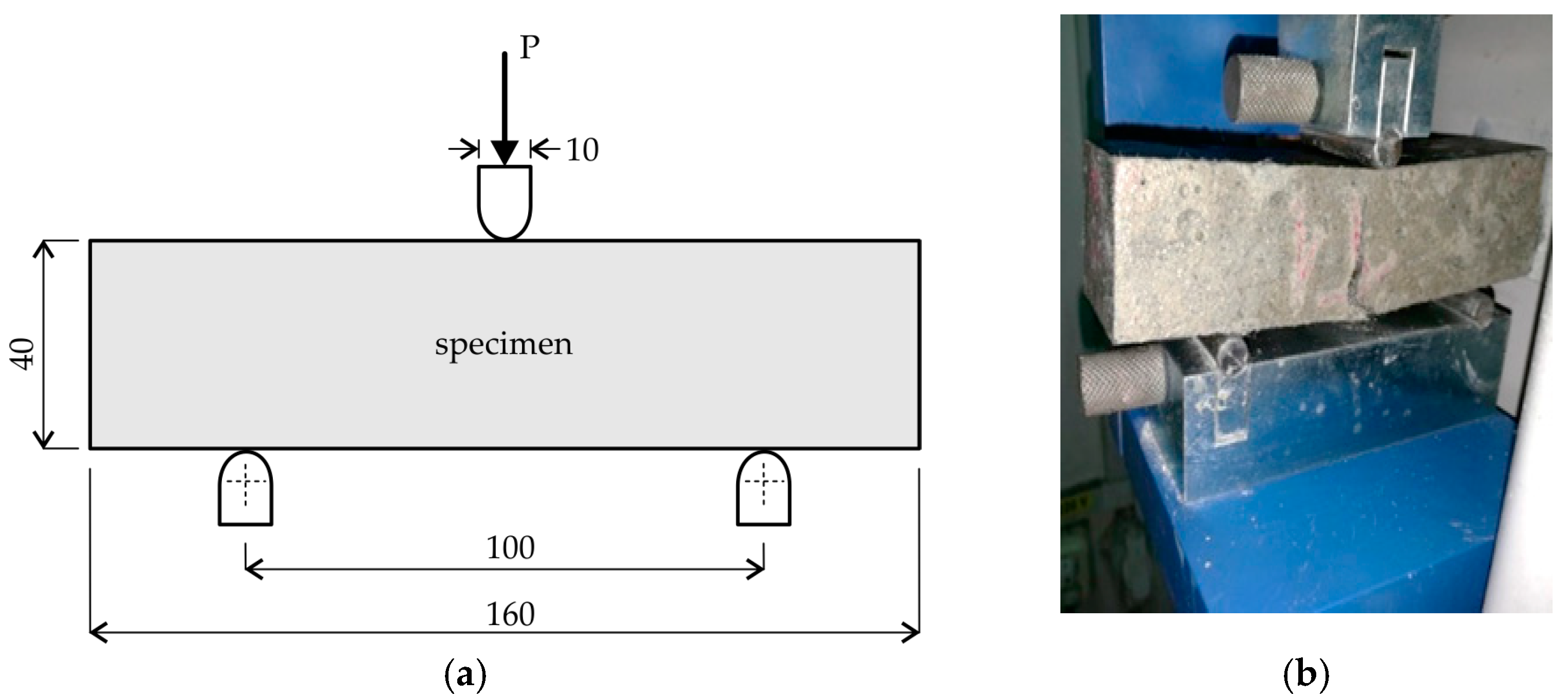

2.2. Specimen Preparation, Preloading and Conditioning

2.3. Self-Sealing Parameters and Evaluation

- Crack closure, considering the relative decrease in the average crack width wav at day t of conditioning, related to the initial moment after preloading

- Closure rate of the crack, considering the decrease in the average crack width related to the corresponding interval t in days

