Investigation on Control Burned of Bagasse Ash on the Properties of Bagasse Ash-Blended Mortars

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Preparation and Characterization of Bagasse Ash

2.2. Preparation and Analysis of BA-Blended Mortar Samples

3. Results and Discussion

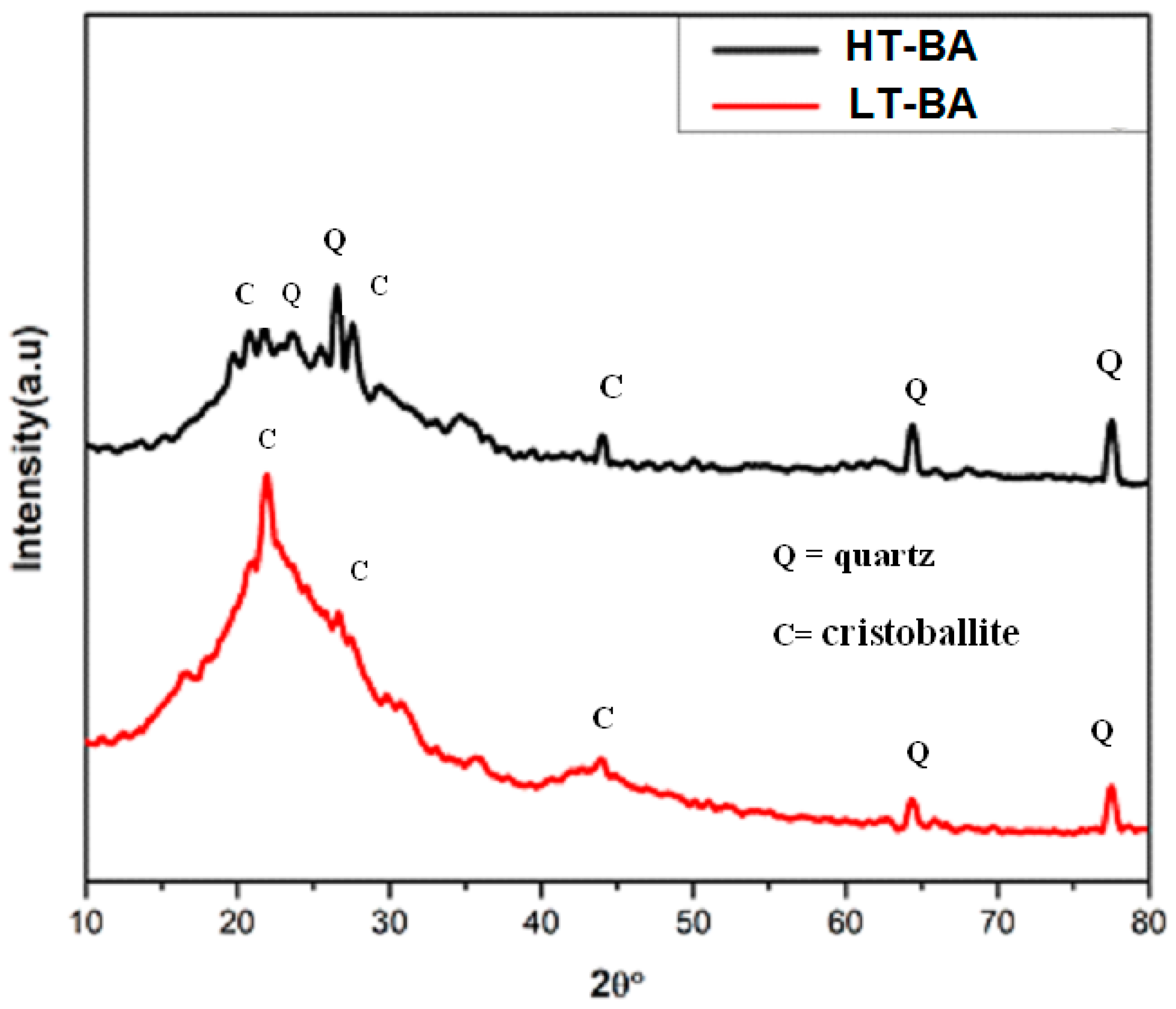

3.1. Mineralogical Compositions of Bagasse Ash (BA)

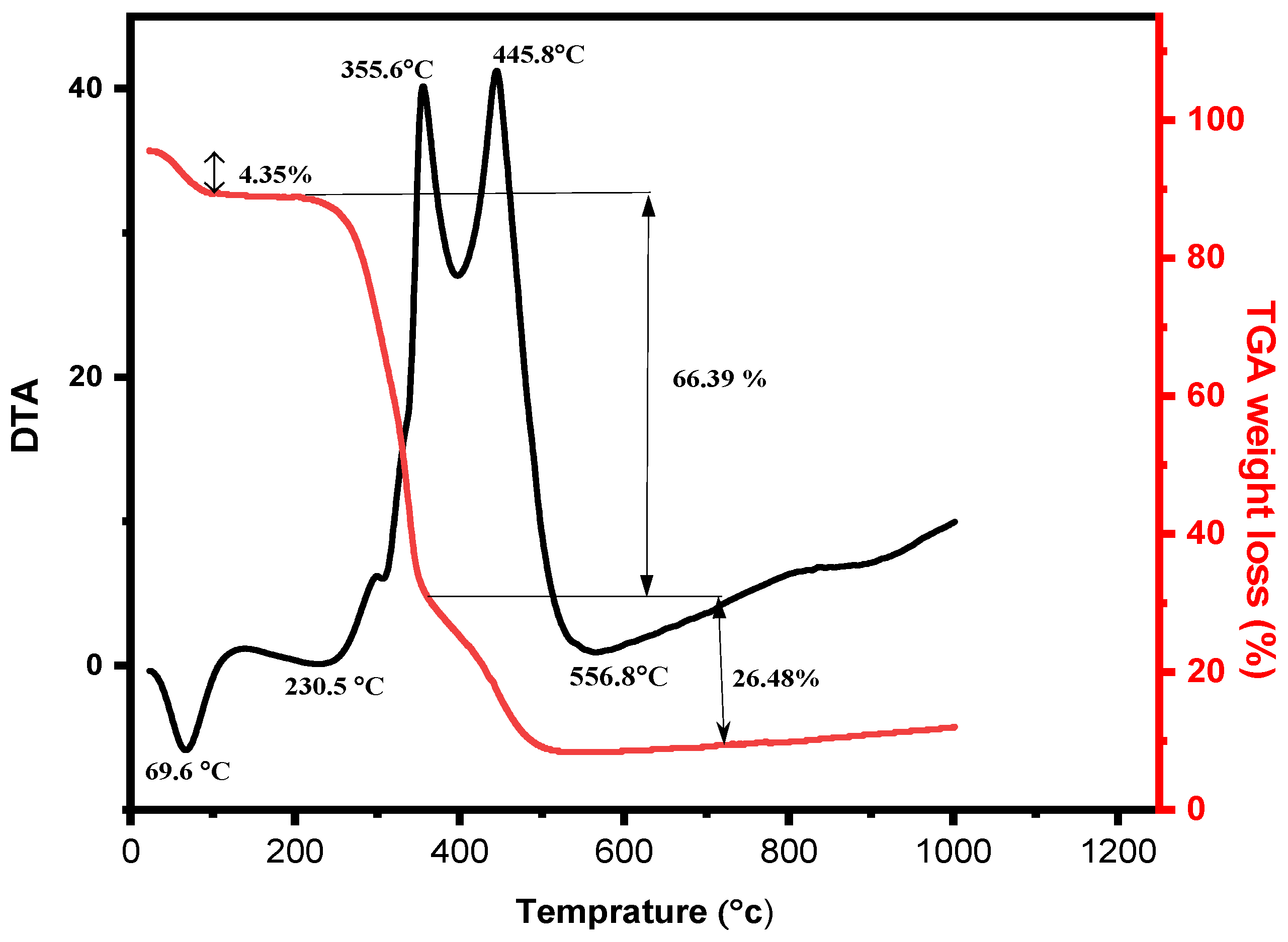

3.2. Thermal Analysis of Bagasse Ash

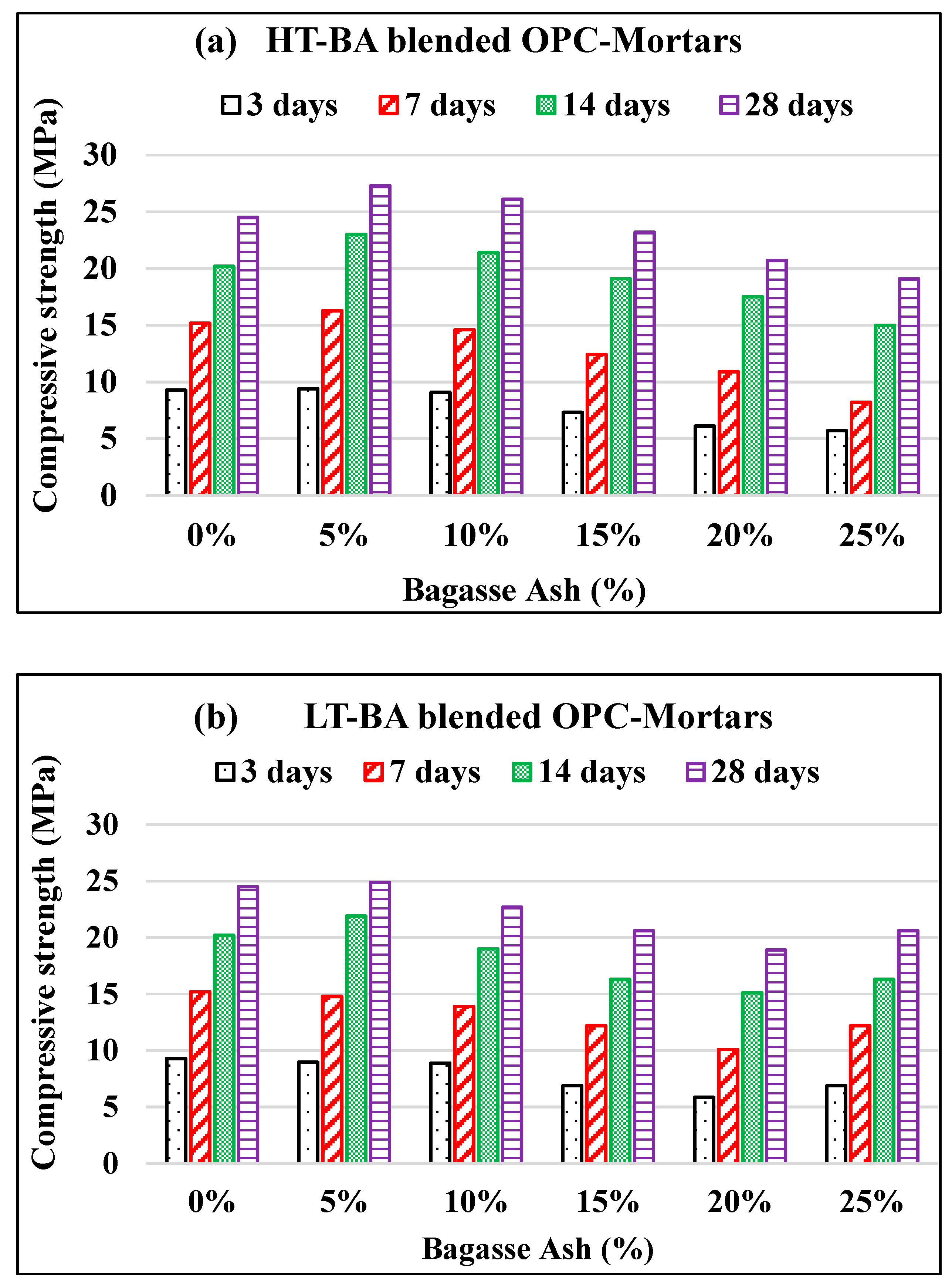

3.3. Compressive Strength of Bagasse Ash (BA)-Blended OPC Mortar Sample

3.4. Compressive Strength of Bagasse Ash-Blended PPC Mortar Samples

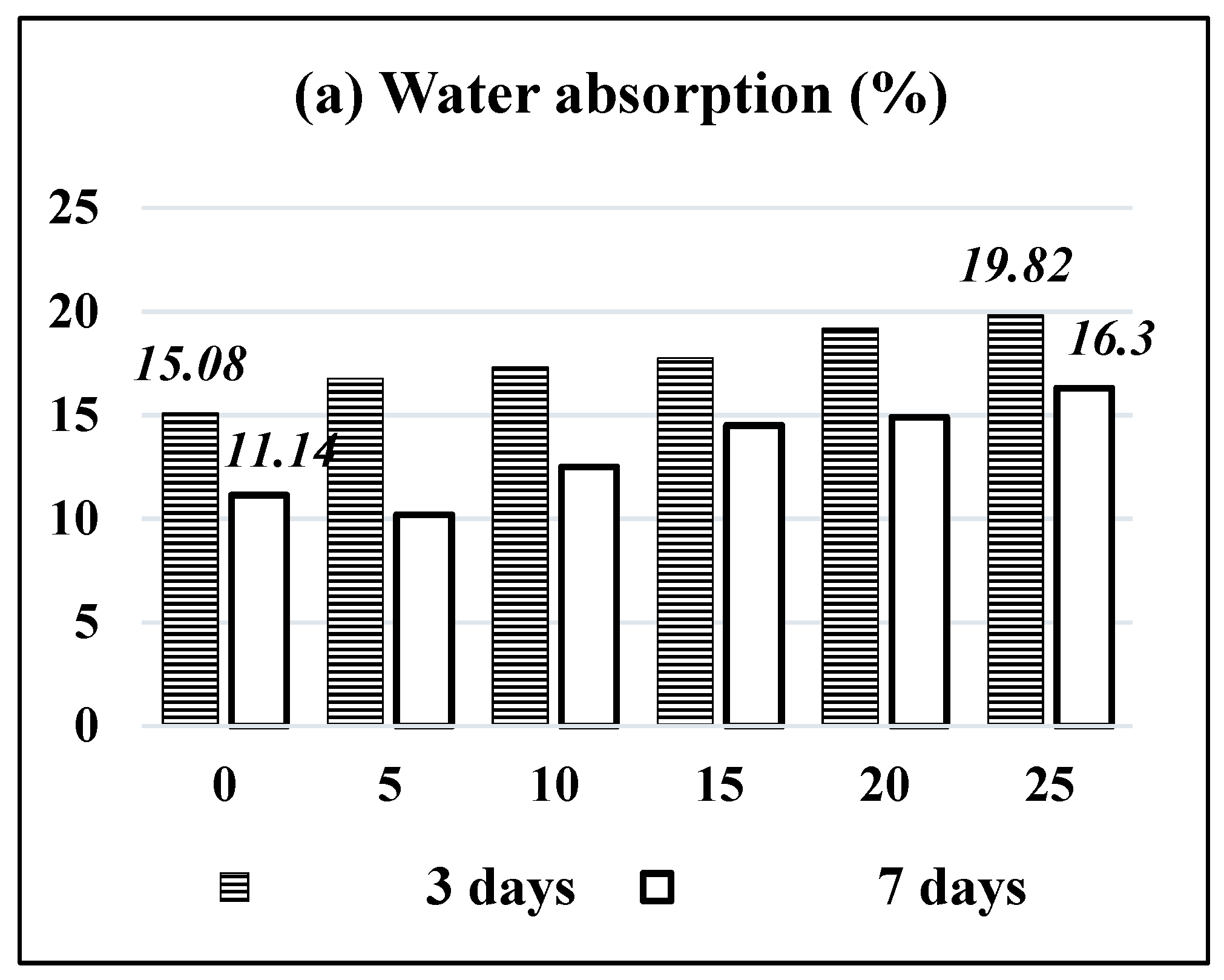

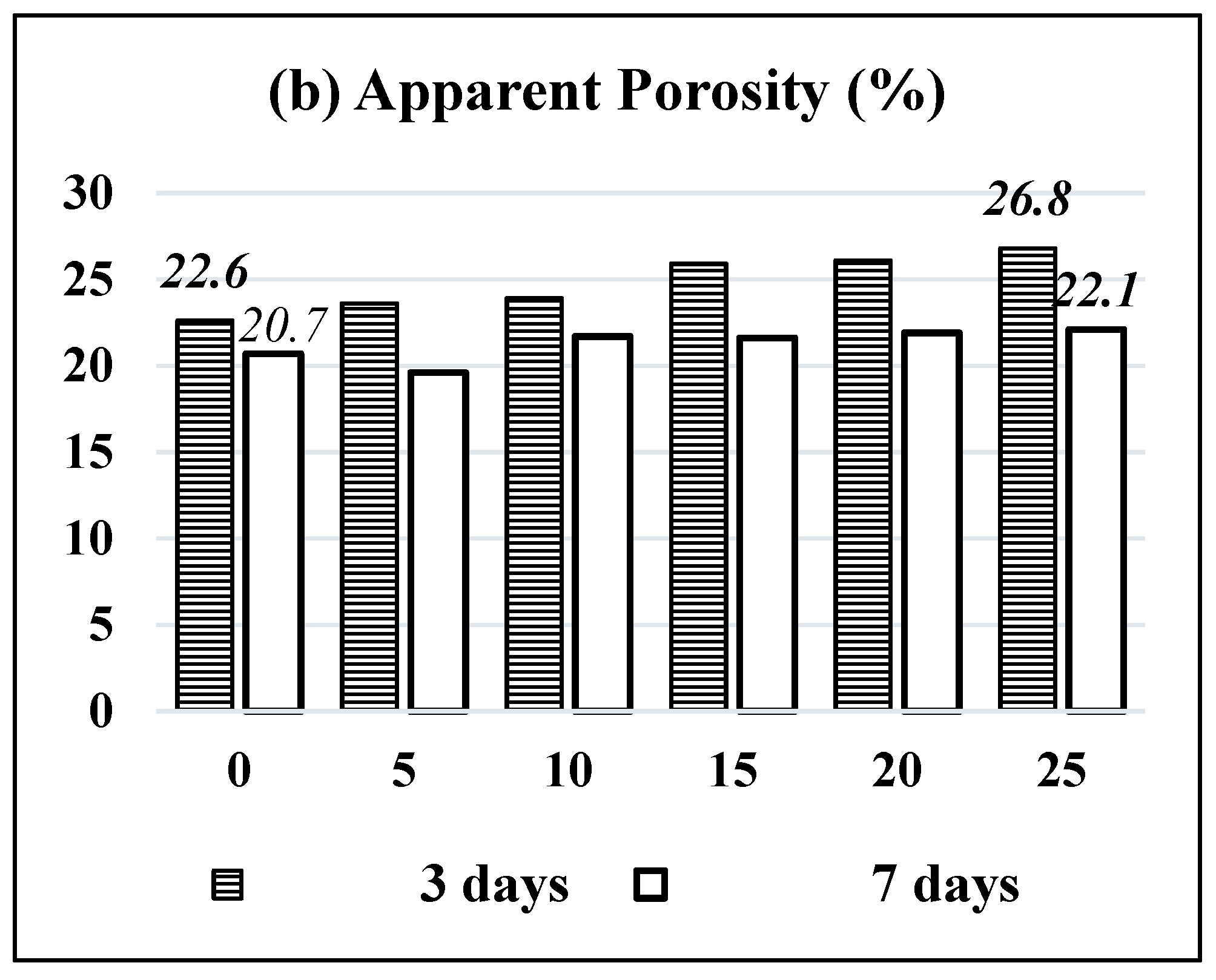

