Sunflower Stalks versus Corn Cobs as Raw Materials for Sustainable Concrete

Abstract

:1. Introduction

2. Materials and Methods

- -

- aggregates: natural sand with diameter of up to 4 mm, and river gravel with diameter of 4–8 mm;

- -

- cement type CEM II/A-LL 42.5R MPa, produced in Romania;

- -

- polycarboxylate ether superplasticizer additive;

- -

- rhodanide-based accelerator additive, to speed up the early strength development of the vegetal concretes [39], so water from the composition to be used in the cement hydration process and not to be absorbed too much by the vegetal aggregates.

2.1. The Performed Tests

2.2. Density Testing

2.3. Compressive Strength Testing

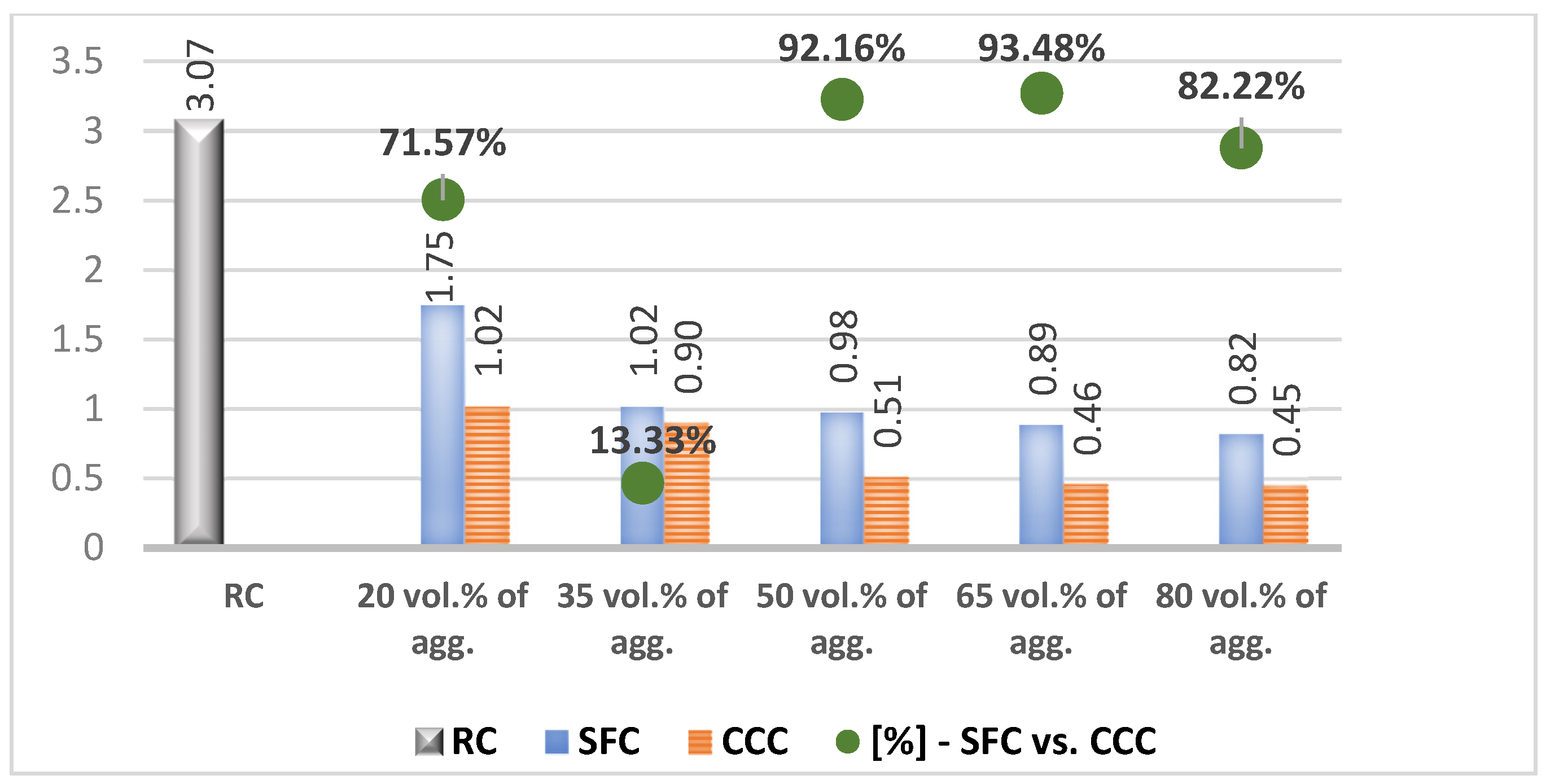

2.4. Splitting Tensile Strength Testing

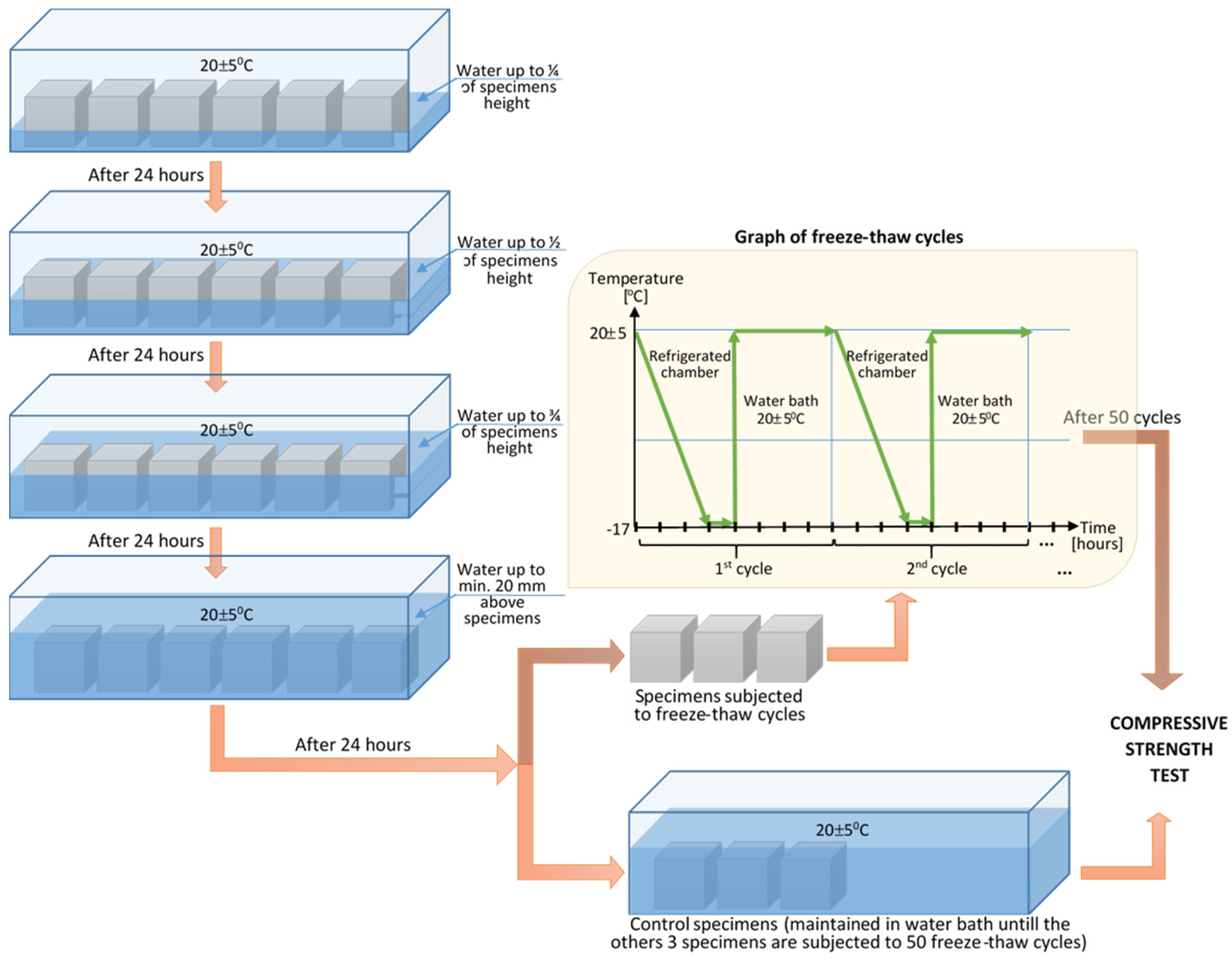

2.5. Freeze-Thaw Resistance Testing