3. Results and Discussion

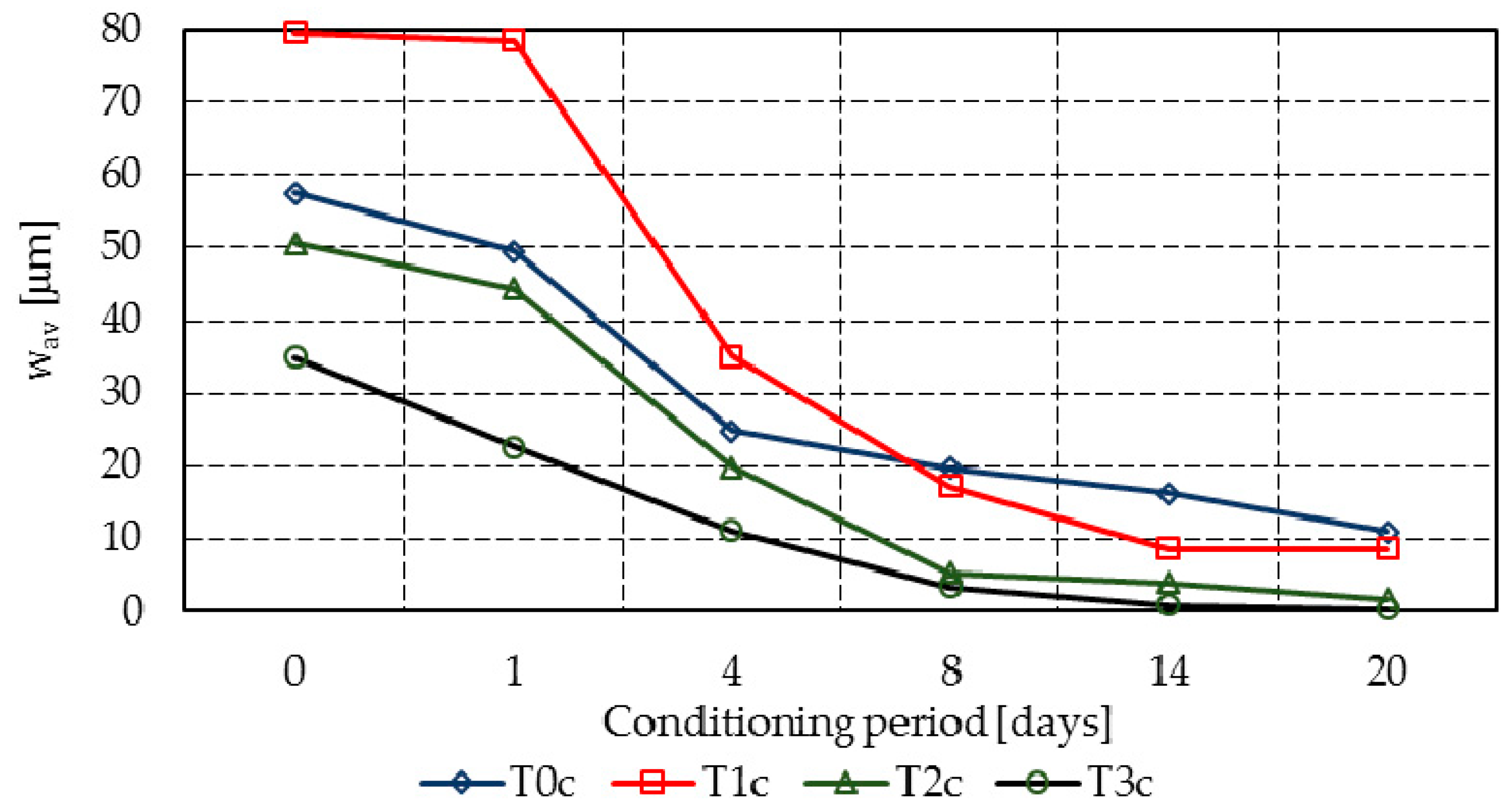

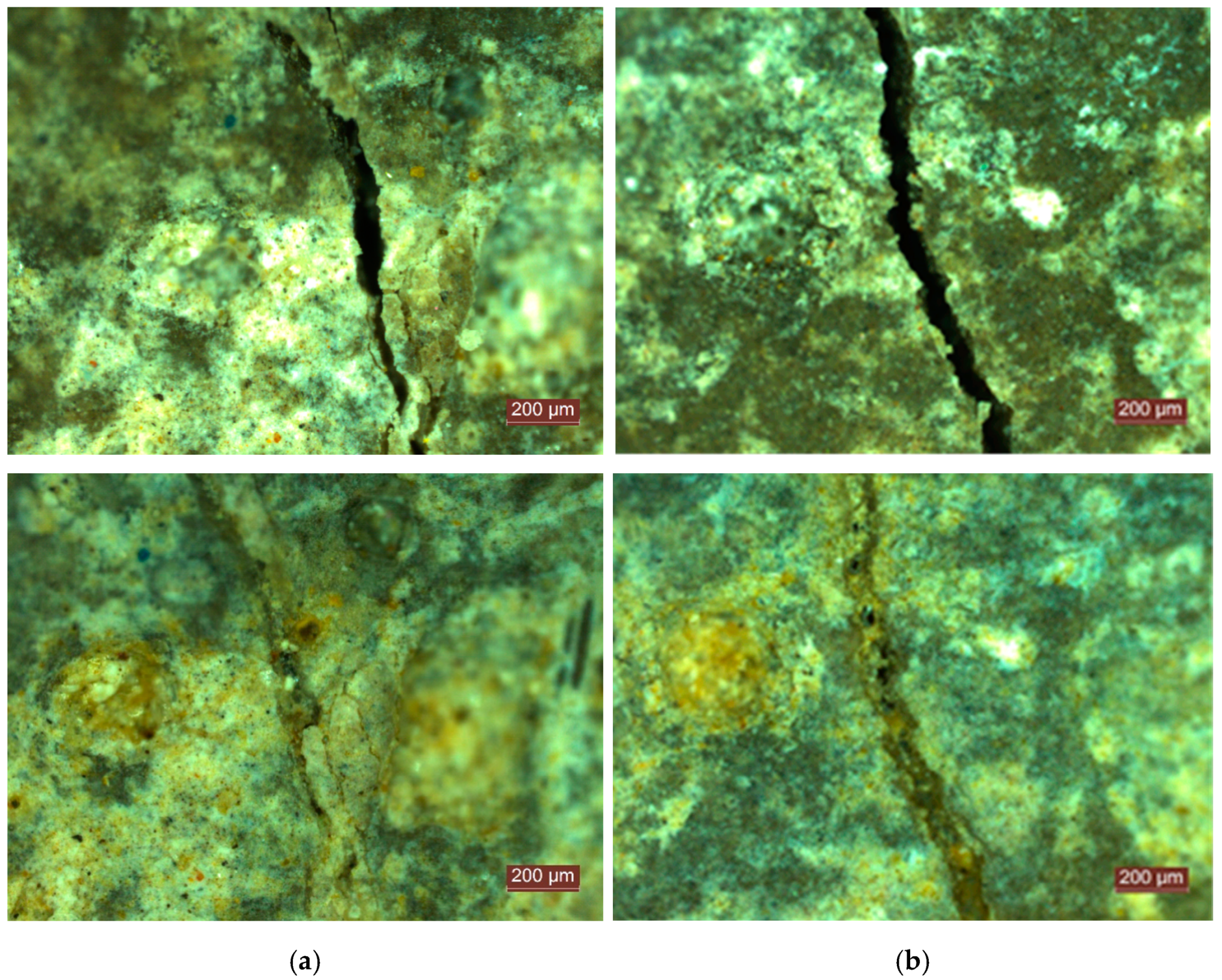

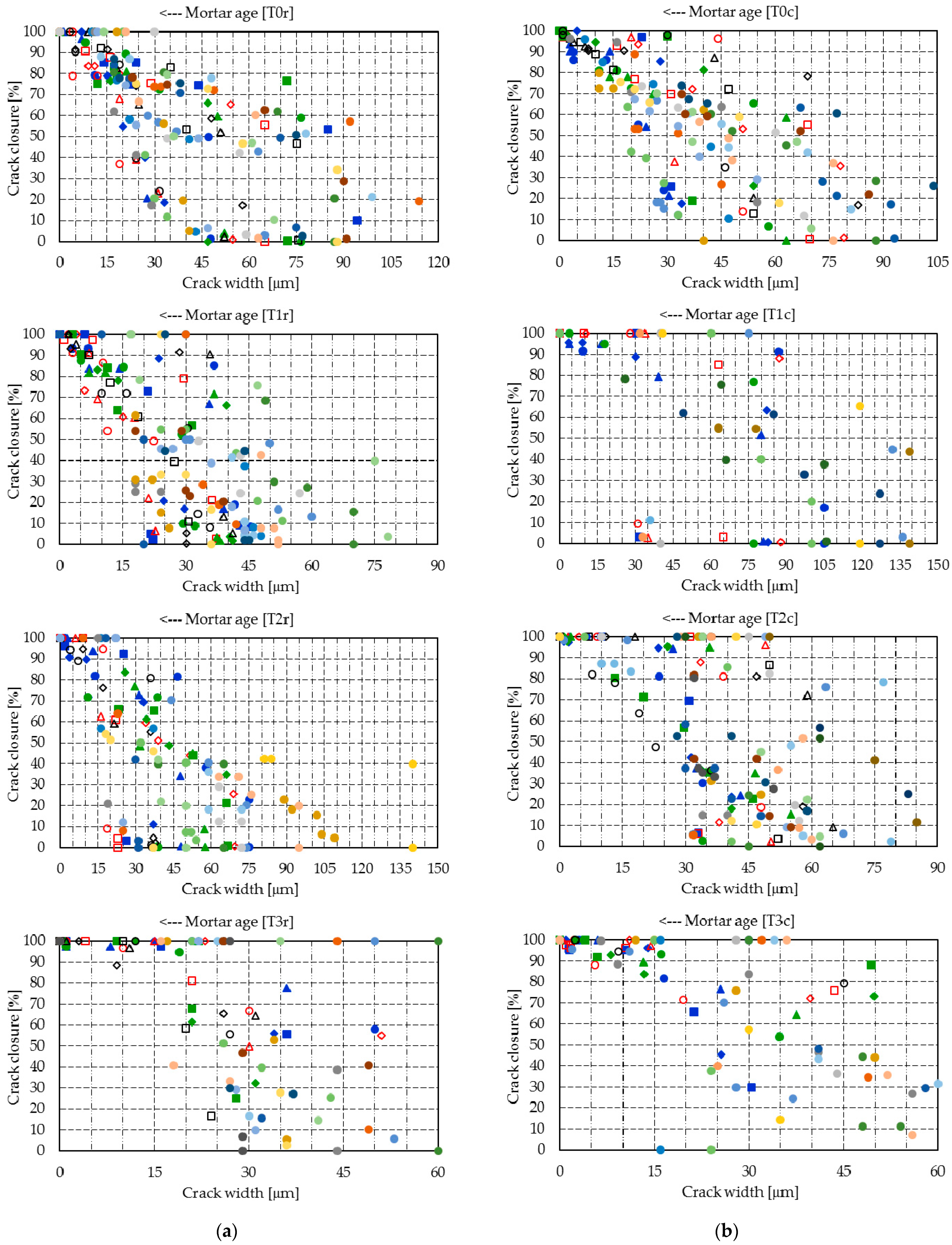

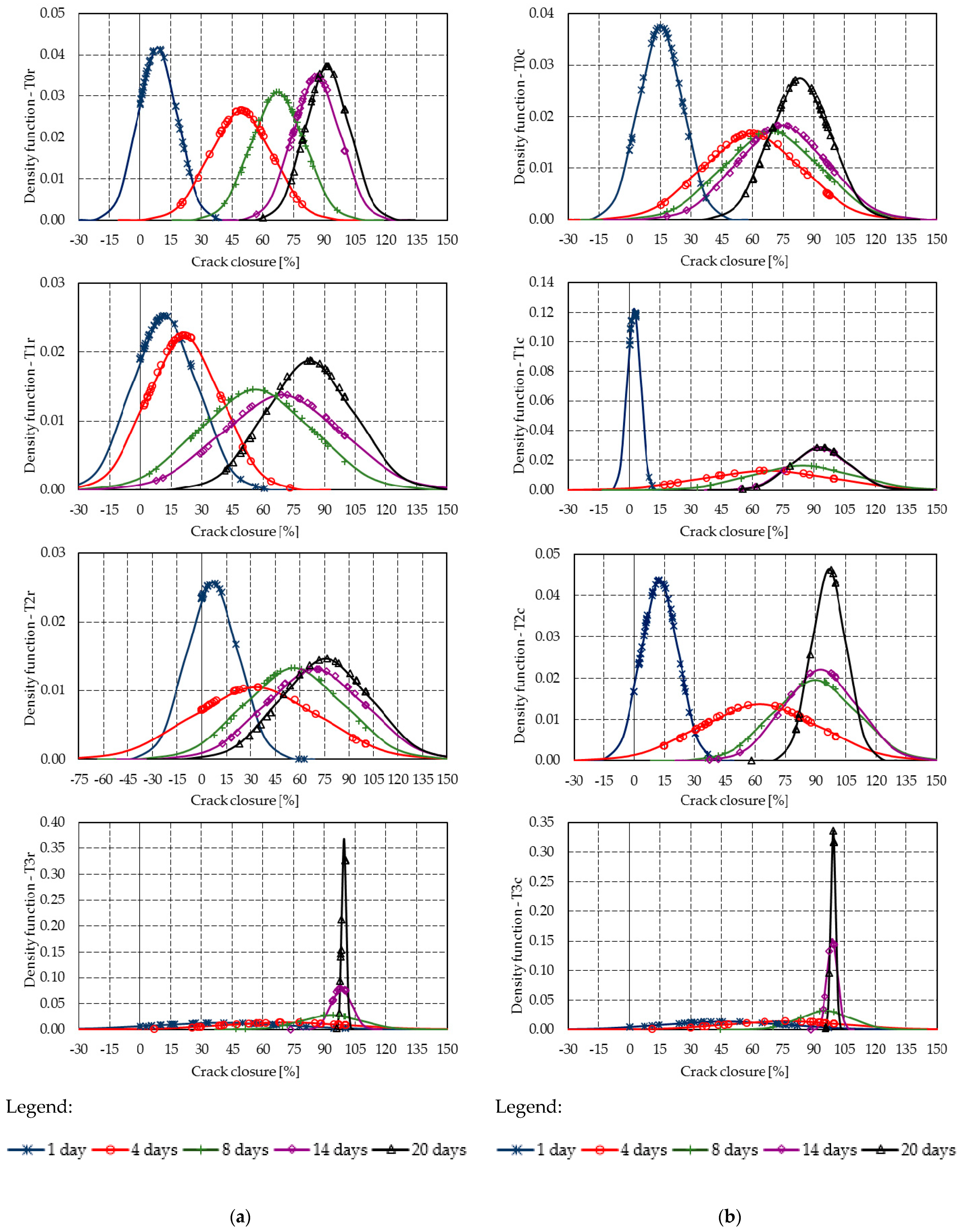

3.1. Self-Sealing Crack Closure

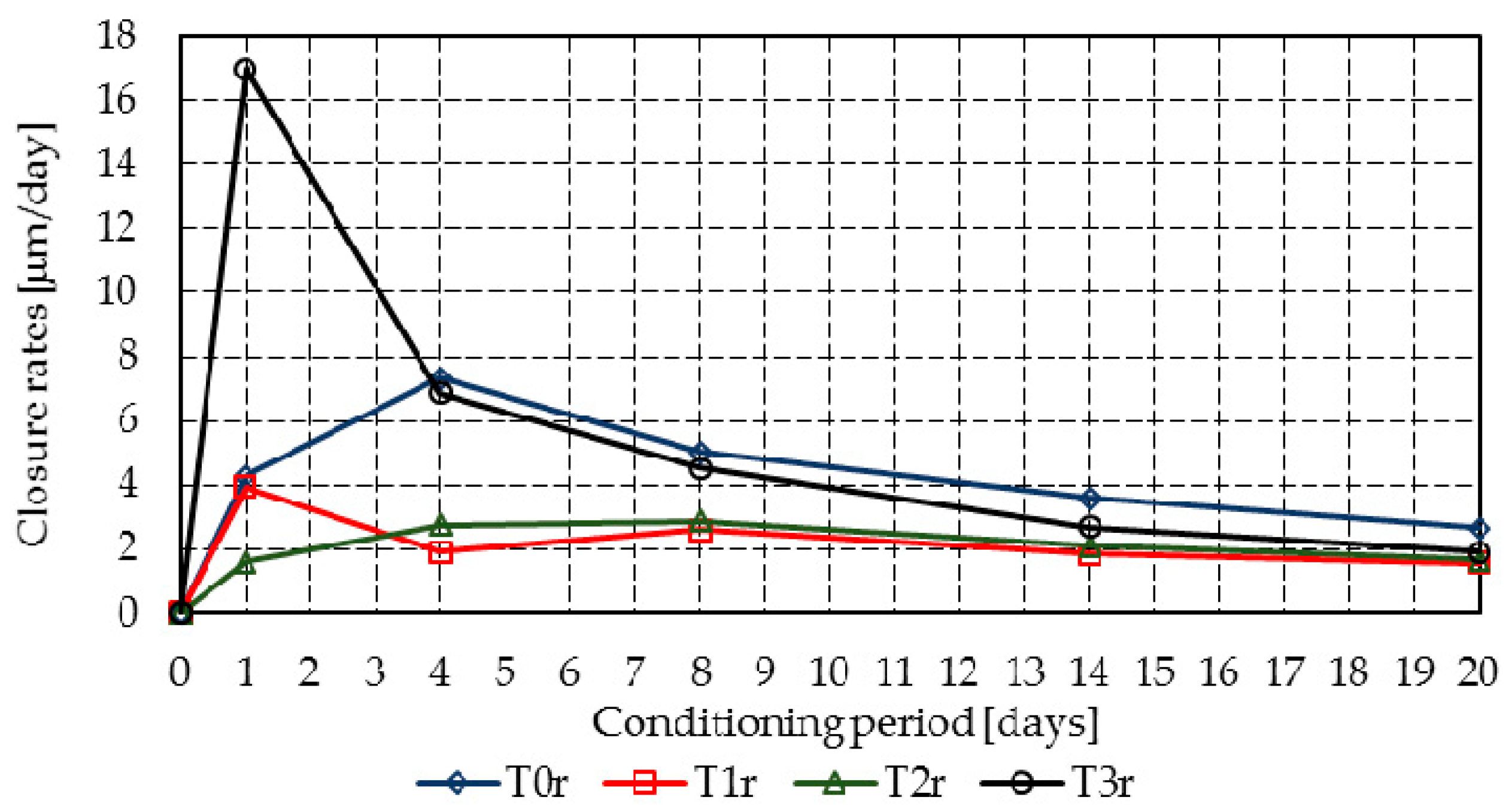

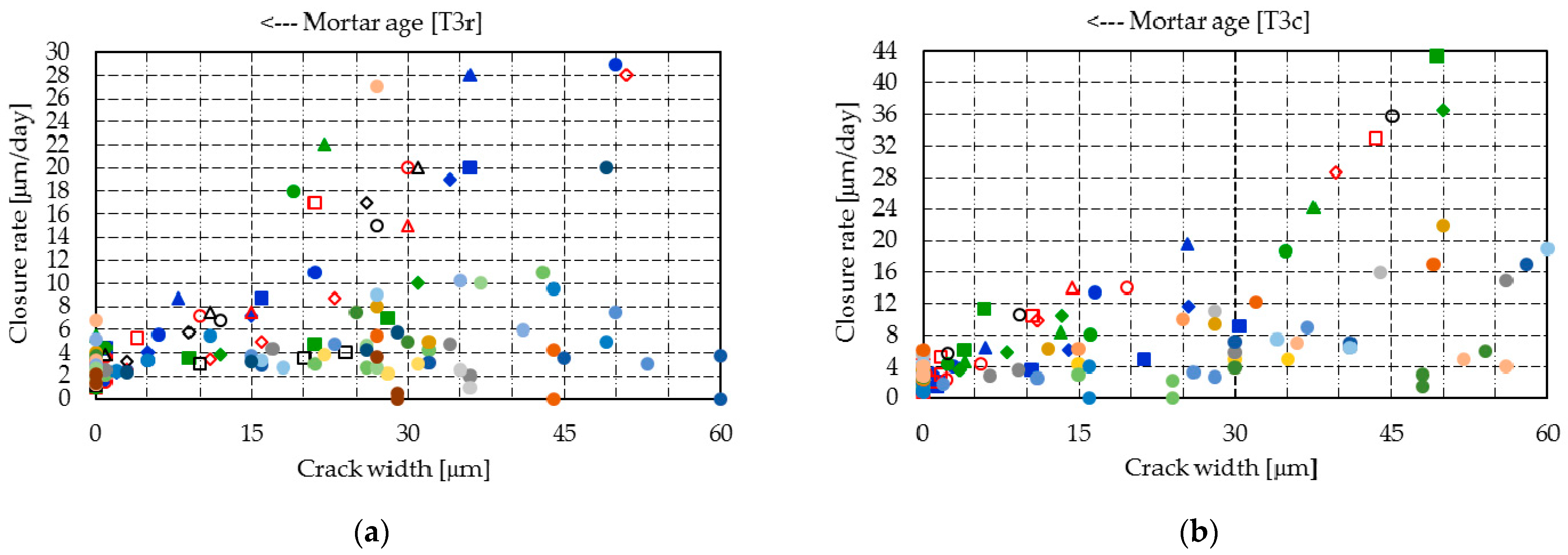

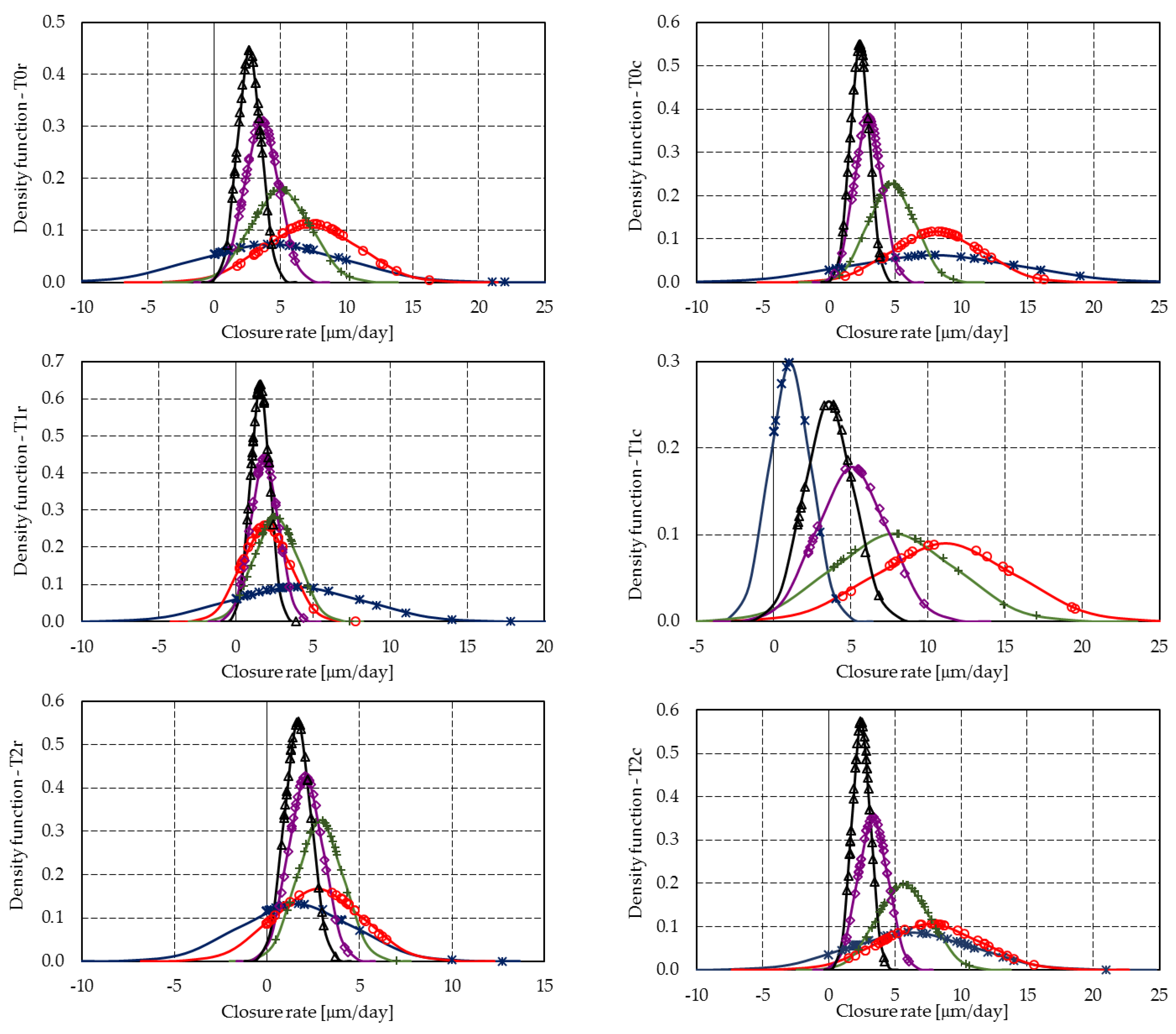

3.2. Self-Sealing Closure Rate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lauer, K.R.; Slate, F.O. Autogenous healing of cement paste. J. Am. Concr. Inst. 1956, 52, 1083–1097. [Google Scholar] [CrossRef]