3.5. Water Absorption and Apparent Porosity of HT–BA-Blended OPC Mortar Samples

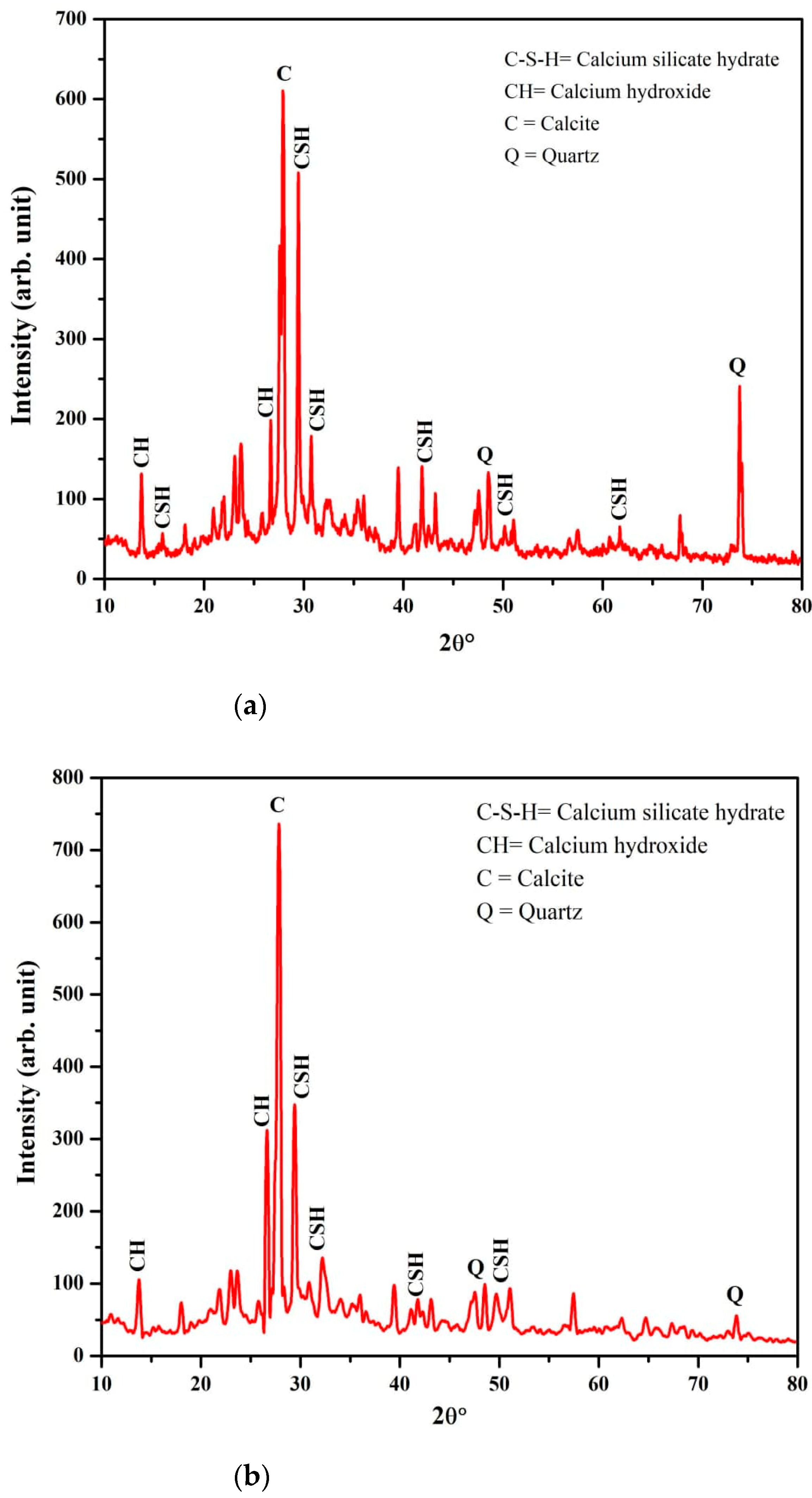

3.6. Microstructure Characterization of Bagasse Ash and Bagasse Ash-Blended Mortar

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Fairbairn, E.M.; Americano, B.B.; Cordeiro, G.C.; Paula, T.P.; Toledo Filho, R.D.; Silvoso, M.M. Cement replacement by sugar cane bagasse ash: CO2 emissions reduction and potential for carbon credits. J. Environ. Manag. 2010, 91, 1864–1871. [Google Scholar] [CrossRef] [PubMed]

- Papadakis, V.; Antiohos, S.; Tsimas, S. Supplementary cementing materials in concrete: Part I: Efficiency and design. Cem. Concr. Res. 2002, 32, 1525–1532. [Google Scholar] [CrossRef]

