Effects of Different Substrates on the Formability and Densification Behaviors of Cemented Carbide Processed by Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Materials and Methods

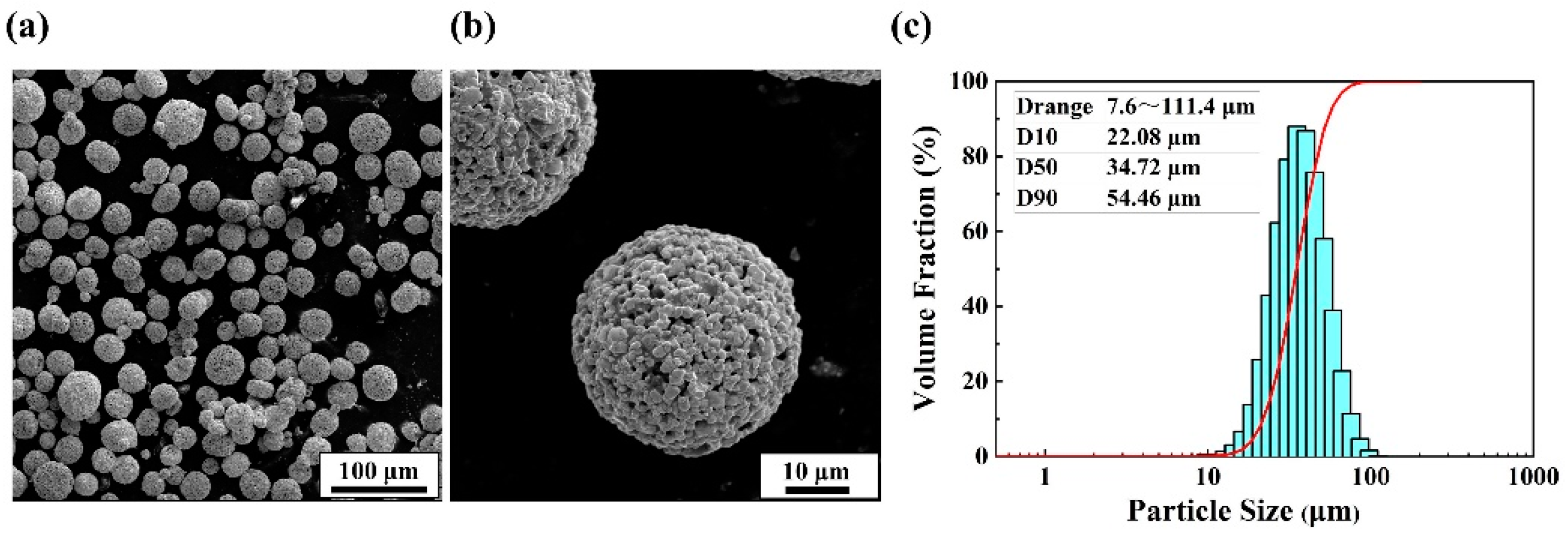

2.1. Powder Materials

2.2. Substrates

2.3. L-PBF Processing

2.4. Characterization

3. Results

3.1. Surface Morphologies of Single Tracks

3.2. Forming Characteristics of Molten Pools

3.3. Blocks Preparation

3.4. Surface Morphologies and Densification Behaviors

4. Discussion

4.1. The Effect of Substrates on Molten Pool Formation

4.2. The Effect of Laser Energy Input on the Molten Pool Formation

4.3. The Effect of Laser Energy Input on Block Formation

5. Conclusions

- (1)

- The high melting point of the YG15 substrate led to an insufficient liquid phase in the melt pool, thus causing an inferior forming quality of the single tracks at all process parameters; this also resulted in a poor success rate for the integrated fabrication of blocks.

- (2)

- The low melting point of the 316L substrate and Ni200 substrate produced sufficient liquid phase, which was beneficial to forming regular and continuous single tracks. Ni200 substrates present a better wettability to WC-17Co materials than those of 316L substrates, which produce an infirm bonding between the built block and Ni200 substrate to restrict the separation of blocks and substrate at a high laser energy input.

- (3)

- The blocks formed on the Ni200 substrates presented a better forming quality than those formed on other substrates, and a block with a relative density of 96.94% and fewer cracks was obtained at the laser power of 185 W and scanning speed of 370 mm/s.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Armstrong, R.W. The Hardness and strength properties of WC-Co composites. Materials 2011, 4, 1287–1308. [Google Scholar] [CrossRef]

- Rizzo, A.; Goel, S.; Grilli, M.L.; Iglesias, R.; Valerini, D. The critical raw materials in cutting tools for machining applications: A review. Materials 2020, 13, 1377. [Google Scholar] [CrossRef] [Green Version]

- Upadhyaya, G.S. Materials science of cemented carbides—An overview. Mater. Des. 2001, 22, 483–489. [Google Scholar] [CrossRef]