- Hearn, N.; Morley, C.T. Self-sealing property of concrete—Experimental evidence. Mater. Struct. 1997, 30, 404–411. [Google Scholar] [CrossRef]

- Hyde, G.W.; Smith, W.J. Results of experiments made to determine the permeability of cements and cement mortars. J. Frankl. Inst. Phila. 1889, 128, 199–207. [Google Scholar] [CrossRef]

- Glanville, W.H. The permeability of Portland cement concrete. Build. Res. J. 1931, 3, 1–61. [Google Scholar]

- Ruttgers, A.; Vidal, E.N.; Wing, S.P. An investigation of the permeability of mass concrete with particular reference to Boulder Dam. J. Am. Concr. Inst. 1935, 6, 389–416. [Google Scholar]

- Bissonnette, B.; Pigeon, M. Tensile creep at early ages of ordinary, silica fume and fiber reinforced concretes. Cem. Concr. Res. 1995, 25, 1075–1085. [Google Scholar] [CrossRef]

- Altoubat, S.; Lange, D.A. Creep, Shrinkage and Cracking of Restrained Concrete at Early Age. ACI Mater. J. 2001, 98, 323–331. [Google Scholar]

- Mircea, C.; Filip, M.; Ioani, A. Investigation of Cracking of Mass Concrete Members Induced by Restrained Contraction, SP-246: Structural Implications of Shrinkage and Creep of Concrete. In Proceedings of the ACI Convention, Fajardo, Puerto Rico, 14–18 October 2007; Gardner, J., Chiorino, M.A., Eds.; ACI: Farmington Hills, MI, USA, 2007; Volume SP-246-14, pp. 229–246. [Google Scholar]

- Edvardsen, C. Water permeability and autogenous healing of cracks in concrete. ACI Mater. J. 1999, 96, 448–454. [Google Scholar]

- Li, M.; Li, V.C. Cracking and healing of engineered cementitious composites under chloride environment. ACI Mater. J. 2011, 108, 333–340. [Google Scholar]

- Mihashi, H.; Nishiwaki, T. Development of Engineered Self-Healing and Self-Repairing Concrete- State-of-the-Art Report. J. Adv. Concr. Technol. 2012, 10, 170–184. [Google Scholar] [CrossRef] [Green Version]