- Zain, M.F.M.; Islam, M.N.; Mahmud, F.; Jamil, M. Production of rice husk ash for use in concrete as a supplementary cementitious material. Constr. Build. Mater. 2011, 25, 798–805. [Google Scholar] [CrossRef]

- Zhang, P.; Liaob, W.; Kumar, A.; Zhang, Q.; Ma, H. Characterization of sugarcane bagasse ash as a potential supplementary cementitious material: Comparison with coal combustion fly ash. J. Clean. Prod. 2020, 277, 123834. [Google Scholar] [CrossRef]

- Deepika, S.; Anand, G.; Bahurudeen, A.; Santhanam, M. Construction products with sugarcane bagasse ash binder. J. Mater. Civil Eng. 2017, 29, 04017189. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Toledo Filho, R.D.; Tavares, L.M.; Fairbairn, E.M.R. Pozzolanic activity and filler effect of sugar cane bagasse ash in Portland cement and lime mortars. Cem. Concr. Compos. 2008, 30, 410–418. [Google Scholar] [CrossRef]

- Chusilp, N.; Jaturapitakkul, C.; Kiattikomol, K. Utilization of bagasse ash as a pozzolanic material in concrete. Constr. Build. Mater. 2009, 23, 3352–3358. [Google Scholar] [CrossRef]

- Lin, L.-K.; Kuo, T.-M.; Hsu, Y.-S. The application and evaluation research of coffee residue ash into mortar. J. Mater. Cycles Waste Manag. 2016, 18, 541–551. [Google Scholar] [CrossRef]

- Adesanya, D.A.; Raheem, A.A. Development of corn cob ash blended cement. Constr. Build. Mater. 2009, 23, 347–352. [Google Scholar] [CrossRef]

- Tan, H.; Nie, K.; He, X.; Deng, X.; Zhang, X.; Su, Y.; Yang, J. Compressive strength and hydration of high-volume wet-grinded coal fly ash cementitious materials. Constr. Build. Mater. 2019, 206, 248–260. [Google Scholar] [CrossRef]