- Liu, G.H.; Li, G.T.; Chen, K.X. Combustion synthesis of refractory and hard materials: A review. Int. J. Refract. Met. Hard Mater. 2013, 39, 90–102. [Google Scholar] [CrossRef]

- Norgren, S.; García, J.; Blomqvist, A.; Yin, L. Trends in the P/M hard metal industry. Int. J. Refract. Met. Hard Mater. 2015, 48, 31–45. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Sun, Z.J.; Tan, X.P.; Tor, S.B.; Wai, Y.Y. Selective laser melting of stainless steel 316 L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Ma, M.M.; Wang, Z.M.; Gao, M.; Zeng, X.Y. Layer Thickness dependence of performance in high-power selective laser melting of 1Cr18Ni9Ti stainless steel. J. Mater. Process. Technol. 2015, 215, 142–150. [Google Scholar] [CrossRef]

- Read, N.; Wang, W.; Essa, K.; Attallah, M.M. Selective laser melting of AlSi10Mg alloy: Process optimisation and mechanical properties development. Mater. Des. 2015, 65, 417–424. [Google Scholar] [CrossRef] [Green Version]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Hague, R. 3D Printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Zhang, B.; Liao, H.; Coddet, C. Selective laser melting commercially pure Ti under vacuum. Vacuum 2013, 95, 25–29. [Google Scholar] [CrossRef]

- Gong, H.J.; Rafi, K.; Gu, H.F.; Janaki, R.G.D.; Starr, T.; Stucker, B. Influence of defects on mechanical properties of Ti–6Al–4 V components produced by selective laser melting and electron beam melting. Mater. Des. 2015, 86, 545–554. [Google Scholar] [CrossRef]

- Tao, P.; Li, H.X.; Huang, B.Y.; Hu, Q.D.; Gong, S.L.; Xu, Q.Y. The crystal growth, intercellular spacing and microsegregation of selective laser melted Inconel 718 superalloy. Vacuum 2019, 159, 382–390. [Google Scholar] [CrossRef]

- Balbaa, M.A.; Elbestawi, M.A.; McIsaac, J. An experimental investigation of surface integrity in selective laser melting of Inconel 625. Int. J. Adv. Manuf. Technol. 2019, 104, 3511–3529. [Google Scholar] [CrossRef]

- Uhlmann, E.; Bergmann, A.; Gridin, W. Investigation on additive manufacturing of tungsten Carbide-cobalt by selective laser melting. Procedia CIRP 2015, 35, 8–15. [Google Scholar] [CrossRef]

- Liu, J.Y.; Chen, J.L.; Liu, B.Y.; Lu, Y.; Wu, S.H.; Deng, X.; Lu, Z.L.; Xie, Z.P.; Liu, W.; Liu, J.Y.; et al. Microstructure evolution of WC-20Co cemented carbide during direct selective laser melting. Powder Met. 2020, 63, 1–8. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W. Microstructure characteristics and formation mechanisms of in situ WC cemented carbide based hardmetals prepared by Selective Laser Melting. Mater. Sci. Eng. 2010, 527, 7585–7592. [Google Scholar] [CrossRef]

- Chen, J.; Huang, M.J.; Fang, Z.Z.; Koopman, M.; Liu, W.; Deng, X.; Zhao, Z.; Chen, S.H.; Wu, S.H.; Liu, J.Y.; et al. Microstructure analysis of high density WC-Co composite prepared by one step selective laser melting. Int. J. Refract. Met. Hard Mater. 2019, 84, 104980. [Google Scholar] [CrossRef]

- Li, C.W.; Chang, K.C.; Yeh, A.C. On the microstructure and properties of an advanced cemented carbide system processed by selective laser melting. J. Alloys Compd. 2018, 782, 440–450. [Google Scholar] [CrossRef]

- Aramian, A.; Razavi, S.; Sadeghian, Z.; Berto, F. A Review of Additive Manufacturing of Cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Li, Y.; Zalonik, M.; Zollinger, J.; Dembinski, L.; Mathieu, A. Effects of the powder, laser parameters and surface conditions on the molten pool formation in the selective laser melting of IN718. J. Mater. Process. Technol. 2021, 289, 116930. [Google Scholar] [CrossRef]

- Lee, J.W.; Terner, M.; Copin, E.; Lours, P.; Hong, H.U. A novel approach to the production of NiCrAlY bond coat onto IN625 superalloy by selective laser melting. Addit. Manuf. 2020, 31, 100998. [Google Scholar] [CrossRef]

- Liu, J.; Gu, D.D.; Chen, H.Y. Influence of substrate surface morphology on wetting behavior of tracks during selective laser melting of aluminum-based alloys. J. Zhejiang Univ. Sci. A 2018, 19, 111–121. [Google Scholar] [CrossRef]