- Van Tittelboom, K.; De Belie, N. A Self-Healing in Cementitious Materials—A Review. Materials 2013, 6, 2182–2217. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Herbert, E.N.; Li, V.C. Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) under a Natural Environment. Materials 2013, 6, 2831–2845. [Google Scholar] [CrossRef] [PubMed]

- De Belie, N.; Gruyaert, E.; Al-Tabbaa, A.; Antonaci, P.; Baera, C.; Bajare, D.; Darquennes, A.; Davies, R.; Ferrara, L.; Jefferson, T.; et al. A Review of Self-Healing Concrete for Damage Management of Structures. Adv. Mater. Interfaces 2018, 5, 1800074. [Google Scholar] [CrossRef]

- Danish, A.; Mosaberpanah, M.A.; Salim, M.U. Past and present techniques of self-healing in cementitious materials: A critical review on efficiency of implemented treatments. J. Mater. Res. Technol. 2020, 9, 6883–6899. [Google Scholar] [CrossRef]

- Fernandez, C.A.; Correa, M.; Nguyen, M.T.; Rod, K.A.; Dai, G.L.; Cosimbescu, L.; Rousseau, R.; Glezakou, V.A. Progress and challenges in self-healing cementitious materials. J. Mater. Sci. 2021, 56, 201–230. [Google Scholar] [CrossRef]

- Yang, Y.; Lepech, M.D.; Yang, E.H.; Li, V.C. Autogenous healing of engineered cementitious composites under wet-dry cycles. Cem. Concr. Res. 2009, 39, 382–390. [Google Scholar] [CrossRef]

- Van Tittelboom, K.; Gruyaert, E.; Rahier, H.; De Belie, N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr. Build. Mater. 2012, 37, 349–359. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. From straw in bricks to modern use of microfibres in cementitious composites for improved autogenous healing—A review. Constr. Build. Mater. 2015, 95, 774–787. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. Autogenous healing in strain-hardening cementitious materials with and without superabsorbent polymers: An 8-year study. Front. Mater. 2019, 6, 1–12. [Google Scholar] [CrossRef]

- Neville, A. Autogenous healing—A concrete miracle? Concr. Int. 2002, 24, 76–82. [Google Scholar]

- Sisomphon, K.; Copuroglu, O.; Koenders, E.A.B. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem. Concr. Compos. 2012, 34, 566–574. [Google Scholar] [CrossRef]

- Hilloulin, B.; Hilloulin, D.; Grondin, F.; Loukili, A.; De Belie, N. Mechanical regains due to self-healing in cementitious materials: Experimental measurements and micro-mechanical model. Cem. Concr. Res. 2016, 80, 21–32. [Google Scholar] [CrossRef]

- Ferrara, L.; Krelani, V.; Morreti, F. Autogenous healing on the recovery of mechanical performanceof High Performance Fibre Reinforced Cementitious Composites (HPFRCCs): Part 2—Correlation between healing of mechanical performance and crack sealing. Cem. Concr. Compos. 2016, 73, 299–315. [Google Scholar] [CrossRef]

- Lăzărescu, A.; Szilagyi, H.; Ioani, A.; Baeră, C. Parameters Affecting the Mechanical Properties of Fly Ash-Based Geopolymer Binders—Experimental Results. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012035. [Google Scholar] [CrossRef] [Green Version]

- Voinitchi, C.; Baeră, C.; Zapciu, M.; Matei, C.; Szilagyi, H. Development of Cement-Based Materials Enriched with Polymeric Coated Reactive Grains as Long-Term Promoter of Matrix Continuous Hydration. IOP Conf. Ser. Mater. Sci. Eng. 2020, 877, 012028. [Google Scholar] [CrossRef]

- Szilagyi, H.; Baeră, C.; Lăzărescu, A.; Mircea, A.C. Preliminary evaluation of local mineral additions (by-products or wastes) valorisation in innovative cementitious composites. Constructions 2018, 19, 3–10. [Google Scholar]

- Huang, H.; Ye, G.; Damidot, D. Effect of blast furnace slag on self-healing of microcracks in cement itious materials. Cem. Concr. Res. 2014, 60, 68–82. [Google Scholar] [CrossRef]

- Olivier, K.; Darquennes, A.; Benboudj, F.; Gagné, R. Early-Age Self-Healing of Cementitious Materials Containing Ground Granulated Blast-Furnace Slag under Water Curing. J. Adv. Concr. Technol. 2016, 14, 717–727. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.; Qian, S.; Ma, H. Investigating mechanical properties and self-healing behavior of micro-cracked ECC with different volume of fly ash. Constr. Build. Mater. 2014, 52, 17–23. [Google Scholar] [CrossRef]

- Yildirim, G.; Sahmaran, M.; Ahmed, H.U. Influence of Hydrated Lime Addition on the SelfHealing Capability of High-Volume Fly Ash Incorporated Cementitious Composites. J. Mater. Civ. Eng. 2015, 27, 4014187. [Google Scholar] [CrossRef]

- Siad, H.; Alyousif, A.; Keskin, O.K.; Keskin, S.B.; Lachemi, M.; Sahmaran, M.; Hossain, K.M.A. Influence of limestone powder on mechanical, physical and self-healing behavior of Engineered Cementitious Composites. Constr. Build. Mater. 2015, 99, 1–10. [Google Scholar] [CrossRef]

- Ouyang, W.; Koleva, D.A.; Ye, G.; Van Breugel, K. Insights into the mechanisms of nucleation and growth of C–S–H on fillers. Mater. Struct. 2017, 50, 213. [Google Scholar] [CrossRef]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A.K. Advances in understanding cement hydration mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Bacarji, E.; Toledo Filho, R.D.; Koenders, E.A.B.; Figueiredo, E.P.; Lopes, J.L.M.P. Sustainability perspective of marble and granite residues as concrete fillers. Cem. Concr. Compos. 2013, 45, 1–10. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. Repeated Autogenous Healing in Strain-Hardening Cementitious Composits by Using Superabsorbent Polymers. J. Mater. Civ. Eng. 2013, 25, 864–870. [Google Scholar]

- Huang, X.; Ge, J.; Kaewunruen, S.; Su, Q. The Self-Sealing Capacity of Environmentally Friendly, Highly Damped, Fibre-Reinforced Concrete. Materials 2020, 13, 298. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Wyrzykowski, M.; Dong, H.; Granja, H.; Azenha, M.; Lura, P.; Ye, G. Internal curing by superabsorbent polymers in alkali-activated slag. Cem. Concr. Res. 2020, 135, 106123. [Google Scholar] [CrossRef]