- Song, H.-W.; Pack, S.-W.; Nam, S.-H.; Jang, J.-C.; Saraswathy, V. Estimation of the permeability of silica fume cement concrete. Constr. Build. Mater. Tech. 2010, 23, 315–321. [Google Scholar] [CrossRef]

- Givi, A.N.; Rashid, S.A.; Aziz, F.N.A.; Mohd-Salleh, M.A. Assessment of the effects of rice husk ash particle size on strength, water permeability and workability of binary blended concrete. Constr. Build. Mater. 2010, 24, 2145–2150. [Google Scholar] [CrossRef]

- Sabir, B.B. High-strength condensed silica fume concrete. Mag. Concr. Res. 1995, 47, 219–226. [Google Scholar] [CrossRef]

- Elsayed, A.A. Influence of silica fume, fly ash, super pozz and high slag cement on water permeability and strength of concrete. Jordan J. Civ. Eng. 2011, 159, 1–13. [Google Scholar]

- Kumar, R.; Dhaka, J. Review paper on partial replacement of cement with silica fume and its effects on concrete properties. Int. J. Eng. Res. 2016, 4, 2347–4718. [Google Scholar]

- Bahurudeen, A.; Kanraj, D.; Dev, G.V.; Santhanam, M. Performance evaluation of sugarcane bagasse ash blended cement in Concrete. Cem. Concr. Compos. 2015, 59, 77–88. [Google Scholar] [CrossRef]

- Lima, S.A.; Sales, A.; Almeida, F.D.C.R.; Moretti, J.P.; Portella, K.F. Concretes made with sugarcane bagasse ash: Evaluation of the durability for carbonation and abrasion tests. Ambient Constr. 2011, 11, 201–212. [Google Scholar] [CrossRef] [Green Version]