2.6. Modulus of Elasticity Testing

2.7. Thermal Conductivity Testing

3. Results and Discussions

3.1. Density

3.2. Compressive Strength

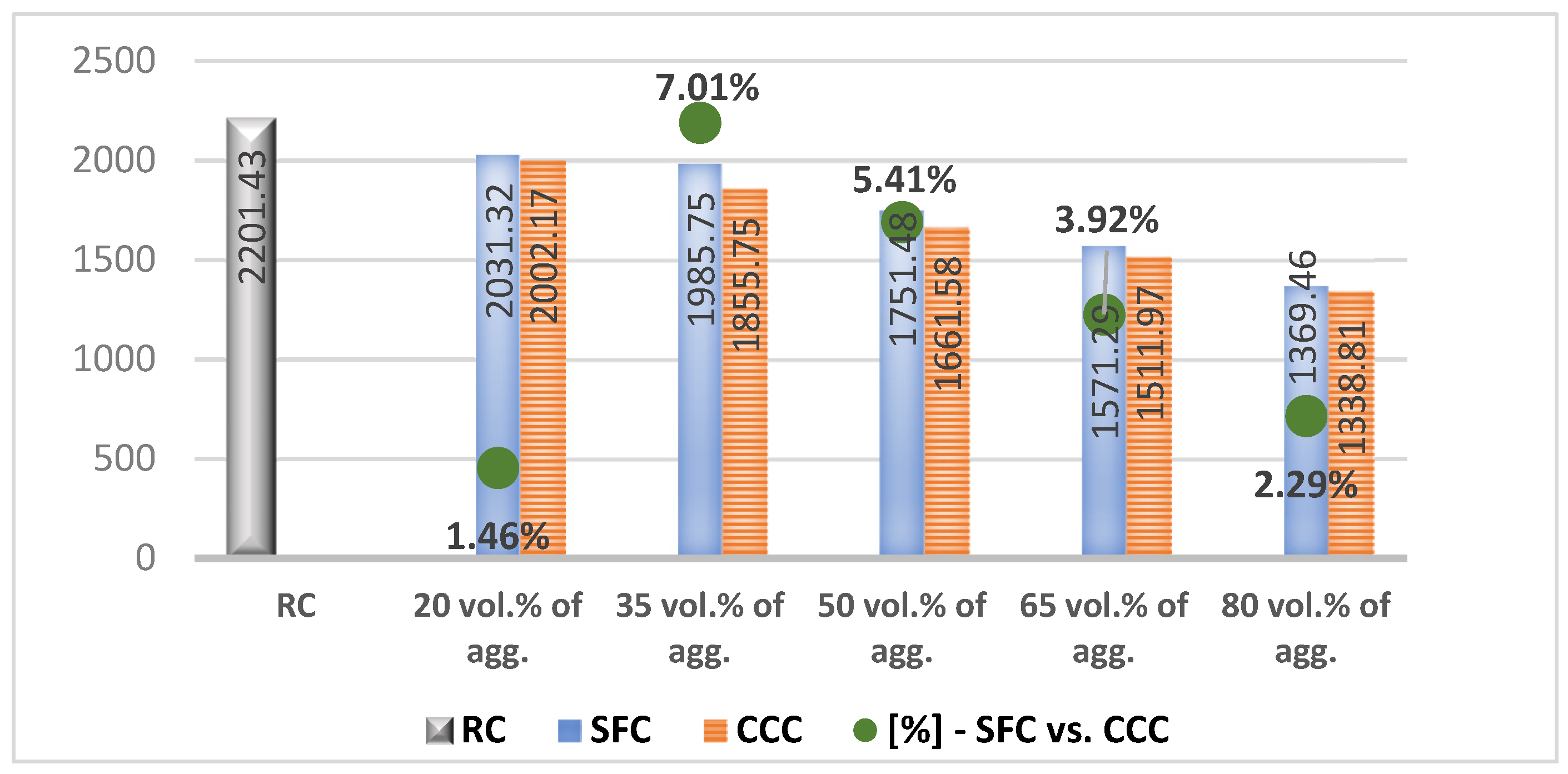

3.3. Splitting Tensile Strength

3.4. Modulus of Elasticity

3.5. Freeze-Thaw Resistance

3.6. Thermal Conductivity

4. Conclusions

- The vegetal aggregates led to concrete density decreasing, as their content increased. As a reference example, the replacement of 50% of mineral aggregates led to around 20% lower density than RC in the case of SFC, and with around 24% in the case of CCC. Lightweight concretes were obtained in the case of mineral aggregates replacing in percentages greater than or equal to 50%, no matter the vegetal raw material used, sunflower stalks or corn cobs. Corn cob aggregates led to lower densities of the microconcretes than those of sunflower stalks.