- Ferrara, L.; Cuenca, E.; Tejedor, A.; Brac, E.G. Performance of concrete with and without crystalline admixtures under repeated cracking/healing cycles. In Proceedings of the International Conference on Concrete Repair, Rehabilitation and Retrofitting, Cape Town, South Africa, 19–21 November 2018; Alexander, M.G., Dehn, F., Moyo, P., Eds.; EDP Sciences: Les Ulis, France, 2018; Volume 199, pp. 1–6. [Google Scholar]

- Roig-Flores, M.; Moscato, S.; Serna, P.; Ferrara, L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr. Build. Mater. 2015, 86, 1–11. [Google Scholar] [CrossRef]

- Roig-Flores, M.; Pirritano, F.; Serna, P.; Ferrara, L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr. Build. Mater. 2016, 114, 447–457. [Google Scholar] [CrossRef]

- Buller, A.S.; Abro, F.R.; Lee, K.M.; Jamg, S.Y. Mechanical Recovery of Cracked Fiber-Reinforced Mortar Incorporating Crystalline Admixture, Expansive Agent, and Geomaterial. Adv. Mater. Sci. Eng. 2019, 2019, 3420349. [Google Scholar] [CrossRef] [Green Version]

- Park, B.; Choi, Y.C. Self-healing capability of cementitious materials with crystalline admixtures and super absorbent polymers (SAPs). Constr. Build. Mater. 2018, 189, 1054–1066. [Google Scholar] [CrossRef]

- Azarsa, P.; Gupta, R.; Biparva, A. Assessment of self-healing and durability parameters of concretes incorporating crystalline admixtures and Portland Limestone Cement. Cem. Concr. Compos. 2019, 99, 17–23. [Google Scholar] [CrossRef]

- Li, D.; Chen, B.; Chen, X.; Fu, B.; Wei, H.; Xiang, X. Synergetic effect of superabsorbent polymer (SAP) and crystalline admixture (CA) on mortar macro-crack healing. Constr. Build. Mater. 2020, 247, 118521. [Google Scholar] [CrossRef]

- Rhee, I.; Lee, J.S.; Roh, Y.S. Fracture Parameters of Cement Mortar with Different Structural Dimensions under the Direct Tension Test. Materials 2019, 12, 1850. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Elices, M.; Rocco, C.G. Effect of aggregate size on the fracture and mechanical properties of a simple concrete. Eng. Fract. Mech. 2008, 75, 3839–3851. [Google Scholar] [CrossRef]

- Karamloo, M.; Mazloom, M.; Payganeh, G. Effects of maximum aggregate size on fracture behaviors of self-compacting lightweight concrete. Constr. Build. Mater. 2016, 123, 508–515. [Google Scholar] [CrossRef]

- Mircea, A.C.; Toader, T.P. Designing Concrete with Self-healing Properties Using Engineered Cementitious Composites as a Model. IOP Conf. Ser. Mater. Sci. Eng. 2020, 877, 012035. [Google Scholar] [CrossRef]

- Nishiwaki, T.; Koda, M.; Yamada, M.; Mihashi, H.; Kikuta, T. Experimental Study on Self-Healing Capability of FRCC Using Sifferent Types of Synthetic Fibers. J. Adv. Concr. Technol. 2012, 10, 195–206. [Google Scholar] [CrossRef] [Green Version]

- Henseler, J.; Ringle, C.; Sinkovics, R. The use of partial least squares path modeling in international marketing. Adv. Int. Mark. 2009, 20, 277–320. [Google Scholar]

- Cuenca, E.; Rigamonti, E.; Brac, E.G.; Ferrara, L.B. Crystalline Admixture as Healing Promoter in Concrete Exposed to Chloride-Rich Environments: Experimental Study. J. Mater. Civ. Eng. 2021, 33, 04020491. [Google Scholar] [CrossRef]

- Jaroenratanapirom, D.; Sahamitmongkol, R. Effects of Different Mineral Additives and Cracking Ages on Self-healing Performance of Mortar. In Proceedings of the 6th Annual Concrete Conference, Phetchaburi, Thailand, 20–23 October 2010. [Google Scholar]

- Wang, X.; Qiao, H.; Zhang, Z.; Tang, S.; Liu, S.; Niu, M.; Li, G. Effect of fly ash on the self-healing capability of cementitious materials with crystalline admixture under different conditions. AIP Adv. 2021, 11, 075018. [Google Scholar] [CrossRef]

- Reddy, T.C.S.; Ravitheja, A.; Sashidhar, C. Self-Healing Ability of High-Strength Fibre-Reinforced Concrete with Fly Ash and Crystalline Admixture. Civ. Eng. J. 2018, 4, 971–979. [Google Scholar] [CrossRef]

| Mixture | Cement (kg) | Fly Ash (kg) | Sand/Gravel (kg) | MS (kg) | HRWRA (kg) | Water (kg) | PVA (kg) |

|---|---|---|---|---|---|---|---|

| T0r | 580 | 650 | 476 | 141 | 12.75 | 327 | 26 |

| T0c | 580 | 650 | 476 | 141 | 12.75 | 327 | 26 |

| Mixture | Cement | Fly Ash | Sand/Gravel | MS | HRWRA | Water | PVA | ICW |

|---|---|---|---|---|---|---|---|---|

| T0r 1, T0c 2 | 1 | 1.12 | 0.82 | 0.24 | 0.02 | 0.56 | 0.04 | - |

| T1r 1, T1c 2 | 1.11 | 0.01 | ||||||

| T2r 1, T2c 2 | 1.10 | 0.02 | ||||||

| T3tr 1, T3c 2 | 1.09 | 0.03 |

| Mixture | Density (kg/m3) | Effective Flexural Strength (MPa) | Mean Flexural Strength (MPa) |

|---|---|---|---|

| T0r | 1921 | 17.2/16.7/16.3 | 16.7 |

| T1r | 1923 | 16.9/15.1/15.2 | 15.7 |

| T2r | 1927 | 18.2/20.1/18.5 | 18.9 |

| T3r | 1931 | 19.3/21.5/19.8 | 20.2 |

| T0c | 1918 | 15.9/16.4/15.0 | 15.8 |

| T1c | 1922 | 15.3/16.2/17.2 | 16.2 |

| T2c | 1923 | 16.7/17.3/14.9 | 16.3 |

| T2c | 1925 | 16.7/16.1/16.7 | 16.5 |

| Mixture | Crack Widths (mm) in the Conditioning Period | |||||

|---|---|---|---|---|---|---|

| 0 Days | 1 Day | 4 Days | 8 Days | 14 Days | 20 Days | |

| T0r | 53.9/65.5/60.4 | 50.2/60.7/56.1 | 23.2/37.6/31.1 | 14.2/25.0/20.1 | 6.8/12.4/9.9 | 4.4/9.0/7.0 |