- Embong, R.; Shafiq, N.; Kusbiantoro, A.; Nuruddin, M.F. Effectiveness of low-concentration acid and solar drying as pre-treatment features for producing pozzolanic sugarcane bagasse ash. J. Clean Prod. 2016, 112, 953–962. [Google Scholar] [CrossRef] [Green Version]

- Trifunovic, P.D.; Marinkovic, S.R.; Tokalic, R.; Matijasevic, T.D. The effect of the content of unburned carbon in bottom ash on its applicability for road construction. Thermochim. Acta 2010, 498, 1–6. [Google Scholar] [CrossRef]

- Xu, Q.; Ji, T.; Gao, S.-J.; Yang, Z.; Wu, N. Characteristics and Applications of Sugar Cane Bagasse Ash Waste in Cementitious Materials. Materials 2019, 12, 39. [Google Scholar] [CrossRef] [Green Version]

- Katare, V.D.; Madurwar, M.V. Experimental characterization of sugarcane biomass ash—A review. Constr. Build. Mater. 2017, 152, 1–15. [Google Scholar] [CrossRef]

- ASTM C20-00(2015). Standard Test Methods for Apparent Porosity, Water Absorption, Apparent Specific Gravity, and Bulk Density of Burned Refractory Brick and Shapes by Boiling Water; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C618: Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019.

- Chusilp, N.; Chai, J.; Kiattikomol, K. Effects of LOI of ground bagasse ash on the compressive strength and sulfate resistance of mortars. Constr. Build. Mater. 2009, 23, 3523–3531. [Google Scholar] [CrossRef]

- Gebreyouhannes, E.; Geremew, M. Bagasse Ash as a Partial Substitute of Cement in Concrete Rigid Pavement. Master’s Thesis, AAU, Addis Ababa, Ethiopia, 2017. [Google Scholar]

- Maliger, V.R.; Doherty, W.; Frost, R.L.; Mousavioun, P. Thermal Decomposition of Bagasse: Effect of Different Sugar Cane Cultivars. Ind. Eng. Chem. Res. 2011, 50, 791–798. [Google Scholar] [CrossRef]

- Garcıa-Perez, M.; Chaala, A.; Yanga, J.; Roy, C. Co-pyrolysis of sugarcane bagasse with petroleum residue. Part I: Thermogravimetric analysis. Fuel 2001, 80, 1245–1258. [Google Scholar] [CrossRef]

- Bahurudeen, A.; Santhanam, M. Influence of different processing methods on the pozzolanic performance of sugarcane bagasse ash. Cem. Concr. Compos. 2015, 56, 32–45. [Google Scholar] [CrossRef]

- Batool, F.; Masood, A.; Ali, M. Characterization of Sugarcane Bagasse Ash as Pozzolan and Influence on Concrete Properties. Arab. J. Sci. Eng. 2020, 45, 3891–3900. [Google Scholar] [CrossRef]

- Baltakys, K.; Jauberthie, R.; Siauciunas, R.; Kaminskas, R. Influence of modification of SiO2 on the formation of calcium silicate hydrate. Mater. Sci.-Pol. 2007, 25, 663–669. [Google Scholar]

- Nasir, M.; Al-Kutti, W. Performance of Date Palm Ash as a Cementitious Materials by Evaluating Strength, Durability, and Characterization. Buildings 2019, 9, 6. [Google Scholar] [CrossRef] [Green Version]

- Bergold, S.T.; Goetz-Neunhoeffer, F.; Neubauer, J. Quantitative analysis of C–S–H in hydrating alite pastes by in-situ XRD. Cem. Concr. Res. 2013, 53, 119–126. [Google Scholar] [CrossRef]

- Ribeiro, D.V.; Morell, M.R. Effect of Calcination Temperature on the Pozzolanic Activity of Brazilian Sugar Cane Bagasse Ash (SCBA). Mater. Res. 2014, 17, 974–981. [Google Scholar] [CrossRef] [Green Version]

| Burning Time | Burning Temperature | |||

|---|---|---|---|---|

| 300 °C | 450 °C | 600 °C | 750 °C | |

| 1 h |  |  |  |  |

| 2 h |  |  |  |  |

| Amount BA (%) | PC-Portland Cements (gm) | LT-BA (gm) | HT-B (gm) | Sand (gm) | Water (mL) |