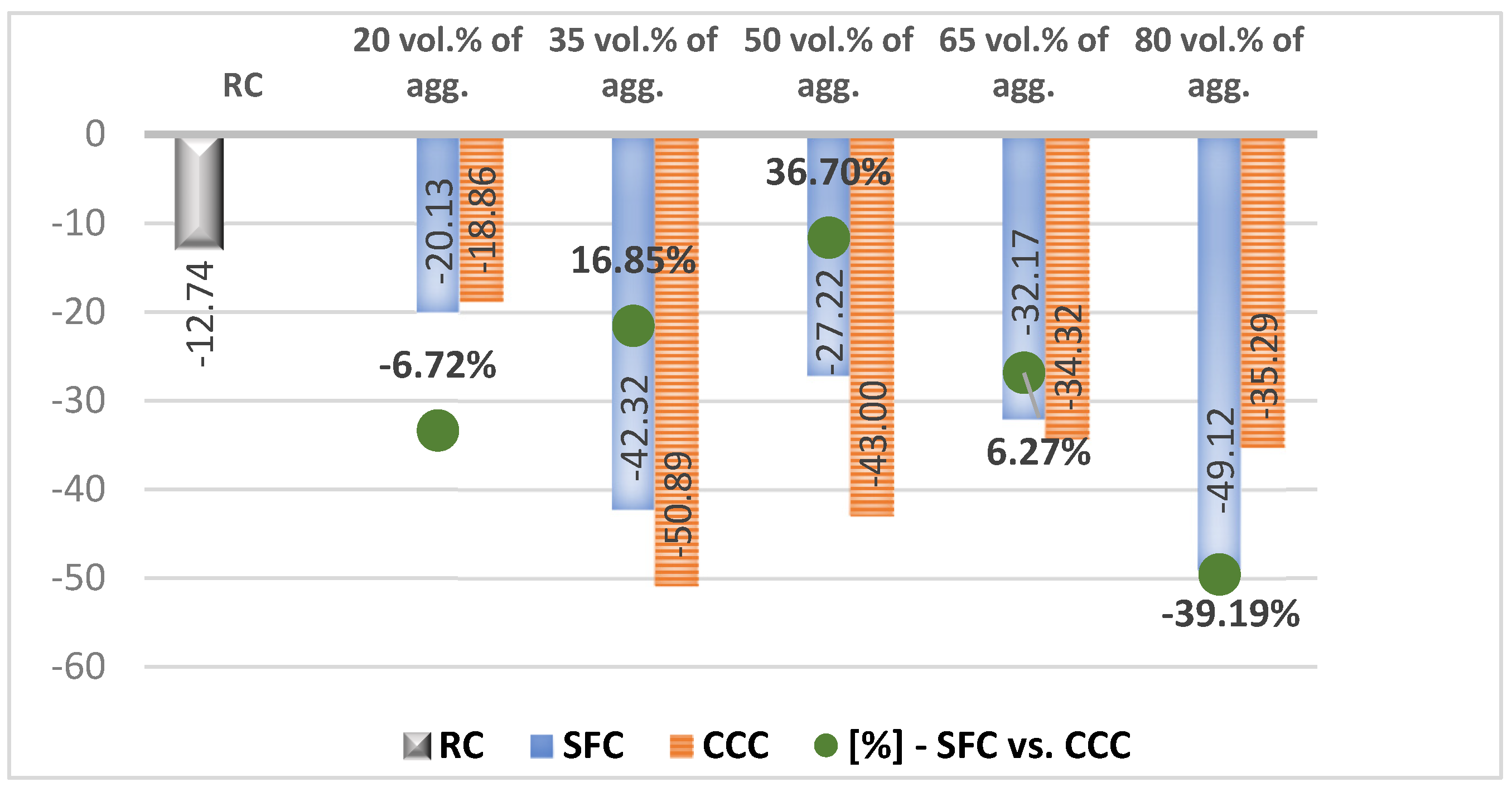

- The compressive strength of the RC was decreased by the vegetal aggregates. The replacement rate of 50%, for example, led to a 75% decrease for SFC and 86% for CCC case. Sunflower stalk aggregates determined higher compressive strengths of the microconcretes than those of corn cobs; the microconcretes made with 50% or smaller rates of sunflower aggregates and those with 35% or smaller rates of corn cob aggregates can be used in nonstructural applications since they registered compressive strengths higher than 6 N/mm2.