| 59.9 ± 5.8 | 55.7 ± 5.3 | 30.6 ± 7.2 | 19.8 ± 5.4 | 9.7 ± 2.8 | 6.8 ± 2.3 | |

| T1r | 37.2/46.3/34.5 | 32.5/42.6/31.2 | 29.4/37.8/27.8 | 9.3/29.2/17.4 | 4.7/23.0/12.9 | 3.2/13.4/7.7 |

| 39.3 ± 6.2 | 35.4 ± 6.2 | 31.6 ± 5.3 | 18.6 ± 10.0 | 13.5 ± 9.2 | 8.1 ± 5.1 | |

| T2r | 53.2/59.1/42.0 | 50.5/58.1/40.9 | 36.4/50.8/34.2 | 21.4/38.9/24.9 | 13.1/33.0/20.1 | 8.9/28.6/16.9 |

| 51.4 ± 8.7 | 49.8 ± 8.6 | 40.5 ± 9.0 | 28.4 ± 9.3 | 22.1 ± 10.1 | 18.1 ± 9.9 | |

| T3r | 32.6/39.0/33.5 | 13.6/32.3/22.0 | 4.3/18.3/11.0 | 1.3/5.6/3.3 | 0.5/1.4/0.9 | 0.2/0.3/0.2 |

| 35.0 ± 3.5 | 22.6 ± 9.4 | 11.2 ± 7.0 | 3.4 ± 2.1 | 0.9 ± 0.4 | 0.3 ± 0.1 | |

| T0c | 49.3/61.5/61.7 | 41.9/53.6/ 53.2 | 13.2/34.4/27.0 | 8.0/29.6/21.4 | 5.7/25.4/17.7 | 4.6/17.8/10.8 |

| 57.5 ± 7.1 | 49.6 ± 6.6 | 24.9 ± 10.8 | 19.7 ± 10.9 | 16.3 ± 9.9 | 11.0 ± 6.6 | |

| T1c | 73.5/88.2/76.9 | 72.6/87.2/75.7 | 27.2/46.1/31.9 | 10.2/28.4/12.9 | 8.0/14.6/3.3 | 7.8/14.0/3.0 |

| 79.5 ± 7.7 | 78.5 ± 7.7 | 35.1 ± 9.8 | 17.3 ± 10.0 | 8.6 ± 5.7 | 8.3 ± 5.5 | |

| T2c | 48.2/54.5/49.3 | 41.7/48.2/43.3 | 14.9/25.9/18.9 | 2.3/8.1/5.7 | 1.3/6.3/4.2 | 0.9/2.4/1.8 |

| 50.7 ± 3.4 | 44.4 ± 3.4 | 19.9 ± 5.6 | 5.3 ± 2.9 | 3.9 ± 2.5 | 1.7 ± 0.7 | |

| T3c | 33.2/39.0/42.6 | 10.0/29.4/24.6 | 2.8/17.0/12.8 | 0.5/3.5/2.6 | 0.2/0.6/0.5 | 0.2/0.1/0.2 |

| 38.3 ± 4.8 | 21.3 ± 10.1 | 10.9 ± 7.3 | 2.2 ± 1.5 | 0.4 ± 0.2 | 0.2 ± 0.0 | |

| Mixture | μ/σ (%) | Probabilities for Significant Crack Closure Intervals of | ||

|---|---|---|---|---|

| ≥50% and <75% | ≥75% and <100% | 100% | ||

| T0r | 91.3/10.7 | 0.07 | 0.59 | 0.21 |

| T1r | 82.7/21.2 | 0.20 | 0.43 | 0.21 |

| T2r | 75.7/27.2 | 0.33 | 0.32 | 0.19 |

| T3r | 99.5/1.0 | 0.00 | 0.62 | 0.36 |

| T0c | 83.4/14.6 | 0.17 | 0.69 | 0.13 |

| T1c | 93.2/13.7 | 0.15 | 0.53 | 0.31 |

| T2c | 96.7/8.6 | 0.02 | 0.64 | 0.35 |

| T3c | 96.7/10.7 | 0.00 | 0.63 | 0.35 |

| Mixture | μ/σ [%] | Probability of Closure Rates | ||

|---|---|---|---|---|

| ≥1 μm/day | ≥3 μm/day | ≥6.0 μm/day | ||

| T0r | 5.02/2.22 | 0.97 | 0.78 | 0.35 |

| T1r | 1.56/0.63 | 0.87 | 0.38 | 0.01 |

| T2r | 2.88/1.22 | 0.94 | 0.45 | 0.01 |

| T3r | 3.95/0.50 | 0.99 | 0.87 | 0.01 |

| T0c | 4.73/1.74 | 1.00 | 0.78 | 0.26 |

| T1c | 7.78/3.94 | 0.96 | 0.89 | 0.68 |

| T2c | 5.67/2.02 | 1.00 | 0.91 | 0.42 |

| T3c | 1.91/0.71 | 1.00 | 0.81 | 0.19 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mircea, C.; Toader, T.-P.; Hegyi, A.; Ionescu, B.-A.; Mircea, A. Early Age Sealing Capacity of Structural Mortar with Integral Crystalline Waterproofing Admixture. Materials 2021, 14, 4951. https://doi.org/10.3390/ma14174951

Mircea C, Toader T-P, Hegyi A, Ionescu B-A, Mircea A. Early Age Sealing Capacity of Structural Mortar with Integral Crystalline Waterproofing Admixture. Materials. 2021; 14(17):4951. https://doi.org/10.3390/ma14174951

Chicago/Turabian StyleMircea, Calin, Tudor-Panfil Toader, Andreea Hegyi, Brăduț-Alexandru Ionescu, and Andreea Mircea. 2021. "Early Age Sealing Capacity of Structural Mortar with Integral Crystalline Waterproofing Admixture" Materials 14, no. 17: 4951. https://doi.org/10.3390/ma14174951

APA StyleMircea, C., Toader, T.-P., Hegyi, A., Ionescu, B.-A., & Mircea, A. (2021). Early Age Sealing Capacity of Structural Mortar with Integral Crystalline Waterproofing Admixture. Materials, 14(17), 4951. https://doi.org/10.3390/ma14174951