|---|---|---|---|---|---|

| BA 0 | 150.0 | 0 | 0 | 450 | 80 |

| LT-BA 5 | 142.5 | 7.5 | 0 | 450 | 80 |

| LT-BA 10 | 135.0 | 15.0 | 0 | 450 | 80 |

| LT-BA 15 | 127.5 | 22.5 | 0 | 450 | 100 |

| LT-BA 20 | 120.0 | 30.0 | 0 | 450 | 100 |

| LT-BA 25 | 112.5 | 37.5 | 0 | 450 | 100 |

| HT-BA 5 | 142.5 | 0 | 7.5 | 450 | 80 |

| HT-BA 10 | 135.0 | 0 | 15.0 | 450 | 80 |

| HT-BA 15 | 127.5 | 0 | 22.5 | 450 | 100 |

| HT-BA 20 | 120.0 | 0 | 30.0 | 450 | 100 |

| HT-BA 25 | 112.5 | 0 | 37.5 | 450 | 100 |

| Amount (%) | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | MnO | P2O5 | TiO2 | H2O | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bagasse Ash | 65.06 | 10.88 | 4.08 | 1.14 | 1.30 | 2.06 | 6.60 | 0.10 | 0.79 | 0.24 | 0.66 | 4.75 |

| OPC [26] | 22.82 | 5.41 | 3.37 | 66.32 | 1.46 | - | - | - | - | - | - | - |

| No. | Bagasse Ash (BA) (%) | Compressive Strength (MPa) of BA Blended OPC–Mortars | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 3 Days | 7 Days | 14 Days | 28 Days | ||||||

| LT-BA | HT-BA | LT-BA | HT-BA | LT-BA | HT-BA | LT-BA | HT-BA | ||

| 1 | BA 0 | 9.26 | 15.20 | 20.2 | 24.5 | ||||

| 2 | BA 5 | 8.97 | 9.40 | 14.8 | 16.29 | 21.9 | 23.0 | 24.9 | 27.3 |

| 3 | BA 10 | 8.88 | 9.10 | 13.9 | 14.61 | 19.0 | 21.4 | 22.7 | 26.1 |

| 4 | BA 15 | 6.89 | 7.32 | 12.2 | 13.50 | 16.3 | 19.1 | 20.6 | 23.2 |

| 5 | BA 20 | 5.85 | 6.12 | 10.1 | 10.90 | 15.1 | 17.5 | 18.9 | 20.7 |

| 6 | BA 25 | 5.30 | 5.71 | 7.71 | 8.21 | 14.3 | 15.0 | 17.30 | 19.1 |

| No. | Bagasse Ash (%) | Compressive Strength (MPa) of BA Blended PPC–Mortar Samples | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 3 Days | 7 Days | 14 Days | 28 Days | ||||||

| LT-BA | HT-BA | LT-BA | HT-BA | LT-BA | HT-BA | LT-BA | HT-BA | ||

| 1 | BA 0 | 2.71 | 3.53 | 7.05 | 16 | ||||

| 2 | BA 5 | 1.73 | 1.83 | 2.61 | 3.08 | 5.10 | 6.08 | 12.5 | 14.7 |

| 3 | BA 10 | 1.81 | 2.34 | 2.78 | 3.02 | 2.42 | 4.31 | 6.69 | 9.36 |

| 4 | BA 15 | 1.77 | 2.04 | 2.46 | 2.77 | 2.12 | 3.28 | 4.67 | 6.91 |

| 5 | BA 20 | 1.73 | 1.79 | 1.83 | 1.98 | 1.48 | 2.67 | 4.34 | 5.95 |

| 6 | BA 25 | 1.38 | 1.42 | 1.48 | 1.77 | 1.44 | 2.30 | 2.42 | 3.97 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seyoum, R.; Tesfamariam, B.B.; Andoshe, D.M.; Algahtani, A.; Ahmed, G.M.S.; Tirth, V. Investigation on Control Burned of Bagasse Ash on the Properties of Bagasse Ash-Blended Mortars. Materials 2021, 14, 4991. https://doi.org/10.3390/ma14174991

Seyoum R, Tesfamariam BB, Andoshe DM, Algahtani A, Ahmed GMS, Tirth V. Investigation on Control Burned of Bagasse Ash on the Properties of Bagasse Ash-Blended Mortars. Materials. 2021; 14(17):4991. https://doi.org/10.3390/ma14174991

Chicago/Turabian StyleSeyoum, Redeat, Belay Brehane Tesfamariam, Dinsefa Mensur Andoshe, Ali Algahtani, Gulam Mohammed Sayeed Ahmed, and Vineet Tirth. 2021. "Investigation on Control Burned of Bagasse Ash on the Properties of Bagasse Ash-Blended Mortars" Materials 14, no. 17: 4991. https://doi.org/10.3390/ma14174991

APA StyleSeyoum, R., Tesfamariam, B. B., Andoshe, D. M., Algahtani, A., Ahmed, G. M. S., & Tirth, V. (2021). Investigation on Control Burned of Bagasse Ash on the Properties of Bagasse Ash-Blended Mortars. Materials, 14(17), 4991. https://doi.org/10.3390/ma14174991