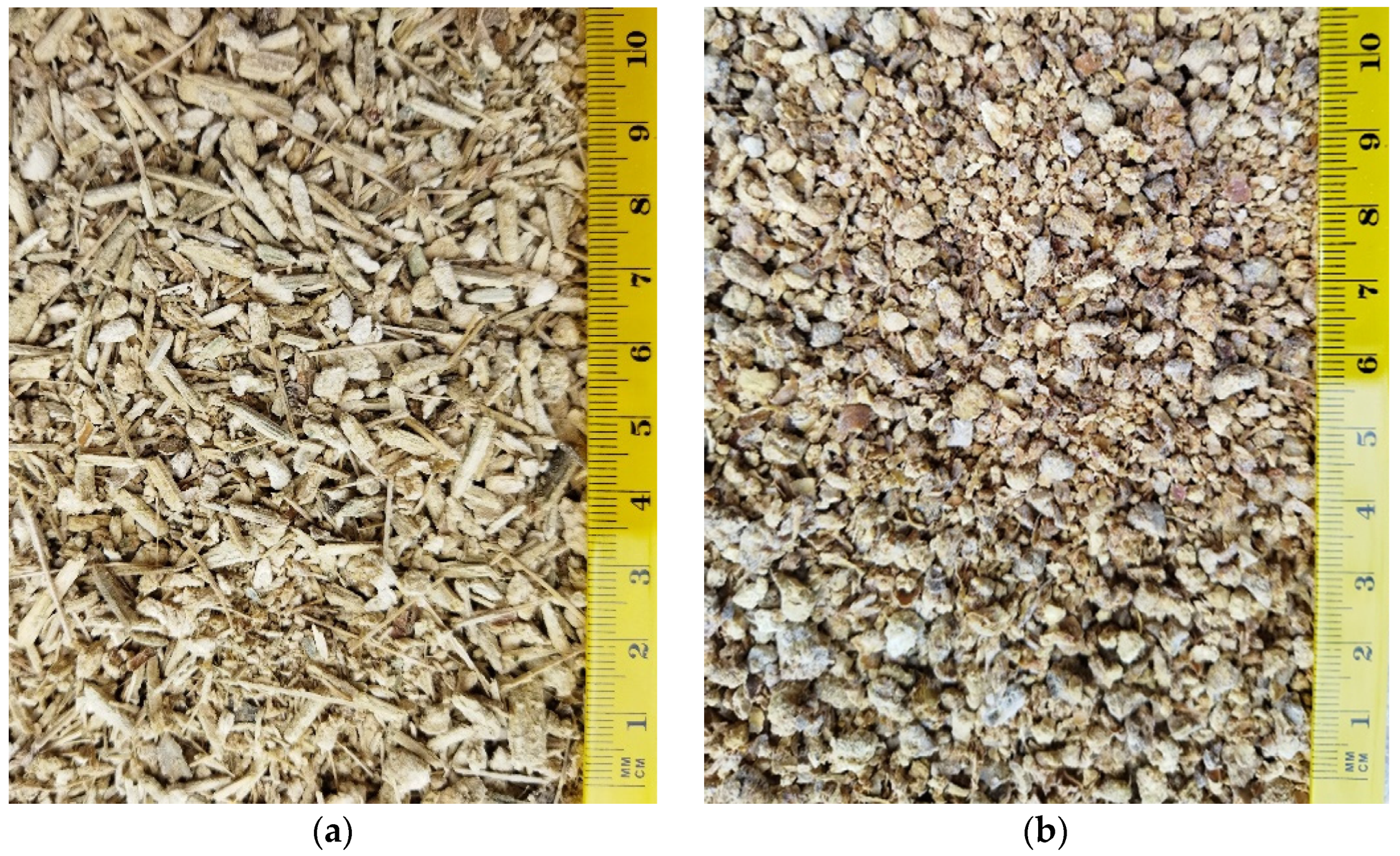

- As regards the splitting tensile strength, compared to RC, vegetal concretes registered also smaller values, SFC50 for example, with 68%, and CCC50 with 83%. The compositions with sunflower aggregates led to significantly higher values than those with corn cob aggregates due to the difference between the two types of vegetal aggregates, the sunflower aggregates being in the form of chips and fibers also, and not just as rounded granules as in the case of corn cob aggregates.