- Khmyrov, R.S.; Protasov, C.E.; Grigoriev, S.N.; Gusarov, A.V. Crack-free selective laser melting of silica glass: Single beads and monolayers on the substrate of the same material. Int. J. Adv. Manuf. Technol. 2016, 85, 1461–1469. [Google Scholar] [CrossRef]

- Zheng, M.; Wei, L.; Chen, J.; Huang, W. Surface morphology evolution during pulsed selective laser melting: Numerical and experimental investigations. Appl. Surf. Sci. 2019, 496, 143649. [Google Scholar] [CrossRef]

- Guraya, T.; Singamneni, S.; Chen, Z.W. Microstructure formed during selective laser melting of IN738LC in keyhole mode. J. Alloys Compd. 2019, 792, 151–160. [Google Scholar] [CrossRef]

- Nie, X.; Zhang, H.; Zhu, H.; Ke, L.; Zeng, X. Analysis of processing parameters and characteristics of selective laser melted high strength Al-Cu-Mg alloys: From single tracks to cubic samples. J. Mater. Process. Technol. 2018, 256, 69–77. [Google Scholar] [CrossRef]

- Shishkovsky, I.; Kakovkina, N.; Sherbakov, V. Layerwise fabrication of refractory NiCrSiB composite with gradient grow of tungsten carbide additives by selective laser melting. Opt. Laser Technol. 2019, 120, 105723. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.S.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing, microstructure, property and developing trends. J. Mater. Process. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Yadroitsev, I.; Krakhmalev, P.; Yadroitsava, I.; Johansson, S.; Smurov, I. Energy input effect on morphology and microstructure of selective laser melting single track from metallic powder. J. Mater. Process. Technol. 2013, 213, 606–613. [Google Scholar] [CrossRef]

- Chen, C.M.; Kovacevic, R. Finite element modeling of friction stir welding-thermal and thermomechanical analysis. Int. J. Mach. Tools Manuf. 2003, 43, 1319–1326. [Google Scholar] [CrossRef]

- Bi, J.; Lei, Z.L.; Chen, Y.B.; Chen, X.; Qin, X.K.; Tian, Z. Effect of process parameters on formability and surface quality of selective laser melted Al-Zn-Sc-Zr alloy from single track to block specimen. Opt. Laser Technol. 2019, 118, 132–139. [Google Scholar] [CrossRef]

- Wang, P.; Shi, K.H.; Gu, J.B.; Zeng, W.; Han, Y.G.; Dong, K.L. A review on WC-based cemented carbide with different content of binder phase (Ⅰ). Cem. Carbide 2020, 37, 74–89. (In Chinese) [Google Scholar]

- Shon, I.J.; Jeong, I.K.; Ko, I.Y.; Doh, J.M.; Woo, K.D. Sintering behavior and mechanical properties of WC–10Co, WC–10Ni and WC–10Fe hard materials produced by high-frequency induction heated sintering. Ceram. Int. 2009, 35, 339–344. [Google Scholar] [CrossRef]

- Jia, Q.B.; Gu, D.D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Pei, W.; Wei, Z.; Chen, Z.; Du, J.; Zhou, Y. The AlSi10Mg samples produced by selective laser melting: Single track, densification, microstructure and mechanical behavior. Appl. Surf. Sci. 2017, 408, 38–50. [Google Scholar]

- Niu, P.; Li, R.; Gan, K.; Yuan, T.; Xie, S.; Chen, C. Microstructure, properties, and metallurgical defects of an equimolar CoCrNi medium entropy alloy additively manufactured by selective laser melting. Met. Mater. Trans. 2021, 52, 753–766. [Google Scholar] [CrossRef]

| Elements | W | Co | C | O | Fe |

|---|---|---|---|---|---|

| wt % | bal. | 17.10 | 5.28 | 0.013 | 0.009 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Yue, W.; Kang, J.; Wang, C. Effects of Different Substrates on the Formability and Densification Behaviors of Cemented Carbide Processed by Laser Powder Bed Fusion. Materials 2021, 14, 5027. https://doi.org/10.3390/ma14175027

Liu D, Yue W, Kang J, Wang C. Effects of Different Substrates on the Formability and Densification Behaviors of Cemented Carbide Processed by Laser Powder Bed Fusion. Materials. 2021; 14(17):5027. https://doi.org/10.3390/ma14175027

Chicago/Turabian StyleLiu, Decheng, Wen Yue, Jiajie Kang, and Chengbiao Wang. 2021. "Effects of Different Substrates on the Formability and Densification Behaviors of Cemented Carbide Processed by Laser Powder Bed Fusion" Materials 14, no. 17: 5027. https://doi.org/10.3390/ma14175027

APA StyleLiu, D., Yue, W., Kang, J., & Wang, C. (2021). Effects of Different Substrates on the Formability and Densification Behaviors of Cemented Carbide Processed by Laser Powder Bed Fusion. Materials, 14(17), 5027. https://doi.org/10.3390/ma14175027