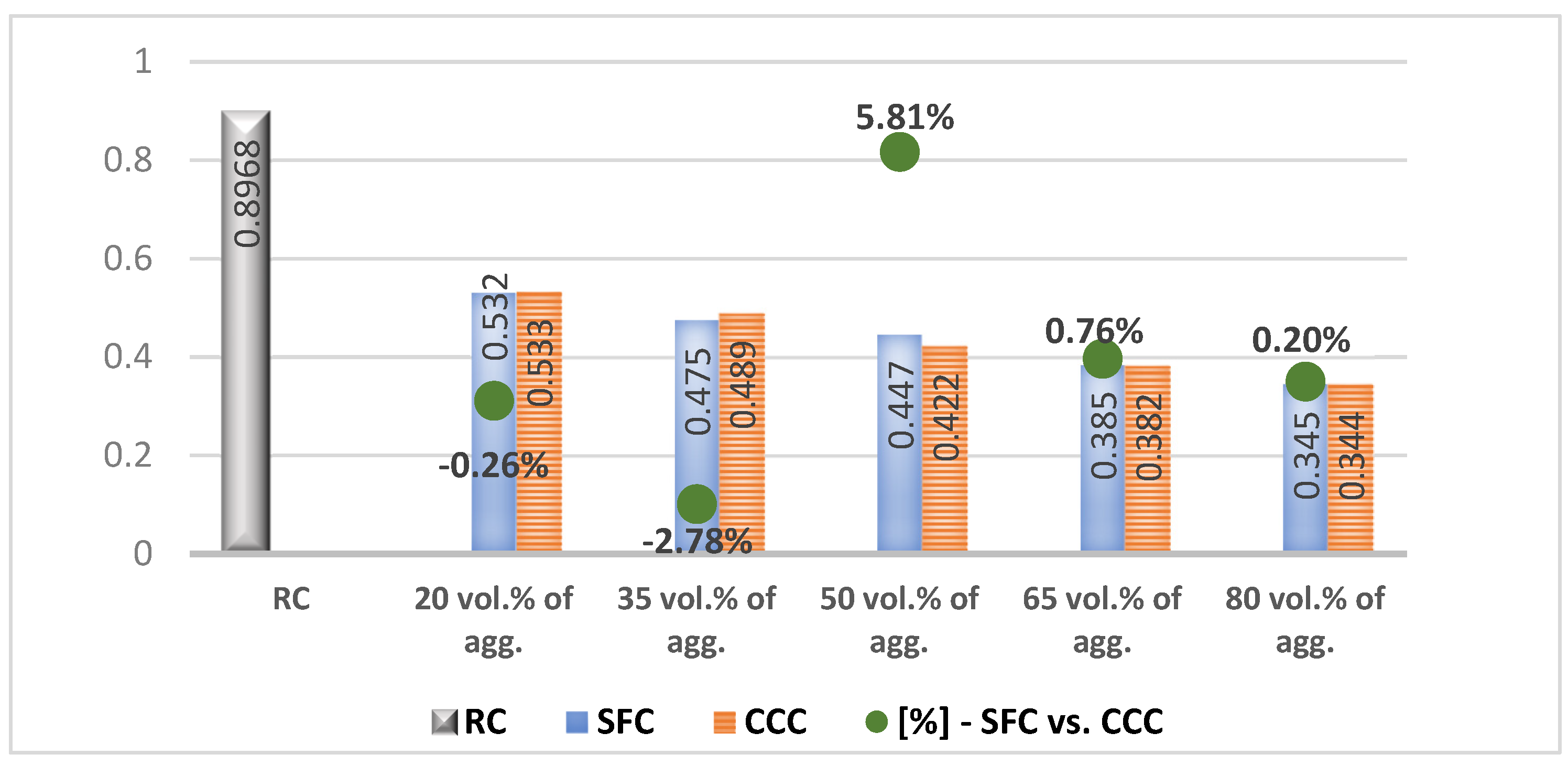

- From the analysis of elasticity, the concrete compositions with up to 35% vegetal matter showed a higher modulus of elasticity in the case of using aggregates from sunflower stalks; for replacement rates of mineral aggregates higher than 35%, aggregates from corn cobs determined higher values of this parameter; compared to RC, the vegetal concretes registered lower values, so they presented higher elastic behavior.

- The vegetal aggregates led to a diminished resistance to repeated freeze-thaw cycles, a rate of 50% in the concrete composition determined a 14% bigger decrease than RC in case of SFC, and one of 30% in case of CCC. Aggregates from sunflower stalks recorded better results than those from corn cobs when using a substitution rate of mineral aggregates between 35% and 65%.

- The thermal conductivity of the RC was very much reduced by the vegetal aggregates. The two types of plant aggregates led to relatively similar results, the differences being very small; the use of a 50% replacement rate of mineral aggregates with vegetal aggregates from sunflower stalks or corn cobs led to a decrease of about 50% in the thermal conductivity of RC; thus, these vegetal aggregates determined an important improvement of the insulation properties of the ordinary concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- GlobalABC/IEA/UNEP (Global Alliance for Buildings and Construction, International Energy Agency, the United Nations Environment Programme). GlobalABC Roadmap for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; IEA: Paris, France, 2020; Available online: https://www.iea.org/reports/globalabc-roadmap-for-buildings-and-construction-2020-2050 (accessed on 30 July 2021).

- Ali, N.; Jaffar, A.; Anwer, M.; Alwi, S.K.K.; Anjum, M.N.; Ali, N.; Raja, M.R.; Hussain, A.; Ming, X. The Greenhouse Gas Emissions Produced by Cement Production and Its Impact on Environment: A Review of Global Cement Processing. Int. J. Res. 2015, 2, 488. Available online: http://internationaljournalofresearch (accessed on 20 May 2021).

- Błaszczyński, T.; Król, M. Usage of Green Concrete Technology in Civil Engineering. Procedia Eng. 2015, 122, 296–301. [Google Scholar] [CrossRef] [Green Version]

- Kubba, S. Handbook of green Building Design and Construction: LEED, BREEAM, and Green Globes; Butterworth-Heinemann, Ed.; Butterworth-Heinemann Ltd.: Oxford, UK, 2012. [Google Scholar]

- Walczak, P.; Szymański, P.; Różycka, A. Autoclaved Aerated Concrete based on fly ash in density 350 kg/m3 as an environmentally friendly material for energy-efficient constructions. Procedia Eng. 2015, 122, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Glazer, B.; Graber, C.; Roose, C.; Syrett, P.; Youssef, C. Fly Ash in Concrete; The Perkins+Will Team Publisher: Chicago, IL, USA, 2011. [Google Scholar]

- Sijakova-Ivanova, T.; Panov, Z.; Blazev, K.; Zajkova-Paneva, V. Investigation of fly ash heavy metals content and physico chemical properties from thermal power plant, Republic of Macedonia. Int. J. Eng. Sci. Technol. 2011, 3, 8219–8225. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ignjatović, I.; Sas, Z.; Dragaš, J.; Somlai, J.; Kovacs, T. Radiological and material characterization of high volume fly ash concrete. J. Environ. Radioact. 2017, 168, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Sua-iam, G.; Makul, N. Rheological and mechanical properties of cement–fly ash self-consolidating concrete incorporating high volumes of alumina-based material as fine aggregate. Constr. Build. Mater. 2015, 95, 736–747. [Google Scholar] [CrossRef]

- Grant, A. Estimating the Marginal Effect of Pits and Quarries on Rural Residential Property Values in Wellington County, Ontario: A Hedonic Approach. Master’s Thesis, University of Guelph, Guelph, ON, Canada, 2017; p. 84. Available online: http://hdl.handle.net/10214/10903 (accessed on 25 May 2021).

- Campbell, B.A. Aggregate Resource Extraction: Examining Environmental Impacts on Optimal Extraction and Reclamation Strategies. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2014. Available online: https://era.library.ualberta.ca/items/a562f94b-dbd1-4c77-b4e8-2c5b53f5_17/view/f2d8eabe-5f45-468b-9f3c-2791b66db455/Campbell_Brett_A_201409_MSc.pdf (accessed on 19 June 2021).

- Langer, W.H.; Arbogast, B.F. Environmental impacts of mining natural aggregate. In Deposit and Geoenvironmental Models for Resource Exploitation and Environmental Security, Nato Science Part-Nership Subseries 2; Fabbri, A.G., Gaál, G., McCammon, R.B., Eds.; Springer: Dordrecht, Switzerland, 2002; p. 80. [Google Scholar]

- Danielsen, S.W.; Kuznetsova, E. Resource management and a Best Available Concept for aggregate sustainability. Geol. Soc. London Spéc. Publ. 2016, 416, 59–70. [Google Scholar] [CrossRef] [Green Version]

- Langer, W.H.; Drew, L.J.; Sachs, J.S. Aggregate and the environment. In American Geological Institute Environmental Awareness Series; American Geological Institute: Silver Spring, MD, USA, 2004; Volume 8, p. 64. [Google Scholar]

- Mo, K.H.; Alengaram, U.J.; Jumaat, M.Z.; Yap, S.P.; Lee, S.C. Green concrete partially comprised of farming waste residues: A review. J. Clean. Prod. 2016, 117, 122–138. [Google Scholar] [CrossRef]

- Azunna, S.U.; Aziz, F.N.A.A.; Cun, P.M.; Elhibir, M.M.O. Characterization of lightweight cement concrete with partial replacement of coconut shell fine aggregate. SN Appl. Sci. 2019, 1, 649. [Google Scholar] [CrossRef] [Green Version]

- Saxena, M.; Pappu, A.; Sharma, A.; Haque, R.; Wankhede, S. Composite Materials from Natural Resources: Recent Trends and Future Potentials. In Advances in Composite Materials—Analysis of Natural and Man-Made Materials; InTechOpen Ltd.: London, UK, 2011. [Google Scholar]

- Agrawal, Y.; Gupta, T.; Sharma, R.; Panwar, N.; Siddique, S. A Comprehensive Review on the Performance of Structural Lightweight Aggregate Concrete for Sustainable Construction. Constr. Mater. 2021, 1, 39–62. [Google Scholar] [CrossRef]

- Amziane, S.; Sonebi, M. Overview on Biobased Building Material made with plant aggregate. RILEM Tech. Lett. 2016, 1, 31–38. [Google Scholar] [CrossRef]

- Sisman, C.B.; Gezer, E.; Kocaman, I. Effects of organic waste (rice husk) on the concrete proper-ties for farm buildings. Bulg. J. Agric. Sci. 2011, 17, 40–48. [Google Scholar]

- Asdrubali, F. Green and sustainable materials for noise control in buildings. In Proceedings of the 19th International Congress on Acoustics, Madrid, Spain, 2–7 September 2007. PACS: 43.55.Ev. [Google Scholar]

- Farias, R.D.; García, C.M.; Cotes Palomino, T.; Andreola, F.; Lancellotti, I.; Barbieri, L. Valorization of agroindustrial wastes in lightweight aggregates for agronomic use: Preliminary study. Environ. Eng. Manag. J. 2017, 16, 1691–1699. [Google Scholar] [CrossRef]

- Pinto, J.; Cruz, D.; Paiva, A.; Pereira, S.; Tavares, P.; Fernandes, L.S.G.; Varum, H. Characterization of corn cob as a possible raw building material. Constr. Build. Mater. 2012, 34, 28–33. [Google Scholar] [CrossRef]

- Pinto, J.; Vieira, B.; Pereira, H.; Jacinto, C.; Vilela, P.; Paiva, A.; Pereira, S.; Cunha, S.P.D.S.; Varum, H. Corn cob lightweight concrete for non-structural applications. Constr. Build. Mater. 2012, 34, 346–351. [Google Scholar] [CrossRef] [Green Version]

- Paiva, A.; Pereira, S.; Sá, A.; Cruza, D.; Varum, H.; Pinto, J. A contribution to the thermal insulation performance characterization of corncob particleboards. Energy Build. 2012, 45, 274–279. [Google Scholar] [CrossRef] [Green Version]

- Nozahic, V.; Amziane, S. Influence of sunflower aggregates surface treatments on physical properties and adhesion with a mineral binder. Compos. Part A 2012, 43, 1837–1849. [Google Scholar] [CrossRef]

- Nozahic, V.; Amziane, S.; Torrent, G.; Saïdi, K.; De Baynast, H. Design of green concrete made of plant-derived aggregates and a pumice–lime binder. Cem. Concr. Compos. 2012, 34, 231–241. [Google Scholar] [CrossRef]

- Mati-Baouche, N.; De Baynast, H.; Lebert, A.; Sun, S.; Lopez-Mingo, C.J.S.; Leclaire, P.; Michaud, P. Mechanical, thermal and acoustical characterizations of an insulating bio-based composite made from sunflower stalks particles and chitosan. Ind. Crop. Prod. 2014, 58, 244–250. [Google Scholar] [CrossRef] [Green Version]

- Cunha, V.M.; Faustino, J.; Silva, E.; Pinto, J.; Soares, E.; Soares, S. Lightweight concrete masonry units based on processed granulate of corn cob as aggregate. Mater. Construcción 2015, 65, e055. [Google Scholar] [CrossRef] [Green Version]

- Chabannes, M.; Nozahic, V.; Amziane, S. Design and multi-physical properties of a new insulating concrete using sunflower stem aggregates and eco-friendly binders. Mater. Struct. 2015, 48, 1815–1829. [Google Scholar] [CrossRef]

- Leff, B.; Ramankutty, N.; Foley, J.A. Geographic distribution of major crops across the world. Glob. Biogeochem. Cycles 2004, 18. [Google Scholar] [CrossRef]

- FAOSTAT. Production Quantities by Country. Available online: http://faostat3.fao.org/ (accessed on 15 June 2021).

- OECD. Crop Production (Indicator). 2020. Available online: https://doi.org/10.1787/49a4e677-en (accessed on 15 June 2021).

- Ashour, A.; Amer, M.; Marzouk, A.; Shimizu, K.; Kondo, R.; El-Sharkawy, S. Corncobs as a Potential Source of Functional Chemicals. Molecules 2013, 18, 13823–13830. [Google Scholar] [CrossRef]

- Mathias, J.D.; Alzina, A.; Grédiac, M.; Michaud, P.; Roux, P.; De Baynast, H.; Delattre, C.; Du-moulin, N.; Faure, T.; Larrey-Lassalle, P.; et al. Upcycling sunflower stems as natural fibers for biocomposite applications. BioResources 2015, 10, 8076–8088. [Google Scholar] [CrossRef]

- Grădinaru, C.M.; Muntean, R.; Șerbănoiu, A.A.; Ciocan, V.; Burlacu, A. Sustainable Development of Human Society in Terms of Natural Depleting Resources Preservation Using Natural Renewable Raw Materials in a Novel Ecological Material Production. Sustainability 2020, 12, 2651. [Google Scholar] [CrossRef] [Green Version]

- NE 012/1-2007. Normativ Pentru Producerea Betonului Și Executarea Lucrărilor Din Beton, Beton Armat Și Beton Precomprimat—Partea 1: Producerea Betonului (Regulations for the Production of Concrete and the Execution of Concrete, Reinforced Concrete and Prestressed Concrete); ASRO—Asociatia de standardizare din Romania (Romanian Standardization Association): Bucharest, Romania, 2007. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Trans-Atlantic Publications, Inc.: Philadelphia, PA, USA, 2012. [Google Scholar]

- EN 12390-7:2019. Testing Hardened Concrete—Part 7: Density of Hardened Concrete; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-3:2019. Testing Hardened Concrete Part 3: Compressive Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- EN 12390-6:2009. Testing Hardened Concrete part 6: Split Tensile Strength of Test Specimens; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- SR 3518:2009. Încercări Pe Betoane. Determinarea Rezistenţei La Îngheţ-Dezgheţ Prin Măsurarea Variaţiei Rezistenţei La Compresiune Şi/Sau Modulului de Elasticitate Dinamic Relativ (Tests Hard-Ened Concrete. Determination of Freeze-Thaw Resistance by Measuring the Variation of the Com-Pressive Strength and/or the Relatively Dynamic Modulus of Elasticity); ASRO—Asociatia de standardizare din Romania (Romanian Standardization Association): Bucharest, Romania, 2009. [Google Scholar]

- EN 13412:2006. Products and Systems for the Protection and Repair of Concrete Structures—Test Methods—Determination of Modulus of Elasticity in Compression; European Committee for Standardization: Brussels, Belgium, 2006. [Google Scholar]

- SR EN 12667:2009. Thermal Performance of Construction Materials and Products. Determination of Thermal Resistance by the Method of Guarded Hot Plate and by the Method with Thermofluxo-Meter. Products with High and Medium Thermal Resistance; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- C155:2013. Normativ Privind Producerea Betoanelor Ușoare (Regulation on the Production of Lightweight Concrete); ASRO—Asociatia de standardizare din Romania (Romanian Standardization Association): Bucharest, Romania, 2013. [Google Scholar]

| Test | Specimens Number Tested for Each Composition | Specimen Geometry | Specimen Dimensions | Standard Applied |

|---|---|---|---|---|

| Density | 3 | cylinder | 100 mm radius 200 mm length | EN 12390-7:2019 [39] |

| Compressive strength | 3 | cylinder | 100 mm radius 200 mm length | EN 12390-3:2019 [40] |

| Splitting tensile strength | 3 | cylinder | 100 mm radius 200 mm length | EN 12390-6:2009 [41] |

| Freeze—thaw resistance | 6 | cube | 100 mm | SR 3518:2009 [42] |

| Modulus of elasticity | 3 | cylinder | 100 mm radius 200 mm length | EN 13412:2006 [43] |

| Thermal conductivity | 3 | cuboid | 300 × 300 × 50 mm | SR EN 12667:2009 [44] C155:2013 [45] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grădinaru, C.M.; Șerbănoiu, A.A.; Șerbănoiu, B.V. Sunflower Stalks versus Corn Cobs as Raw Materials for Sustainable Concrete. Materials 2021, 14, 5078. https://doi.org/10.3390/ma14175078

Grădinaru CM, Șerbănoiu AA, Șerbănoiu BV. Sunflower Stalks versus Corn Cobs as Raw Materials for Sustainable Concrete. Materials. 2021; 14(17):5078. https://doi.org/10.3390/ma14175078

Chicago/Turabian StyleGrădinaru, Cătălina Mihaela, Adrian Alexandru Șerbănoiu, and Bogdan Vasile Șerbănoiu. 2021. "Sunflower Stalks versus Corn Cobs as Raw Materials for Sustainable Concrete" Materials 14, no. 17: 5078. https://doi.org/10.3390/ma14175078

APA StyleGrădinaru, C. M., Șerbănoiu, A. A., & Șerbănoiu, B. V. (2021). Sunflower Stalks versus Corn Cobs as Raw Materials for Sustainable Concrete. Materials, 14(17), 5078. https://doi.org/10.3390/ma14175078